bcfc56107a0718555f3c066ff7f1730c.ppt

- Количество слайдов: 20

Process Automation System for Integration and Operation of Large Volume Plasma Device P. K. Srivastava and LVPD Team* (Abstract ID: 013) *LVPD Team: Ritesh Sugandhi, A. K. Sanyasi, Prabhakar Srivastava, L. M. Awasthi, R. Jha, S. K. Mattoo and P. K. Kaw 21/04/15 10 th IAEA conference on data acquisition and control system 1

Process Automation System for Integration and Operation of Large Volume Plasma Device P. K. Srivastava and LVPD Team* (Abstract ID: 013) *LVPD Team: Ritesh Sugandhi, A. K. Sanyasi, Prabhakar Srivastava, L. M. Awasthi, R. Jha, S. K. Mattoo and P. K. Kaw 21/04/15 10 th IAEA conference on data acquisition and control system 1

Plan of Talk Motivation Large volume plasma device Introduction Operation cycle Scope for automation Automation process Process artefacts – Operational logic preparation, Instrumentation models development Interface : Hardware and software Lab. VIEW as SCADA Results Conclusion 21/04/15 10 th IAEA conference on data acquisition and control system 2

Plan of Talk Motivation Large volume plasma device Introduction Operation cycle Scope for automation Automation process Process artefacts – Operational logic preparation, Instrumentation models development Interface : Hardware and software Lab. VIEW as SCADA Results Conclusion 21/04/15 10 th IAEA conference on data acquisition and control system 2

Motivation • Process automation: Critical for Plasma Physics Experiments • Complex systems with multiple inter subsystem dependencies • System distributed over large area • Process & Time criticality • Fault identification and trouble shooting • Sequential as well parallel operations • Complex interlocks • Enforcing operational limits • Real time feedback & control • System and Human Safety • Data Management • Few working examples are as follows: Tokamaks • VINETA • LAPD • CLM 21/04/15 Linear Machines • JET • Tore Supra • Aditya & SST -1 10 th IAEA conference on data acquisition and control system 3

Motivation • Process automation: Critical for Plasma Physics Experiments • Complex systems with multiple inter subsystem dependencies • System distributed over large area • Process & Time criticality • Fault identification and trouble shooting • Sequential as well parallel operations • Complex interlocks • Enforcing operational limits • Real time feedback & control • System and Human Safety • Data Management • Few working examples are as follows: Tokamaks • VINETA • LAPD • CLM 21/04/15 Linear Machines • JET • Tore Supra • Aditya & SST -1 10 th IAEA conference on data acquisition and control system 3

