c359e804f1b7cf0f3a3e6fd2ee36ea0d.ppt

- Количество слайдов: 46

Pro. Star 335 Detector Petro van Poppel – Field Support Specialist Thursday, 15 March 2018

Pro. Star 335 Detector Petro van Poppel – Field Support Specialist Thursday, 15 March 2018

Overview Introduction to PS 335 Detector • Dual Array option • Poly Verify Software • Flow cell • Communications Poly Verify • Production Tests with 0 x 0 flow cell • Wavescan • (Settings Tab) • (Input/Output Tab) • (EEPROM) • (COMMS Tab) • (Calibration Tab) PS 335 Shipping Test Problems

Overview Introduction to PS 335 Detector • Dual Array option • Poly Verify Software • Flow cell • Communications Poly Verify • Production Tests with 0 x 0 flow cell • Wavescan • (Settings Tab) • (Input/Output Tab) • (EEPROM) • (COMMS Tab) • (Calibration Tab) PS 335 Shipping Test Problems

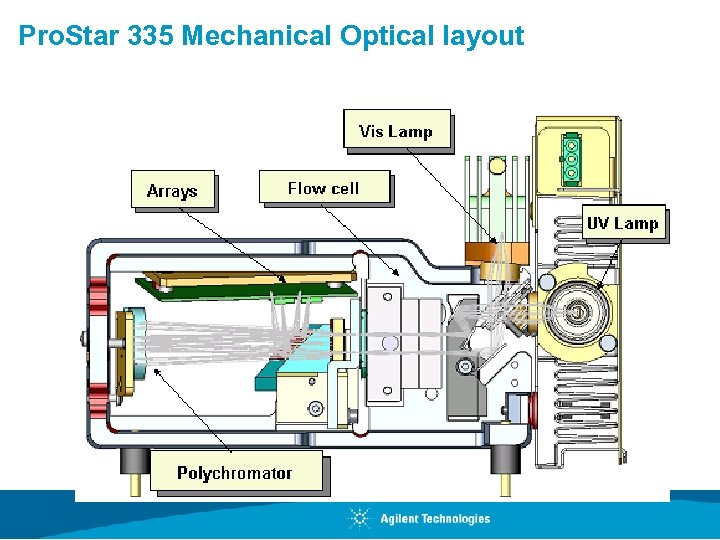

Pro. Star 335 Mechanical Optical layout

Pro. Star 335 Mechanical Optical layout

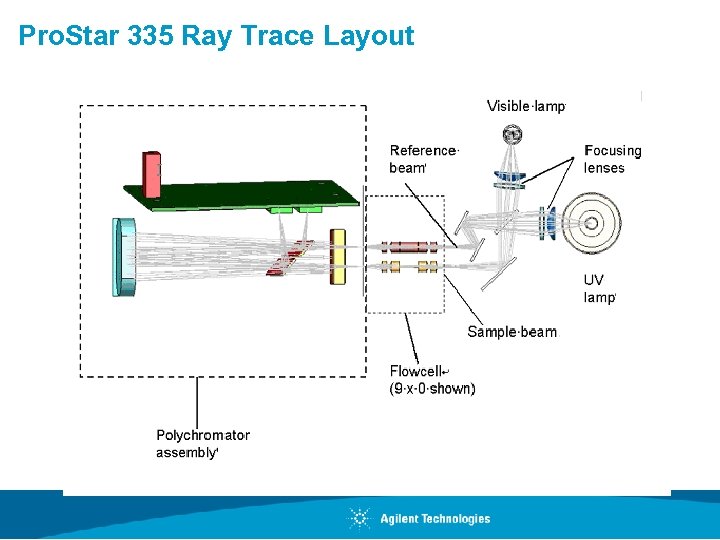

Pro. Star 335 Ray Trace Layout

Pro. Star 335 Ray Trace Layout

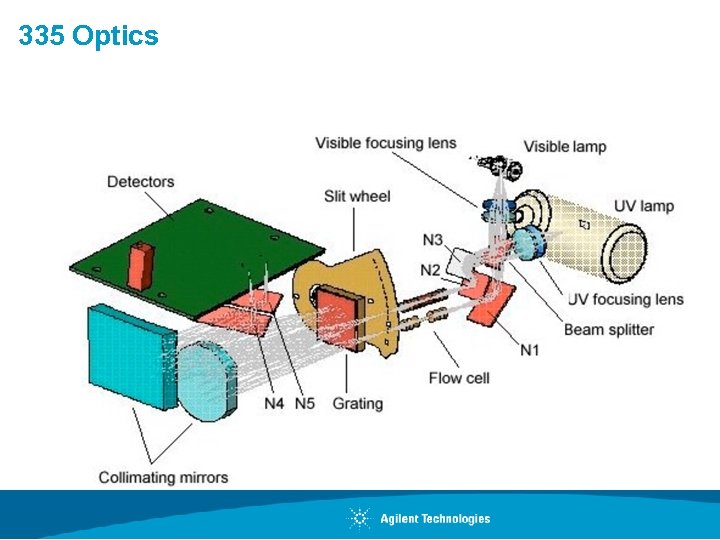

335 Optics

335 Optics

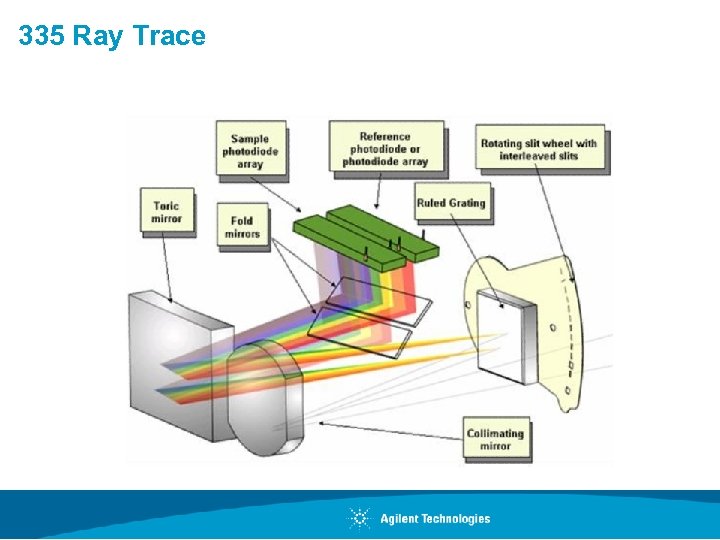

335 Ray Trace

335 Ray Trace

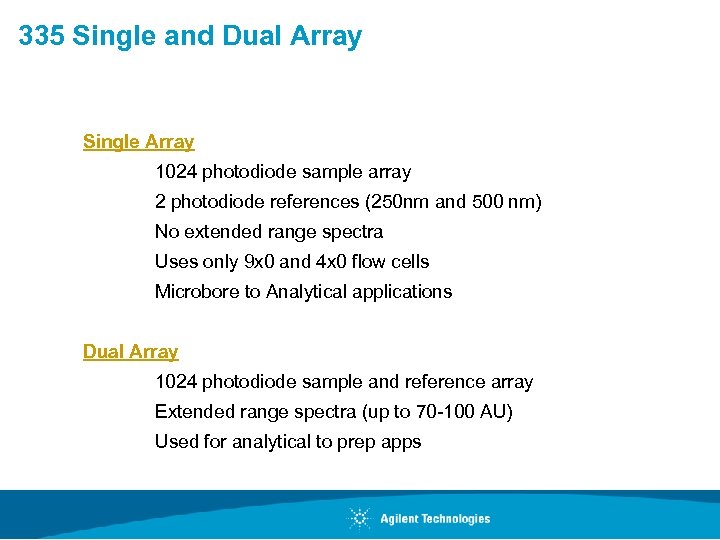

335 Single and Dual Array Single Array 1024 photodiode sample array 2 photodiode references (250 nm and 500 nm) No extended range spectra Uses only 9 x 0 and 4 x 0 flow cells Microbore to Analytical applications Dual Array 1024 photodiode sample and reference array Extended range spectra (up to 70 -100 AU) Used for analytical to prep apps

