683ced59f38679e291a3a6aa9b10e478.ppt

- Количество слайдов: 20

PRE-formance™

PRE-formance™ Ø PRE-formance “Basic” PRE-formance Standard Pre-fabricated Assemblies Ø PRE-formance “Custom” Assembled to Order Pre. Fab products for both AC/MC & EMT applications Ø PRE-formance™ “Complete” A complete engineered solution – take offs & drawings, patented products, customized markings & shipping, each engineered and manufactured to job specific requirements 2

PRE-formance™ Ø PRE-formance “Basic” PRE-formance • Standard cataloged & inventoried CCH boxes with pigtail & ground-screw. - e. g. TP 404 -PF - e. g. TP 403 -PF • PF adder available with ANY CCH box by adding PF to part number. • Stranded Fork Terminal Pigtails available by adding PFA • Net Price adder for either PF or PFA 3

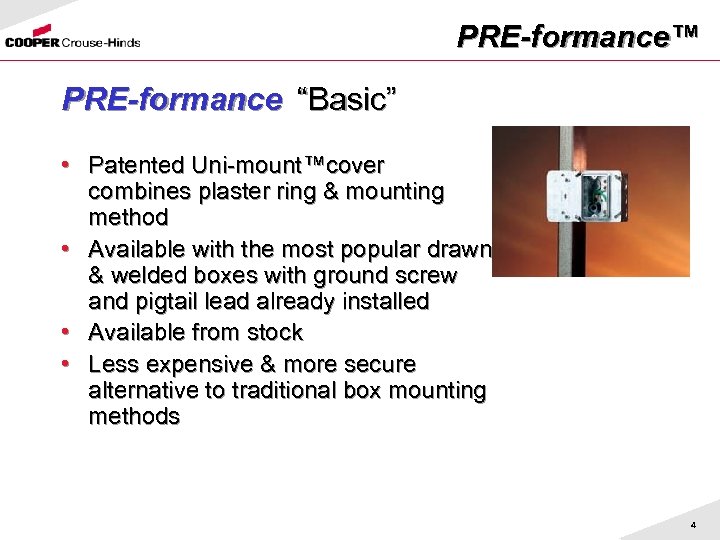

PRE-formance™ PRE-formance “Basic” • Patented Uni-mount™cover combines plaster ring & mounting method • Available with the most popular drawn & welded boxes with ground screw and pigtail lead already installed • Available from stock • Less expensive & more secure alternative to traditional box mounting methods 4

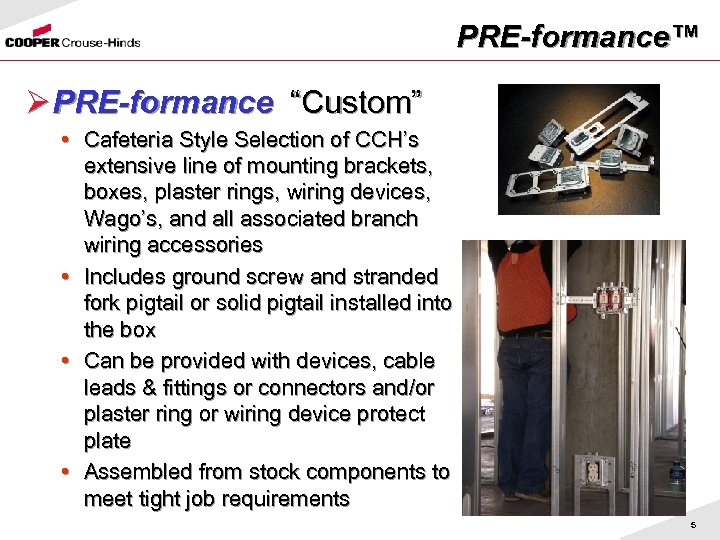

PRE-formance™ Ø PRE-formance “Custom” PRE-formance • Cafeteria Style Selection of CCH’s extensive line of mounting brackets, boxes, plaster rings, wiring devices, Wago’s, and all associated branch wiring accessories • Includes ground screw and stranded fork pigtail or solid pigtail installed into the box • Can be provided with devices, cable leads & fittings or connectors and/or plaster ring or wiring device protect plate • Assembled from stock components to meet tight job requirements 5

