b3855dc335fd38f2673e2ee218f8b3c6.ppt

- Количество слайдов: 29

Process System Capability An introduction to 9103 ‘VARIATION MANAGEMENT OF KEY CHARACTERISTICS’ Bernard LAURAS AIRBUS

Objectives of this presentation • Show importance of managing Key Characteristics and Increase your understanding of 9103 content. • Share experiences of implementing 9103 including who was involved and what they got out of it. • Inspire you that 9103 has broader benefits and is not just a Customer requirement. • Illustrate that small organisations can do this type of activity.

Why do we need such presentation ? • 9103 should help resolve the first 4 main causes of Quality problems identified by AIA (Aerospace? s lem Industry Association) ob pr – Personnel fail to understand thehe t design requirement hy w – Process changed without understanding the impact so ts, initial production fails to detect defects – Process to review is ex – Design 3 10 requirements exceed the capability of the 9 manufacturing process

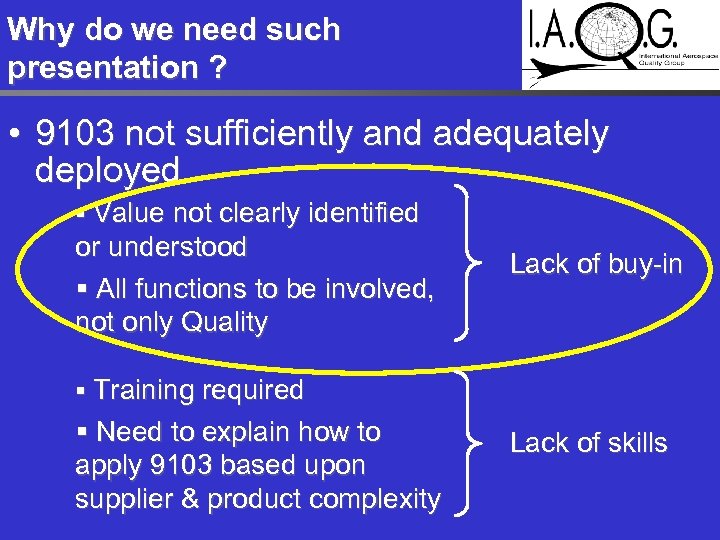

Why do we need such presentation ? • 9103 not sufficiently and adequately deployed § Value not clearly identified or understood § All functions to be involved, not only Quality Lack of buy-in § Training required § Need to explain how to apply 9103 based upon supplier & product complexity Lack of skills

What are Key Characteristics ? Key Characteristics are the main ones guaranteeing full Customer satisfaction, that means ensuring all his needs are effectively & permanently met

Why do we need to focus on key characteristics ? • To enhance confidence that true Customer expectations are met • To drive the continuous improvement of manufacturing processes through adequate planning • To reduce costs by eliminating wastes and unnecessary efforts

Scope of 9103 • Establishes requirements for management of key characteristics variation – Specifies general requirements – Provides a process • Primarily intended to apply to new parts but should also be applied through out the life of the programme to ensure that changes are taken into consideration.

