c4e77bbe955a99ca57f60909d7576beb.ppt

- Количество слайдов: 40

Printing Safe Food Packaging Zagreb, May 2016 We assume responsibility for safe products

Agenda § The 4 elements for safe food packaging § Migration : Examples - Mechanisms § Regulations § Risk assessment - Migration testing § UV Low Migration systems § Siegwerk solutions : SICURA NUTRI systems

Agenda § The 4 elements for safe food packaging § Migration : Examples - Mechanisms § Regulations § Risk assessment - Migration testing § UV Low Migration systems § Siegwerk solutions : SICURA NUTRI systems 3

Your and our continuous challenge is to produce safe and compliant products Example Press Articles High risk regarding food contamination & compliance 4

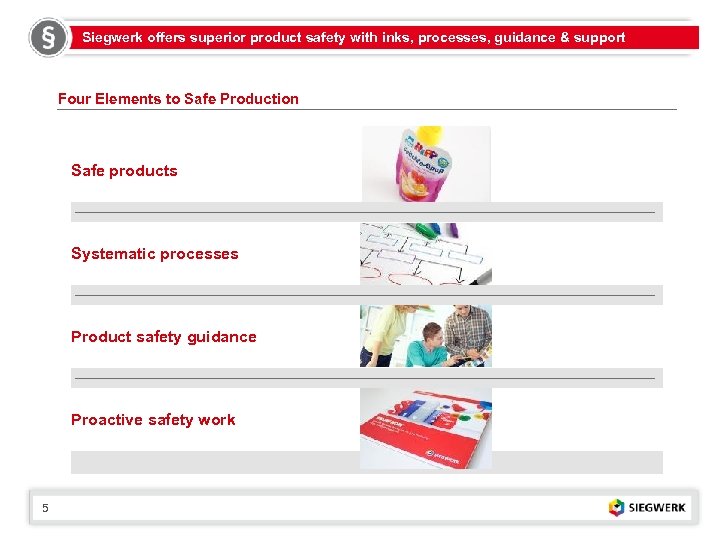

Siegwerk offers superior product safety with inks, processes, guidance & support Four Elements to Safe Production Safe products Systematic processes Product safety guidance Proactive safety work 5

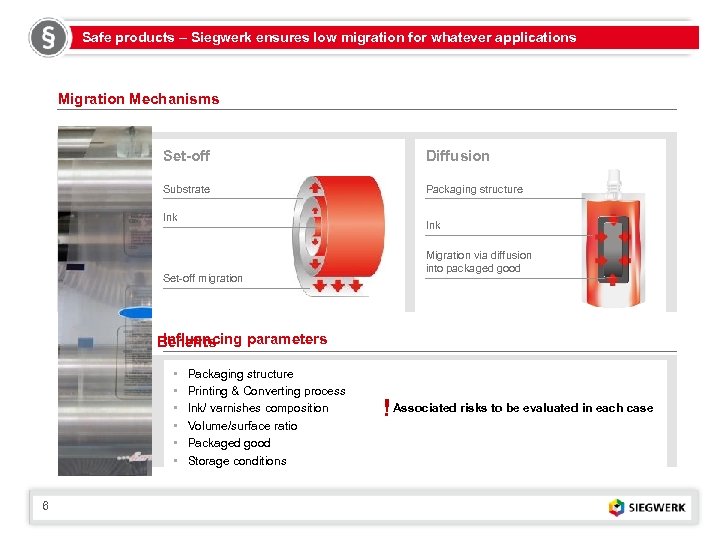

Safe products – Siegwerk ensures low migration for whatever applications Migration Mechanisms Set-off Diffusion Substrate Packaging structure Ink Migration via diffusion into packaged good Set-off migration Influencing parameters Benefits • Packaging structure SB, WB, Converting process • + Printing & UV or vegetable oil-based inks with best low migration standards • Ink/ varnishes composition Associated risks to be evaluated in each case + Volume/surface all relevant migrants and support for risk evaluation Information on • ratio • + Packaged good Safe inks reflecting the printing, conversion and end-use of whatever packaging • Storage conditions ! 6

Concrete examples: Food packaging Shrink Sleeves PP, PE or PS & Shrink Sleeves PET In-Mould Labels & Selfadhesive Labels on Cups PS&R recommendations Depending on storage time and thickness of bottles there is a high risk of direct migration Low migration inks and varnishes 7 Possible set-off due to storage in stack. Low but existing migration risk depending on cup thickness Low migration inks and varnishes

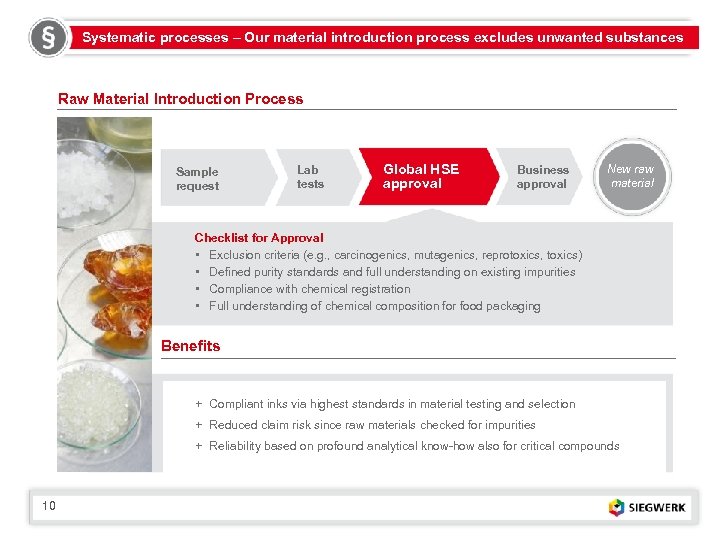

Systematic processes – Our material introduction process excludes unwanted substances Raw Material Introduction Process Sample request Lab tests Global HSE approval Business approval New raw material Checklist for Approval • Exclusion criteria (e. g. , carcinogenics, mutagenics, reprotoxics, toxics) • Defined purity standards and full understanding on existing impurities • Compliance with chemical registration • Full understanding of chemical composition for food packaging Benefits + Compliant inks via highest standards in material testing and selection + Reduced claim risk since raw materials checked for impurities + Reliability based on profound analytical know-how also for critical compounds 10

