9c28f3f3340d2c318a45d57bdcbc0c6c.ppt

- Количество слайдов: 65

Product Training for the Driveline Vibration Analyzer (DVA) Truck Vibration Technology (TVT) Truck Vibration Technology

Ø INTRODUCTION Ø REQUIREMENTS Ø INSTALLATION Ø DVA ACQUISITION Ø BASIC VERSION Ø ADVANCED VERSION Ø DVA ANALYSIS Ø REPAIR STRATEGIES Truck Vibration Technology 2

THE NEED • Several Eaton customers (including OEM’s and dealers) have communicated a need for vibration analysis tools • Eaton Truck has great experience in vibration analysis technology and vibration complaint resolution • The Eaton DVA is leveraging these competencies, along with our diagnostic know-how and brand reputation, to bring these tools to market Truck Vibration Technology 3

DVA Driveline Vibration Analyzer The Eaton DVA is designed to: • Provide the ability to isolate fundamental vehicle vibrations • Using vehicle speed, pinpoint vibration problems that, in the past, have been difficult to diagnose. • Allow quicker diagnostics and repair of vibration complaints. Truck Vibration Technology 4

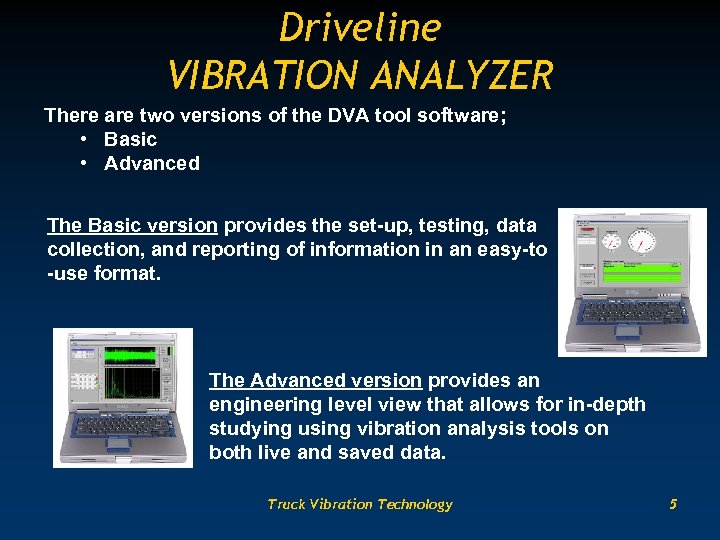

Driveline VIBRATION ANALYZER There are two versions of the DVA tool software; • Basic • Advanced The Basic version provides the set-up, testing, data collection, and reporting of information in an easy-to -use format. The Advanced version provides an engineering level view that allows for in-depth studying using vibration analysis tools on both live and saved data. Truck Vibration Technology 5

DVA BASIC VERSION • MSRP – $5, 175 • Target: Dealers, fleets and repair facilities • Benefits: – Increased diagnostic efficiency – Less vehicle down time – No part swapping Functions – Sensor input for signal verification – Chart With vibration criteria • Green Good • Red Bad – File saving and sending • Can be transferred to expert for analysis – Report printing Truck Vibration Technology 6

DVA ADVANCED VERSION • MSRP - $10, 000 Functions • Target: OEM’s and companies involved in the design of vehicles, suspensions, tires, wheels or driveline components • • Live spectrum view Cursors for common vibrations File collection for post analysis Post analysis of both linear and torsional vibrations • Analysis print-out for reporting • Benefits: – Powerful vehicle development tool – Improved ability to troubleshoot • End of line issues • Field complaints Truck Vibration Technology 7

Ø INTRODUCTION Ø REQUIREMENTS Ø INSTALLATION Ø DVA ACQUISITION Ø BASIC VERSION Ø ADVANCED VERSION Ø DVA ANALYSIS Ø REPAIR STRATEGIES Truck Vibration Technology 8

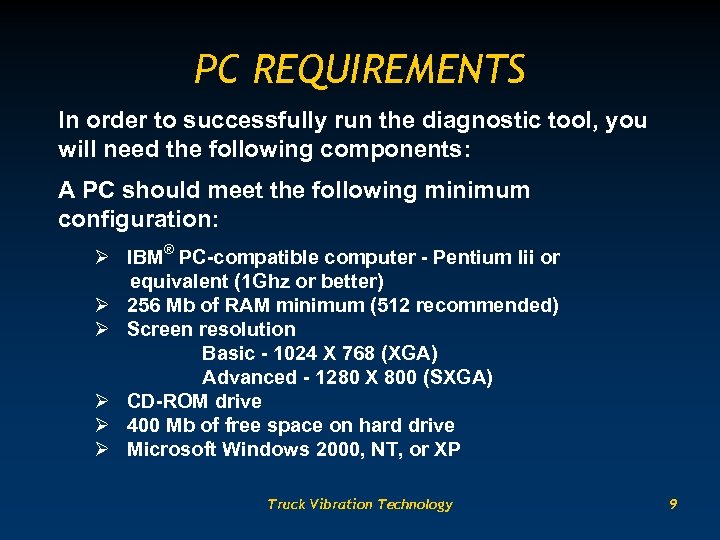

PC REQUIREMENTS In order to successfully run the diagnostic tool, you will need the following components: A PC should meet the following minimum configuration: Ø IBM® PC-compatible computer - Pentium Iii or equivalent (1 Ghz or better) Ø 256 Mb of RAM minimum (512 recommended) Ø Screen resolution Basic - 1024 X 768 (XGA) Advanced - 1280 X 800 (SXGA) Ø CD-ROM drive Ø 400 Mb of free space on hard drive Ø Microsoft Windows 2000, NT, or XP Truck Vibration Technology 9

KIT CONTAINS Truck Vibration Technology 10

Ø INTRODUCTION Ø REQUIREMENTS Ø INSTALLATION Ø DVA ACQUISITION Ø BASIC VERSION Ø ADVANCED VERSION Ø DVA ANALYSIS Ø REPAIR STRATEGIES Truck Vibration Technology 11

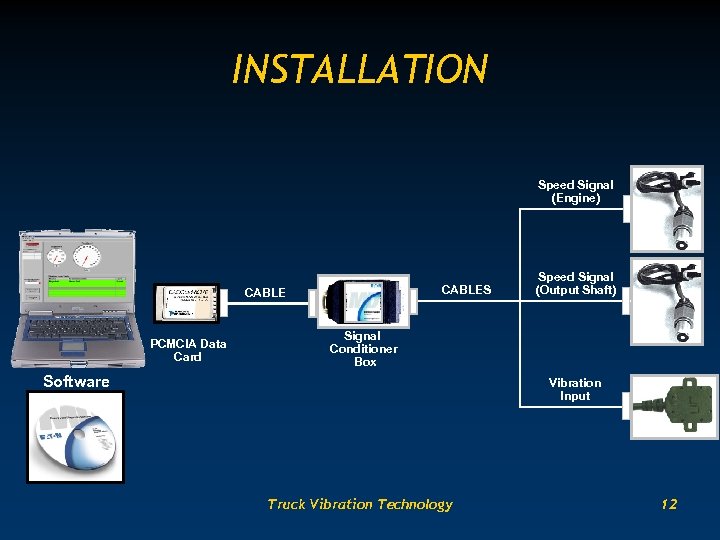

INSTALLATION Speed Signal (Engine) CABLES CABLE PCMCIA Data Card Speed Signal (Output Shaft) Signal Conditioner Box Software Vibration Input Truck Vibration Technology 12

