bdaad8b74acb4b61f2872cae2c905520.ppt

- Количество слайдов: 43

Presentation Joppe Burgers 29 May 2008 Busan, Korea Automated Container Terminals Will they ever catch up…? 1

Automated Container Terminals Will they ever catch up…? Contents of presentation Introduction Examples Case Study Introduction Conventional Terminals n Automated Terminals n n Conventional Terminals Examples Automated Terminals n Case study n Conclusion 2

Automated Container Terminals Will they ever catch up…? Introduction Conventional Terminals Automated Terminals Examples Case Study Three types of container terminals: n Conventional n Semi automated n Automated Conclusion 3

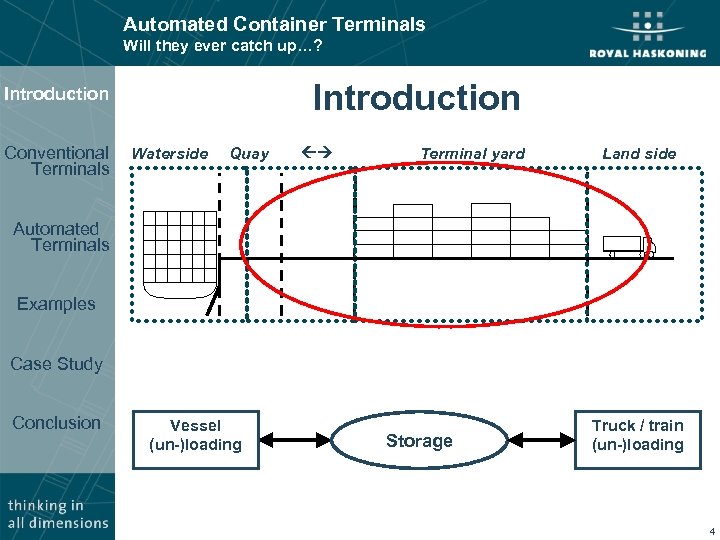

Automated Container Terminals Will they ever catch up…? Introduction Conventional Terminals Waterside Quay Terminal yard Land side Automated Terminals Examples Case Study Conclusion Vessel (un-)loading Storage Truck / train (un-)loading 4

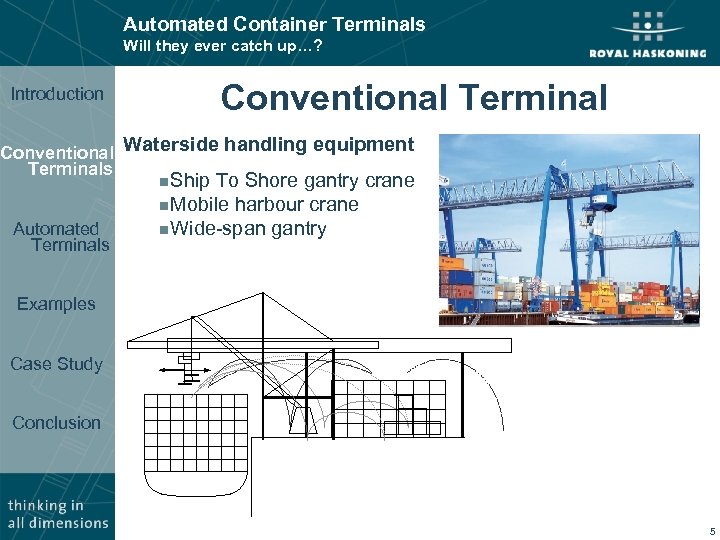

Automated Container Terminals Will they ever catch up…? Conventional Terminal Introduction Conventional Waterside handling equipment Terminals n. Ship Automated Terminals To Shore gantry crane n. Mobile harbour crane n. Wide-span gantry Examples Case Study Conclusion 5

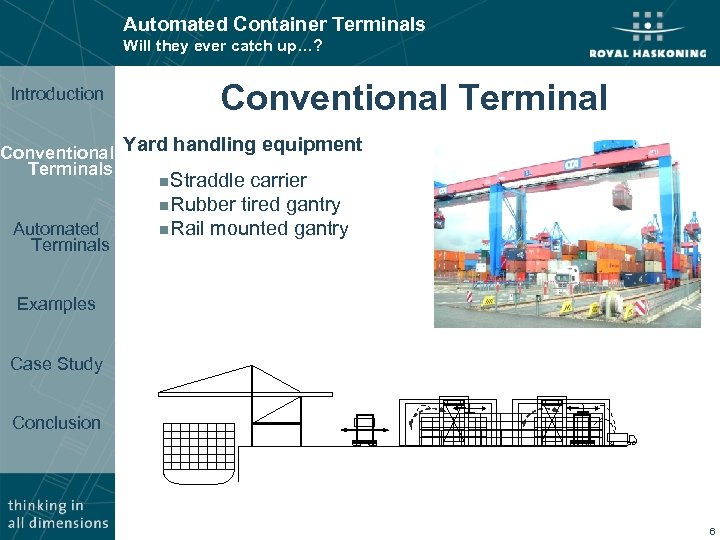

Automated Container Terminals Will they ever catch up…? Introduction Conventional Terminal Conventional Yard handling equipment Terminals n. Straddle Automated Terminals carrier n. Rubber tired gantry n. Rail mounted gantry Examples Case Study Conclusion 6

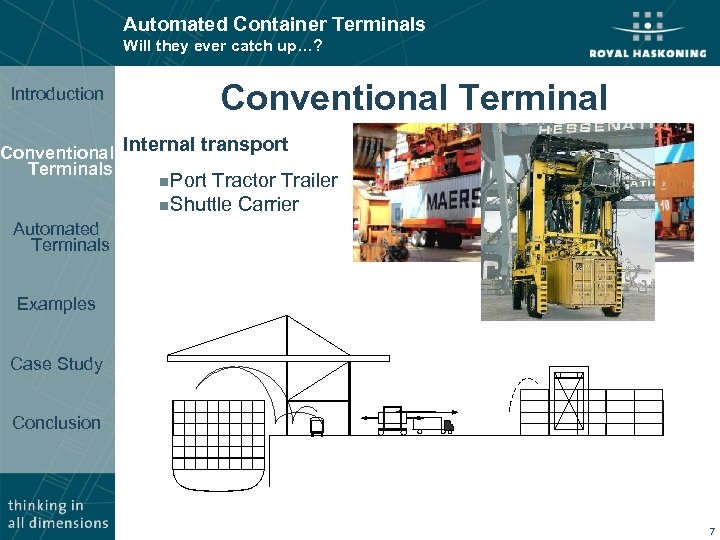

Automated Container Terminals Will they ever catch up…? Conventional Terminal Introduction Conventional Internal transport Terminals n. Port Tractor Trailer n. Shuttle Carrier Automated Terminals Examples Case Study Conclusion 7