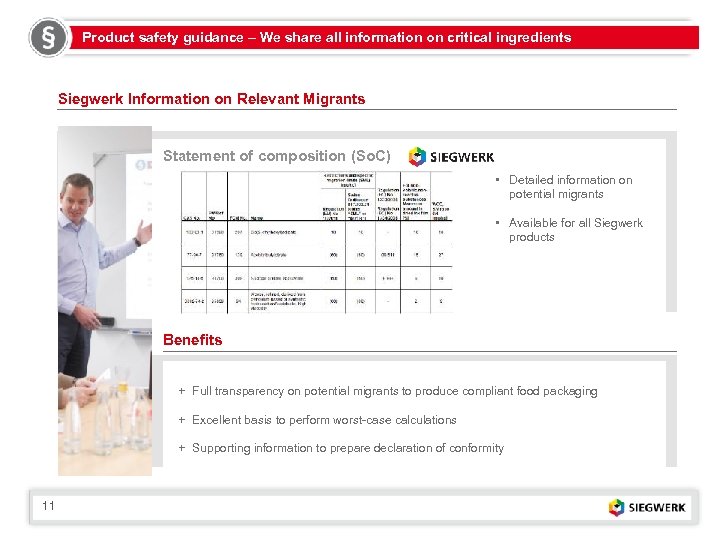

Product safety guidance – We share all information on critical ingredients Siegwerk Information on Relevant Migrants Statement of composition (So. C) • Detailed information on potential migrants • Available for all Siegwerk products Benefits + Full transparency on potential migrants to produce compliant food packaging + Excellent basis to perform worst-case calculations + Supporting information to prepare declaration of conformity 11

12

Agenda § The 4 elements for safe food packaging § Migration : Examples - Mechanisms § Regulations § Risk assessment - Migration testing § UV Low Migration systems § Siegwerk solutions : SICURA NUTRI systems 11

The Migration Risk Labels – Sleeves 2009: What happened, when Benzophenone from Sleeves migrated. . . The HDPE bottle was not a barrier 12

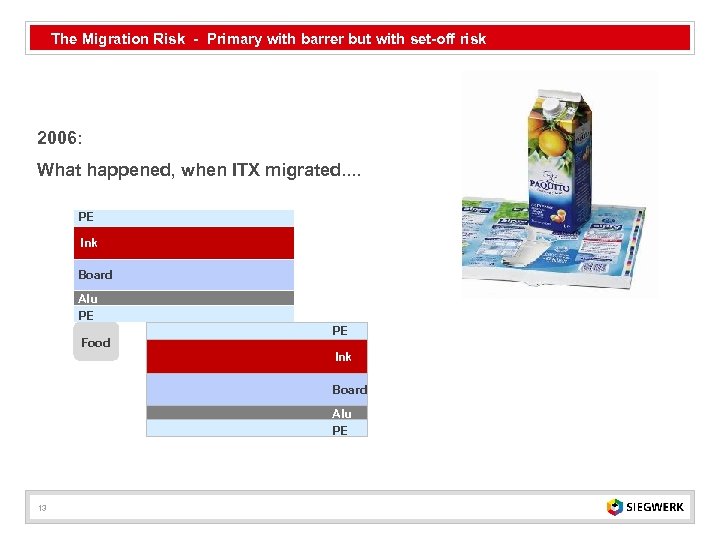

The Migration Risk - Primary with barrer but with set-off risk 2006: What happened, when ITX migrated. . PE Ink Board Alu PE Food PE Ink Board Alu PE 13

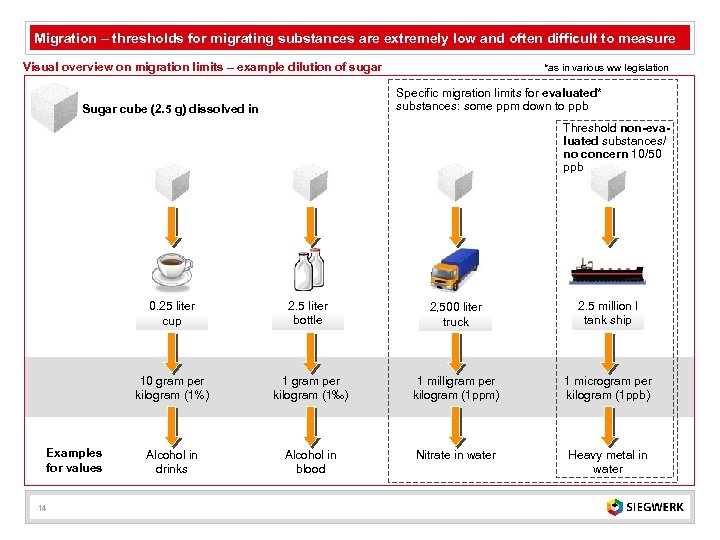

Migration – thresholds for migrating substances are extremely low and often difficult to measure Visual overview on migration limits – example dilution of sugar *as in various ww legislation Specific migration limits for evaluated* substances: some ppm down to ppb Sugar cube (2. 5 g) dissolved in Threshold non-evaluated substances/ no concern 10/50 ppb 0. 25 liter cup 14 2, 500 liter truck 2. 5 million l tank ship 10 gram per kilogram (1%) Examples for values 2. 5 liter bottle 1 gram per kilogram (1‰) 1 milligram per kilogram (1 ppm) 1 microgram per kilogram (1 ppb) Alcohol in drinks Alcohol in blood Nitrate in water Heavy metal in water