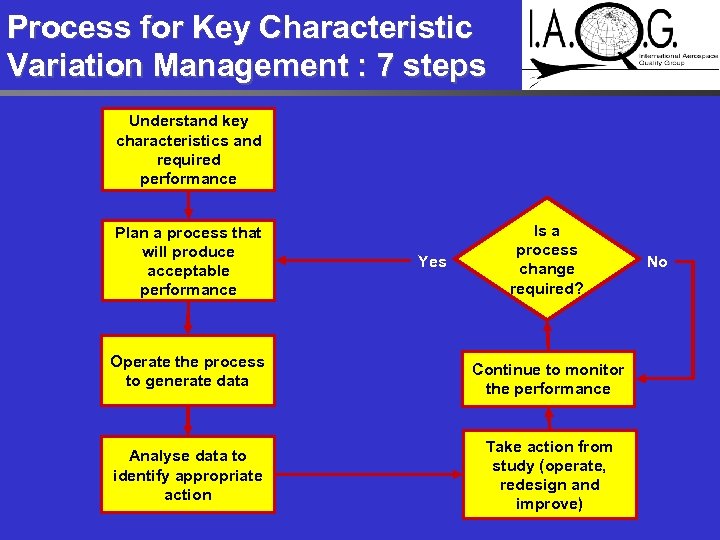

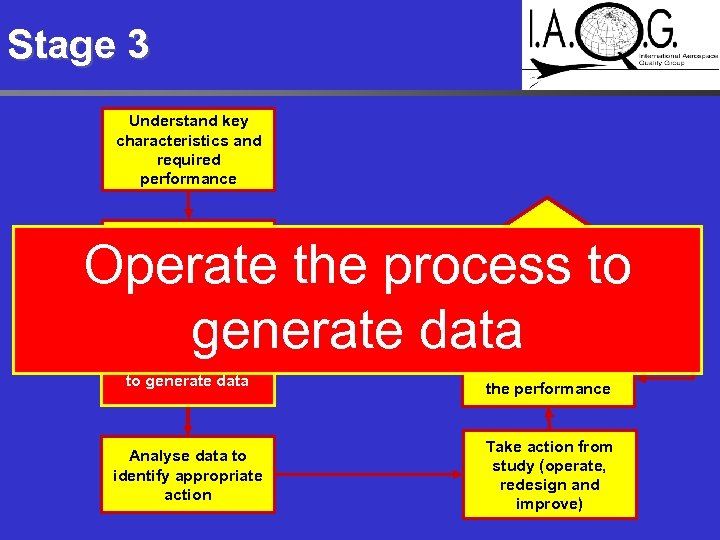

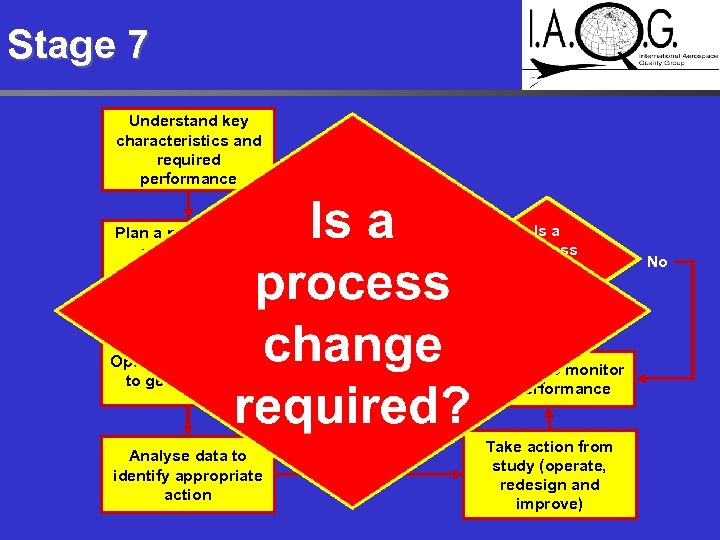

Process for Key Characteristic Variation Management : 7 steps Understand key characteristics and required performance Plan a process that will produce acceptable performance Yes Is a process change required? Operate the process to generate data Continue to monitor the performance Analyse data to identify appropriate action Take action from study (operate, redesign and improve) No

