5a5ef2d3c61ec42364cb3d49d73ad5c7.ppt

- Количество слайдов: 32

PRO-2003 Natural Gas Processing Produced and Processed Adjunct Professor Jon Steinar Gudmundsson Department of Engineering and Safety University of Tromsø February 2014 Pictures from www. naturalgas. org

PRO-2003 Natural Gas Processing Produced and Processed Adjunct Professor Jon Steinar Gudmundsson Department of Engineering and Safety University of Tromsø February 2014 Pictures from www. naturalgas. org

Outline • • Types of natural gas Phase diagrams (envelopes) Classification and terminology Composition and specifications Production and separation Processing and products Summary

Outline • • Types of natural gas Phase diagrams (envelopes) Classification and terminology Composition and specifications Production and separation Processing and products Summary

Formation of Natural Gas • Natural gas originates from two different natural processes known as thermogenic (great depths) and biogenic processes (shallow depths). • Thermogenic gas is formed over millions of years from decaying organic matter in reservoirs deep within the earth and under the sea. • There are three principal supplies of natural gas produced and processed from thermogenic gas wells: – Gas that is dissolved in crude oil (associated gas). – Gas that is extracted from the top of the crude reservoir (associated gas). – Gas that has been extracted from gas or condensate reservoirs that contain only trace elements of crude are known as non-associated gas. • Biogenic gas on the other hand is formed by methagenic (bacterial) organisms breaking down under anaerobic conditions being found in coal seams, landfill sites, and marshes.

Formation of Natural Gas • Natural gas originates from two different natural processes known as thermogenic (great depths) and biogenic processes (shallow depths). • Thermogenic gas is formed over millions of years from decaying organic matter in reservoirs deep within the earth and under the sea. • There are three principal supplies of natural gas produced and processed from thermogenic gas wells: – Gas that is dissolved in crude oil (associated gas). – Gas that is extracted from the top of the crude reservoir (associated gas). – Gas that has been extracted from gas or condensate reservoirs that contain only trace elements of crude are known as non-associated gas. • Biogenic gas on the other hand is formed by methagenic (bacterial) organisms breaking down under anaerobic conditions being found in coal seams, landfill sites, and marshes.

Gas for Heat, Electricity, Chemicals and Fuels • • • Non-associated gas (from gas reservoirs) Associated gas (from oil reservoirs) Unconventional gas – – • • Tight gas (sandstone, needs fracturing) Shale gas (shale, needs fracturing) Coal bed methane (biogenic, adsorbed on coal) Hydrate (permafrost and offshore, overstated potential? ) Town gas (from coal, H 2, CH 4, CO 2 & CO, historical) Biogas (modern)

Gas for Heat, Electricity, Chemicals and Fuels • • • Non-associated gas (from gas reservoirs) Associated gas (from oil reservoirs) Unconventional gas – – • • Tight gas (sandstone, needs fracturing) Shale gas (shale, needs fracturing) Coal bed methane (biogenic, adsorbed on coal) Hydrate (permafrost and offshore, overstated potential? ) Town gas (from coal, H 2, CH 4, CO 2 & CO, historical) Biogas (modern)

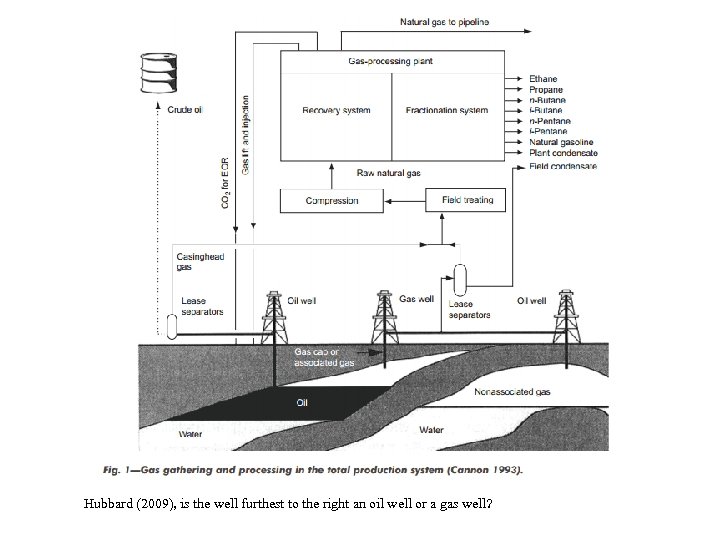

Hubbard (2009), is the well furthest to the right an oil well or a gas well?

Hubbard (2009), is the well furthest to the right an oil well or a gas well?

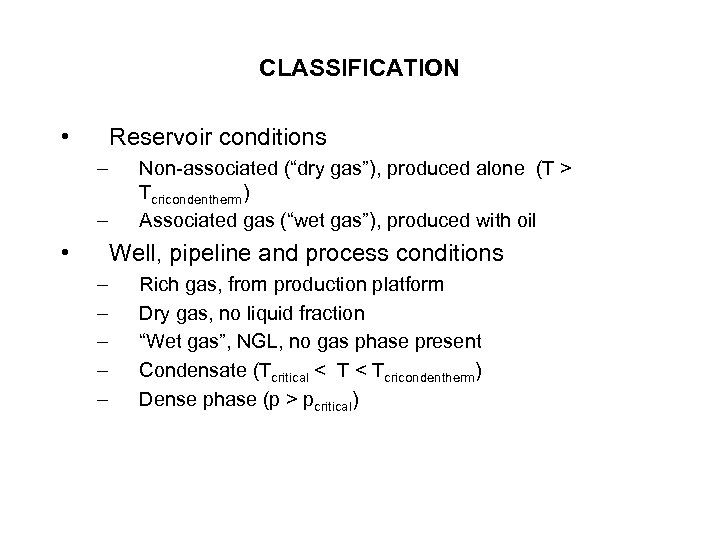

CLASSIFICATION • Reservoir conditions – – • Non-associated (“dry gas”), produced alone (T > Tcricondentherm) Associated gas (“wet gas”), produced with oil Well, pipeline and process conditions – – – Rich gas, from production platform Dry gas, no liquid fraction “Wet gas”, NGL, no gas phase present Condensate (Tcritical < Tcricondentherm) Dense phase (p > pcritical)