Agenda § The 4 elements for safe food packaging § Migration : Examples - Mechanisms § Regulations § Risk assessment - Migration testing § UV Low Migration systems § Siegwerk solutions : SICURA NUTRI systems

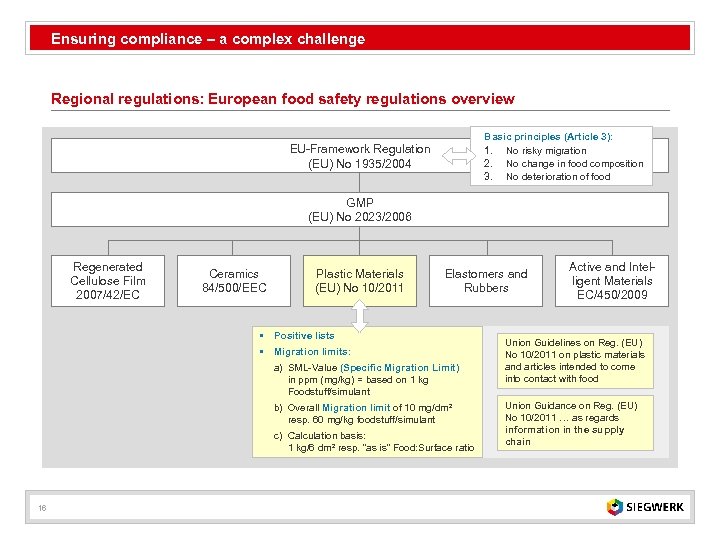

Ensuring compliance – a complex challenge Regional regulations: European food safety regulations overview Basic principles (Article 3): 1. No risky migration 2. No change in food composition 3. No deterioration of food EU-Framework Regulation (EU) No 1935/2004 GMP (EU) No 2023/2006 Regenerated Cellulose Film 2007/42/EC Ceramics 84/500/EEC Plastic Materials (EU) No 10/2011 Elastomers and Rubbers § Positive lists § Migration limits: a) SML-Value (Specific Migration Limit) in ppm (mg/kg) = based on 1 kg Foodstuff/simulant b) Overall Migration limit of 10 mg/dm² resp. 60 mg/kg foodstuff/simulant c) Calculation basis: 1 kg/6 dm² resp. “as is” Food: Surface ratio 16 Active and Intelligent Materials EC/450/2009 Union Guidelines on Reg. (EU) No 10/2011 on plastic materials and articles intended to come into contact with food Union Guidance on Reg. (EU) No 10/2011 … as regards information in the supply chain

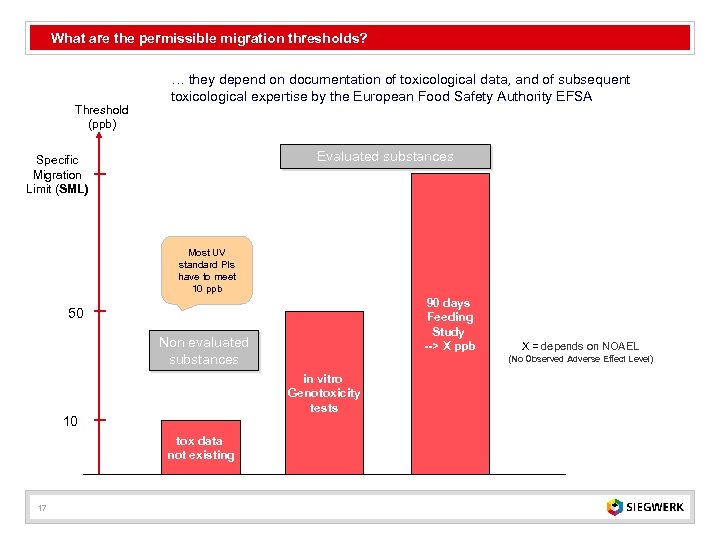

What are the permissible migration thresholds? Threshold (ppb) … they depend on documentation of toxicological data, and of subsequent toxicological expertise by the European Food Safety Authority EFSA Evaluated substances Specific Migration Limit (SML) Most UV standard PIs have to meet 10 ppb 90 days Feeding Study --> X ppb 50 Non evaluated substances X = depends on NOAEL (No Observed Adverse Effect Level) in vitro Genotoxicity tests 10 tox data not existing 17 17

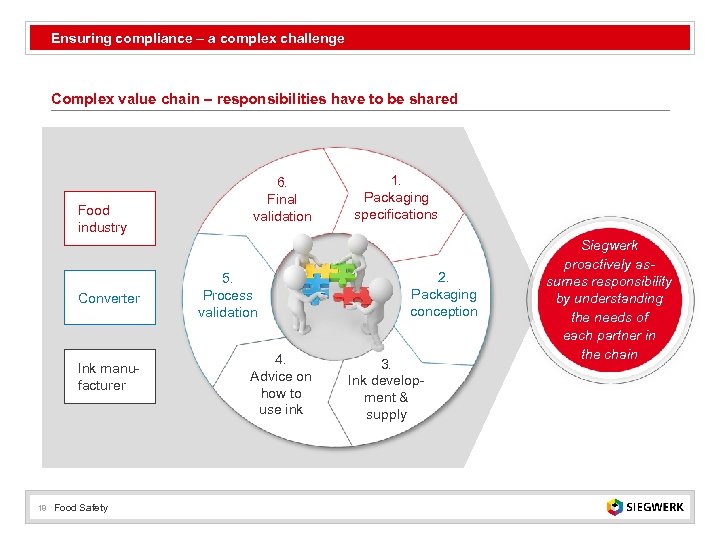

Ensuring compliance – a complex challenge Complex value chain – responsibilities have to be shared Food industry Converter Ink manufacturer 18 Food Safety 6. Final validation 5. Process validation 4. Advice on how to use ink 1. Packaging specifications 2. Packaging conception 3. Ink development & supply Siegwerk proactively assumes responsibility by understanding the needs of each partner in the chain