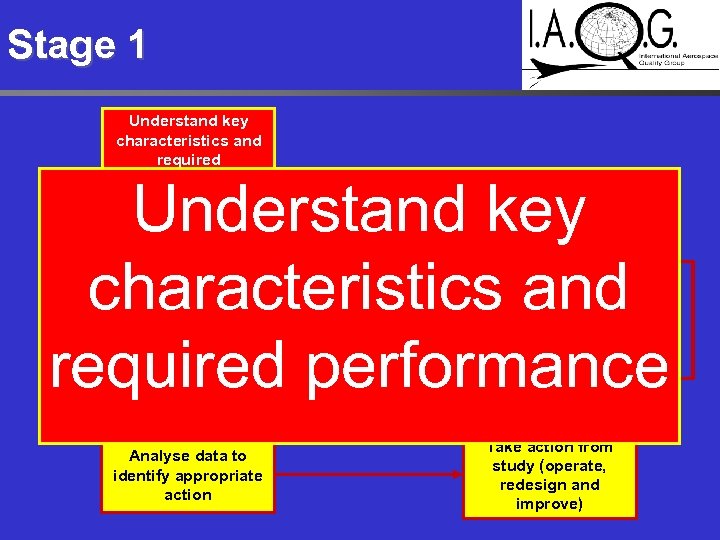

Stage 1 Understand key characteristics and required performance Plan a process that will produce acceptable performance Yes Is a process change required? Operate the process to generate data Continue to monitor the performance Analyse data to identify appropriate action Take action from study (operate, redesign and improve) No

Stage 1 - Understand Key Characteristics and Required Performance • Establish an appropriate cross-functional team – – – y… an s Design Engineer: Potential design r mp ratofailure modes, o and Ccauses pe effects. ur Process issues, bpotential failures, O jo ! Manufacturing Engineer: yo he he tcausestand effects. to t it orget Definition of inspection methods and Inspection Department: f ap ’t do d y A elcriteria. n do fectiv Feedback from Supply Chain and Buyer (Purchasing): nd flow down of requirements. a ef Quality Engineerho from similar product, w (Facilitator): Feedbackreturns, guarantee that customer process is adequately followed.

Stage 1 - Understand Key Characteristics and Required Performance • Establish an appropriate cross-functional team – Design Engineer: – – Potential design failure modes, causeser effects. and r m issues, potential failures, Manufacturing Engineer: Process me sto to effects. causes and u s CDefinition of inspection methods and Inspection Department: r Cu ou ur y o criteria. Buyer (Purchasing): to h y Feedback from Supply Chain and n flow down of requirements. te wit Quality Engineer Lis (Facilitator): Feedback from similar product, ak customer returns, guarantee that e process is adequately followed. Sp • Look at product, process & Customer requirements: What does he want and how we can do it ?

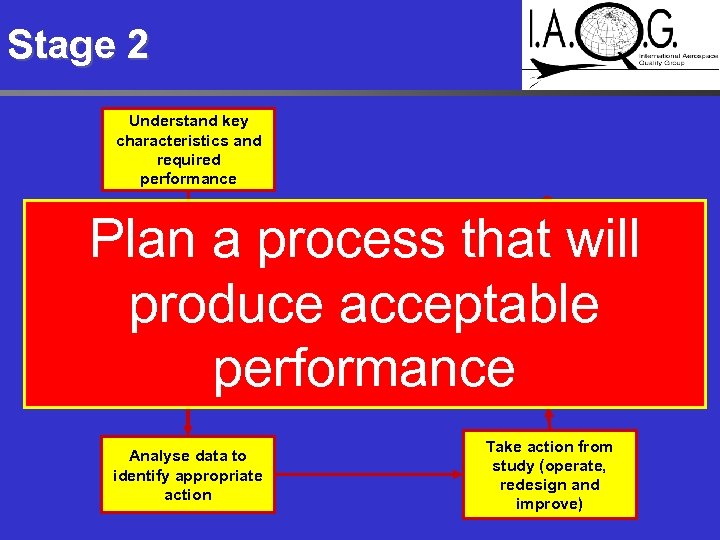

Stage 2 Understand key characteristics and required performance Plan a process that will produce acceptable performance Yes Is a process change required? Operate the process to generate data Continue to monitor the performance Analyse data to identify appropriate action Take action from study (operate, redesign and improve) No

Stage 2 - Plan Manufacturing Processes • Identify key manufacturing processes impacting key characteristics • Ensure process owner exist for each key characteristic • Establish a minimum acceptable capability ratio (Ck, Cpk, …) for each key characteristic • Identify sources of variation and potential risks… and mitigate them • Relate process data back to what designers want… • … and designers: Also understand capability of manufacturing Processes