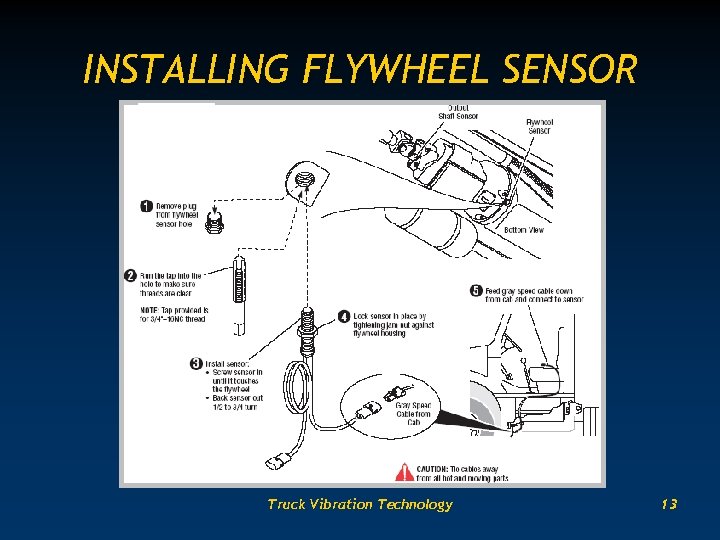

INSTALLING FLYWHEEL SENSOR Truck Vibration Technology 13

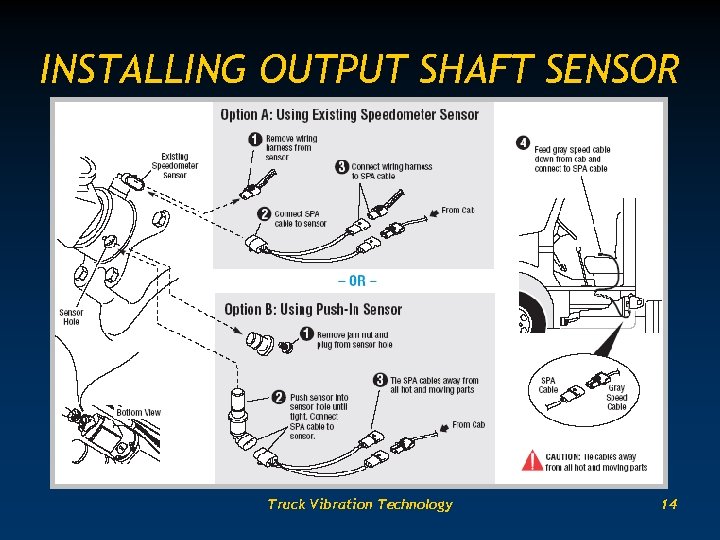

INSTALLING OUTPUT SHAFT SENSOR Truck Vibration Technology 14

INSTALLING ACCELEROMETER Accelerometer Truck Vibration Technology 15

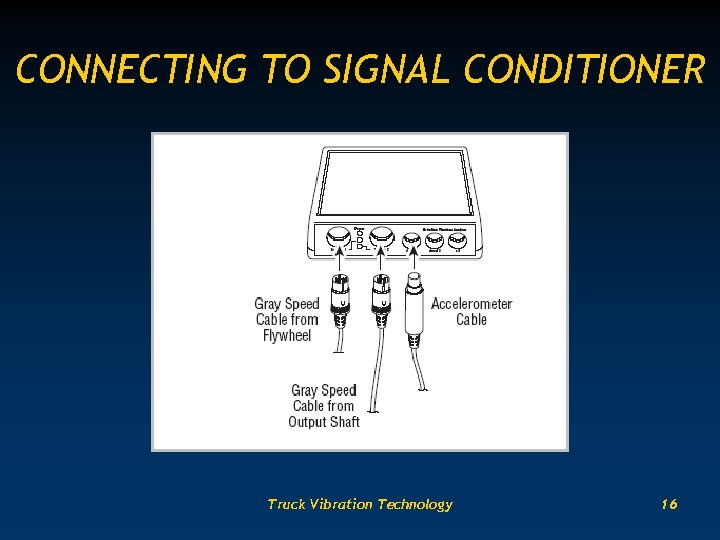

CONNECTING TO SIGNAL CONDITIONER Truck Vibration Technology 16

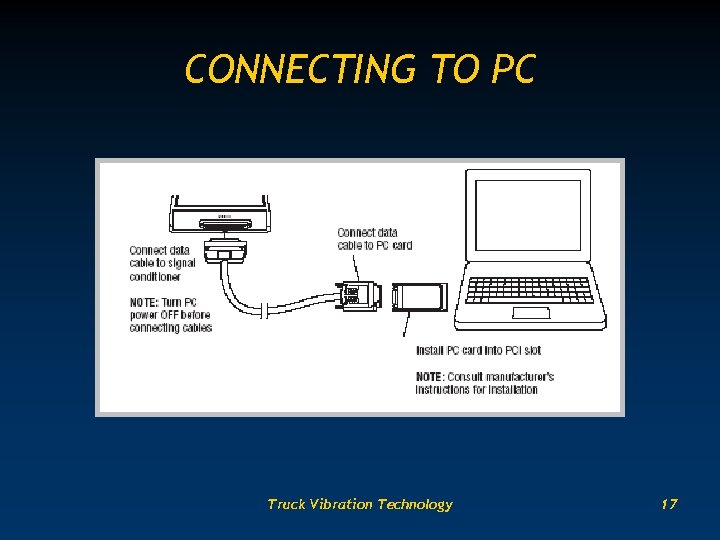

CONNECTING TO PC Truck Vibration Technology 17

Ø INTRODUCTION Ø REQUIREMENTS Ø INSTALLATION Ø DVA ACQUISITION Ø BASIC VERSION Ø ADVANCED VERSION Ø DVA ANALYSIS Ø REPAIR STRATEGIES Truck Vibration Technology 18

