f9f443a6b1dcfba4a6acb2a87c555948.ppt

- Количество слайдов: 23

Process Excellence in Du. Pont Supply Chain Transformation Global Benchmarking Council November 2004

Process Excellence in Du. Pont Supply Chain Transformation Global Benchmarking Council November 2004

Our Vision To be the world’s most dynamic science company, creating sustainable solutions essential to a better, safer, healthier life for people everywhere. – 2– Mar-18

Our Vision To be the world’s most dynamic science company, creating sustainable solutions essential to a better, safer, healthier life for people everywhere. – 2– Mar-18

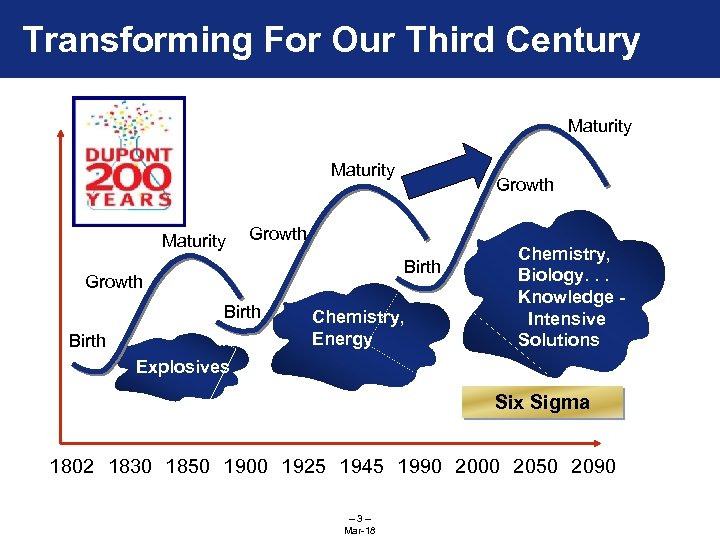

Transforming For Our Third Century Maturity Growth Birth Chemistry, Energy Chemistry, Biology. . . Knowledge Intensive Solutions Explosives Six Sigma 1802 1830 1850 1900 1925 1945 1990 2000 2050 2090 – 3– Mar-18

Transforming For Our Third Century Maturity Growth Birth Chemistry, Energy Chemistry, Biology. . . Knowledge Intensive Solutions Explosives Six Sigma 1802 1830 1850 1900 1925 1945 1990 2000 2050 2090 – 3– Mar-18

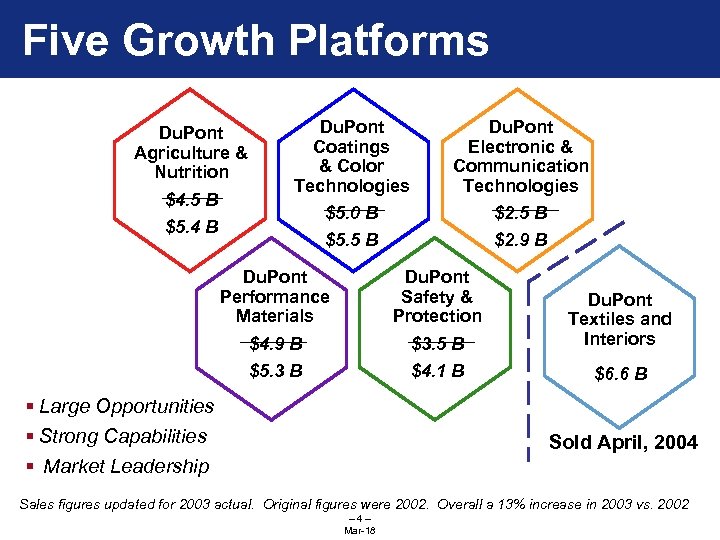

Five Growth Platforms $4. 5 B $5. 4 B Du. Pont Coatings & Color Technologies Du. Pont Electronic & Communication Technologies $5. 0 B $5. 5 B Du. Pont Agriculture & Nutrition $2. 5 B $2. 9 B Du. Pont Performance Materials Du. Pont Safety & Protection $4. 9 B $5. 3 B $3. 5 B $4. 1 B § Large Opportunities § Strong Capabilities § Market Leadership Du. Pont Textiles and Interiors $6. 6 B Sold April, 2004 Sales figures updated for 2003 actual. Original figures were 2002. Overall a 13% increase in 2003 vs. 2002 – 4– Mar-18

