a870fd0a58d26a21c5103ba5ee047170.ppt

- Количество слайдов: 21

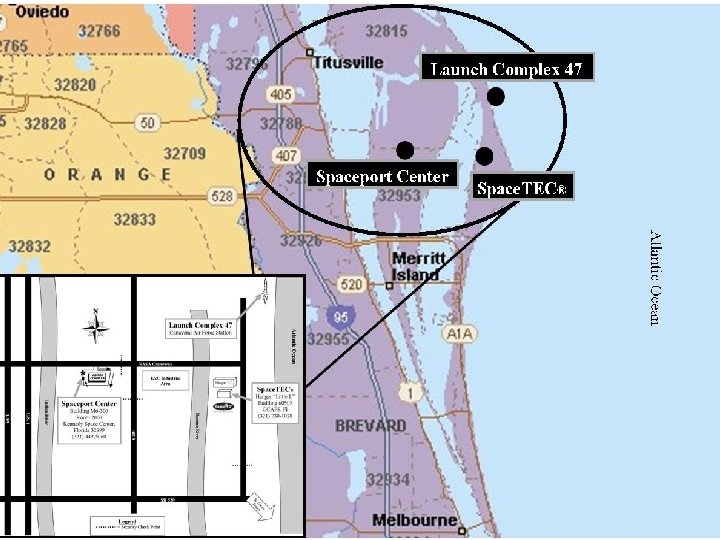

Preparing Technicians for the Commercial Space Industry Briefing to the COMSTAC RLV Working Group May 2006 Dr. Al Koller, Space. TEC® Executive Director Frank Margiotta, Space. TEC® Program Manager

Opportunities and Challenges n The future will be different for many reasons. n Interest/support for RLVs is growing • Zero-G, Bigelow, X-Cor, Space. X, x. Prize Cup • NASA in transition: CEV, CLV, COTS • Large “Space Lift” future uncertain: ULA, Constellation n Technologies emerging in related industries • Composites -- Boeing 787 “Dreamliner” • Non-traditional Systems – Rocket Racing League, Space. Ship. One • GPS, VMS for Space-based Tracking

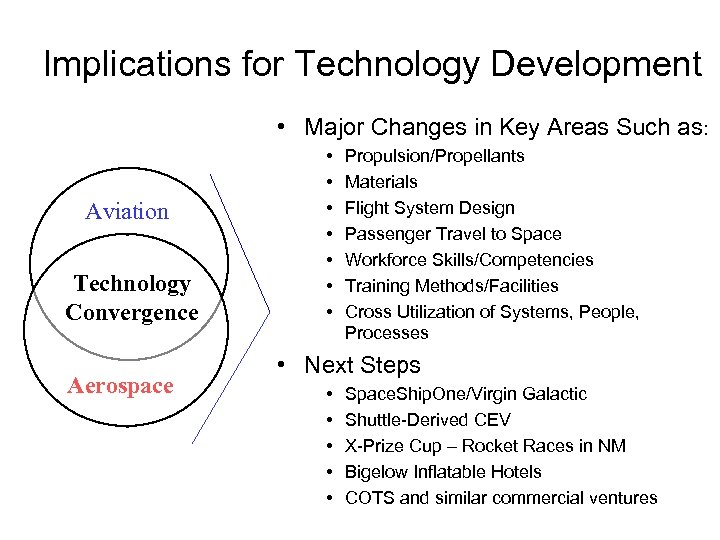

Implications for Technology Development • Major Changes in Key Areas Such as: Aviation Technology Convergence Aerospace • • Propulsion/Propellants Materials Flight System Design Passenger Travel to Space Workforce Skills/Competencies Training Methods/Facilities Cross Utilization of Systems, People, Processes • Next Steps • • • Space. Ship. One/Virgin Galactic Shuttle-Derived CEV X-Prize Cup – Rocket Races in NM Bigelow Inflatable Hotels COTS and similar commercial ventures

