912bb52dbfb43fa39140f272204445b3.ppt

- Количество слайдов: 21

Presentation October, 2015 1

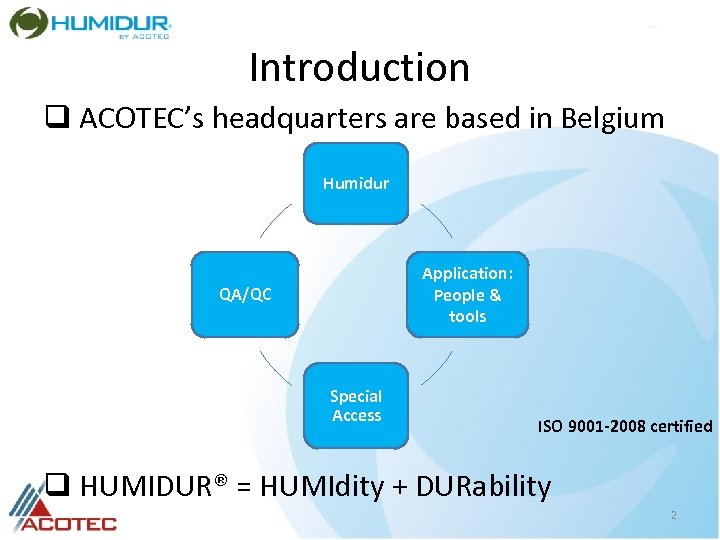

Introduction q ACOTEC’s headquarters are based in Belgium Humidur Application: People & tools QA/QC Special Access ISO 9001 -2008 certified q HUMIDUR® = HUMIdity + DURability 2

Acotec Around The World 3

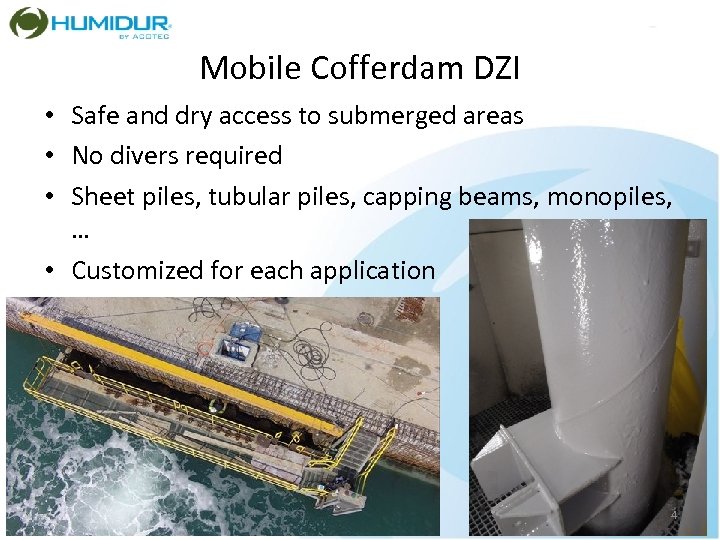

Mobile Cofferdam DZI • Safe and dry access to submerged areas • No divers required • Sheet piles, tubular piles, capping beams, monopiles, … • Customized for each application 4

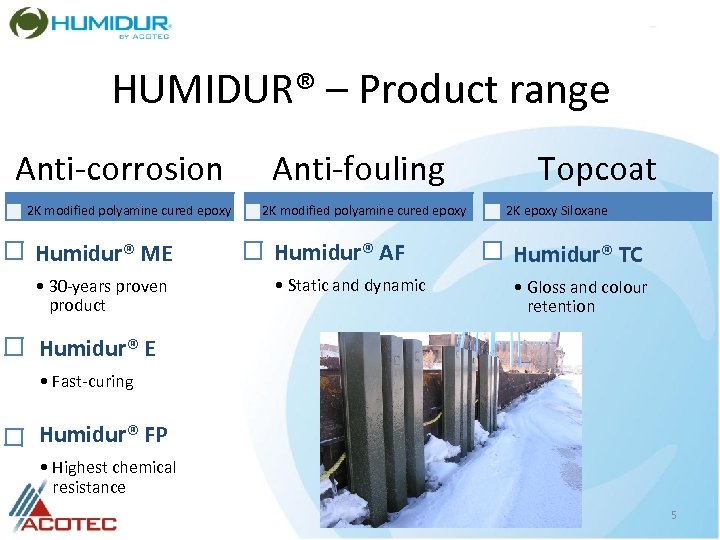

HUMIDUR® – Product range Anti-corrosion 2 K modified polyamine cured epoxy Anti-fouling 2 K modified polyamine cured epoxy Topcoat 2 K epoxy Siloxane Humidur® ME Humidur® AF Humidur® TC • 30 -years proven product • Static and dynamic • Gloss and colour retention Humidur® E • Fast-curing Humidur® FP • Highest chemical resistance 5

