4b6f34d4ebaf5a3445c8791f69d937f7.ppt

- Количество слайдов: 25

Precipitate Formation above the Cloud Point in Soy-, Cottonseed-, and Poultry Fat-based Biodiesel Blends Present to International Congress on Biodiesel: The Science and The Technologies November 7, 2007 Haiying Tang, Steve O. Salley, and K. Y. Simon Ng National Biofuels Energy Laborotory Next. Energy/Wayne State University Detroit, MI 48202

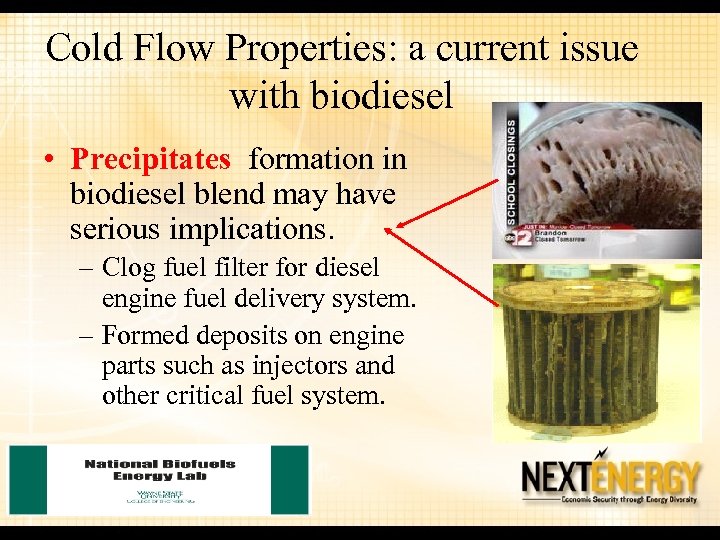

Cold Flow Properties: a current issue with biodiesel • Precipitates formation in biodiesel blend may have serious implications. – Clog fuel filter for diesel engine fuel delivery system. – Formed deposits on engine parts such as injectors and other critical fuel system.

ASTM Test Methods • Cold –flow properties: traditional petroleum wax precipitation – Cloud point (CP, ASTM 2500): at which crystallization begins. – Pour point (PP, ASTM 97): at which the fuel no longer pour. – Cold filter plugging point (CFPP, ASTM 6371): at which fuel starts to plug a fuel filter. • Total insoluble: High temperature in the presence of oxygen – ASTM D 2274 (Accelerated Method): Oxidation Stability of Distillate Fuel ( 95 ºC for 16 h). – ASTM D 4625: Storage Stability of Middle Distillate, Petroleum ( 43 ºC for selected periods up to 24 weeks).

Critical Issues • The effects of biodiesel on cold-flow fuel properties when blended with ULSD have not been fully elucidated; • Few studies on the effect of biodiesel blends on the amount of precipitate formation under low temperature storage.

Objectives • Investigate the effect of blend levels on the precipitate formation at low temperature storage; • Understand the mechanism of precipitate formation; • Correlate the relationship between CP, PP, and CFPP and precipitate formation; • Investigate the nature of precipitates.

