933372ab7b2c4af29da1664c2c8bf542.ppt

- Количество слайдов: 26

Product and Process Measures Drive Continuous Product Quality and Business Improvement QSG Quality Support Group, Inc. Angelo G. Scangas, President Quality Support Group, Inc. 978 -430 -7611 www. qualitysupportgroup. com

Product and Process Measures Drive Continuous Product Quality and Business Improvement QSG Quality Support Group, Inc. Angelo G. Scangas, President Quality Support Group, Inc. 978 -430 -7611 www. qualitysupportgroup. com

What is on your mind? Do you have any questions? What have you tried? • Worked or not? Why? Your feedback and engagement QSG Quality Support Group, Inc.

What is on your mind? Do you have any questions? What have you tried? • Worked or not? Why? Your feedback and engagement QSG Quality Support Group, Inc.

Continuous Improvement Vision / Definition Continuous Improvement is the relentless effort of top management to seek out and eliminate waste at all levels of the organization. This is achieved through a sustained, results oriented process to instill this culture changing mindset into all levels of the organization through leadership, tools and training. QSG Quality Support Group, Inc.

Continuous Improvement Vision / Definition Continuous Improvement is the relentless effort of top management to seek out and eliminate waste at all levels of the organization. This is achieved through a sustained, results oriented process to instill this culture changing mindset into all levels of the organization through leadership, tools and training. QSG Quality Support Group, Inc.

Continuous Improvement Vision / Definition Align your QMS with the achievement of organizational and business success. QSG Quality Support Group, Inc.

Continuous Improvement Vision / Definition Align your QMS with the achievement of organizational and business success. QSG Quality Support Group, Inc.

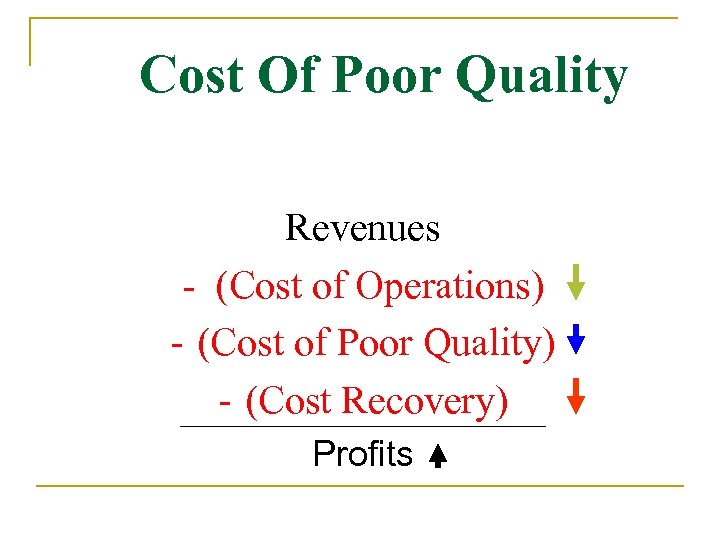

Cost Of Poor Quality Revenues - (Cost of Operations) - (Cost of Poor Quality) - (Cost Recovery) Profits

Cost Of Poor Quality Revenues - (Cost of Operations) - (Cost of Poor Quality) - (Cost Recovery) Profits

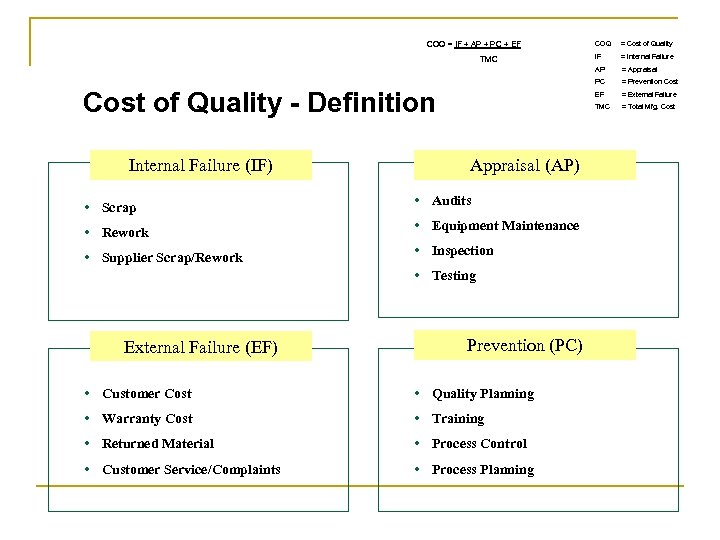

TMC COQ = Cost of Quality IF = Internal Failure AP COQ = IF + AP + PC + EF = Appraisal PC Internal Failure (IF) Appraisal (AP) • Scrap • Audits • Rework • Equipment Maintenance • Supplier Scrap/Rework • Inspection • Testing External Failure (EF) Prevention (PC) • Customer Cost • Quality Planning • Warranty Cost • Training • Returned Material • Process Control • Customer Service/Complaints • Process Planning = External Failure TMC Cost of Quality - Definition = Prevention Cost EF = Total Mfg. Cost