Five Growth Platforms $4. 5 B $5. 4 B Du. Pont Coatings & Color Technologies Du. Pont Electronic & Communication Technologies $5. 0 B $5. 5 B Du. Pont Agriculture & Nutrition $2. 5 B $2. 9 B Du. Pont Performance Materials Du. Pont Safety & Protection $4. 9 B $5. 3 B $3. 5 B $4. 1 B § Large Opportunities § Strong Capabilities § Market Leadership Du. Pont Textiles and Interiors $6. 6 B Sold April, 2004 Sales figures updated for 2003 actual. Original figures were 2002. Overall a 13% increase in 2003 vs. 2002 – 4– Mar-18

A Six Sigma Foundation provides the Discipline to achieve success

A Six Sigma Foundation provides the Discipline to achieve success

The Beginning of Six Sigma in Du. Pont Deployment began in February 1999 with a decision by Du. Pont CEO Chad Holliday and his key leaders n Du. Pont contracted with the Six Sigma Academy to provide initial deployment guidance and training Six Sigma was seen as a results driven process that has a track record of dramatically improving productivity the “right” way, by removing defects – 6– Mar-18

The Beginning of Six Sigma in Du. Pont Deployment began in February 1999 with a decision by Du. Pont CEO Chad Holliday and his key leaders n Du. Pont contracted with the Six Sigma Academy to provide initial deployment guidance and training Six Sigma was seen as a results driven process that has a track record of dramatically improving productivity the “right” way, by removing defects – 6– Mar-18

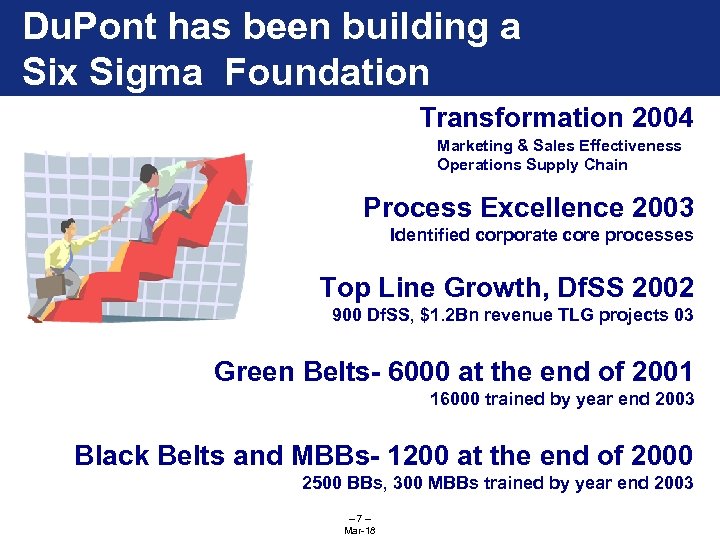

Du. Pont has been building a Six Sigma Foundation Transformation 2004 Marketing & Sales Effectiveness Operations Supply Chain Process Excellence 2003 Identified corporate core processes Top Line Growth, Df. SS 2002 900 Df. SS, $1. 2 Bn revenue TLG projects 03 Green Belts- 6000 at the end of 2001 16000 trained by year end 2003 Black Belts and MBBs- 1200 at the end of 2000 2500 BBs, 300 MBBs trained by year end 2003 – 7– Mar-18

Du. Pont has been building a Six Sigma Foundation Transformation 2004 Marketing & Sales Effectiveness Operations Supply Chain Process Excellence 2003 Identified corporate core processes Top Line Growth, Df. SS 2002 900 Df. SS, $1. 2 Bn revenue TLG projects 03 Green Belts- 6000 at the end of 2001 16000 trained by year end 2003 Black Belts and MBBs- 1200 at the end of 2000 2500 BBs, 300 MBBs trained by year end 2003 – 7– Mar-18