CLASSIFICATION • Reservoir conditions – – • Non-associated (“dry gas”), produced alone (T > Tcricondentherm) Associated gas (“wet gas”), produced with oil Well, pipeline and process conditions – – – Rich gas, from production platform Dry gas, no liquid fraction “Wet gas”, NGL, no gas phase present Condensate (Tcritical < Tcricondentherm) Dense phase (p > pcritical)

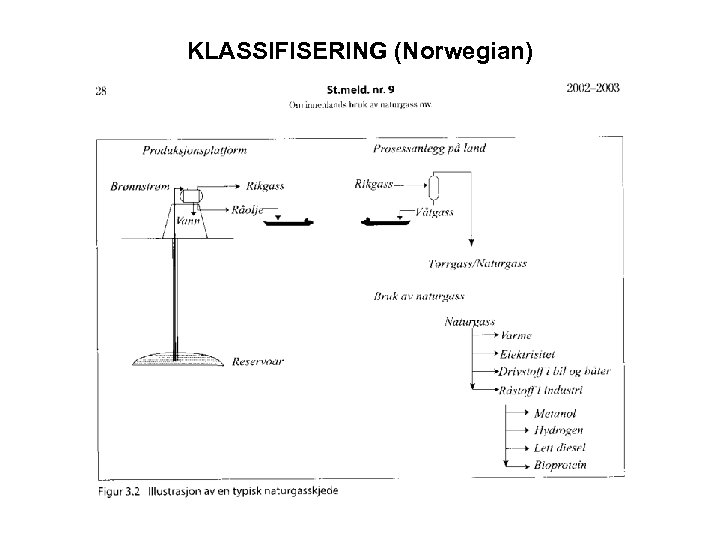

KLASSIFISERING (Norwegian)

KLASSIFISERING (Norwegian)

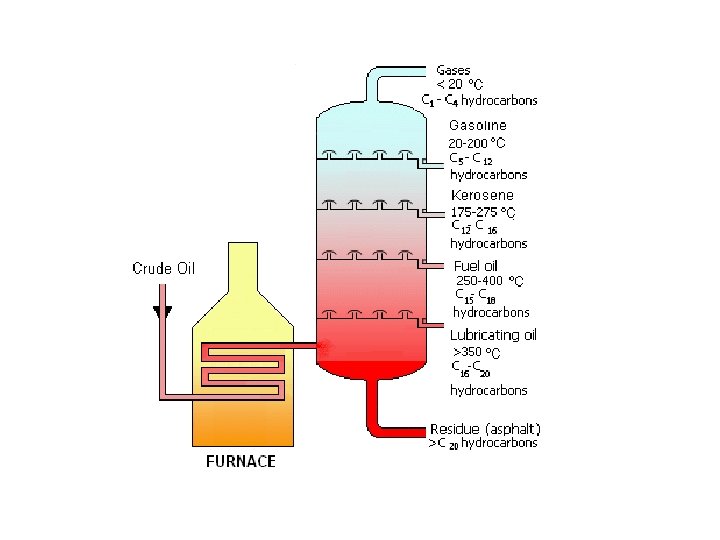

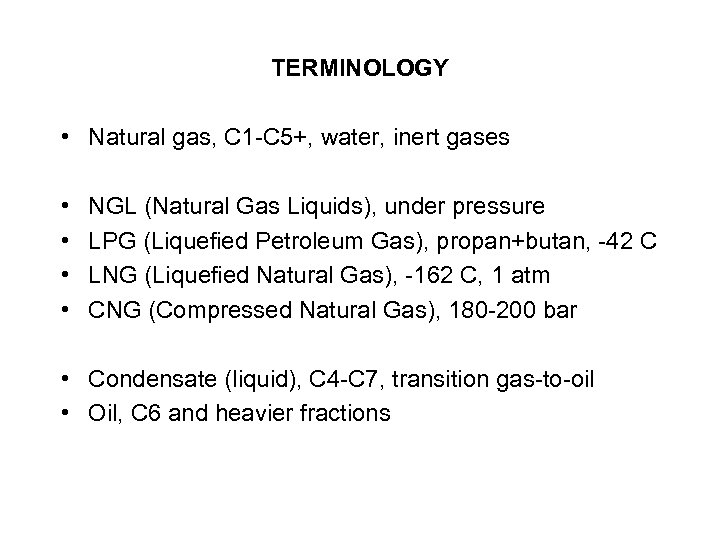

TERMINOLOGY • Natural gas, C 1 -C 5+, water, inert gases • • NGL (Natural Gas Liquids), under pressure LPG (Liquefied Petroleum Gas), propan+butan, -42 C LNG (Liquefied Natural Gas), -162 C, 1 atm CNG (Compressed Natural Gas), 180 -200 bar • Condensate (liquid), C 4 -C 7, transition gas-to-oil • Oil, C 6 and heavier fractions

TERMINOLOGY • Natural gas, C 1 -C 5+, water, inert gases • • NGL (Natural Gas Liquids), under pressure LPG (Liquefied Petroleum Gas), propan+butan, -42 C LNG (Liquefied Natural Gas), -162 C, 1 atm CNG (Compressed Natural Gas), 180 -200 bar • Condensate (liquid), C 4 -C 7, transition gas-to-oil • Oil, C 6 and heavier fractions

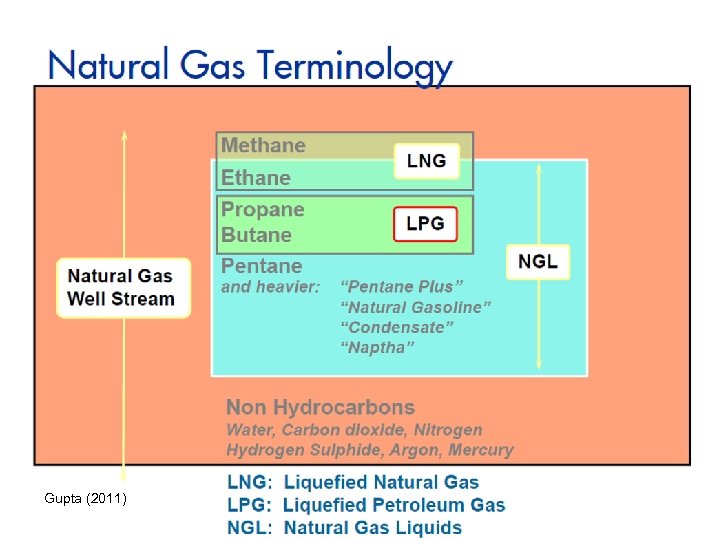

Gupta (2011)

