Topic 6.pptx

- Количество слайдов: 25

Production Capacity of Enterprise 1. Production Capacity: Definition, types and factors 2. Calculation of Production Capacity 3. Production capacity usage and ways of its enhancement. 1

Production Capacity of Enterprise 1. Production Capacity: Definition, types and factors 2. Calculation of Production Capacity 3. Production capacity usage and ways of its enhancement. 1

1. Production Capacity: Definition, types and factors. 2

1. Production Capacity: Definition, types and factors. 2

Production Capacity of enterprise - Maximal volume of products that can be generated by a production plant or enterprise in a given period by using current resources 3

Production Capacity of enterprise - Maximal volume of products that can be generated by a production plant or enterprise in a given period by using current resources 3

Types of Production Capacity • Project • Current (input, output, average annual) • Reserve 4

Types of Production Capacity • Project • Current (input, output, average annual) • Reserve 4

Main Factors, that influence the Project Production Capacity • Size and potential of sales market • Prospective sales volume • Break-even production volume • Production Enhancement in the future (reserve capacities) • Access to External sources of production capacities. 5

Main Factors, that influence the Project Production Capacity • Size and potential of sales market • Prospective sales volume • Break-even production volume • Production Enhancement in the future (reserve capacities) • Access to External sources of production capacities. 5

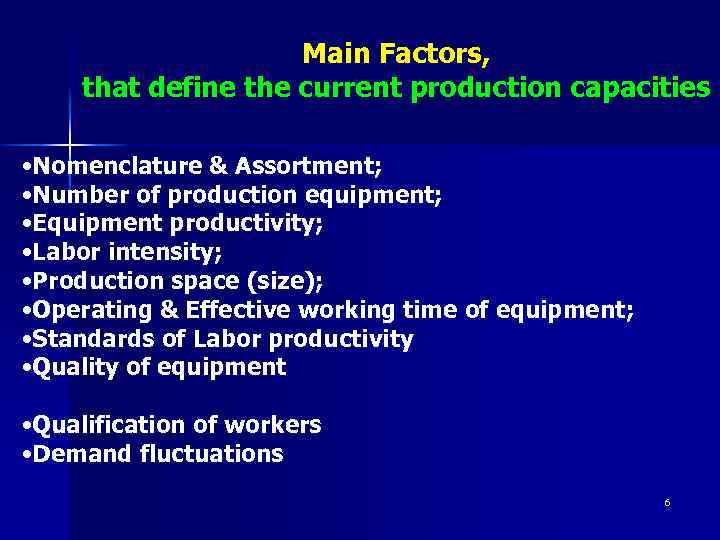

Main Factors, that define the current production capacities • Nomenclature & Assortment; • Number of production equipment; • Equipment productivity; • Labor intensity; • Production space (size); • Operating & Effective working time of equipment; • Standards of Labor productivity • Quality of equipment • Qualification of workers • Demand fluctuations 6

Main Factors, that define the current production capacities • Nomenclature & Assortment; • Number of production equipment; • Equipment productivity; • Labor intensity; • Production space (size); • Operating & Effective working time of equipment; • Standards of Labor productivity • Quality of equipment • Qualification of workers • Demand fluctuations 6