335 Single and Dual Array Single Array 1024 photodiode sample array 2 photodiode references (250 nm and 500 nm) No extended range spectra Uses only 9 x 0 and 4 x 0 flow cells Microbore to Analytical applications Dual Array 1024 photodiode sample and reference array Extended range spectra (up to 70 -100 AU) Used for analytical to prep apps

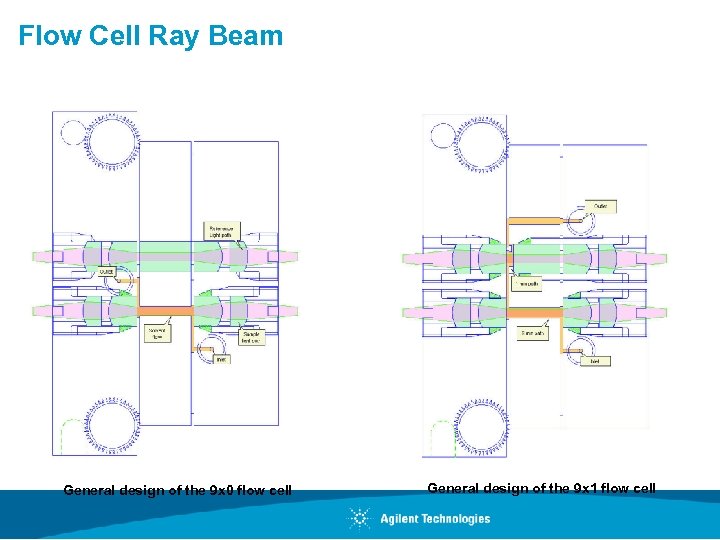

Flow Cell Ray Beam General design of the 9 x 0 flow cell General design of the 9 x 1 flow cell

Flow Cell Ray Beam General design of the 9 x 0 flow cell General design of the 9 x 1 flow cell

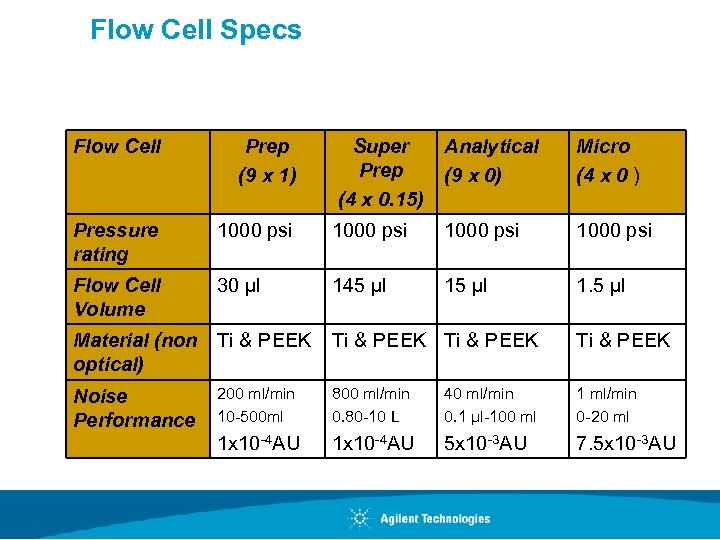

Flow Cell Specs Flow Cell Prep (9 x 1) Pressure rating 1000 psi Flow Cell Volume 30 µl Material (non Ti & PEEK optical) Noise Performance Super Prep (4 x 0. 15) Analytical (9 x 0) Micro (4 x 0 ) 1000 psi 145 µl 1. 5 µl Ti & PEEK 200 ml/min 10 -500 ml 800 ml/min 0. 80 -10 L 40 ml/min 0. 1 µl-100 ml 1 ml/min 0 -20 ml 1 x 10 -4 AU 5 x 10 -3 AU 7. 5 x 10 -3 AU

Flow Cell Specs Flow Cell Prep (9 x 1) Pressure rating 1000 psi Flow Cell Volume 30 µl Material (non Ti & PEEK optical) Noise Performance Super Prep (4 x 0. 15) Analytical (9 x 0) Micro (4 x 0 ) 1000 psi 145 µl 1. 5 µl Ti & PEEK 200 ml/min 10 -500 ml 800 ml/min 0. 80 -10 L 40 ml/min 0. 1 µl-100 ml 1 ml/min 0 -20 ml 1 x 10 -4 AU 5 x 10 -3 AU 7. 5 x 10 -3 AU

Communications TCP/IP communications for Detector: • Static or Dynamic • Networked or standalone • Firewall • Access on Network, OS or PC

Communications TCP/IP communications for Detector: • Static or Dynamic • Networked or standalone • Firewall • Access on Network, OS or PC