Gupta (2011)

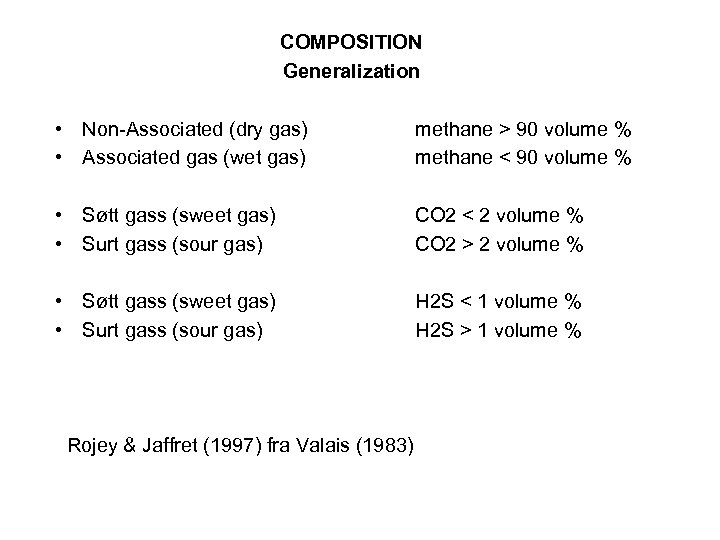

COMPOSITION Generalization • Non-Associated (dry gas) • Associated gas (wet gas) methane > 90 volume % methane < 90 volume % • Søtt gass (sweet gas) • Surt gass (sour gas) CO 2 < 2 volume % CO 2 > 2 volume % • Søtt gass (sweet gas) • Surt gass (sour gas) H 2 S < 1 volume % H 2 S > 1 volume % Rojey & Jaffret (1997) fra Valais (1983)

COMPOSITION Generalization • Non-Associated (dry gas) • Associated gas (wet gas) methane > 90 volume % methane < 90 volume % • Søtt gass (sweet gas) • Surt gass (sour gas) CO 2 < 2 volume % CO 2 > 2 volume % • Søtt gass (sweet gas) • Surt gass (sour gas) H 2 S < 1 volume % H 2 S > 1 volume % Rojey & Jaffret (1997) fra Valais (1983)

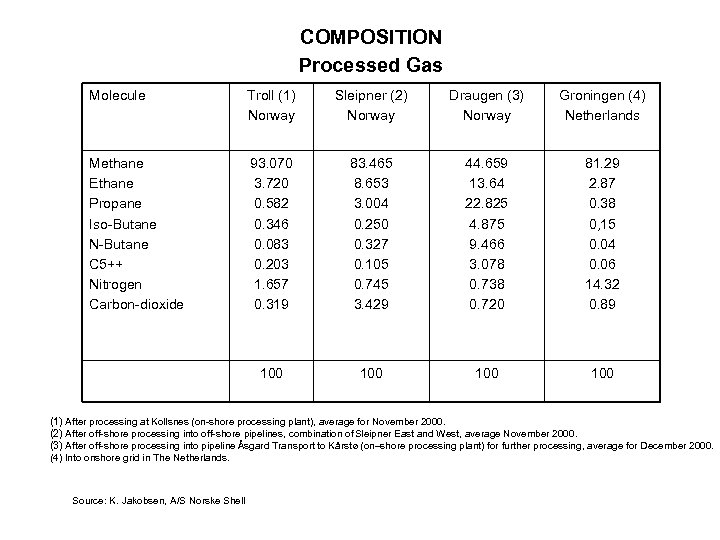

COMPOSITION Processed Gas Molecule Troll (1) Norway Sleipner (2) Norway Draugen (3) Norway Groningen (4) Netherlands Methane Ethane Propane Iso-Butane N-Butane C 5++ Nitrogen Carbon-dioxide 93. 070 3. 720 0. 582 0. 346 0. 083 0. 203 1. 657 0. 319 83. 465 8. 653 3. 004 0. 250 0. 327 0. 105 0. 745 3. 429 44. 659 13. 64 22. 825 4. 875 9. 466 3. 078 0. 738 0. 720 81. 29 2. 87 0. 38 0, 15 0. 04 0. 06 14. 32 0. 89 100 100 (1) After processing at Kollsnes (on-shore processing plant), average for November 2000. (2) After off-shore processing into off-shore pipelines, combination of Sleipner East and West, average November 2000. (3) After off-shore processing into pipeline Åsgard Transport to Kårstø (on–shore processing plant) for further processing, average for December 2000. (4) Into onshore grid in The Netherlands. Source: K. Jakobsen, A/S Norske Shell

COMPOSITION Processed Gas Molecule Troll (1) Norway Sleipner (2) Norway Draugen (3) Norway Groningen (4) Netherlands Methane Ethane Propane Iso-Butane N-Butane C 5++ Nitrogen Carbon-dioxide 93. 070 3. 720 0. 582 0. 346 0. 083 0. 203 1. 657 0. 319 83. 465 8. 653 3. 004 0. 250 0. 327 0. 105 0. 745 3. 429 44. 659 13. 64 22. 825 4. 875 9. 466 3. 078 0. 738 0. 720 81. 29 2. 87 0. 38 0, 15 0. 04 0. 06 14. 32 0. 89 100 100 (1) After processing at Kollsnes (on-shore processing plant), average for November 2000. (2) After off-shore processing into off-shore pipelines, combination of Sleipner East and West, average November 2000. (3) After off-shore processing into pipeline Åsgard Transport to Kårstø (on–shore processing plant) for further processing, average for December 2000. (4) Into onshore grid in The Netherlands. Source: K. Jakobsen, A/S Norske Shell