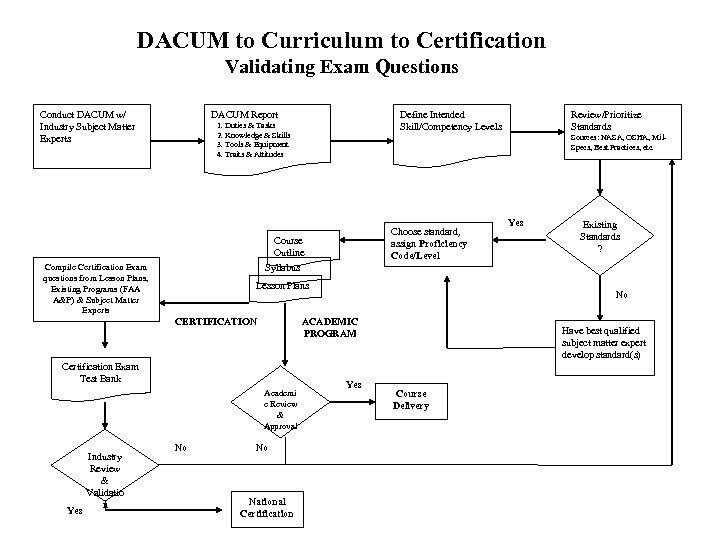

DACUM to Curriculum to Certification Validating Exam Questions Conduct DACUM w/ Industry Subject Matter Experts 1. Duties & Tasks 2. Knowledge & Skills 3. Tools & Equipment 4. Traits & Attitudes Academi c Review & Approval No No National Certification Yes Existing Standards ? No ACADEMIC PROGRAM Certification Exam Test Bank Yes Choose standard, assign Proficiency Code/Level Lesson Plans CERTIFICATION Review/Prioritize Standards Sources: NASA, OSHA, Mil. Specs, Best Practices, etc. Course Outline Syllabus Compile Certification Exam questions from Lesson Plans, Existing Programs (FAA A&P) & Subject Matter Experts Industry Review & Validatio n Define Intended Skill/Competency Levels DACUM Report Yes Have best qualified subject matter expert develop standard(s) Course Delivery

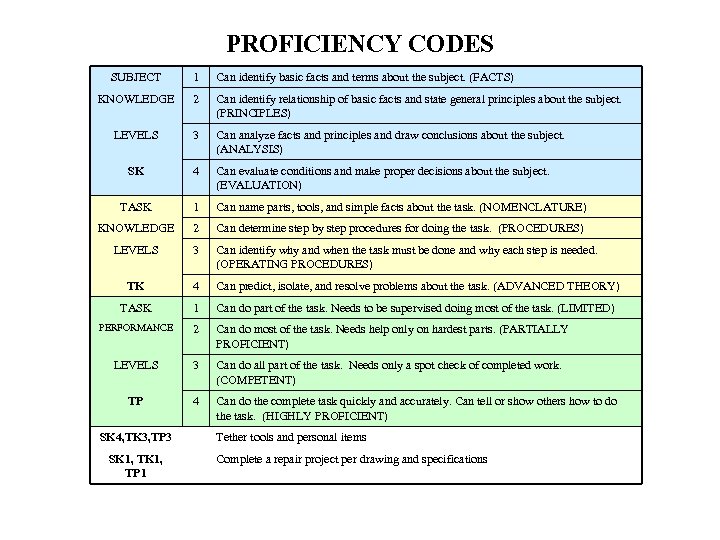

PROFICIENCY CODES SUBJECT 1 Can identify basic facts and terms about the subject. (FACTS) KNOWLEDGE 2 Can identify relationship of basic facts and state general principles about the subject. (PRINCIPLES) LEVELS 3 Can analyze facts and principles and draw conclusions about the subject. (ANALYSIS) SK 4 Can evaluate conditions and make proper decisions about the subject. (EVALUATION) TASK 1 Can name parts, tools, and simple facts about the task. (NOMENCLATURE) KNOWLEDGE 2 Can determine step by step procedures for doing the task. (PROCEDURES) LEVELS 3 Can identify why and when the task must be done and why each step is needed. (OPERATING PROCEDURES) TK 4 Can predict, isolate, and resolve problems about the task. (ADVANCED THEORY) TASK 1 Can do part of the task. Needs to be supervised doing most of the task. (LIMITED) PERFORMANCE 2 Can do most of the task. Needs help only on hardest parts. (PARTIALLY PROFICIENT) LEVELS 3 Can do all part of the task. Needs only a spot check of completed work. (COMPETENT) TP 4 Can do the complete task quickly and accurately. Can tell or show others how to do the task. (HIGHLY PROFICIENT) SK 4, TK 3, TP 3 SK 1, TP 1 Tether tools and personal items Complete a repair project per drawing and specifications