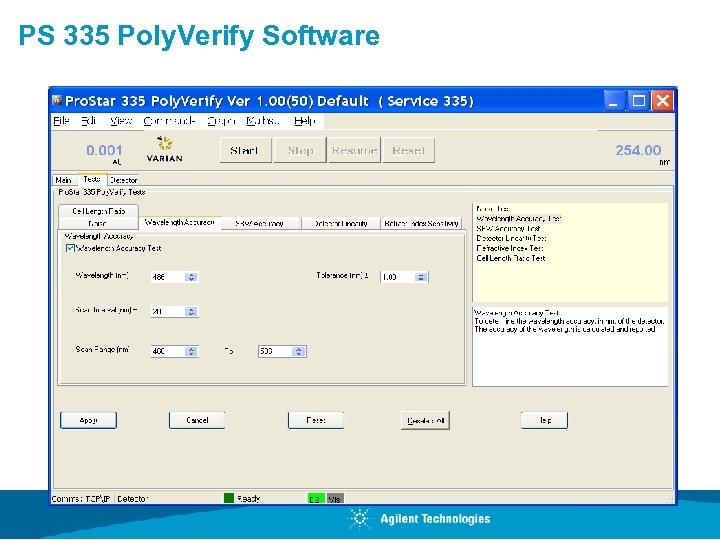

PS 335 Poly. Verify Software

PS 335 Poly. Verify Software

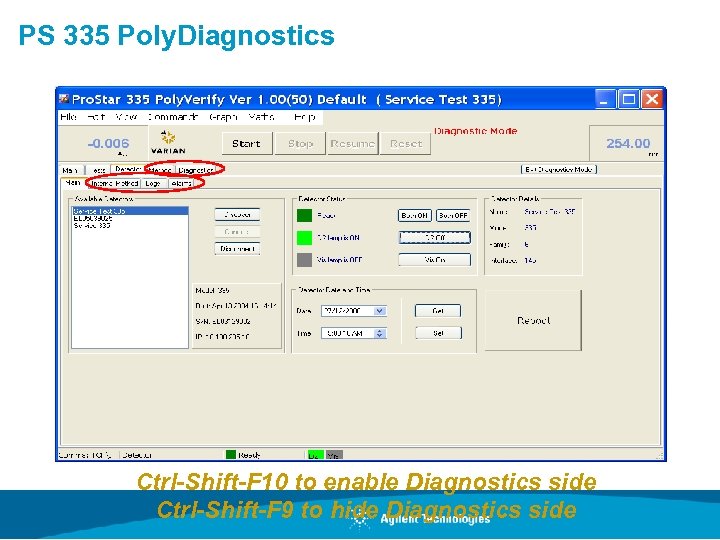

PS 335 Poly. Diagnostics Ctrl-Shift-F 10 to enable Diagnostics side Ctrl-Shift-F 9 to hide Diagnostics side

PS 335 Poly. Diagnostics Ctrl-Shift-F 10 to enable Diagnostics side Ctrl-Shift-F 9 to hide Diagnostics side

