42751d2559d486d4147ad61b7de0e02c.ppt

- Количество слайдов: 25

Preliminary Design of the e. XTP Satellite Institute of Spacecraft System Engineering , CAST Hong Bin Mar 22 th , 2017 , Beijing

Preliminary Design of the e. XTP Satellite Institute of Spacecraft System Engineering , CAST Hong Bin Mar 22 th , 2017 , Beijing

Outlines 1. General Description 2. Design Evolution 3. Basic Parameters 4. Preliminary Design 5. Programme Schedule 6. Problems 7. Conclusions

Outlines 1. General Description 2. Design Evolution 3. Basic Parameters 4. Preliminary Design 5. Programme Schedule 6. Problems 7. Conclusions

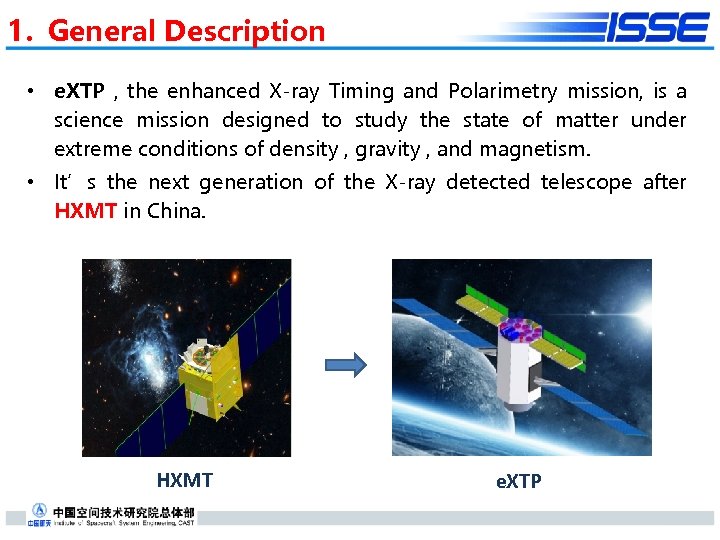

1. General Description • e. XTP , the enhanced X-ray Timing and Polarimetry mission, is a science mission designed to study the state of matter under extreme conditions of density , gravity , and magnetism. • It’s the next generation of the X-ray detected telescope after HXMT in China. HXMT e. XTP

1. General Description • e. XTP , the enhanced X-ray Timing and Polarimetry mission, is a science mission designed to study the state of matter under extreme conditions of density , gravity , and magnetism. • It’s the next generation of the X-ray detected telescope after HXMT in China. HXMT e. XTP

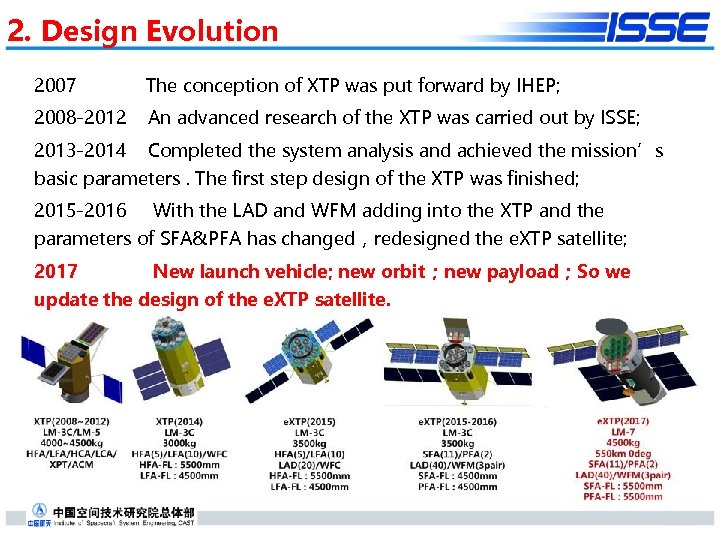

2. Design Evolution 2007 The conception of XTP was put forward by IHEP; 2008 -2012 An advanced research of the XTP was carried out by ISSE; 2013 -2014 Completed the system analysis and achieved the mission’s basic parameters. The first step design of the XTP was finished; 2015 -2016 With the LAD and WFM adding into the XTP and the parameters of SFA&PFA has changed,redesigned the e. XTP satellite; 2017 New launch vehicle; new orbit;new payload;So we update the design of the e. XTP satellite.

2. Design Evolution 2007 The conception of XTP was put forward by IHEP; 2008 -2012 An advanced research of the XTP was carried out by ISSE; 2013 -2014 Completed the system analysis and achieved the mission’s basic parameters. The first step design of the XTP was finished; 2015 -2016 With the LAD and WFM adding into the XTP and the parameters of SFA&PFA has changed,redesigned the e. XTP satellite; 2017 New launch vehicle; new orbit;new payload;So we update the design of the e. XTP satellite.