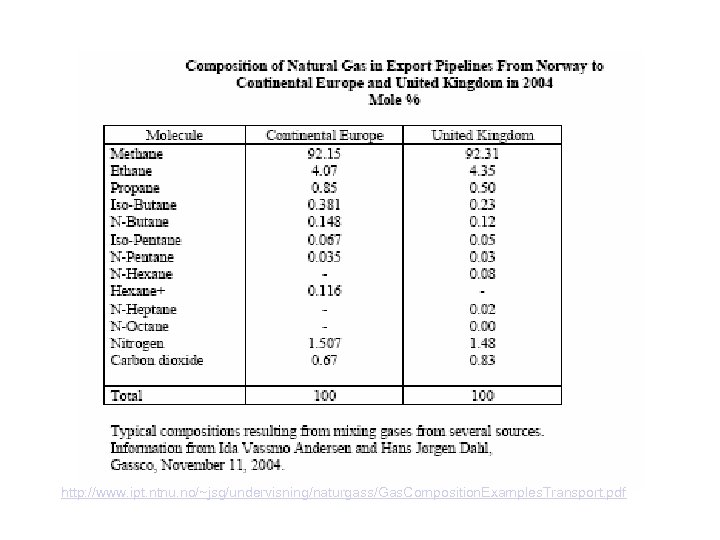

http: //www. ipt. ntnu. no/~jsg/undervisning/naturgass/Gas. Composition. Examples. Transport. pdf

http: //www. ipt. ntnu. no/~jsg/undervisning/naturgass/Gas. Composition. Examples. Transport. pdf

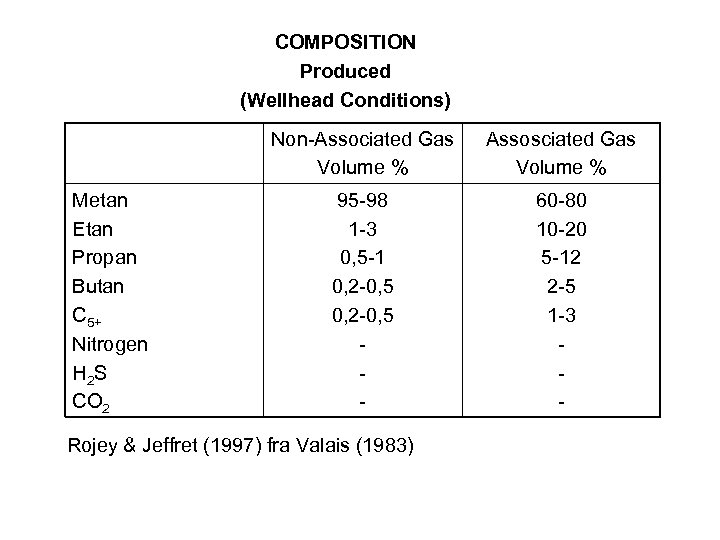

COMPOSITION Produced (Wellhead Conditions) Non-Associated Gas Volume % Metan Etan Propan Butan C 5+ Nitrogen H 2 S CO 2 Assosciated Gas Volume % 95 -98 1 -3 0, 5 -1 0, 2 -0, 5 - 60 -80 10 -20 5 -12 2 -5 1 -3 - Rojey & Jeffret (1997) fra Valais (1983)

COMPOSITION Produced (Wellhead Conditions) Non-Associated Gas Volume % Metan Etan Propan Butan C 5+ Nitrogen H 2 S CO 2 Assosciated Gas Volume % 95 -98 1 -3 0, 5 -1 0, 2 -0, 5 - 60 -80 10 -20 5 -12 2 -5 1 -3 - Rojey & Jeffret (1997) fra Valais (1983)

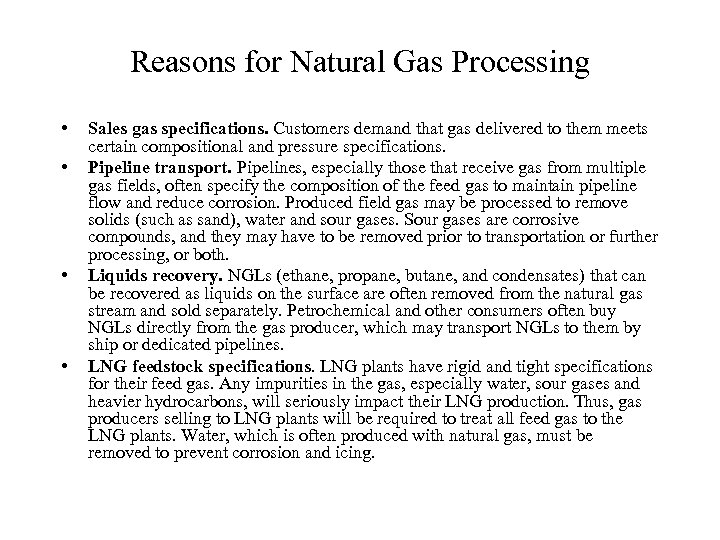

Reasons for Natural Gas Processing • • Sales gas specifications. Customers demand that gas delivered to them meets certain compositional and pressure specifications. Pipeline transport. Pipelines, especially those that receive gas from multiple gas fields, often specify the composition of the feed gas to maintain pipeline flow and reduce corrosion. Produced field gas may be processed to remove solids (such as sand), water and sour gases. Sour gases are corrosive compounds, and they may have to be removed prior to transportation or further processing, or both. Liquids recovery. NGLs (ethane, propane, butane, and condensates) that can be recovered as liquids on the surface are often removed from the natural gas stream and sold separately. Petrochemical and other consumers often buy NGLs directly from the gas producer, which may transport NGLs to them by ship or dedicated pipelines. LNG feedstock specifications. LNG plants have rigid and tight specifications for their feed gas. Any impurities in the gas, especially water, sour gases and heavier hydrocarbons, will seriously impact their LNG production. Thus, gas producers selling to LNG plants will be required to treat all feed gas to the LNG plants. Water, which is often produced with natural gas, must be removed to prevent corrosion and icing.