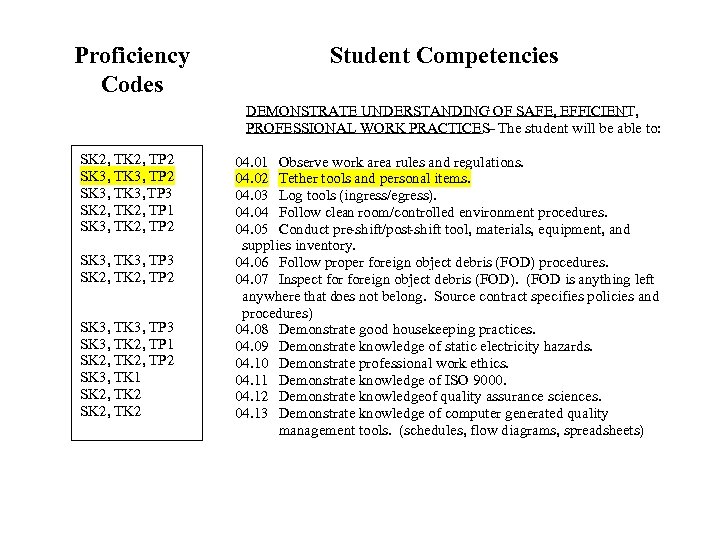

Proficiency Codes Student Competencies DEMONSTRATE UNDERSTANDING OF SAFE, EFFICIENT, PROFESSIONAL WORK PRACTICES– The student will be able to: SK 2, TP 2 SK 3, TK 3, TP 3 SK 2, TP 1 SK 3, TK 2, TP 2 SK 3, TP 3 SK 3, TK 2, TP 1 SK 2, TP 2 SK 3, TK 1 SK 2, TK 2 04. 01 Observe work area rules and regulations. 04. 02 Tether tools and personal items. 04. 03 Log tools (ingress/egress). 04 Follow clean room/controlled environment procedures. 04. 05 Conduct pre-shift/post-shift tool, materials, equipment, and supplies inventory. 04. 06 Follow proper foreign object debris (FOD) procedures. 04. 07 Inspect foreign object debris (FOD). (FOD is anything left anywhere that does not belong. Source contract specifies policies and procedures) 04. 08 Demonstrate good housekeeping practices. 04. 09 Demonstrate knowledge of static electricity hazards. 04. 10 Demonstrate professional work ethics. 04. 11 Demonstrate knowledge of ISO 9000. 04. 12 Demonstrate knowledgeof quality assurance sciences. 04. 13 Demonstrate knowledge of computer generated quality management tools. (schedules, flow diagrams, spreadsheets)

CERTIFIED AEROSPACE TECHNICIAN

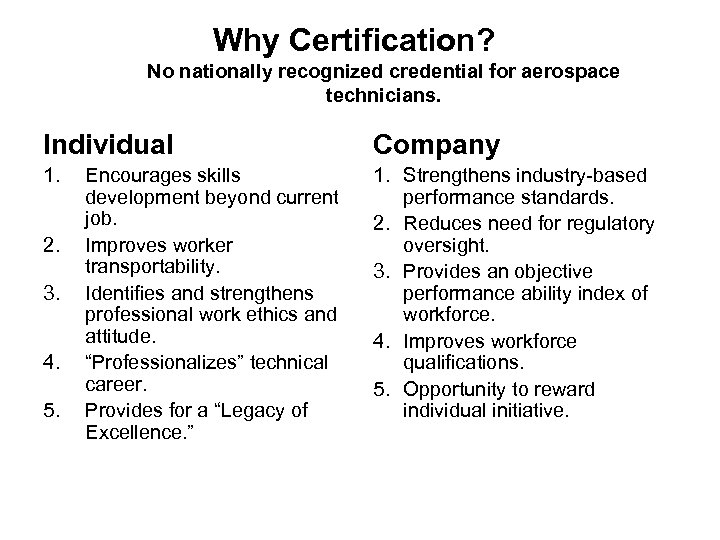

Why Certification? No nationally recognized credential for aerospace technicians. Individual Company 1. Strengthens industry-based performance standards. 2. Reduces need for regulatory oversight. 3. Provides an objective performance ability index of workforce. 4. Improves workforce qualifications. 5. Opportunity to reward individual initiative. 2. 3. 4. 5. Encourages skills development beyond current job. Improves worker transportability. Identifies and strengthens professional work ethics and attitude. “Professionalizes” technical career. Provides for a “Legacy of Excellence. ”

Exam Infrastructure • • • National Scope – (Baseline 5 States) Secure Internet-Based Testing -- Anytime, Anywhere Trained/Certified Space. TEC Examiners (STEs) Standardized Performance-Based Test Kits (Audited) Procedures, Checklists & Manuals for Proctors & Examiners • Self-Sustaining Fee-Based Cost Recovery

Certification Format (3 -part Exam) • Core – – – Introduction to Workplace Safety Applied Mechanics Basic Electricity Materials & Processes Tests & Measurements • Written (Computer-based) • Oral • Practical (Hands-On)

17 Trained STEs in 5 states

Endorsements Industry/Government/Workforce

Current & Future Initiatives • Core Exam Modified – Certification Readiness Courses – Credit/Non-Credit • Developing Concentrations – Vehicle Processing – Manufacturing – Troubleshooting – Composites • National Implementation – Industry/DOD/Labor – Credit for Experience – Skills Assessments

