16d1b79b5793f28b3ded63ba68cd7f25.ppt

- Количество слайдов: 14

PROCON SYSTEMS Company Presentation

PROCON SYSTEMS Company Presentation

GENERAL DATA • Engineering Contractor specialized in Industrial Process Automation. • Company founded in 1995. • Staff of 65 employees (80% engineers and technicians). • Customers and projects in 14 countries. • 13, 0 M€ turn over in 2016 (50% export sales). • Head Office in Badalona, Barcelona (Spain). • Quality certified ISO 9001: 2015 & ISO/IEC 15504 2

GENERAL DATA • Engineering Contractor specialized in Industrial Process Automation. • Company founded in 1995. • Staff of 65 employees (80% engineers and technicians). • Customers and projects in 14 countries. • 13, 0 M€ turn over in 2016 (50% export sales). • Head Office in Badalona, Barcelona (Spain). • Quality certified ISO 9001: 2015 & ISO/IEC 15504 2

COMPANY PROFILE BUSINESS UNITS Assembly Big Processes Physics Surface Information Treatment Technology 3

COMPANY PROFILE BUSINESS UNITS Assembly Big Processes Physics Surface Information Treatment Technology 3

COMPANY PROFILE MAIN ACTIVITIES - Process Simulation and Engineering. - Hardware Design. - PLC, SCADA and Software Development. - Systems Engineering and Information Technology. - Cabinets Fabrication and Electrical Installation. - Commissioning. - Production support and on site training. - Specialized Maintenance. 4

COMPANY PROFILE MAIN ACTIVITIES - Process Simulation and Engineering. - Hardware Design. - PLC, SCADA and Software Development. - Systems Engineering and Information Technology. - Cabinets Fabrication and Electrical Installation. - Commissioning. - Production support and on site training. - Specialized Maintenance. 4

MARKETS & CUSTOMERS CAR INDUSTRY LARGE SCIENTIFIC FACILITIES AIRCRAFT MANUFACTURER 5

MARKETS & CUSTOMERS CAR INDUSTRY LARGE SCIENTIFIC FACILITIES AIRCRAFT MANUFACTURER 5

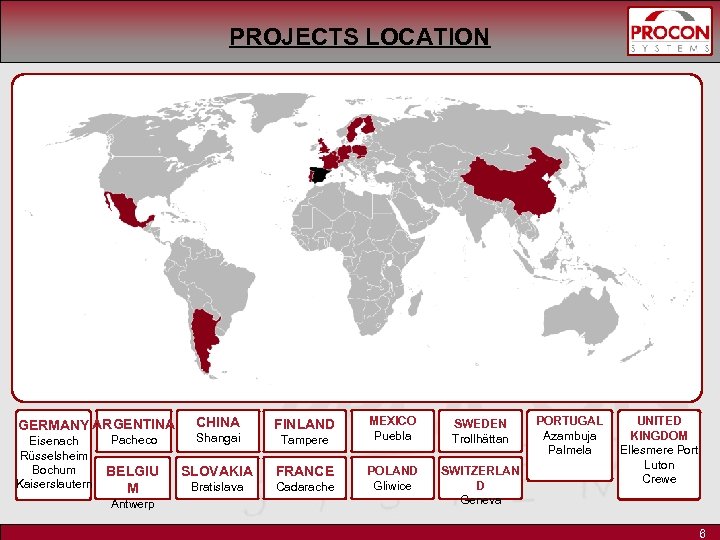

PROJECTS LOCATION GERMANY ARGENTINA Eisenach Rüsselsheim Bochum Kaiserslautern CHINA FINLAND Pacheco Shangai BELGIU M SLOVAKIA FRANCE Bratislava Cadarache Antwerp Tampere MEXICO Puebla SWEDEN Trollhättan POLAND Gliwice SWITZERLAN D Geneva PORTUGAL Azambuja Palmela UNITED KINGDOM Ellesmere Port Luton Crewe 6

