Basic Engineering.pptx

- Количество слайдов: 13

Process parameters of wells operation considering the equipment installed in the Karachaganak deposit. Student: Sagingaliyev Temirbek Superviser: Kalmykova A. G

Process parameters of wells operation considering the equipment installed in the Karachaganak deposit. Student: Sagingaliyev Temirbek Superviser: Kalmykova A. G

Plan: Ø Wellhead equipment Ø Problem Ø Decision Ø Conclusion

Plan: Ø Wellhead equipment Ø Problem Ø Decision Ø Conclusion

Actuality of work : A extraction of oil and gas in Kazakhstan is one of major reasons in the state budget. Efficiency of extraction of oil straight depends on the correct selection of equipment. The index of efficiency of the applied equipment are debits of mining wells and their accordance to the plan selections. The aim of the science work: There is a choice of the most effective equipment for exploitation of wells in the conditions of Karachaganak deposit. For the achievement of the indicated aim were decided next tasks: 1 Analysis of the state of equipment and his external environments on the wells of working collection on the Karachaganak deposit. 2. Estimation of the technological operations conducted on trade (Workovers or MRW, PRW and GTO)

Actuality of work : A extraction of oil and gas in Kazakhstan is one of major reasons in the state budget. Efficiency of extraction of oil straight depends on the correct selection of equipment. The index of efficiency of the applied equipment are debits of mining wells and their accordance to the plan selections. The aim of the science work: There is a choice of the most effective equipment for exploitation of wells in the conditions of Karachaganak deposit. For the achievement of the indicated aim were decided next tasks: 1 Analysis of the state of equipment and his external environments on the wells of working collection on the Karachaganak deposit. 2. Estimation of the technological operations conducted on trade (Workovers or MRW, PRW and GTO)

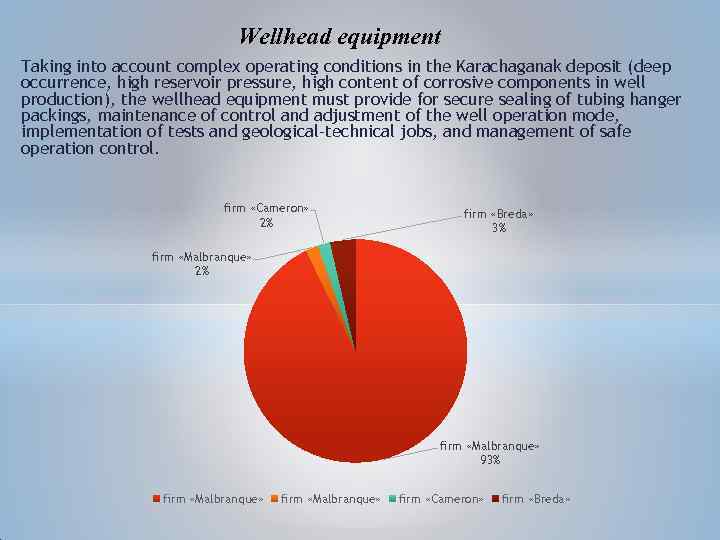

Wellhead equipment Taking into account complex operating conditions in the Karachaganak deposit (deep occurrence, high reservoir pressure, high content of corrosive components in well production), the wellhead equipment must provide for secure sealing of tubing hanger packings, maintenance of control and adjustment of the well operation mode, implementation of tests and geological-technical jobs, and management of safe operation control. firm «Cameron» 2% firm «Breda» 3% firm «Malbranque» 2% firm «Malbranque» 93% firm «Malbranque» firm «Cameron» firm «Breda»

Wellhead equipment Taking into account complex operating conditions in the Karachaganak deposit (deep occurrence, high reservoir pressure, high content of corrosive components in well production), the wellhead equipment must provide for secure sealing of tubing hanger packings, maintenance of control and adjustment of the well operation mode, implementation of tests and geological-technical jobs, and management of safe operation control. firm «Cameron» 2% firm «Breda» 3% firm «Malbranque» 2% firm «Malbranque» 93% firm «Malbranque» firm «Cameron» firm «Breda»

The Xmas tree includes the casing head, tubing head, and Xmas tree itself.

The Xmas tree includes the casing head, tubing head, and Xmas tree itself.