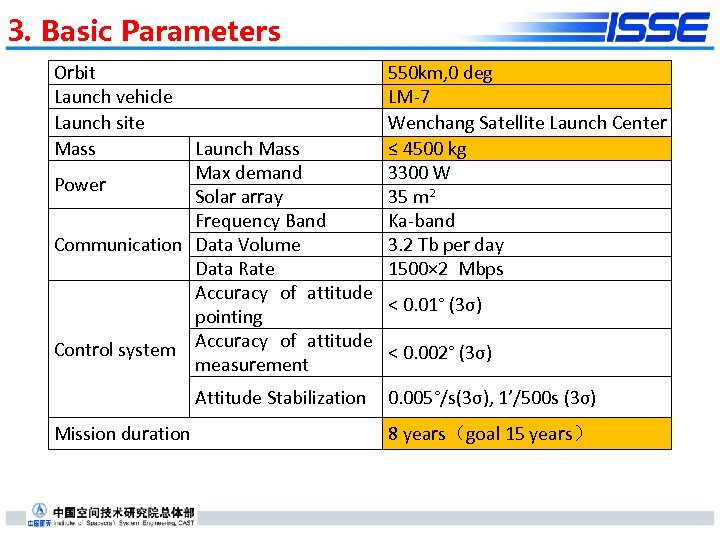

3. Basic Parameters Orbit Launch vehicle Launch site Mass 550 km, 0 deg LM-7 Wenchang Satellite Launch Center ≤ 4500 kg 3300 W 35 m 2 Ka-band 3. 2 Tb per day 1500× 2 Mbps Launch Mass Max demand Power Solar array Frequency Band Communication Data Volume Data Rate Accuracy of attitude < 0. 01° (3σ) pointing Control system Accuracy of attitude < 0. 002° (3σ) measurement Attitude Stabilization Mission duration 0. 005°/s(3σ), 1’/500 s (3σ) 8 years(goal 15 years)

3. Basic Parameters Orbit Launch vehicle Launch site Mass 550 km, 0 deg LM-7 Wenchang Satellite Launch Center ≤ 4500 kg 3300 W 35 m 2 Ka-band 3. 2 Tb per day 1500× 2 Mbps Launch Mass Max demand Power Solar array Frequency Band Communication Data Volume Data Rate Accuracy of attitude < 0. 01° (3σ) pointing Control system Accuracy of attitude < 0. 002° (3σ) measurement Attitude Stabilization Mission duration 0. 005°/s(3σ), 1’/500 s (3σ) 8 years(goal 15 years)

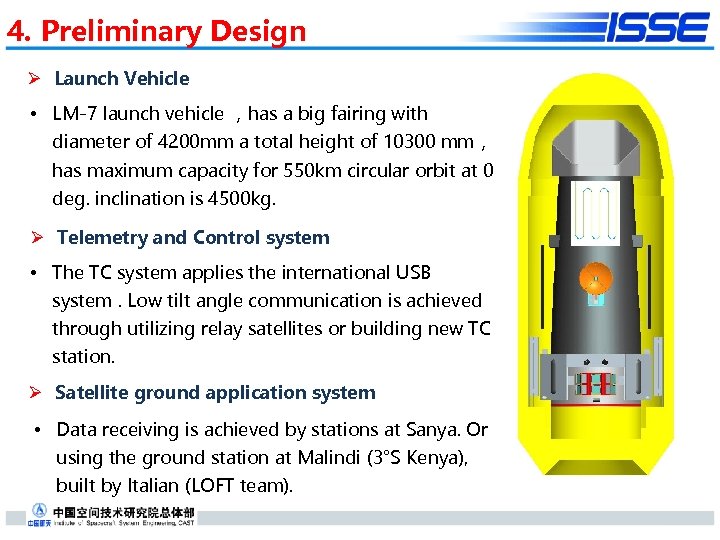

4. Preliminary Design Ø Launch Vehicle • LM-7 launch vehicle ,has a big fairing with diameter of 4200 mm a total height of 10300 mm, has maximum capacity for 550 km circular orbit at 0 deg. inclination is 4500 kg. Ø Telemetry and Control system • The TC system applies the international USB system. Low tilt angle communication is achieved through utilizing relay satellites or building new TC station. Ø Satellite ground application system • Data receiving is achieved by stations at Sanya. Or using the ground station at Malindi (3°S Kenya), built by Italian (LOFT team).

4. Preliminary Design Ø Launch Vehicle • LM-7 launch vehicle ,has a big fairing with diameter of 4200 mm a total height of 10300 mm, has maximum capacity for 550 km circular orbit at 0 deg. inclination is 4500 kg. Ø Telemetry and Control system • The TC system applies the international USB system. Low tilt angle communication is achieved through utilizing relay satellites or building new TC station. Ø Satellite ground application system • Data receiving is achieved by stations at Sanya. Or using the ground station at Malindi (3°S Kenya), built by Italian (LOFT team).

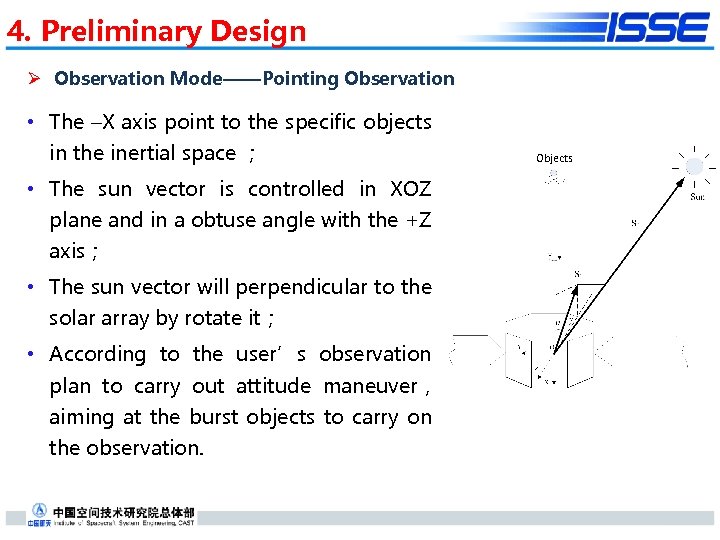

4. Preliminary Design Ø Observation Mode——Pointing Observation • The –X axis point to the specific objects in the inertial space ; • The sun vector is controlled in XOZ plane and in a obtuse angle with the +Z axis; • The sun vector will perpendicular to the solar array by rotate it; • According to the user’s observation plan to carry out attitude maneuver, aiming at the burst objects to carry on the observation. Objects