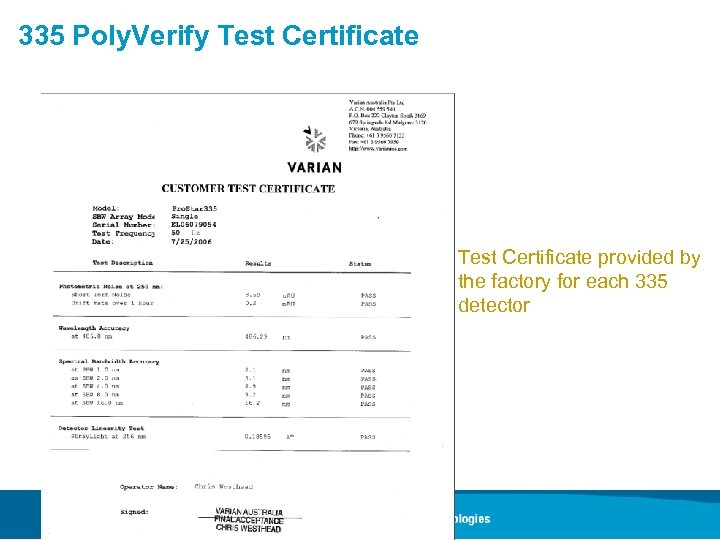

335 Poly. Verify Test Certificate provided by the factory for each 335 detector

335 Poly. Verify Test Certificate provided by the factory for each 335 detector

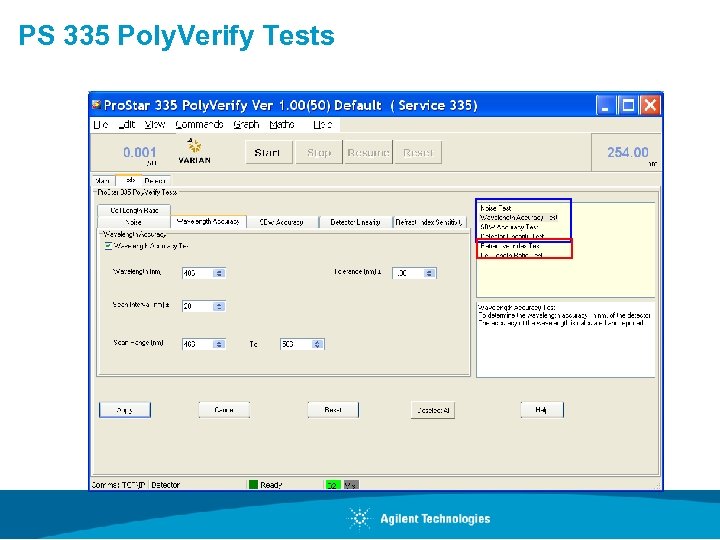

PS 335 Poly. Verify Tests

PS 335 Poly. Verify Tests

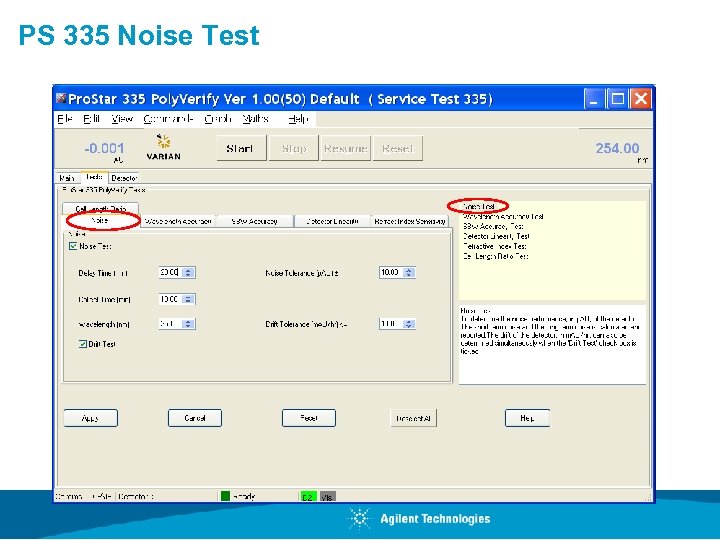

PS 335 Noise Test

PS 335 Noise Test

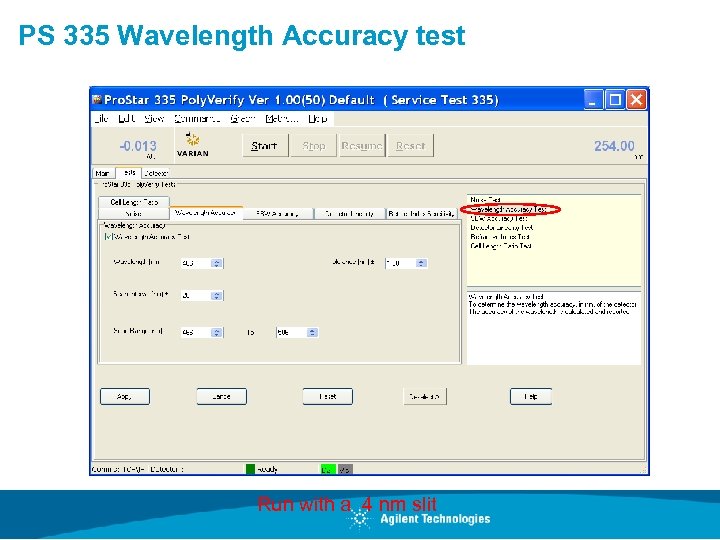

PS 335 Wavelength Accuracy test Run with a 4 nm slit

PS 335 Wavelength Accuracy test Run with a 4 nm slit

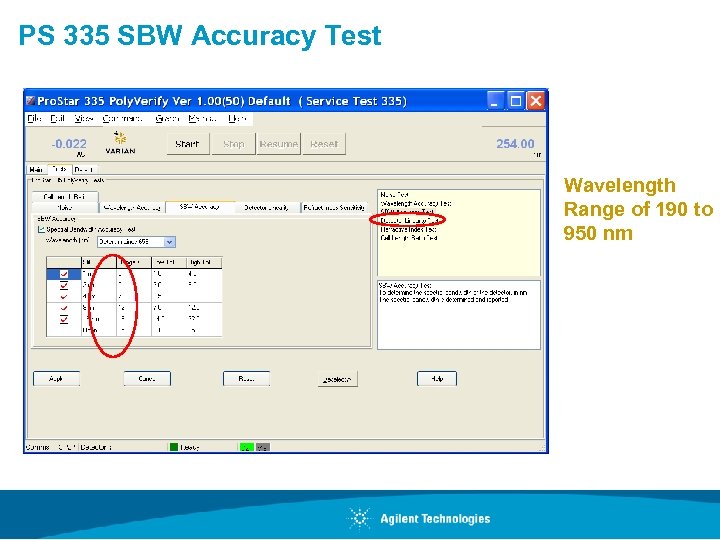

PS 335 SBW Accuracy Test Wavelength Range of 190 to 950 nm

PS 335 SBW Accuracy Test Wavelength Range of 190 to 950 nm

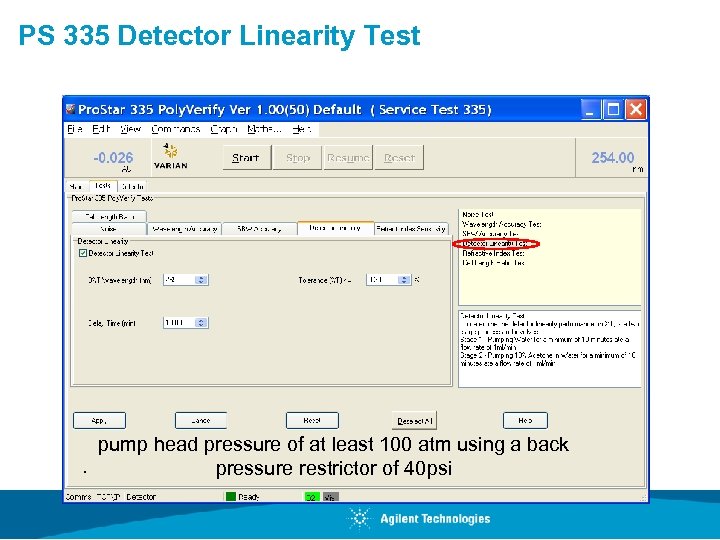

PS 335 Detector Linearity Test . pump head pressure of at least 100 atm using a back pressure restrictor of 40 psi

PS 335 Detector Linearity Test . pump head pressure of at least 100 atm using a back pressure restrictor of 40 psi