Agenda § The 4 elements for safe food packaging § Migration : Examples - Mechanisms § Regulations § Risk assessment – Migration testing § UV Low Migration systems § Siegwerk solutions : SICURA NUTRI systems 19

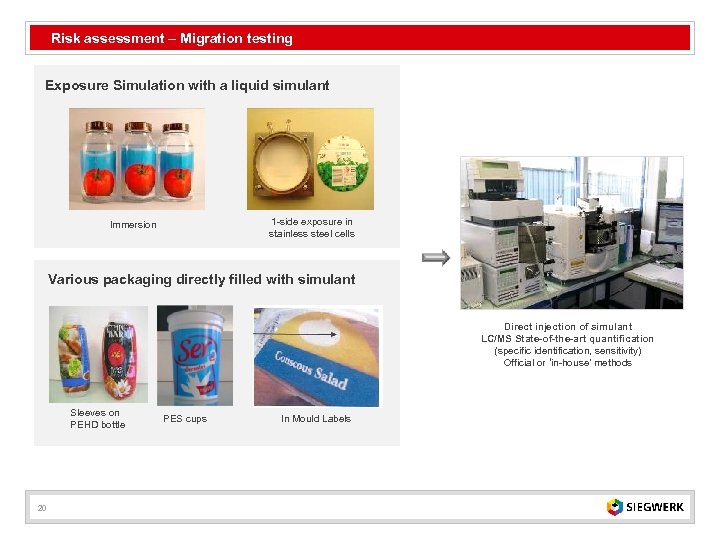

Risk assessment – Migration testing Exposure Simulation with a liquid simulant 1 -side exposure in stainless steel cells Immersion Various packaging directly filled with simulant Direct injection of simulant LC/MS State-of-the-art quantification (specific identification, sensitivity) Official or ‘in-house’ methods Sleeves on PEHD bottle 20 PES cups In Mould Labels

Agenda § The 4 elements for safe food packaging § Migration : Examples - Mechanisms § Regulations § Risk assessment – Migration testing § UV Low Migration systems § Siegwerk solutions : SICURA NUTRI systems 21

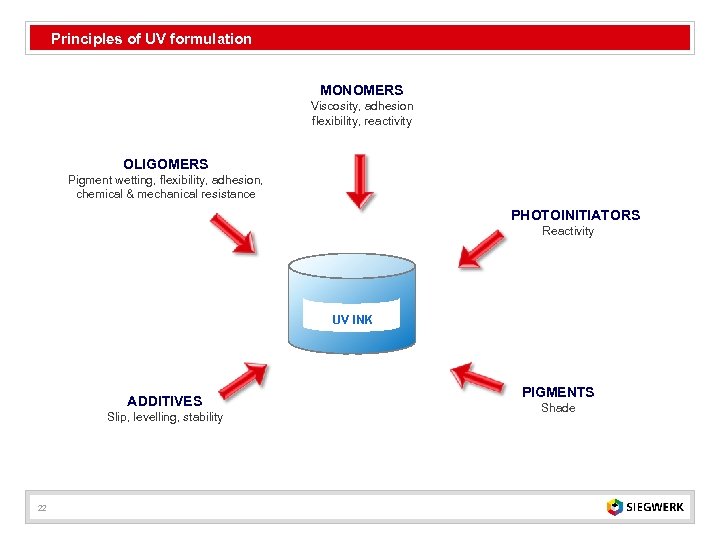

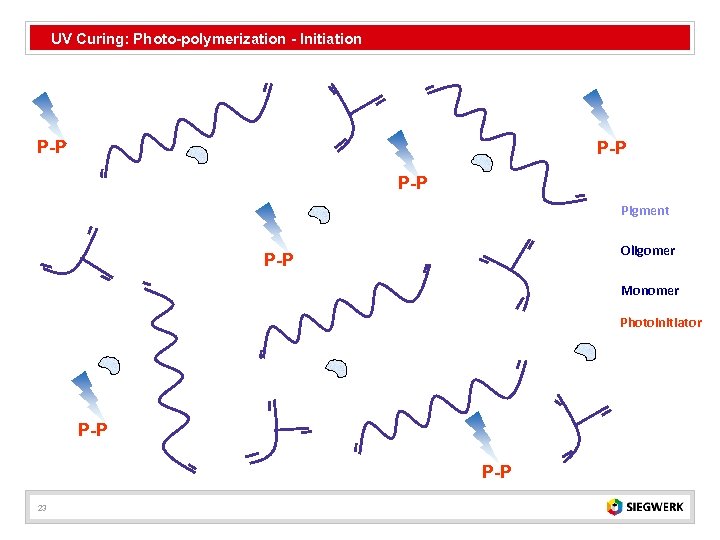

Principles of UV formulation MONOMERS Viscosity, adhesion flexibility, reactivity OLIGOMERS Pigment wetting, flexibility, adhesion, chemical & mechanical resistance PHOTOINITIATORS Reactivity UV INK ADDITIVES Slip, levelling, stability 22 PIGMENTS Shade .

