30a6cce3490337bbaf6fd28e515f533f.ppt

- Количество слайдов: 6

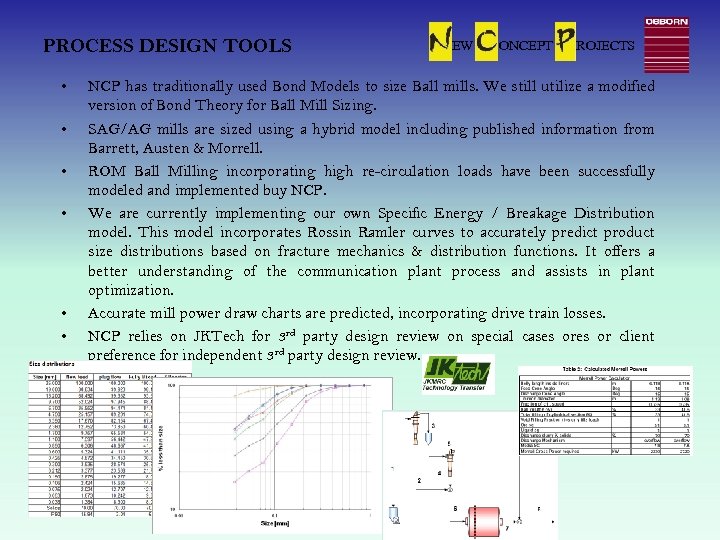

PROCESS DESIGN TOOLS • • • EW ONCEPT ROJECTS NCP has traditionally used Bond Models to size Ball mills. We still utilize a modified version of Bond Theory for Ball Mill Sizing. SAG/AG mills are sized using a hybrid model including published information from Barrett, Austen & Morrell. ROM Ball Milling incorporating high re-circulation loads have been successfully modeled and implemented buy NCP. We are currently implementing our own Specific Energy / Breakage Distribution model. This model incorporates Rossin Ramler curves to accurately predict product size distributions based on fracture mechanics & distribution functions. It offers a better understanding of the communication plant process and assists in plant optimization. Accurate mill power draw charts are predicted, incorporating drive train losses. NCP relies on JKTech for 3 rd party design review on special cases or client preference for independent 3 rd party design review.

PROCESS DESIGN TOOLS • • • EW ONCEPT ROJECTS NCP has traditionally used Bond Models to size Ball mills. We still utilize a modified version of Bond Theory for Ball Mill Sizing. SAG/AG mills are sized using a hybrid model including published information from Barrett, Austen & Morrell. ROM Ball Milling incorporating high re-circulation loads have been successfully modeled and implemented buy NCP. We are currently implementing our own Specific Energy / Breakage Distribution model. This model incorporates Rossin Ramler curves to accurately predict product size distributions based on fracture mechanics & distribution functions. It offers a better understanding of the communication plant process and assists in plant optimization. Accurate mill power draw charts are predicted, incorporating drive train losses. NCP relies on JKTech for 3 rd party design review on special cases or client preference for independent 3 rd party design review.

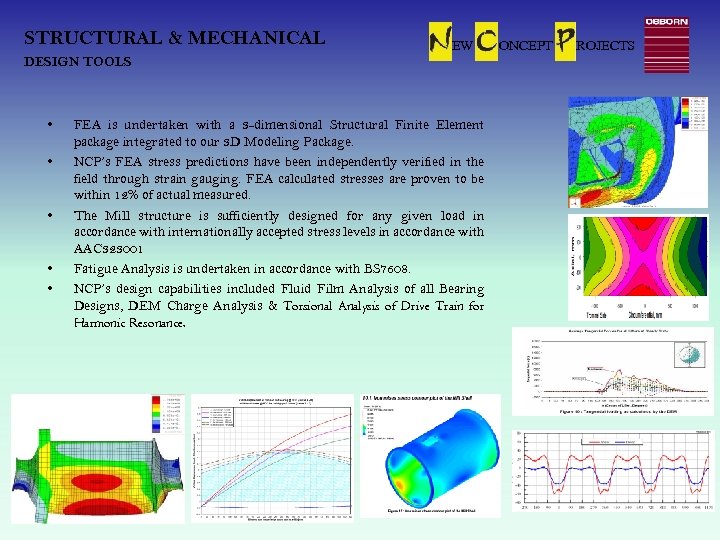

STRUCTURAL & MECHANICAL EW DESIGN TOOLS • • • FEA is undertaken with a 3 -dimensional Structural Finite Element package integrated to our 3 D Modeling Package. NCP’s FEA stress predictions have been independently verified in the field through strain gauging. FEA calculated stresses are proven to be within 12% of actual measured. The Mill structure is sufficiently designed for any given load in accordance with internationally accepted stress levels in accordance with AAC 323001 Fatigue Analysis is undertaken in accordance with BS 7608. NCP’s design capabilities included Fluid Film Analysis of all Bearing Designs, DEM Charge Analysis & Torsional Analysis of Drive Train for Harmonic Resonance. ONCEPT ROJECTS