TMC COQ = Cost of Quality IF = Internal Failure AP COQ = IF + AP + PC + EF = Appraisal PC Internal Failure (IF) Appraisal (AP) • Scrap • Audits • Rework • Equipment Maintenance • Supplier Scrap/Rework • Inspection • Testing External Failure (EF) Prevention (PC) • Customer Cost • Quality Planning • Warranty Cost • Training • Returned Material • Process Control • Customer Service/Complaints • Process Planning = External Failure TMC Cost of Quality - Definition = Prevention Cost EF = Total Mfg. Cost

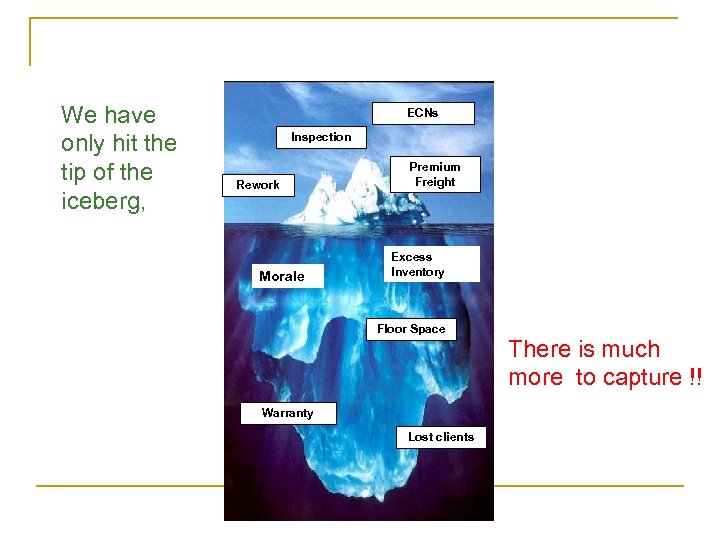

We have only hit the tip of the iceberg, ECNs Inspection Rework Morale Premium Freight Excess Inventory Floor Space Warranty Lost clients There is much more to capture !!

We have only hit the tip of the iceberg, ECNs Inspection Rework Morale Premium Freight Excess Inventory Floor Space Warranty Lost clients There is much more to capture !!

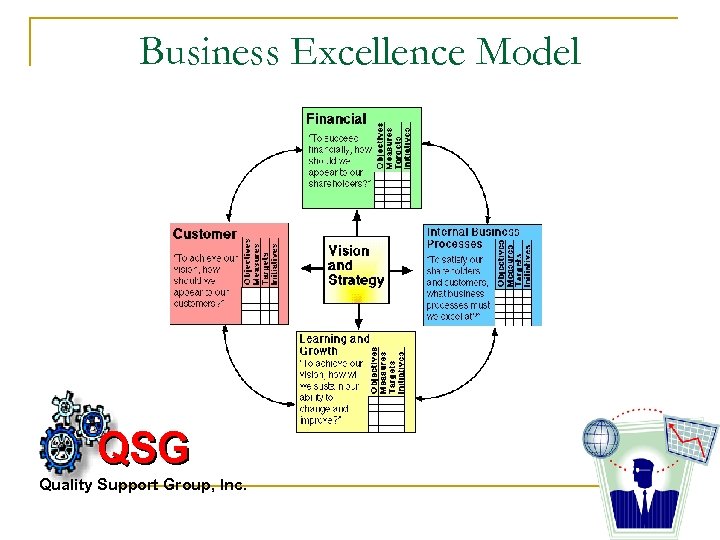

Business Excellence Model QSG Quality Support Group, Inc.

Business Excellence Model QSG Quality Support Group, Inc.