Reasons for Natural Gas Processing • • Sales gas specifications. Customers demand that gas delivered to them meets certain compositional and pressure specifications. Pipeline transport. Pipelines, especially those that receive gas from multiple gas fields, often specify the composition of the feed gas to maintain pipeline flow and reduce corrosion. Produced field gas may be processed to remove solids (such as sand), water and sour gases. Sour gases are corrosive compounds, and they may have to be removed prior to transportation or further processing, or both. Liquids recovery. NGLs (ethane, propane, butane, and condensates) that can be recovered as liquids on the surface are often removed from the natural gas stream and sold separately. Petrochemical and other consumers often buy NGLs directly from the gas producer, which may transport NGLs to them by ship or dedicated pipelines. LNG feedstock specifications. LNG plants have rigid and tight specifications for their feed gas. Any impurities in the gas, especially water, sour gases and heavier hydrocarbons, will seriously impact their LNG production. Thus, gas producers selling to LNG plants will be required to treat all feed gas to the LNG plants. Water, which is often produced with natural gas, must be removed to prevent corrosion and icing.

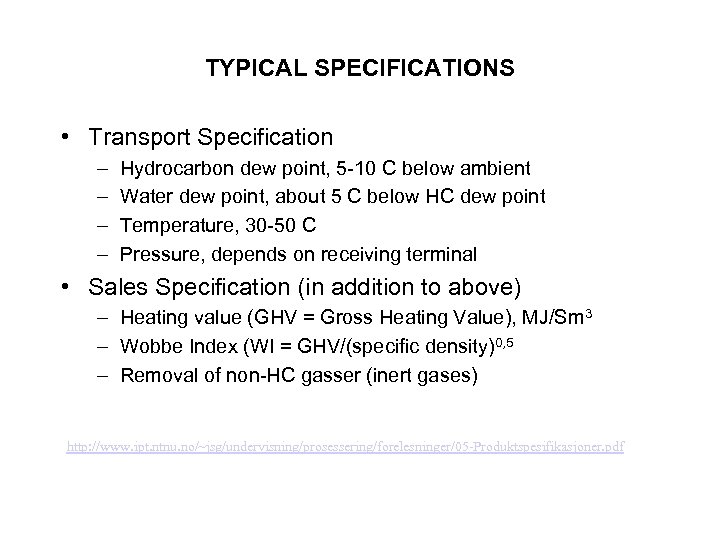

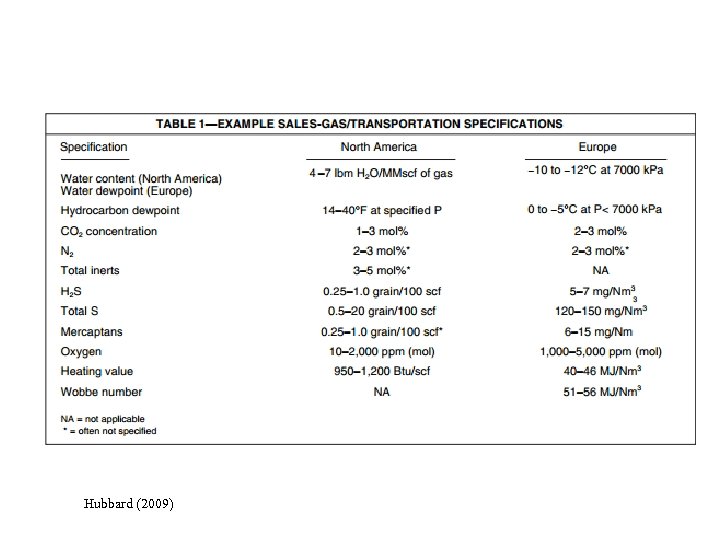

TYPICAL SPECIFICATIONS • Transport Specification – – Hydrocarbon dew point, 5 -10 C below ambient Water dew point, about 5 C below HC dew point Temperature, 30 -50 C Pressure, depends on receiving terminal • Sales Specification (in addition to above) – Heating value (GHV = Gross Heating Value), MJ/Sm 3 – Wobbe Index (WI = GHV/(specific density)0, 5 – Removal of non-HC gasser (inert gases) http: //www. ipt. ntnu. no/~jsg/undervisning/prosessering/forelesninger/05 -Produktspesifikasjoner. pdf

TYPICAL SPECIFICATIONS • Transport Specification – – Hydrocarbon dew point, 5 -10 C below ambient Water dew point, about 5 C below HC dew point Temperature, 30 -50 C Pressure, depends on receiving terminal • Sales Specification (in addition to above) – Heating value (GHV = Gross Heating Value), MJ/Sm 3 – Wobbe Index (WI = GHV/(specific density)0, 5 – Removal of non-HC gasser (inert gases) http: //www. ipt. ntnu. no/~jsg/undervisning/prosessering/forelesninger/05 -Produktspesifikasjoner. pdf