PROJECTS LOCATION GERMANY ARGENTINA Eisenach Rüsselsheim Bochum Kaiserslautern CHINA FINLAND Pacheco Shangai BELGIU M SLOVAKIA FRANCE Bratislava Cadarache Antwerp Tampere MEXICO Puebla SWEDEN Trollhättan POLAND Gliwice SWITZERLAN D Geneva PORTUGAL Azambuja Palmela UNITED KINGDOM Ellesmere Port Luton Crewe 6

SUMMARY OF REFERENCES CAR INDUSTRY Body Shop • • • VW 428 (Sharan) L&R Rear Rails Welding Cells, Palmela (Portugal), Volkswagen AE, 2011 Vivaro X 82 Hood Cell, Luton (UK), IPC Vehicles Ltd. , 2011 -2013 Vivaro X 82 Body Side Lines, Luton (UK), IPC Vehicles Ltd. , 2011 -2014 VW 428 (Sharan) Underbody Capacity Increase, Palmela (Portugal), Volkswagen AE, 2012 Opel Delta D 2 XX (Astra) Body Side Lines and Front Rails, Elsmere Port (UK), Gliwice (Poland), 2013 -2016 Opel Meriva/Picasso P 1 MX Body Side Lines, Zaragoza (Spain). 2014 -2017 Opel E 2 XX (Insignia) Front Rails, Rüsselsheim (Germany). 2015 -2016 Opel 9 BXX Corsa Body Side Lines, Zaragoza (Spain)/Eisenach (Germany), 2016 -2018 Opel 9 BXX Corsa Dash Panel, Zaragoza (Spain)/Eisenach (Germany), 2016 -2018 Paint Shop & Automatic Sealing Lines • • • Automatic Sealing Lines (Underbody & Inner), Martorell (Spain), Seat, 2005 -2016 Hang on Parts Sealing Lines, Pamplona (Spain), Volkswagen 2012 -2014 Interior Sealing Line in Stop and Go Station, Palmela (Portugal), Volkswagen AE, 2009 Underbody and Hang on Parts Sealing Lines, Vitoria (Spain), Mercedes-Benz, 2012 -2014 Replacement of Robots in Sealing Lines, Programming new VW-270. Palmela (Portugal). 2015 -2016 Revamping of Underbody Sealing Lines 2 A and 2 B, Programming new VW-270, Pamplona (Spain) 2015 -2016 Final Assembly • Automatic Cell for Sun Roof Assembly, Pamplona (Spain), Volkswagen, 2009 -2011 • Wax Door Coating, Pamplona (Spain), Volkswagen, 2012 -2013 • Pick To Light (P 2 L) System, Martorell (Spain), SEAT, 2012 Information Technology • Spindle Management System (Tra. Sys), Martorell (Spain), SEAT, 2004 -2016 • Automatic Warehouse Management System, Martorell (Spain), SEAT, 2009 -2014 7

SUMMARY OF REFERENCES CAR INDUSTRY Body Shop • • • VW 428 (Sharan) L&R Rear Rails Welding Cells, Palmela (Portugal), Volkswagen AE, 2011 Vivaro X 82 Hood Cell, Luton (UK), IPC Vehicles Ltd. , 2011 -2013 Vivaro X 82 Body Side Lines, Luton (UK), IPC Vehicles Ltd. , 2011 -2014 VW 428 (Sharan) Underbody Capacity Increase, Palmela (Portugal), Volkswagen AE, 2012 Opel Delta D 2 XX (Astra) Body Side Lines and Front Rails, Elsmere Port (UK), Gliwice (Poland), 2013 -2016 Opel Meriva/Picasso P 1 MX Body Side Lines, Zaragoza (Spain). 2014 -2017 Opel E 2 XX (Insignia) Front Rails, Rüsselsheim (Germany). 2015 -2016 Opel 9 BXX Corsa Body Side Lines, Zaragoza (Spain)/Eisenach (Germany), 2016 -2018 Opel 9 BXX Corsa Dash Panel, Zaragoza (Spain)/Eisenach (Germany), 2016 -2018 Paint Shop & Automatic Sealing Lines • • • Automatic Sealing Lines (Underbody & Inner), Martorell (Spain), Seat, 2005 -2016 Hang on Parts Sealing Lines, Pamplona (Spain), Volkswagen 2012 -2014 Interior Sealing Line in Stop and Go Station, Palmela (Portugal), Volkswagen AE, 2009 Underbody and Hang on Parts Sealing Lines, Vitoria (Spain), Mercedes-Benz, 2012 -2014 Replacement of Robots in Sealing Lines, Programming new VW-270. Palmela (Portugal). 2015 -2016 Revamping of Underbody Sealing Lines 2 A and 2 B, Programming new VW-270, Pamplona (Spain) 2015 -2016 Final Assembly • Automatic Cell for Sun Roof Assembly, Pamplona (Spain), Volkswagen, 2009 -2011 • Wax Door Coating, Pamplona (Spain), Volkswagen, 2012 -2013 • Pick To Light (P 2 L) System, Martorell (Spain), SEAT, 2012 Information Technology • Spindle Management System (Tra. Sys), Martorell (Spain), SEAT, 2004 -2016 • Automatic Warehouse Management System, Martorell (Spain), SEAT, 2009 -2014 7