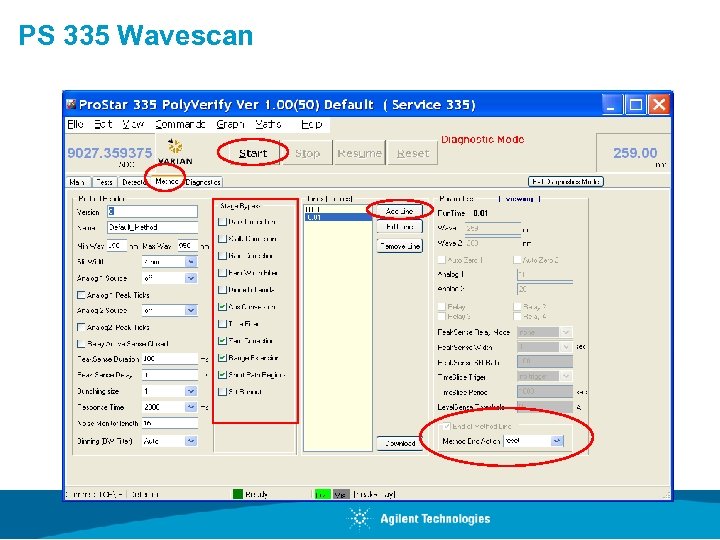

PS 335 Wavescan

PS 335 Wavescan

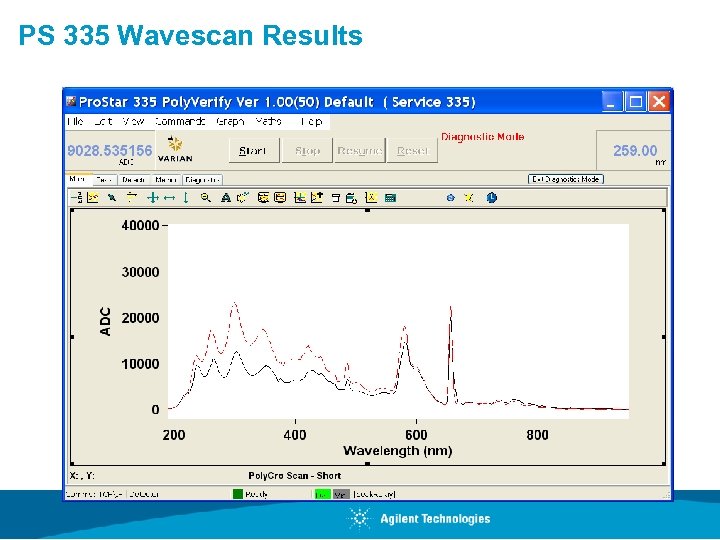

PS 335 Wavescan Results

PS 335 Wavescan Results

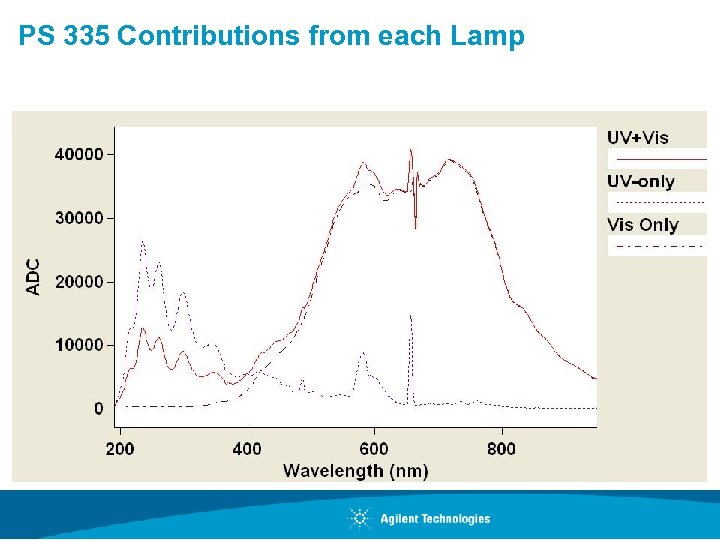

PS 335 Contributions from each Lamp

PS 335 Contributions from each Lamp

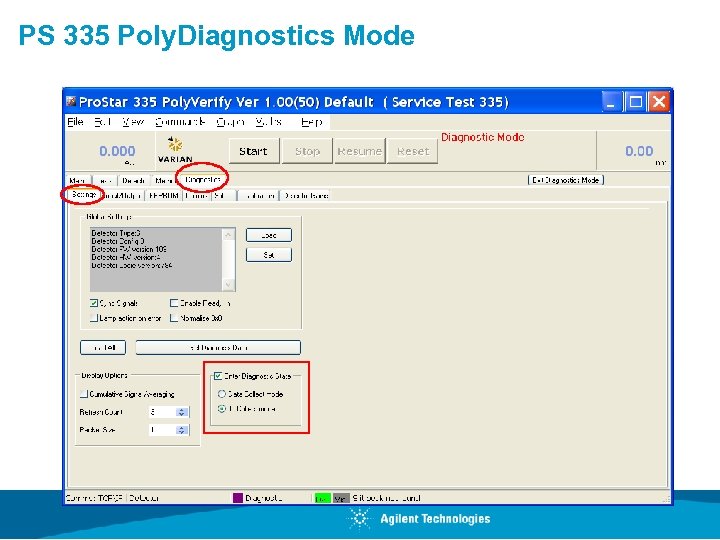

PS 335 Poly. Diagnostics Mode

PS 335 Poly. Diagnostics Mode

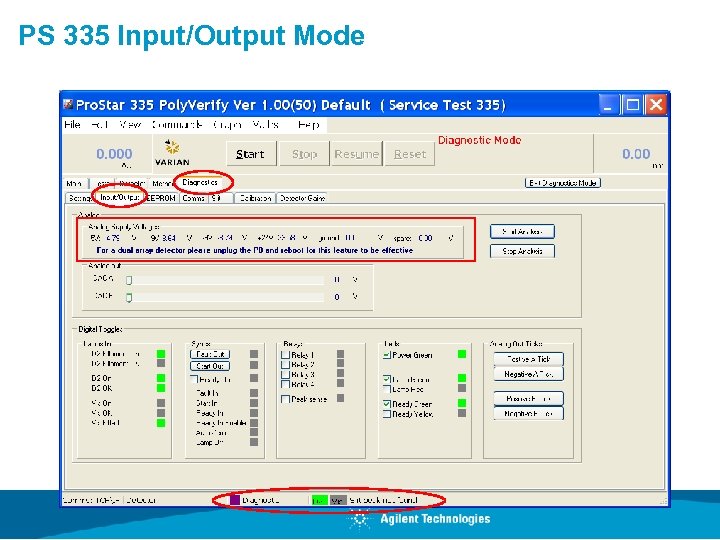

PS 335 Input/Output Mode

PS 335 Input/Output Mode

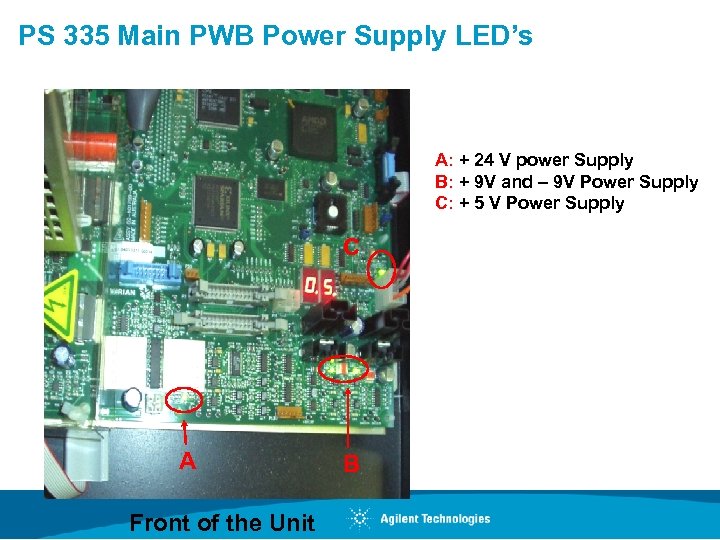

PS 335 Main PWB Power Supply LED’s A: + 24 V power Supply B: + 9 V and – 9 V Power Supply C: + 5 V Power Supply C A Front of the Unit B

PS 335 Main PWB Power Supply LED’s A: + 24 V power Supply B: + 9 V and – 9 V Power Supply C: + 5 V Power Supply C A Front of the Unit B

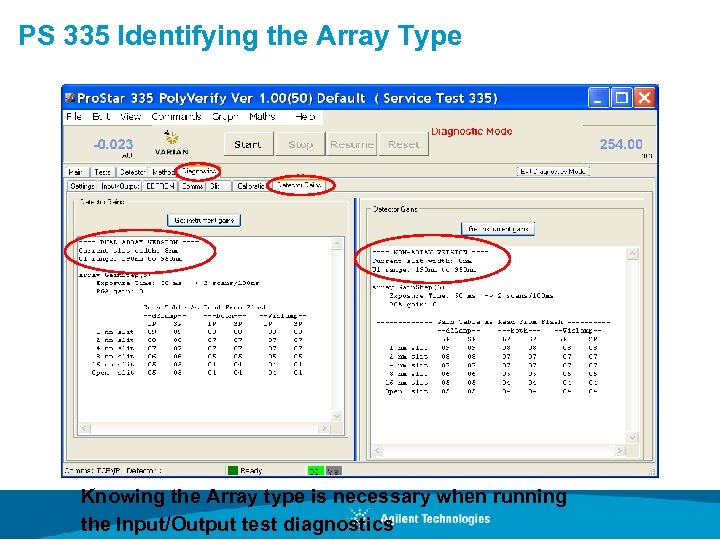

PS 335 Identifying the Array Type Knowing the Array type is necessary when running the Input/Output test diagnostics

PS 335 Identifying the Array Type Knowing the Array type is necessary when running the Input/Output test diagnostics