UV Curing: Photo-polymerization - Initiation P-P P-P Pigment Oligomer P-P Monomer Photoinitiator P-P 23

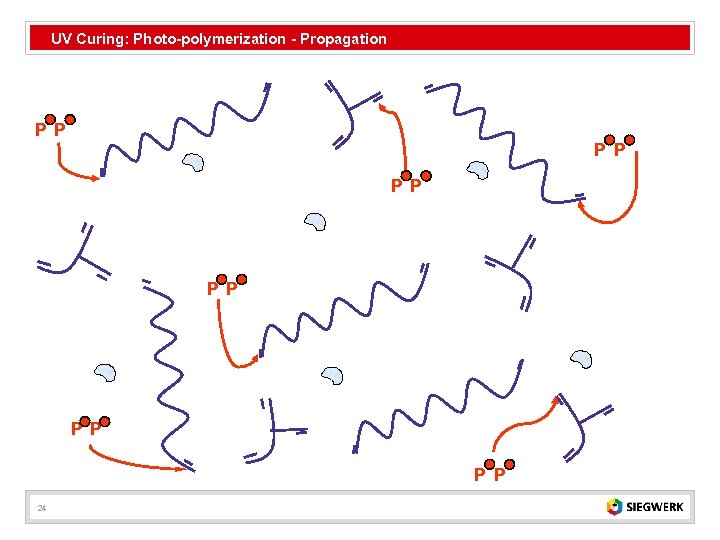

UV Curing: Photo-polymerization - Propagation . . P P 24

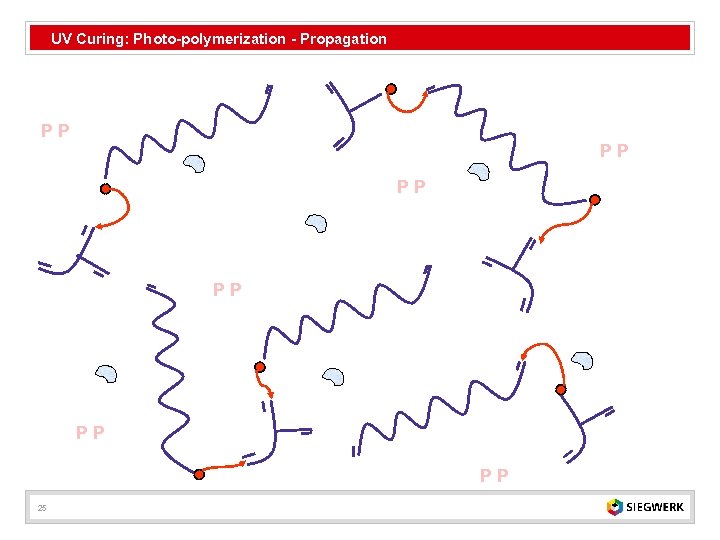

UV Curing: Photo-polymerization - Propagation PP PP PP 25

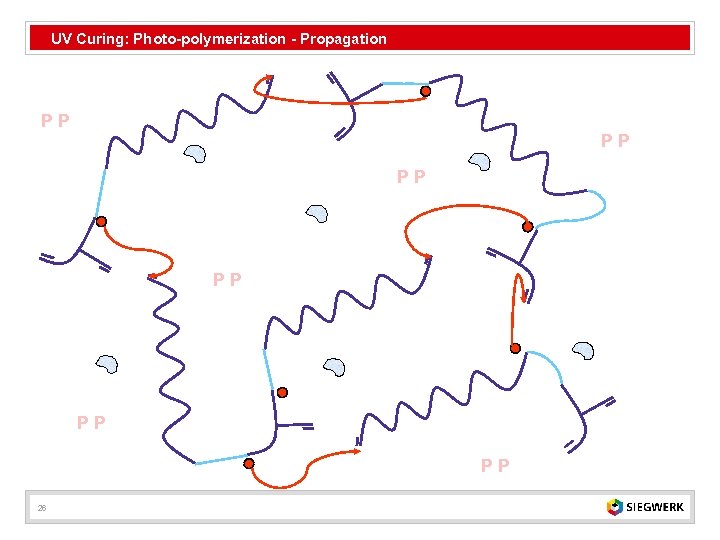

UV Curing: Photo-polymerization - Propagation PP PP PP 26

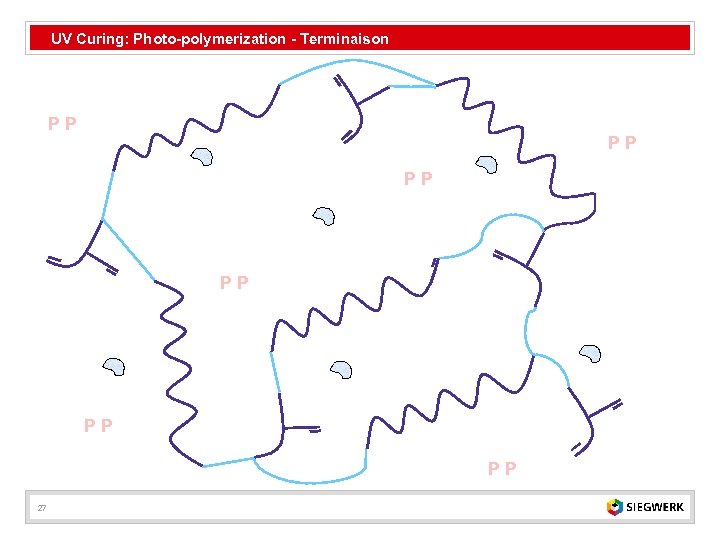

UV Curing: Photo-polymerization - Terminaison PP PP PP 27

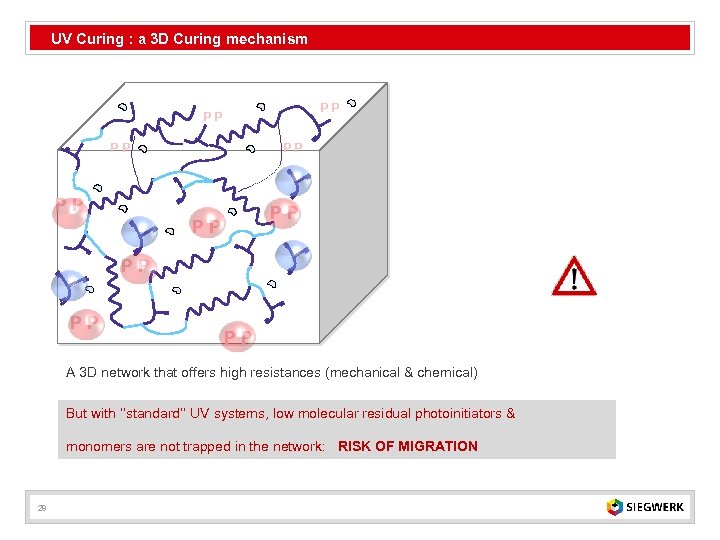

UV Curing : a 3 D Curing mechanism PP PP PP A 3 D network that offers high resistances (mechanical & chemical) But with ‘’standard’’ UV systems, low molecular residual photoinitiators & monomers are not trapped in the network: RISK OF MIGRATION 28