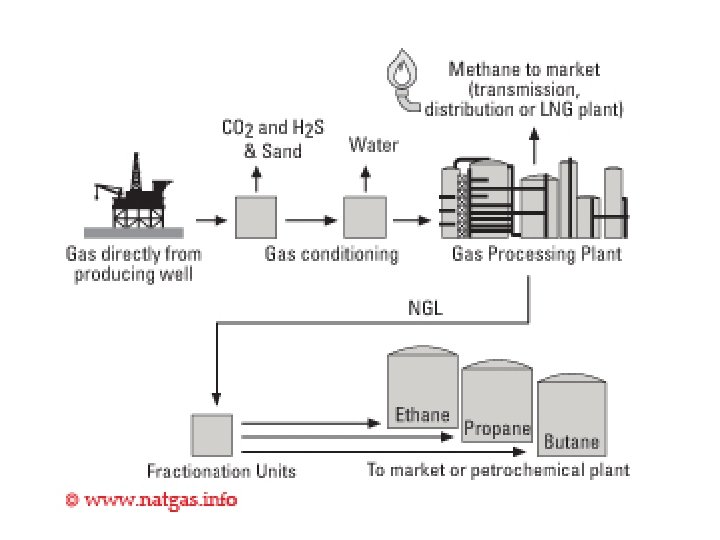

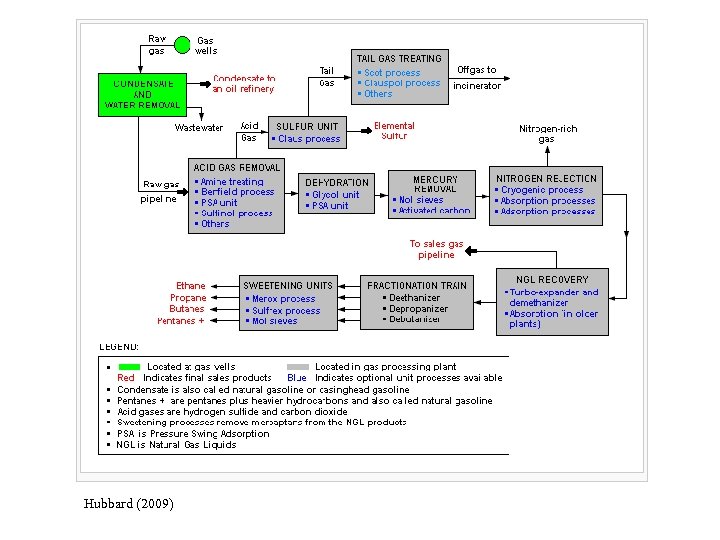

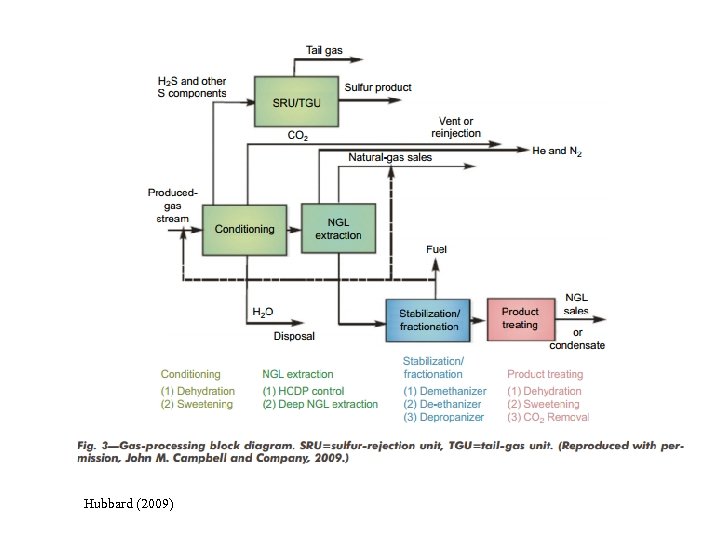

Hubbard (2009)

Hubbard (2009)

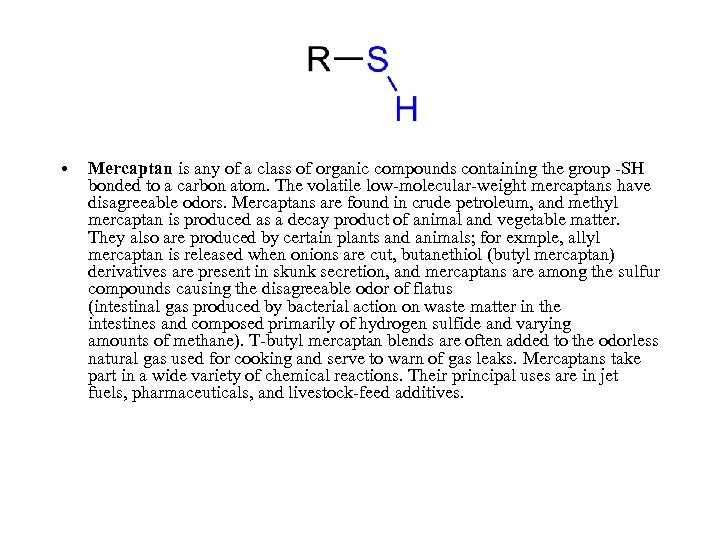

• Mercaptan is any of a class of organic compounds containing the group -SH bonded to a carbon atom. The volatile low-molecular-weight mercaptans have disagreeable odors. Mercaptans are found in crude petroleum, and methyl mercaptan is produced as a decay product of animal and vegetable matter. They also are produced by certain plants and animals; for exmple, allyl mercaptan is released when onions are cut, butanethiol (butyl mercaptan) derivatives are present in skunk secretion, and mercaptans are among the sulfur compounds causing the disagreeable odor of flatus (intestinal gas produced by bacterial action on waste matter in the intestines and composed primarily of hydrogen sulfide and varying amounts of methane). T-butyl mercaptan blends are often added to the odorless natural gas used for cooking and serve to warn of gas leaks. Mercaptans take part in a wide variety of chemical reactions. Their principal uses are in jet fuels, pharmaceuticals, and livestock-feed additives.

• Mercaptan is any of a class of organic compounds containing the group -SH bonded to a carbon atom. The volatile low-molecular-weight mercaptans have disagreeable odors. Mercaptans are found in crude petroleum, and methyl mercaptan is produced as a decay product of animal and vegetable matter. They also are produced by certain plants and animals; for exmple, allyl mercaptan is released when onions are cut, butanethiol (butyl mercaptan) derivatives are present in skunk secretion, and mercaptans are among the sulfur compounds causing the disagreeable odor of flatus (intestinal gas produced by bacterial action on waste matter in the intestines and composed primarily of hydrogen sulfide and varying amounts of methane). T-butyl mercaptan blends are often added to the odorless natural gas used for cooking and serve to warn of gas leaks. Mercaptans take part in a wide variety of chemical reactions. Their principal uses are in jet fuels, pharmaceuticals, and livestock-feed additives.