2. Calculation of Production Capacity. 7

2. Calculation of Production Capacity. 7

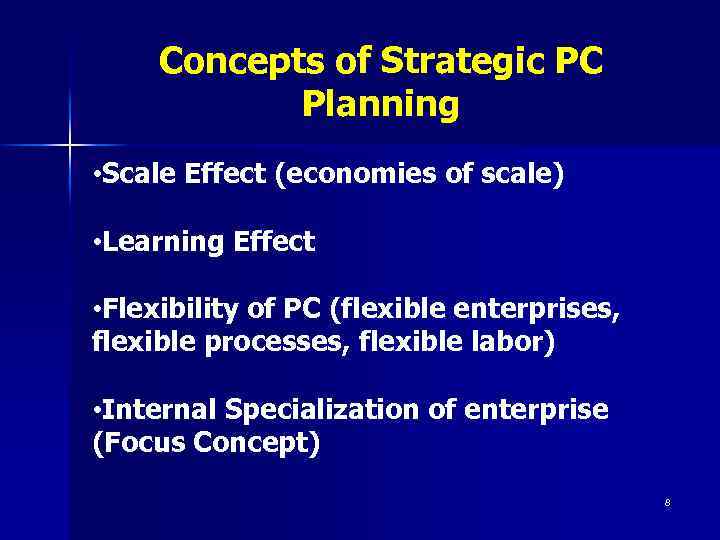

Concepts of Strategic PC Planning • Scale Effect (economies of scale) • Learning Effect • Flexibility of PC (flexible enterprises, flexible processes, flexible labor) • Internal Specialization of enterprise (Focus Concept) 8

Concepts of Strategic PC Planning • Scale Effect (economies of scale) • Learning Effect • Flexibility of PC (flexible enterprises, flexible processes, flexible labor) • Internal Specialization of enterprise (Focus Concept) 8

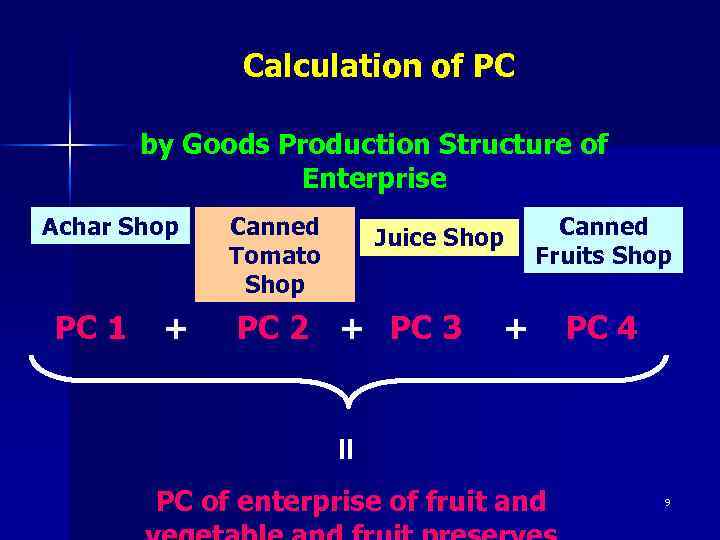

Calculation of PC by Goods Production Structure of Enterprise Achar Shop PC 1 + Canned Tomato Shop Juice Shop PC 2 + PC 3 Canned Fruits Shop + PC 4 = PC of enterprise of fruit and 9

Calculation of PC by Goods Production Structure of Enterprise Achar Shop PC 1 + Canned Tomato Shop Juice Shop PC 2 + PC 3 Canned Fruits Shop + PC 4 = PC of enterprise of fruit and 9

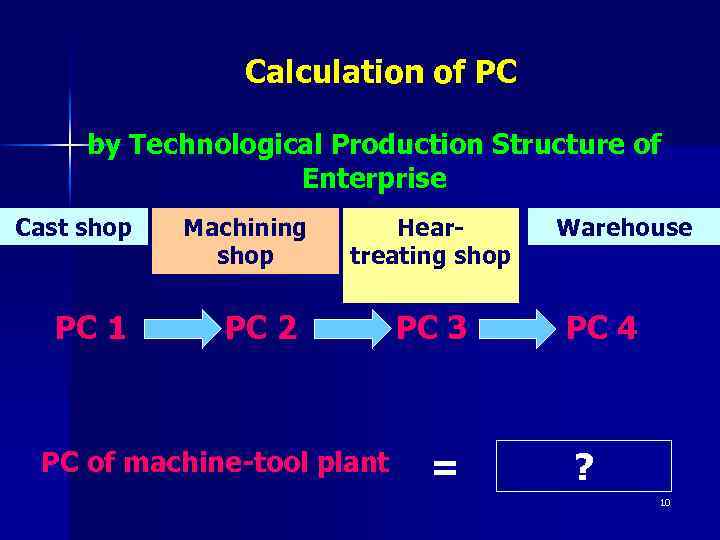

Calculation of PC by Technological Production Structure of Enterprise Cast shop PC 1 Machining shop Heartreating shop PC 2 PC of machine-tool plant PC 3 = Warehouse PC 4 ? 10

