2c994f6539e10d0655769659d64878d3.ppt

- Количество слайдов: 60

Process Heat Transfer The Cause and Effect of Various Design Concepts www. armstronginternational. com © 2006 Armstrong International, Inc.

Process Heat Transfer The Cause and Effect of Various Design Concepts www. armstronginternational. com © 2006 Armstrong International, Inc.

Exchanger Variables • Fouled surface area • Non-condensible gases • Flooded surface area • Variable process inlet and outlet temperatures • Variable process flow rates • All of these change the BTU demand on the heater, changing the pressure and temperature of the heat transfer media ® “Expect many enjoyable experiences!” David M. Armstrong 2

Exchanger Variables • Fouled surface area • Non-condensible gases • Flooded surface area • Variable process inlet and outlet temperatures • Variable process flow rates • All of these change the BTU demand on the heater, changing the pressure and temperature of the heat transfer media ® “Expect many enjoyable experiences!” David M. Armstrong 2

Fouled Surface Area • Fouled surface area decreases the heat transfer efficiency of the tube bundle • This inherently causes adjustments in the pressure and/or temperature of the heat transfer media being supplied to the exchanger ® “Expect many enjoyable experiences!” David M. Armstrong 3

Fouled Surface Area • Fouled surface area decreases the heat transfer efficiency of the tube bundle • This inherently causes adjustments in the pressure and/or temperature of the heat transfer media being supplied to the exchanger ® “Expect many enjoyable experiences!” David M. Armstrong 3

Fouled Surface Area • Resulting in more surface exposed to the transfer media in a level control system. This will increase the BTU transfer rate. • Higher delivery pressure from the inlet control valve decreases the efficiency of the heat exchanger. Higher pressure lacks the same latent heat content of lower pressure. Energy consumption will increase, while production levels remain unchanged. ® “Expect many enjoyable experiences!” David M. Armstrong 4

Fouled Surface Area • Resulting in more surface exposed to the transfer media in a level control system. This will increase the BTU transfer rate. • Higher delivery pressure from the inlet control valve decreases the efficiency of the heat exchanger. Higher pressure lacks the same latent heat content of lower pressure. Energy consumption will increase, while production levels remain unchanged. ® “Expect many enjoyable experiences!” David M. Armstrong 4

Non-Condensible Gases • Presence of non-condensibles’ occupies valuable steam space • A reduction of viable heat transfer area can result due to the insulating properties • Promotion of carbonic acid formation is inherent • Excessive amounts can inhibit drainage ® “Expect many enjoyable experiences!” David M. Armstrong 5

Non-Condensible Gases • Presence of non-condensibles’ occupies valuable steam space • A reduction of viable heat transfer area can result due to the insulating properties • Promotion of carbonic acid formation is inherent • Excessive amounts can inhibit drainage ® “Expect many enjoyable experiences!” David M. Armstrong 5

Flooded Surface Area • Promotes corrosion and fouling • Can develop into water hammer • Controls process temperature by decreasing available surface area for heat transfer (Level Control) • Typically causes process outlet variations ® “Expect many enjoyable experiences!” David M. Armstrong 6

Flooded Surface Area • Promotes corrosion and fouling • Can develop into water hammer • Controls process temperature by decreasing available surface area for heat transfer (Level Control) • Typically causes process outlet variations ® “Expect many enjoyable experiences!” David M. Armstrong 6

Variable Process Inlet & Outlet Temperatures • Changes the BTU exchange rate required or (Delta T) • These variable temperatures can increase or decrease exiting pressure based on condensing rate of the heater • Will promote flooding on low exchange rate demand ® “Expect many enjoyable experiences!” David M. Armstrong 7

Variable Process Inlet & Outlet Temperatures • Changes the BTU exchange rate required or (Delta T) • These variable temperatures can increase or decrease exiting pressure based on condensing rate of the heater • Will promote flooding on low exchange rate demand ® “Expect many enjoyable experiences!” David M. Armstrong 7

Variable Process Flow Rates • Variable flows will change BTU demand on the exchanger • Higher flow rates will increase the surface area needed, raising or lowering the outlet pressure based on available surface area • Lower flow rates will decrease surface area needed, raising or lowering the outlet pressure based on available surface area ® “Expect many enjoyable experiences!” David M. Armstrong 8

Variable Process Flow Rates • Variable flows will change BTU demand on the exchanger • Higher flow rates will increase the surface area needed, raising or lowering the outlet pressure based on available surface area • Lower flow rates will decrease surface area needed, raising or lowering the outlet pressure based on available surface area ® “Expect many enjoyable experiences!” David M. Armstrong 8

Control Options • Level Control • Steam Control ® “Expect many enjoyable experiences!” David M. Armstrong 9

Control Options • Level Control • Steam Control ® “Expect many enjoyable experiences!” David M. Armstrong 9

Level Control • Level control systems flood exchangers to reduce the amount of useable surface area for BTU transfer • Exchangers run flooded due to the control valve on the condensate outlet, modulating to maintain the desired process outlet temperature ® “Expect many enjoyable experiences!” David M. Armstrong 10

Level Control • Level control systems flood exchangers to reduce the amount of useable surface area for BTU transfer • Exchangers run flooded due to the control valve on the condensate outlet, modulating to maintain the desired process outlet temperature ® “Expect many enjoyable experiences!” David M. Armstrong 10

Steam Control • Allows the exchanger to run at the lowest possible steam pressure, which maximizes energy efficiency due to latent heat content • Less energy consumed for the same amount of product produced ® “Expect many enjoyable experiences!” David M. Armstrong 11

Steam Control • Allows the exchanger to run at the lowest possible steam pressure, which maximizes energy efficiency due to latent heat content • Less energy consumed for the same amount of product produced ® “Expect many enjoyable experiences!” David M. Armstrong 11

Process Design Summary • Utilize all of the surface area • Eliminate corrosion and fouling by keeping the exchanger dry • Eliminate non-condensibles • Optimize the design by using the lowest pressure steam, to gain more latent heat content per pound ® “Expect many enjoyable experiences!” David M. Armstrong 12

Process Design Summary • Utilize all of the surface area • Eliminate corrosion and fouling by keeping the exchanger dry • Eliminate non-condensibles • Optimize the design by using the lowest pressure steam, to gain more latent heat content per pound ® “Expect many enjoyable experiences!” David M. Armstrong 12

Operating Characteristics www. armstronginternational. com © 2006 Armstrong International, Inc.

Operating Characteristics www. armstronginternational. com © 2006 Armstrong International, Inc.