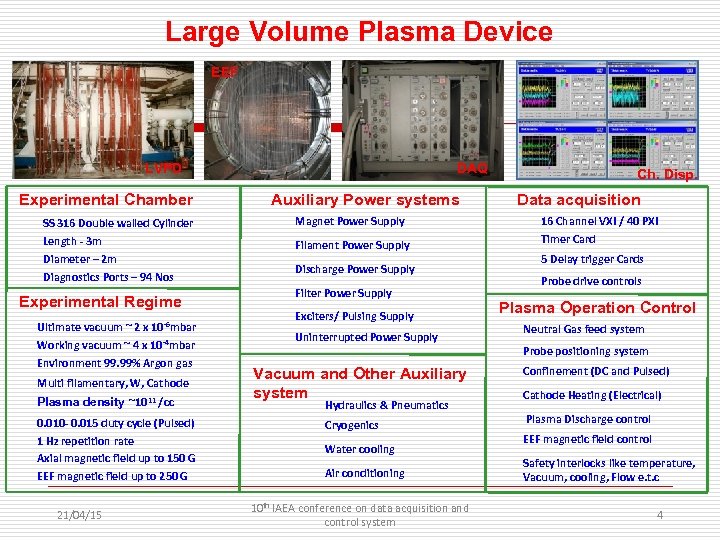

Large Volume Plasma Device EEF LVPD Experimental Chamber SS 316 Double walled Cylinder Length - 3 m Diameter – 2 m Diagnostics Ports – 94 Nos Experimental Regime 10 -6 mbar Ultimate vacuum ~ 2 x Working vacuum ~ 4 x 10 -4 mbar Environment 99. 99% Argon gas Multi filamentary, W, Cathode Plasma density ~1011 /cc 0. 010 - 0. 015 duty cycle (Pulsed) 1 Hz repetition rate Axial magnetic field up to 150 G EEF magnetic field up to 250 G 21/04/15 DAQ Auxiliary Power systems Magnet Power Supply Filament Power Supply Discharge Power Supply Filter Power Supply Exciters/ Pulsing Supply Uninterrupted Power Supply Vacuum and Other Auxiliary system Hydraulics & Pneumatics Cryogenics Water cooling Air conditioning 10 th IAEA conference on data acquisition and control system Ch. Disp. Data acquisition 16 Channel VXI / 40 PXI Timer Card 5 Delay trigger Cards Probe drive controls Plasma Operation Control Neutral Gas feed system Probe positioning system Confinement (DC and Pulsed) Cathode Heating (Electrical) Plasma Discharge control EEF magnetic field control Safety interlocks like temperature, Vacuum, cooling, Flow e. t. c 4

Large Volume Plasma Device EEF LVPD Experimental Chamber SS 316 Double walled Cylinder Length - 3 m Diameter – 2 m Diagnostics Ports – 94 Nos Experimental Regime 10 -6 mbar Ultimate vacuum ~ 2 x Working vacuum ~ 4 x 10 -4 mbar Environment 99. 99% Argon gas Multi filamentary, W, Cathode Plasma density ~1011 /cc 0. 010 - 0. 015 duty cycle (Pulsed) 1 Hz repetition rate Axial magnetic field up to 150 G EEF magnetic field up to 250 G 21/04/15 DAQ Auxiliary Power systems Magnet Power Supply Filament Power Supply Discharge Power Supply Filter Power Supply Exciters/ Pulsing Supply Uninterrupted Power Supply Vacuum and Other Auxiliary system Hydraulics & Pneumatics Cryogenics Water cooling Air conditioning 10 th IAEA conference on data acquisition and control system Ch. Disp. Data acquisition 16 Channel VXI / 40 PXI Timer Card 5 Delay trigger Cards Probe drive controls Plasma Operation Control Neutral Gas feed system Probe positioning system Confinement (DC and Pulsed) Cathode Heating (Electrical) Plasma Discharge control EEF magnetic field control Safety interlocks like temperature, Vacuum, cooling, Flow e. t. c 4

Large Volume Plasma Device Physics studies Up gradation is underway Electron Temperature Gradient (ETG) driven Turbulence Automation towards Single window operation of the LVPD experiment. Vacuum operation Power supplies operation Linear Probe drives with Stepper motors based operation, etc Plasma Transport: Relevance to fusion Devices Understanding Electro - Magnetic Filter Physics Exploring Active ETG experiments in LVPD Understanding role of energetic electrons in the physical processes involved in Magnetospheric plasma, Solar flares etc. Up gradation to new PXIe based DAQ with 40 channels Role of magnetic filter in production of – ve (H-) ions in a plasma. Enhancement of EEF pulse width from 15 ms to 55 ms. 21/04/15 Enhancement of Plasma discharge period from 10 ms - 50 ms Up gradation to high density (1012/cm 3) uniform plasma source. 10 th IAEA conference on data acquisition and control system 5

Large Volume Plasma Device Physics studies Up gradation is underway Electron Temperature Gradient (ETG) driven Turbulence Automation towards Single window operation of the LVPD experiment. Vacuum operation Power supplies operation Linear Probe drives with Stepper motors based operation, etc Plasma Transport: Relevance to fusion Devices Understanding Electro - Magnetic Filter Physics Exploring Active ETG experiments in LVPD Understanding role of energetic electrons in the physical processes involved in Magnetospheric plasma, Solar flares etc. Up gradation to new PXIe based DAQ with 40 channels Role of magnetic filter in production of – ve (H-) ions in a plasma. Enhancement of EEF pulse width from 15 ms to 55 ms. 21/04/15 Enhancement of Plasma discharge period from 10 ms - 50 ms Up gradation to high density (1012/cm 3) uniform plasma source. 10 th IAEA conference on data acquisition and control system 5