4. Preliminary Design Ø Observation Mode——Pointing Observation • The –X axis point to the specific objects in the inertial space ; • The sun vector is controlled in XOZ plane and in a obtuse angle with the +Z axis; • The sun vector will perpendicular to the solar array by rotate it; • According to the user’s observation plan to carry out attitude maneuver, aiming at the burst objects to carry on the observation. Objects

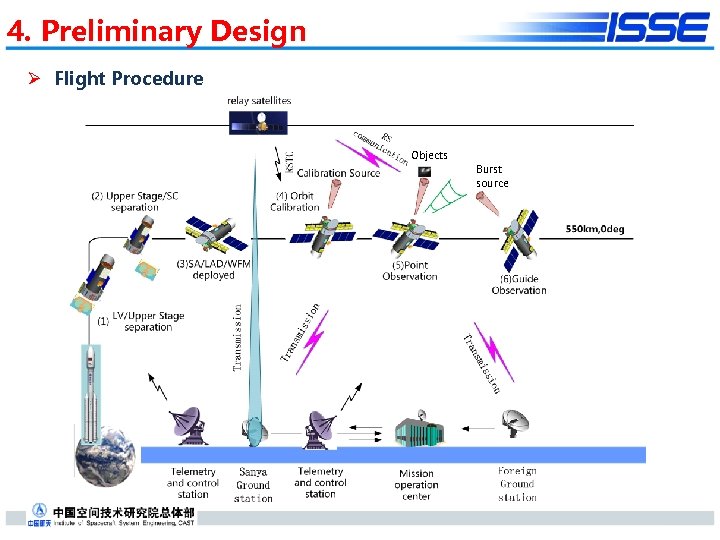

4. Preliminary Design Ø Flight Procedure Objects Burst source

4. Preliminary Design Ø Flight Procedure Objects Burst source

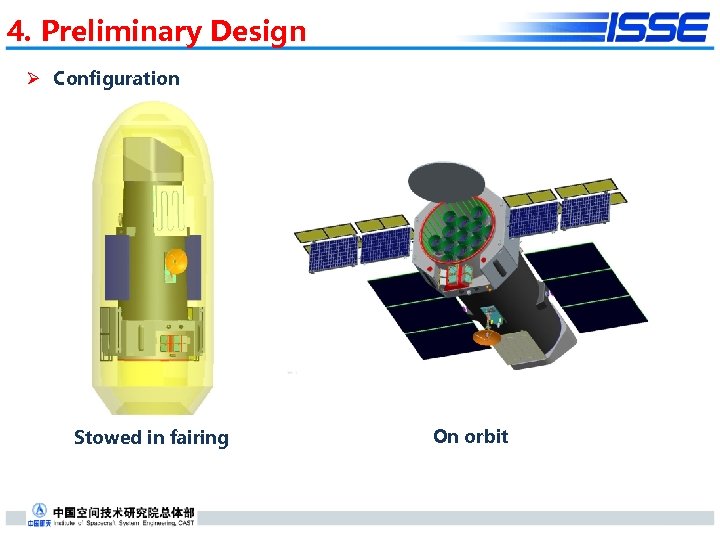

4. Preliminary Design Ø Configuration Stowed in fairing On orbit

4. Preliminary Design Ø Configuration Stowed in fairing On orbit

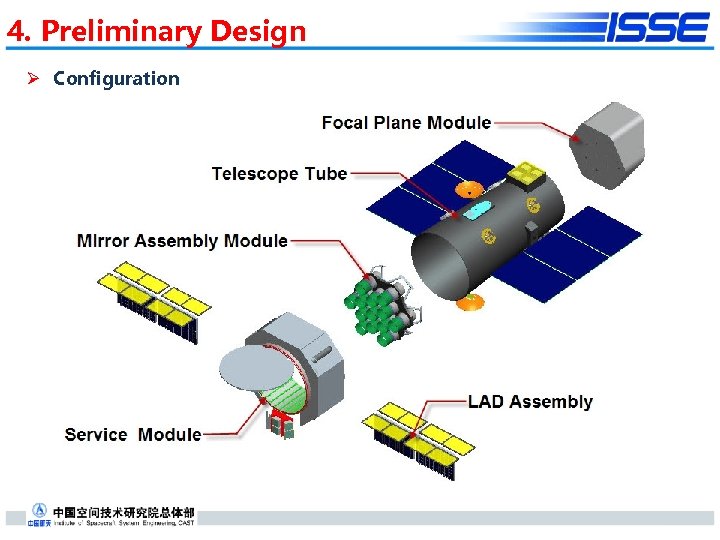

4. Preliminary Design Ø Configuration

4. Preliminary Design Ø Configuration

4. Preliminary Design Ø Configuration • Service module(SVM): the SVM includes all units required to control and operate the S/C platform. The WFM and GRM are accommodated in the SVM, too. • LAD Assembly(LADA): the LADA consists of LAD panel(#1~#4), LAD sunshields, deployment mechanisms. The LADA are accomodated on either sides of the SVM. • Mirror Assembly Module(MAM): the MAM is located inside the telescope tube , contains the SFA & PFA mirror module and star trackers, with the associated supporting platform. • Telescope Tube(TT): the TT allows to maintain the SFA&PFA at the required distance from the focal planes. • Focal Plane Assembly (FPA) : the FPA hosts the 13 focal plane cameras, including thermal control hardware.

