PRECISION FARMING DEVELOMENT CENTRE ICAR- Central Institute for Subtropical Horticulture Rehmankhera, Lucknow- 226 101

PRECISION FARMING DEVELOMENT CENTRE ICAR- Central Institute for Subtropical Horticulture Rehmankhera, Lucknow- 226 101

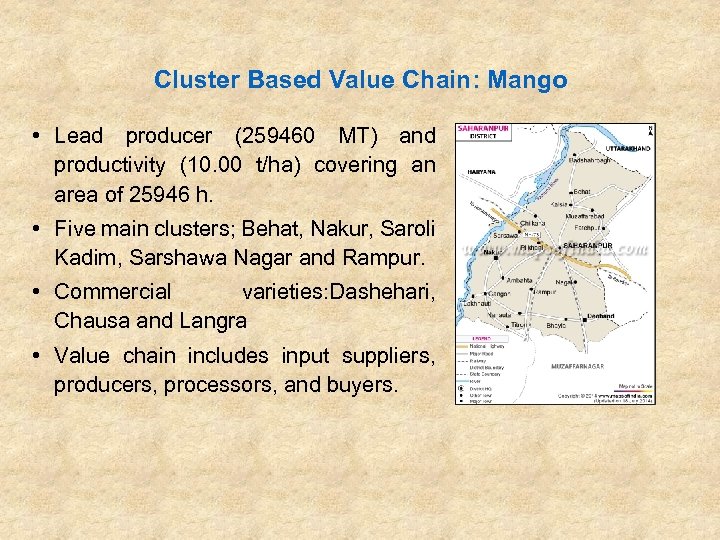

Cluster Based Value Chain: Mango • Lead producer (259460 MT) and productivity (10. 00 t/ha) covering an area of 25946 h. • Five main clusters; Behat, Nakur, Saroli Kadim, Sarshawa Nagar and Rampur. • Commercial varieties: Dashehari, Chausa and Langra • Value chain includes input suppliers, producers, processors, and buyers.

Cluster Based Value Chain: Mango • Lead producer (259460 MT) and productivity (10. 00 t/ha) covering an area of 25946 h. • Five main clusters; Behat, Nakur, Saroli Kadim, Sarshawa Nagar and Rampur. • Commercial varieties: Dashehari, Chausa and Langra • Value chain includes input suppliers, producers, processors, and buyers.

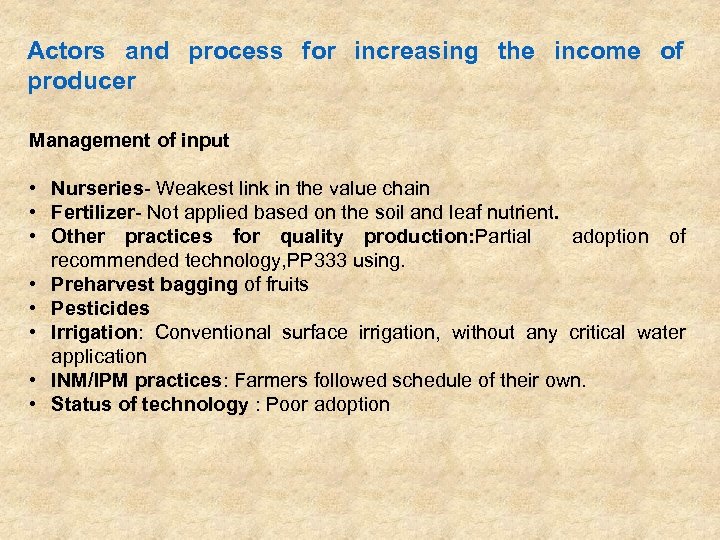

Actors and process for increasing the income of producer Management of input • Nurseries- Weakest link in the value chain • Fertilizer- Not applied based on the soil and leaf nutrient. • Other practices for quality production: Partial adoption of recommended technology, PP 333 using. • Preharvest bagging of fruits • Pesticides • Irrigation: Conventional surface irrigation, without any critical water application • INM/IPM practices: Farmers followed schedule of their own. • Status of technology : Poor adoption

Actors and process for increasing the income of producer Management of input • Nurseries- Weakest link in the value chain • Fertilizer- Not applied based on the soil and leaf nutrient. • Other practices for quality production: Partial adoption of recommended technology, PP 333 using. • Preharvest bagging of fruits • Pesticides • Irrigation: Conventional surface irrigation, without any critical water application • INM/IPM practices: Farmers followed schedule of their own. • Status of technology : Poor adoption

Common nursery practices (Veneer grafting) Bagging for quality mango Profuse fruiting after soil application of paclobutrazol Harvester

Common nursery practices (Veneer grafting) Bagging for quality mango Profuse fruiting after soil application of paclobutrazol Harvester