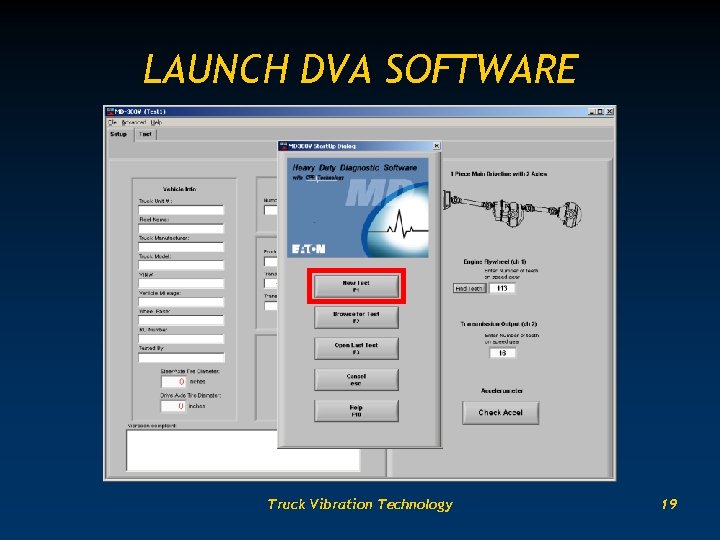

LAUNCH DVA SOFTWARE Truck Vibration Technology 19

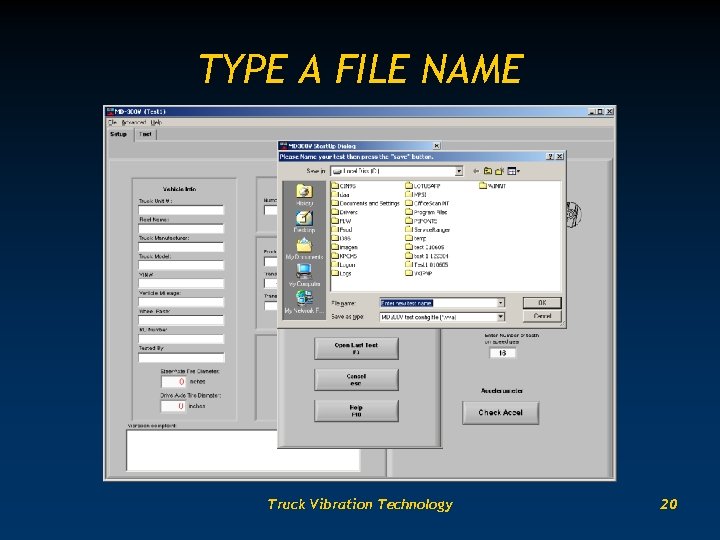

TYPE A FILE NAME Truck Vibration Technology 20

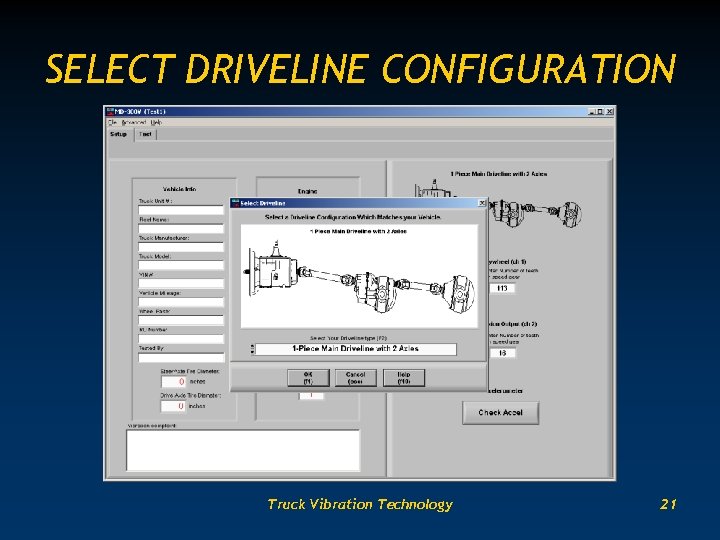

SELECT DRIVELINE CONFIGURATION Truck Vibration Technology 21

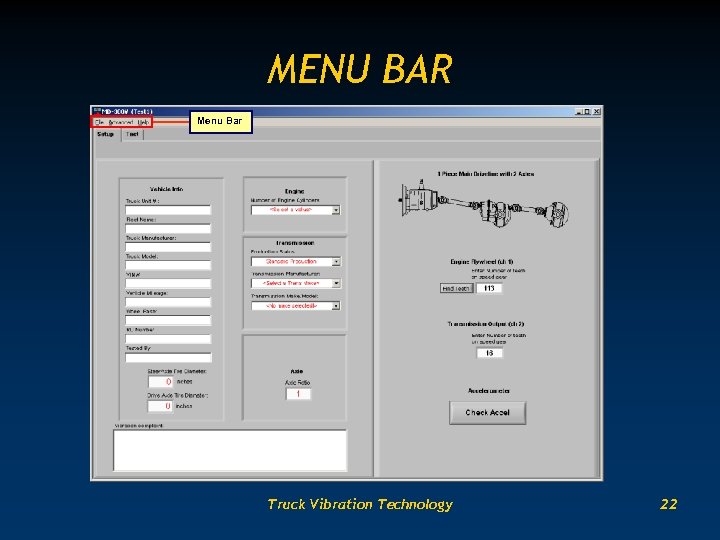

MENU BAR Menu Bar Truck Vibration Technology 22

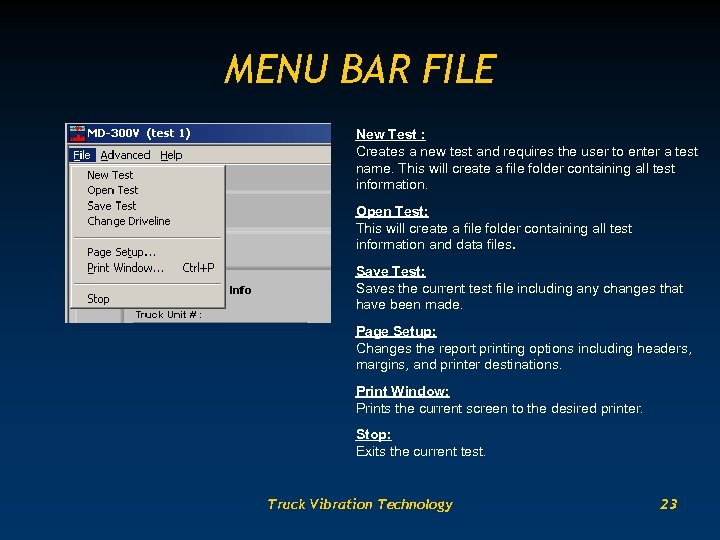

MENU BAR FILE New Test : Creates a new test and requires the user to enter a test name. This will create a file folder containing all test information. Open Test: This will create a file folder containing all test information and data files. Save Test: Saves the current test file including any changes that have been made. Page Setup: Changes the report printing options including headers, margins, and printer destinations. Print Window: Prints the current screen to the desired printer. Stop: Exits the current test. Truck Vibration Technology 23

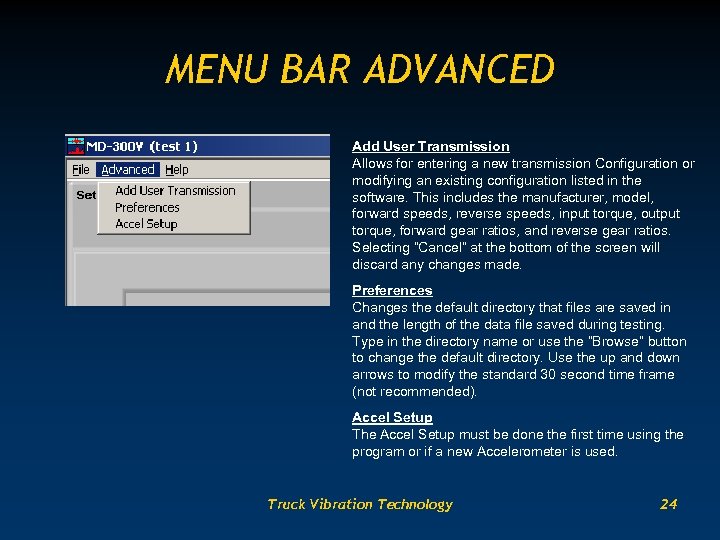

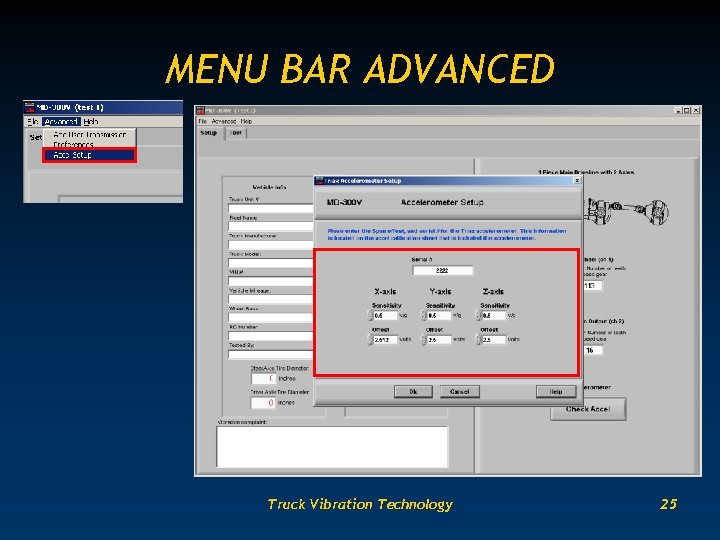

MENU BAR ADVANCED Add User Transmission Allows for entering a new transmission Configuration or modifying an existing configuration listed in the software. This includes the manufacturer, model, forward speeds, reverse speeds, input torque, output torque, forward gear ratios, and reverse gear ratios. Selecting “Cancel” at the bottom of the screen will discard any changes made. Preferences Changes the default directory that files are saved in and the length of the data file saved during testing. Type in the directory name or use the “Browse” button to change the default directory. Use the up and down arrows to modify the standard 30 second time frame (not recommended). Accel Setup The Accel Setup must be done the first time using the program or if a new Accelerometer is used. Truck Vibration Technology 24

MENU BAR ADVANCED Truck Vibration Technology 25

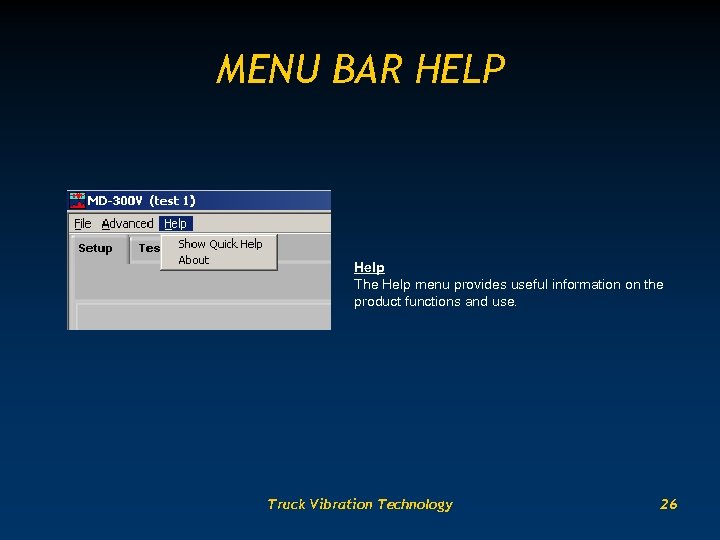

MENU BAR HELP Help The Help menu provides useful information on the product functions and use. Truck Vibration Technology 26

Ø INTRODUCTION Ø REQUIREMENTS Ø INSTALLATION Ø DVA ACQUISITION Ø BASIC VERSION Ø ADVANCED VERSION Ø DVA ANALYSIS Ø REPAIR STRATEGIES Truck Vibration Technology 27

