6506e9dd055fd7ed8a1aae6d0bf8ddbf.ppt

- Количество слайдов: 20

PRILOX ® S XV ICF 2003 Saint Omer - France BENEFITS OBTAINED WITH “READY FOR PRODUCTION” GLASS BATCH Tony Butt / Chemson Group Graham Brooks / Industrial Analysis Limited

PRILOX ® S XV ICF 2003 Saint Omer - France BENEFITS OBTAINED WITH “READY FOR PRODUCTION” GLASS BATCH Tony Butt / Chemson Group Graham Brooks / Industrial Analysis Limited

Content PRILOX ® S XV ICF 2003 Saint Omer - France • Introduction • Advantages in Production and Logistics • Savings using Prilox • Quality • Furnace Benefits • Summary

Content PRILOX ® S XV ICF 2003 Saint Omer - France • Introduction • Advantages in Production and Logistics • Savings using Prilox • Quality • Furnace Benefits • Summary

Introduction PRILOX ® S XV ICF 2003 Saint Omer - France Market conditions for crystal glass Ø Stagnation in the glass markets Ø Short production forecasts Ø Flexibility required Ø Demand for capital investements Ø Ever increasing environmental pressures Ø High Pressure on all glass companies Each glass producer has to consider its own strategy to deal with these issues Prilox ® S provides a way forward for the future

Introduction PRILOX ® S XV ICF 2003 Saint Omer - France Market conditions for crystal glass Ø Stagnation in the glass markets Ø Short production forecasts Ø Flexibility required Ø Demand for capital investements Ø Ever increasing environmental pressures Ø High Pressure on all glass companies Each glass producer has to consider its own strategy to deal with these issues Prilox ® S provides a way forward for the future

Introduction PRILOX ® S XV ICF 2003 Saint Omer - France Chemson originally launched Prilox ® at the ICF conference in Salzburg in 2000 Two notable producers – ü Waterford since 1999 ü Inn Crystal since 2001 Chemson presented a summary of Benefits at the ICF conference in Siena in 2001 This presentation now re-confirms the previous results and provides further evidence of the advantages of pre-blended glassbatch

Introduction PRILOX ® S XV ICF 2003 Saint Omer - France Chemson originally launched Prilox ® at the ICF conference in Salzburg in 2000 Two notable producers – ü Waterford since 1999 ü Inn Crystal since 2001 Chemson presented a summary of Benefits at the ICF conference in Siena in 2001 This presentation now re-confirms the previous results and provides further evidence of the advantages of pre-blended glassbatch

Advantages in Production and Logistics PRILOX ® S XV ICF 2003 Saint Omer - France Advantages in production Prilox ® – Two components Prilox ® S – One component + Auto handling of batch + Eliminates batch house problems + Reduced number of raw materials + Higher cullet ratio can be used + Increased melting rate flexibility

Advantages in Production and Logistics PRILOX ® S XV ICF 2003 Saint Omer - France Advantages in production Prilox ® – Two components Prilox ® S – One component + Auto handling of batch + Eliminates batch house problems + Reduced number of raw materials + Higher cullet ratio can be used + Increased melting rate flexibility

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Savings using Prilox ® Energy + Reduced batch house handling and mixing + Higher cullet ratio + Higher energy efficiency in melt process + Reduced exhaust air Environment + Reduced waste, less dust + Reduced disposal costs + Better working conditions, reduced exposure for employees

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Savings using Prilox ® Energy + Reduced batch house handling and mixing + Higher cullet ratio + Higher energy efficiency in melt process + Reduced exhaust air Environment + Reduced waste, less dust + Reduced disposal costs + Better working conditions, reduced exposure for employees

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Energy consumption Measured by Inn Crystal + Better homogenous batch + A closed batch blanket + Higher flexibility output + Higher cullet ratio can be achieved + Reduction of the overflow + A shorter melting time Achieved an energy saving of more than 10%

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Energy consumption Measured by Inn Crystal + Better homogenous batch + A closed batch blanket + Higher flexibility output + Higher cullet ratio can be achieved + Reduction of the overflow + A shorter melting time Achieved an energy saving of more than 10%