SUMMARY OF REFERENCES LARGE SCIENTIFIC FACILITIES • Divertor Remote Handling System, Tampere (Finland), EFDA, 2006 -2007 • Prototyping Interlock Control Systems, Cadarache (France), ITER. 2010 -2012 • I&C Cabinets Prototyping, Cadarache (France), ITER, 2010 -2013 • Personnel Safety System (PSS), Cerdanyola del Valles (Spain), ALBA, 2007 -2018 • HVAC System for PS Accelerator Ring, Geneva (Switzerland) CERN, 2012 -2015 • Personnel Protection System for the SPS, Meyrin (Switzerland) CERN, 2017 -2022 8

SUMMARY OF REFERENCES LARGE SCIENTIFIC FACILITIES • Divertor Remote Handling System, Tampere (Finland), EFDA, 2006 -2007 • Prototyping Interlock Control Systems, Cadarache (France), ITER. 2010 -2012 • I&C Cabinets Prototyping, Cadarache (France), ITER, 2010 -2013 • Personnel Safety System (PSS), Cerdanyola del Valles (Spain), ALBA, 2007 -2018 • HVAC System for PS Accelerator Ring, Geneva (Switzerland) CERN, 2012 -2015 • Personnel Protection System for the SPS, Meyrin (Switzerland) CERN, 2017 -2022 8

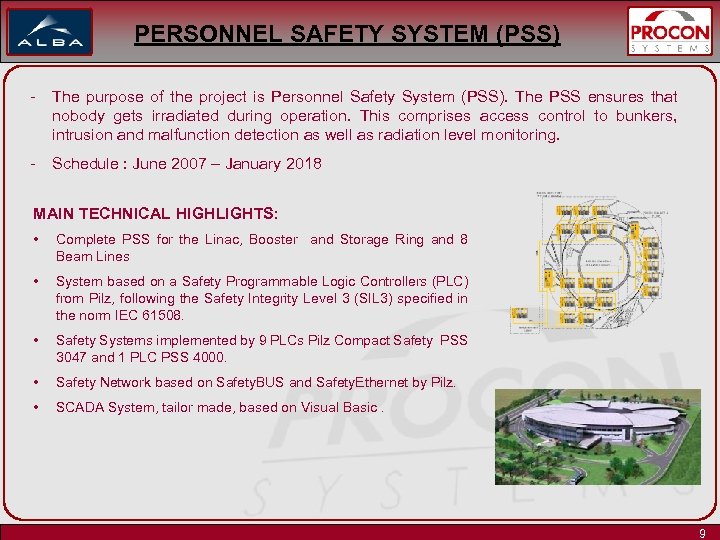

PERSONNEL SAFETY SYSTEM (PSS) - The purpose of the project is Personnel Safety System (PSS). The PSS ensures that nobody gets irradiated during operation. This comprises access control to bunkers, intrusion and malfunction detection as well as radiation level monitoring. - Schedule : June 2007 – January 2018 MAIN TECHNICAL HIGHLIGHTS: • Complete PSS for the Linac, Booster and Storage Ring and 8 Beam Lines • System based on a Safety Programmable Logic Controllers (PLC) from Pilz, following the Safety Integrity Level 3 (SIL 3) specified in the norm IEC 61508. • Safety Systems implemented by 9 PLCs Pilz Compact Safety PSS 3047 and 1 PLC PSS 4000. • Safety Network based on Safety. BUS and Safety. Ethernet by Pilz. • SCADA System, tailor made, based on Visual Basic. 9