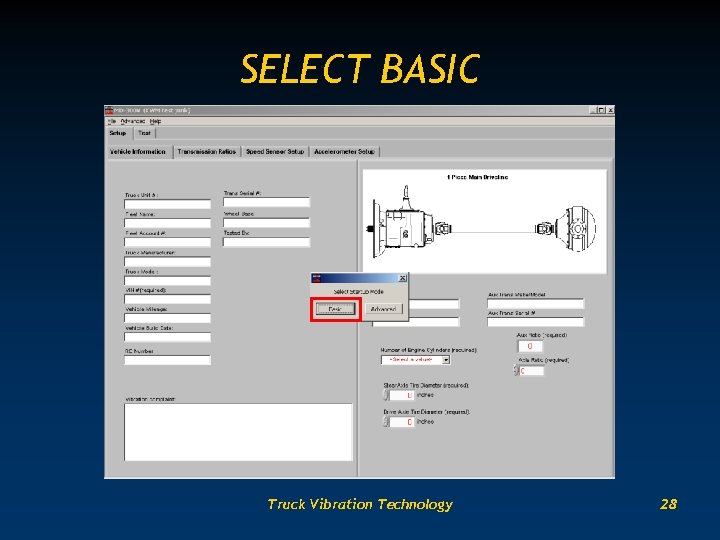

SELECT BASIC Truck Vibration Technology 28

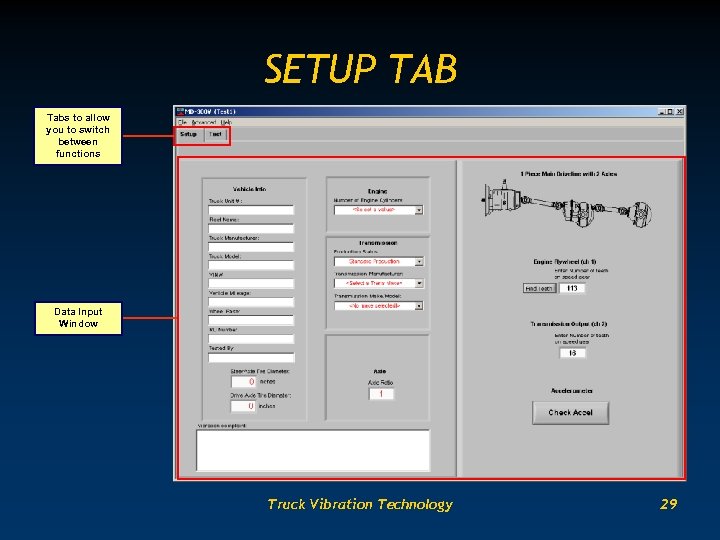

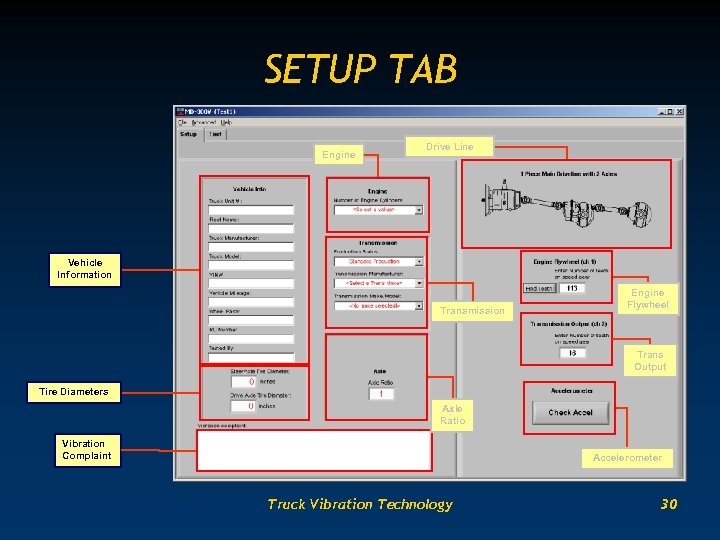

SETUP TAB Tabs to allow you to switch between functions Data Input Window Truck Vibration Technology 29

SETUP TAB Engine Drive Line Vehicle Information Transmission Engine Flywheel Trans Output Tire Diameters Axle Ratio Vibration Complaint Accelerometer Truck Vibration Technology 30

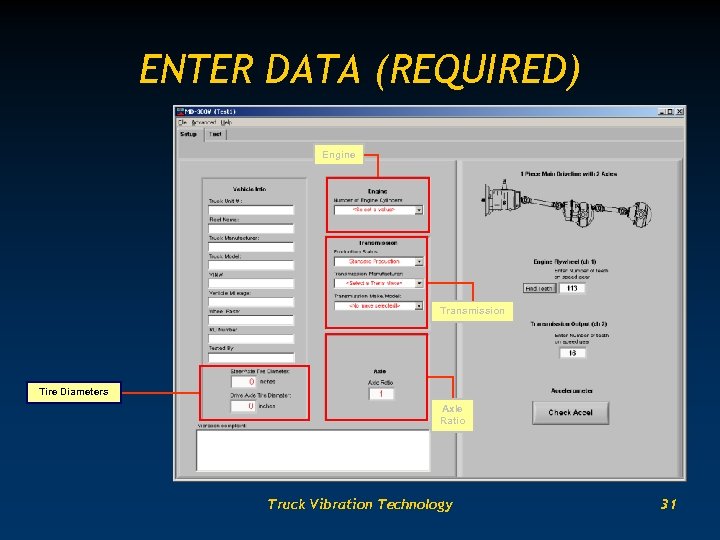

ENTER DATA (REQUIRED) Engine Transmission Tire Diameters Axle Ratio Truck Vibration Technology 31

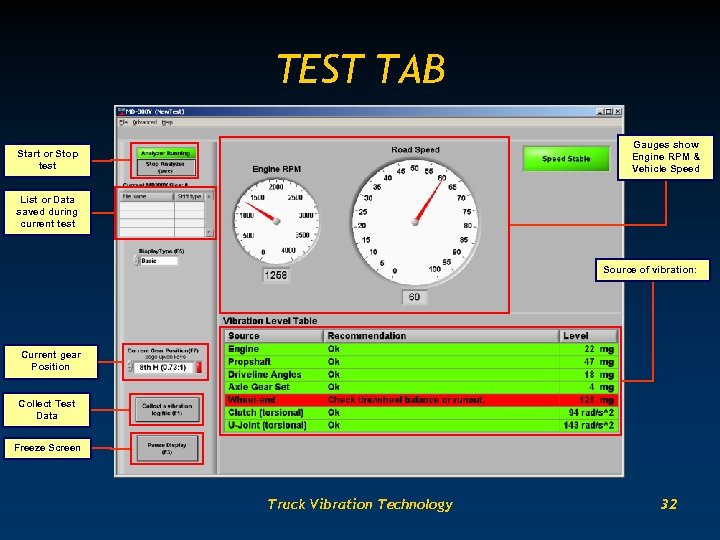

TEST TAB Gauges show Engine RPM & Vehicle Speed Start or Stop test List or Data saved during current test Source of vibration: Current gear Position Collect Test Data Freeze Screen Truck Vibration Technology 32

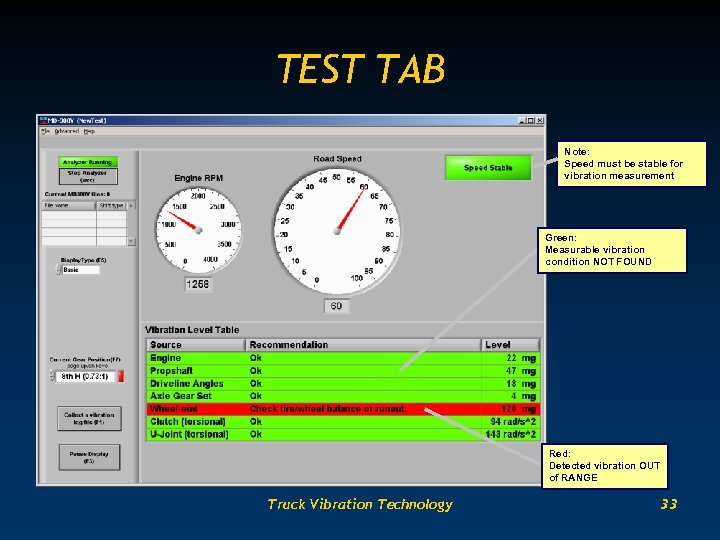

TEST TAB Note: Speed must be stable for vibration measurement Green: Measurable vibration condition NOT FOUND Red: Detected vibration OUT of RANGE Truck Vibration Technology 33

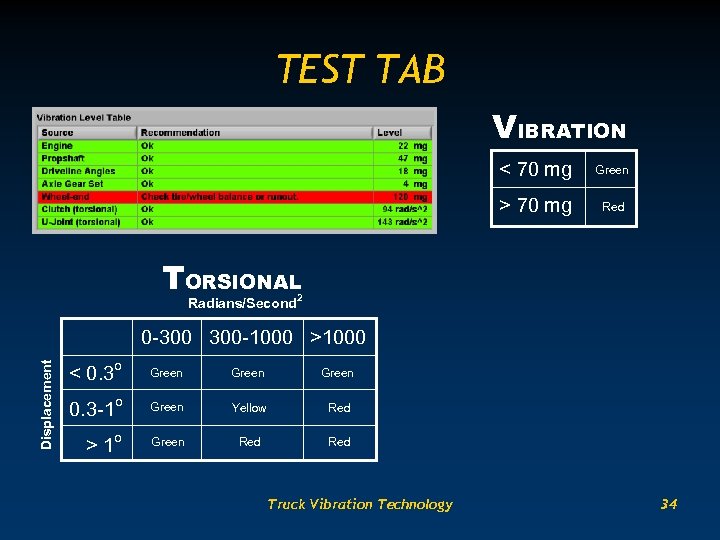

TEST TAB VIBRATION < 70 mg Green > 70 mg Red TORSIONAL Radians/Second 2 Displacement 0 -300 300 -1000 >1000 < 0. 3 o Green 0. 3 -1 o Green Yellow Red > 1 o Green Red Truck Vibration Technology 34

Ø INTRODUCTION Ø REQUIREMENTS Ø INSTALLATION Ø DVA ACQUISITION Ø BASIC VERSION Ø ADVANCED VERSION Ø DVA ANALYSIS Ø REPAIR STRATEGIES Truck Vibration Technology 35