STRUCTURAL & MECHANICAL EW DESIGN TOOLS • • • FEA is undertaken with a 3 -dimensional Structural Finite Element package integrated to our 3 D Modeling Package. NCP’s FEA stress predictions have been independently verified in the field through strain gauging. FEA calculated stresses are proven to be within 12% of actual measured. The Mill structure is sufficiently designed for any given load in accordance with internationally accepted stress levels in accordance with AAC 323001 Fatigue Analysis is undertaken in accordance with BS 7608. NCP’s design capabilities included Fluid Film Analysis of all Bearing Designs, DEM Charge Analysis & Torsional Analysis of Drive Train for Harmonic Resonance. ONCEPT ROJECTS

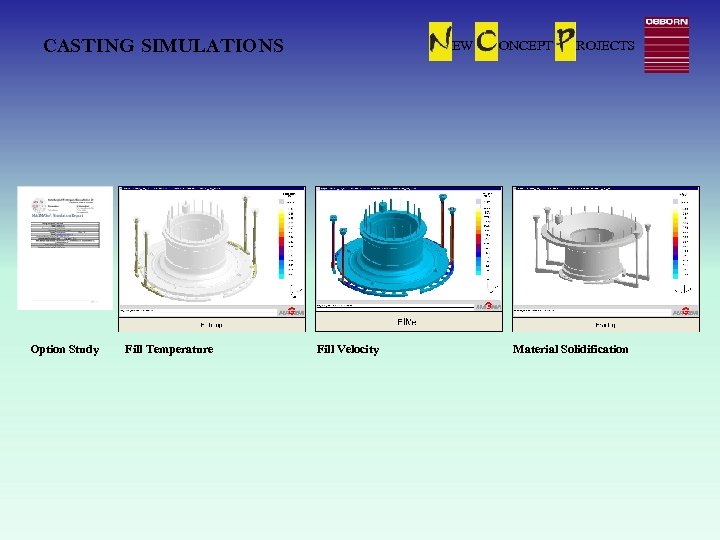

CASTING SIMULATIONS Option Study Fill Temperature EW Fill Velocity ONCEPT ROJECTS Material Solidification

CASTING SIMULATIONS Option Study Fill Temperature EW Fill Velocity ONCEPT ROJECTS Material Solidification

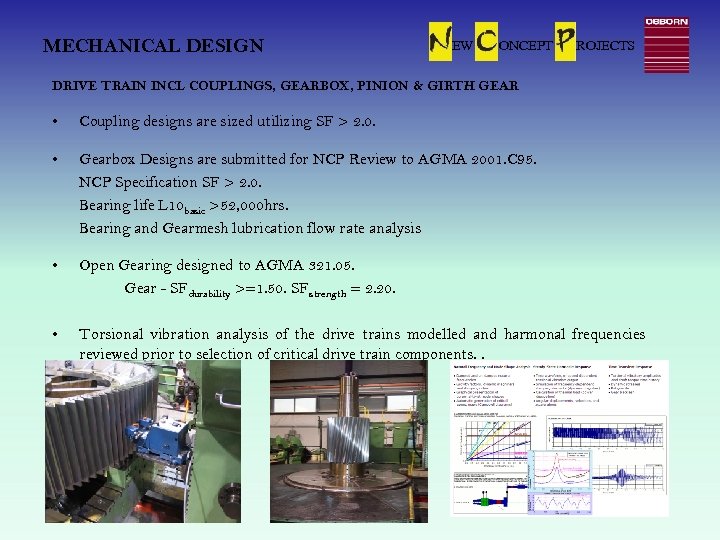

MECHANICAL DESIGN EW ONCEPT ROJECTS DRIVE TRAIN INCL COUPLINGS, GEARBOX, PINION & GIRTH GEAR • Coupling designs are sized utilizing SF > 2. 0. • Gearbox Designs are submitted for NCP Review to AGMA 2001. C 95. NCP Specification SF > 2. 0. Bearing life L 10 basic >52, 000 hrs. Bearing and Gearmesh lubrication flow rate analysis • Open Gearing designed to AGMA 321. 05. Gear - SFdurability >=1. 50. SFstrength = 2. 20. • Torsional vibration analysis of the drive trains modelled and harmonal frequencies reviewed prior to selection of critical drive train components. .