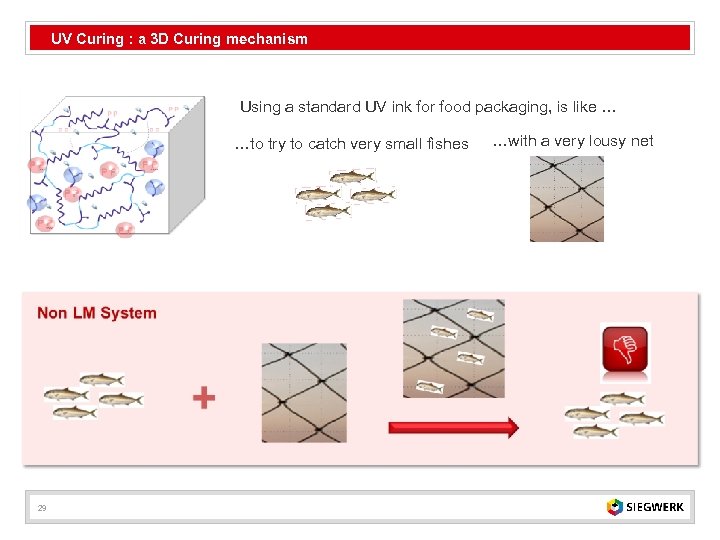

UV Curing : a 3 D Curing mechanism Using a standard UV ink for food packaging, is like … …to try to catch very small fishes 29 …with a very lousy net

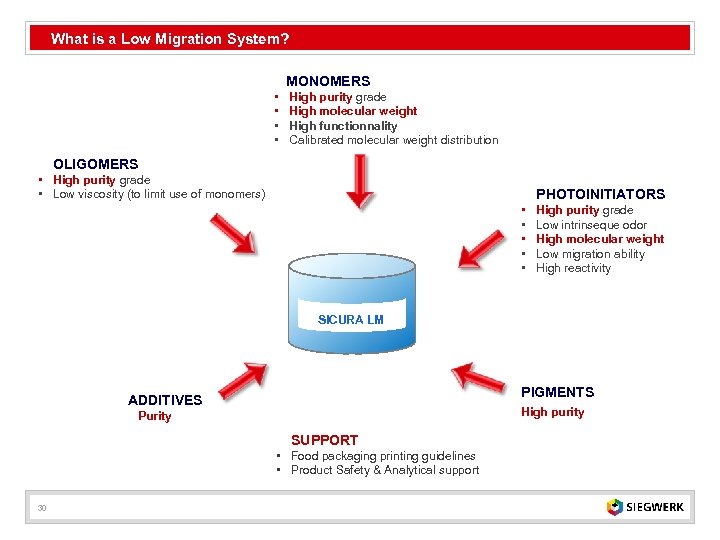

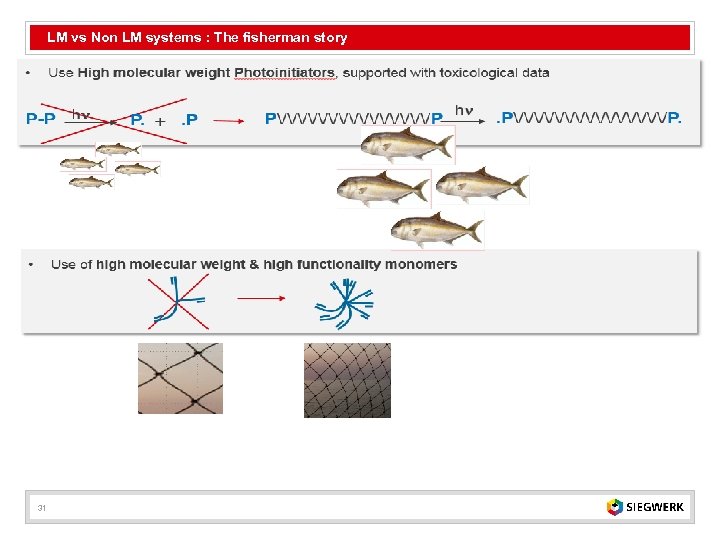

What is a Low Migration System? MONOMERS • • High purity grade High molecular weight High functionnality Calibrated molecular weight distribution OLIGOMERS • High purity grade • Low viscosity (to limit use of monomers) PHOTOINITIATORS • • • High purity grade Low intrinseque odor High molecular weight Low migration ability High reactivity SICURA LM PIGMENTS ADDITIVES High purity. Purity SUPPORT • Food packaging printing guidelines • Product Safety & Analytical support 30