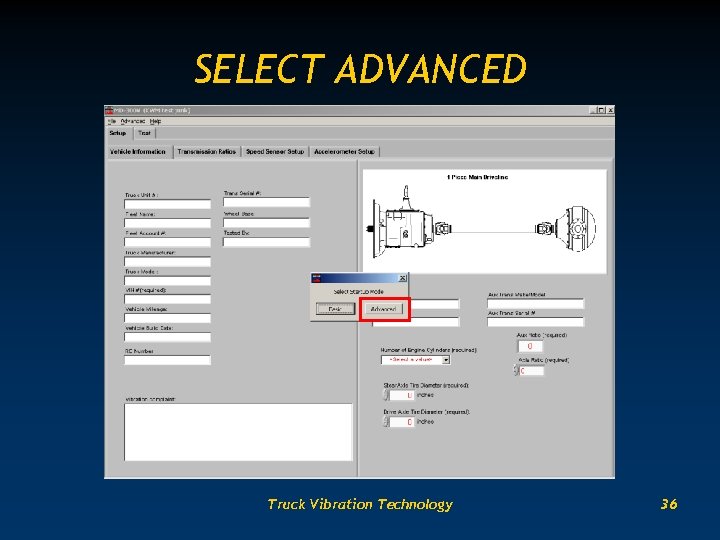

SELECT ADVANCED Truck Vibration Technology 36

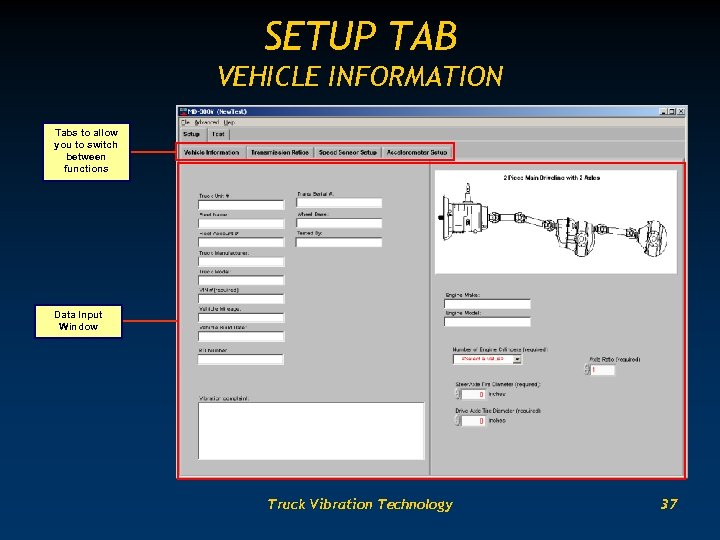

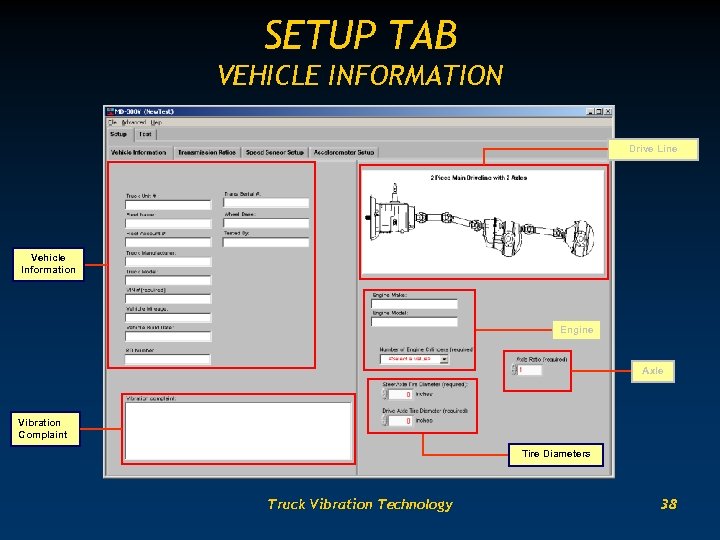

SETUP TAB VEHICLE INFORMATION Tabs to allow you to switch between functions Data Input Window Truck Vibration Technology 37

SETUP TAB VEHICLE INFORMATION Drive Line Vehicle Information Engine Axle Vibration Complaint Tire Diameters Truck Vibration Technology 38

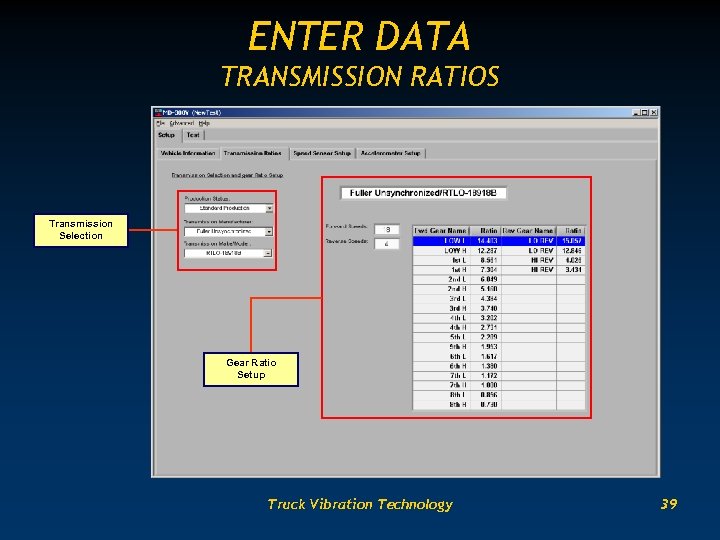

ENTER DATA TRANSMISSION RATIOS Transmission Selection Gear Ratio Setup Truck Vibration Technology 39

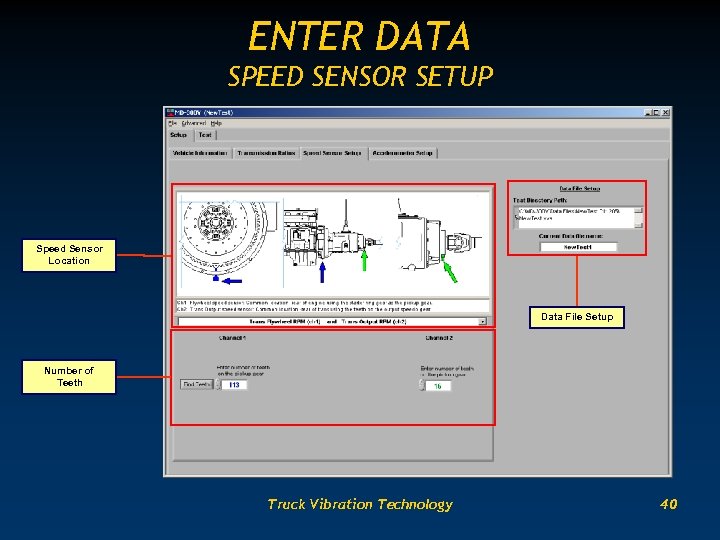

ENTER DATA SPEED SENSOR SETUP Speed Sensor Location Data File Setup Number of Teeth Truck Vibration Technology 40

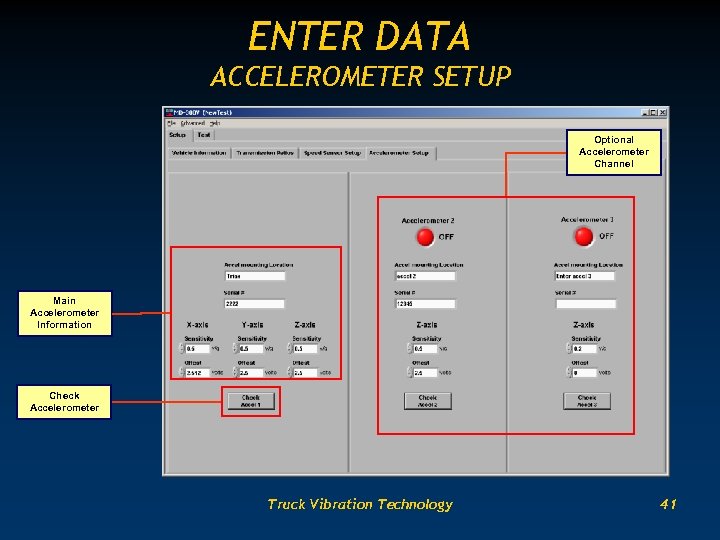

ENTER DATA ACCELEROMETER SETUP Optional Accelerometer Channel Main Accelerometer Information Check Accelerometer Truck Vibration Technology 41

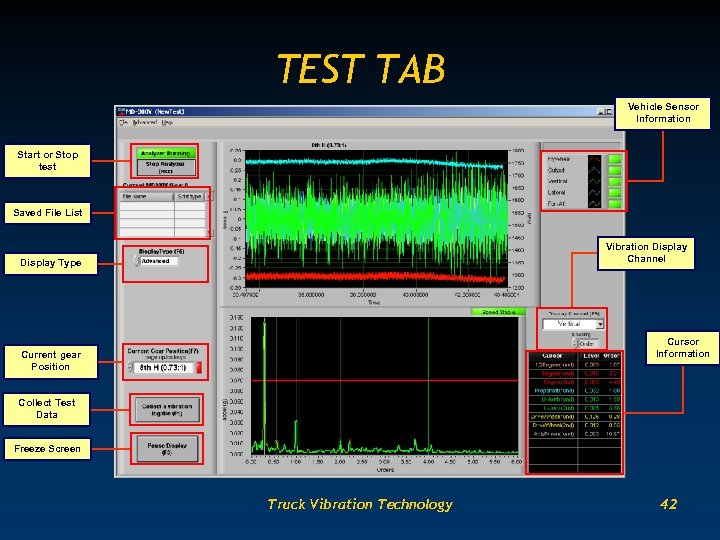

TEST TAB Vehicle Sensor Information Start or Stop test Saved File List Vibration Display Channel Display Type Cursor Information Current gear Position Collect Test Data Freeze Screen Truck Vibration Technology 42

Ø INTRODUCTION Ø REQUIREMENTS Ø INSTALLATION Ø DVA ACQUISITION Ø BASIC VERSION Ø ADVANCED VERSION Ø DVA ANALYSIS Ø REPAIR STRATEGIES Truck Vibration Technology 43