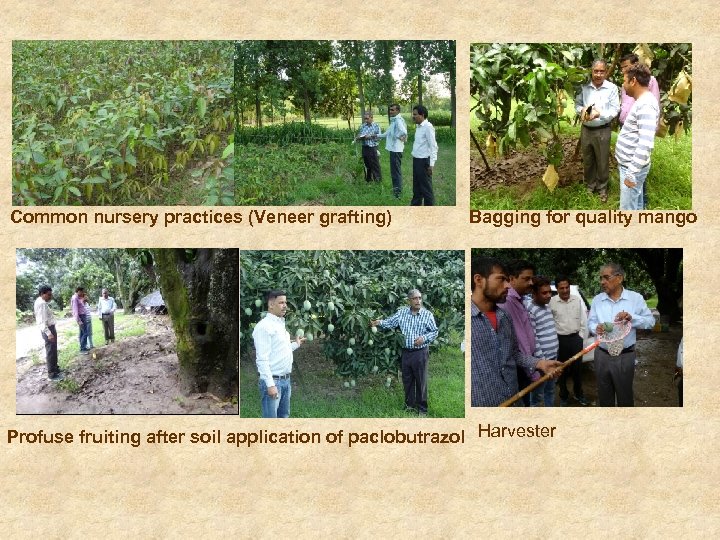

Post production practices • Harvesting time : Visual method • Harvest tool: Harvester, lack of awareness • Chemical for ripening: Calcium carbide and chinese pudia as ethylene ripener • Pre cooling of mangoes • Sorting, grading, cleaning and packing practices • Storage facility • Market linkage: Not exist within the exporter and producer Institutional gap • FPO/FIGs and other producer group: Does not exist • Status of skill development • Public private partnership (PPP): Not operating Infrastructure gaps • Infrastructure for quality planting materials • Post harvest management • Pack house: 5 tonne/day capacity with VHT

Post production practices • Harvesting time : Visual method • Harvest tool: Harvester, lack of awareness • Chemical for ripening: Calcium carbide and chinese pudia as ethylene ripener • Pre cooling of mangoes • Sorting, grading, cleaning and packing practices • Storage facility • Market linkage: Not exist within the exporter and producer Institutional gap • FPO/FIGs and other producer group: Does not exist • Status of skill development • Public private partnership (PPP): Not operating Infrastructure gaps • Infrastructure for quality planting materials • Post harvest management • Pack house: 5 tonne/day capacity with VHT

Packaging house for export and discussion with exporter Packaging of fruit at producing site Awareness programme

Packaging house for export and discussion with exporter Packaging of fruit at producing site Awareness programme

Major issues v Lack of organizational setup, co-ordination amongst growers v Lack of proper infrastructures such as packing sheds or collection points. v Transportation barriers v Cold chain logistics unavailable. v Underdeveloped market information v Poorly resourced horticulture research stations, Saharanpur and dearth of extension support in mango production.

Major issues v Lack of organizational setup, co-ordination amongst growers v Lack of proper infrastructures such as packing sheds or collection points. v Transportation barriers v Cold chain logistics unavailable. v Underdeveloped market information v Poorly resourced horticulture research stations, Saharanpur and dearth of extension support in mango production.

Recommendations for future improvement üSetting up of an optimal crop management system, postharvest infrastructure, entrepreneurial management and expertise and finally improving post-harvest operations. üMarket strategy üNearby international markets should also be tapped for the export of Chausa üSmall and cost effective pulping units should be installed to utilize the C and D grade fruits. üTraining for enhancing the capacity building üGovernment department may be sensitized to ease the policies with respect to export of mango and declare these products as ‘priority product’ for export.

Recommendations for future improvement üSetting up of an optimal crop management system, postharvest infrastructure, entrepreneurial management and expertise and finally improving post-harvest operations. üMarket strategy üNearby international markets should also be tapped for the export of Chausa üSmall and cost effective pulping units should be installed to utilize the C and D grade fruits. üTraining for enhancing the capacity building üGovernment department may be sensitized to ease the policies with respect to export of mango and declare these products as ‘priority product’ for export.

Acknowledgement We gratefully acknowledged the MIDH, Mo. A and FW, Go. I and NCPAH, New Delhi for financial assistance to collect this information. Thanks to Director, Horticulture and Food Processing & SHM, UP and officers with other staff of Horticulture research station, Saharanpur for support and coordination.

Acknowledgement We gratefully acknowledged the MIDH, Mo. A and FW, Go. I and NCPAH, New Delhi for financial assistance to collect this information. Thanks to Director, Horticulture and Food Processing & SHM, UP and officers with other staff of Horticulture research station, Saharanpur for support and coordination.