Calculation of PC by Technological Production Structure of Enterprise Cast shop PC 1 Machining shop Heartreating shop PC 2 PC of machine-tool plant PC 3 = Warehouse PC 4 ? 10

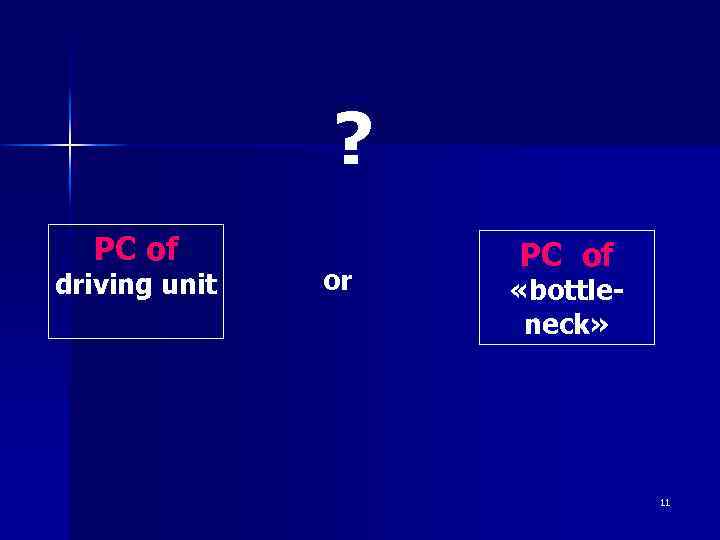

? PC of driving unit or PC of «bottleneck» 11

? PC of driving unit or PC of «bottleneck» 11

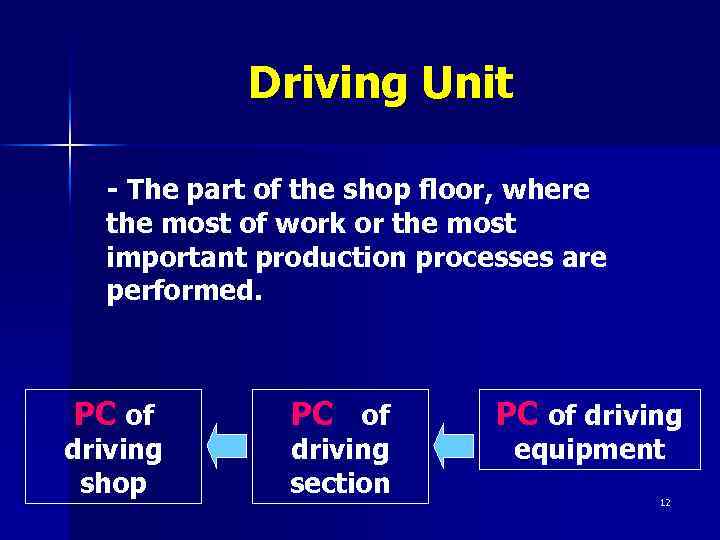

Driving Unit - The part of the shop floor, where the most of work or the most important production processes are performed. PC of driving shop PC of driving section PC of driving equipment 12

Driving Unit - The part of the shop floor, where the most of work or the most important production processes are performed. PC of driving shop PC of driving section PC of driving equipment 12