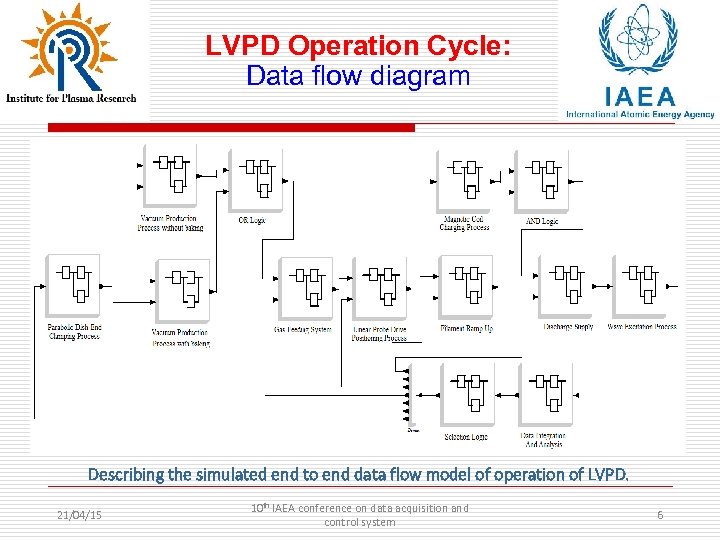

LVPD Operation Cycle: Data flow diagram Describing the simulated end to end data flow model of operation of LVPD. 21/04/15 10 th IAEA conference on data acquisition and control system 6

LVPD Operation Cycle: Data flow diagram Describing the simulated end to end data flow model of operation of LVPD. 21/04/15 10 th IAEA conference on data acquisition and control system 6

Scope of automation (1/2) • Approach: • Automate the new technical subsystems starting from its development • Up-gradation of the manual controls and interlock to computerized control • Apply standardized protocols & conventions and A Graphical User Interface (GUI) • Scope • Proof of concept: • Automation of new Filament Power Supply (20 V/10 k. A) and Linear Probe Drive System (12 No's) • Use of standard Process Modelling Techniques and Instrumentation Models 21/04/15 10 th IAEA conference on data acquisition and control system 7

Scope of automation (1/2) • Approach: • Automate the new technical subsystems starting from its development • Up-gradation of the manual controls and interlock to computerized control • Apply standardized protocols & conventions and A Graphical User Interface (GUI) • Scope • Proof of concept: • Automation of new Filament Power Supply (20 V/10 k. A) and Linear Probe Drive System (12 No's) • Use of standard Process Modelling Techniques and Instrumentation Models 21/04/15 10 th IAEA conference on data acquisition and control system 7

Scope of automation (2/2) • Scope • Interlock • Subsystem level interlocks e. g. Operating limits and conditions for probe drive movement • System level interlock e. g. Filament PS and vacuum system interlock • Emergency stop • Safety • User level safety • Machine level safety by hardwired interlocks 21/04/15 10 th IAEA conference on data acquisition and control system 8

Scope of automation (2/2) • Scope • Interlock • Subsystem level interlocks e. g. Operating limits and conditions for probe drive movement • System level interlock e. g. Filament PS and vacuum system interlock • Emergency stop • Safety • User level safety • Machine level safety by hardwired interlocks 21/04/15 10 th IAEA conference on data acquisition and control system 8

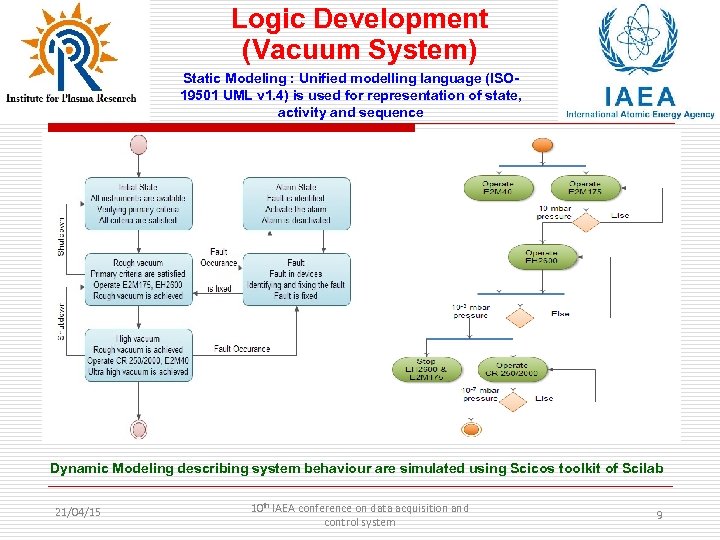

Logic Development (Vacuum System) Static Modeling : Unified modelling language (ISO 19501 UML v 1. 4) is used for representation of state, activity and sequence Dynamic Modeling describing system behaviour are simulated using Scicos toolkit of Scilab 21/04/15 10 th IAEA conference on data acquisition and control system 9