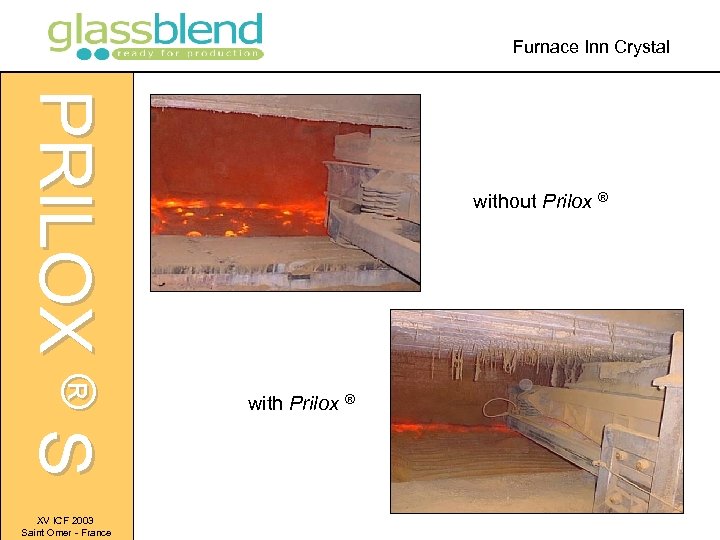

Furnace Inn Crystal PRILOX ® S XV ICF 2003 Saint Omer - France without Prilox ® with Prilox ®

Furnace Inn Crystal PRILOX ® S XV ICF 2003 Saint Omer - France without Prilox ® with Prilox ®

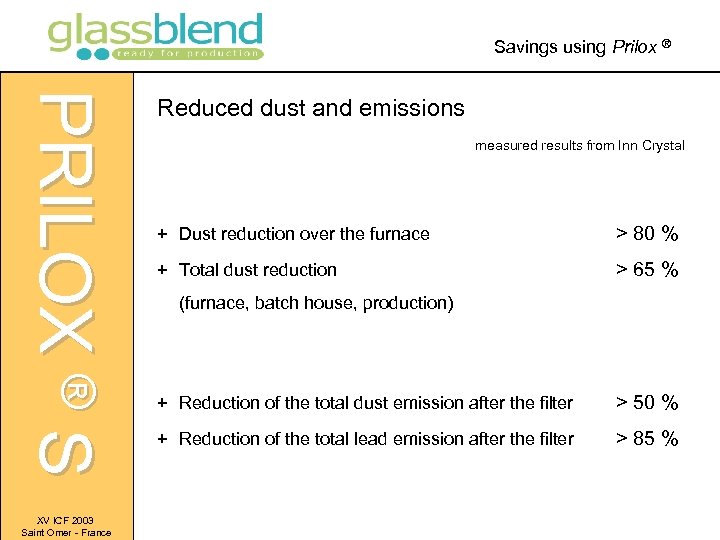

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Reduced dust and emissions measured results from Inn Crystal + Dust reduction over the furnace > 80 % + Total dust reduction > 65 % (furnace, batch house, production) + Reduction of the total dust emission after the filter > 50 % + Reduction of the total lead emission after the filter > 85 %

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Reduced dust and emissions measured results from Inn Crystal + Dust reduction over the furnace > 80 % + Total dust reduction > 65 % (furnace, batch house, production) + Reduction of the total dust emission after the filter > 50 % + Reduction of the total lead emission after the filter > 85 %

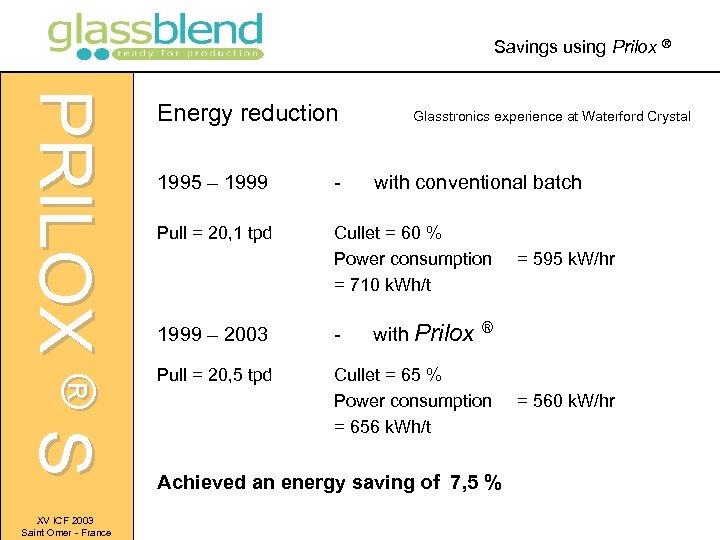

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Energy reduction Glasstronics experience at Waterford Crystal 1995 – 1999 - with conventional batch Pull = 20, 1 tpd Cullet = 60 % Power consumption = 710 k. Wh/t with Prilox = 595 k. W/hr ® 1999 – 2003 - Pull = 20, 5 tpd Cullet = 65 % Power consumption = 656 k. Wh/t Achieved an energy saving of 7, 5 % = 560 k. W/hr