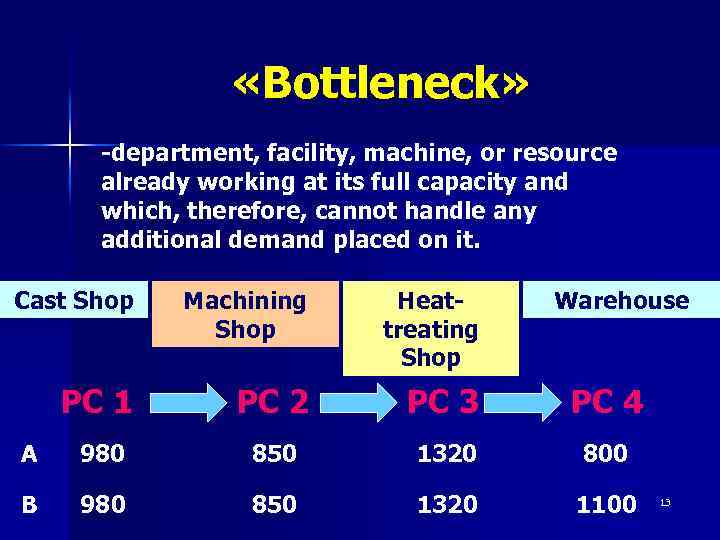

«Bottleneck» -department, facility, machine, or resource already working at its full capacity and which, therefore, cannot handle any additional demand placed on it. Cast Shop Machining Shop Heattreating Shop Warehouse PC 1 PC 2 PC 3 PC 4 А 980 850 1320 800 B 980 850 1320 1100 13

«Bottleneck» -department, facility, machine, or resource already working at its full capacity and which, therefore, cannot handle any additional demand placed on it. Cast Shop Machining Shop Heattreating Shop Warehouse PC 1 PC 2 PC 3 PC 4 А 980 850 1320 800 B 980 850 1320 1100 13

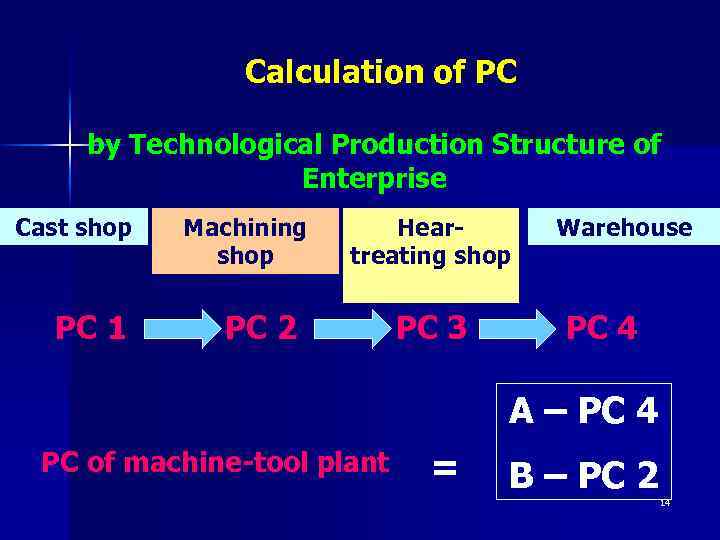

Calculation of PC by Technological Production Structure of Enterprise Cast shop PC 1 Machining shop Heartreating shop PC 2 PC 3 Warehouse PC 4 A – PC 4 PC of machine-tool plant = B – PC 2 14

Calculation of PC by Technological Production Structure of Enterprise Cast shop PC 1 Machining shop Heartreating shop PC 2 PC 3 Warehouse PC 4 A – PC 4 PC of machine-tool plant = B – PC 2 14