Stage 3 Understand key characteristics and required performance Plan a process that will produce acceptable performance Is a process change required? Operate the process to generate data Yes Operate the process to generate data Continue to monitor the performance Analyse data to identify appropriate action Take action from study (operate, redesign and improve) No

Stage 3 - Operate on Trial Basis to Generate Data • Create Data collection plan for all key characteristics (who, what, where, frequency, conditions, …) • Produce parts/components to specified work instructions in a representative environment • Measure key characteristics and collect data to document any deviations • Perform First Article Inspection (9102 Refers).

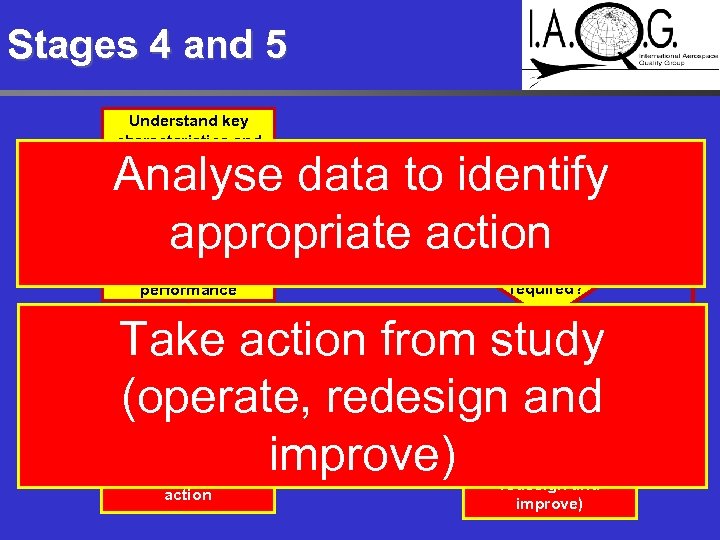

Stages 4 and 5 Understand key characteristics and required performance Analyse data to identify appropriate action Plan a process that will produce acceptable performance Yes Is a process change required? Take action from study (operate, redesign and improve) Operate the process to generate data Continue to monitor the performance Analyse data to identify appropriate action Take action from study (operate, redesign and improve) No

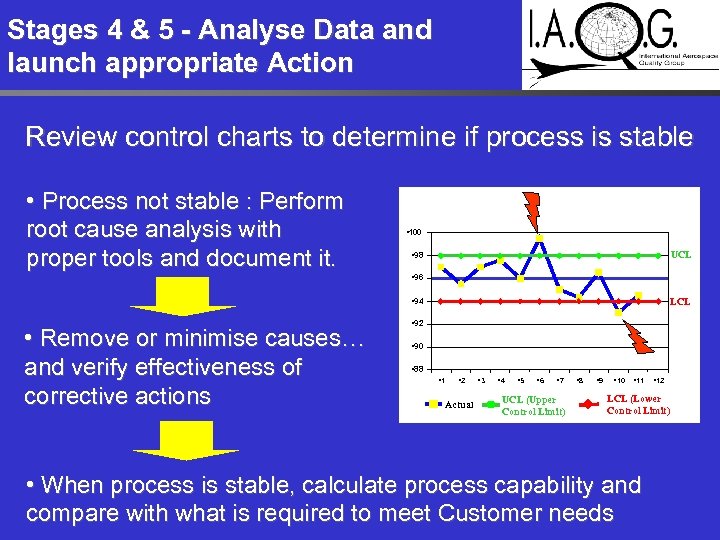

Stages 4 & 5 - Analyse Data and launch appropriate Action Review control charts to determine if process is stable • Process not stable : Perform root cause analysis with proper tools and document it. • 100 UCL • 98 • 96 • 94 • Remove or minimise causes… and verify effectiveness of corrective actions LCL • 92 • 90 • 88 • 1 • 2 Actual • 3 • 4 • 5 • 6 • 7 UCL (Upper Control Limit) • 8 • 9 • 10 • 11 • 12 LCL (Lower Control Limit) • When process is stable, calculate process capability and compare with what is required to meet Customer needs