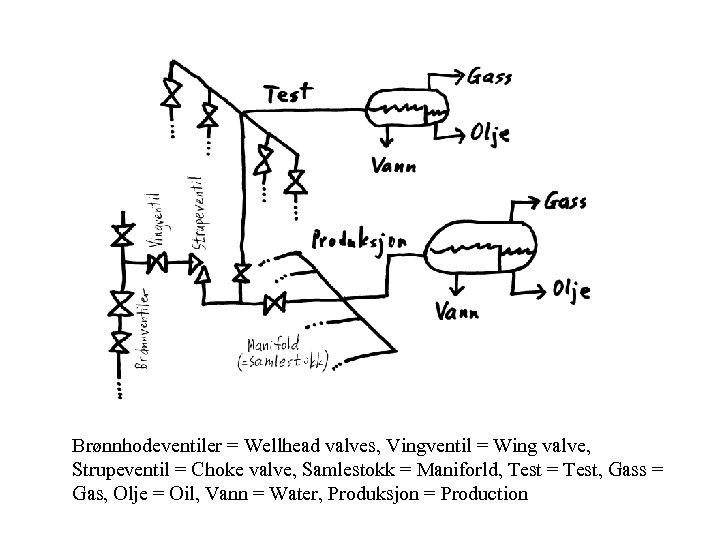

Brønnhodeventiler = Wellhead valves, Vingventil = Wing valve, Strupeventil = Choke valve, Samlestokk = Maniforld, Test = Test, Gass = Gas, Olje = Oil, Vann = Water, Produksjon = Production

Brønnhodeventiler = Wellhead valves, Vingventil = Wing valve, Strupeventil = Choke valve, Samlestokk = Maniforld, Test = Test, Gass = Gas, Olje = Oil, Vann = Water, Produksjon = Production

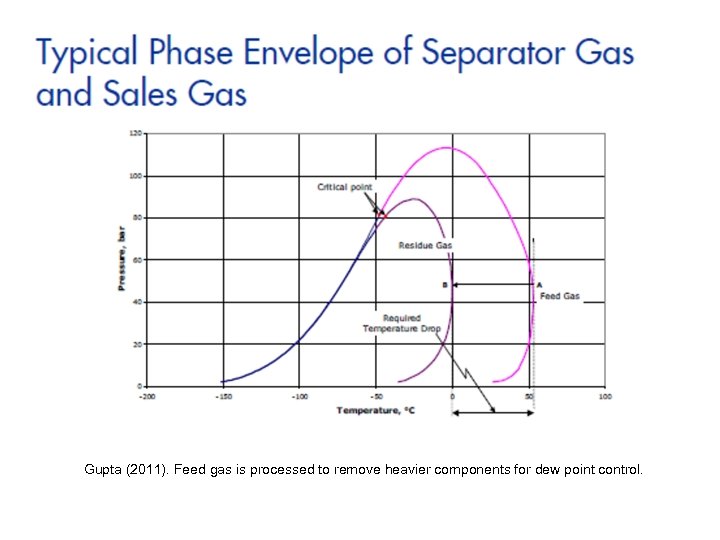

Gupta (2011). Feed gas is processed to remove heavier components for dew point control.

Gupta (2011). Feed gas is processed to remove heavier components for dew point control.

Hubbard (2009)

Hubbard (2009)

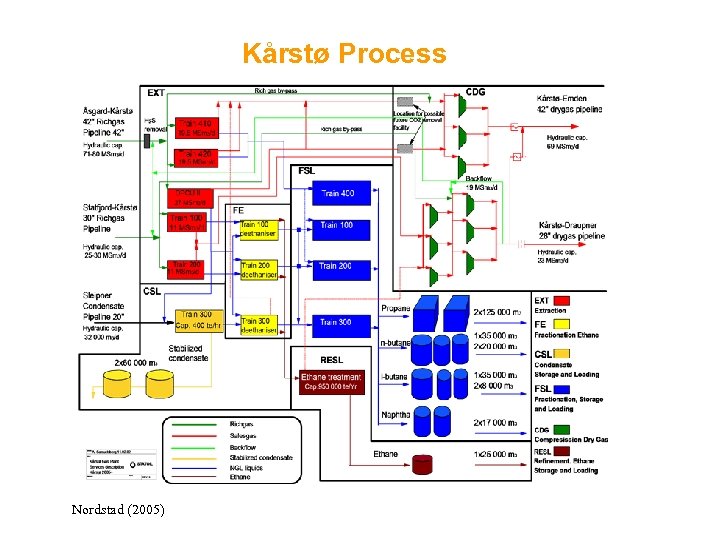

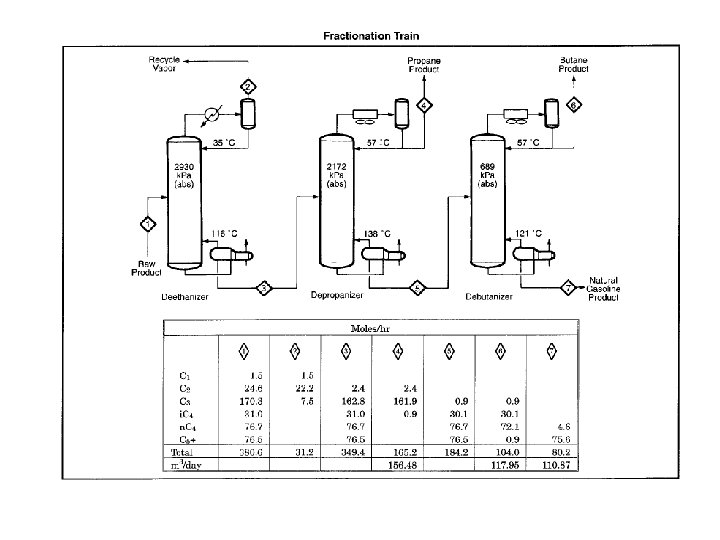

Kårstø Process Nordstad (2005)

Kårstø Process Nordstad (2005)

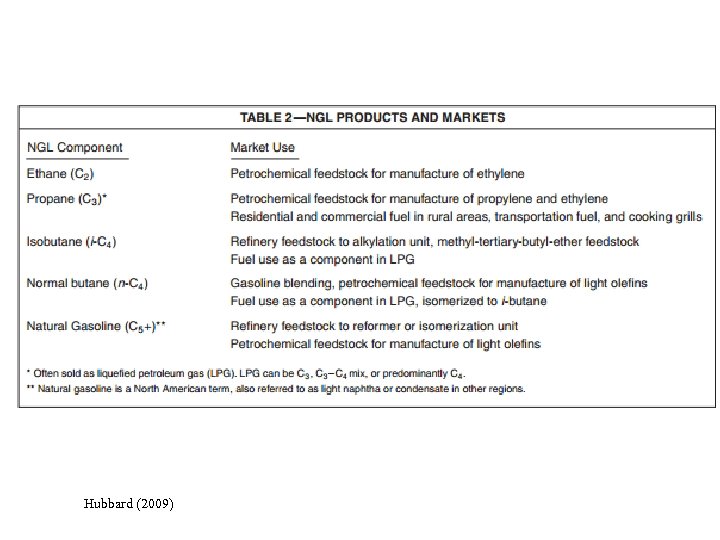

Hubbard (2009)