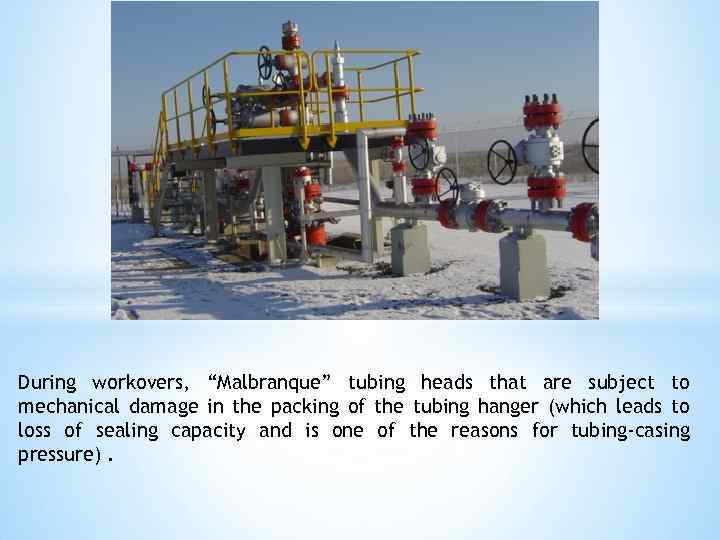

During workovers, “Malbranque” tubing heads that are subject to mechanical damage in the packing of the tubing hanger (which leads to loss of sealing capacity and is one of the reasons for tubing-casing pressure).

During workovers, “Malbranque” tubing heads that are subject to mechanical damage in the packing of the tubing hanger (which leads to loss of sealing capacity and is one of the reasons for tubing-casing pressure).

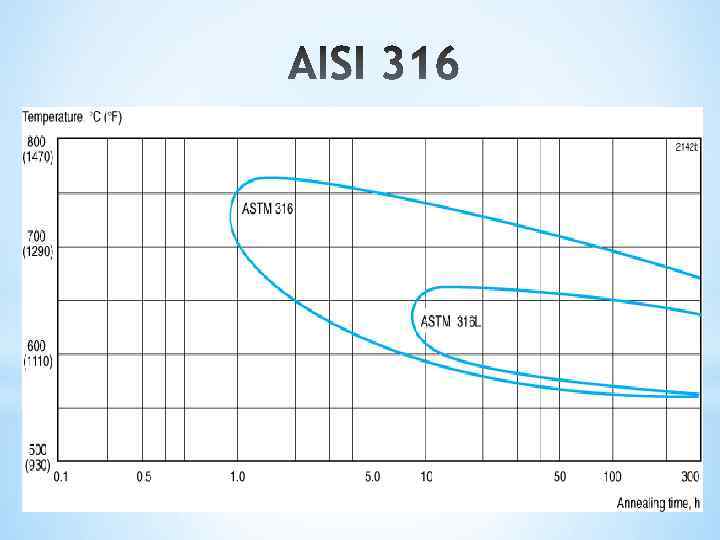

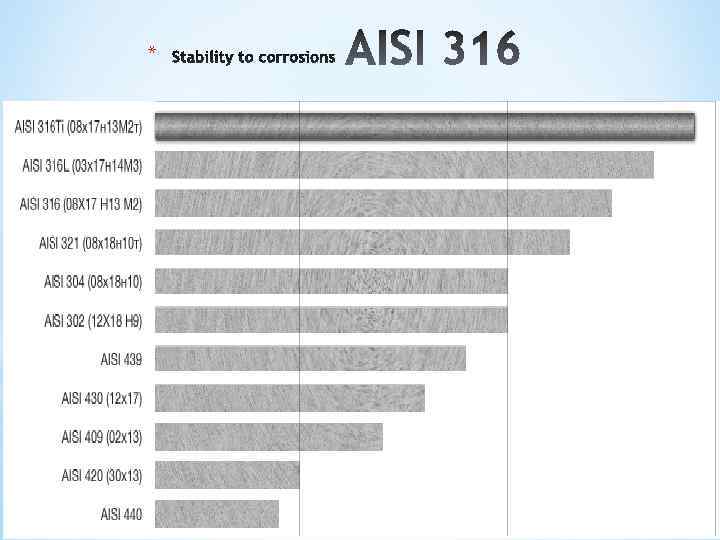

*

*

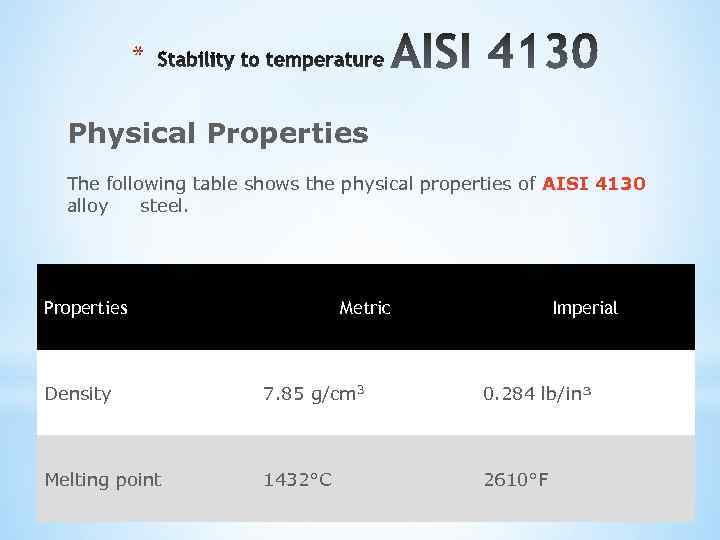

* Physical Properties The following table shows the physical properties of AISI 4130 alloy steel. Properties Metric Imperial Density 7. 85 g/cm 3 0. 284 lb/in³ Melting point 1432°C 2610°F