Humidur AF – Recommended Use Protection against fouling in all circumstances (biocidal) • Static structures, slow- and fast moving vessels • Fresh, brackish and sea water • Effective in all climates • • Shipping: yachting, navy ships, merchant ships, … Offshore structures Marine structures: e. g. lock door Intakes of cooling systems and inside of pipelines 5/10 years life time in 300 µm • If anti-corrosion coating needed: apply 400 µm Humidur anticorrosion coat • Insured warranty available on Humidur anti-corrosion coatings 6

Humidur AF – Properties Life time • 5 or 10 years (proven in practice) • In theory: 100 years anti-fouling activity Environmentally friendly • Solvent-free, No VOC, 100% solids, No TBT, no asbestos • No hazardous materials • Safe for aquatic organisms 7

Humidur AF - Properties Excellent mechanical properties • Shore D > 60 • High abrasion resistance • High impact resistance 2 K modified polyamine cured epoxy • Excellent adhesion (> 5 Mpa) • High compability with anti-corrosion coatings 8

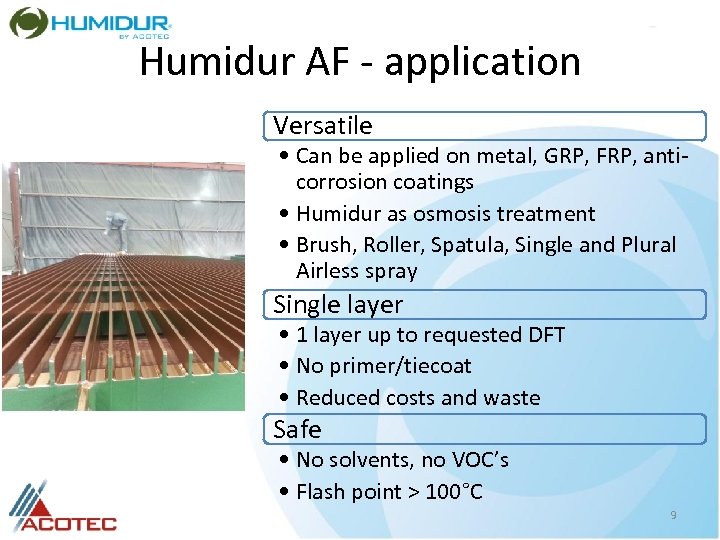

Humidur AF - application Versatile • Can be applied on metal, GRP, FRP, anticorrosion coatings • Humidur as osmosis treatment • Brush, Roller, Spatula, Single and Plural Airless spray Single layer • 1 layer up to requested DFT • No primer/tiecoat • Reduced costs and waste Safe • No solvents, no VOC’s • Flash point > 100°C 9

Humidur AF - application Cures under water • Immediate use • Minimal downtime Easy to repair • By brush in one layer under minimal surface prep • Unlimited overcoating in time 10

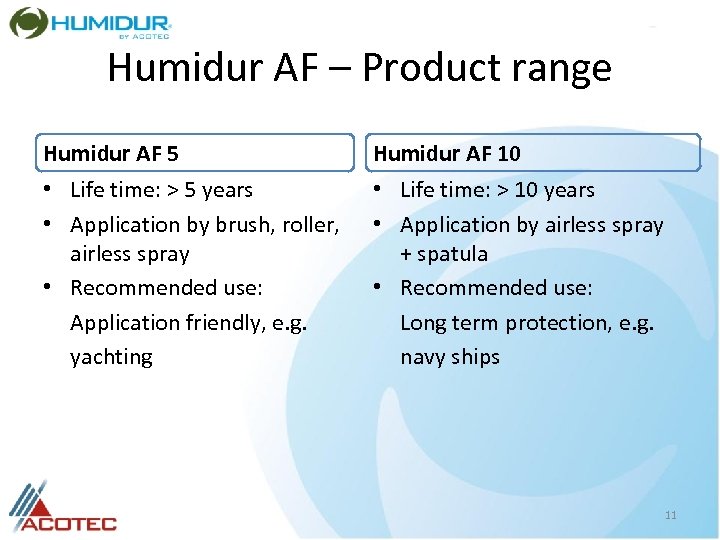

Humidur AF – Product range Humidur AF 5 Humidur AF 10 • Life time: > 5 years • Application by brush, roller, airless spray • Recommended use: Application friendly, e. g. yachting • Life time: > 10 years • Application by airless spray + spatula • Recommended use: Long term protection, e. g. navy ships 11