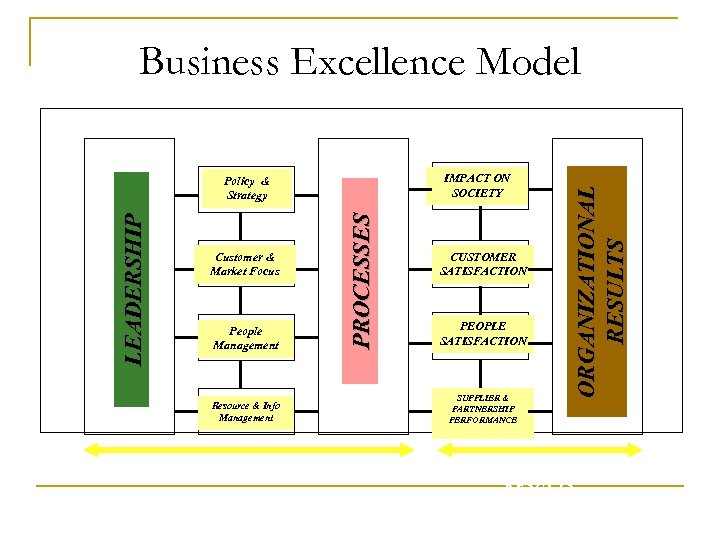

IMPACT ON SOCIETY Customer & Market Focus People Management Resource & Info Management ENABLERS PROCESSES LEADERSHIP Policy & Strategy CUSTOMER SATISFACTION PEOPLE SATISFACTION SUPPLIER & PARTNERSHIP PERFORMANCE ORGANIZATIONAL RESULTS Business Excellence Model RESULTS

IMPACT ON SOCIETY Customer & Market Focus People Management Resource & Info Management ENABLERS PROCESSES LEADERSHIP Policy & Strategy CUSTOMER SATISFACTION PEOPLE SATISFACTION SUPPLIER & PARTNERSHIP PERFORMANCE ORGANIZATIONAL RESULTS Business Excellence Model RESULTS

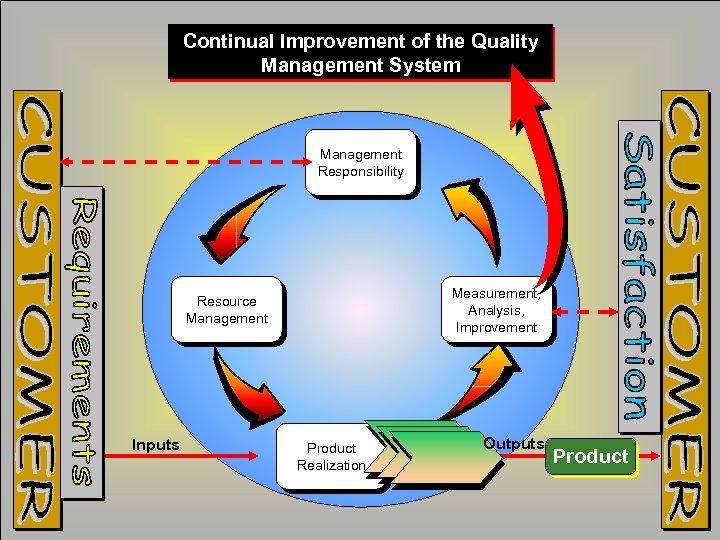

The ISO Model Continual Improvement of the Quality Management System Management Responsibility Measurement, Analysis, Improvement Resource Management Inputs Product Realization Outputs Product

The ISO Model Continual Improvement of the Quality Management System Management Responsibility Measurement, Analysis, Improvement Resource Management Inputs Product Realization Outputs Product

The new ISO 9001: 2008 requirements demand that a company: n n n understand its operations as a series of linked, interactive processes manage each process by allocating resources, defining methods and criteria for monitoring and improvement taking action when a process fails to meet expectations. QSG Quality Support Group, Inc.

The new ISO 9001: 2008 requirements demand that a company: n n n understand its operations as a series of linked, interactive processes manage each process by allocating resources, defining methods and criteria for monitoring and improvement taking action when a process fails to meet expectations. QSG Quality Support Group, Inc.

Effectiveness Extent to which planned activities are realized and planned results achieved. ISO 9000: 2000 3. 2. 14

Effectiveness Extent to which planned activities are realized and planned results achieved. ISO 9000: 2000 3. 2. 14

Improvement and Effectiveness Top Management shall ensure that the quality policy includes a commitment to comply with requirements and continually improve the effectiveness of the quality management system. ISO 9001: 2008 5. 3 The organization shall continually improve the effectiveness of the quality management system through the use of the quality policy, quality objectives, audit results, analysis of data, corrective and preventive actions and management review. ISO 9001: 2008 8. 5

Improvement and Effectiveness Top Management shall ensure that the quality policy includes a commitment to comply with requirements and continually improve the effectiveness of the quality management system. ISO 9001: 2008 5. 3 The organization shall continually improve the effectiveness of the quality management system through the use of the quality policy, quality objectives, audit results, analysis of data, corrective and preventive actions and management review. ISO 9001: 2008 8. 5