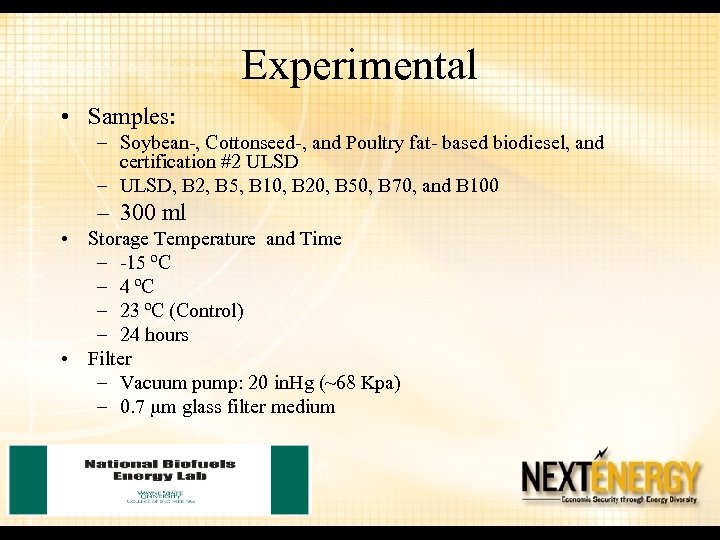

Experimental • Samples: – Soybean-, Cottonseed-, and Poultry fat- based biodiesel, and certification #2 ULSD – ULSD, B 2, B 5, B 10, B 20, B 50, B 70, and B 100 – 300 ml • Storage Temperature and Time – -15 ºC – 4 ºC – 23 ºC (Control) – 24 hours • Filter – Vacuum pump: 20 in. Hg (~68 Kpa) – 0. 7 mm glass filter medium

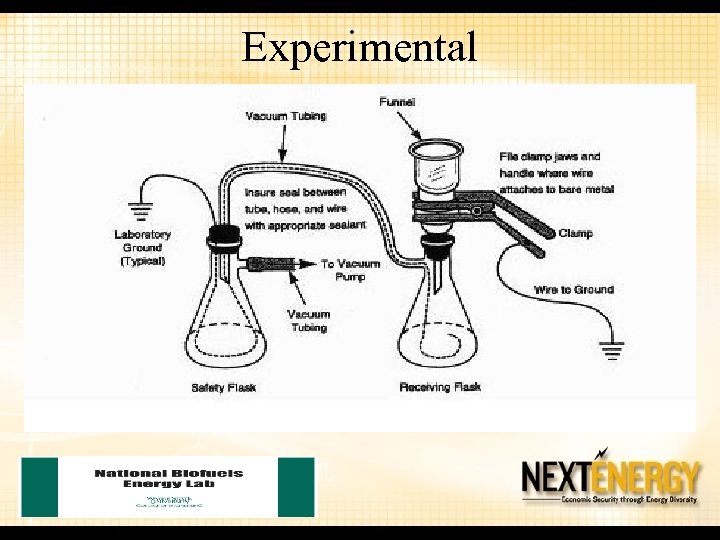

Experimental

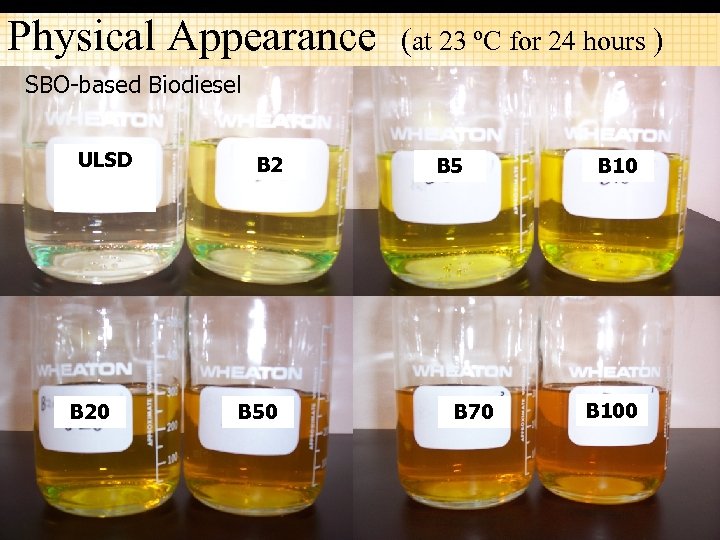

Physical Appearance (at 23 ºC for 24 hours ) SBO-based Biodiesel ULSD B 20 B 2 B 50 B 5 B 70 B 100