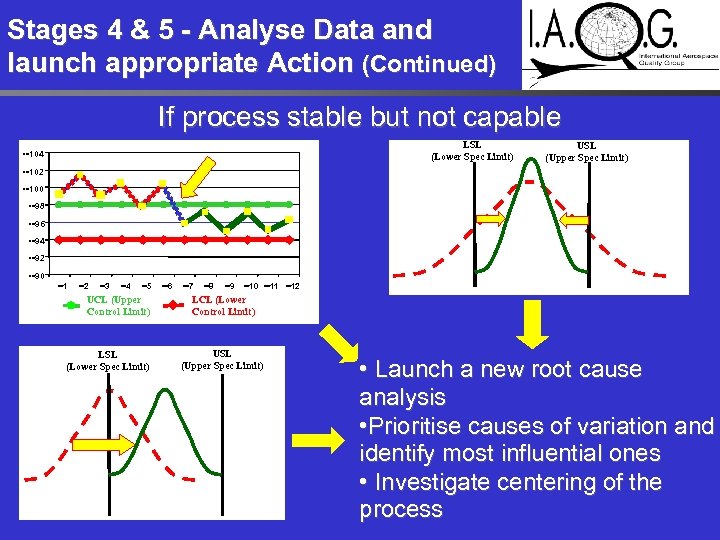

Stages 4 & 5 - Analyse Data and launch appropriate Action (Continued) If process stable but not capable LSL (Lower Spec Limit) • • 104 USL (Upper Spec Limit) • • 102 • • 100 • • 98 • • 96 • • 94 • • 92 • • 90 • • 1 • • 2 • • 3 • • 4 • • 5 UCL (Upper Control Limit) LSL (Lower Spec Limit) • • 6 • • 7 • • 8 • • 9 • • 10 • • 11 • • 12 LCL (Lower Control Limit) USL (Upper Spec Limit) • Launch a new root cause analysis • Prioritise causes of variation and identify most influential ones • Investigate centering of the process

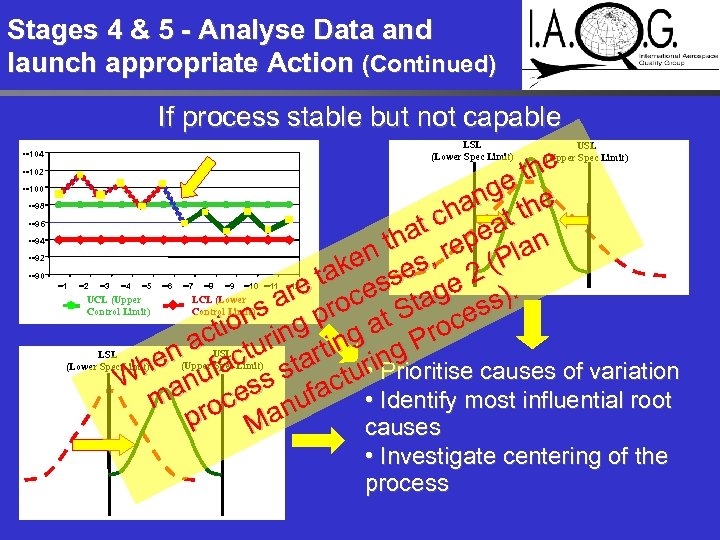

Stages 4 & 5 - Analyse Data and launch appropriate Action (Continued) If process stable but not capable LSL (Lower Spec Limit) • • 104 • • 102 • • 100 • • 98 • • 96 • • 94 • • 92 • • 90 • • 1 • • 2 • • 3 USL (Upper Spec Limit) the ge e an th t ch eat tha rep lan ken ses, 2 (P ta s are roce Stage ss). s on ing p g at roce cti ur n a act tartin ring P he uf W an s s factu • Prioritise causes of variation • Identify most influential root m roces nu p Ma causes • • 4 • • 5 UCL (Upper Control Limit) LSL (Lower Spec Limit) • • 6 • • 7 • • 8 • • 9 • • 10 • • 11 • • 12 LCL (Lower Control Limit) USL (Upper Spec Limit) • Investigate centering of the process