Automated Container Terminals Will they ever catch up…? Automated Terminals Introduction Conventional Terminals Automated Terminals Conventional vs. Automated container terminal? n n n Examples n n Case Study Conclusion n n n Higher capital investment? Lower operational costs? Labour Costs? Technical skills? Predictable productivity? Experience? Increase reliability? Environmental issues? Energy prices? Regulations? Health & Safety? 8

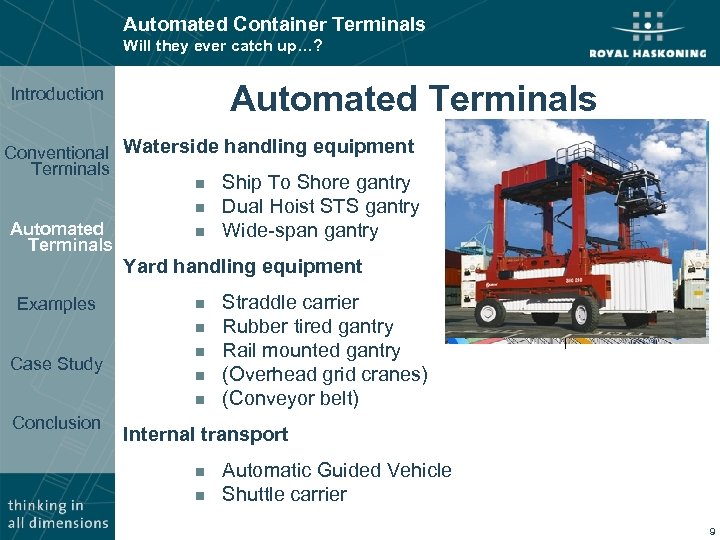

Automated Container Terminals Will they ever catch up…? Automated Terminals Introduction Conventional Waterside handling equipment Terminals n n Automated Terminals n Ship To Shore gantry Dual Hoist STS gantry Wide-span gantry Yard handling equipment Examples n n Case Study n n n Conclusion Straddle carrier Rubber tired gantry Rail mounted gantry (Overhead grid cranes) (Conveyor belt) Internal transport n n Automatic Guided Vehicle Shuttle carrier 9

Automated Container Terminals Will they ever catch up…? Introduction Conventional Terminals Automated Terminals Examples Case Study Conclusion Examples ECT Rotterdam n Single hoist Cranes, AGV’s and ASC’s Thamesport n ASC’s Hamburg CT Altenwerder n Double hoist Cranes, AGV’s and ASC’s Nagoya Port Terminal - Nagoya n Semi automated RTG Wan Hai lines - Tokyo n Semi automated RMG during day n Automated house keeping during night Euromax Rotterdam n Double hoist Cranes and ASC n Remote control desk EMC-Kaohsiung n Partly automated Taipei Container Port Terminal n Semi automated Busan New Port 2 -1 n Double hoist Cranes and ASC PNC 1 -2 n Double hoist Cranes and ASC Antwerp Gateway n Started with Straddles, transition to auto RMG 10

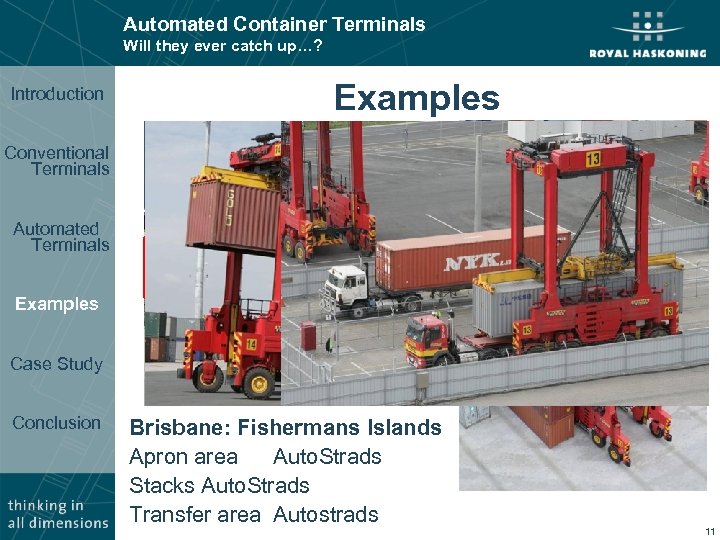

Automated Container Terminals Will they ever catch up…? Introduction Examples Conventional Terminals Automated Terminals Examples Case Study Conclusion Brisbane: Fishermans Islands Apron area Auto. Strads Stacks Auto. Strads Transfer area Autostrads 11

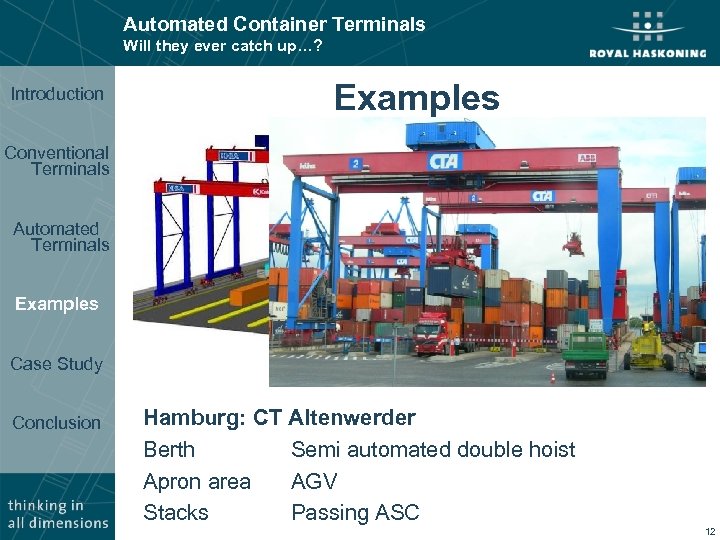

Automated Container Terminals Will they ever catch up…? Introduction Examples Conventional Terminals Automated Terminals Examples Case Study Conclusion Hamburg: CT Altenwerder Berth Semi automated double hoist Apron area AGV Stacks Passing ASC 12