LAUNCH DVA SOFTWARE Menu Bar Truck Vibration Technology 44

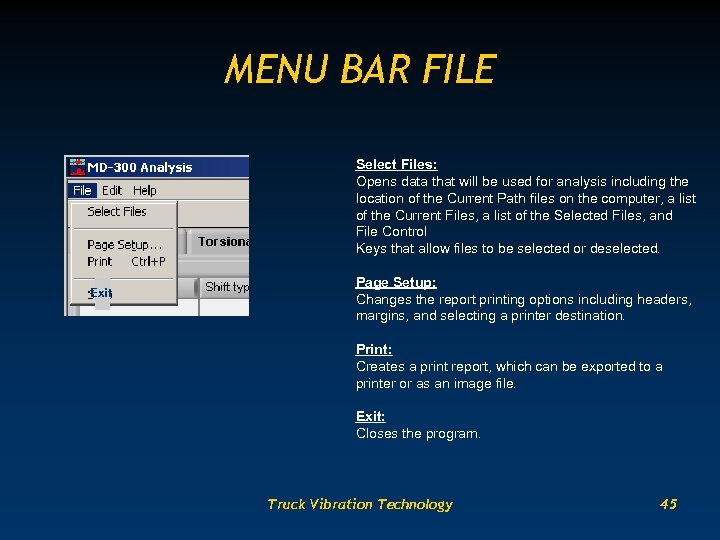

MENU BAR FILE Select Files: Opens data that will be used for analysis including the location of the Current Path files on the computer, a list of the Current Files, a list of the Selected Files, and File Control Keys that allow files to be selected or deselected. Exit Page Setup: Changes the report printing options including headers, margins, and selecting a printer destination. Print: Creates a print report, which can be exported to a printer or as an image file. Exit: Closes the program. Truck Vibration Technology 45

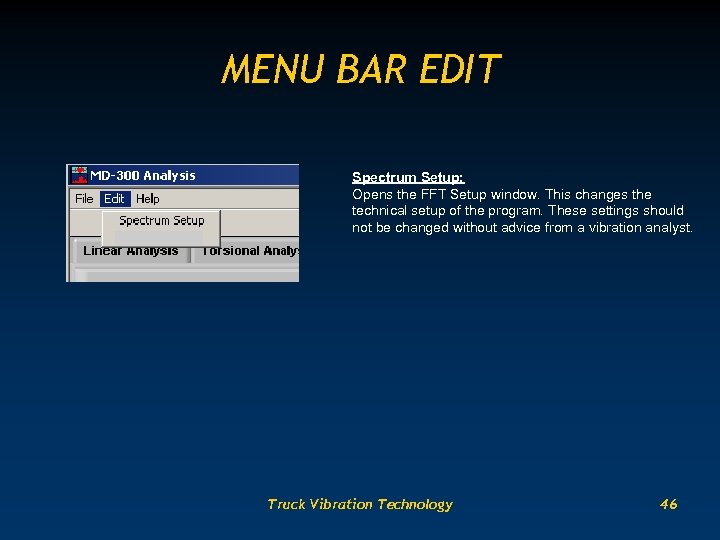

MENU BAR EDIT Spectrum Setup: Opens the FFT Setup window. This changes the technical setup of the program. These settings should not be changed without advice from a vibration analyst. Truck Vibration Technology 46

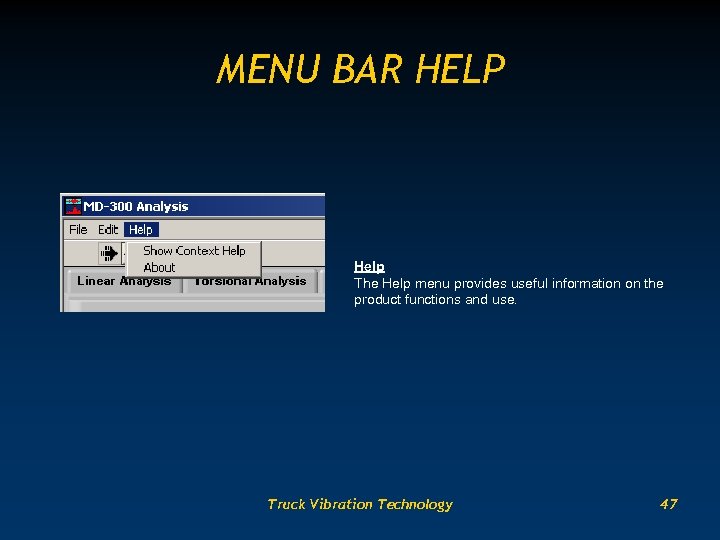

MENU BAR HELP Help The Help menu provides useful information on the product functions and use. Truck Vibration Technology 47

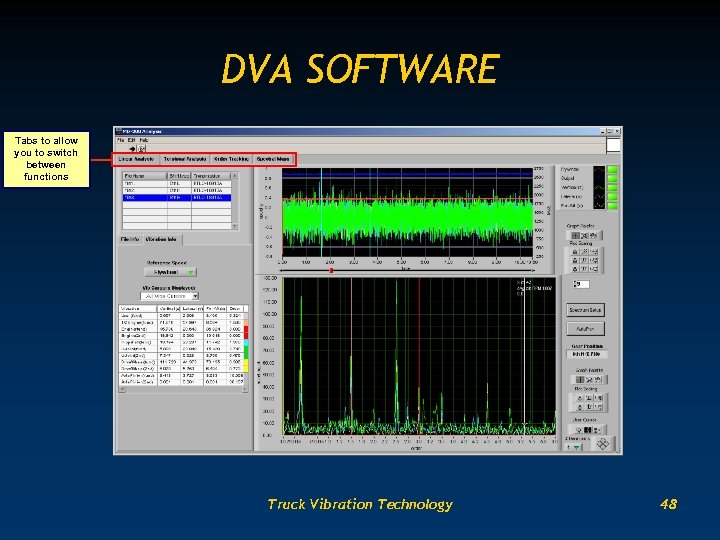

DVA SOFTWARE Tabs to allow you to switch between functions Truck Vibration Technology 48

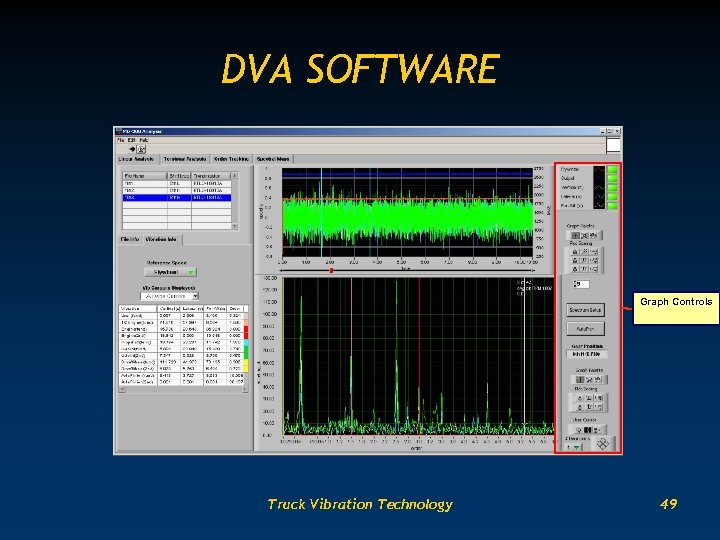

DVA SOFTWARE Graph Controls Truck Vibration Technology 49

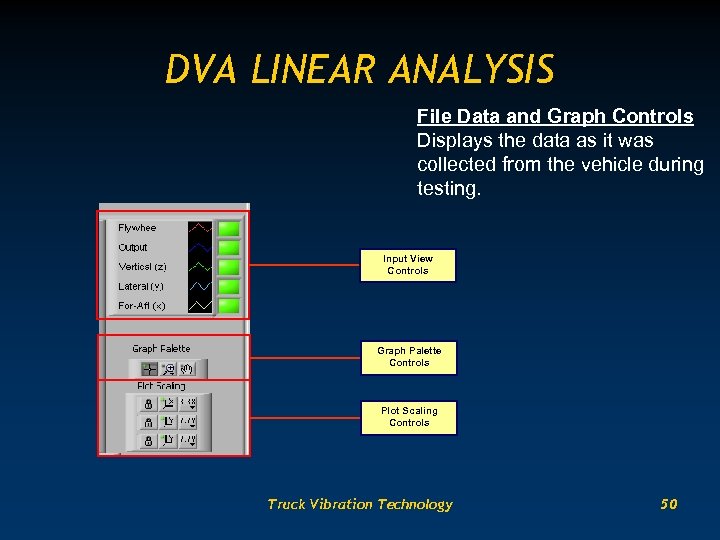

DVA LINEAR ANALYSIS File Data and Graph Controls Displays the data as it was collected from the vehicle during testing. Input View Controls Graph Palette Controls Plot Scaling Controls Truck Vibration Technology 50