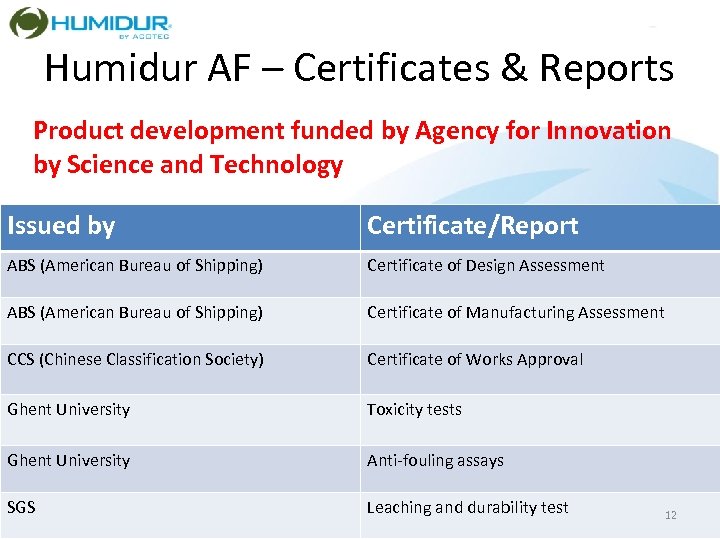

Humidur AF – Certificates & Reports Product development funded by Agency for Innovation by Science and Technology Issued by Certificate/Report ABS (American Bureau of Shipping) Certificate of Design Assessment ABS (American Bureau of Shipping) Certificate of Manufacturing Assessment CCS (Chinese Classification Society) Certificate of Works Approval Ghent University Toxicity tests Ghent University Anti-fouling assays SGS Leaching and durability test 12

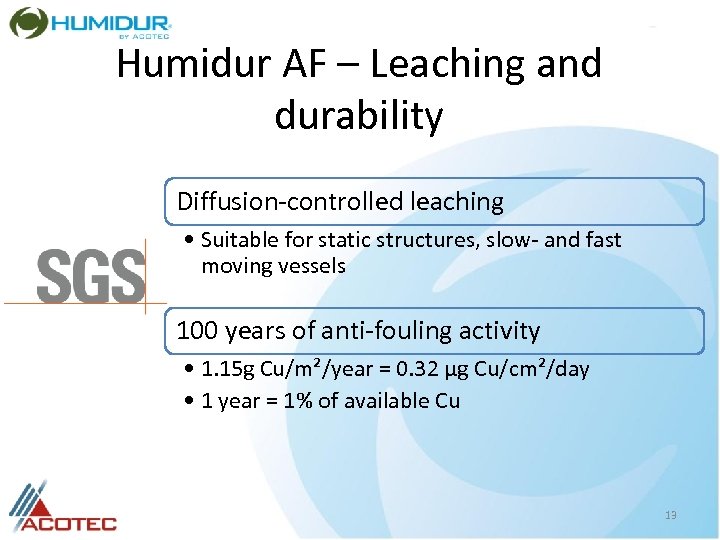

Humidur AF – Leaching and durability Diffusion-controlled leaching • Suitable for static structures, slow- and fast moving vessels 100 years of anti-fouling activity • 1. 15 g Cu/m²/year = 0. 32 µg Cu/cm²/day • 1 year = 1% of available Cu 13

Humidur AF – Lab results Ecological Solution • Toxicity tests in accordance with OECD guidelines • Humidur® is approved as an ecological solution. Humidur® is a product without solvents, VOC or other contaminants. The product is safe for animals, plants, etc. , and it is safe for usage in the environment. – Prof. Dr. Johan Mertens Anti-fouling assays • In fresh, brackish and seawater • GB/T 5370 Shallow sea immersion 14