PERSONNEL SAFETY SYSTEM (PSS) - The purpose of the project is Personnel Safety System (PSS). The PSS ensures that nobody gets irradiated during operation. This comprises access control to bunkers, intrusion and malfunction detection as well as radiation level monitoring. - Schedule : June 2007 – January 2018 MAIN TECHNICAL HIGHLIGHTS: • Complete PSS for the Linac, Booster and Storage Ring and 8 Beam Lines • System based on a Safety Programmable Logic Controllers (PLC) from Pilz, following the Safety Integrity Level 3 (SIL 3) specified in the norm IEC 61508. • Safety Systems implemented by 9 PLCs Pilz Compact Safety PSS 3047 and 1 PLC PSS 4000. • Safety Network based on Safety. BUS and Safety. Ethernet by Pilz. • SCADA System, tailor made, based on Visual Basic. 9

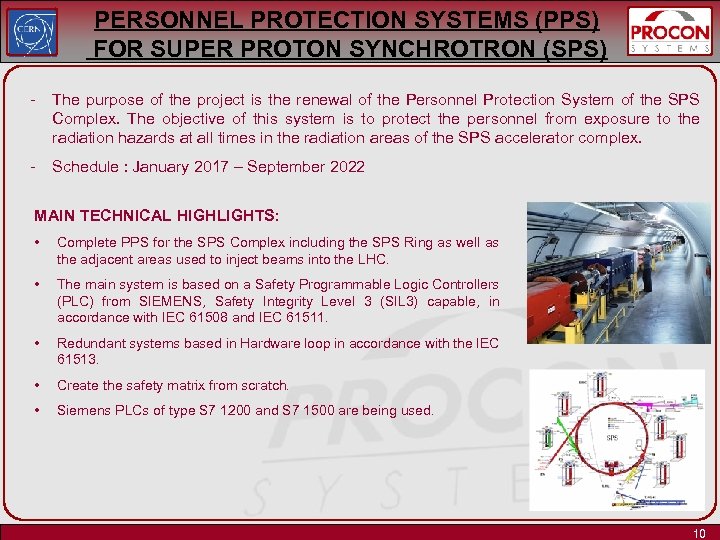

PERSONNEL PROTECTION SYSTEMS (PPS) FOR SUPER PROTON SYNCHROTRON (SPS) - The purpose of the project is the renewal of the Personnel Protection System of the SPS Complex. The objective of this system is to protect the personnel from exposure to the radiation hazards at all times in the radiation areas of the SPS accelerator complex. - Schedule : January 2017 – September 2022 MAIN TECHNICAL HIGHLIGHTS: • Complete PPS for the SPS Complex including the SPS Ring as well as the adjacent areas used to inject beams into the LHC. • The main system is based on a Safety Programmable Logic Controllers (PLC) from SIEMENS, Safety Integrity Level 3 (SIL 3) capable, in accordance with IEC 61508 and IEC 61511. • Redundant systems based in Hardware loop in accordance with the IEC 61513. • Create the safety matrix from scratch. • Siemens PLCs of type S 7 1200 and S 7 1500 are being used. 10