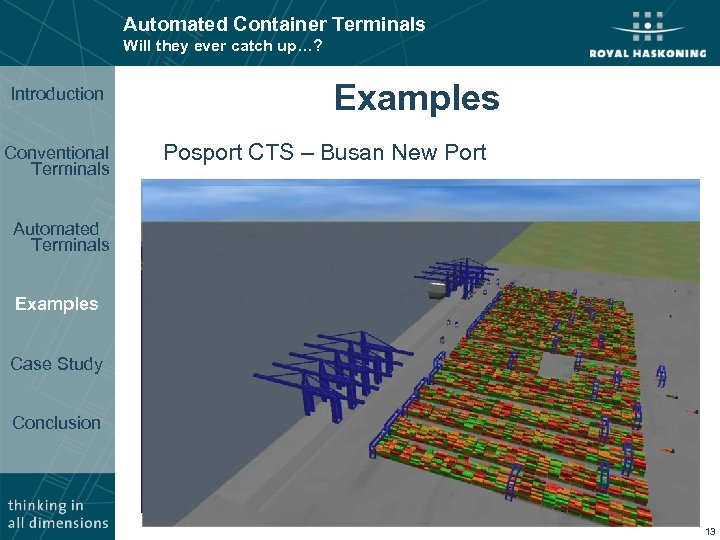

Automated Container Terminals Will they ever catch up…? Introduction Conventional Terminals Examples Posport CTS – Busan New Port Automated Terminals Examples Case Study Conclusion 13

Automated Container Terminals Will they ever catch up…? Case Study Introduction Conventional Terminals n MSc project Wieger Rademaker (TU Delft & Royal Haskoning) Automated Terminals n Is automation of container handling on small terminals feasible as a commercial investment? Examples n Hurdles n n n Case Study n n Conclusion n High investments Uncertain future development No development budget High technical level of personnel required Proven technology preferred Advantage n n Lower operating and labour costs High level of services 14

Automated Container Terminals Will they ever catch up…? Case Study Introduction Conventional Terminals Approach n Examples n Estimate of required investments n Automated Terminals Preliminary design of an automated container terminal Cash flow analysis n Comparison with conventional alternative Case Study Conclusion 15

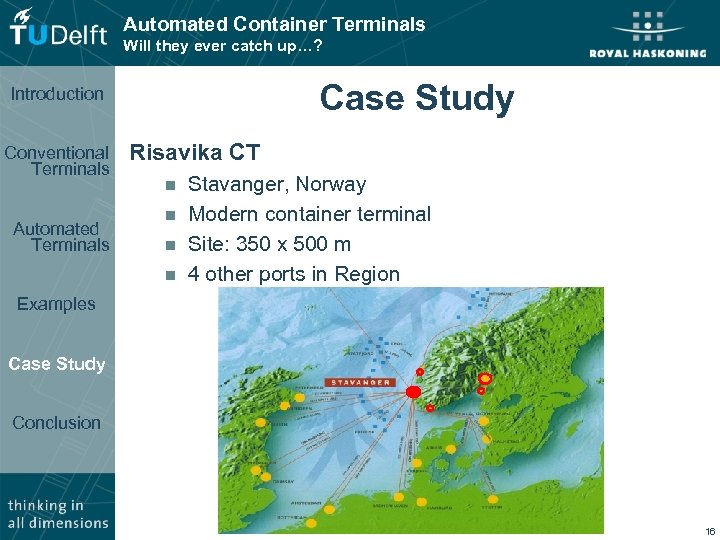

Automated Container Terminals Will they ever catch up…? Case Study Introduction Conventional Terminals Automated Terminals Risavika CT n n Stavanger, Norway Modern container terminal Site: 350 x 500 m 4 other ports in Region Examples Case Study Conclusion 16

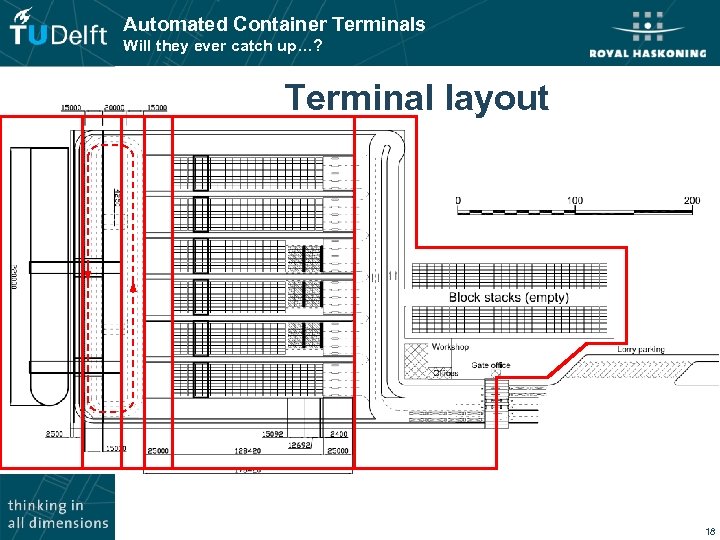

Automated Container Terminals Will they ever catch up…? Case Study Introduction Conventional Terminals Design conclusions (KPI’s and Posport CTS) n Automated Terminals n n 2 Quay cranes 6 AGVs per quay crane 6 RMGs Examples Case Study Conclusion 17