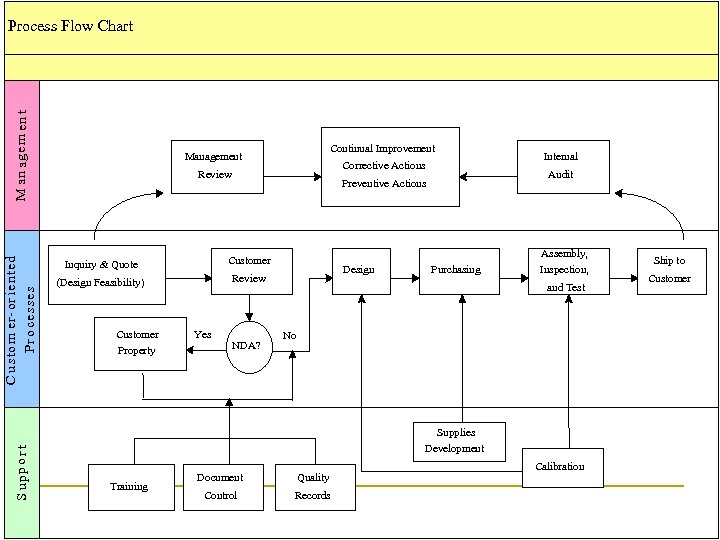

C u s to m e r- or ie nte d Pr o c e sse s M a n a ge m e n t Process Flow Chart Continual Improvement Management Review (Design Feasibility) Assembly, Customer Review Property Yes Audit Preventive Actions Inquiry & Quote Customer Internal Corrective Actions NDA? Design Purchasing Inspection, and Test No S u pp o r t Supplies Development Training Document Quality Control Records Calibration Ship to Customer

C u s to m e r- or ie nte d Pr o c e sse s M a n a ge m e n t Process Flow Chart Continual Improvement Management Review (Design Feasibility) Assembly, Customer Review Property Yes Audit Preventive Actions Inquiry & Quote Customer Internal Corrective Actions NDA? Design Purchasing Inspection, and Test No S u pp o r t Supplies Development Training Document Quality Control Records Calibration Ship to Customer

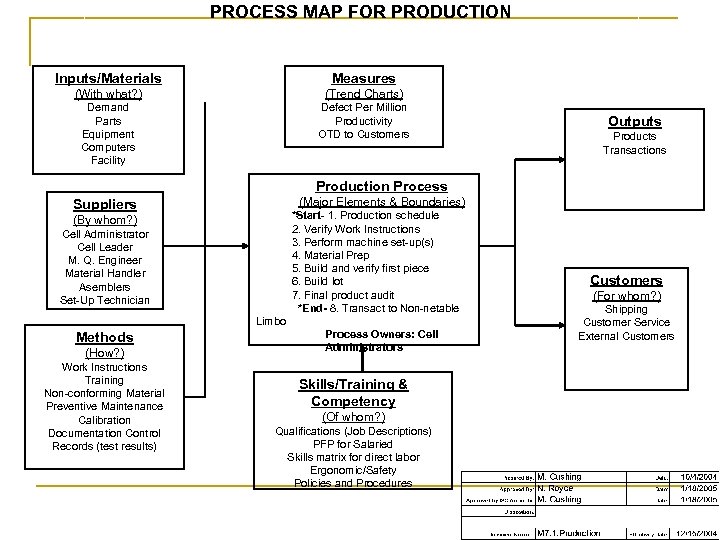

PROCESS MAP FOR PRODUCTION Inputs/Materials Measures (With what? ) (Trend Charts) Demand Parts Equipment Computers Facility Defect Per Million Productivity OTD to Customers Outputs Products Transactions Production Process (Major Elements & Boundaries) Suppliers *Start- 1. Production schedule 2. Verify Work Instructions 3. Perform machine set-up(s) 4. Material Prep 5. Build and verify first piece 6. Build lot 7. Final product audit *End- 8. Transact to Non-netable (By whom? ) Cell Administrator Cell Leader M. Q. Engineer Material Handler Asemblers Set-Up Technician Limbo Methods (How? ) Work Instructions Training Non-conforming Material Preventive Maintenance Calibration Documentation Control Records (test results) Process Owners: Cell Administrators Skills/Training & Competency (Of whom? ) Qualifications (Job Descriptions) PFP for Salaried Skills matrix for direct labor Ergonomic/Safety Policies and Procedures Customers (For whom? ) Shipping Customer Service External Customers

PROCESS MAP FOR PRODUCTION Inputs/Materials Measures (With what? ) (Trend Charts) Demand Parts Equipment Computers Facility Defect Per Million Productivity OTD to Customers Outputs Products Transactions Production Process (Major Elements & Boundaries) Suppliers *Start- 1. Production schedule 2. Verify Work Instructions 3. Perform machine set-up(s) 4. Material Prep 5. Build and verify first piece 6. Build lot 7. Final product audit *End- 8. Transact to Non-netable (By whom? ) Cell Administrator Cell Leader M. Q. Engineer Material Handler Asemblers Set-Up Technician Limbo Methods (How? ) Work Instructions Training Non-conforming Material Preventive Maintenance Calibration Documentation Control Records (test results) Process Owners: Cell Administrators Skills/Training & Competency (Of whom? ) Qualifications (Job Descriptions) PFP for Salaried Skills matrix for direct labor Ergonomic/Safety Policies and Procedures Customers (For whom? ) Shipping Customer Service External Customers