4. Preliminary Design Ø Configuration • Service module(SVM): the SVM includes all units required to control and operate the S/C platform. The WFM and GRM are accommodated in the SVM, too. • LAD Assembly(LADA): the LADA consists of LAD panel(#1~#4), LAD sunshields, deployment mechanisms. The LADA are accomodated on either sides of the SVM. • Mirror Assembly Module(MAM): the MAM is located inside the telescope tube , contains the SFA & PFA mirror module and star trackers, with the associated supporting platform. • Telescope Tube(TT): the TT allows to maintain the SFA&PFA at the required distance from the focal planes. • Focal Plane Assembly (FPA) : the FPA hosts the 13 focal plane cameras, including thermal control hardware.

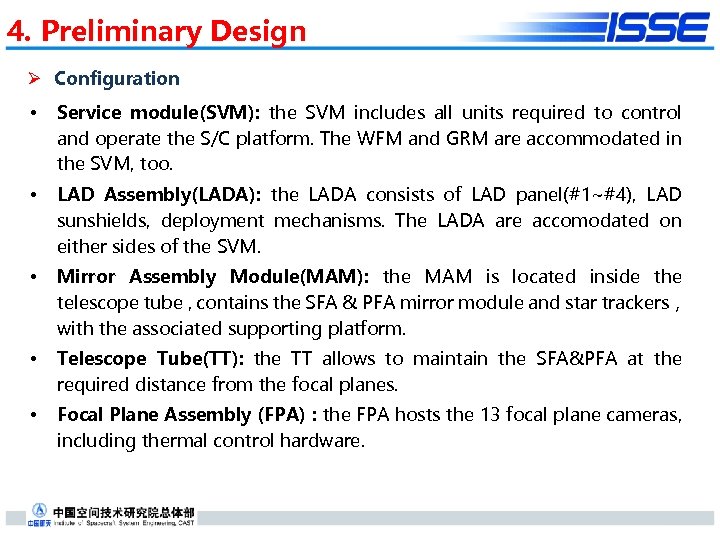

4. Preliminary Design Ø Service module(SVM) : • Hosts all platform subsystems; -four tanks -six reaction wheels -two star trackers -four sun acquisition senors -three gyroscopes • Support the LAD,WFM and GRM; • Downside of SVM is the interface of the launch vehicle; • Inside the SVM there’s a contamination cover , it’s also the sun-shield of the WFM.

4. Preliminary Design Ø Service module(SVM) : • Hosts all platform subsystems; -four tanks -six reaction wheels -two star trackers -four sun acquisition senors -three gyroscopes • Support the LAD,WFM and GRM; • Downside of SVM is the interface of the launch vehicle; • Inside the SVM there’s a contamination cover , it’s also the sun-shield of the WFM.

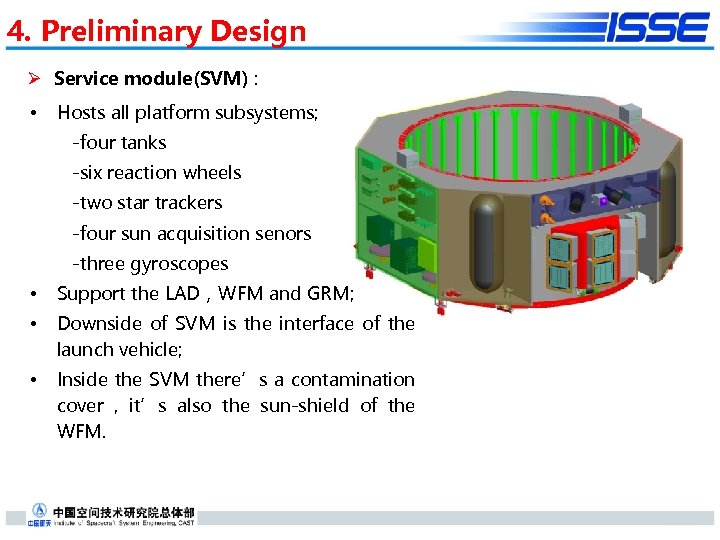

4. Preliminary Design Ø Mirror Assembly(MA) : • SFA and PFA are accomodated in the mirror platform. • Conceived as independent unit. • Can be later integrated into the telescope support structure. • Kinematic mounts : Minimising the impact of mechanical and thermal -elastic loads onto the optics alignment.

4. Preliminary Design Ø Mirror Assembly(MA) : • SFA and PFA are accomodated in the mirror platform. • Conceived as independent unit. • Can be later integrated into the telescope support structure. • Kinematic mounts : Minimising the impact of mechanical and thermal -elastic loads onto the optics alignment.