LM vs Non LM systems : The fisherman story 31

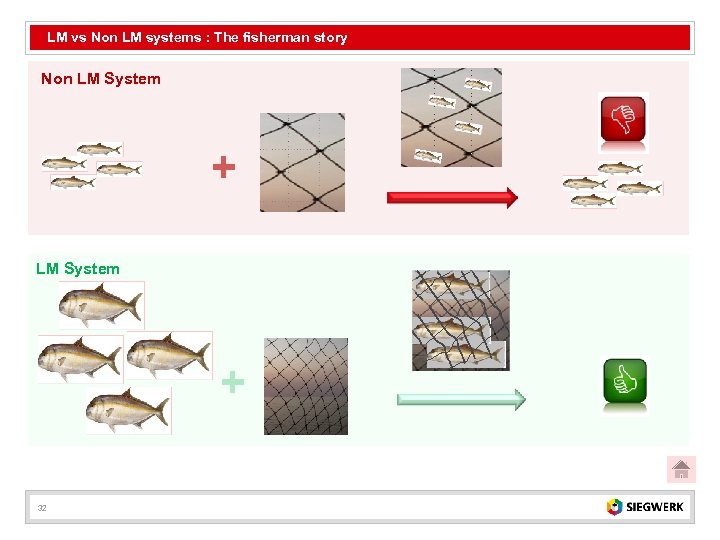

LM vs Non LM systems : The fisherman story Non LM System + 32

Agenda § The 4 elements for safe food packaging § Migration : Examples - Mechanisms § Regulations § Risk assessment – Migration testing § UV Low Migration systems § Siegwerk solutions : SICURA NUTRI systems

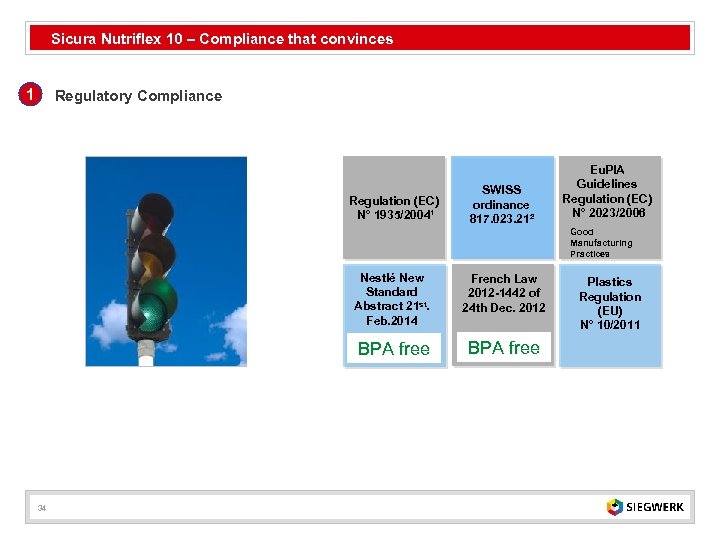

Sicura Nutriflex 10 – Compliance that convinces 1 Regulatory Compliance Regulation (EC) N° 1935/2004¹ SWISS ordinance 817. 023. 21² Eu. PIA Guidelines Regulation (EC) N° 2023/2006 Good Manufacturing Practices Nestlé New Standard Abstract 21 st. Feb. 2014 BPA free 34 French Law 2012 -1442 of 24 th Dec. 2012 BPA free Plastics Regulation (EU) N° 10/2011

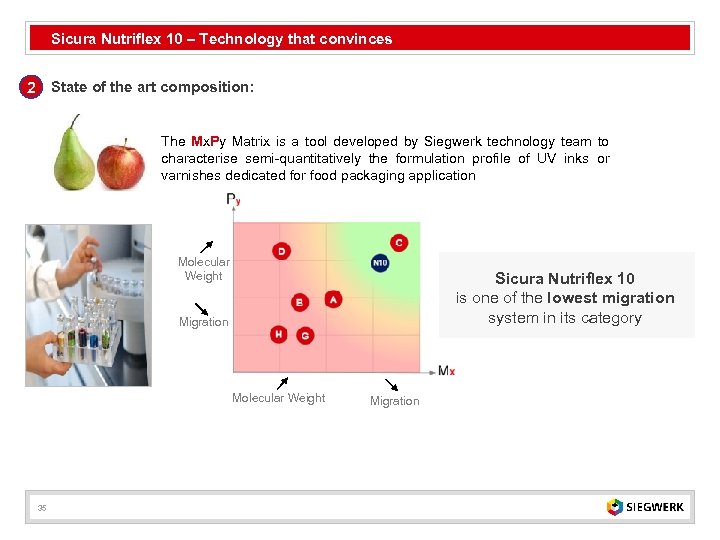

Sicura Nutriflex 10 – Technology that convinces 2 State of the art composition: The Mx. Py Matrix is a tool developed by Siegwerk technology team to characterise semi-quantitatively the formulation profile of UV inks or varnishes dedicated for food packaging application Benchmark vs competition Molecular Weight Sicura Nutriflex 10 is one of the lowest migration system in its category Migration Molecular Weight 35 Migration