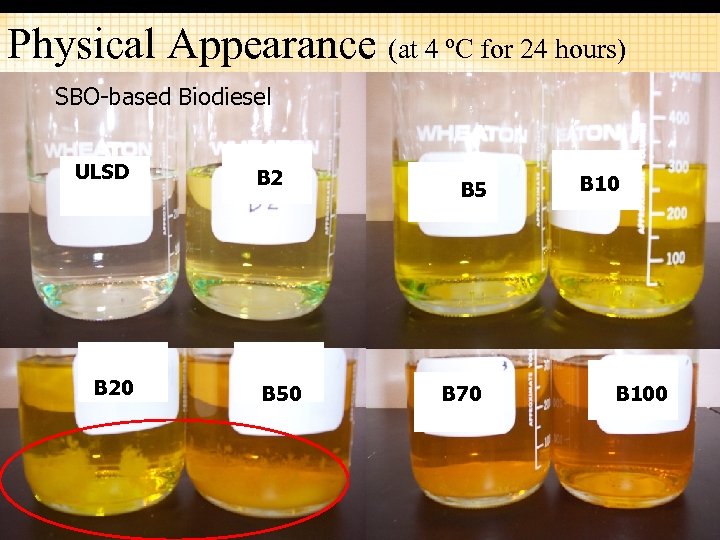

Physical Appearance (at 4 ºC for 24 hours) SBO-based Biodiesel ULSD B 20 B 2 B 50 ULSD B 5 B 70 B 100

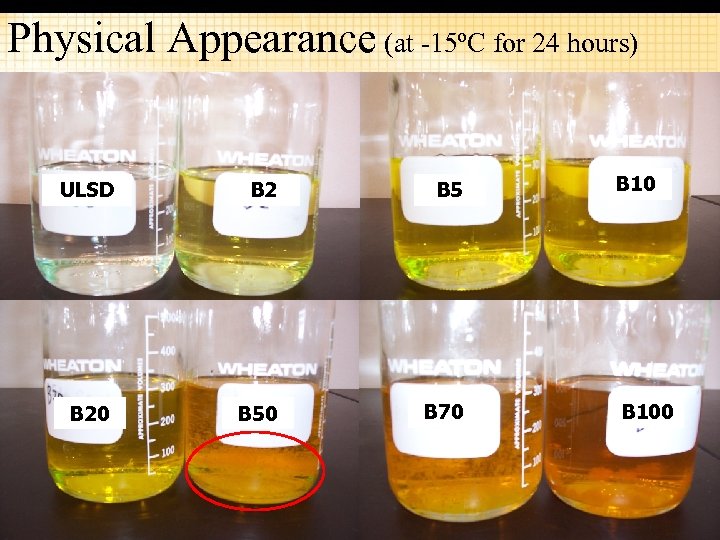

Physical Appearance (at -15ºC for 24 hours) ULSD B 2 B 5 B 20 B 50 B 70 B 100

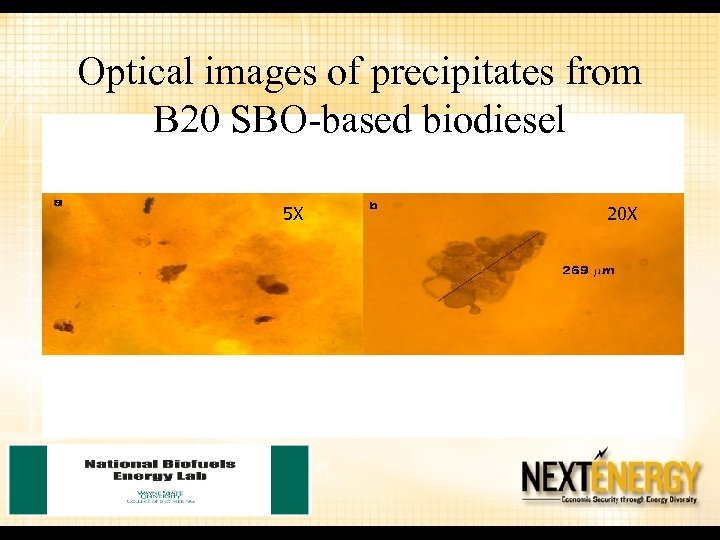

Optical images of precipitates from B 20 SBO-based biodiesel 5 X 20 X

Precipitates above Cloud Point • Precipitates are observed above cloud point for biodiesel blends – Storage temperature – Storage time – Blending levels – Feedstock