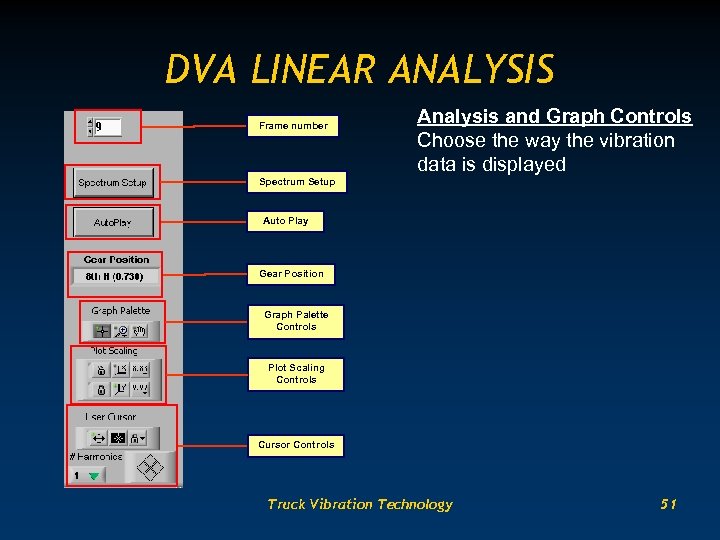

DVA LINEAR ANALYSIS Frame number Analysis and Graph Controls Choose the way the vibration data is displayed Spectrum Setup Auto Play Gear Position Graph Palette Controls Plot Scaling Controls Cursor Controls Truck Vibration Technology 51

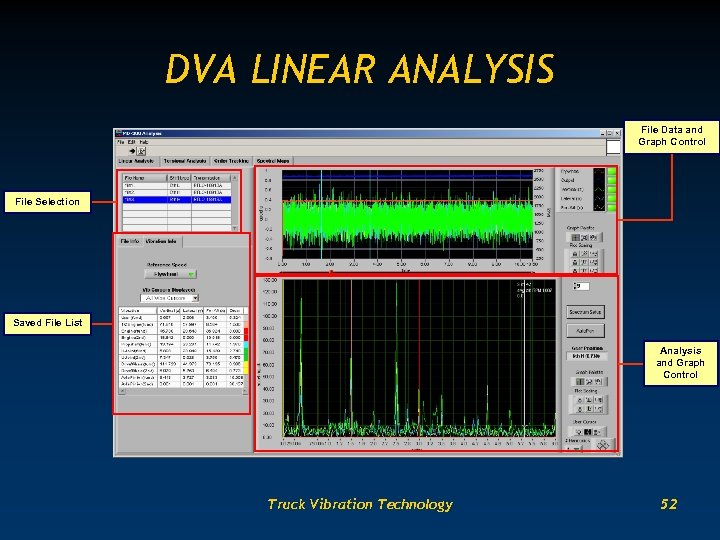

DVA LINEAR ANALYSIS File Data and Graph Control File Selection Saved File List Analysis and Graph Control Truck Vibration Technology 52

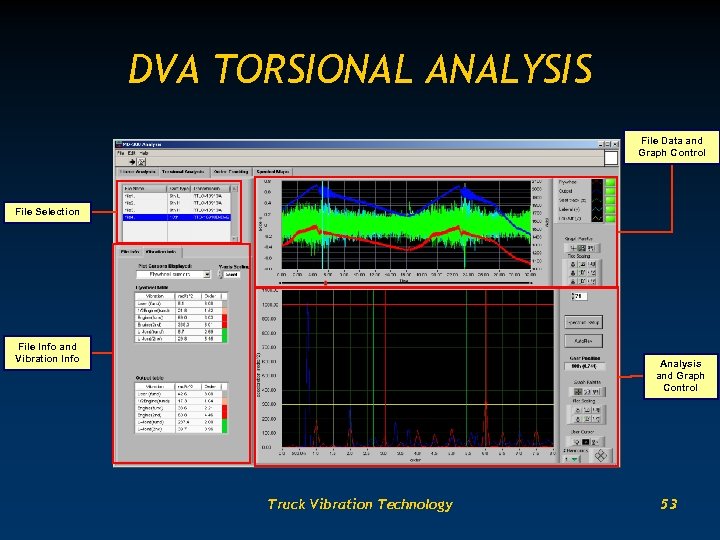

DVA TORSIONAL ANALYSIS File Data and Graph Control File Selection File Info and Vibration Info Analysis and Graph Control Truck Vibration Technology 53

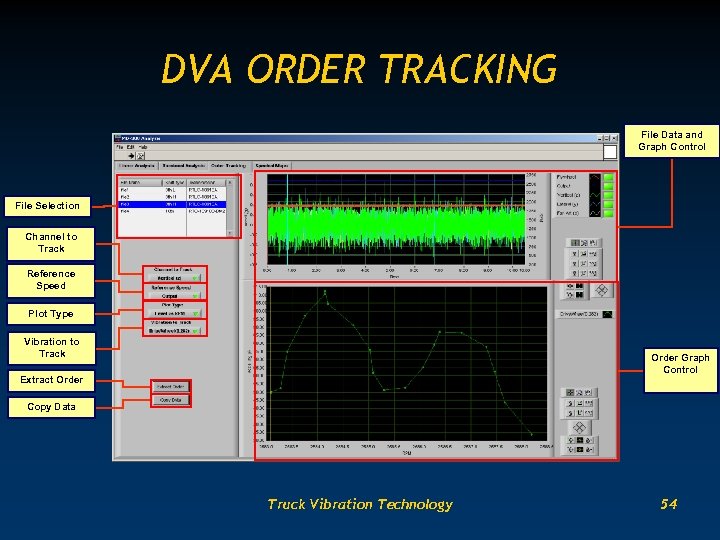

DVA ORDER TRACKING File Data and Graph Control File Selection Channel to Track Reference Speed Plot Type Vibration to Track Order Graph Control Extract Order Copy Data Truck Vibration Technology 54

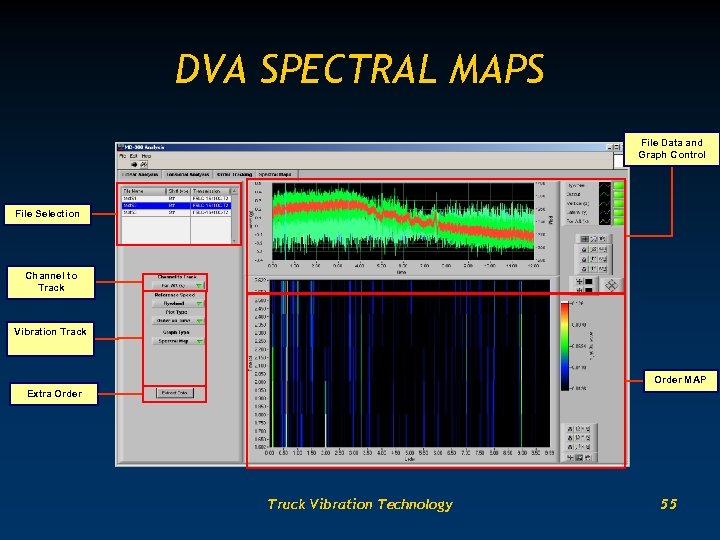

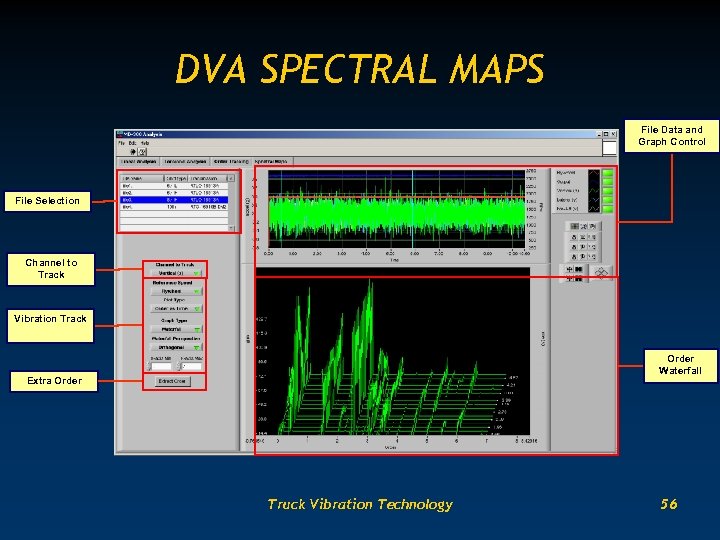

DVA SPECTRAL MAPS File Data and Graph Control File Selection Channel to Track Vibration Track Order MAP Extra Order Truck Vibration Technology 55

DVA SPECTRAL MAPS File Data and Graph Control File Selection Channel to Track Vibration Track Order Waterfall Extra Order Truck Vibration Technology 56

Ø INTRODUCTION Ø REQUIREMENTS Ø INSTALLATION Ø DVA ACQUISITION Ø BASIC VERSION Ø ADVANCED VERSION Ø DVA ANALYSIS Ø REPAIR STRATEGIES Truck Vibration Technology 57