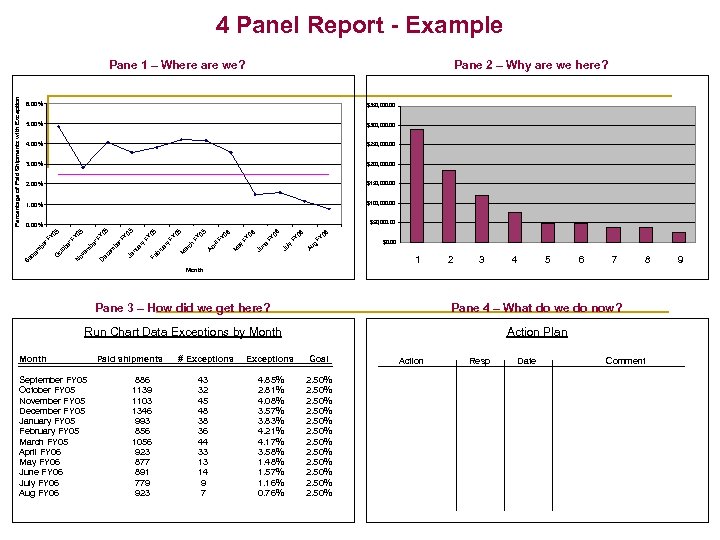

4 Panel Report - Example Pane 2 – Why are we here? 4. 00% $250, 000. 00 3. 00% $200, 000. 00 2. 00% $150, 000. 00 1. 00% $100, 000. 00% $50, 000. 00 06 FY Au g FY ly Ju ne FY Ju ay M Ap r il FY 06 06 05 FY ar M ua r ch y FY FY 05 5 y nu ar Ja Fe br D ec em be r. F Y 0 05 N ov em be r. F FY FY ob er ct O be r em pt Se 06 $300, 000. 00 FY 06 5. 00% 05 $350, 000. 00 5 6. 00% 05 Percentage of Paid Shipments with Exception Pane 1 – Where are we? $0. 00 1 2 3 4 5 6 7 Month Pane 3 – How did we get here? Pane 4 – What do we do now? Run Chart Data Exceptions by Month Action Plan Month September FY 05 October FY 05 November FY 05 December FY 05 January FY 05 February FY 05 March FY 05 April FY 06 May FY 06 June FY 06 July FY 06 Aug FY 06 Paid shipments 886 1139 1103 1346 993 856 1056 923 877 891 779 923 # Exceptions 43 32 45 48 38 36 44 33 13 14 9 7 Exceptions Goal 4. 85% 2. 81% 4. 08% 3. 57% 3. 83% 4. 21% 4. 17% 3. 58% 1. 48% 1. 57% 1. 16% 0. 76% 2. 50% 2. 50% Action Resp Date Comment 8 9

4 Panel Report - Example Pane 2 – Why are we here? 4. 00% $250, 000. 00 3. 00% $200, 000. 00 2. 00% $150, 000. 00 1. 00% $100, 000. 00% $50, 000. 00 06 FY Au g FY ly Ju ne FY Ju ay M Ap r il FY 06 06 05 FY ar M ua r ch y FY FY 05 5 y nu ar Ja Fe br D ec em be r. F Y 0 05 N ov em be r. F FY FY ob er ct O be r em pt Se 06 $300, 000. 00 FY 06 5. 00% 05 $350, 000. 00 5 6. 00% 05 Percentage of Paid Shipments with Exception Pane 1 – Where are we? $0. 00 1 2 3 4 5 6 7 Month Pane 3 – How did we get here? Pane 4 – What do we do now? Run Chart Data Exceptions by Month Action Plan Month September FY 05 October FY 05 November FY 05 December FY 05 January FY 05 February FY 05 March FY 05 April FY 06 May FY 06 June FY 06 July FY 06 Aug FY 06 Paid shipments 886 1139 1103 1346 993 856 1056 923 877 891 779 923 # Exceptions 43 32 45 48 38 36 44 33 13 14 9 7 Exceptions Goal 4. 85% 2. 81% 4. 08% 3. 57% 3. 83% 4. 21% 4. 17% 3. 58% 1. 48% 1. 57% 1. 16% 0. 76% 2. 50% 2. 50% Action Resp Date Comment 8 9