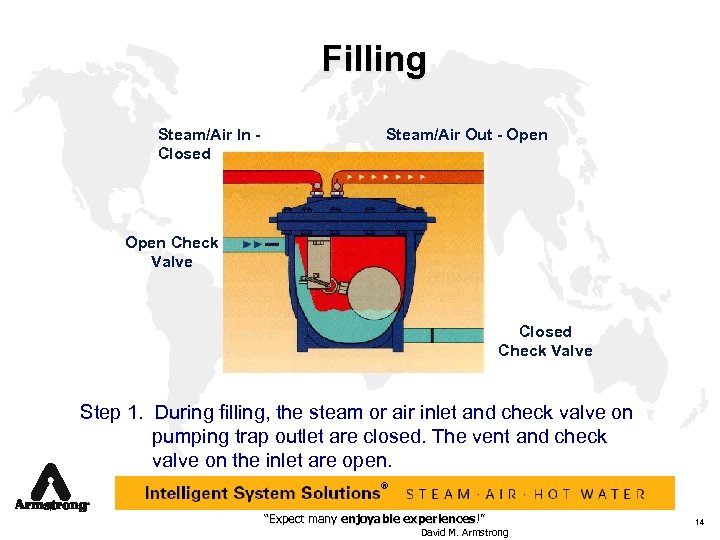

Filling Steam/Air In Closed Steam/Air Out - Open Check Valve Closed Check Valve Step 1. During filling, the steam or air inlet and check valve on pumping trap outlet are closed. The vent and check valve on the inlet are open. ® “Expect many enjoyable experiences!” David M. Armstrong 14

Filling Steam/Air In Closed Steam/Air Out - Open Check Valve Closed Check Valve Step 1. During filling, the steam or air inlet and check valve on pumping trap outlet are closed. The vent and check valve on the inlet are open. ® “Expect many enjoyable experiences!” David M. Armstrong 14

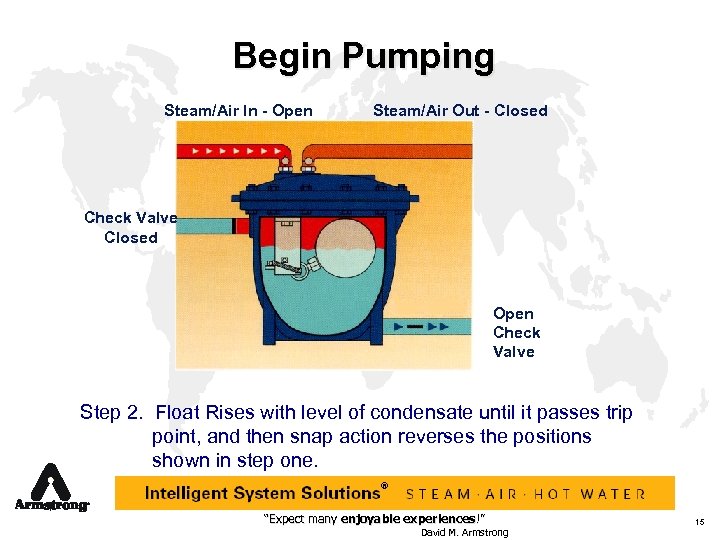

Begin Pumping Steam/Air In - Open Steam/Air Out - Closed Check Valve Closed Open Check Valve Step 2. Float Rises with level of condensate until it passes trip point, and then snap action reverses the positions shown in step one. ® “Expect many enjoyable experiences!” David M. Armstrong 15

Begin Pumping Steam/Air In - Open Steam/Air Out - Closed Check Valve Closed Open Check Valve Step 2. Float Rises with level of condensate until it passes trip point, and then snap action reverses the positions shown in step one. ® “Expect many enjoyable experiences!” David M. Armstrong 15

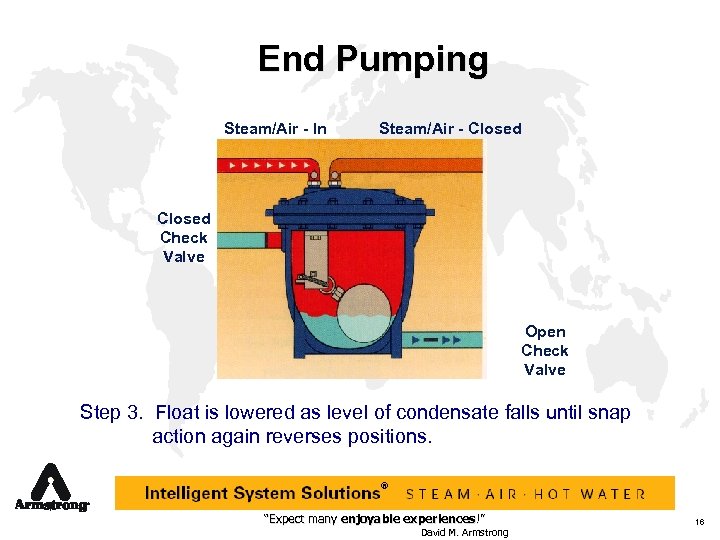

End Pumping Steam/Air - In Steam/Air - Closed Check Valve Open Check Valve Step 3. Float is lowered as level of condensate falls until snap action again reverses positions. ® “Expect many enjoyable experiences!” David M. Armstrong 16

End Pumping Steam/Air - In Steam/Air - Closed Check Valve Open Check Valve Step 3. Float is lowered as level of condensate falls until snap action again reverses positions. ® “Expect many enjoyable experiences!” David M. Armstrong 16

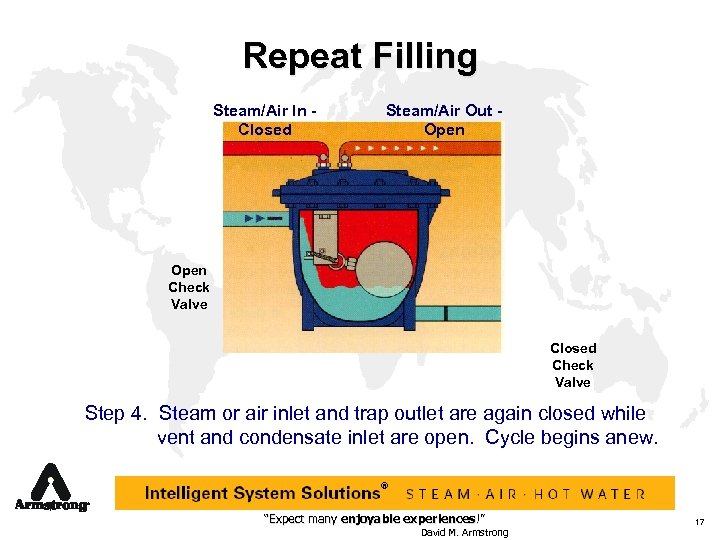

Repeat Filling Steam/Air In Closed Steam/Air Out Open Check Valve Closed Check Valve Step 4. Steam or air inlet and trap outlet are again closed while vent and condensate inlet are open. Cycle begins anew. ® “Expect many enjoyable experiences!” David M. Armstrong 17

Repeat Filling Steam/Air In Closed Steam/Air Out Open Check Valve Closed Check Valve Step 4. Steam or air inlet and trap outlet are again closed while vent and condensate inlet are open. Cycle begins anew. ® “Expect many enjoyable experiences!” David M. Armstrong 17

Pump Trap Applications www. armstronginternational. com © 2006 Armstrong International, Inc.