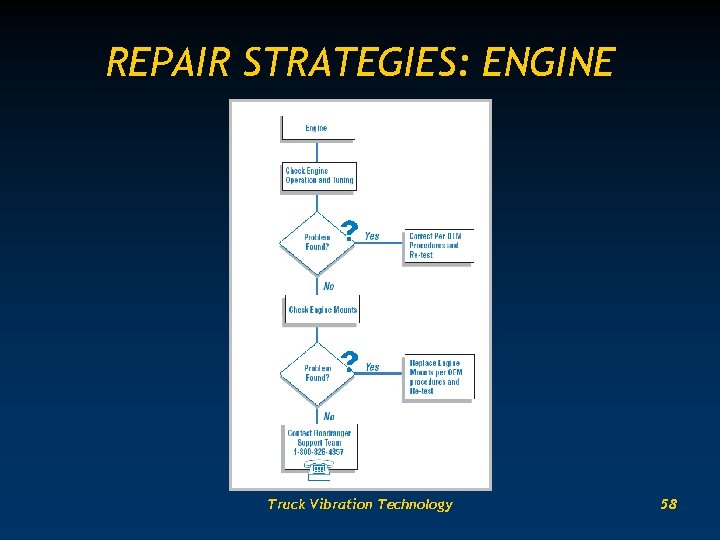

REPAIR STRATEGIES: ENGINE Truck Vibration Technology 58

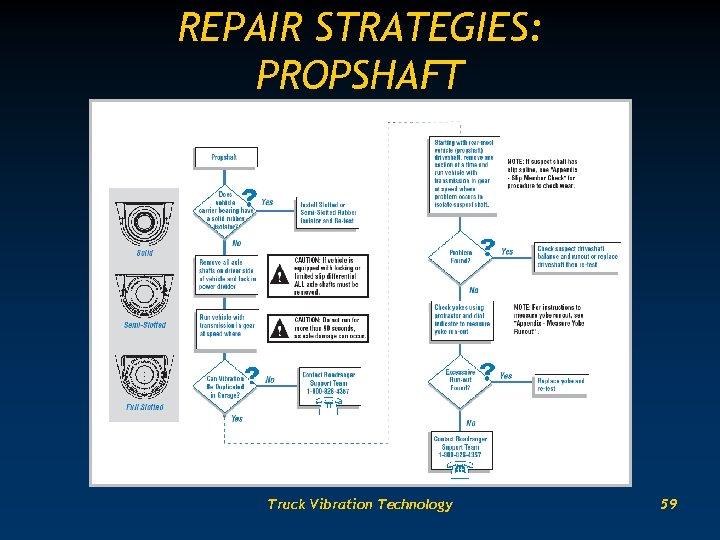

REPAIR STRATEGIES: PROPSHAFT Truck Vibration Technology 59

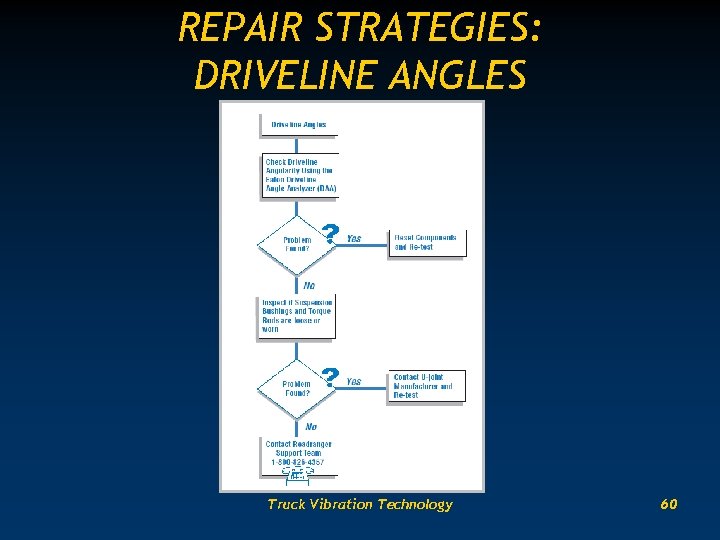

REPAIR STRATEGIES: DRIVELINE ANGLES Truck Vibration Technology 60

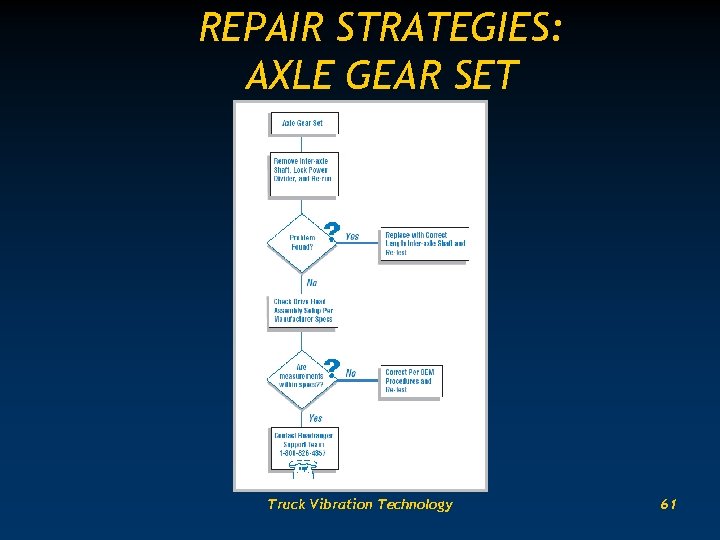

REPAIR STRATEGIES: AXLE GEAR SET Truck Vibration Technology 61

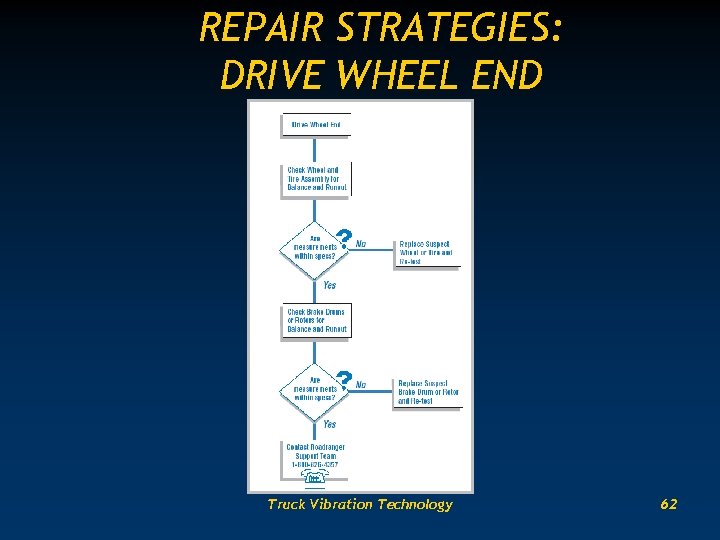

REPAIR STRATEGIES: DRIVE WHEEL END Truck Vibration Technology 62

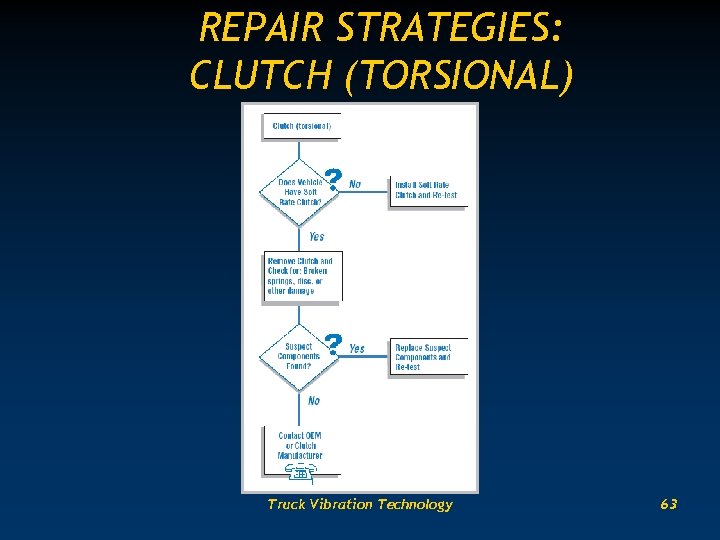

REPAIR STRATEGIES: CLUTCH (TORSIONAL) Truck Vibration Technology 63

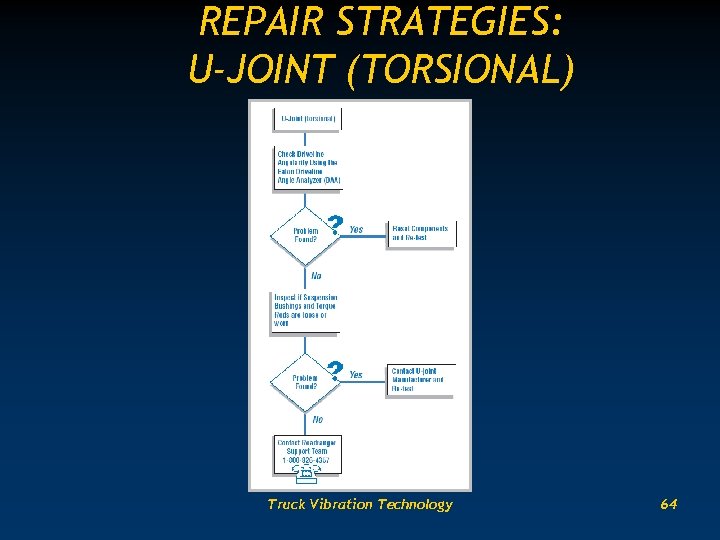

REPAIR STRATEGIES: U-JOINT (TORSIONAL) Truck Vibration Technology 64

QUESTIONS Truck Vibration Technology 65

9c28f3f3340d2c318a45d57bdcbc0c6c.ppt