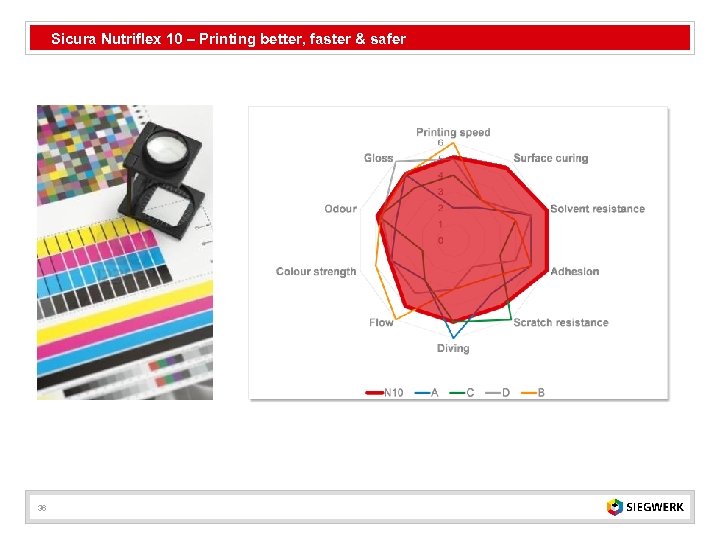

Sicura Nutriflex 10 – Printing better, faster & safer 36

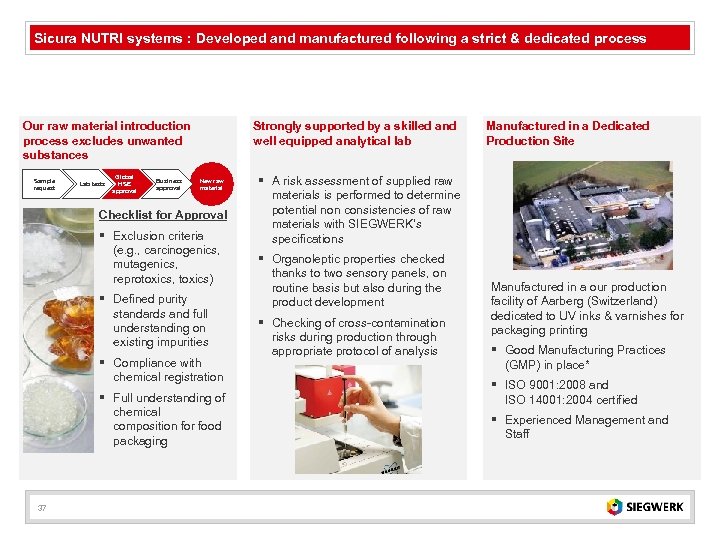

Sicura NUTRI systems : Developed and manufactured following a strict & dedicated process Our raw material introduction process excludes unwanted substances Sample request Lab tests Global HSE approval Business approval Strongly supported by a skilled and well equipped analytical lab New raw material Checklist for Approval § Exclusion criteria (e. g. , carcinogenics, mutagenics, reprotoxics, toxics) § Defined purity standards and full understanding on existing impurities § Compliance with chemical registration § Full understanding of chemical composition for food packaging 37 Manufactured in a Dedicated Production Site § A risk assessment of supplied raw materials is performed to determine potential non consistencies of raw materials with SIEGWERK‘s specifications § Organoleptic properties checked thanks to two sensory panels, on routine basis but also during the product development § Checking of cross-contamination risks during production through appropriate protocol of analysis Manufactured in a our production facility of Aarberg (Switzerland) dedicated to UV inks & varnishes for packaging printing § Good Manufacturing Practices (GMP) in place* § ISO 9001: 2008 and ISO 14001: 2004 certified § Experienced Management and Staff

TAKE AWAY SICURA Nutriflex 10 ► process & bases SICURA Nutriflex 10 38

Thank you! Hvala! Contact person: Marc Larvor Head of Technical Marketing Business Unit Sheetfed/Narrow Web Mobile: +33 (0)607325351 Mail: marc. larvor@siegwerk. com

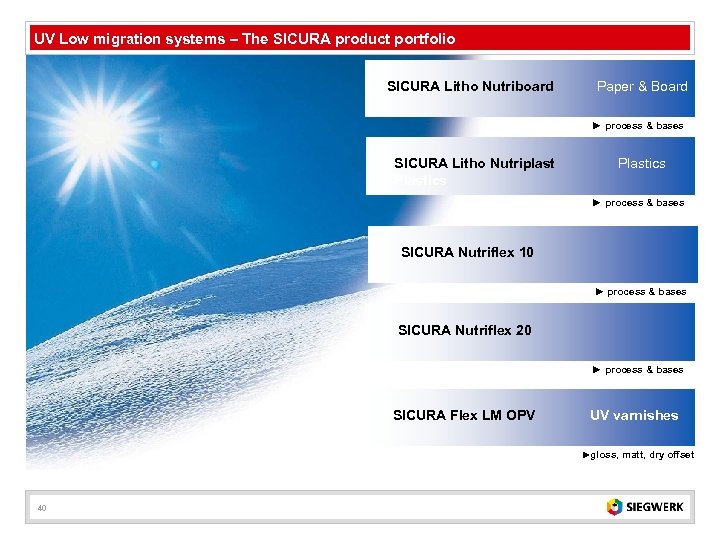

UV Low migration systems – The SICURA product portfolio SICURA Litho Nutriboard Paper & Board ► process & bases SICURA Litho Nutriplast Plastics ► process & bases SICURA Nutriflex 10 ► process & bases SICURA Nutriflex 20 ► process & bases SICURA Flex LM OPV UV varnishes ►gloss, matt, dry offset 40

c4e77bbe955a99ca57f60909d7576beb.ppt