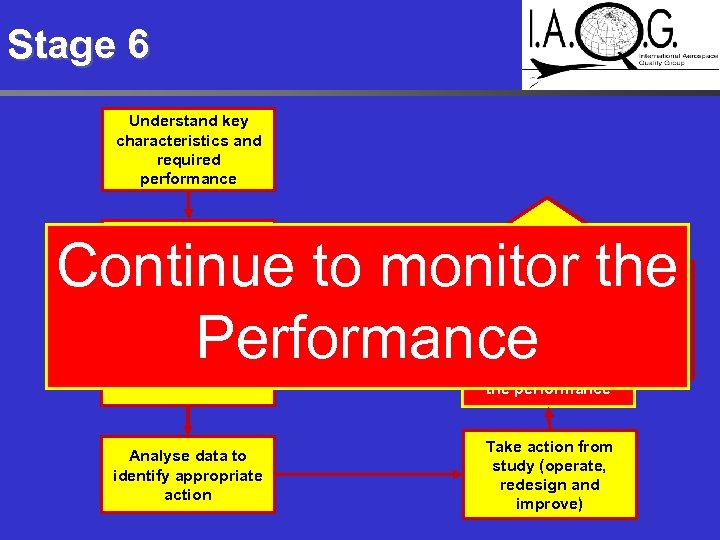

Stage 6 Understand key characteristics and required performance Plan a process that will produce acceptable performance Is a process change required? Continue to monitor the Performance Yes Operate the process to generate data Continue to monitor the performance Analyse data to identify appropriate action Take action from study (operate, redesign and improve) No

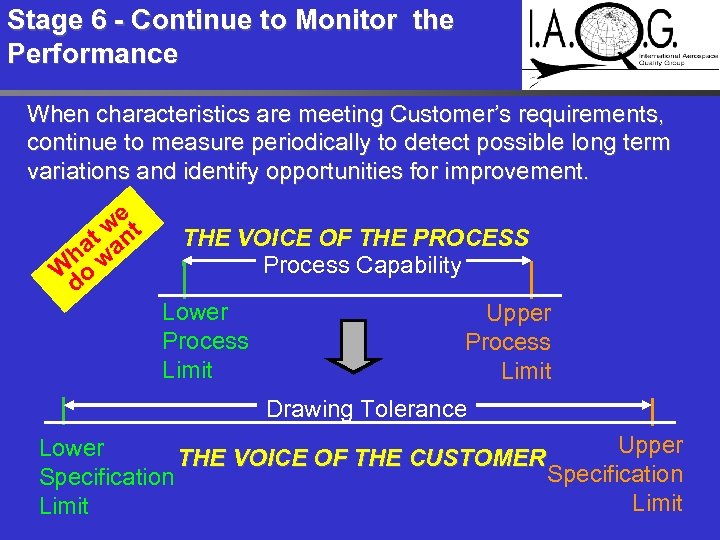

Stage 6 - Continue to Monitor the Performance When characteristics are meeting Customer’s requirements, continue to measure periodically to detect possible long term variations and identify opportunities for improvement. e w t at an h w W o d THE VOICE OF THE PROCESS Process Capability Lower Process Limit Upper Process Limit Drawing Tolerance Upper Lower THE VOICE OF THE CUSTOMER Specification Limit