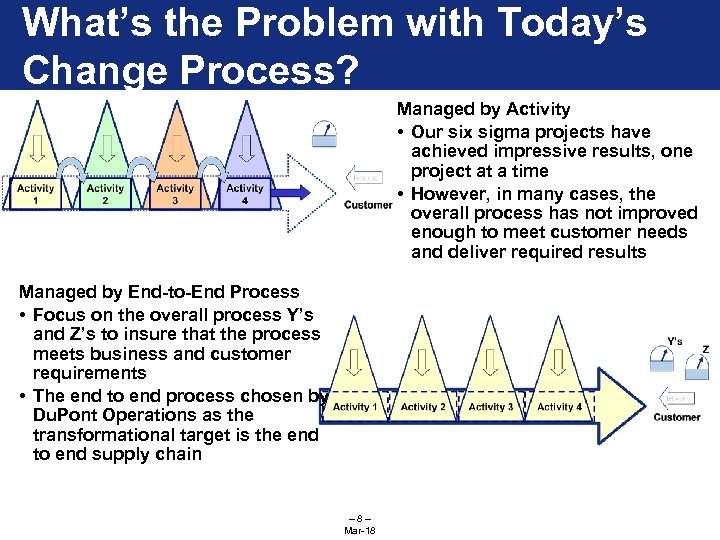

What’s the Problem with Today’s Change Process? Managed by Activity • Our six sigma projects have achieved impressive results, one project at a time • However, in many cases, the overall process has not improved enough to meet customer needs and deliver required results Managed by End-to-End Process • Focus on the overall process Y’s and Z’s to insure that the process meets business and customer requirements • The end to end process chosen by Du. Pont Operations as the transformational target is the end to end supply chain – 8– Mar-18

What’s the Problem with Today’s Change Process? Managed by Activity • Our six sigma projects have achieved impressive results, one project at a time • However, in many cases, the overall process has not improved enough to meet customer needs and deliver required results Managed by End-to-End Process • Focus on the overall process Y’s and Z’s to insure that the process meets business and customer requirements • The end to end process chosen by Du. Pont Operations as the transformational target is the end to end supply chain – 8– Mar-18

Systems support end to end business processes n The power of an ERP systems is in the integration, not in individual component functional excellence n Du. Pont started its SAP journey before it began six sigma (the first projects were kicked off 7 years ago) as discrete, business by business projects… a one Du. Pont, end to end process view was not envisioned n Most of the business cases were based on transactional and inventory benefits from better data and improved business processes, but…. ► The improvement process must consider and deal with the complexity of partially installed ERP plus legacy environment that will exist for years ► ERP systems manage flow… material, information, dollars; the primary end to end process where the opportunity exists is supply chain – 9– Mar-18

Systems support end to end business processes n The power of an ERP systems is in the integration, not in individual component functional excellence n Du. Pont started its SAP journey before it began six sigma (the first projects were kicked off 7 years ago) as discrete, business by business projects… a one Du. Pont, end to end process view was not envisioned n Most of the business cases were based on transactional and inventory benefits from better data and improved business processes, but…. ► The improvement process must consider and deal with the complexity of partially installed ERP plus legacy environment that will exist for years ► ERP systems manage flow… material, information, dollars; the primary end to end process where the opportunity exists is supply chain – 9– Mar-18

The world has changed… n Power has shifted from the manufacturers controlling the supply chain to “point of sale” control n The new battle front is supply chain to supply chain Industry Week notes that with the consumer in the supply chain drivers seat, companies such as P&G are transforming themselves to meet the new challenge. Retailers such as Wal-Mart are forcing change in everything from how consumers buy to how products are manufactured and distributed. The Wall Street Journal notes that there is $600 Bn in working capital waiting to be spent by US companies and that industry leaders like Wal-Mart, P&G, Gillette, and 3 M are making huge strides to free it up. Others, notably Dell, are already industry leaders and continue to drive WC as a competitive advantage. – 10 – Mar-18

The world has changed… n Power has shifted from the manufacturers controlling the supply chain to “point of sale” control n The new battle front is supply chain to supply chain Industry Week notes that with the consumer in the supply chain drivers seat, companies such as P&G are transforming themselves to meet the new challenge. Retailers such as Wal-Mart are forcing change in everything from how consumers buy to how products are manufactured and distributed. The Wall Street Journal notes that there is $600 Bn in working capital waiting to be spent by US companies and that industry leaders like Wal-Mart, P&G, Gillette, and 3 M are making huge strides to free it up. Others, notably Dell, are already industry leaders and continue to drive WC as a competitive advantage. – 10 – Mar-18