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Energy reduction Glasstronics experience at Waterford Crystal 1995 – 1999 - with conventional batch Pull = 20, 1 tpd Cullet = 60 % Power consumption = 710 k. Wh/t with Prilox = 595 k. W/hr ® 1999 – 2003 - Pull = 20, 5 tpd Cullet = 65 % Power consumption = 656 k. Wh/t Achieved an energy saving of 7, 5 % = 560 k. W/hr

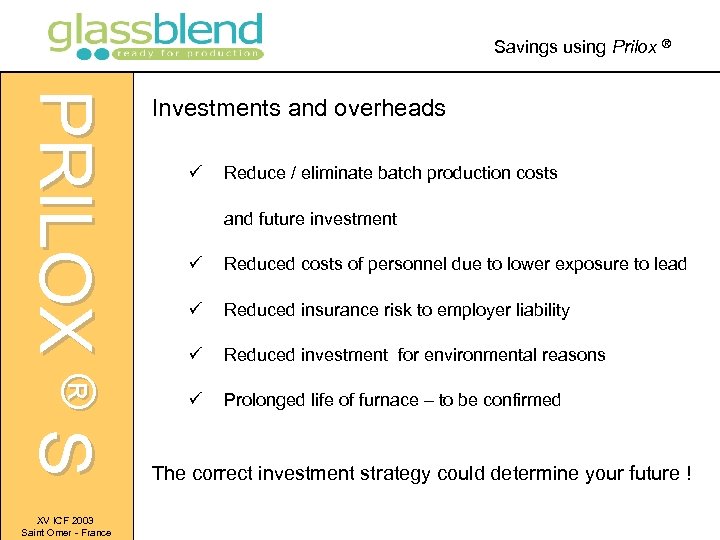

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Investments and overheads ü Reduce / eliminate batch production costs and future investment ü Reduced costs of personnel due to lower exposure to lead ü Reduced insurance risk to employer liability ü Reduced investment for environmental reasons ü Prolonged life of furnace – to be confirmed The correct investment strategy could determine your future !

Savings using Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Investments and overheads ü Reduce / eliminate batch production costs and future investment ü Reduced costs of personnel due to lower exposure to lead ü Reduced insurance risk to employer liability ü Reduced investment for environmental reasons ü Prolonged life of furnace – to be confirmed The correct investment strategy could determine your future !

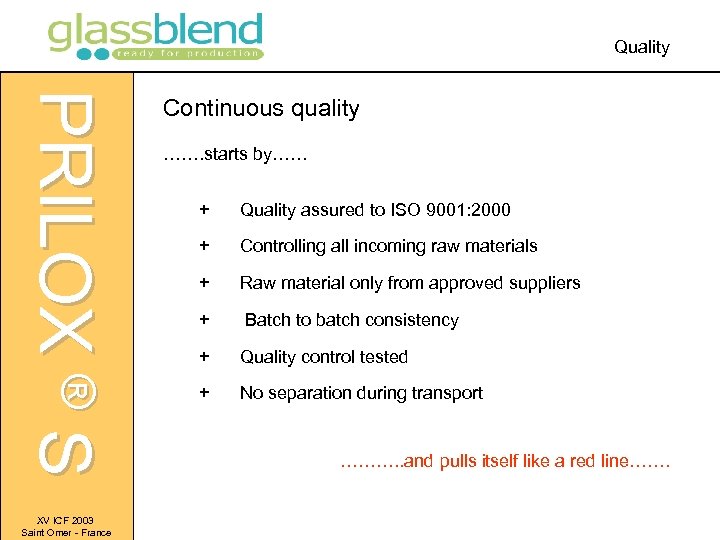

Quality PRILOX ® S XV ICF 2003 Saint Omer - France Continuous quality ……. starts by…… + Quality assured to ISO 9001: 2000 + Controlling all incoming raw materials + Raw material only from approved suppliers + Batch to batch consistency + Quality control tested + No separation during transport ………. . and pulls itself like a red line…….