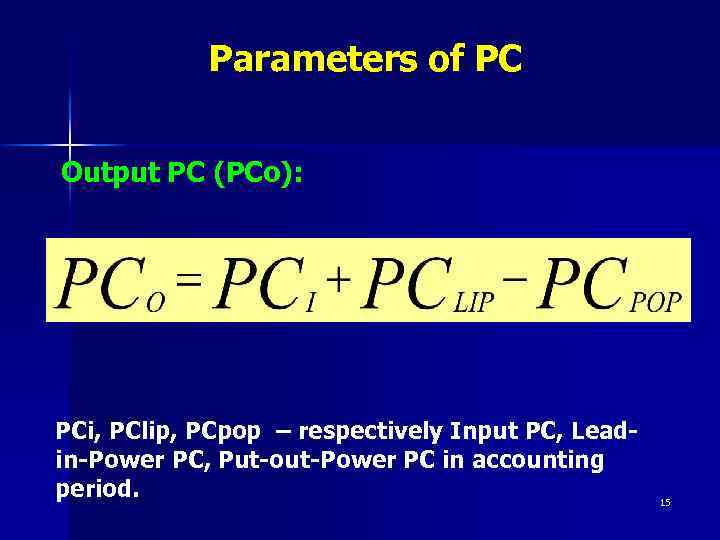

Parameters of PC Output PC (PCo): PCi, PClip, PCpop – respectively Input PC, Leadin-Power PC, Put-out-Power PC in accounting period. 15

Parameters of PC Output PC (PCo): PCi, PClip, PCpop – respectively Input PC, Leadin-Power PC, Put-out-Power PC in accounting period. 15

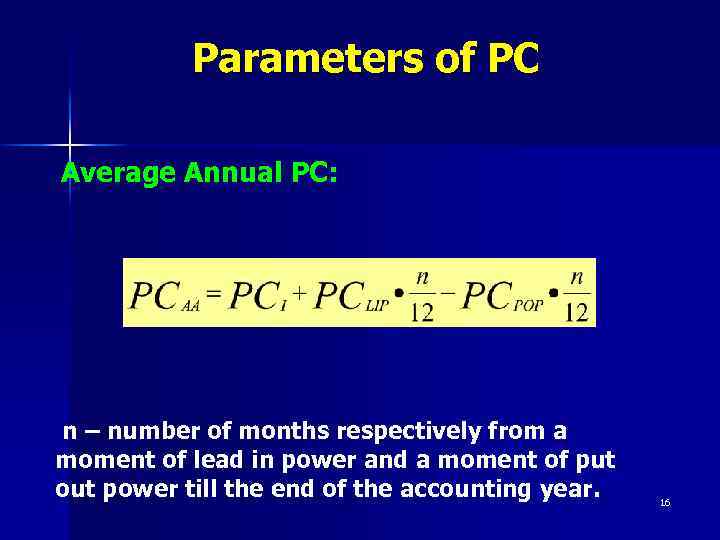

Parameters of PC Average Annual PC: n – number of months respectively from a moment of lead in power and a moment of put out power till the end of the accounting year. 16

Parameters of PC Average Annual PC: n – number of months respectively from a moment of lead in power and a moment of put out power till the end of the accounting year. 16

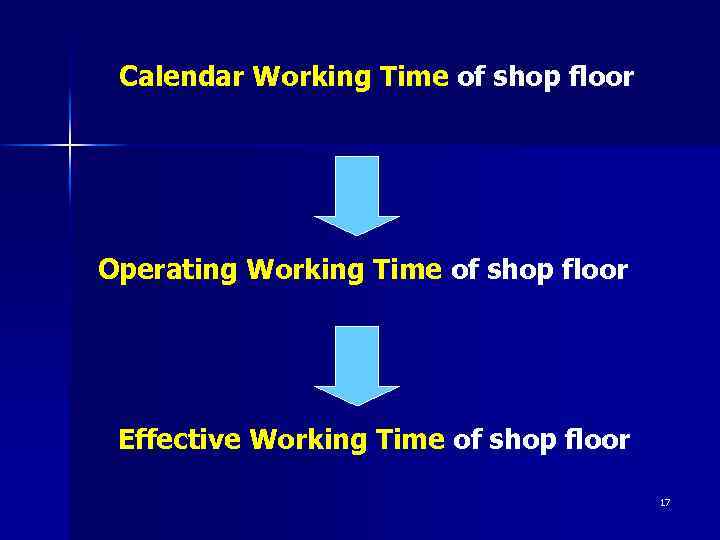

Calendar Working Time of shop floor Operating Working Time of shop floor Effective Working Time of shop floor 17