* Physical Properties The following table shows the physical properties of AISI 4130 alloy steel. Properties Metric Imperial Density 7. 85 g/cm 3 0. 284 lb/in³ Melting point 1432°C 2610°F

Chemical Composition The chemical composition of AISI 4130 alloy steel is listed in the following table. Element Content (%) Iron, Fe 97. 03 – 98. 22 Chromium, Cr 0. 80 – 1. 10 Manganese, Mn 0. 40 – 0. 60 Carbon, C 0. 280 – 0. 330 Silicon, Si 0. 15 – 0. 30 Molybdenum, Mo 0. 15 – 0. 25 Sulfur, S 0. 040 Phosphorous, P 0. 035

Chemical Composition The chemical composition of AISI 4130 alloy steel is listed in the following table. Element Content (%) Iron, Fe 97. 03 – 98. 22 Chromium, Cr 0. 80 – 1. 10 Manganese, Mn 0. 40 – 0. 60 Carbon, C 0. 280 – 0. 330 Silicon, Si 0. 15 – 0. 30 Molybdenum, Mo 0. 15 – 0. 25 Sulfur, S 0. 040 Phosphorous, P 0. 035

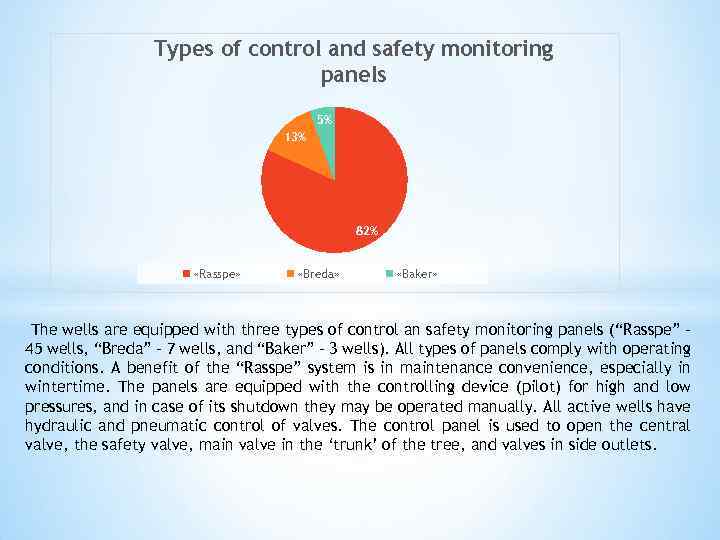

Types of control and safety monitoring panels 5% 13% 82% «Rasspe» «Bredа» «Baker» The wells are equipped with three types of control an safety monitoring panels (“Rasspe” – 45 wells, “Bredа” – 7 wells, and “Baker” – 3 wells). All types of panels comply with operating conditions. A benefit of the “Rasspe” system is in maintenance convenience, especially in wintertime. The panels are equipped with the controlling device (pilot) for high and low pressures, and in case of its shutdown they may be operated manually. All active wells have hydraulic and pneumatic control of valves. The control panel is used to open the central valve, the safety valve, main valve in the ‘trunk’ of the tree, and valves in side outlets.

Types of control and safety monitoring panels 5% 13% 82% «Rasspe» «Bredа» «Baker» The wells are equipped with three types of control an safety monitoring panels (“Rasspe” – 45 wells, “Bredа” – 7 wells, and “Baker” – 3 wells). All types of panels comply with operating conditions. A benefit of the “Rasspe” system is in maintenance convenience, especially in wintertime. The panels are equipped with the controlling device (pilot) for high and low pressures, and in case of its shutdown they may be operated manually. All active wells have hydraulic and pneumatic control of valves. The control panel is used to open the central valve, the safety valve, main valve in the ‘trunk’ of the tree, and valves in side outlets.

Conclusion: All of the mentioned above allows to draw a conclusion that wellhead equipment and safety control systems being used in the field comply to the recommendations set forth in the project document and meet complex operating conditions of the Karachaganak deposit wells. I suppose to recommend application of this equipment on the deposit of Yrikhtau of the Aqtobe area.

Conclusion: All of the mentioned above allows to draw a conclusion that wellhead equipment and safety control systems being used in the field comply to the recommendations set forth in the project document and meet complex operating conditions of the Karachaganak deposit wells. I suppose to recommend application of this equipment on the deposit of Yrikhtau of the Aqtobe area.

*

*