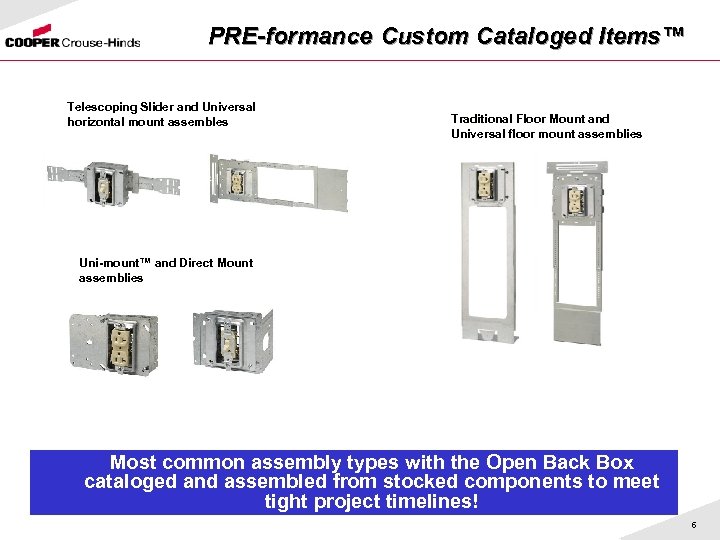

PRE-formance Custom Cataloged Items™ Telescoping Slider and Universal horizontal mount assembles Traditional Floor Mount and Universal floor mount assemblies Uni-mount™ and Direct Mount assemblies Most common assembly types with the Open Back Box cataloged and assembled from stocked components to meet tight project timelines! 6

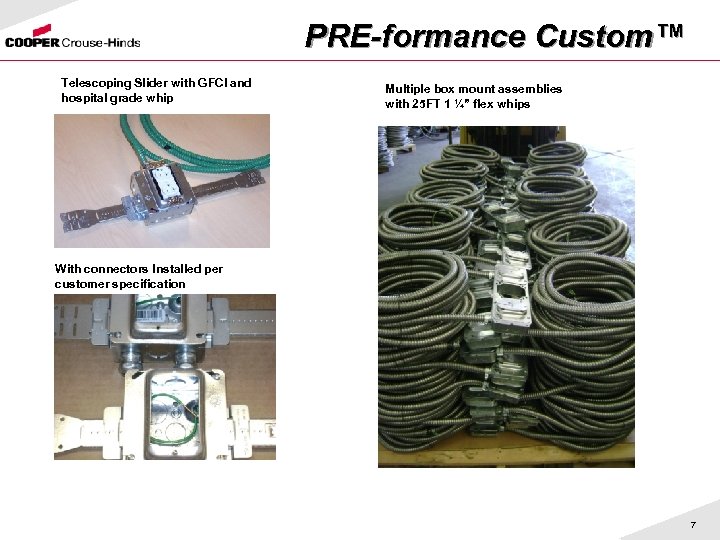

PRE-formance Custom™ Telescoping Slider with GFCI and hospital grade whip Multiple box mount assemblies with 25 FT 1 ¼” flex whips With connectors Installed per customer specification 7