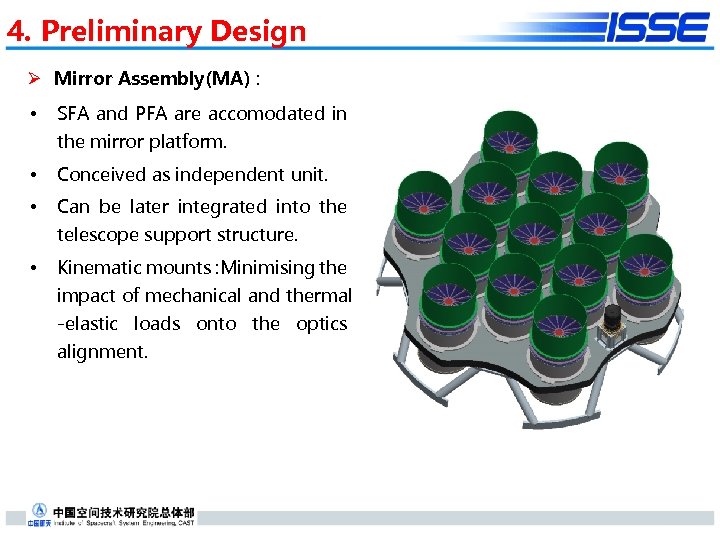

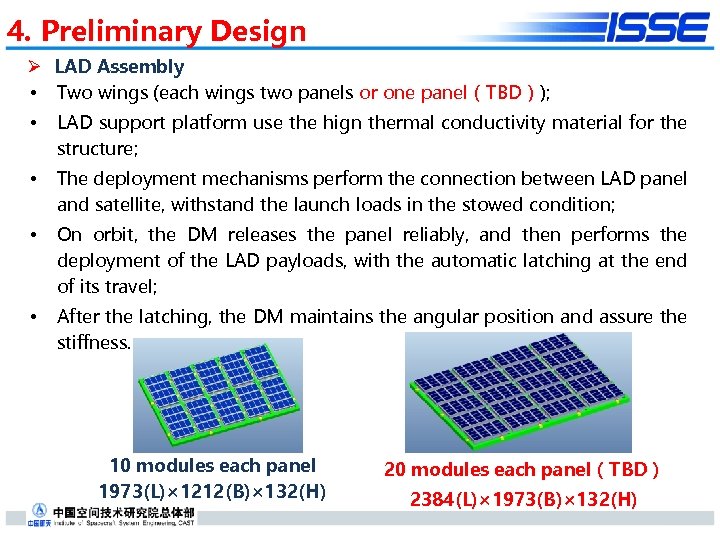

4. Preliminary Design Ø LAD Assembly • Two wings (each wings two panels or one panel(TBD)); • LAD support platform use the hign thermal conductivity material for the structure; • The deployment mechanisms perform the connection between LAD panel and satellite, withstand the launch loads in the stowed condition; • On orbit, the DM releases the panel reliably, and then performs the deployment of the LAD payloads, with the automatic latching at the end of its travel; • After the latching, the DM maintains the angular position and assure the stiffness. 10 modules each panel 1973(L)× 1212(B)× 132(H) 20 modules each panel(TBD) 2384(L)× 1973(B)× 132(H)

4. Preliminary Design Ø LAD Assembly • Two wings (each wings two panels or one panel(TBD)); • LAD support platform use the hign thermal conductivity material for the structure; • The deployment mechanisms perform the connection between LAD panel and satellite, withstand the launch loads in the stowed condition; • On orbit, the DM releases the panel reliably, and then performs the deployment of the LAD payloads, with the automatic latching at the end of its travel; • After the latching, the DM maintains the angular position and assure the stiffness. 10 modules each panel 1973(L)× 1212(B)× 132(H) 20 modules each panel(TBD) 2384(L)× 1973(B)× 132(H)

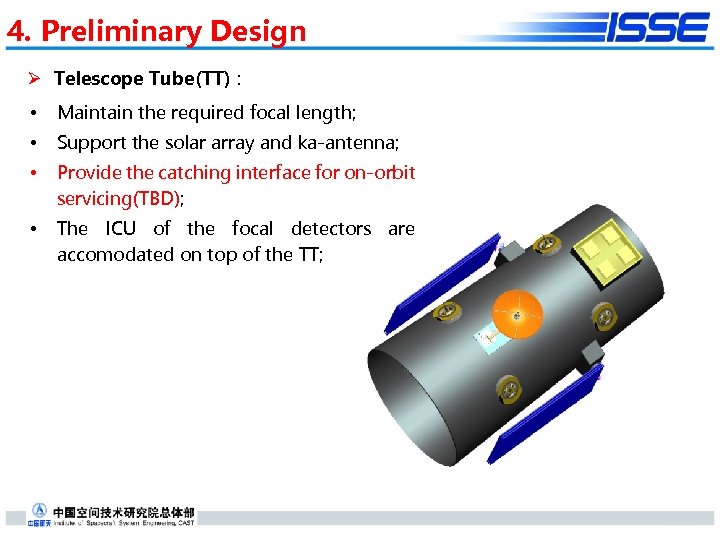

4. Preliminary Design Ø Telescope Tube(TT) : • Maintain the required focal length; • Support the solar array and ka-antenna; • Provide the catching interface for on-orbit servicing(TBD); • The ICU of the focal detectors are accomodated on top of the TT;

4. Preliminary Design Ø Telescope Tube(TT) : • Maintain the required focal length; • Support the solar array and ka-antenna; • Provide the catching interface for on-orbit servicing(TBD); • The ICU of the focal detectors are accomodated on top of the TT;

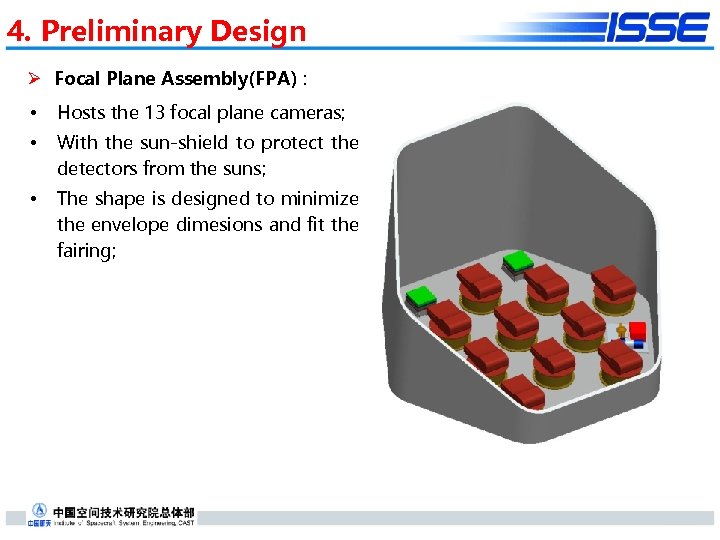

4. Preliminary Design Ø Focal Plane Assembly(FPA) : • Hosts the 13 focal plane cameras; • With the sun-shield to protect the detectors from the suns; • The shape is designed to minimize the envelope dimesions and fit the fairing;