Calendar Working Time of shop floor Operating Working Time of shop floor Effective Working Time of shop floor 17

Calendar Working Time : in days: WTc(d) = 365 (366) days; in hours: WTc(h) = 365 * 24 = 8760 hours. 18

Calendar Working Time : in days: WTc(d) = 365 (366) days; in hours: WTc(h) = 365 * 24 = 8760 hours. 18

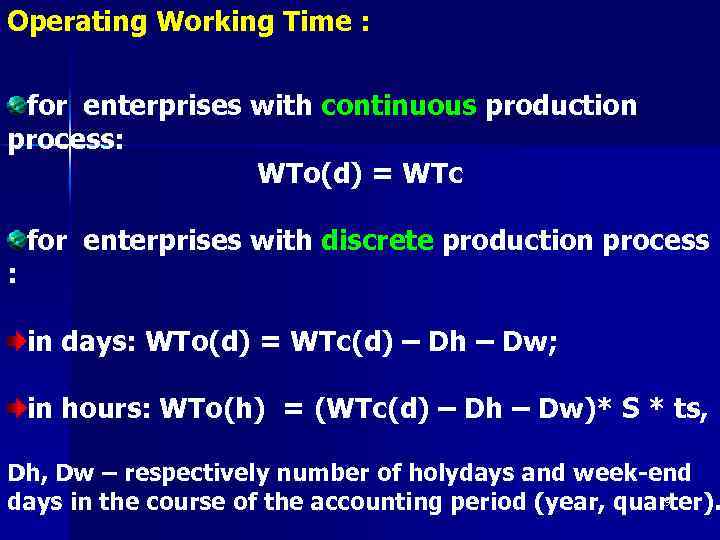

Operating Working Time : for enterprises with continuous production process: WTo(d) = WTc : for enterprises with discrete production process in days: WTo(d) = WTc(d) – Dh – Dw; in hours: WTo(h) = (WTc(d) – Dh – Dw)* S * ts, Dh, Dw – respectively number of holydays and week-end 19 days in the course of the accounting period (year, quarter).

Operating Working Time : for enterprises with continuous production process: WTo(d) = WTc : for enterprises with discrete production process in days: WTo(d) = WTc(d) – Dh – Dw; in hours: WTo(h) = (WTc(d) – Dh – Dw)* S * ts, Dh, Dw – respectively number of holydays and week-end 19 days in the course of the accounting period (year, quarter).

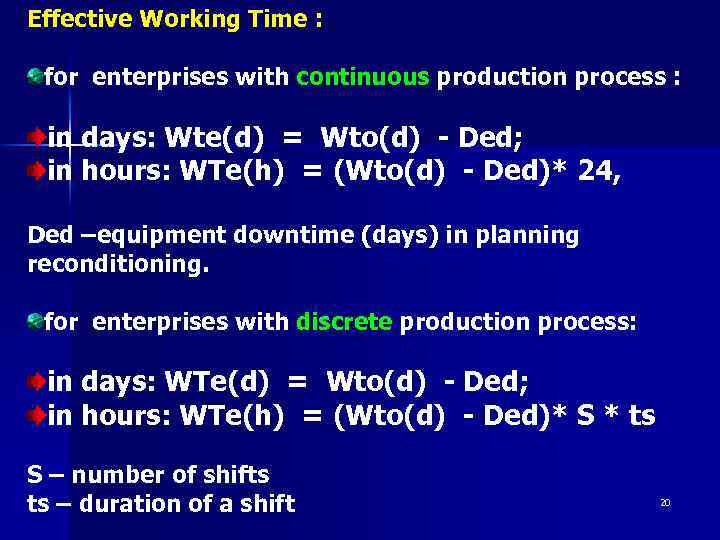

Effective Working Time : for enterprises with continuous production process : in days: Wtе(d) = Wto(d) - Ded; in hours: WTе(h) = (Wto(d) - Ded)* 24, Ded –equipment downtime (days) in planning reconditioning. for enterprises with discrete production process: in days: WTе(d) = Wto(d) - Ded; in hours: WTе(h) = (Wto(d) - Ded)* S * ts S – number of shifts ts – duration of a shift 20