We Benchmarked the Supply Chain Performance of Excellent Companies – 11 – Mar-18

We Benchmarked the Supply Chain Performance of Excellent Companies – 11 – Mar-18

We cannot show the Detailed Data, but… n The data showed that Du. Pont invests significantly more than its peers in like industries in working capital invested per dollar of revenue n The practices of peer company leaders and other industry leaders were critical to identifying the supply chain critical x’s that Du. Pont needs to manage to also become excellent n The performance opportunity convinced Du. Pont leadership to support supply chain transformation across all of our businesses and to pursue a significant inventory reduction of at least a $Bn plus removing the associated carrying costs – 12 – Mar-18

We cannot show the Detailed Data, but… n The data showed that Du. Pont invests significantly more than its peers in like industries in working capital invested per dollar of revenue n The practices of peer company leaders and other industry leaders were critical to identifying the supply chain critical x’s that Du. Pont needs to manage to also become excellent n The performance opportunity convinced Du. Pont leadership to support supply chain transformation across all of our businesses and to pursue a significant inventory reduction of at least a $Bn plus removing the associated carrying costs – 12 – Mar-18

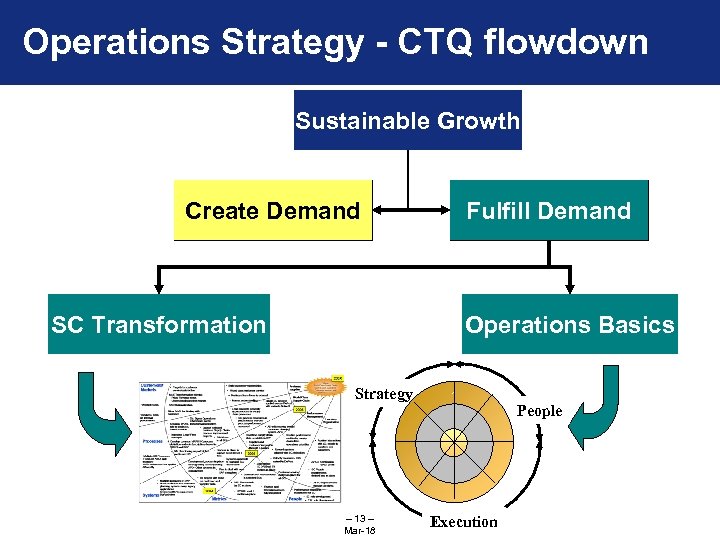

Operations Strategy - CTQ flowdown Sustainable Growth Create Demand SC Transformation Fulfill Demand Operations Basics Strategy – 13 – Mar-18 People Execution

Operations Strategy - CTQ flowdown Sustainable Growth Create Demand SC Transformation Fulfill Demand Operations Basics Strategy – 13 – Mar-18 People Execution

Supply Chain Transformation is about… n Improving end to end supply chain process capability to execute business plans and deliver customer expectations ►It is not about reducing inventory, but will reduce the need for inventory and associated hidden costs ►It will also reduce overall supply chain management costs and variable costs – 14 – Mar-18

Supply Chain Transformation is about… n Improving end to end supply chain process capability to execute business plans and deliver customer expectations ►It is not about reducing inventory, but will reduce the need for inventory and associated hidden costs ►It will also reduce overall supply chain management costs and variable costs – 14 – Mar-18