MECHANICAL DESIGN EW ONCEPT ROJECTS DRIVE TRAIN INCL COUPLINGS, GEARBOX, PINION & GIRTH GEAR • Coupling designs are sized utilizing SF > 2. 0. • Gearbox Designs are submitted for NCP Review to AGMA 2001. C 95. NCP Specification SF > 2. 0. Bearing life L 10 basic >52, 000 hrs. Bearing and Gearmesh lubrication flow rate analysis • Open Gearing designed to AGMA 321. 05. Gear - SFdurability >=1. 50. SFstrength = 2. 20. • Torsional vibration analysis of the drive trains modelled and harmonal frequencies reviewed prior to selection of critical drive train components. .

DESIGN OVERVIEW EW ONCEPT ROJECTS ANCILLARY ITEM DESIGN LUBE SYSTEMS • • • Lube System design will be undertaken by NCP based on NCP Osborn design Specification. Flow rates are established through first principle fluid film analysis. Each project is unique and a stringent specification is in place to ensure lube systems are designed and supplied fit for the intended purpose. FEED SPOUT/CHUTE DESIGN • Feed Spout arrangements are designed according to discharge trajectory theory & bulk solids chute design principals (Wouter Deijs). Ore specific tests are also conducted for selection of the appropriate wear resistant liners.

DESIGN OVERVIEW EW ONCEPT ROJECTS ANCILLARY ITEM DESIGN LUBE SYSTEMS • • • Lube System design will be undertaken by NCP based on NCP Osborn design Specification. Flow rates are established through first principle fluid film analysis. Each project is unique and a stringent specification is in place to ensure lube systems are designed and supplied fit for the intended purpose. FEED SPOUT/CHUTE DESIGN • Feed Spout arrangements are designed according to discharge trajectory theory & bulk solids chute design principals (Wouter Deijs). Ore specific tests are also conducted for selection of the appropriate wear resistant liners.

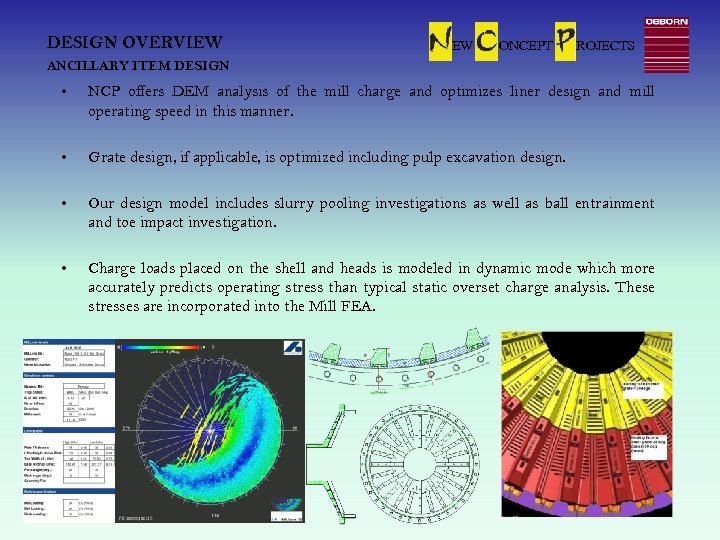

DESIGN OVERVIEW EW ONCEPT ROJECTS ANCILLARY ITEM DESIGN • NCP offers DEM analysis of the mill charge and optimizes liner design and mill operating speed in this manner. • Grate design, if applicable, is optimized including pulp excavation design. • Our design model includes slurry pooling investigations as well as ball entrainment and toe impact investigation. • Charge loads placed on the shell and heads is modeled in dynamic mode which more accurately predicts operating stress than typical static overset charge analysis. These stresses are incorporated into the Mill FEA.

DESIGN OVERVIEW EW ONCEPT ROJECTS ANCILLARY ITEM DESIGN • NCP offers DEM analysis of the mill charge and optimizes liner design and mill operating speed in this manner. • Grate design, if applicable, is optimized including pulp excavation design. • Our design model includes slurry pooling investigations as well as ball entrainment and toe impact investigation. • Charge loads placed on the shell and heads is modeled in dynamic mode which more accurately predicts operating stress than typical static overset charge analysis. These stresses are incorporated into the Mill FEA.