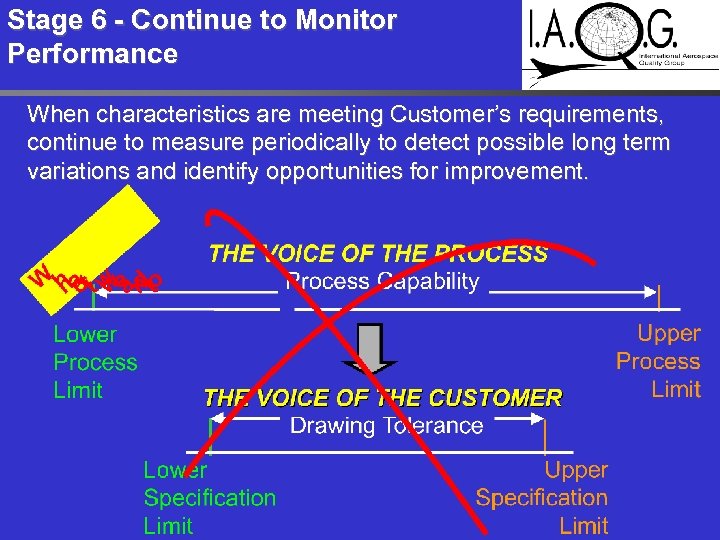

Stage 6 - Continue to Monitor Performance When characteristics are meeting Customer’s requirements, continue to measure periodically to detect possible long term variations and identify opportunities for improvement.

Stage 7 Understand key characteristics and required performance Plan a process that will produce acceptable performance Yes Is a process change required? Operate the process to generate data Continue to monitor the performance Analyse data to identify appropriate action Take action from study (operate, redesign and improve) No

Stage 7 – Is a process change required ? • If no change is required, continue to monitor process performance per Stage 6. • If a change is required, repeat Stages 1 to 5 prior to implementing any change. • Document any planned manufacturing process changes, including reasons for change.

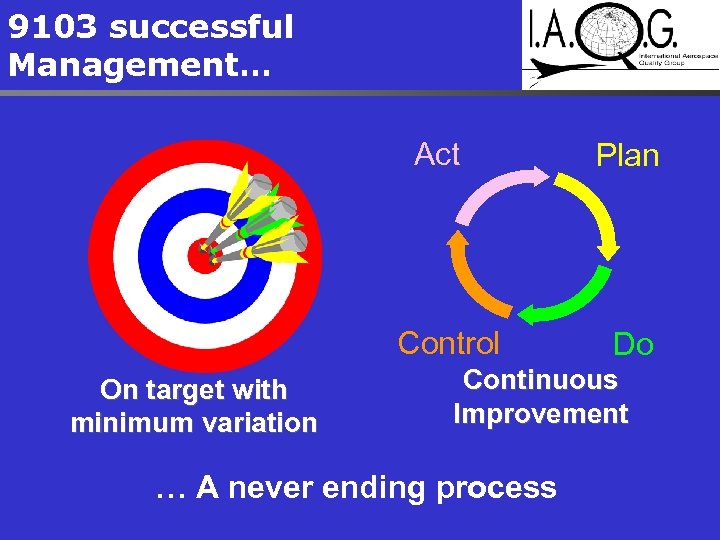

9103 successful Management… Act Control On target with minimum variation Plan Do Continuous Improvement … A never ending process

Summary : Don’t forget these key factors of success… • Manage Keys characteristics during all life of the programme, in particular when introducing a change • Involve all concerned functions • Focus on key characteristics and associated processes… but don’t forget the others ! • Record all what you do… and keep history: – Potential loss of experience during the programme life – Change of rationale for a characteristics being key or not • Feedback from manufacturing & supply chain to engineering … and flow them down internally and within your Sub-Tiers

Next Step • Training module, guidance material, on line training packs, etc …will be created by IAQG

Any Questions ? They will be answered at the end of the 3 presentations

Existing experience of 9103 Implementation Brian Harvey - Clamonta Dave Wentworth - Delta Industries

b3855dc335fd38f2673e2ee218f8b3c6.ppt