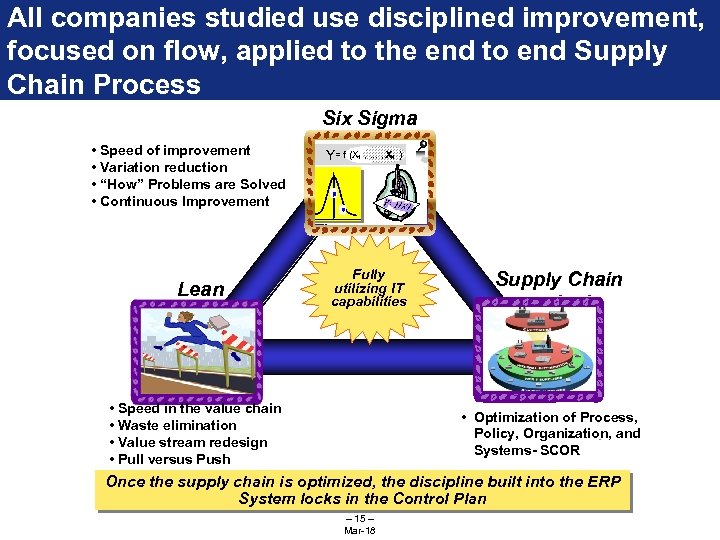

All companies studied use disciplined improvement, focused on flow, applied to the end to end Supply Chain Process Six Sigma • Speed of improvement • Variation reduction • “How” Problems are Solved • Continuous Improvement Lean Y= f (X 1 , . . . , XN ) m s Fully utilizing IT capabilities • Speed in the value chain • Waste elimination • Value stream redesign • Pull versus Push Supply Chain • Optimization of Process, Policy, Organization, and Systems- SCOR Once the supply chain is optimized, the discipline built into the ERP System locks in the Control Plan – 15 – Mar-18

All companies studied use disciplined improvement, focused on flow, applied to the end to end Supply Chain Process Six Sigma • Speed of improvement • Variation reduction • “How” Problems are Solved • Continuous Improvement Lean Y= f (X 1 , . . . , XN ) m s Fully utilizing IT capabilities • Speed in the value chain • Waste elimination • Value stream redesign • Pull versus Push Supply Chain • Optimization of Process, Policy, Organization, and Systems- SCOR Once the supply chain is optimized, the discipline built into the ERP System locks in the Control Plan – 15 – Mar-18

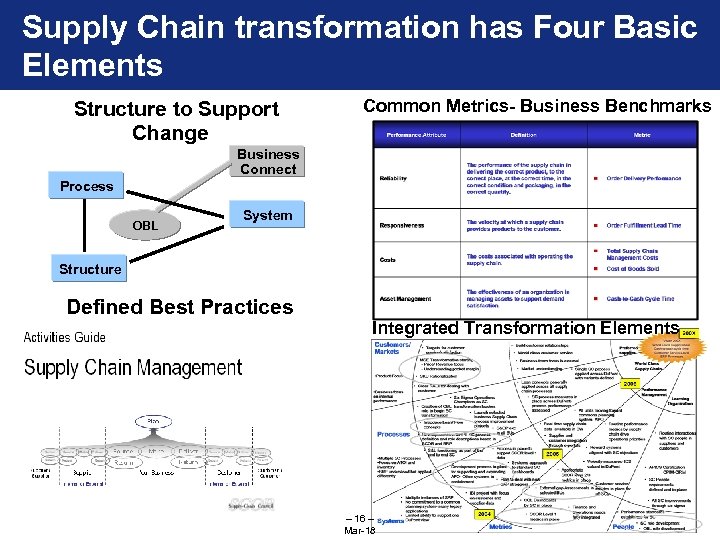

Supply Chain transformation has Four Basic Elements Structure to Support Change Common Metrics- Business Benchmarks Business Connect Process OBL System Structure Defined Best Practices Integrated Transformation Elements – 16 – Mar-18

Supply Chain transformation has Four Basic Elements Structure to Support Change Common Metrics- Business Benchmarks Business Connect Process OBL System Structure Defined Best Practices Integrated Transformation Elements – 16 – Mar-18

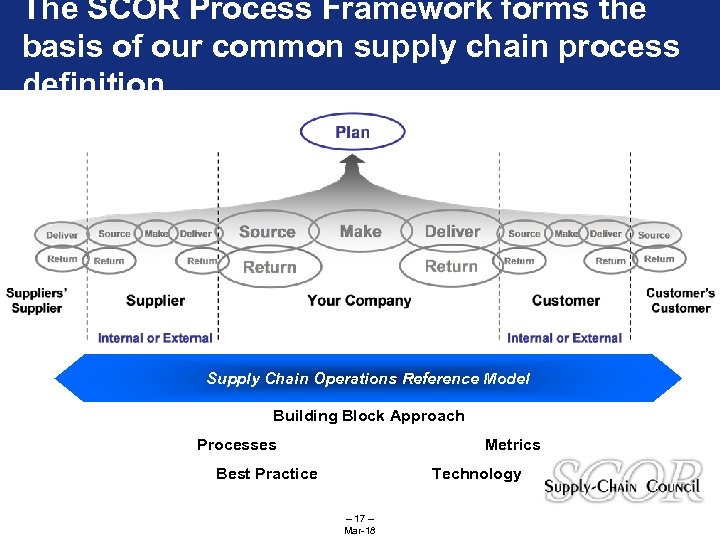

The SCOR Process Framework forms the basis of our common supply chain process definition Supply Chain Operations Reference Model Building Block Approach Processes Metrics Best Practice Technology – 17 – Mar-18