Pump Trap Applications www. armstronginternational. com © 2006 Armstrong International, Inc.

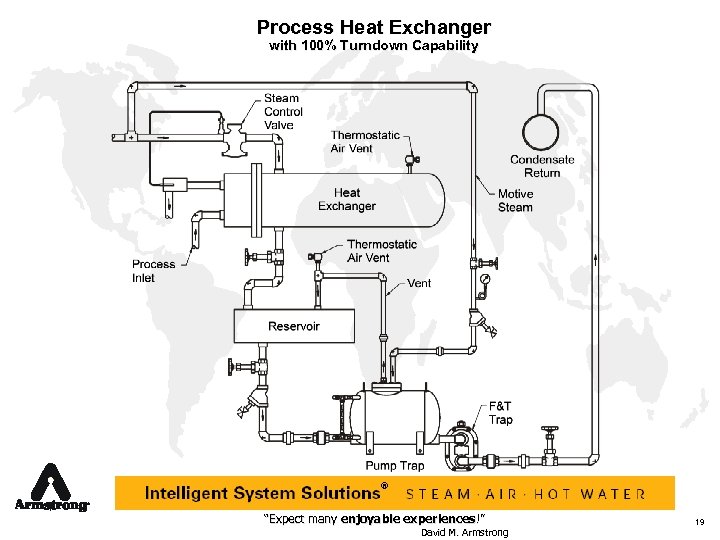

Process Heat Exchanger with 100% Turndown Capability ® “Expect many enjoyable experiences!” David M. Armstrong 19

Process Heat Exchanger with 100% Turndown Capability ® “Expect many enjoyable experiences!” David M. Armstrong 19

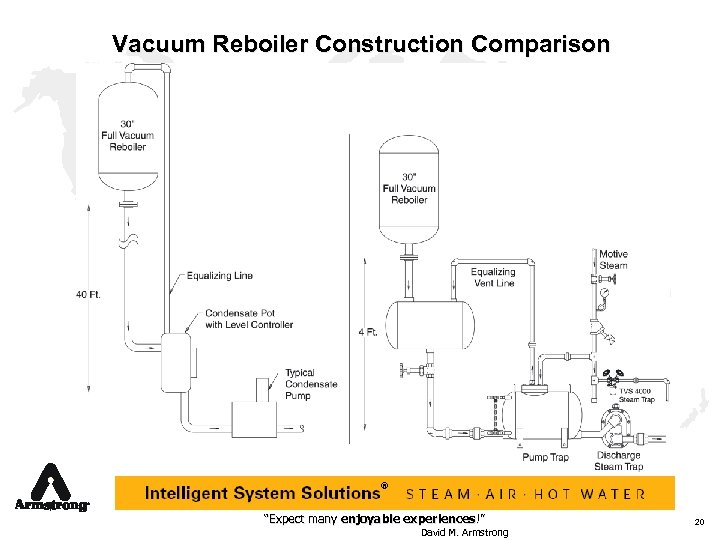

Vacuum Reboiler Construction Comparison ® “Expect many enjoyable experiences!” David M. Armstrong 20

Vacuum Reboiler Construction Comparison ® “Expect many enjoyable experiences!” David M. Armstrong 20

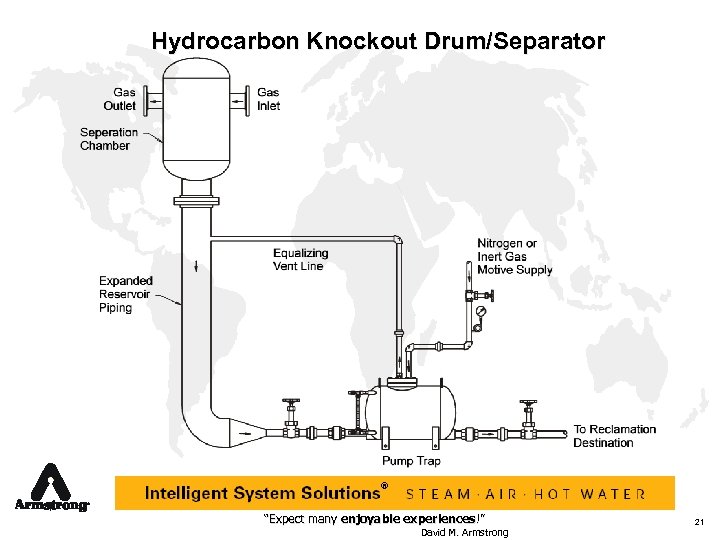

Hydrocarbon Knockout Drum/Separator ® “Expect many enjoyable experiences!” David M. Armstrong 21

Hydrocarbon Knockout Drum/Separator ® “Expect many enjoyable experiences!” David M. Armstrong 21