Hubbard (2009)

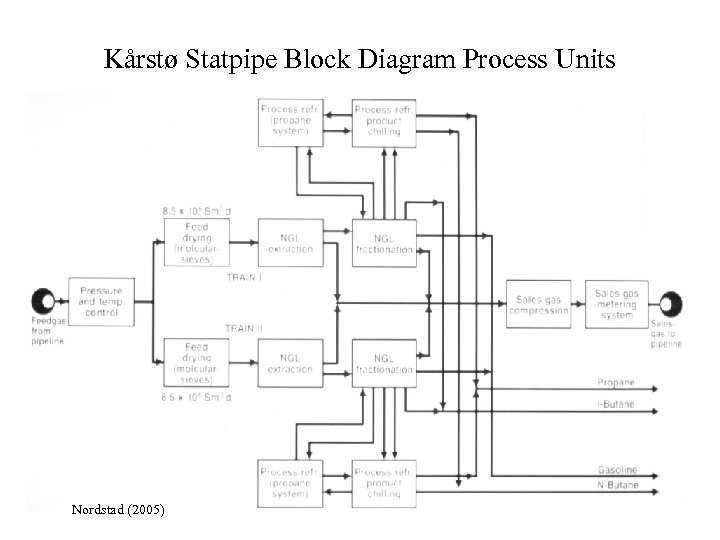

Kårstø Statpipe Block Diagram Process Units Nordstad (2005)

Kårstø Statpipe Block Diagram Process Units Nordstad (2005)

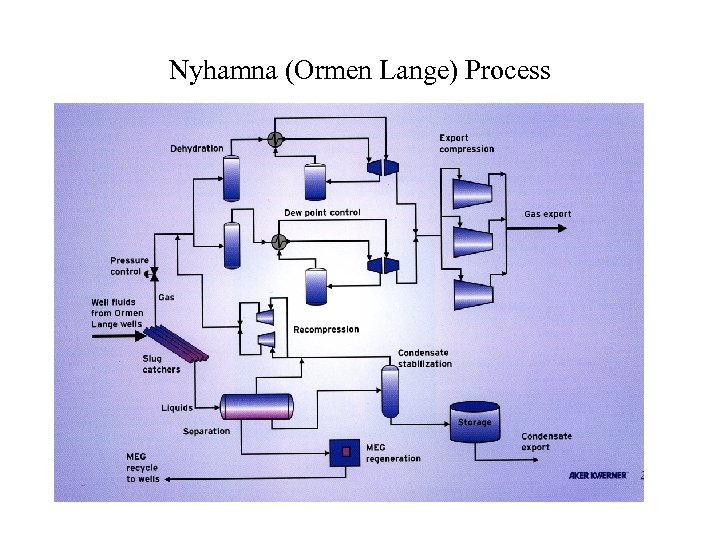

Nyhamna (Ormen Lange) Process

Nyhamna (Ormen Lange) Process

SUMMARY • • Non-associated gas and associated gas (& unconventionals). Terminology uses English-derived abbreviations, for example such products as LPG and LNG. Classification expresses origin and physical condition of natural gas in reservoirs, wells, pipelines and processing plants. Phase envelope shows physical state of oil and gas at all reservoir conditions and all processing conditions. Natural gases have different composition, from production to processing. Non-HC included (water, inert gases). Specifications state requirements for transport and sale, mainly composition and heating value, but also pressure and temperature. Volume specifications vary from country to country. Norway uses 1 atm and 15 C (USA uses 1 atm and 60 F).

SUMMARY • • Non-associated gas and associated gas (& unconventionals). Terminology uses English-derived abbreviations, for example such products as LPG and LNG. Classification expresses origin and physical condition of natural gas in reservoirs, wells, pipelines and processing plants. Phase envelope shows physical state of oil and gas at all reservoir conditions and all processing conditions. Natural gases have different composition, from production to processing. Non-HC included (water, inert gases). Specifications state requirements for transport and sale, mainly composition and heating value, but also pressure and temperature. Volume specifications vary from country to country. Norway uses 1 atm and 15 C (USA uses 1 atm and 60 F).

REFERENCES Hubbard, R. (2009): The Role of Gas Processing in the Natural-Gas Value Chain, JPT, August, 65 -71. Rojey, A. & Jaffret, C. (1997): Natural Gas: Production, Processing, Transport, Éditions Technip, Paris, 429 pp. Gupta, N. (2011): Overview of Ormen Lange Project, Presentation, TPG 4041, Department of Petroleum Engineering and Applied Geophysics, NTNU, October 27, 32 pp. Pedersen, K. S. , Fredenslund, Aa. & Thomassen, P. (1989): Properties of Oils and Natural Gases, Gulf Publishing Company, Houston, 252 pp. Nordstad, K. H. (2005): Gas Processing Facilities, Presentation, TPG 4041, Department of Petroleum Engineering and Applied Geophysics, NTNU, September 19, 28 pp. Jahn, F. , Cook, M. & Graham, M. (1998): Hydrocarbon Exploration and Production, Elsevier, Amsterdam, 383 pp.

REFERENCES Hubbard, R. (2009): The Role of Gas Processing in the Natural-Gas Value Chain, JPT, August, 65 -71. Rojey, A. & Jaffret, C. (1997): Natural Gas: Production, Processing, Transport, Éditions Technip, Paris, 429 pp. Gupta, N. (2011): Overview of Ormen Lange Project, Presentation, TPG 4041, Department of Petroleum Engineering and Applied Geophysics, NTNU, October 27, 32 pp. Pedersen, K. S. , Fredenslund, Aa. & Thomassen, P. (1989): Properties of Oils and Natural Gases, Gulf Publishing Company, Houston, 252 pp. Nordstad, K. H. (2005): Gas Processing Facilities, Presentation, TPG 4041, Department of Petroleum Engineering and Applied Geophysics, NTNU, September 19, 28 pp. Jahn, F. , Cook, M. & Graham, M. (1998): Hydrocarbon Exploration and Production, Elsevier, Amsterdam, 383 pp.

Hubbard (2009)

Hubbard (2009)