The SCOR Process Framework forms the basis of our common supply chain process definition Supply Chain Operations Reference Model Building Block Approach Processes Metrics Best Practice Technology – 17 – Mar-18

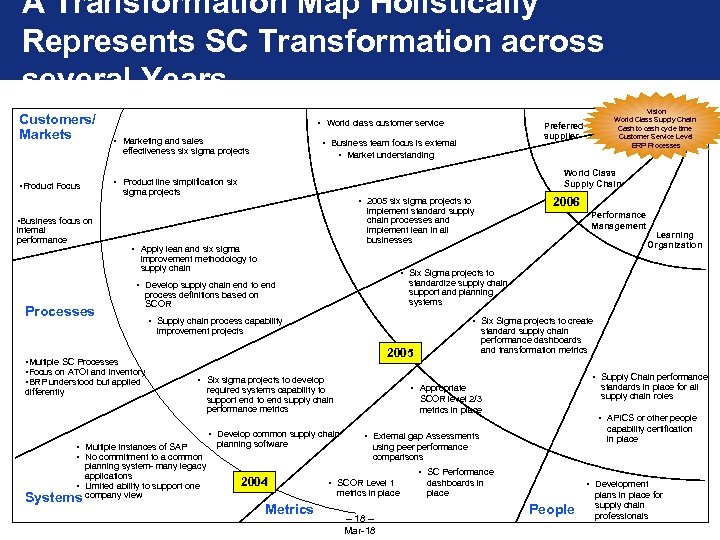

A Transformation Map Holistically Represents SC Transformation across several Years Customers/ Markets • World class customer service • Marketing and sales • Product Focus World Class Supply Chain • Product line simplification six sigma projects implement standard supply chain processes and implement lean in all businesses • Apply lean and six sigma improvement methodology to supply chain • Supply chain process capability • Six Sigma projects to create improvement projects standard supply chain performance dashboards and transformation metrics 2005 • Supply Chain performance • Six sigma projects to develop differently required systems capability to support end to end supply chain performance metrics planning system- many legacy applications • Limited ability to support one Systems company view planning software 2004 Metrics standards in place for all supply chain roles • Appropriate SCOR level 2/3 metrics in place • Develop common supply chain • Multiple instances of SAP • No commitment to a common Learning Organization standardize supply chain support and planning systems process definitions based on SCOR • Multiple SC Processes • Focus on ATOI and inventory • BRP understood but applied Performance Management • Six Sigma projects to • Develop supply chain end to end Processes 2006 • 2005 six sigma projects to • Business focus on internal performance Preferred supplier • Business team focus is external • Market understanding effectiveness six sigma projects Vision World Class Supply Chain Cash to cash cycle time Customer Service Level ERP Processes • APICS or other people capability certification in place • External gap Assessments using peer performance comparisons • SC Performance • SCOR Level 1 metrics in place – 18 – Mar-18 dashboards in place • Development People plans in place for supply chain professionals

A Transformation Map Holistically Represents SC Transformation across several Years Customers/ Markets • World class customer service • Marketing and sales • Product Focus World Class Supply Chain • Product line simplification six sigma projects implement standard supply chain processes and implement lean in all businesses • Apply lean and six sigma improvement methodology to supply chain • Supply chain process capability • Six Sigma projects to create improvement projects standard supply chain performance dashboards and transformation metrics 2005 • Supply Chain performance • Six sigma projects to develop differently required systems capability to support end to end supply chain performance metrics planning system- many legacy applications • Limited ability to support one Systems company view planning software 2004 Metrics standards in place for all supply chain roles • Appropriate SCOR level 2/3 metrics in place • Develop common supply chain • Multiple instances of SAP • No commitment to a common Learning Organization standardize supply chain support and planning systems process definitions based on SCOR • Multiple SC Processes • Focus on ATOI and inventory • BRP understood but applied Performance Management • Six Sigma projects to • Develop supply chain end to end Processes 2006 • 2005 six sigma projects to • Business focus on internal performance Preferred supplier • Business team focus is external • Market understanding effectiveness six sigma projects Vision World Class Supply Chain Cash to cash cycle time Customer Service Level ERP Processes • APICS or other people capability certification in place • External gap Assessments using peer performance comparisons • SC Performance • SCOR Level 1 metrics in place – 18 – Mar-18 dashboards in place • Development People plans in place for supply chain professionals