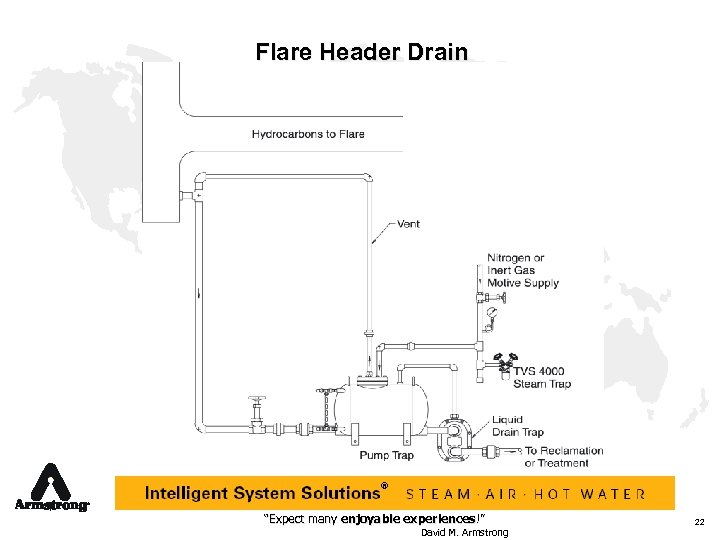

Flare Header Drain ® “Expect many enjoyable experiences!” David M. Armstrong 22

Flare Header Drain ® “Expect many enjoyable experiences!” David M. Armstrong 22

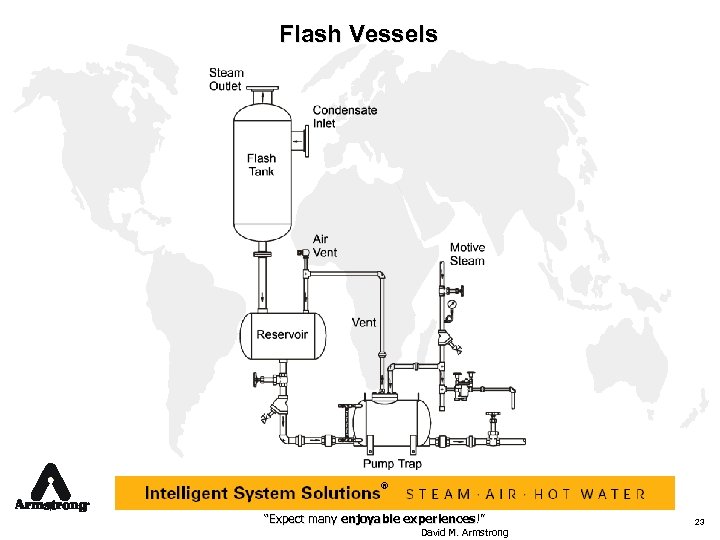

Flash Vessels ® “Expect many enjoyable experiences!” David M. Armstrong 23

Flash Vessels ® “Expect many enjoyable experiences!” David M. Armstrong 23

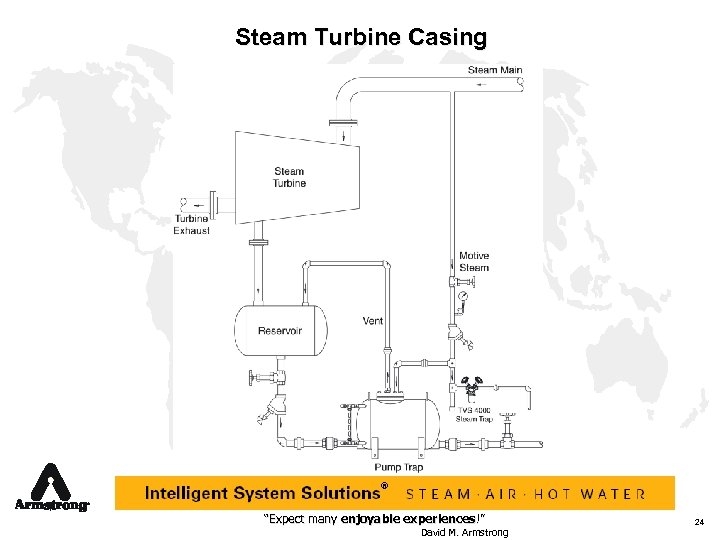

Steam Turbine Casing ® “Expect many enjoyable experiences!” David M. Armstrong 24

Steam Turbine Casing ® “Expect many enjoyable experiences!” David M. Armstrong 24

Pump Trap Applications • Process Heat Exchangers • Liquid Separators • Sumps • Vacuum Systems • Condensate Drum – Flash Tanks • Vented Systems • Closed Loop Applications ® “Expect many enjoyable experiences!” David M. Armstrong 25

Pump Trap Applications • Process Heat Exchangers • Liquid Separators • Sumps • Vacuum Systems • Condensate Drum – Flash Tanks • Vented Systems • Closed Loop Applications ® “Expect many enjoyable experiences!” David M. Armstrong 25

Understanding and Benefiting from Equipment Stall www. armstronginternational. com © 2006 Armstrong International, Inc.

Understanding and Benefiting from Equipment Stall www. armstronginternational. com © 2006 Armstrong International, Inc.

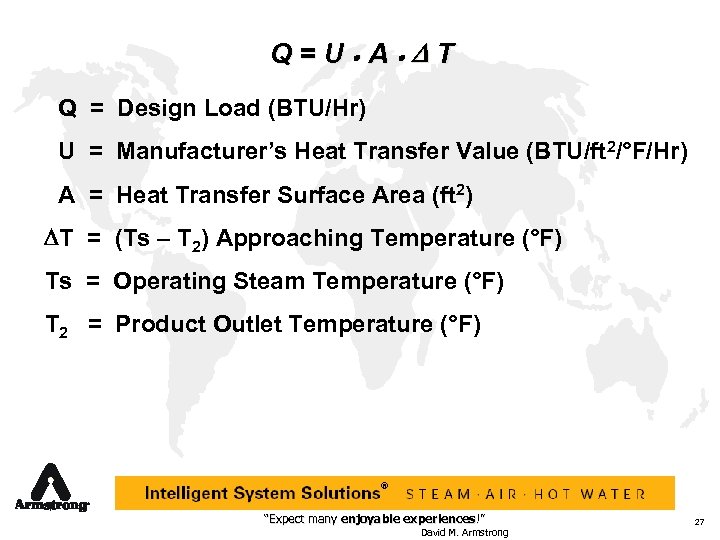

Q=U·A·DT Q = Design Load (BTU/Hr) U = Manufacturer’s Heat Transfer Value (BTU/ft 2/°F/Hr) A = Heat Transfer Surface Area (ft 2) DT = (Ts – T 2) Approaching Temperature (°F) Ts = Operating Steam Temperature (°F) T 2 = Product Outlet Temperature (°F) ® “Expect many enjoyable experiences!” David M. Armstrong 27

Q=U·A·DT Q = Design Load (BTU/Hr) U = Manufacturer’s Heat Transfer Value (BTU/ft 2/°F/Hr) A = Heat Transfer Surface Area (ft 2) DT = (Ts – T 2) Approaching Temperature (°F) Ts = Operating Steam Temperature (°F) T 2 = Product Outlet Temperature (°F) ® “Expect many enjoyable experiences!” David M. Armstrong 27

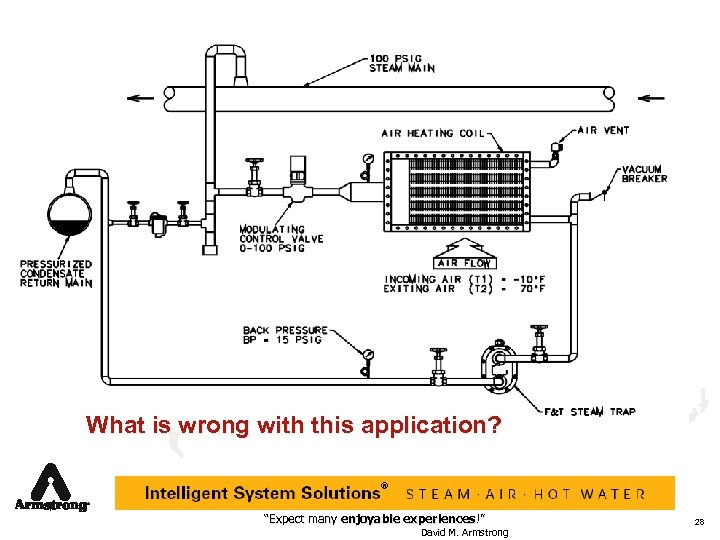

What is wrong with this application? ® “Expect many enjoyable experiences!” David M. Armstrong 28