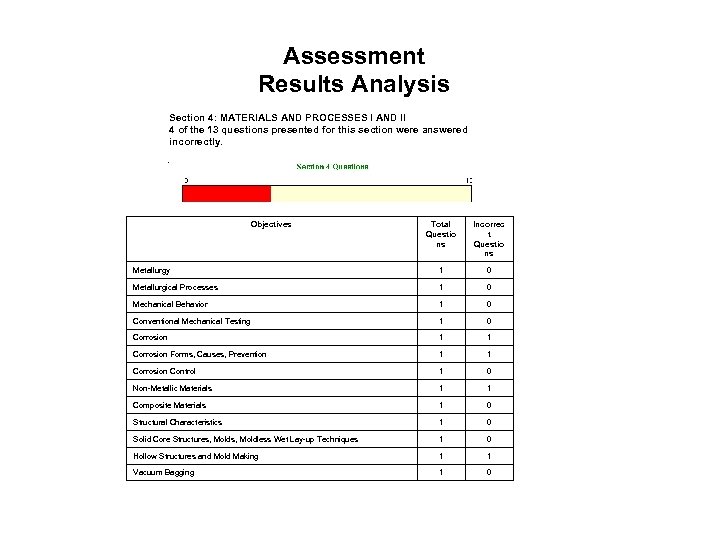

Assessment Results Analysis Section 4: MATERIALS AND PROCESSES I AND II 4 of the 13 questions presented for this section were answered incorrectly. Objectives Total Questio ns Incorrec t Questio ns Metallurgy 1 0 Metallurgical Processes 1 0 Mechanical Behavior 1 0 Conventional Mechanical Testing 1 0 Corrosion 1 1 Corrosion Forms, Causes, Prevention 1 1 Corrosion Control 1 0 Non-Metallic Materials 1 1 Composite Materials 1 0 Structural Characteristics 1 0 Solid Core Structures, Moldless Wet Lay-up Techniques 1 0 Hollow Structures and Mold Making 1 1 Vacuum Bagging 1 0

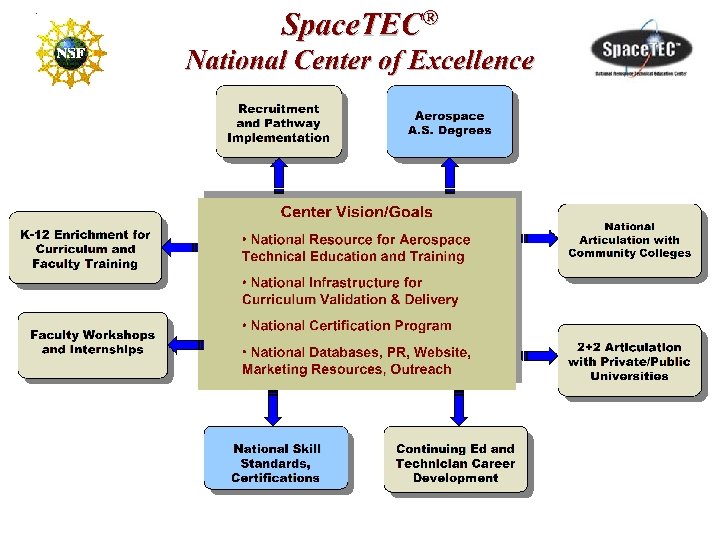

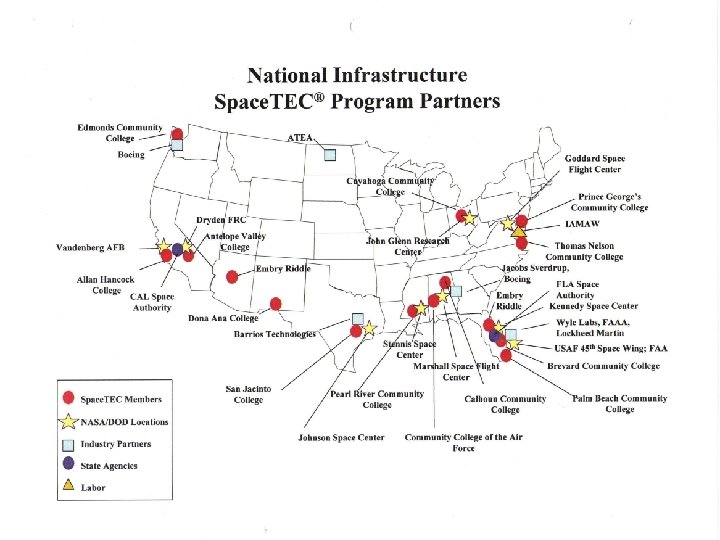

Partnership For Action n NSF Center of Excellence for Aerospace • Focus on technician credentialing • Early successes provide lessons in motivation • Initial work at NASA/Do. D sites n Opportunity to Support RLV Operators • Lessons learned; pathfinder approaches • Early preparation for inevitable comparisons • Opportunity to manage change in favor of RLV needs

a870fd0a58d26a21c5103ba5ee047170.ppt