Effective Working Time : for enterprises with continuous production process : in days: Wtе(d) = Wto(d) - Ded; in hours: WTе(h) = (Wto(d) - Ded)* 24, Ded –equipment downtime (days) in planning reconditioning. for enterprises with discrete production process: in days: WTе(d) = Wto(d) - Ded; in hours: WTе(h) = (Wto(d) - Ded)* S * ts S – number of shifts ts – duration of a shift 20

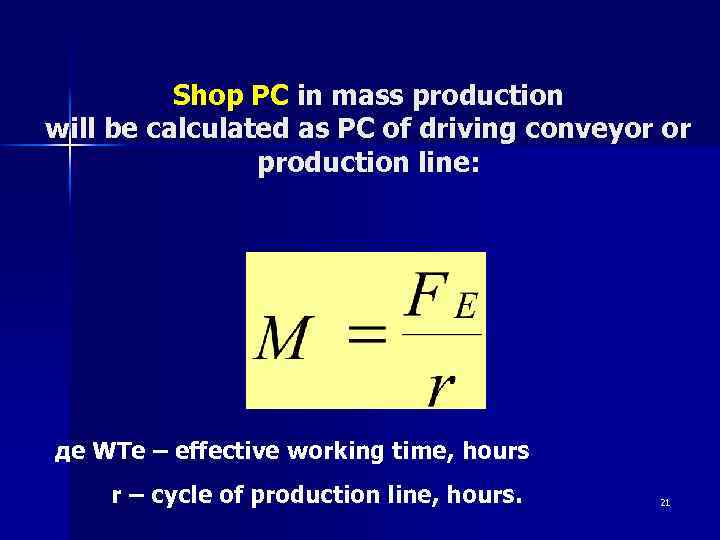

Shop PC in mass production will be calculated as PC of driving conveyor or production line: де WTe – effective working time, hours r – cycle of production line, hours. 21

Shop PC in mass production will be calculated as PC of driving conveyor or production line: де WTe – effective working time, hours r – cycle of production line, hours. 21

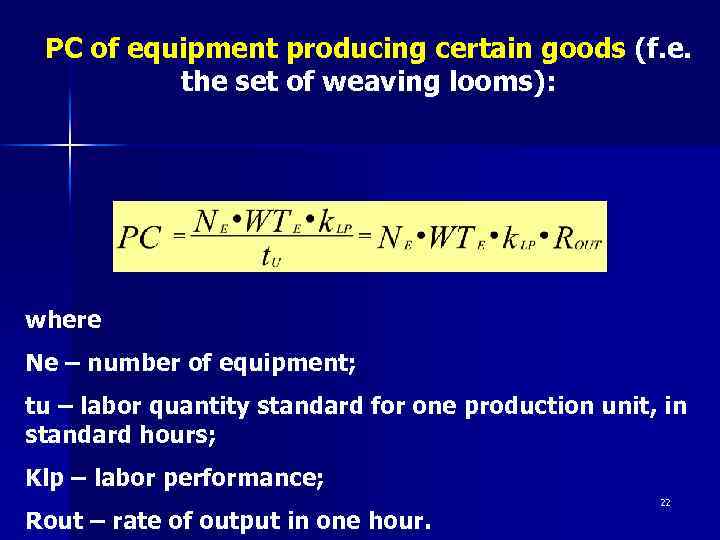

PC of equipment producing certain goods (f. e. the set of weaving looms): where Ne – number of equipment; tu – labor quantity standard for one production unit, in standard hours; Klp – labor performance; Rout – rate of output in one hour. 22