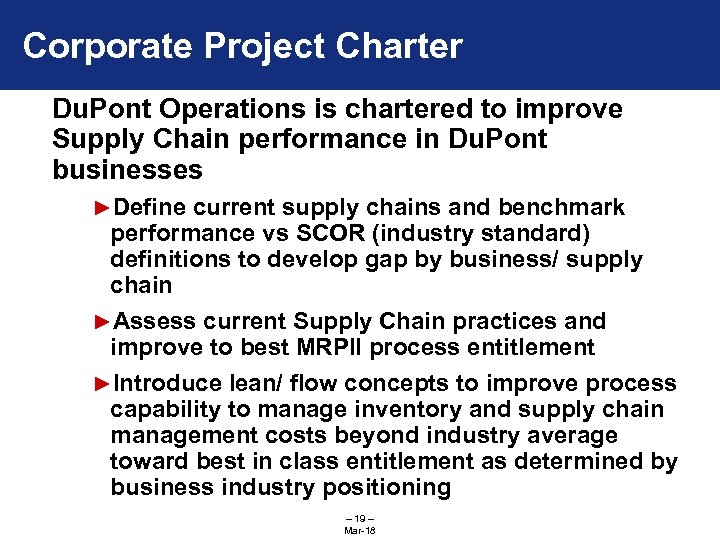

Corporate Project Charter Du. Pont Operations is chartered to improve Supply Chain performance in Du. Pont businesses ►Define current supply chains and benchmark performance vs SCOR (industry standard) definitions to develop gap by business/ supply chain ►Assess current Supply Chain practices and improve to best MRPII process entitlement ►Introduce lean/ flow concepts to improve process capability to manage inventory and supply chain management costs beyond industry average toward best in class entitlement as determined by business industry positioning – 19 – Mar-18

Corporate Project Charter Du. Pont Operations is chartered to improve Supply Chain performance in Du. Pont businesses ►Define current supply chains and benchmark performance vs SCOR (industry standard) definitions to develop gap by business/ supply chain ►Assess current Supply Chain practices and improve to best MRPII process entitlement ►Introduce lean/ flow concepts to improve process capability to manage inventory and supply chain management costs beyond industry average toward best in class entitlement as determined by business industry positioning – 19 – Mar-18

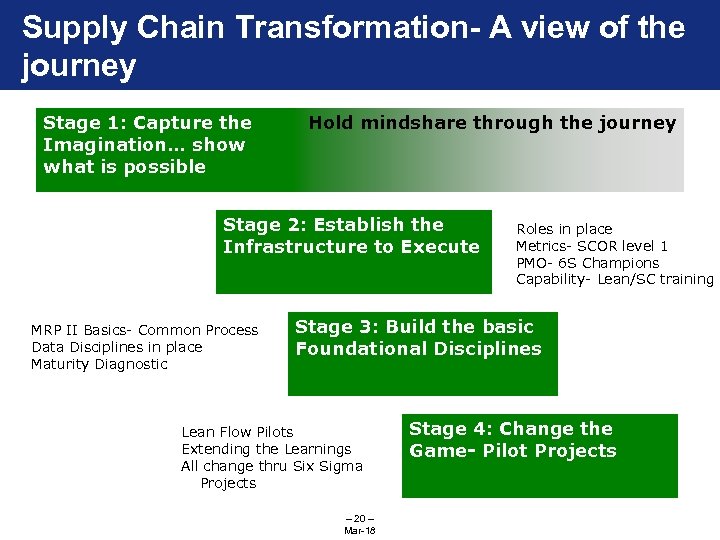

Supply Chain Transformation- A view of the journey Stage 1: Capture the Imagination… show what is possible Hold mindshare through the journey Stage 2: Establish the Infrastructure to Execute MRP II Basics- Common Process Data Disciplines in place Maturity Diagnostic Roles in place Metrics- SCOR level 1 PMO- 6 S Champions Capability- Lean/SC training Stage 3: Build the basic Foundational Disciplines Lean Flow Pilots Extending the Learnings All change thru Six Sigma Projects – 20 – Mar-18 Stage 4: Change the Game- Pilot Projects