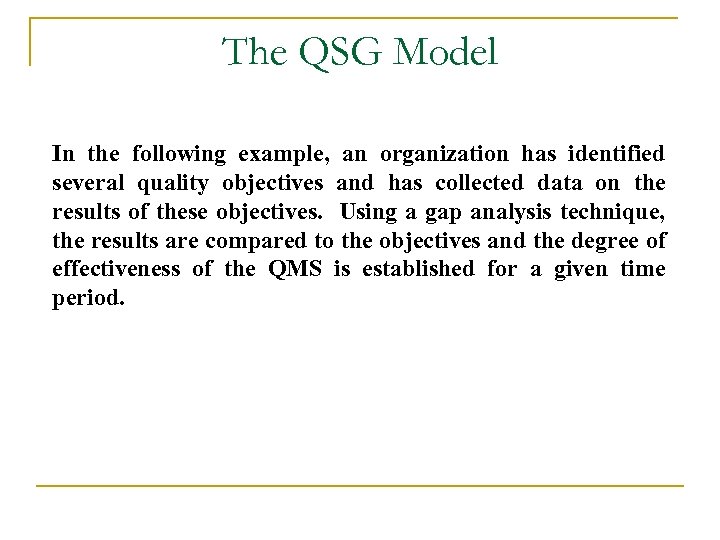

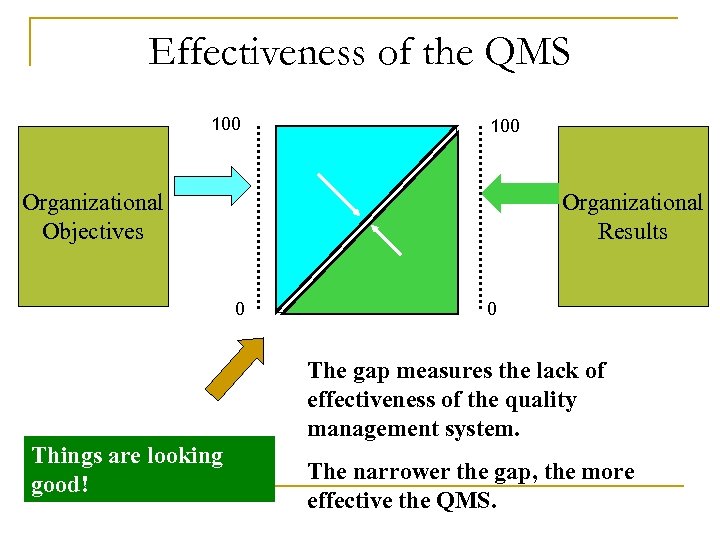

The QSG Model In the following example, an organization has identified several quality objectives and has collected data on the results of these objectives. Using a gap analysis technique, the results are compared to the objectives and the degree of effectiveness of the QMS is established for a given time period.

The QSG Model In the following example, an organization has identified several quality objectives and has collected data on the results of these objectives. Using a gap analysis technique, the results are compared to the objectives and the degree of effectiveness of the QMS is established for a given time period.

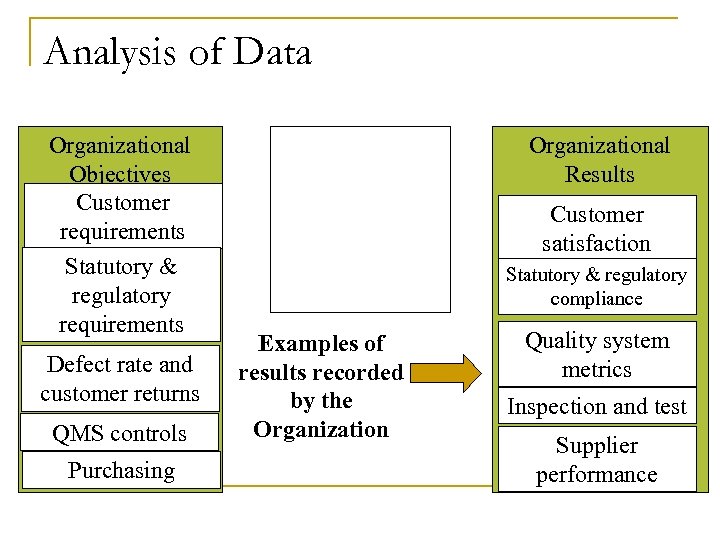

Analysis of Data Organizational Objectives Customer requirements Statutory & regulatory requirements Defect rate and customer returns QMS controls Purchasing Organizational Results Customer satisfaction Statutory & regulatory compliance Examples of results recorded by the Organization Quality system metrics Inspection and test Supplier performance

Analysis of Data Organizational Objectives Customer requirements Statutory & regulatory requirements Defect rate and customer returns QMS controls Purchasing Organizational Results Customer satisfaction Statutory & regulatory compliance Examples of results recorded by the Organization Quality system metrics Inspection and test Supplier performance

Effectiveness of the QMS 100 Organizational Objectives Organizational Results 0 0 The gap measures the lack of effectiveness of the quality management system. Things are looking good! The narrower the gap, the more effective the QMS.