PERSONNEL PROTECTION SYSTEMS (PPS) FOR SUPER PROTON SYNCHROTRON (SPS) - The purpose of the project is the renewal of the Personnel Protection System of the SPS Complex. The objective of this system is to protect the personnel from exposure to the radiation hazards at all times in the radiation areas of the SPS accelerator complex. - Schedule : January 2017 – September 2022 MAIN TECHNICAL HIGHLIGHTS: • Complete PPS for the SPS Complex including the SPS Ring as well as the adjacent areas used to inject beams into the LHC. • The main system is based on a Safety Programmable Logic Controllers (PLC) from SIEMENS, Safety Integrity Level 3 (SIL 3) capable, in accordance with IEC 61508 and IEC 61511. • Redundant systems based in Hardware loop in accordance with the IEC 61513. • Create the safety matrix from scratch. • Siemens PLCs of type S 7 1200 and S 7 1500 are being used. 10

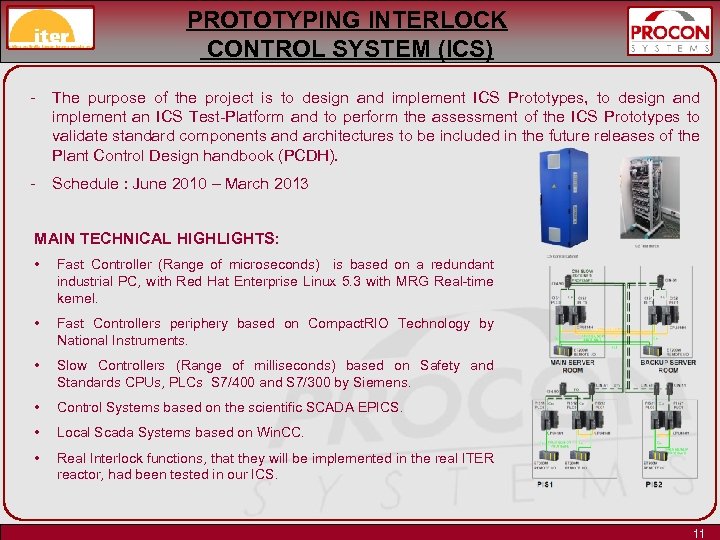

PROTOTYPING INTERLOCK CONTROL SYSTEM (ICS) - The purpose of the project is to design and implement ICS Prototypes, to design and implement an ICS Test-Platform and to perform the assessment of the ICS Prototypes to validate standard components and architectures to be included in the future releases of the Plant Control Design handbook (PCDH). - Schedule : June 2010 – March 2013 MAIN TECHNICAL HIGHLIGHTS: • Fast Controller (Range of microseconds) is based on a redundant industrial PC, with Red Hat Enterprise Linux 5. 3 with MRG Real-time kernel. • Fast Controllers periphery based on Compact. RIO Technology by National Instruments. • Slow Controllers (Range of milliseconds) based on Safety and Standards CPUs, PLCs S 7/400 and S 7/300 by Siemens. • Control Systems based on the scientific SCADA EPICS. • Local Scada Systems based on Win. CC. • Real Interlock functions, that they will be implemented in the real ITER reactor, had been tested in our ICS. 11

PROTOTYPING INTERLOCK CONTROL SYSTEM (ICS) - The purpose of the project is to design and implement ICS Prototypes, to design and implement an ICS Test-Platform and to perform the assessment of the ICS Prototypes to validate standard components and architectures to be included in the future releases of the Plant Control Design handbook (PCDH). - Schedule : June 2010 – March 2013 MAIN TECHNICAL HIGHLIGHTS: • Fast Controller (Range of microseconds) is based on a redundant industrial PC, with Red Hat Enterprise Linux 5. 3 with MRG Real-time kernel. • Fast Controllers periphery based on Compact. RIO Technology by National Instruments. • Slow Controllers (Range of milliseconds) based on Safety and Standards CPUs, PLCs S 7/400 and S 7/300 by Siemens. • Control Systems based on the scientific SCADA EPICS. • Local Scada Systems based on Win. CC. • Real Interlock functions, that they will be implemented in the real ITER reactor, had been tested in our ICS. 11