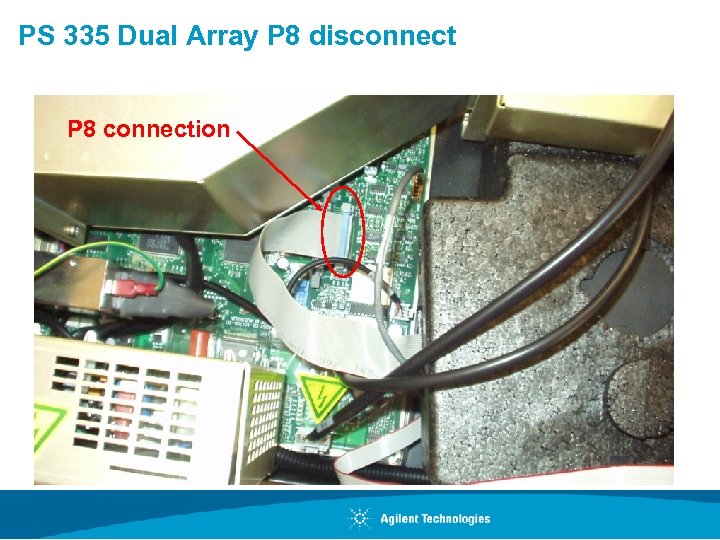

PS 335 Dual Array P 8 disconnect P 8 connection

PS 335 Dual Array P 8 disconnect P 8 connection

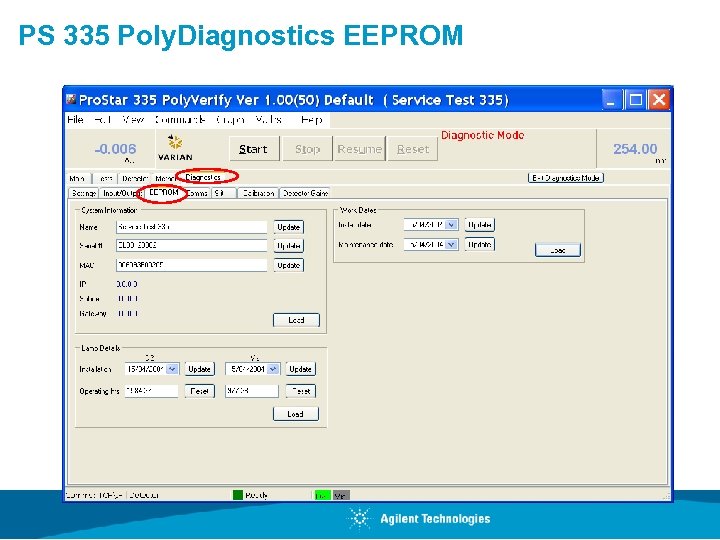

PS 335 Poly. Diagnostics EEPROM

PS 335 Poly. Diagnostics EEPROM

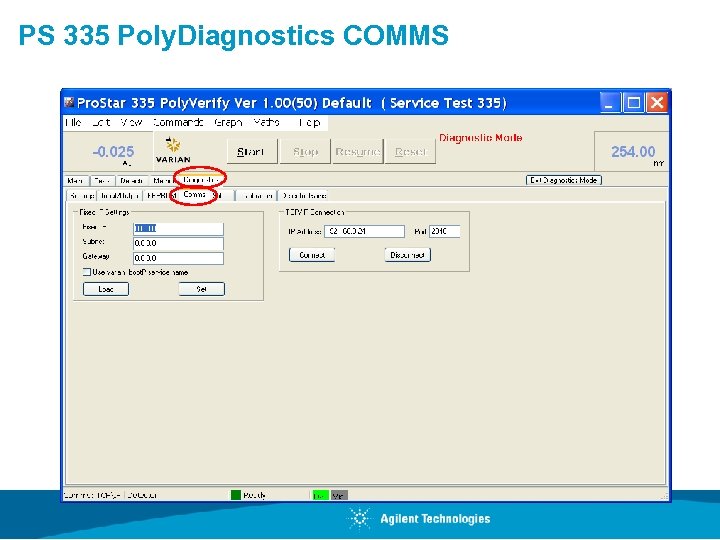

PS 335 Poly. Diagnostics COMMS

PS 335 Poly. Diagnostics COMMS

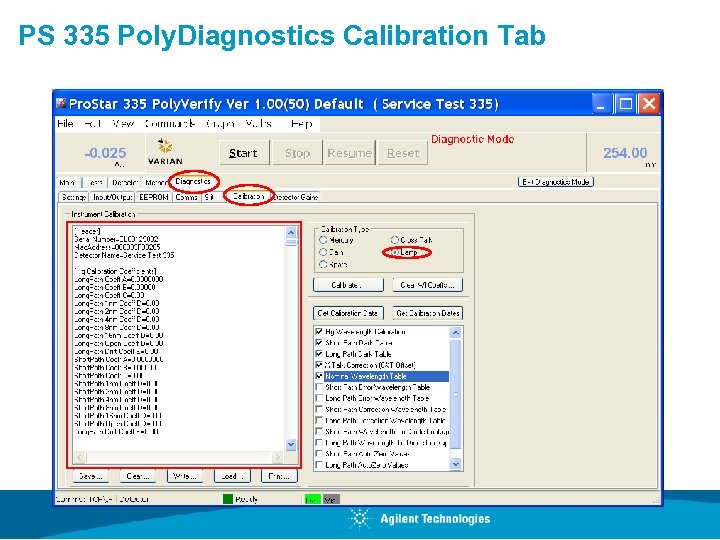

PS 335 Poly. Diagnostics Calibration Tab

PS 335 Poly. Diagnostics Calibration Tab

Caffeine Shipping Test PS 335 Caffeine Shipping Test: Test made up of 1 components: • Loop injection using 25 µg/ml caffeine Test is conducted using Galaxie Software

Caffeine Shipping Test PS 335 Caffeine Shipping Test: Test made up of 1 components: • Loop injection using 25 µg/ml caffeine Test is conducted using Galaxie Software

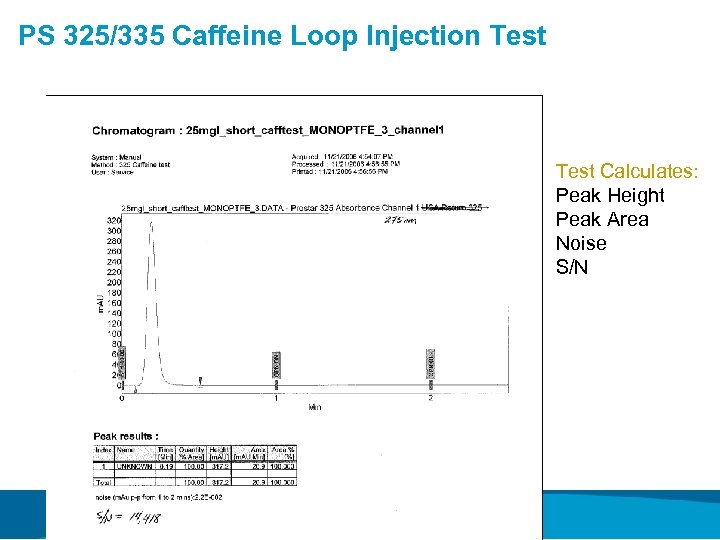

PS 325/335 Caffeine Loop Injection Test Calculates: Peak Height Peak Area Noise S/N

PS 325/335 Caffeine Loop Injection Test Calculates: Peak Height Peak Area Noise S/N

Common Problems • High Noise • Lamp on, not ready • SIG_CC_SLIT_PEAK_NOT_FOUND • SIG_CC_SIGNAL_OVERRANGE_REPREFORM_ LAMP_CAL • COM_CC_CIRCULAR_BUFFER_OVERRUN _OCCURED • 9555 LMP_CC_D 2_FILAMENT_FAILURE • Foggy Optics PS 335 Error Messages Table can be found: • PS 335 Service Manual

Common Problems • High Noise • Lamp on, not ready • SIG_CC_SLIT_PEAK_NOT_FOUND • SIG_CC_SIGNAL_OVERRANGE_REPREFORM_ LAMP_CAL • COM_CC_CIRCULAR_BUFFER_OVERRUN _OCCURED • 9555 LMP_CC_D 2_FILAMENT_FAILURE • Foggy Optics PS 335 Error Messages Table can be found: • PS 335 Service Manual

Foggy Optics What is Foggy Optics?