Effectiveness of the QMS 100 Organizational Objectives Organizational Results 0 0 The gap measures the lack of effectiveness of the quality management system. Things are looking good! The narrower the gap, the more effective the QMS.

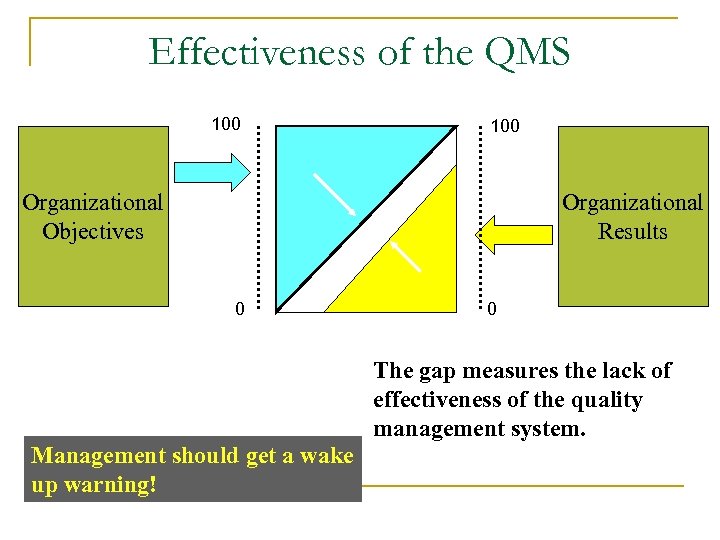

Effectiveness of the QMS 100 Organizational Objectives Organizational Results 0 0 The gap measures the lack of effectiveness of the quality management system. Management should get a wake up warning!

Effectiveness of the QMS 100 Organizational Objectives Organizational Results 0 0 The gap measures the lack of effectiveness of the quality management system. Management should get a wake up warning!

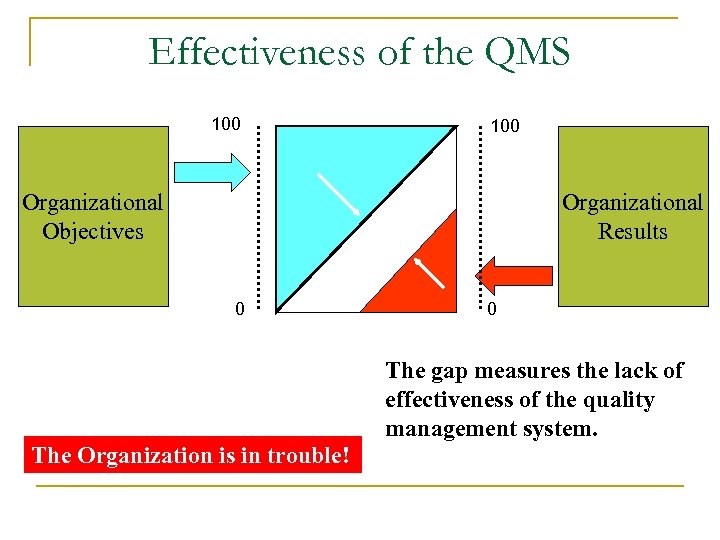

Effectiveness of the QMS 100 Organizational Objectives Organizational Results 0 0 The gap measures the lack of effectiveness of the quality management system. The Organization is in trouble!

Effectiveness of the QMS 100 Organizational Objectives Organizational Results 0 0 The gap measures the lack of effectiveness of the quality management system. The Organization is in trouble!

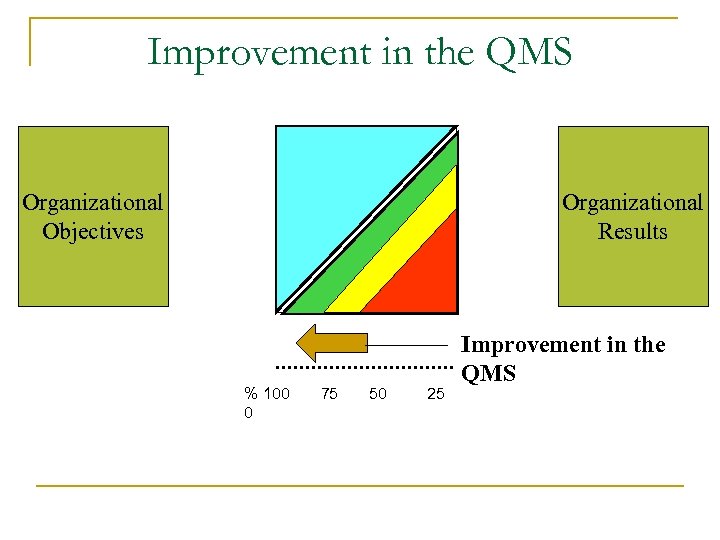

Improvement in the QMS Organizational Objectives Organizational Results % 100 0 75 50 25 Improvement in the QMS