4. Preliminary Design Ø Focal Plane Assembly(FPA) : • Hosts the 13 focal plane cameras; • With the sun-shield to protect the detectors from the suns; • The shape is designed to minimize the envelope dimesions and fit the fairing;

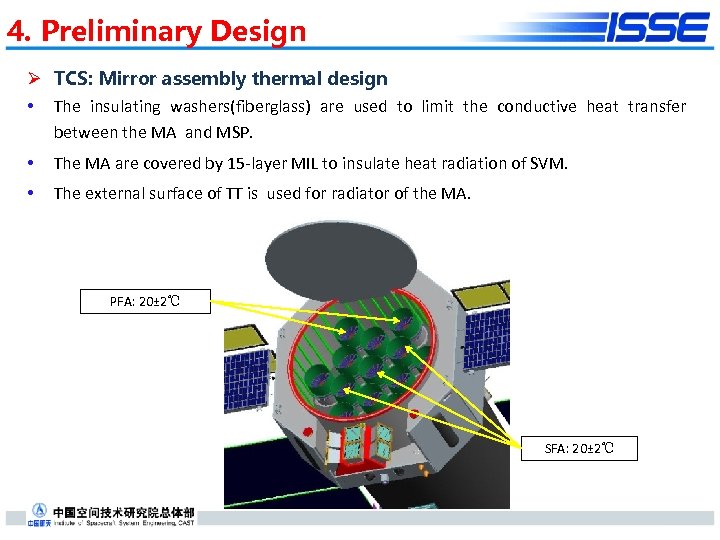

4. Preliminary Design Ø TCS: Mirror assembly thermal design • The insulating washers(fiberglass) are used to limit the conductive heat transfer between the MA and MSP. • The MA are covered by 15 -layer MIL to insulate heat radiation of SVM. • The external surface of TT is used for radiator of the MA. PFA: 20± 2℃ SFA: 20± 2℃

4. Preliminary Design Ø TCS: Mirror assembly thermal design • The insulating washers(fiberglass) are used to limit the conductive heat transfer between the MA and MSP. • The MA are covered by 15 -layer MIL to insulate heat radiation of SVM. • The external surface of TT is used for radiator of the MA. PFA: 20± 2℃ SFA: 20± 2℃

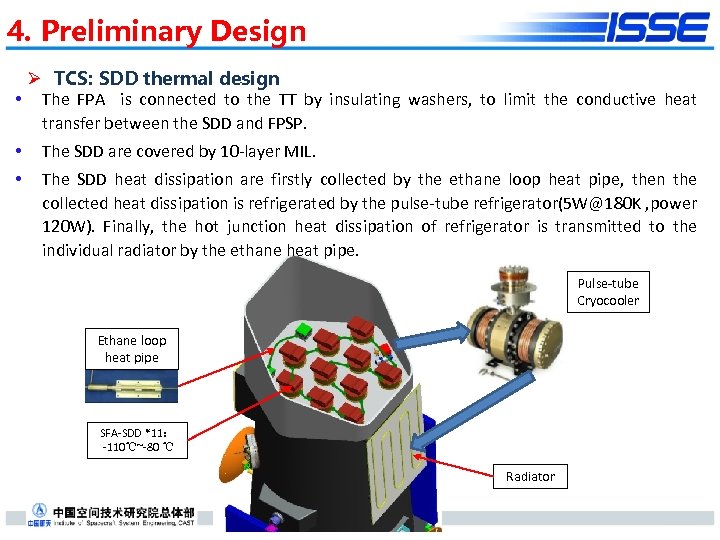

4. Preliminary Design Ø TCS: SDD thermal design • The FPA is connected to the TT by insulating washers, to limit the conductive heat transfer between the SDD and FPSP. • The SDD are covered by 10 -layer MIL. • The SDD heat dissipation are firstly collected by the ethane loop heat pipe, then the collected heat dissipation is refrigerated by the pulse-tube refrigerator(5 W@180 K , power 120 W). Finally, the hot junction heat dissipation of refrigerator is transmitted to the individual radiator by the ethane heat pipe. Pulse-tube Cryocooler Ethane loop heat pipe SFA-SDD *11: -110℃~-80 ℃ Radiator

4. Preliminary Design Ø TCS: SDD thermal design • The FPA is connected to the TT by insulating washers, to limit the conductive heat transfer between the SDD and FPSP. • The SDD are covered by 10 -layer MIL. • The SDD heat dissipation are firstly collected by the ethane loop heat pipe, then the collected heat dissipation is refrigerated by the pulse-tube refrigerator(5 W@180 K , power 120 W). Finally, the hot junction heat dissipation of refrigerator is transmitted to the individual radiator by the ethane heat pipe. Pulse-tube Cryocooler Ethane loop heat pipe SFA-SDD *11: -110℃~-80 ℃ Radiator