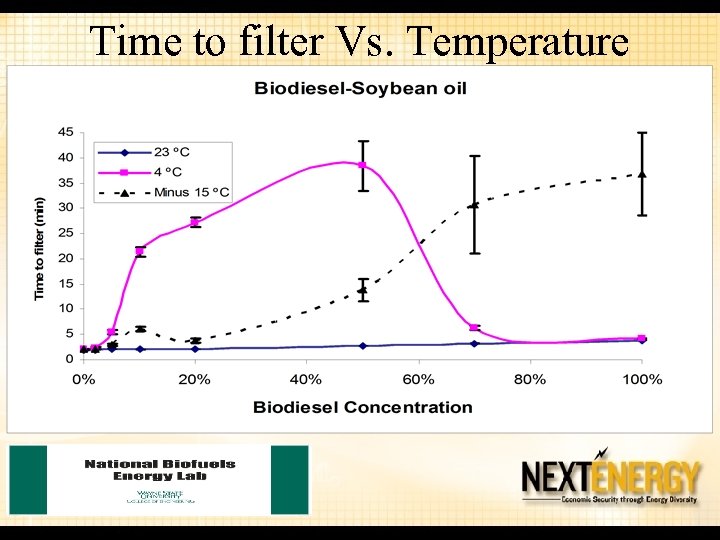

Time to filter Vs. Temperature

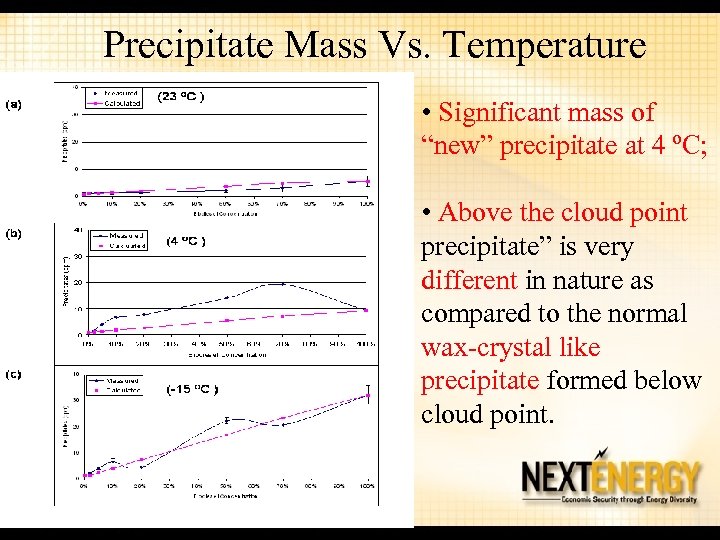

Precipitate Mass Vs. Temperature • Significant mass of “new” precipitate at 4 ºC; • Above the cloud point precipitate” is very different in nature as compared to the normal wax-crystal like precipitate formed below cloud point.

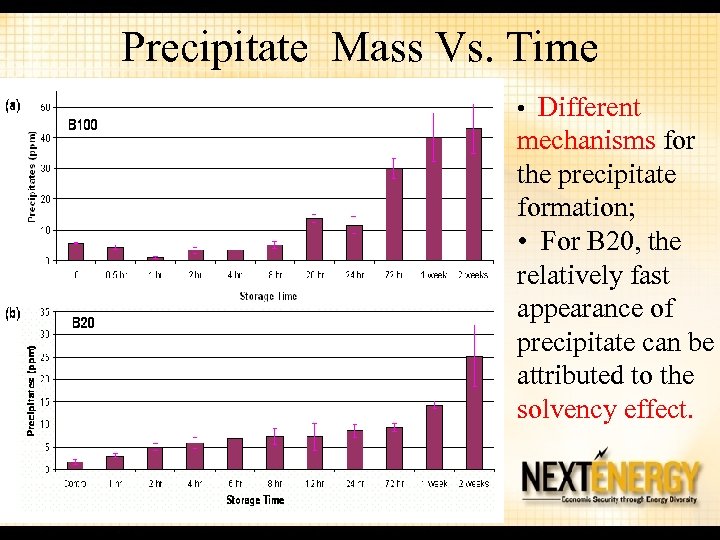

Precipitate Mass Vs. Time • Different mechanisms for the precipitate formation; • For B 20, the relatively fast appearance of precipitate can be attributed to the solvency effect.