PC of equipment producing certain goods (f. e. the set of weaving looms): where Ne – number of equipment; tu – labor quantity standard for one production unit, in standard hours; Klp – labor performance; Rout – rate of output in one hour. 22

3. Production capacity usage and ways of its enhancement. 23

3. Production capacity usage and ways of its enhancement. 23

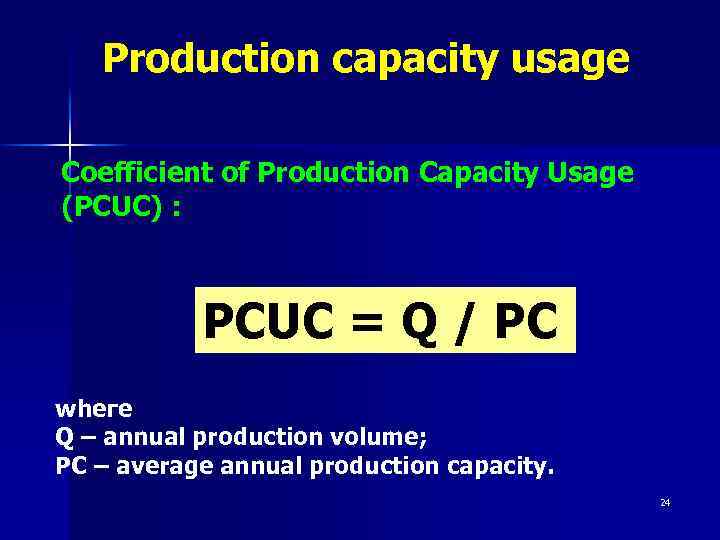

Production capacity usage Coefficient of Production Capacity Usage (PCUC) : PCUC = Q / PC wheге Q – annual production volume; PC – average annual production capacity. 24

Production capacity usage Coefficient of Production Capacity Usage (PCUC) : PCUC = Q / PC wheге Q – annual production volume; PC – average annual production capacity. 24

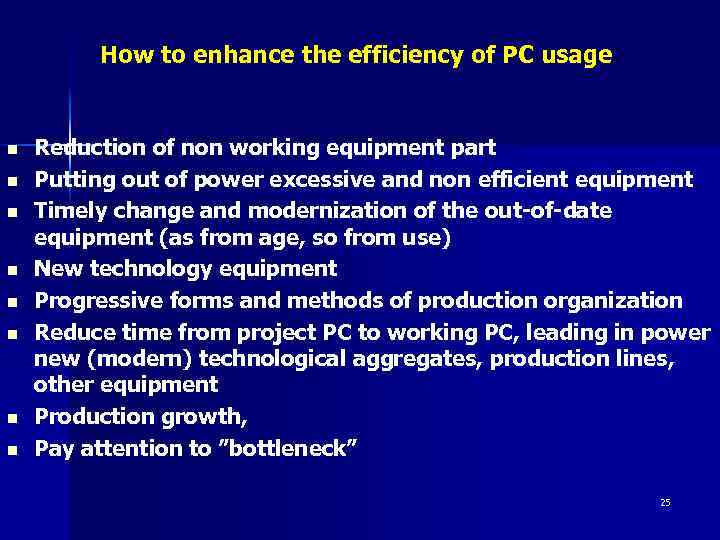

How to enhance the efficiency of PC usage n n n n Reduction of non working equipment part Putting out of power excessive and non efficient equipment Timely change and modernization of the out-of-date equipment (as from age, so from use) New technology equipment Progressive forms and methods of production organization Reduce time from project PC to working PC, leading in power new (modern) technological aggregates, production lines, other equipment Production growth, Pay attention to ”bottleneck” 25

How to enhance the efficiency of PC usage n n n n Reduction of non working equipment part Putting out of power excessive and non efficient equipment Timely change and modernization of the out-of-date equipment (as from age, so from use) New technology equipment Progressive forms and methods of production organization Reduce time from project PC to working PC, leading in power new (modern) technological aggregates, production lines, other equipment Production growth, Pay attention to ”bottleneck” 25