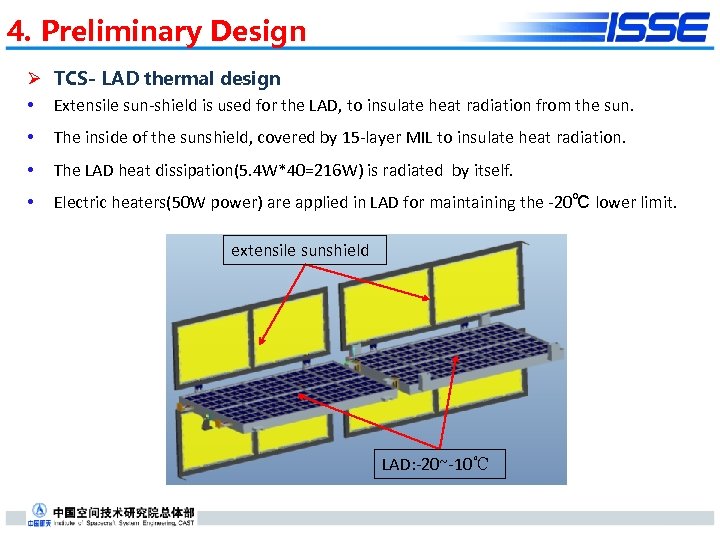

4. Preliminary Design Ø TCS- LAD thermal design • Extensile sun-shield is used for the LAD, to insulate heat radiation from the sun. • The inside of the sunshield, covered by 15 -layer MIL to insulate heat radiation. • The LAD heat dissipation(5. 4 W*40=216 W) is radiated by itself. • Electric heaters(50 W power) are applied in LAD for maintaining the -20℃ lower limit. extensile sunshield LAD: -20~-10℃

4. Preliminary Design Ø TCS- LAD thermal design • Extensile sun-shield is used for the LAD, to insulate heat radiation from the sun. • The inside of the sunshield, covered by 15 -layer MIL to insulate heat radiation. • The LAD heat dissipation(5. 4 W*40=216 W) is radiated by itself. • Electric heaters(50 W power) are applied in LAD for maintaining the -20℃ lower limit. extensile sunshield LAD: -20~-10℃

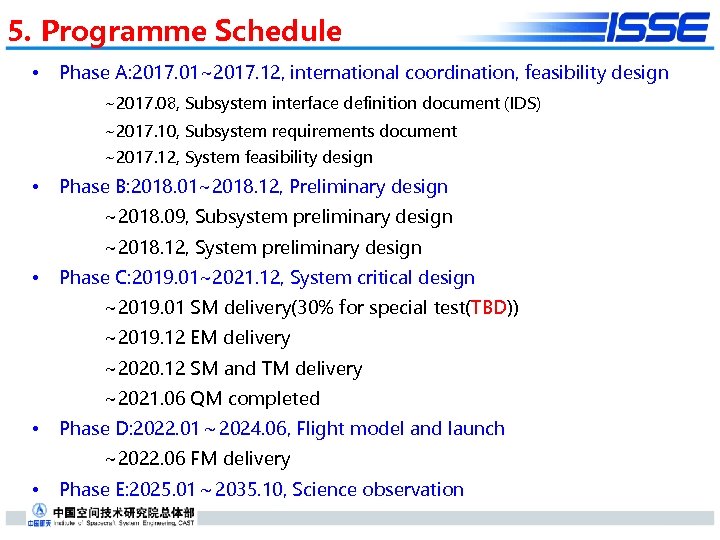

5. Programme Schedule • Phase A: 2017. 01~2017. 12, international coordination, feasibility design ~2017. 08, Subsystem interface definition document (IDS) ~2017. 10, Subsystem requirements document ~2017. 12, System feasibility design • Phase B: 2018. 01~2018. 12, Preliminary design ~2018. 09, Subsystem preliminary design ~2018. 12, System preliminary design • Phase C: 2019. 01~2021. 12, System critical design ~2019. 01 SM delivery(30% for special test(TBD)) ~2019. 12 EM delivery ~2020. 12 SM and TM delivery ~2021. 06 QM completed • Phase D: 2022. 01~ 2024. 06, Flight model and launch ~2022. 06 FM delivery • Phase E: 2025. 01~ 2035. 10, Science observation

5. Programme Schedule • Phase A: 2017. 01~2017. 12, international coordination, feasibility design ~2017. 08, Subsystem interface definition document (IDS) ~2017. 10, Subsystem requirements document ~2017. 12, System feasibility design • Phase B: 2018. 01~2018. 12, Preliminary design ~2018. 09, Subsystem preliminary design ~2018. 12, System preliminary design • Phase C: 2019. 01~2021. 12, System critical design ~2019. 01 SM delivery(30% for special test(TBD)) ~2019. 12 EM delivery ~2020. 12 SM and TM delivery ~2021. 06 QM completed • Phase D: 2022. 01~ 2024. 06, Flight model and launch ~2022. 06 FM delivery • Phase E: 2025. 01~ 2035. 10, Science observation