Logic Development (Vacuum System) Static Modeling : Unified modelling language (ISO 19501 UML v 1. 4) is used for representation of state, activity and sequence Dynamic Modeling describing system behaviour are simulated using Scicos toolkit of Scilab 21/04/15 10 th IAEA conference on data acquisition and control system 9

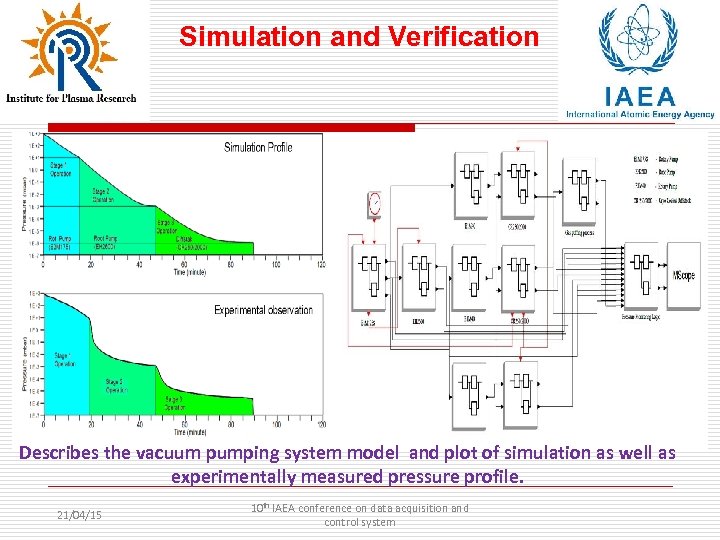

Simulation and Verification Describes the vacuum pumping system model and plot of simulation as well as experimentally measured pressure profile. 21/04/15 10 th IAEA conference on data acquisition and control system

Simulation and Verification Describes the vacuum pumping system model and plot of simulation as well as experimentally measured pressure profile. 21/04/15 10 th IAEA conference on data acquisition and control system

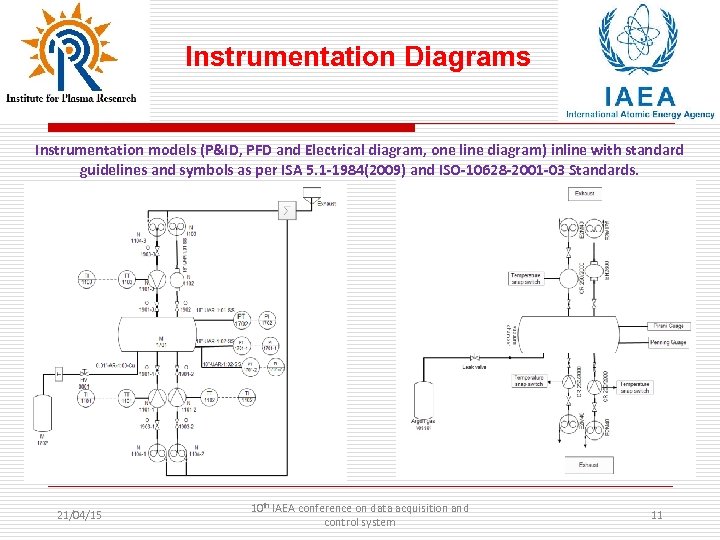

Instrumentation Diagrams Instrumentation models (P&ID, PFD and Electrical diagram, one line diagram) inline with standard guidelines and symbols as per ISA 5. 1 -1984(2009) and ISO-10628 -2001 -03 Standards. 21/04/15 10 th IAEA conference on data acquisition and control system 11