Quality PRILOX ® S XV ICF 2003 Saint Omer - France Continuous quality ……. starts by…… + Quality assured to ISO 9001: 2000 + Controlling all incoming raw materials + Raw material only from approved suppliers + Batch to batch consistency + Quality control tested + No separation during transport ………. . and pulls itself like a red line…….

Quality PRILOX ® S XV ICF 2003 Saint Omer - France Continuous quality ………. and pulls itself like a red line…… + For consistency and reliability through the melt process + For a flexible melting rate to assist various product types + Quicker melting process than normal glass batch + Reduced exposure of employees to dangerous goods + Improved total quality of final product ……and stops in a clear and brilliant end product.

Quality PRILOX ® S XV ICF 2003 Saint Omer - France Continuous quality ………. and pulls itself like a red line…… + For consistency and reliability through the melt process + For a flexible melting rate to assist various product types + Quicker melting process than normal glass batch + Reduced exposure of employees to dangerous goods + Improved total quality of final product ……and stops in a clear and brilliant end product.

Furnace Benefits PRILOX ® S XV ICF 2003 Saint Omer - France Furnace benefits + Higher consistency of glass melt + A reduced erosion of electrodes • approx. 30% reduced wear – Waterford Crystal • constant and improved wear performance – Inn Crystal + Homogenously bonded material melts easier with lower temperature + Smaller bubbles

Furnace Benefits PRILOX ® S XV ICF 2003 Saint Omer - France Furnace benefits + Higher consistency of glass melt + A reduced erosion of electrodes • approx. 30% reduced wear – Waterford Crystal • constant and improved wear performance – Inn Crystal + Homogenously bonded material melts easier with lower temperature + Smaller bubbles

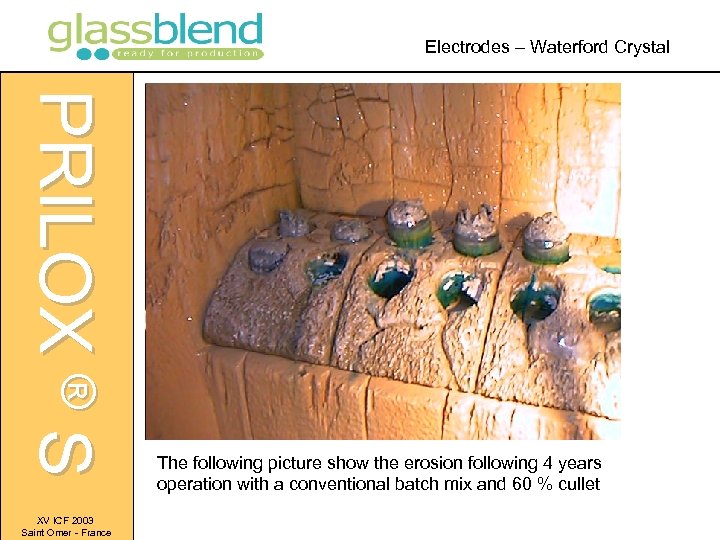

Electrodes – Waterford Crystal PRILOX ® S XV ICF 2003 Saint Omer - France The following picture show the erosion following 4 years operation with a conventional batch mix and 60 % cullet

Electrodes – Waterford Crystal PRILOX ® S XV ICF 2003 Saint Omer - France The following picture show the erosion following 4 years operation with a conventional batch mix and 60 % cullet