Humidur AF - results 15

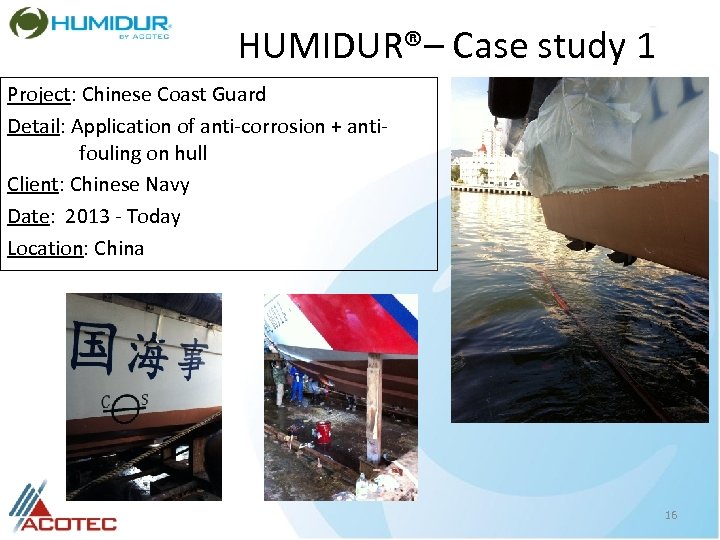

HUMIDUR®– Case study 1 Project: Chinese Coast Guard Detail: Application of anti-corrosion + antifouling on hull Client: Chinese Navy Date: 2013 - Today Location: China 16

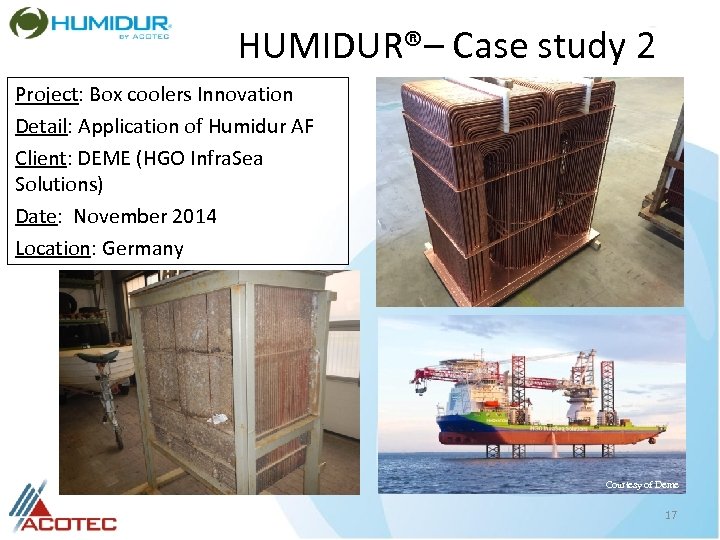

HUMIDUR®– Case study 2 Project: Box coolers Innovation Detail: Application of Humidur AF Client: DEME (HGO Infra. Sea Solutions) Date: November 2014 Location: Germany Courtesy of Deme 17

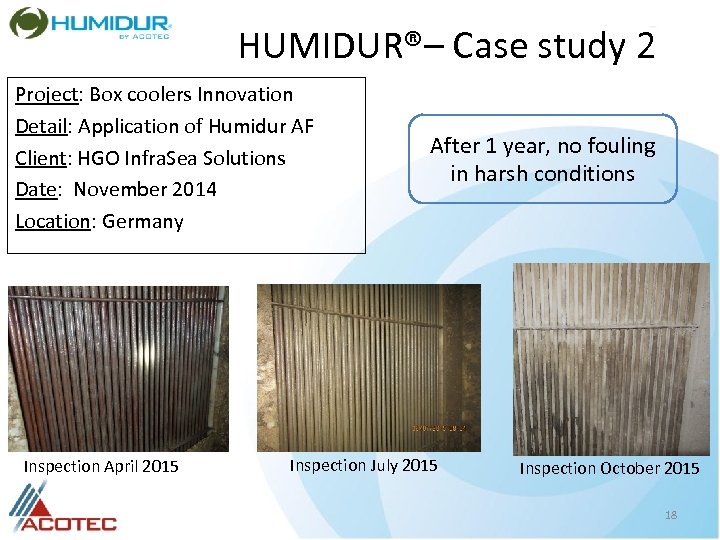

HUMIDUR®– Case study 2 Project: Box coolers Innovation Detail: Application of Humidur AF Client: HGO Infra. Sea Solutions Date: November 2014 Location: Germany Inspection April 2015 After 1 year, no fouling in harsh conditions Inspection July 2015 Inspection October 2015 18