Instrumentation Diagrams Instrumentation models (P&ID, PFD and Electrical diagram, one line diagram) inline with standard guidelines and symbols as per ISA 5. 1 -1984(2009) and ISO-10628 -2001 -03 Standards. 21/04/15 10 th IAEA conference on data acquisition and control system 11

Programmable Controller Interface • Selection of multi-drop serial RS 485 interface • Semi autonomous operation • Each subsystem has a embedded controller (or PLC) program to locally control the unit and respond to a centralized master controller. • Modbus communication protocol: • 21/04/15 Open source, standardized and portable software interface , request-reply mode of operation, 1 master and up to 247 addressable slaves 10 th IAEA conference on data acquisition and control system 12

Programmable Controller Interface • Selection of multi-drop serial RS 485 interface • Semi autonomous operation • Each subsystem has a embedded controller (or PLC) program to locally control the unit and respond to a centralized master controller. • Modbus communication protocol: • 21/04/15 Open source, standardized and portable software interface , request-reply mode of operation, 1 master and up to 247 addressable slaves 10 th IAEA conference on data acquisition and control system 12

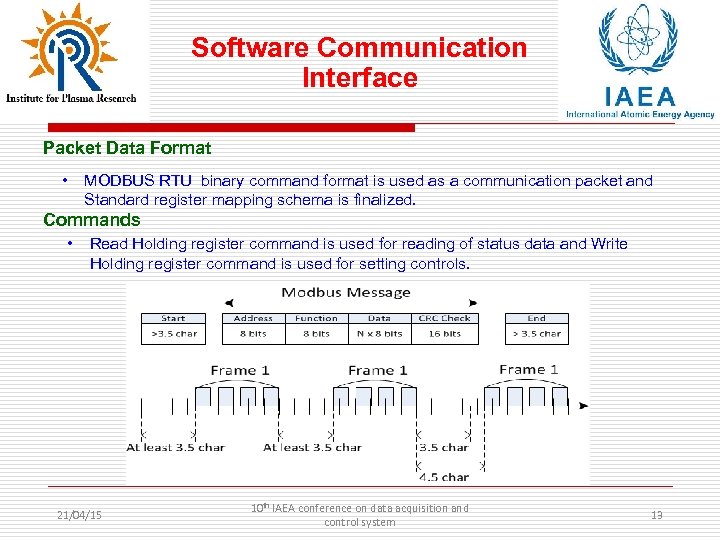

Software Communication Interface Packet Data Format • MODBUS RTU binary command format is used as a communication packet and Standard register mapping schema is finalized. Commands • Read Holding register command is used for reading of status data and Write Holding register command is used for setting controls. 21/04/15 10 th IAEA conference on data acquisition and control system 13

Software Communication Interface Packet Data Format • MODBUS RTU binary command format is used as a communication packet and Standard register mapping schema is finalized. Commands • Read Holding register command is used for reading of status data and Write Holding register command is used for setting controls. 21/04/15 10 th IAEA conference on data acquisition and control system 13

Lab. VIEW for Automation Lab. VIEW is used as a development platform for machine automation and control. Reasons for selections are: • Graphical programming environment • Data flow programming • User and Logic integration under same toolkit • Data Analysis and field bus interface • In-house campus license and support available 21/04/15 10 th IAEA conference on data acquisition and control system 14

Lab. VIEW for Automation Lab. VIEW is used as a development platform for machine automation and control. Reasons for selections are: • Graphical programming environment • Data flow programming • User and Logic integration under same toolkit • Data Analysis and field bus interface • In-house campus license and support available 21/04/15 10 th IAEA conference on data acquisition and control system 14