Foggy Optics What is Foggy Optics?

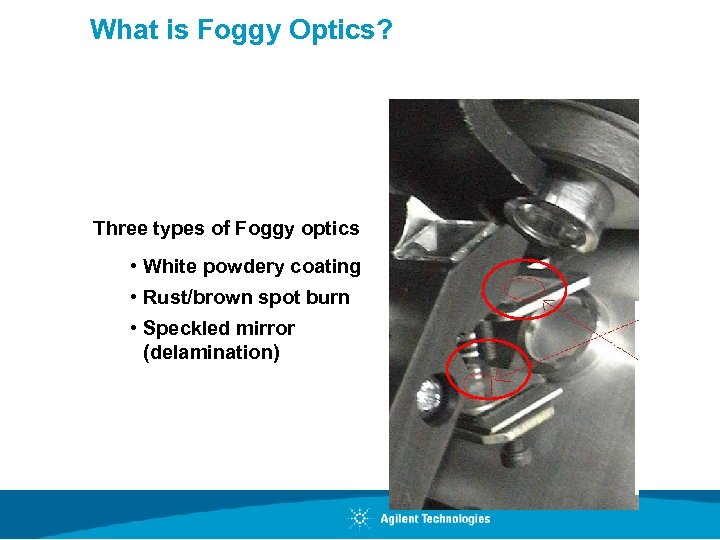

What is Foggy Optics? Three types of Foggy optics • White powdery coating • Rust/brown spot burn • Speckled mirror (delamination)

What is Foggy Optics? Three types of Foggy optics • White powdery coating • Rust/brown spot burn • Speckled mirror (delamination)

Foggy Optics What is Foggy Optics? Diagnosing Foggy Optics

Foggy Optics What is Foggy Optics? Diagnosing Foggy Optics

Diagnosing Foggy Optics Run a “wavescan” test, When bad Open the optics and inspect.

Diagnosing Foggy Optics Run a “wavescan” test, When bad Open the optics and inspect.

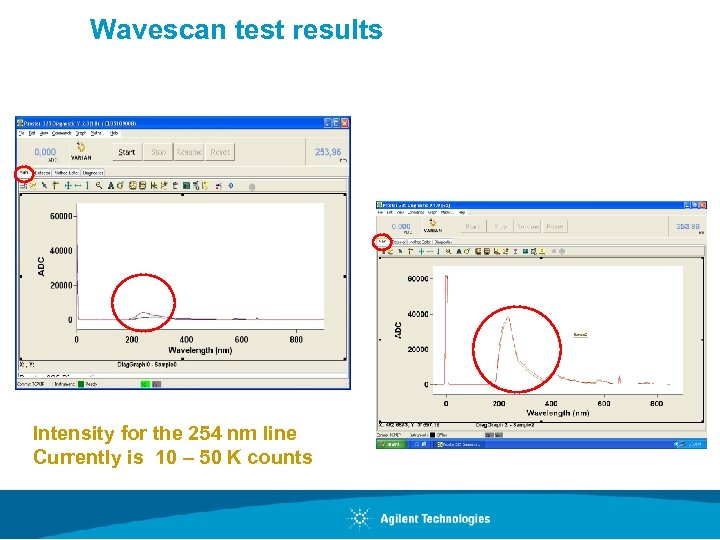

Wavescan test results Intensity for the 254 nm line Currently is 10 – 50 K counts

Wavescan test results Intensity for the 254 nm line Currently is 10 – 50 K counts

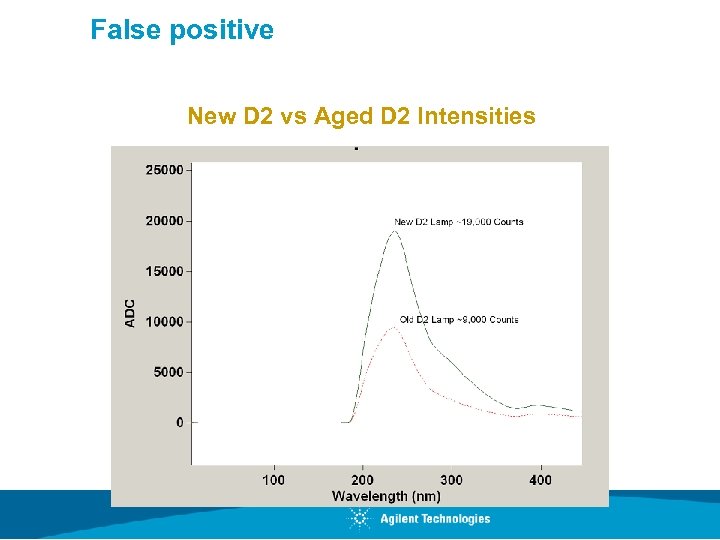

False positive New D 2 vs Aged D 2 Intensities

False positive New D 2 vs Aged D 2 Intensities

Foggy Optics What is Foggy Optics? Diagnosing Foggy Optics Treating Foggy optics

Foggy Optics What is Foggy Optics? Diagnosing Foggy Optics Treating Foggy optics

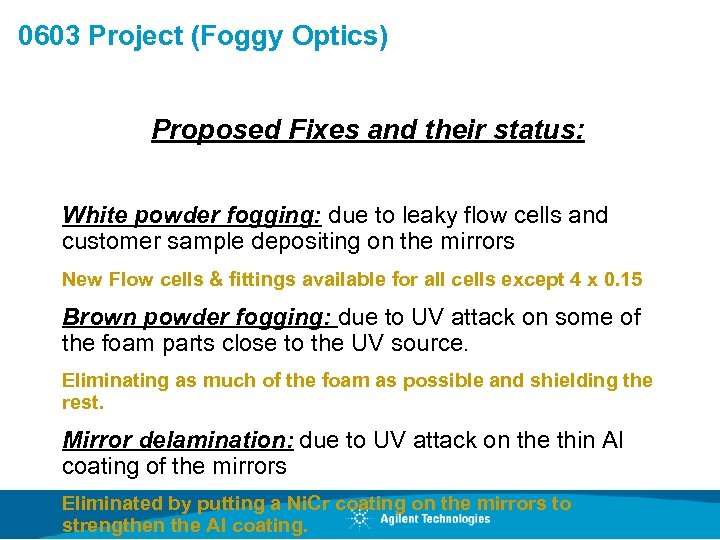

0603 Project (Foggy Optics) Proposed Fixes and their status: White powder fogging: due to leaky flow cells and customer sample depositing on the mirrors New Flow cells & fittings available for all cells except 4 x 0. 15 Brown powder fogging: due to UV attack on some of the foam parts close to the UV source. Eliminating as much of the foam as possible and shielding the rest. Mirror delamination: due to UV attack on the thin Al coating of the mirrors Eliminated by putting a Ni. Cr coating on the mirrors to strengthen the Al coating.