What is wrong with this application? ® “Expect many enjoyable experiences!” David M. Armstrong 28

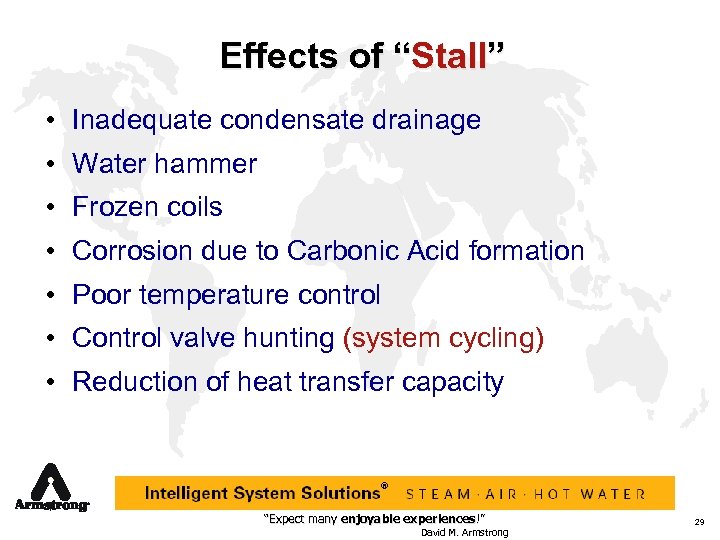

Effects of “Stall” • Inadequate condensate drainage • Water hammer • Frozen coils • Corrosion due to Carbonic Acid formation • Poor temperature control • Control valve hunting (system cycling) • Reduction of heat transfer capacity ® “Expect many enjoyable experiences!” David M. Armstrong 29

Effects of “Stall” • Inadequate condensate drainage • Water hammer • Frozen coils • Corrosion due to Carbonic Acid formation • Poor temperature control • Control valve hunting (system cycling) • Reduction of heat transfer capacity ® “Expect many enjoyable experiences!” David M. Armstrong 29

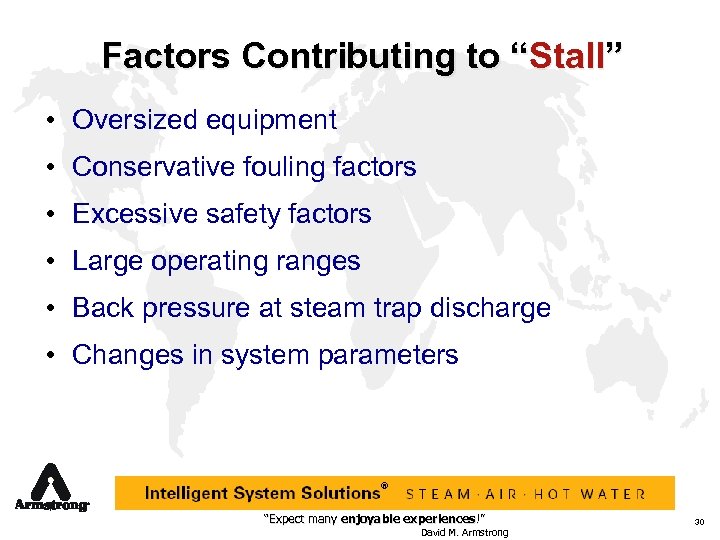

Factors Contributing to “Stall” • Oversized equipment • Conservative fouling factors • Excessive safety factors • Large operating ranges • Back pressure at steam trap discharge • Changes in system parameters ® “Expect many enjoyable experiences!” David M. Armstrong 30

Factors Contributing to “Stall” • Oversized equipment • Conservative fouling factors • Excessive safety factors • Large operating ranges • Back pressure at steam trap discharge • Changes in system parameters ® “Expect many enjoyable experiences!” David M. Armstrong 30

Finding “Stall” Where does Stall occur? ? • Air heating coils • Shell & tube heat exchangers • Plate & frame heat exchangers • Absorption chillers • Kettles • Any type of heat transfer equipment that has Modulating Control ® “Expect many enjoyable experiences!” David M. Armstrong 31

Finding “Stall” Where does Stall occur? ? • Air heating coils • Shell & tube heat exchangers • Plate & frame heat exchangers • Absorption chillers • Kettles • Any type of heat transfer equipment that has Modulating Control ® “Expect many enjoyable experiences!” David M. Armstrong 31

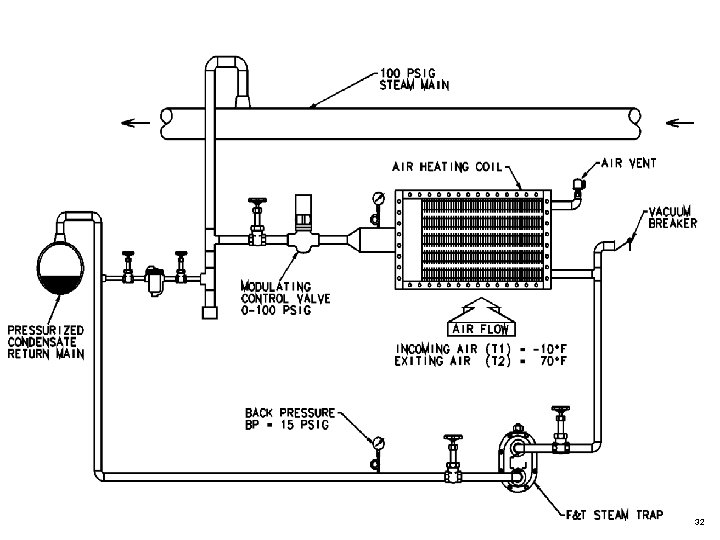

® “Expect many enjoyable experiences!” David M. Armstrong 32

® “Expect many enjoyable experiences!” David M. Armstrong 32

What is the “Stall” Solution? • Use a bigger steam trap? • Use a vacuum breaker? • Implement a safety drain? • Install a Posi-Pressure system? • Use an electric pump? ® “Expect many enjoyable experiences!” David M. Armstrong 33

What is the “Stall” Solution? • Use a bigger steam trap? • Use a vacuum breaker? • Implement a safety drain? • Install a Posi-Pressure system? • Use an electric pump? ® “Expect many enjoyable experiences!” David M. Armstrong 33