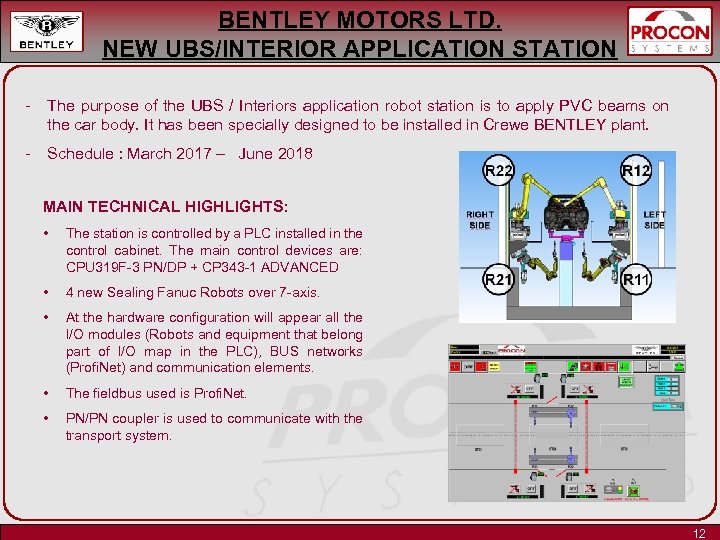

BENTLEY MOTORS LTD. NEW UBS/INTERIOR APPLICATION STATION - The purpose of the UBS / Interiors application robot station is to apply PVC beams on the car body. It has been specially designed to be installed in Crewe BENTLEY plant. - Schedule : March 2017 – June 2018 MAIN TECHNICAL HIGHLIGHTS: • The station is controlled by a PLC installed in the control cabinet. The main control devices are: CPU 319 F-3 PN/DP + CP 343 -1 ADVANCED • 4 new Sealing Fanuc Robots over 7 -axis. • At the hardware configuration will appear all the I/O modules (Robots and equipment that belong part of I/O map in the PLC), BUS networks (Profi. Net) and communication elements. • The fieldbus used is Profi. Net. • PN/PN coupler is used to communicate with the transport system. 12

BENTLEY MOTORS LTD. NEW UBS/INTERIOR APPLICATION STATION - The purpose of the UBS / Interiors application robot station is to apply PVC beams on the car body. It has been specially designed to be installed in Crewe BENTLEY plant. - Schedule : March 2017 – June 2018 MAIN TECHNICAL HIGHLIGHTS: • The station is controlled by a PLC installed in the control cabinet. The main control devices are: CPU 319 F-3 PN/DP + CP 343 -1 ADVANCED • 4 new Sealing Fanuc Robots over 7 -axis. • At the hardware configuration will appear all the I/O modules (Robots and equipment that belong part of I/O map in the PLC), BUS networks (Profi. Net) and communication elements. • The fieldbus used is Profi. Net. • PN/PN coupler is used to communicate with the transport system. 12

OPEL P 1 MX (Crossland X/ C-Aircross) BODY SIDE LINES - Scope: Mechanical and Electrical Engineering. Electrical Package including Supply of Electrical and Control Cabinets, Electrical Installation and Commissioning - Schedule: May 2015 – September 2017 MAIN TECHNICAL HIGHLIGHTS: • Supply, installation and commissioning of 16 Rockwell PLC’s • Programming and commissioning standard code & safety code • Programming and Device. Net fieldbus • Programming and commissioning of the HMI interface screen. commissioning of 13

OPEL P 1 MX (Crossland X/ C-Aircross) BODY SIDE LINES - Scope: Mechanical and Electrical Engineering. Electrical Package including Supply of Electrical and Control Cabinets, Electrical Installation and Commissioning - Schedule: May 2015 – September 2017 MAIN TECHNICAL HIGHLIGHTS: • Supply, installation and commissioning of 16 Rockwell PLC’s • Programming and commissioning standard code & safety code • Programming and Device. Net fieldbus • Programming and commissioning of the HMI interface screen. commissioning of 13

CONTACT Arquímedes, 26 08918 Badalona (Barcelona) Spain +34 93 460 99 40 +34 93 383 16 01 http: //www. proconsystems. net procon@proconsystems. net 14

CONTACT Arquímedes, 26 08918 Badalona (Barcelona) Spain +34 93 460 99 40 +34 93 383 16 01 http: //www. proconsystems. net procon@proconsystems. net 14