Supply Chain Transformation- A view of the journey Stage 1: Capture the Imagination… show what is possible Hold mindshare through the journey Stage 2: Establish the Infrastructure to Execute MRP II Basics- Common Process Data Disciplines in place Maturity Diagnostic Roles in place Metrics- SCOR level 1 PMO- 6 S Champions Capability- Lean/SC training Stage 3: Build the basic Foundational Disciplines Lean Flow Pilots Extending the Learnings All change thru Six Sigma Projects – 20 – Mar-18 Stage 4: Change the Game- Pilot Projects

One Du. Pont SC Projects Underway n Transformation Project Management Office to guide the change process n Development of the structure to support Transformation n SCOR Level One Metrics n Supply Chain Common Process Definition n SAP Systems integration, legacy system reduction n Lean tool addition to our Six Sigma deployment n SAP/ APO pilot development n APICS Certification Process for SC Professionals n Platform Supply Chain kickoff meetings – 21 – Mar-18

One Du. Pont SC Projects Underway n Transformation Project Management Office to guide the change process n Development of the structure to support Transformation n SCOR Level One Metrics n Supply Chain Common Process Definition n SAP Systems integration, legacy system reduction n Lean tool addition to our Six Sigma deployment n SAP/ APO pilot development n APICS Certification Process for SC Professionals n Platform Supply Chain kickoff meetings – 21 – Mar-18

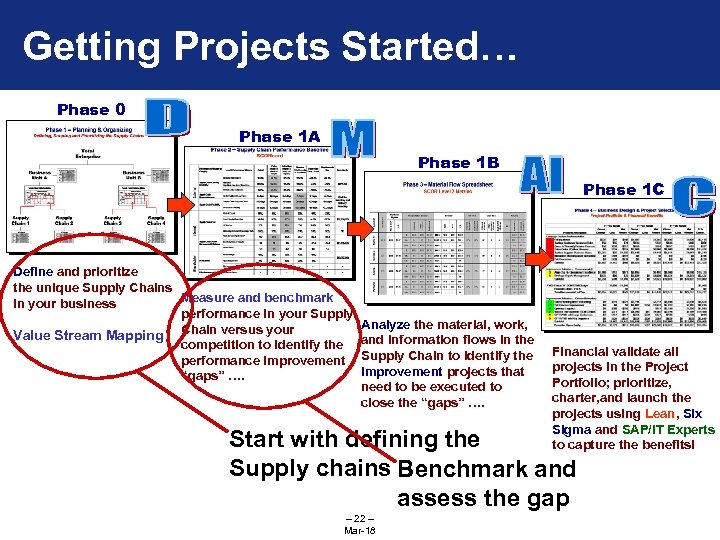

Getting Projects Started… Phase 0 Phase 1 A Phase 1 B Phase 1 C Define and prioritize the unique Supply Chains Measure and benchmark in your business performance in your Supply Value Stream Mapping Chain versus your competition to identify the performance improvement “gaps” …. Analyze the material, work, and information flows in the Supply Chain to identify the improvement projects that need to be executed to close the “gaps” …. Financial validate all projects in the Project Portfolio; prioritize, charter, and launch the projects using Lean, Six Sigma and SAP/IT Experts to capture the benefits! Start with defining the Supply chains Benchmark and assess the gap – 22 – Mar-18

Getting Projects Started… Phase 0 Phase 1 A Phase 1 B Phase 1 C Define and prioritize the unique Supply Chains Measure and benchmark in your business performance in your Supply Value Stream Mapping Chain versus your competition to identify the performance improvement “gaps” …. Analyze the material, work, and information flows in the Supply Chain to identify the improvement projects that need to be executed to close the “gaps” …. Financial validate all projects in the Project Portfolio; prioritize, charter, and launch the projects using Lean, Six Sigma and SAP/IT Experts to capture the benefits! Start with defining the Supply chains Benchmark and assess the gap – 22 – Mar-18

m

m