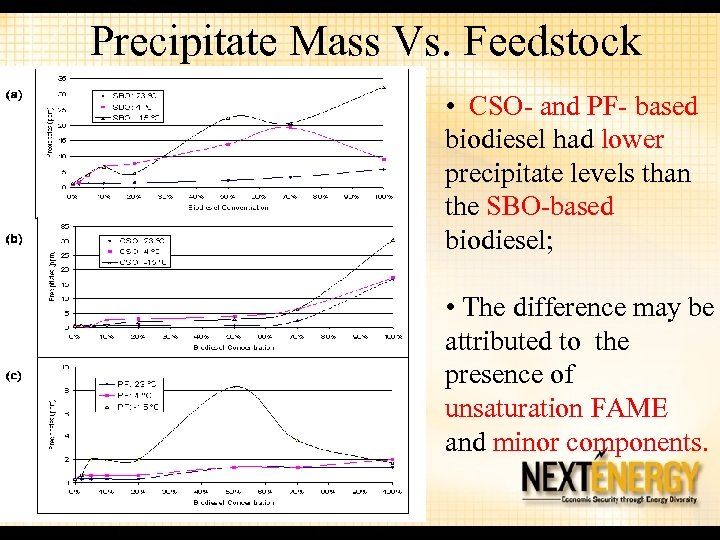

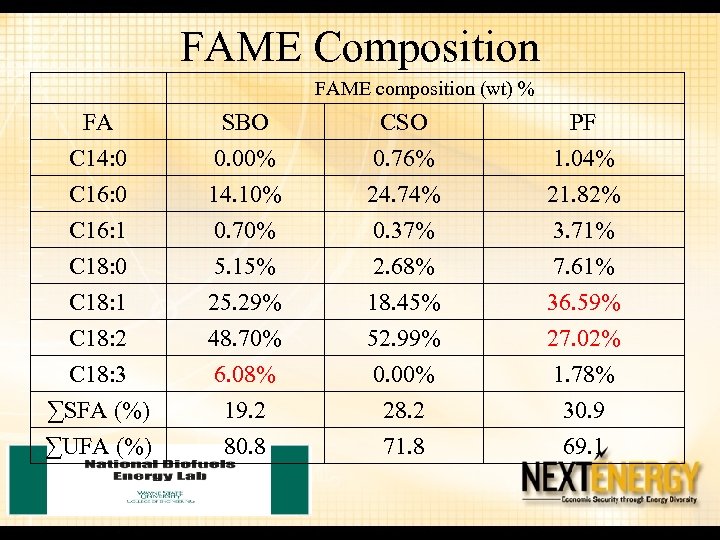

Precipitate Mass Vs. Feedstock • CSO- and PF- based biodiesel had lower precipitate levels than the SBO-based biodiesel; • The difference may be attributed to the presence of unsaturation FAME and minor components.

FAME Composition FAME composition (wt) % FA SBO CSO PF C 14: 0 C 16: 1 C 18: 0 0. 00% 14. 10% 0. 70% 5. 15% 0. 76% 24. 74% 0. 37% 2. 68% 1. 04% 21. 82% 3. 71% 7. 61% C 18: 1 C 18: 2 C 18: 3 ∑SFA (%) ∑UFA (%) 25. 29% 48. 70% 6. 08% 19. 2 80. 8 18. 45% 52. 99% 0. 00% 28. 2 71. 8 36. 59% 27. 02% 1. 78% 30. 9 69. 1

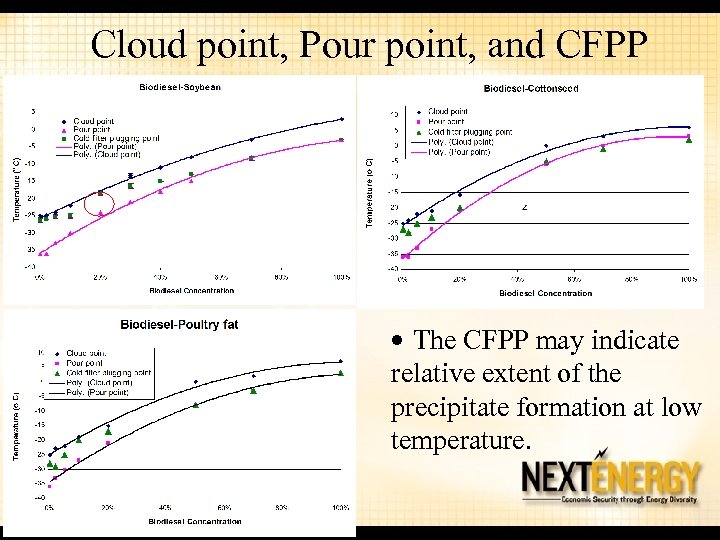

Cloud point, Pour point, and CFPP • The CFPP may indicate relative extent of the precipitate formation at low temperature.