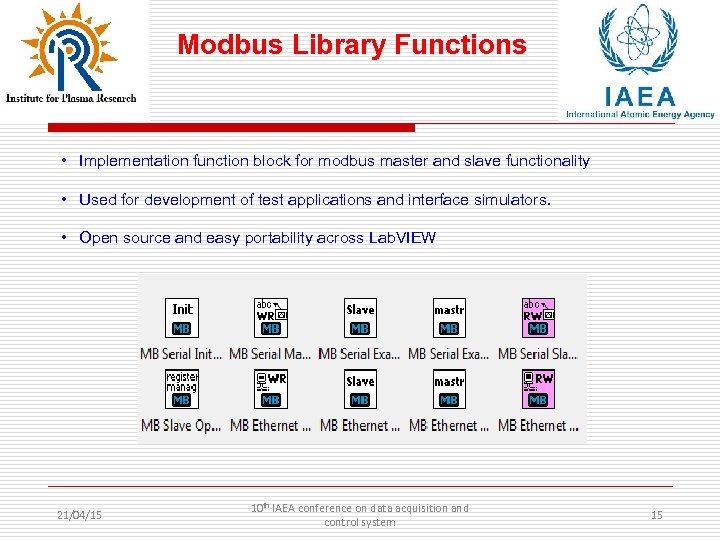

Modbus Library Functions • Implementation function block for modbus master and slave functionality • Used for development of test applications and interface simulators. • Open source and easy portability across Lab. VIEW 21/04/15 10 th IAEA conference on data acquisition and control system 15

Modbus Library Functions • Implementation function block for modbus master and slave functionality • Used for development of test applications and interface simulators. • Open source and easy portability across Lab. VIEW 21/04/15 10 th IAEA conference on data acquisition and control system 15

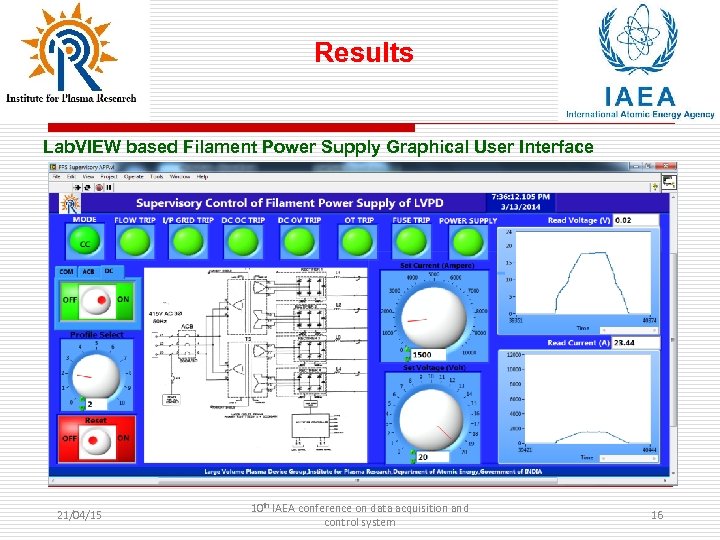

Results Lab. VIEW based Filament Power Supply Graphical User Interface 21/04/15 10 th IAEA conference on data acquisition and control system 16

Results Lab. VIEW based Filament Power Supply Graphical User Interface 21/04/15 10 th IAEA conference on data acquisition and control system 16

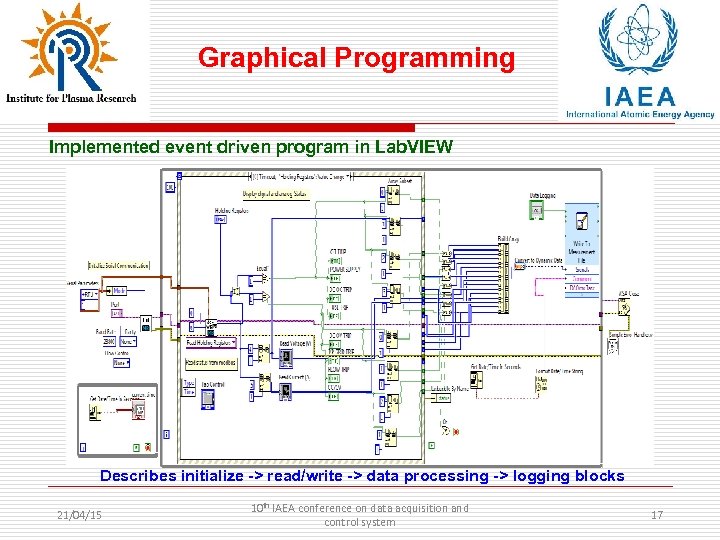

Graphical Programming Implemented event driven program in Lab. VIEW Describes initialize -> read/write -> data processing -> logging blocks 21/04/15 10 th IAEA conference on data acquisition and control system 17