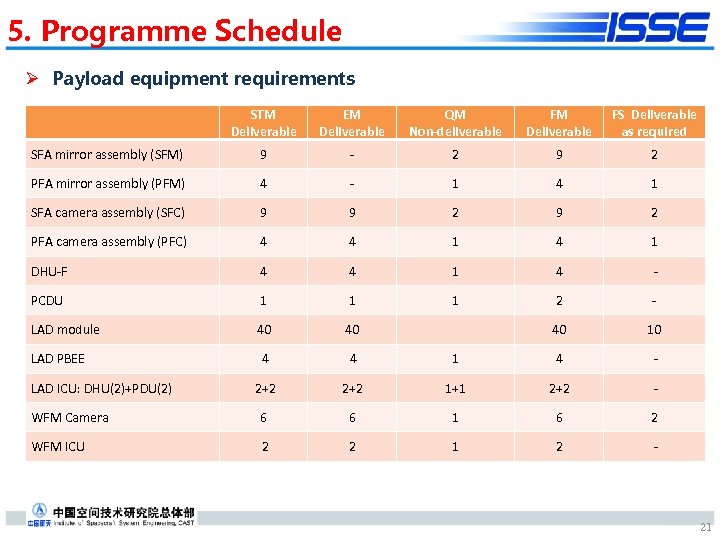

5. Programme Schedule Ø Payload equipment requirements STM Deliverable EM Deliverable QM Non-deliverable FM Deliverable FS Deliverable as required SFA mirror assembly (SFM) 9 - 2 9 2 PFA mirror assembly (PFM) 4 - 1 4 1 SFA camera assembly (SFC) 9 9 2 PFA camera assembly (PFC) 4 4 1 DHU-F 4 4 1 4 - PCDU 1 1 1 2 - LAD module 40 40 40 10 LAD PBEE 4 4 1 4 - 2+2 1+1 2+2 - WFM Camera 6 6 1 6 2 WFM ICU 2 2 1 2 - LAD ICU: DHU(2)+PDU(2) 21

5. Programme Schedule Ø Payload equipment requirements STM Deliverable EM Deliverable QM Non-deliverable FM Deliverable FS Deliverable as required SFA mirror assembly (SFM) 9 - 2 9 2 PFA mirror assembly (PFM) 4 - 1 4 1 SFA camera assembly (SFC) 9 9 2 PFA camera assembly (PFC) 4 4 1 DHU-F 4 4 1 4 - PCDU 1 1 1 2 - LAD module 40 40 40 10 LAD PBEE 4 4 1 4 - 2+2 1+1 2+2 - WFM Camera 6 6 1 6 2 WFM ICU 2 2 1 2 - LAD ICU: DHU(2)+PDU(2) 21

6. Problems Ø LAD Assembly The following key requirements should be confirmed: • Panels: ~The interface between panel structure and sun-shield, DM, module, PBEE. ~The requirements for strength, stiffness, alignment, thermo-stability, material, connection style. ~The technical flow about the delivery, assembly, test(How? Where? ). • LAD sun-shield: ~The requirements for materials, frequency, weight, thermal control. ~Interface of the HDRM. • Deployment Mechanisms: ~The interface between DM and the panels. ~Requirements for Frequency, Accuracy, Drive torque, Thermo-stability, Weight. ~AIT process and items.

6. Problems Ø LAD Assembly The following key requirements should be confirmed: • Panels: ~The interface between panel structure and sun-shield, DM, module, PBEE. ~The requirements for strength, stiffness, alignment, thermo-stability, material, connection style. ~The technical flow about the delivery, assembly, test(How? Where? ). • LAD sun-shield: ~The requirements for materials, frequency, weight, thermal control. ~Interface of the HDRM. • Deployment Mechanisms: ~The interface between DM and the panels. ~Requirements for Frequency, Accuracy, Drive torque, Thermo-stability, Weight. ~AIT process and items.

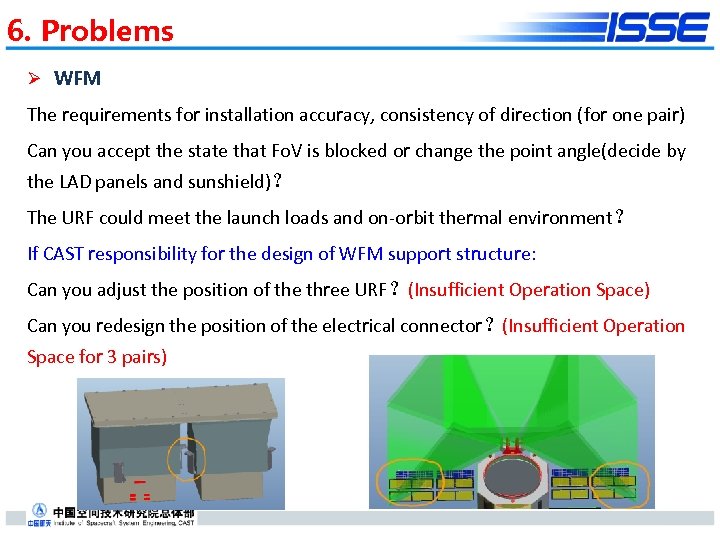

6. Problems Ø WFM The requirements for installation accuracy, consistency of direction (for one pair) Can you accept the state that Fo. V is blocked or change the point angle(decide by the LAD panels and sunshield)? The URF could meet the launch loads and on-orbit thermal environment? If CAST responsibility for the design of WFM support structure: Can you adjust the position of the three URF?(Insufficient Operation Space) Can you redesign the position of the electrical connector?(Insufficient Operation Space for 3 pairs)

6. Problems Ø WFM The requirements for installation accuracy, consistency of direction (for one pair) Can you accept the state that Fo. V is blocked or change the point angle(decide by the LAD panels and sunshield)? The URF could meet the launch loads and on-orbit thermal environment? If CAST responsibility for the design of WFM support structure: Can you adjust the position of the three URF?(Insufficient Operation Space) Can you redesign the position of the electrical connector?(Insufficient Operation Space for 3 pairs)

7. Conclusions • We have updated the design of e. XTP satellites, which could meet the requirement of the science; • Something should be confirmed to help us understanding the design and requirements of the science.

7. Conclusions • We have updated the design of e. XTP satellites, which could meet the requirement of the science; • Something should be confirmed to help us understanding the design and requirements of the science.

Thanks for your attention! 探索宇宙奥秘 造福人类社会

Thanks for your attention! 探索宇宙奥秘 造福人类社会