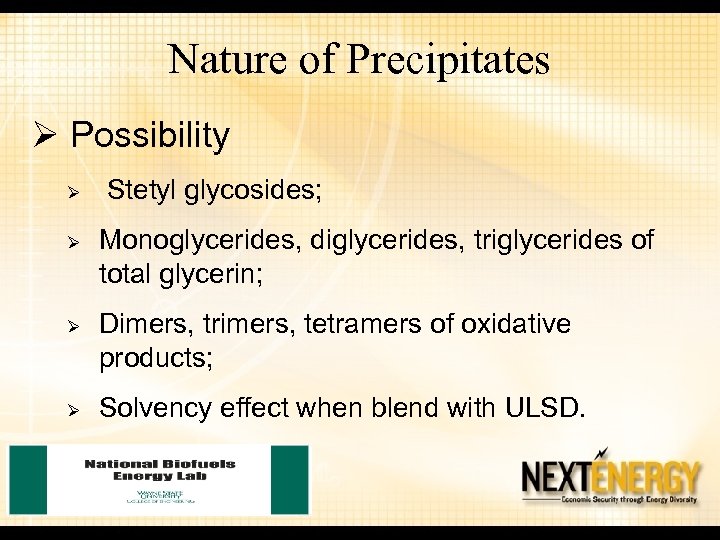

Nature of Precipitates Ø Possibility Ø Ø Stetyl glycosides; Monoglycerides, diglycerides, triglycerides of total glycerin; Dimers, trimers, tetramers of oxidative products; Solvency effect when blend with ULSD.

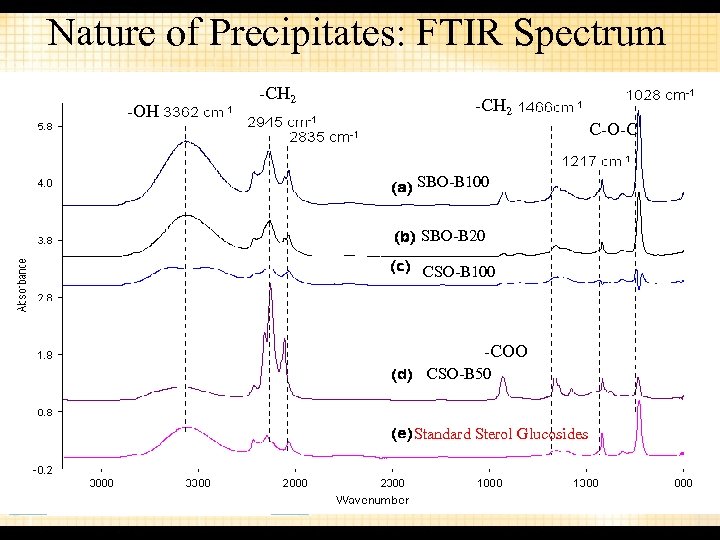

Nature of Precipitates: FTIR Spectrum -OH -CH 2 C-O-C SBO-B 100 SBO-B 20 CSO-B 100 -COO CSO-B 50 Standard Sterol Glucosides

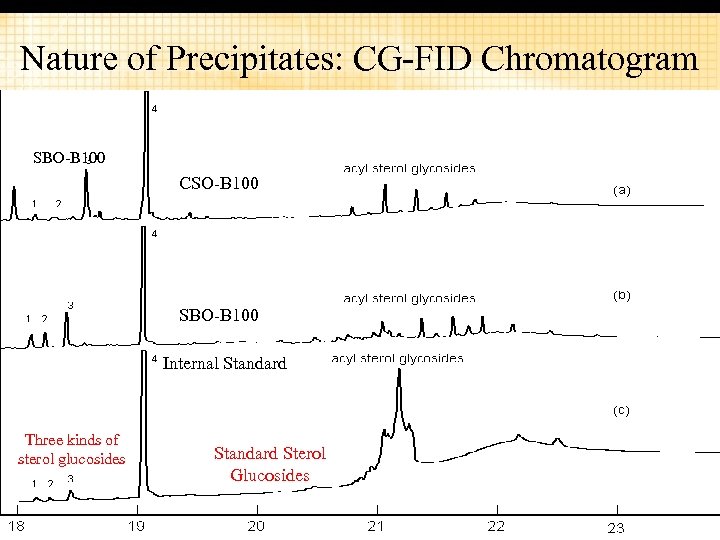

Nature of Precipitates: CG-FID Chromatogram SBO-B 100 CSO-B 100 SBO-B 100 Internal Standard Three kinds of sterol glucosides Standard Sterol Glucosides