0603 Project (Foggy Optics) Proposed Fixes and their status: White powder fogging: due to leaky flow cells and customer sample depositing on the mirrors New Flow cells & fittings available for all cells except 4 x 0. 15 Brown powder fogging: due to UV attack on some of the foam parts close to the UV source. Eliminating as much of the foam as possible and shielding the rest. Mirror delamination: due to UV attack on the thin Al coating of the mirrors Eliminated by putting a Ni. Cr coating on the mirrors to strengthen the Al coating.

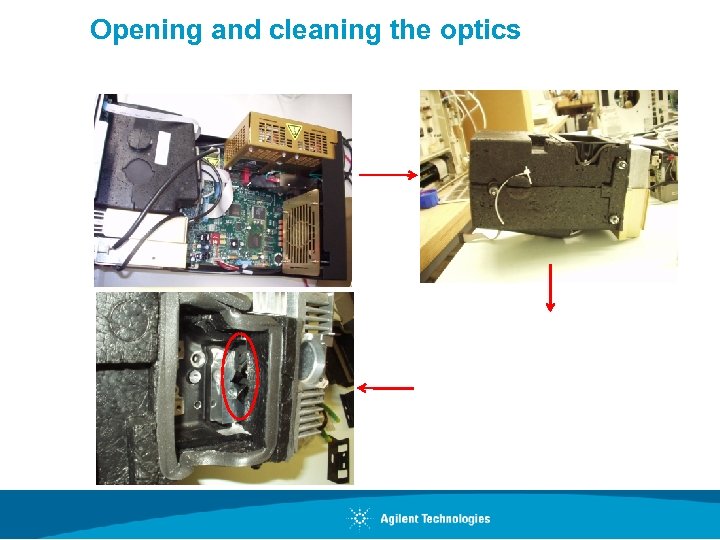

Opening and cleaning the optics

Opening and cleaning the optics

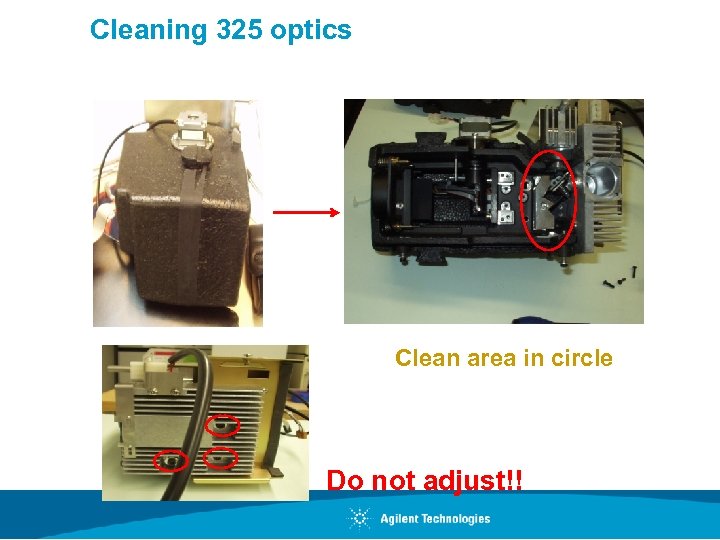

Cleaning 325 optics Clean area in circle Do not adjust!!

Cleaning 325 optics Clean area in circle Do not adjust!!

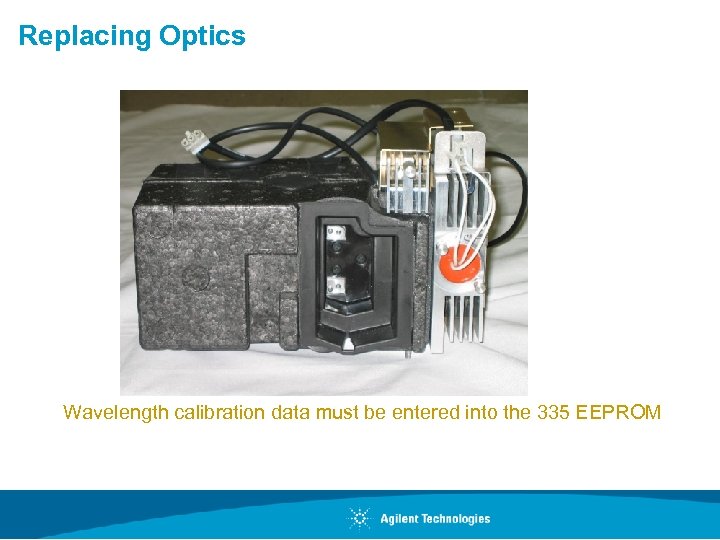

Replacing Optics Wavelength calibration data must be entered into the 335 EEPROM

Replacing Optics Wavelength calibration data must be entered into the 335 EEPROM

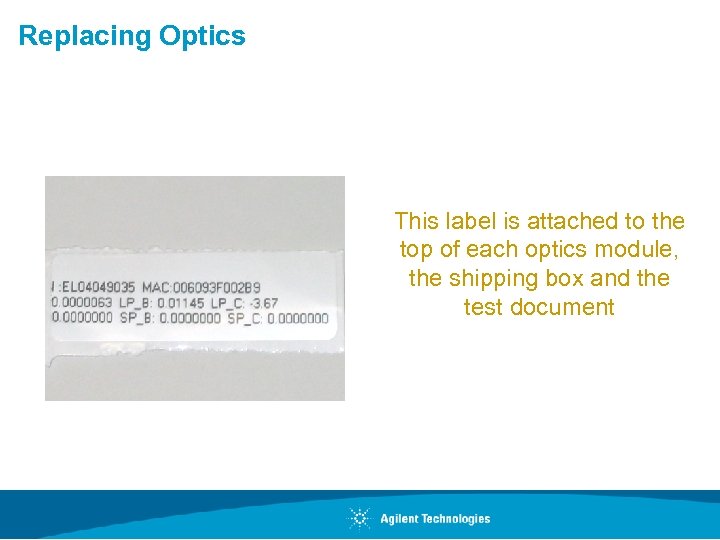

Replacing Optics This label is attached to the top of each optics module, the shipping box and the test document

Replacing Optics This label is attached to the top of each optics module, the shipping box and the test document

Summary • Single and Dual Array • Optical path is open • Flow cell is dual path • Diagnostics Tests, like wavescan • Shipping Test • Main Problems (Foggy Optics)

Summary • Single and Dual Array • Optical path is open • Flow cell is dual path • Diagnostics Tests, like wavescan • Shipping Test • Main Problems (Foggy Optics)