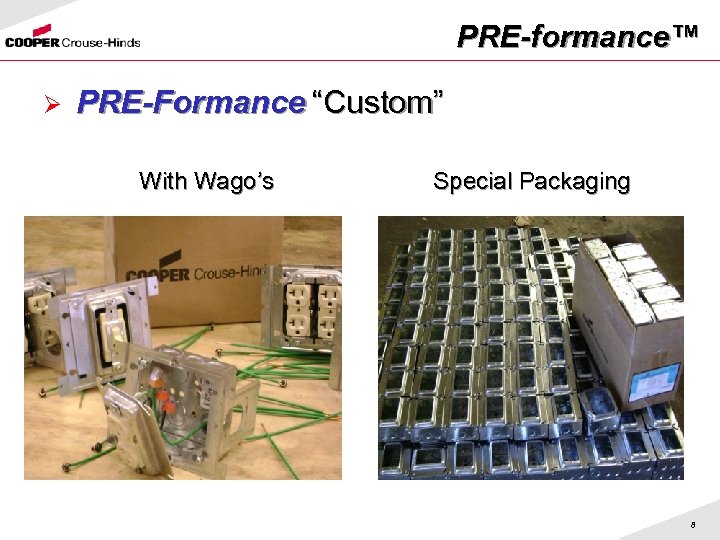

PRE-formance™ Ø PRE-Formance “Custom” With Wago’s Special Packaging 8

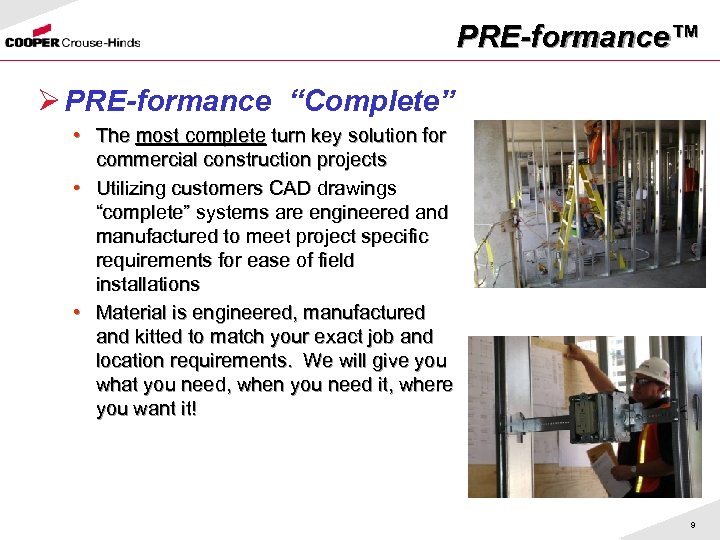

PRE-formance™ Ø PRE-formance “Complete” • The most complete turn key solution for commercial construction projects • Utilizing customers CAD drawings “complete” systems are engineered and manufactured to meet project specific requirements for ease of field installations • Material is engineered, manufactured and kitted to match your exact job and location requirements. We will give you what you need, when you need it, where you want it! 9

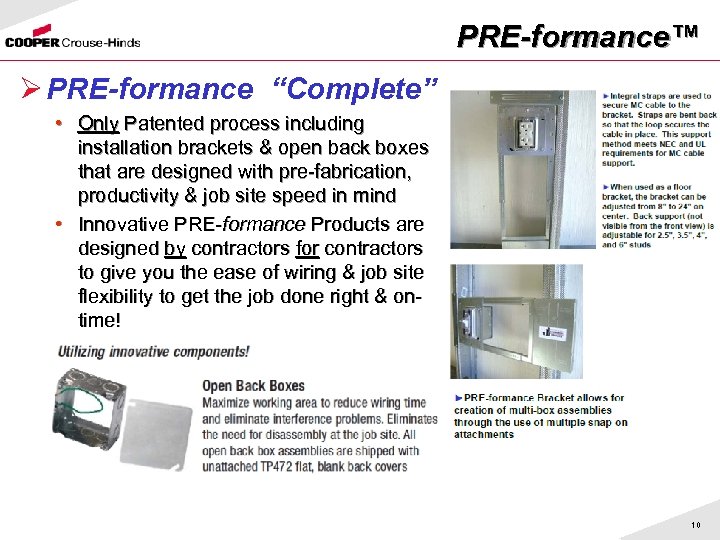

PRE-formance™ Ø PRE-formance “Complete” • Only Patented process including installation brackets & open back boxes that are designed with pre-fabrication, productivity & job site speed in mind • Innovative PRE-formance Products are designed by contractors for contractors to give you the ease of wiring & job site flexibility to get the job done right & ontime! 10