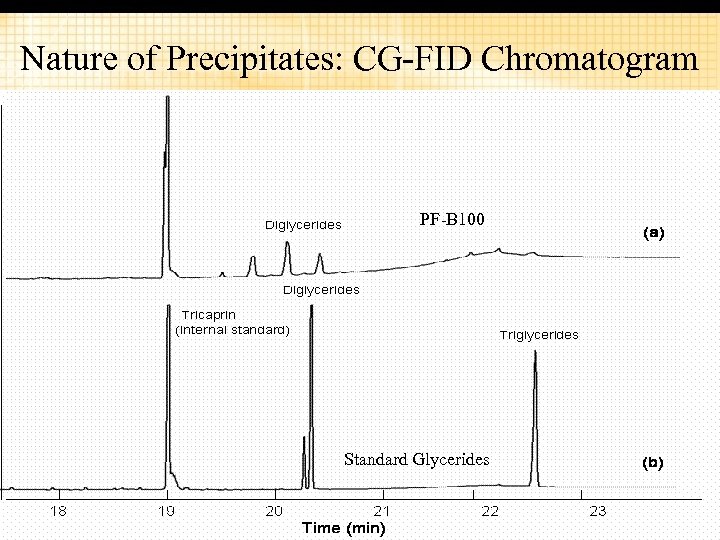

Nature of Precipitates: CG-FID Chromatogram PF-B 100 Standard Glycerides

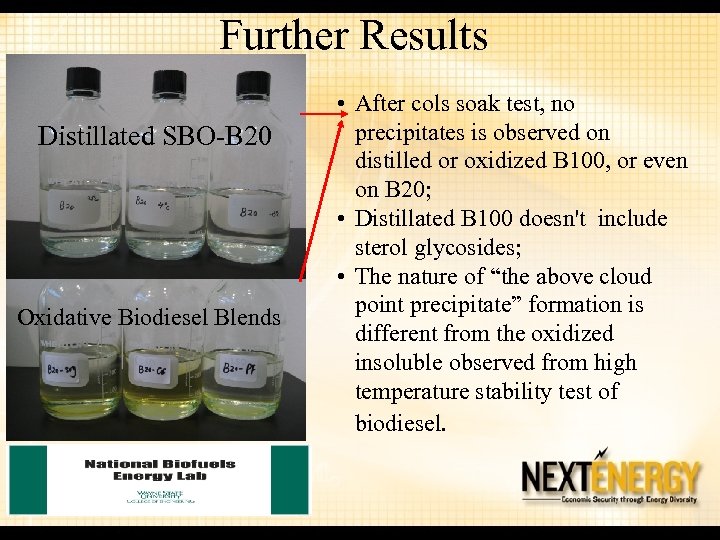

Further Results Distillated SBO-B 20 Oxidative Biodiesel Blends • After cols soak test, no precipitates is observed on distilled or oxidized B 100, or even on B 20; • Distillated B 100 doesn't include sterol glycosides; • The nature of “the above cloud point precipitate” formation is different from the oxidized insoluble observed from high temperature stability test of biodiesel.

Conclusions • Storage temperature, storage time, biodiesel blend level, and feedstock affect the mass of precipitate formed; • Solvency of ULSD has a significant influence on precipitates formation; • Precipitates from SBO- and CSO-based biodiesel are due to sterol glucosides. However, the precipitates from PF-based biodiesel can be attributed to glycerides.

Acknowledgement Financial support from the Department of Energy (Grant # DE FG 36 -05 GO 85005) and Michigan’s 21 st Century Job Fund is gratefully acknowledged.

4b6f34d4ebaf5a3445c8791f69d937f7.ppt