Keys to Operation • How quick it can fill: This is dictated by head pressure & inlet pipe and check valve size • Vent/Equalization: Vent connection must always be in vapor space • Pump Out: Motive vs. back pressure and gas used ® “Expect many enjoyable experiences!” David M. Armstrong 34

Keys to Operation • How quick it can fill: This is dictated by head pressure & inlet pipe and check valve size • Vent/Equalization: Vent connection must always be in vapor space • Pump Out: Motive vs. back pressure and gas used ® “Expect many enjoyable experiences!” David M. Armstrong 34

Vocabulary Filling Head: Distance between the top of the pump and the bottom of the receiver or reservoir pipe ® “Expect many enjoyable experiences!” David M. Armstrong 35

Vocabulary Filling Head: Distance between the top of the pump and the bottom of the receiver or reservoir pipe ® “Expect many enjoyable experiences!” David M. Armstrong 35

Vocabulary (Continued) Receiver/Reservoir Pipe: This is a temporary holding place to store condensate while the pump is in the pump down cycle. The receiver/reservoir pipe is designed and sized to prevent condensate from backing up into the system. ® “Expect many enjoyable experiences!” David M. Armstrong 36

Vocabulary (Continued) Receiver/Reservoir Pipe: This is a temporary holding place to store condensate while the pump is in the pump down cycle. The receiver/reservoir pipe is designed and sized to prevent condensate from backing up into the system. ® “Expect many enjoyable experiences!” David M. Armstrong 36

Open System Configuration Closed System Configuration www. armstronginternational. com © 2006 Armstrong International, Inc.

Open System Configuration Closed System Configuration www. armstronginternational. com © 2006 Armstrong International, Inc.

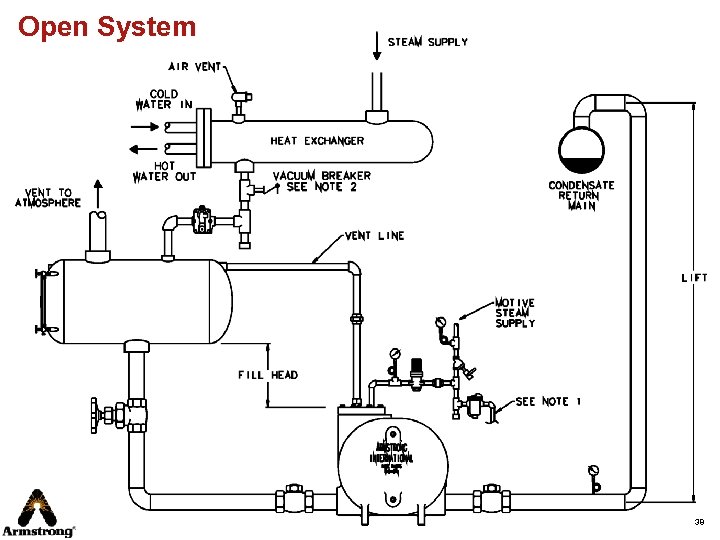

Open System ® “Expect many enjoyable experiences!” David M. Armstrong 38

Open System ® “Expect many enjoyable experiences!” David M. Armstrong 38

Open System Advantages: • Drain multiple pieces of equipment • Can use Air or Steam for pump trap operation • Easiest to understand Disadvantages: • Lose valuable flash steam • Must run a potentially expensive atmospheric vent line • Size the pump trap based total design load • Must compete with electric pumps ® “Expect many enjoyable experiences!” David M. Armstrong 39

Open System Advantages: • Drain multiple pieces of equipment • Can use Air or Steam for pump trap operation • Easiest to understand Disadvantages: • Lose valuable flash steam • Must run a potentially expensive atmospheric vent line • Size the pump trap based total design load • Must compete with electric pumps ® “Expect many enjoyable experiences!” David M. Armstrong 39

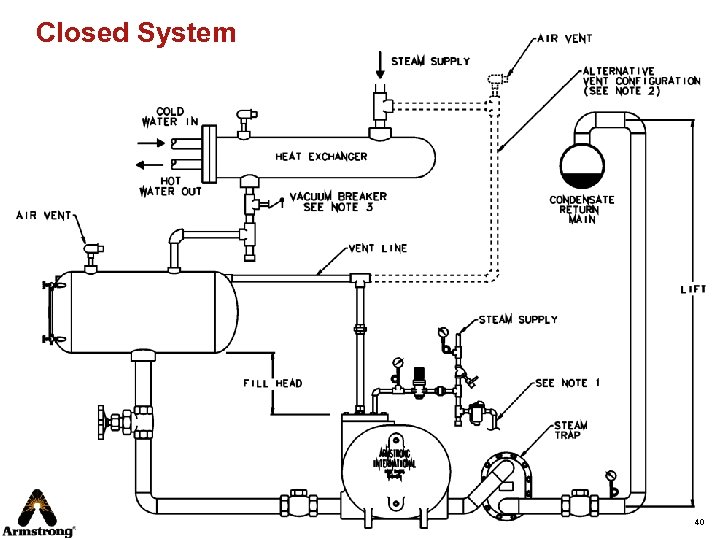

Closed System ® “Expect many enjoyable experiences!” David M. Armstrong 40

Closed System ® “Expect many enjoyable experiences!” David M. Armstrong 40

Closed System Advantages: • No flash steam loss • No need to run long expensive vent lines • Use a smaller pump than in a open system* • Return condensate hotter Disadvantages: • Dedicated pump for a single piece of equipment • More complex • Cannot use air as motive force ® “Expect many enjoyable experiences!” David M. Armstrong 41

Closed System Advantages: • No flash steam loss • No need to run long expensive vent lines • Use a smaller pump than in a open system* • Return condensate hotter Disadvantages: • Dedicated pump for a single piece of equipment • More complex • Cannot use air as motive force ® “Expect many enjoyable experiences!” David M. Armstrong 41

Pump Sizing / Receiver Sizing Pump Sizing • Determine head available from equipment (distance from equipment outlet to grade) • Select either closed loop or vented design (Note: If multiple sources of condensate, vented system must be used to prevent short circuiting) ® “Expect many enjoyable experiences!” David M. Armstrong 42

Pump Sizing / Receiver Sizing Pump Sizing • Determine head available from equipment (distance from equipment outlet to grade) • Select either closed loop or vented design (Note: If multiple sources of condensate, vented system must be used to prevent short circuiting) ® “Expect many enjoyable experiences!” David M. Armstrong 42

Pump Sizing / Receiver Sizing Pump Sizing • Determine maximum pumping load • Calculate maximum back pressure (including lift) • Determine motive pressure and gas to be used (use capacity correction factor if using a medium other than steam) ® “Expect many enjoyable experiences!” David M. Armstrong 43

Pump Sizing / Receiver Sizing Pump Sizing • Determine maximum pumping load • Calculate maximum back pressure (including lift) • Determine motive pressure and gas to be used (use capacity correction factor if using a medium other than steam) ® “Expect many enjoyable experiences!” David M. Armstrong 43