Improvement in the QMS Organizational Objectives Organizational Results % 100 0 75 50 25 Improvement in the QMS

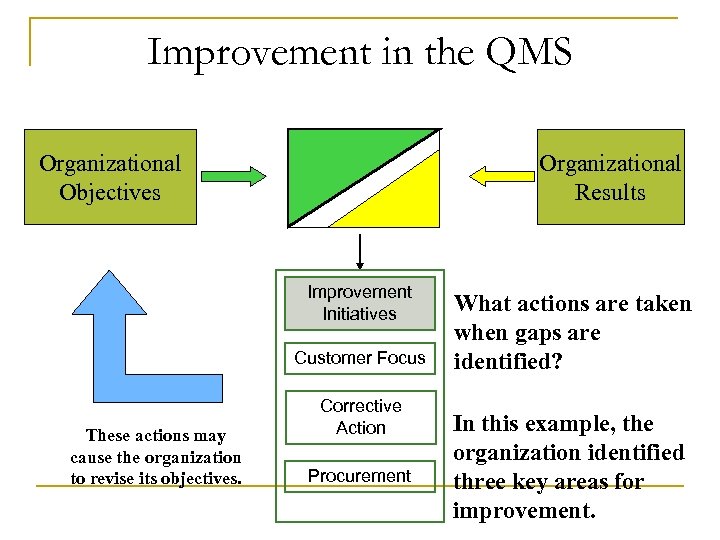

Improvement in the QMS Organizational Objectives Organizational Results Improvement Initiatives Customer Focus These actions may cause the organization to revise its objectives. Corrective Action Procurement What actions are taken when gaps are identified? In this example, the organization identified three key areas for improvement.

Improvement in the QMS Organizational Objectives Organizational Results Improvement Initiatives Customer Focus These actions may cause the organization to revise its objectives. Corrective Action Procurement What actions are taken when gaps are identified? In this example, the organization identified three key areas for improvement.

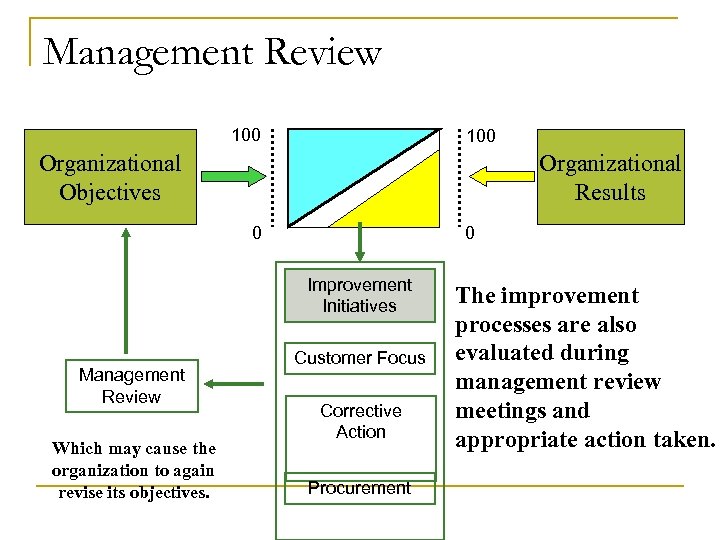

Management Review 100 Organizational Objectives Organizational Results 0 0 Improvement Initiatives Management Review Which may cause the organization to again revise its objectives. Customer Focus Corrective Action Procurement The improvement processes are also evaluated during management review meetings and appropriate action taken.

Management Review 100 Organizational Objectives Organizational Results 0 0 Improvement Initiatives Management Review Which may cause the organization to again revise its objectives. Customer Focus Corrective Action Procurement The improvement processes are also evaluated during management review meetings and appropriate action taken.

Conclusion The overall result of using the QSG model is an enhanced pro-active approach to meet QMS objectives and more importantly their related corporate business and/or financial objectives. The effectiveness of the quality management system in meeting both quality and/or business objectives is likely to be the key attribute that ensures the on-going support and resource allocation to maintain the quality management system within the corporate environment.

Conclusion The overall result of using the QSG model is an enhanced pro-active approach to meet QMS objectives and more importantly their related corporate business and/or financial objectives. The effectiveness of the quality management system in meeting both quality and/or business objectives is likely to be the key attribute that ensures the on-going support and resource allocation to maintain the quality management system within the corporate environment.

QSG Quality Support Group, Inc. THANK YOU! Angelo G. Scangas President Quality Support Group, Inc. 978 -430 -7611 WWW. QUALITYSUPPORTGROUP. COM

QSG Quality Support Group, Inc. THANK YOU! Angelo G. Scangas President Quality Support Group, Inc. 978 -430 -7611 WWW. QUALITYSUPPORTGROUP. COM