Automated Container Terminals Will they ever catch up…? Terminal layout 18

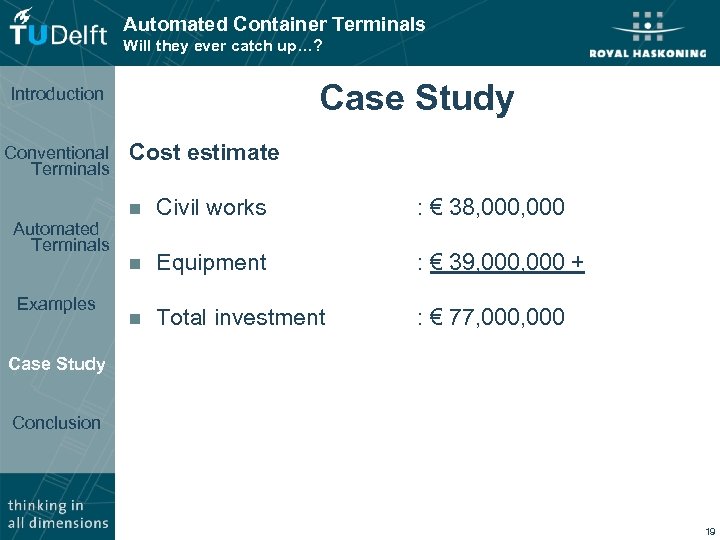

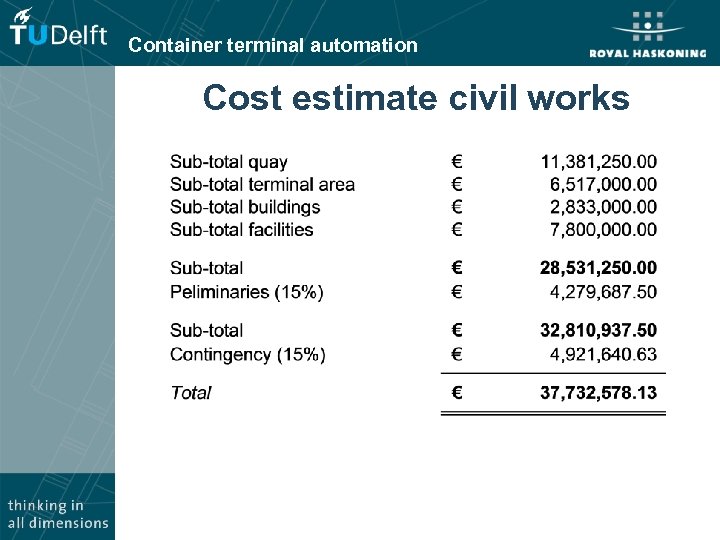

Automated Container Terminals Will they ever catch up…? Case Study Introduction Conventional Terminals Cost estimate Examples Civil works : € 38, 000 n Automated Terminals n Equipment : € 39, 000 + n Total investment : € 77, 000 Case Study Conclusion 19

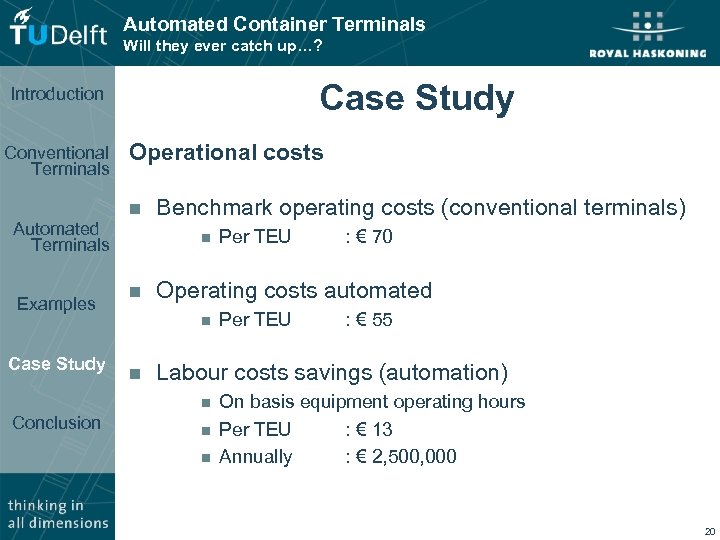

Automated Container Terminals Will they ever catch up…? Case Study Introduction Conventional Terminals Automated Terminals Examples Case Study Operational costs n Benchmark operating costs (conventional terminals) n n Per TEU : € 55 Labour costs savings (automation) n Conclusion : € 70 Operating costs automated n n Per TEU n n On basis equipment operating hours Per TEU : € 13 Annually : € 2, 500, 000 20