Pump Sizing / Receiver Sizing Pump Sizing • Check and specify head pressure (distance from bottom of receiver/reservoir to top of selected pump) • Make sure to use capacity correction if more or less head is available than standard catalog dimension ® “Expect many enjoyable experiences!” David M. Armstrong 44

Pump Sizing / Receiver Sizing Pump Sizing • Check and specify head pressure (distance from bottom of receiver/reservoir to top of selected pump) • Make sure to use capacity correction if more or less head is available than standard catalog dimension ® “Expect many enjoyable experiences!” David M. Armstrong 44

Pump Sizing / Receiver Sizing Pump Sizing • Calculate maximum flash rate & needed vent size – if vented system • Determine and size reservoir – if closed loop system • Size downstream F&T trap if needed for closed loop system ® “Expect many enjoyable experiences!” David M. Armstrong 45

Pump Sizing / Receiver Sizing Pump Sizing • Calculate maximum flash rate & needed vent size – if vented system • Determine and size reservoir – if closed loop system • Size downstream F&T trap if needed for closed loop system ® “Expect many enjoyable experiences!” David M. Armstrong 45

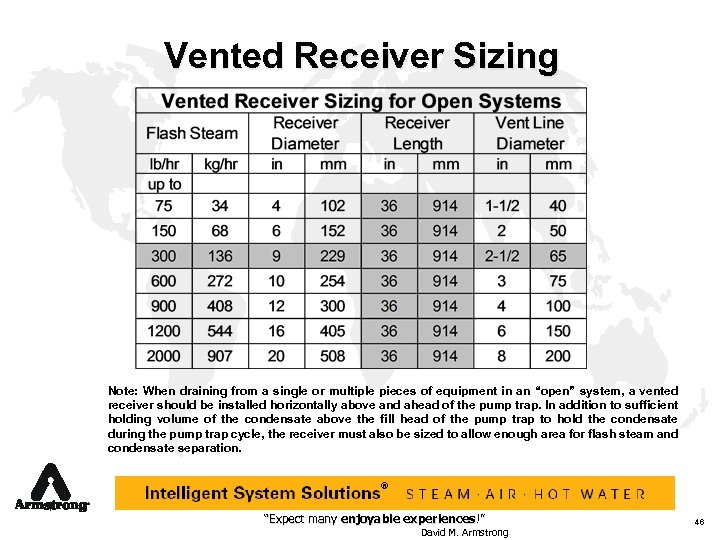

Vented Receiver Sizing Note: When draining from a single or multiple pieces of equipment in an “open” system, a vented receiver should be installed horizontally above and ahead of the pump trap. In addition to sufficient holding volume of the condensate above the fill head of the pump trap to hold the condensate during the pump trap cycle, the receiver must also be sized to allow enough area for flash steam and condensate separation. ® “Expect many enjoyable experiences!” David M. Armstrong 46

Vented Receiver Sizing Note: When draining from a single or multiple pieces of equipment in an “open” system, a vented receiver should be installed horizontally above and ahead of the pump trap. In addition to sufficient holding volume of the condensate above the fill head of the pump trap to hold the condensate during the pump trap cycle, the receiver must also be sized to allow enough area for flash steam and condensate separation. ® “Expect many enjoyable experiences!” David M. Armstrong 46

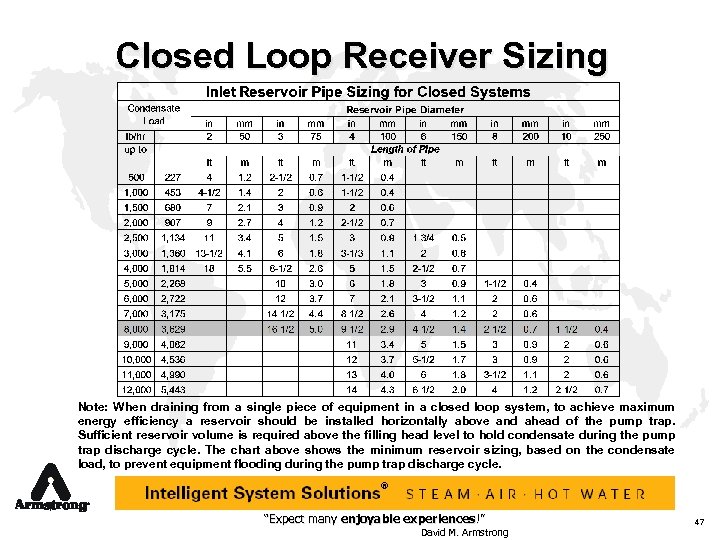

Closed Loop Receiver Sizing Note: When draining from a single piece of equipment in a closed loop system, to achieve maximum energy efficiency a reservoir should be installed horizontally above and ahead of the pump trap. Sufficient reservoir volume is required above the filling head level to hold condensate during the pump trap discharge cycle. The chart above shows the minimum reservoir sizing, based on the condensate load, to prevent equipment flooding during the pump trap discharge cycle. ® “Expect many enjoyable experiences!” David M. Armstrong 47

Closed Loop Receiver Sizing Note: When draining from a single piece of equipment in a closed loop system, to achieve maximum energy efficiency a reservoir should be installed horizontally above and ahead of the pump trap. Sufficient reservoir volume is required above the filling head level to hold condensate during the pump trap discharge cycle. The chart above shows the minimum reservoir sizing, based on the condensate load, to prevent equipment flooding during the pump trap discharge cycle. ® “Expect many enjoyable experiences!” David M. Armstrong 47

Critical Design Criteria Summary 1. 2. 3. 4. 5. Maximum condensate flow from exchangers and reboilers Maximum differential pressure across the system Minimum differential pressure across the system (specifically when clean) Minimum tower height needed to achieve maximum condensate flow rate at minimum differential Maximum motive pressure (steam, air, nitrogen, etc. ) available to power pumps ® “Expect many enjoyable experiences!” David M. Armstrong 48

Critical Design Criteria Summary 1. 2. 3. 4. 5. Maximum condensate flow from exchangers and reboilers Maximum differential pressure across the system Minimum differential pressure across the system (specifically when clean) Minimum tower height needed to achieve maximum condensate flow rate at minimum differential Maximum motive pressure (steam, air, nitrogen, etc. ) available to power pumps ® “Expect many enjoyable experiences!” David M. Armstrong 48

Critical Design Criteria Summary 6. Maximum instantaneous discharge rate for downstream pipe sizing & trap sizing 7. Temperature differential of condensate source vs. condensate header design 8. Piping layout to prevent hydraulic shock 9. Total installed cost savings, including construction, on turnkey jobs 10. Integrity of mechanical design due to the critical nature of the service 11. Minimize potential problems with proper designs ® “Expect many enjoyable experiences!” David M. Armstrong 49