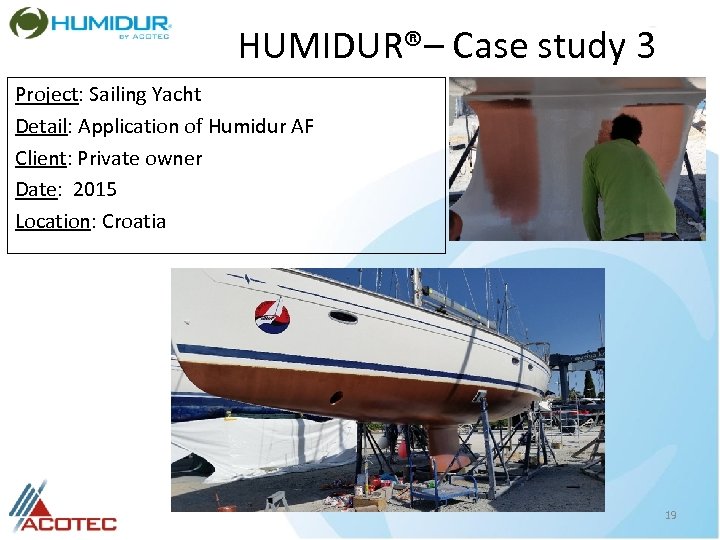

HUMIDUR®– Case study 3 Project: Sailing Yacht Detail: Application of Humidur AF Client: Private owner Date: 2015 Location: Croatia 19

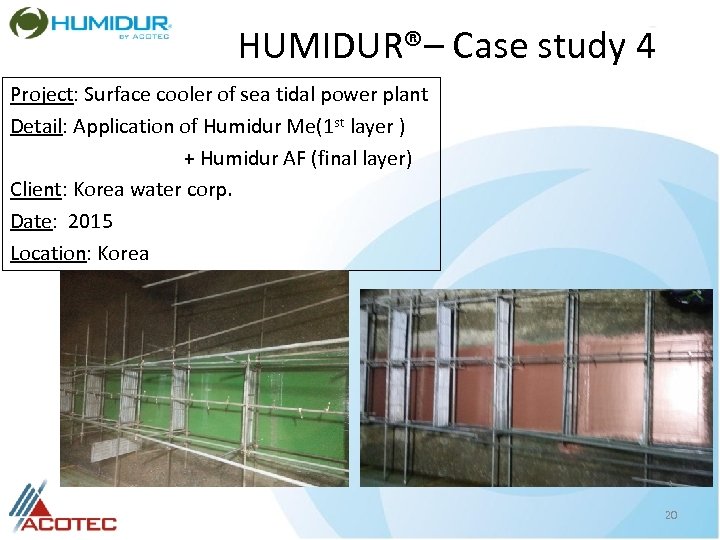

HUMIDUR®– Case study 4 Project: Surface cooler of sea tidal power plant Detail: Application of Humidur Me(1 st layer ) + Humidur AF (final layer) Client: Korea water corp. Date: 2015 Location: Korea 20

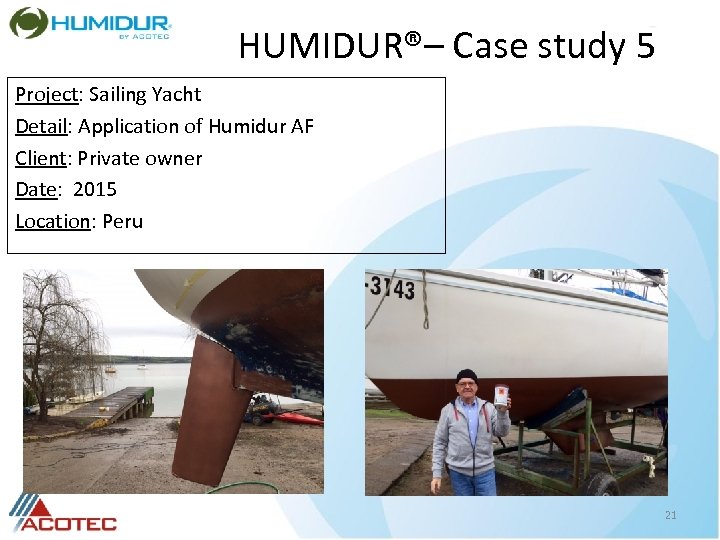

HUMIDUR®– Case study 5 Project: Sailing Yacht Detail: Application of Humidur AF Client: Private owner Date: 2015 Location: Peru 21

912bb52dbfb43fa39140f272204445b3.ppt