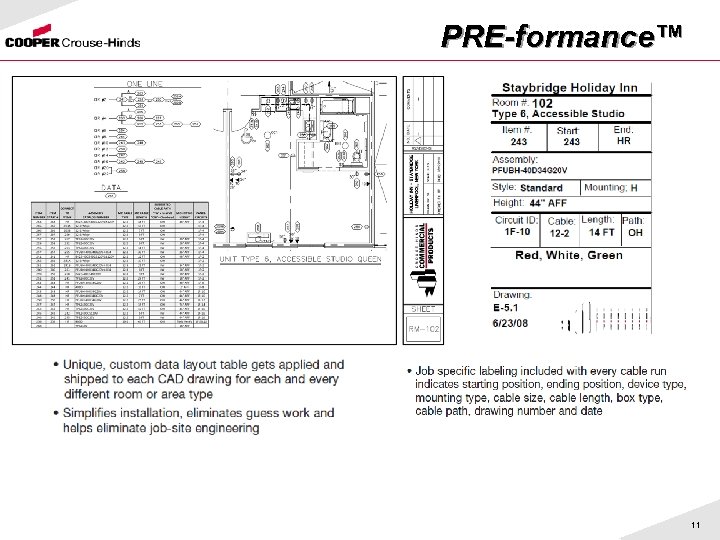

PRE-formance™ 11

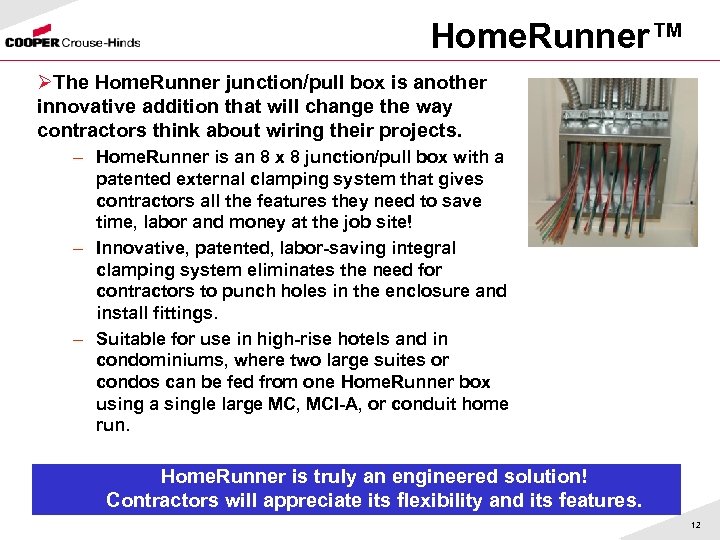

Home. Runner™ ØThe Home. Runner junction/pull box is another innovative addition that will change the way contractors think about wiring their projects. – Home. Runner is an 8 x 8 junction/pull box with a patented external clamping system that gives contractors all the features they need to save time, labor and money at the job site! – Innovative, patented, labor-saving integral clamping system eliminates the need for contractors to punch holes in the enclosure and install fittings. – Suitable for use in high-rise hotels and in condominiums, where two large suites or condos can be fed from one Home. Runner box using a single large MC, MCI-A, or conduit home run. Home. Runner is truly an engineered solution! Contractors will appreciate its flexibility and its features. 12

PRE-formance™ Ø PRE-formance Benefits PRE-formance • Labor Savings & Associated Impact • Material Considerations • Other (often overlooked) Considerations & Advantages 13