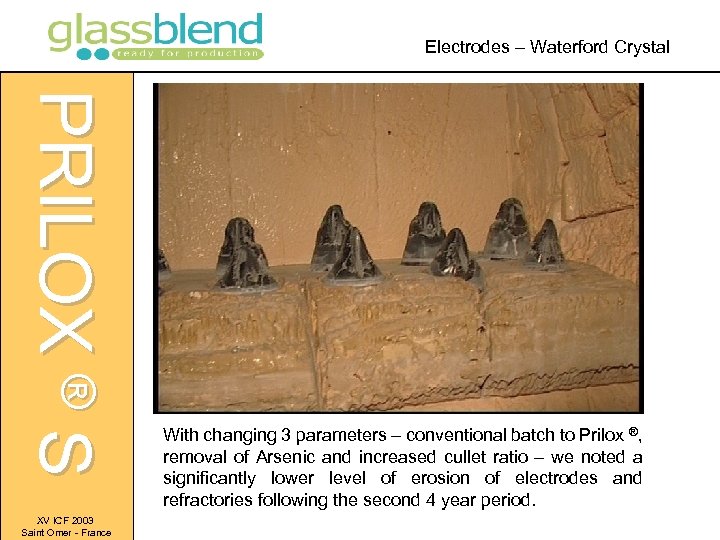

Electrodes – Waterford Crystal PRILOX ® S XV ICF 2003 Saint Omer - France With changing 3 parameters – conventional batch to Prilox ®, removal of Arsenic and increased cullet ratio – we noted a significantly lower level of erosion of electrodes and refractories following the second 4 year period.

Electrodes – Waterford Crystal PRILOX ® S XV ICF 2003 Saint Omer - France With changing 3 parameters – conventional batch to Prilox ®, removal of Arsenic and increased cullet ratio – we noted a significantly lower level of erosion of electrodes and refractories following the second 4 year period.

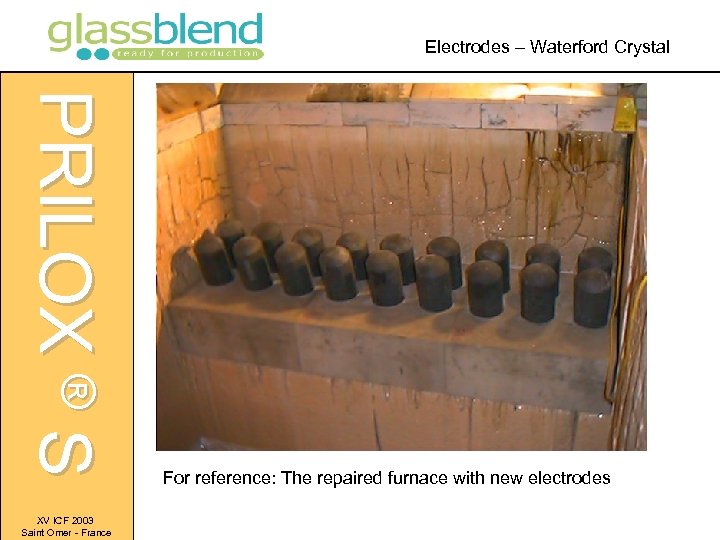

Electrodes – Waterford Crystal PRILOX ® S XV ICF 2003 Saint Omer - France For reference: The repaired furnace with new electrodes

Electrodes – Waterford Crystal PRILOX ® S XV ICF 2003 Saint Omer - France For reference: The repaired furnace with new electrodes

Summary PRILOX ® S XV ICF 2003 Saint Omer - France Summary Ø Prilox ® now has full experience of more than 4 years Ø Prilox ® S with sand is available Ø Benefits include + Environmental improvements + Reduced energy consumption + Improved quality + Production efficiency and flexibility + Reduced capital investment

Summary PRILOX ® S XV ICF 2003 Saint Omer - France Summary Ø Prilox ® now has full experience of more than 4 years Ø Prilox ® S with sand is available Ø Benefits include + Environmental improvements + Reduced energy consumption + Improved quality + Production efficiency and flexibility + Reduced capital investment

Development of Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Prilox ® (glass batch without sand), Chemson set the first step + To reach the legal guidelines • health and safety - to reduce the level for lead in blood • environment - lower emissions + To react faster to changed market situation + To provide a solution for the future + A cost acceptable solution With Prilox + ® S – (glass batch with sand) from “glassblend” Same benefits supplied “ready for Production”

Development of Prilox ® PRILOX ® S XV ICF 2003 Saint Omer - France Prilox ® (glass batch without sand), Chemson set the first step + To reach the legal guidelines • health and safety - to reduce the level for lead in blood • environment - lower emissions + To react faster to changed market situation + To provide a solution for the future + A cost acceptable solution With Prilox + ® S – (glass batch with sand) from “glassblend” Same benefits supplied “ready for Production”

Development to Prilox ® S PRILOX ® S XV ICF 2003 Saint Omer - France Two strong companies with large experience, both supplier to the glass industry for a very long time. & form the Joint Venture Find out more from our exhibition stand.

Development to Prilox ® S PRILOX ® S XV ICF 2003 Saint Omer - France Two strong companies with large experience, both supplier to the glass industry for a very long time. & form the Joint Venture Find out more from our exhibition stand.