Graphical Programming Implemented event driven program in Lab. VIEW Describes initialize -> read/write -> data processing -> logging blocks 21/04/15 10 th IAEA conference on data acquisition and control system 17

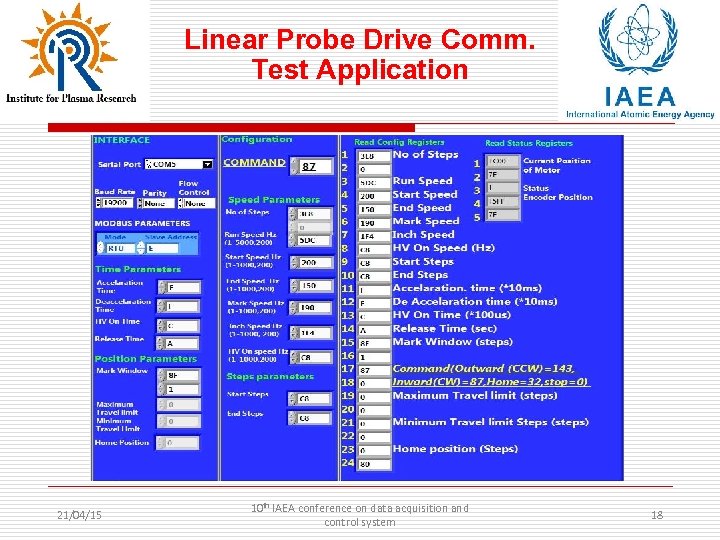

Linear Probe Drive Comm. Test Application 21/04/15 10 th IAEA conference on data acquisition and control system 18

Linear Probe Drive Comm. Test Application 21/04/15 10 th IAEA conference on data acquisition and control system 18

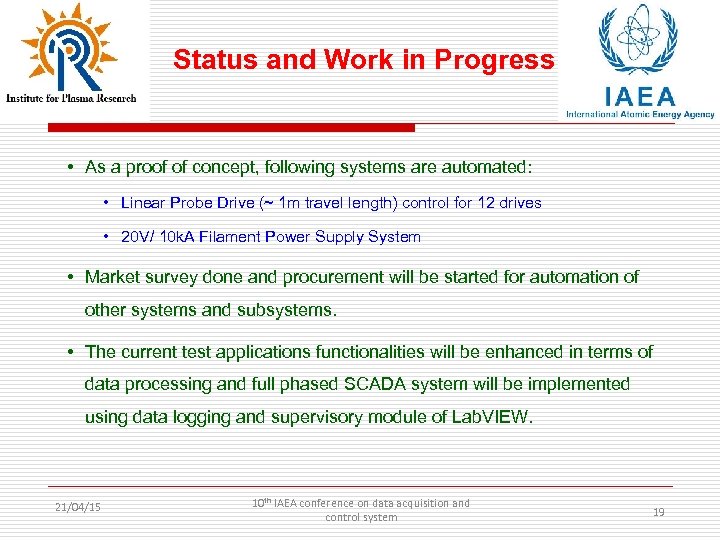

Status and Work in Progress • As a proof of concept, following systems are automated: • Linear Probe Drive (~ 1 m travel length) control for 12 drives • 20 V/ 10 k. A Filament Power Supply System • Market survey done and procurement will be started for automation of other systems and subsystems. • The current test applications functionalities will be enhanced in terms of data processing and full phased SCADA system will be implemented using data logging and supervisory module of Lab. VIEW. 21/04/15 10 th IAEA conference on data acquisition and control system 19

Status and Work in Progress • As a proof of concept, following systems are automated: • Linear Probe Drive (~ 1 m travel length) control for 12 drives • 20 V/ 10 k. A Filament Power Supply System • Market survey done and procurement will be started for automation of other systems and subsystems. • The current test applications functionalities will be enhanced in terms of data processing and full phased SCADA system will be implemented using data logging and supervisory module of Lab. VIEW. 21/04/15 10 th IAEA conference on data acquisition and control system 19

Thank you for your kind attention !!! 21/04/15 10 th IAEA conference on data acquisition and control system 20

Thank you for your kind attention !!! 21/04/15 10 th IAEA conference on data acquisition and control system 20