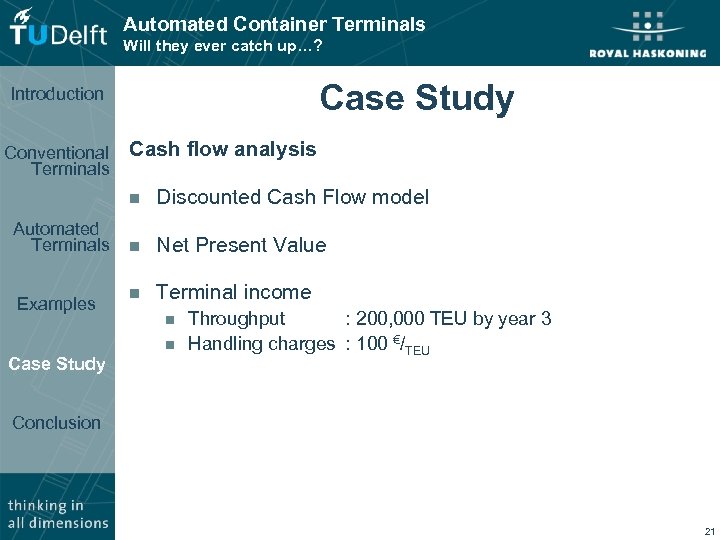

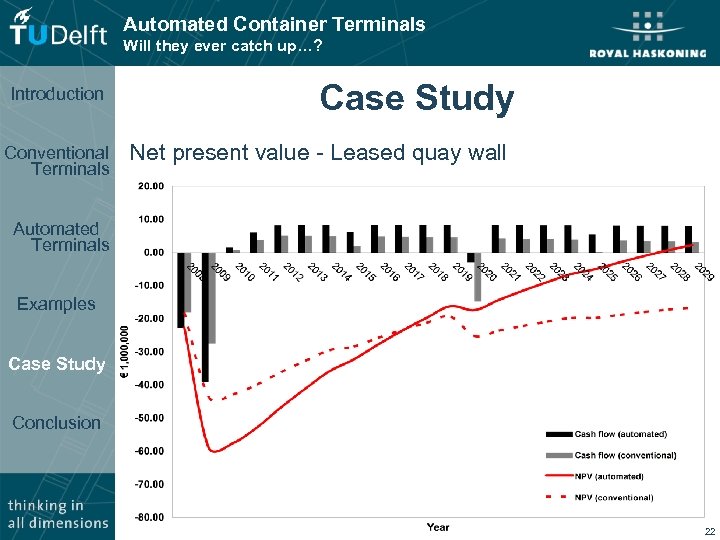

Automated Container Terminals Will they ever catch up…? Case Study Introduction Conventional Terminals Cash flow analysis n Automated Terminals Examples Discounted Cash Flow model n Net Present Value n Terminal income n n Case Study Throughput : 200, 000 TEU by year 3 Handling charges : 100 €/TEU Conclusion 21

Automated Container Terminals Will they ever catch up…? Introduction Conventional Terminals Case Study Net present value - Leased quay wall Automated Terminals Examples Case Study Conclusion 22

Automated Container Terminals Will they ever catch up…? Conclusions Introduction Conventional Terminals Is automation of container handling on small terminals feasible as a commercial investment? n Automated Terminals Terminal not feasible as a commercial investment due to n n n Size of initial capital outlay Investment risk from long investment period Public sector involvement is required! Examples However results show that Automation is catching up!!! Case Study Conclusion 23

Automated Container Terminals Will they ever catch up…? Introduction Questions? Conventional Terminals Automated Terminals Examples Case Study Conclusion 24