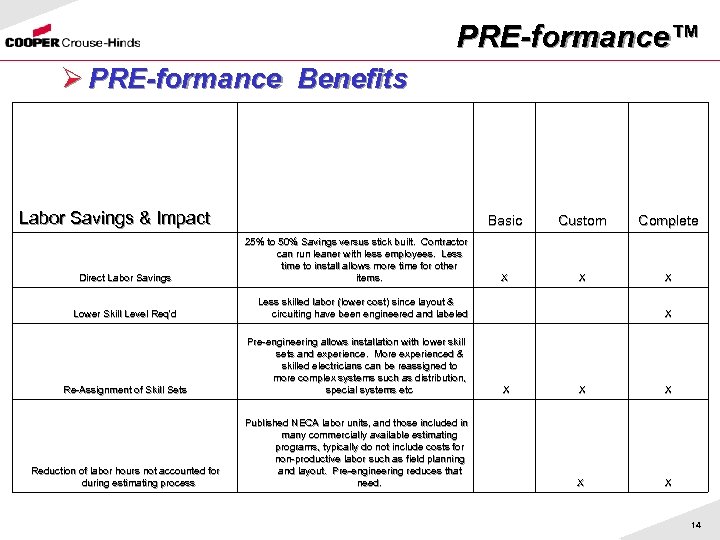

PRE-formance™ Ø PRE-formance Benefits Labor Savings & Impact Direct Labor Savings Lower Skill Level Req'd Basic Custom Complete 25% to 50% Savings versus stick built. Contractor can run leaner with less employees. Less time to install allows more time for other items. X X X Less skilled labor (lower cost) since layout & circuiting have been engineered and labeled X Re-Assignment of Skill Sets Pre-engineering allows installation with lower skill sets and experience. More experienced & skilled electricians can be reassigned to more complex systems such as distribution, special systems etc X X X Reduction of labor hours not accounted for during estimating process Published NECA labor units, and those included in many commercially available estimating programs, typically do not include costs for non-productive labor such as field planning and layout. Pre-engineering reduces that need. X X 14

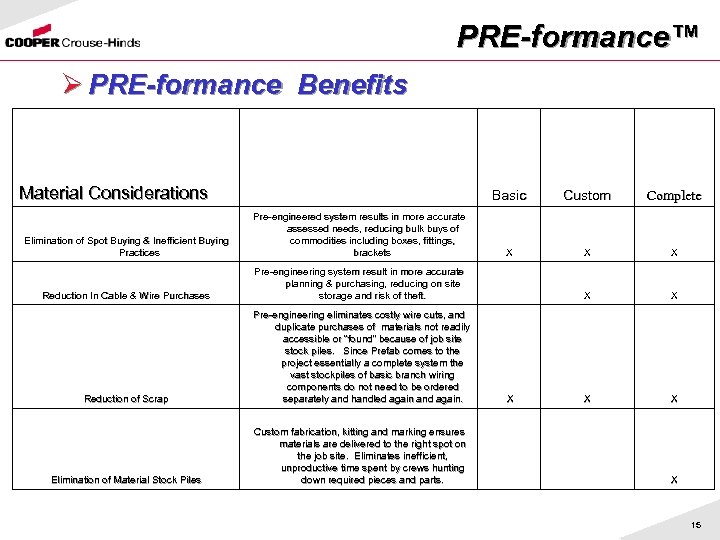

PRE-formance™ Ø PRE-formance Benefits Material Considerations Basic Custom Complete Elimination of Spot Buying & Inefficient Buying Practices Pre-engineered system results in more accurate assessed needs, reducing bulk buys of commodities including boxes, fittings, brackets X X X Reduction In Cable & Wire Purchases Pre-engineering system result in more accurate planning & purchasing, reducing on site storage and risk of theft. X X Reduction of Scrap Pre-engineering eliminates costly wire cuts, and duplicate purchases of materials not readily accessible or “found” because of job site stock piles. Since Prefab comes to the project essentially a complete system the vast stockpiles of basic branch wiring components do not need to be ordered separately and handled again and again. X X X Elimination of Material Stock Piles Custom fabrication, kitting and marking ensures materials are delivered to the right spot on the job site. Eliminates inefficient, unproductive time spent by crews hunting down required pieces and parts. X 15

PRE-formance™ Ø PRE-formance™ Economic Advantages • Cost for commodities (cable/wire) can be locked in well in advance of actual project delivery requirements • Prefab systems can be purchased and stored similar to lighting packages & distribution equipment which allows contractor to receive payment long before systems are ever installed • CCH design engineers can ID potential problems & conflicts long before field install is performed. CCH will issue RFI’s (on Pre-formance Complete) to resolve problems prior to fabrication of the system. This eases some of the burden on the contractor project managers and foreman allowing them to focus on other tasks 16

PRE-formance™ • PRE-formance™ Economic Advantages • Thorough and accurate engineering minimizes circuiting and related problems which reduce costly punch-list items and warranty calls • Higher productivity means that schedules can be more readily adhered to • Single greatest advantage for the Electrical Sub to control the pace of the job 17

PRE-formance™ Successes Ø PRE-formance Markets Served PRE-formance – – – Hotels/Motels Assisted Living Centers & Medical Facilities Educational Facilities Condominiums Military Installations 18

PRE-formance™ Selling Support Tools – New Comprehensive Catalog Pages – Power. Point Presentation – Distributor Price Sheets – Samples! 19

PRE-formance™ Questions? Thank You! 20

683ced59f38679e291a3a6aa9b10e478.ppt