Critical Design Criteria Summary 6. Maximum instantaneous discharge rate for downstream pipe sizing & trap sizing 7. Temperature differential of condensate source vs. condensate header design 8. Piping layout to prevent hydraulic shock 9. Total installed cost savings, including construction, on turnkey jobs 10. Integrity of mechanical design due to the critical nature of the service 11. Minimize potential problems with proper designs ® “Expect many enjoyable experiences!” David M. Armstrong 49

Maximum Differential Pressure Across the System • Maximum pressure from control valve, including minimal drop • Minimum drop across exchanger • Maximum pressure – should tube leak occur • Elimination of back pressure (bypass to grade) • Consider fouled surface area ® “Expect many enjoyable experiences!” David M. Armstrong 50

Maximum Differential Pressure Across the System • Maximum pressure from control valve, including minimal drop • Minimum drop across exchanger • Maximum pressure – should tube leak occur • Elimination of back pressure (bypass to grade) • Consider fouled surface area ® “Expect many enjoyable experiences!” David M. Armstrong 50

Minimum Differential Pressure Across the System • Consider maximum percentage of turndown on process flow vs. design flow (plus factor) • Consider over-surfaced heat transfer area • Evaluate downstream relief valve settings on condensate side as traps (etc. ) fail and pressurize the return system • Undersized return lines are common in facility expansions. Verify effects of additional flow on pipe velocities and back pressures. ® “Expect many enjoyable experiences!” David M. Armstrong 51

Minimum Differential Pressure Across the System • Consider maximum percentage of turndown on process flow vs. design flow (plus factor) • Consider over-surfaced heat transfer area • Evaluate downstream relief valve settings on condensate side as traps (etc. ) fail and pressurize the return system • Undersized return lines are common in facility expansions. Verify effects of additional flow on pipe velocities and back pressures. ® “Expect many enjoyable experiences!” David M. Armstrong 51

Minimum Head Pressure • Skirt height on reboilers can be minimized by evaluating discharge capacity needed and setting height accordingly. This should be done early in the job scope as it effects tower construction. • Additional pump capacity can be achieved by increasing head pressure ® “Expect many enjoyable experiences!” David M. Armstrong 52

Minimum Head Pressure • Skirt height on reboilers can be minimized by evaluating discharge capacity needed and setting height accordingly. This should be done early in the job scope as it effects tower construction. • Additional pump capacity can be achieved by increasing head pressure ® “Expect many enjoyable experiences!” David M. Armstrong 52

Maximum Motive Pressure Steam, Air, Nitrogen • Ensure stable source with negligible variations • Install drip station to insure dry gas is always present at motive steam valve (pipers often do not realize it is a dead-end steam line) ® “Expect many enjoyable experiences!” David M. Armstrong 53

Maximum Motive Pressure Steam, Air, Nitrogen • Ensure stable source with negligible variations • Install drip station to insure dry gas is always present at motive steam valve (pipers often do not realize it is a dead-end steam line) ® “Expect many enjoyable experiences!” David M. Armstrong 53

Maximum Design Pressure • Utilization of 2/3 Rule can eliminate relief valves on low pressure side needed for tube rupture cases • Use of liquid drain traps can eliminate gas discharge into return header ® “Expect many enjoyable experiences!” David M. Armstrong 54

Maximum Design Pressure • Utilization of 2/3 Rule can eliminate relief valves on low pressure side needed for tube rupture cases • Use of liquid drain traps can eliminate gas discharge into return header ® “Expect many enjoyable experiences!” David M. Armstrong 54

Maximum Instantaneous Discharge Rate • Pump discharge rate must be used when sizing condensate return leads (use bi-phase flow) • Pump discharge rate also critical to downstream traps in Pump / Trap combinations ® “Expect many enjoyable experiences!” David M. Armstrong 55

Maximum Instantaneous Discharge Rate • Pump discharge rate must be used when sizing condensate return leads (use bi-phase flow) • Pump discharge rate also critical to downstream traps in Pump / Trap combinations ® “Expect many enjoyable experiences!” David M. Armstrong 55

Temperature Differential of Source vs. Header • Minimize thermal shock by maintaining DT of 150°F or less • When feasible, run separate headers for vacuum temperature condensate • Vacuum condensate headers can be sized on single phase flow if dedicated solely for vacuum temperature condensate ® “Expect many enjoyable experiences!” David M. Armstrong 56

Temperature Differential of Source vs. Header • Minimize thermal shock by maintaining DT of 150°F or less • When feasible, run separate headers for vacuum temperature condensate • Vacuum condensate headers can be sized on single phase flow if dedicated solely for vacuum temperature condensate ® “Expect many enjoyable experiences!” David M. Armstrong 56

Piping Layout to Prevent Hydraulic Shock • Discharge lead from pumps should be piped into top of return header • Flow patterns should be continual – no opposing flows • Check valves should be installed at major elevation changes to disperse hydraulic shock ® “Expect many enjoyable experiences!” David M. Armstrong 57

Piping Layout to Prevent Hydraulic Shock • Discharge lead from pumps should be piped into top of return header • Flow patterns should be continual – no opposing flows • Check valves should be installed at major elevation changes to disperse hydraulic shock ® “Expect many enjoyable experiences!” David M. Armstrong 57

Pipe Sizing 1. Discharge piping should be based on 2 -3 times the normal condensing rate due to instantaneous discharge rate of the pump 2. Minimize elevation changes to prevent hydraulic shock 3. Utilize check valves at main header to minimize backflow ® “Expect many enjoyable experiences!” David M. Armstrong 58

Pipe Sizing 1. Discharge piping should be based on 2 -3 times the normal condensing rate due to instantaneous discharge rate of the pump 2. Minimize elevation changes to prevent hydraulic shock 3. Utilize check valves at main header to minimize backflow ® “Expect many enjoyable experiences!” David M. Armstrong 58

Pipe Sizing 4. Run separate lines for vacuum temperature condensate to minimize thermal shock potential 5. Always calculate the maximum flash rate in return lines 6. Insure adequate pipe and nozzle diameters to facilitate bidirectional two-phase flow ® “Expect many enjoyable experiences!” David M. Armstrong 59

Pipe Sizing 4. Run separate lines for vacuum temperature condensate to minimize thermal shock potential 5. Always calculate the maximum flash rate in return lines 6. Insure adequate pipe and nozzle diameters to facilitate bidirectional two-phase flow ® “Expect many enjoyable experiences!” David M. Armstrong 59

www. armstronginternational. com “Expect many enjoyable experiences!” David M. Armstrong

www. armstronginternational. com “Expect many enjoyable experiences!” David M. Armstrong