Container terminal automation Cost estimate civil works

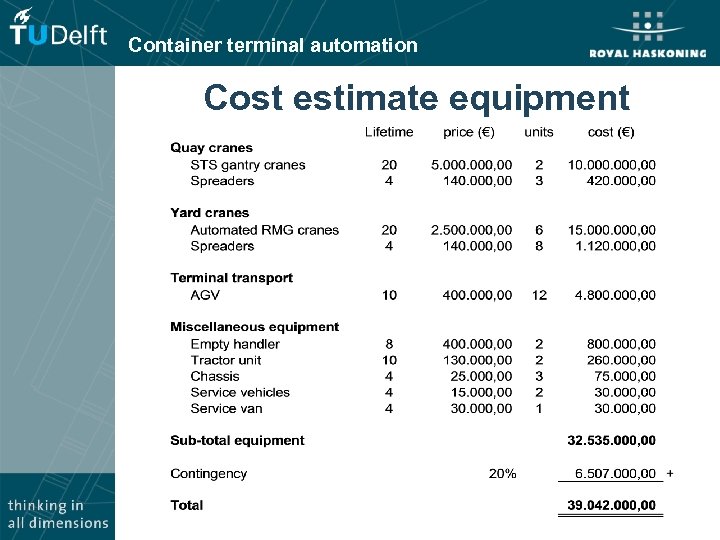

Container terminal automation Cost estimate equipment

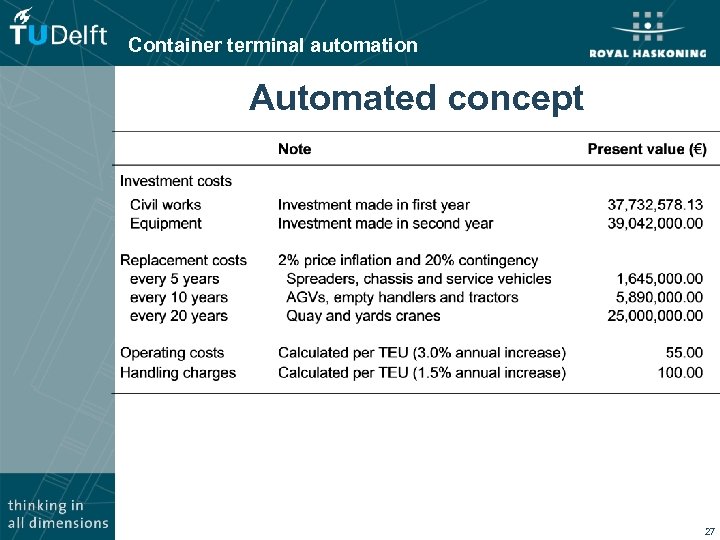

Container terminal automation Automated concept 27

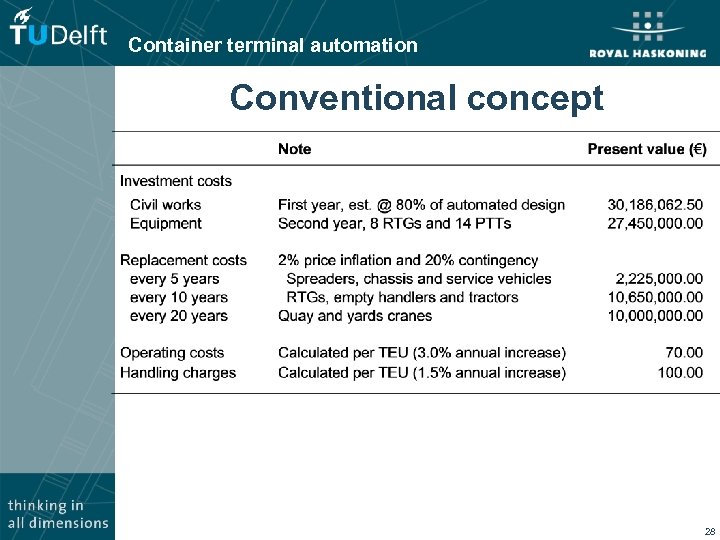

Container terminal automation Conventional concept 28

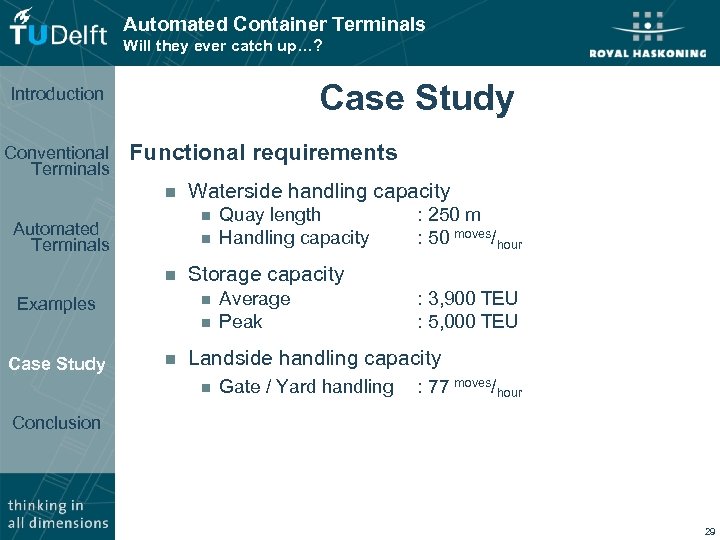

Automated Container Terminals Will they ever catch up…? Case Study Introduction Conventional Terminals Functional requirements n Waterside handling capacity n Automated Terminals n n n Case Study n : 250 m : 50 moves/hour Storage capacity n Examples Quay length Handling capacity Average Peak : 3, 900 TEU : 5, 000 TEU Landside handling capacity n Gate / Yard handling : 77 moves/hour Conclusion 29

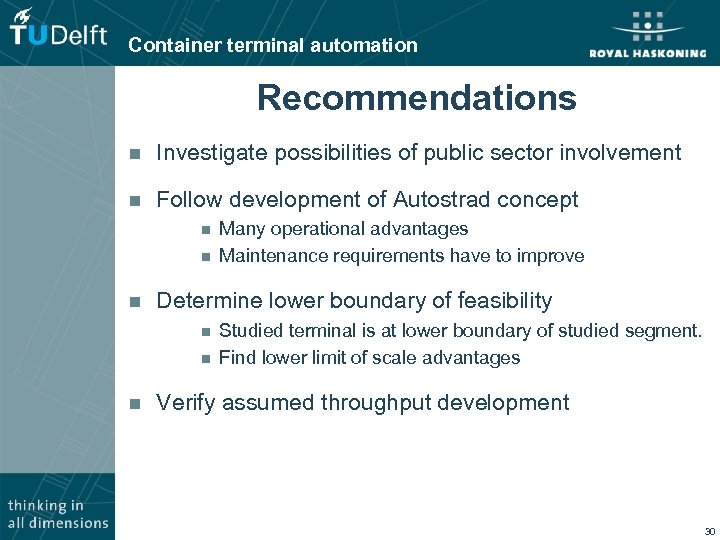

Container terminal automation Recommendations n Investigate possibilities of public sector involvement n Follow development of Autostrad concept n n n Determine lower boundary of feasibility n n n Many operational advantages Maintenance requirements have to improve Studied terminal is at lower boundary of studied segment. Find lower limit of scale advantages Verify assumed throughput development 30

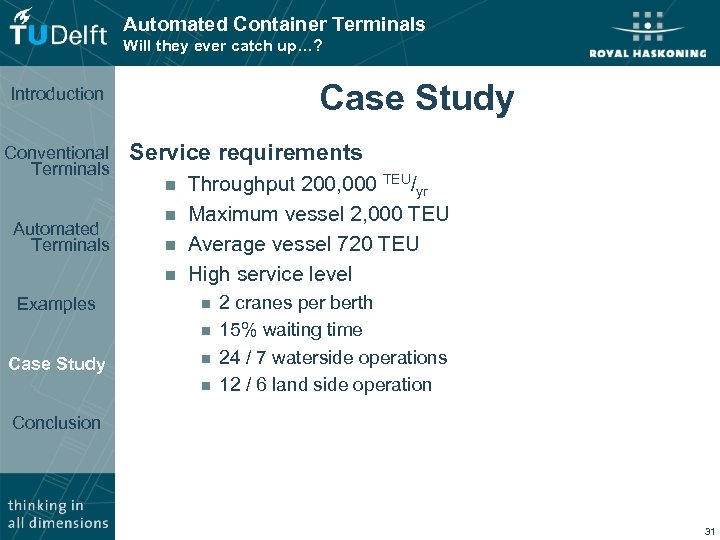

Automated Container Terminals Will they ever catch up…? Case Study Introduction Conventional Terminals Automated Terminals Service requirements n n Examples Throughput 200, 000 TEU/yr Maximum vessel 2, 000 TEU Average vessel 720 TEU High service level n n Case Study n n 2 cranes per berth 15% waiting time 24 / 7 waterside operations 12 / 6 land side operation Conclusion 31

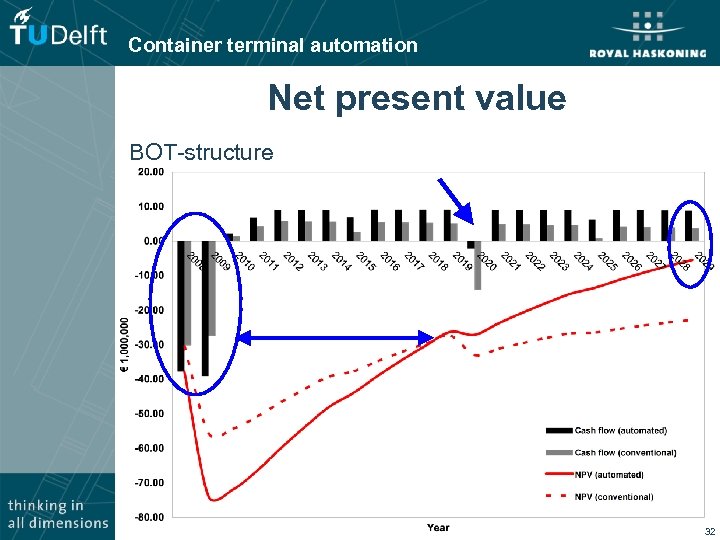

Container terminal automation Net present value BOT-structure 32

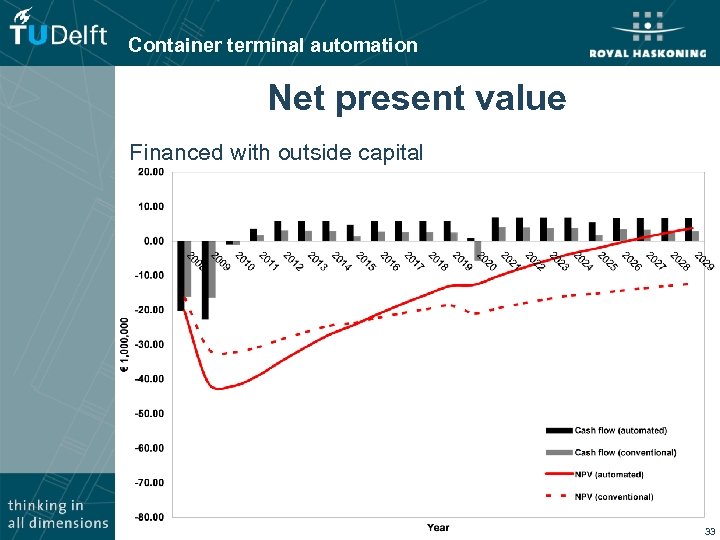

Container terminal automation Net present value Financed with outside capital 33

Container terminal automation Conclusions DCF analysis n Outside investments reduce payback period n n n Investment in terminal infrastructure Outside financing BOT-structure will not achieve 8% return in 20 years 34

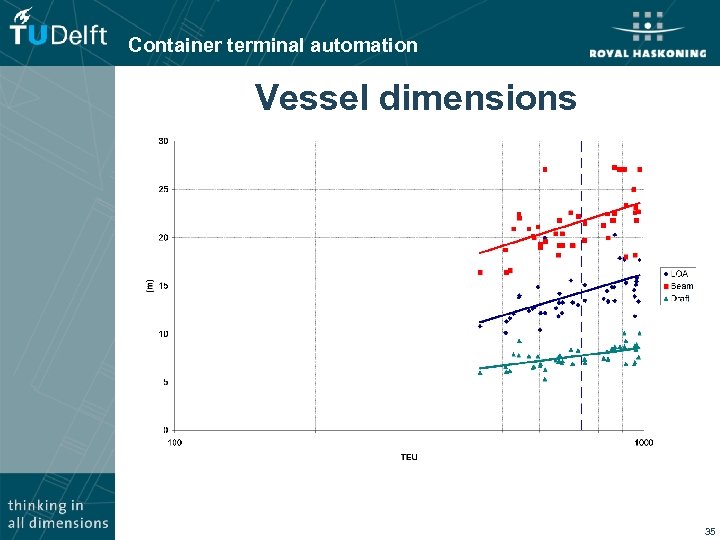

Container terminal automation Vessel dimensions 35

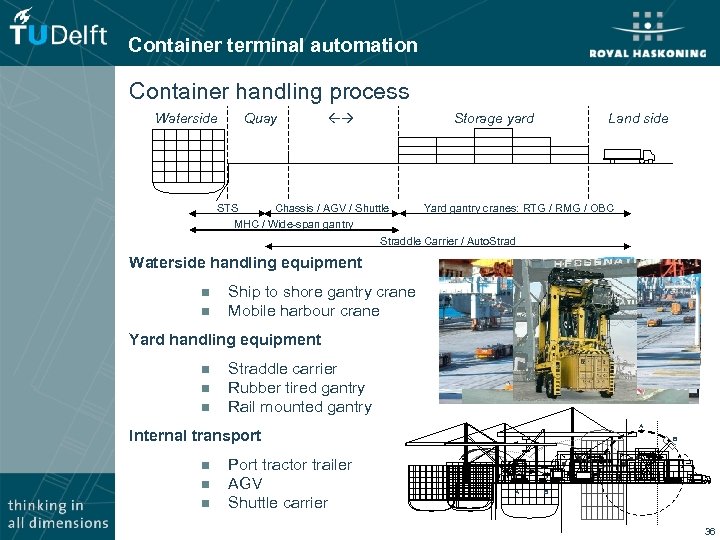

Container terminal automation Container handling process Waterside Quay Storage yard STS Chassis / AGV / Shuttle MHC / Wide-span gantry Land side Yard gantry cranes: RTG / RMG / OBC Straddle Carrier / Auto. Strad Waterside handling equipment n n Ship to shore gantry crane Mobile harbour crane Yard handling equipment n n n Straddle carrier Rubber tired gantry Rail mounted gantry A Internal transport n n n Port tractor trailer AGV Shuttle carrier B A B 36

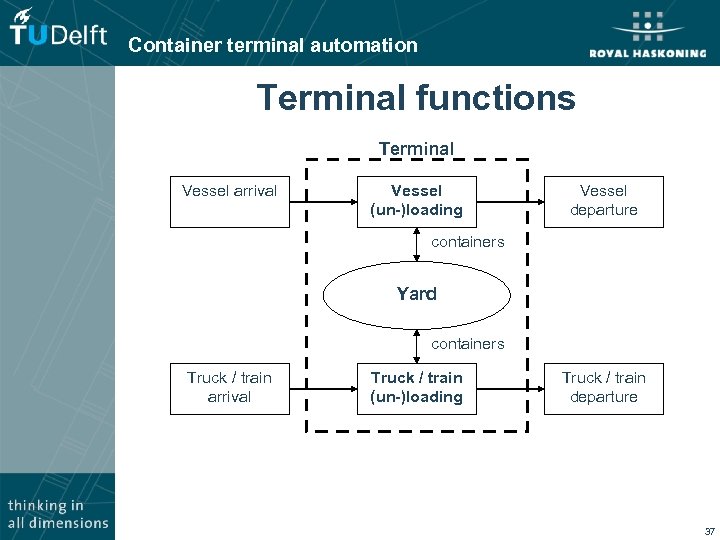

Container terminal automation Terminal functions Terminal Vessel arrival Vessel (un-)loading Vessel departure containers Yard containers Truck / train arrival Truck / train (un-)loading Truck / train departure 37

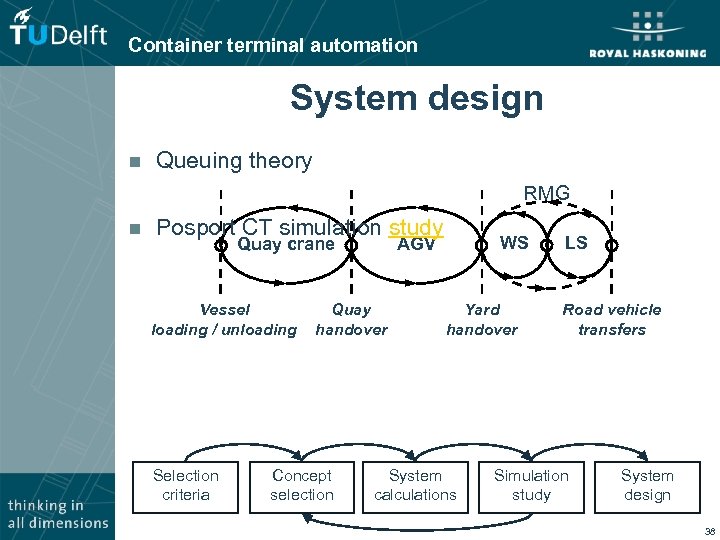

Container terminal automation System design n Queuing theory RMG n Posport CT simulation study Quay crane Vessel loading / unloading Selection criteria Quay handover Concept selection WS AGV Yard handover System calculations LS Road vehicle transfers Simulation study System design 38

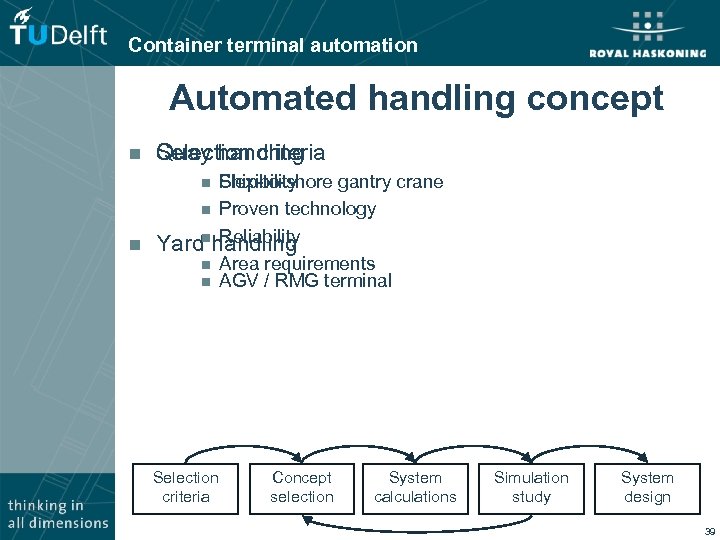

Container terminal automation Automated handling concept n Selection criteria Quay handling Flexibility Ship-to-shore gantry crane n Proven technology n Reliability n Yard handling n Area requirements n AGV / RMG terminal n Selection criteria Concept selection System calculations Simulation study System design 39

Container terminal automation Research question n How can automated container handling be implemented on small terminals with “off-the-shelf” technology? 40

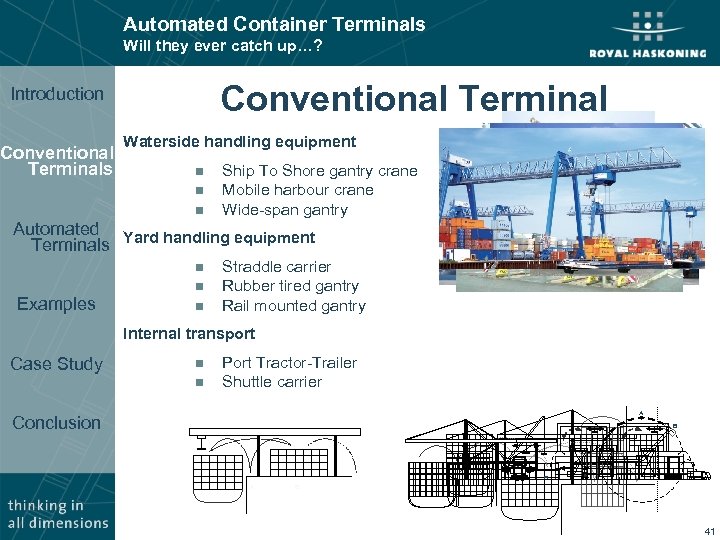

Automated Container Terminals Will they ever catch up…? Conventional Terminal Introduction Conventional Terminals Waterside handling equipment n n n Ship To Shore gantry crane Mobile harbour crane Wide-span gantry Automated Yard handling equipment Terminals n n Examples n Straddle carrier Rubber tired gantry Rail mounted gantry Internal transport Case Study n n Port Tractor-Trailer Shuttle carrier A Conclusion B A A B B 41

Automated Container Terminals Will they ever catch up…? Automated Terminals Introduction Conventional Terminals Automated Terminals Aids to increase human (in)efficiency n n n Examples n n Case Study n Anti Collision System, Anti Sway Stack positioning aids, Efficiency improvement, Automatic number recognition, Etcetera Conclusion 42

Automated Container Terminals Will they ever catch up…? Automated Terminals Introduction Conventional Terminals Automated Terminals Eliminate dependency on human intervention n Examples n n Case Study n (Semi-) Automated STS Cranes Automatic Guided Vehicles Auto Strads/ Shuttle Carriers Auto RMG/ RTG Conveyor belt system Etcetera Conclusion 43

bdaad8b74acb4b61f2872cae2c905520.ppt