c91d241d2d892e760a674f62ab5c08d8.ppt

- Количество слайдов: 59

Practical Enterprise Modelling: ISA 88 and ISA 95 standards IEC SB 3 Sponsored Seminar Workshop on Industrial Automation Objects 3 -4 April 2001, Geneva, Switzerland Jean Vieille, Consultant ISA SP 88 & SP 95 committees member jean-vieille@usa. net

Practical Enterprise Modelling: ISA 88 and ISA 95 standards IEC SB 3 Sponsored Seminar Workshop on Industrial Automation Objects 3 -4 April 2001, Geneva, Switzerland Jean Vieille, Consultant ISA SP 88 & SP 95 committees member jean-vieille@usa. net

Agenda · ISA 88 and 95 in SCM and Production Scheduling · ISA 95 : Enterprise-Production Communication · ISA 88 : Modular Control

Agenda · ISA 88 and 95 in SCM and Production Scheduling · ISA 95 : Enterprise-Production Communication · ISA 88 : Modular Control

ISA 88 and 95 in SCM and Production Scheduling

ISA 88 and 95 in SCM and Production Scheduling

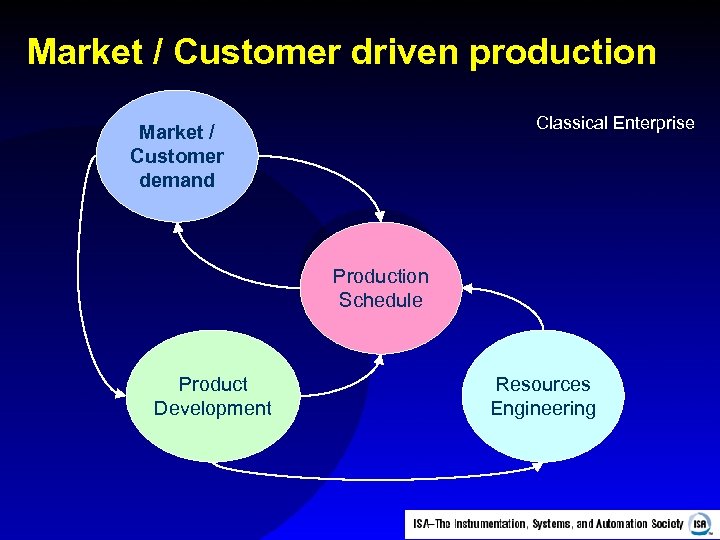

Market / Customer driven production Classical Enterprise Market / Customer demand Production Schedule Product Development Resources Engineering

Market / Customer driven production Classical Enterprise Market / Customer demand Production Schedule Product Development Resources Engineering

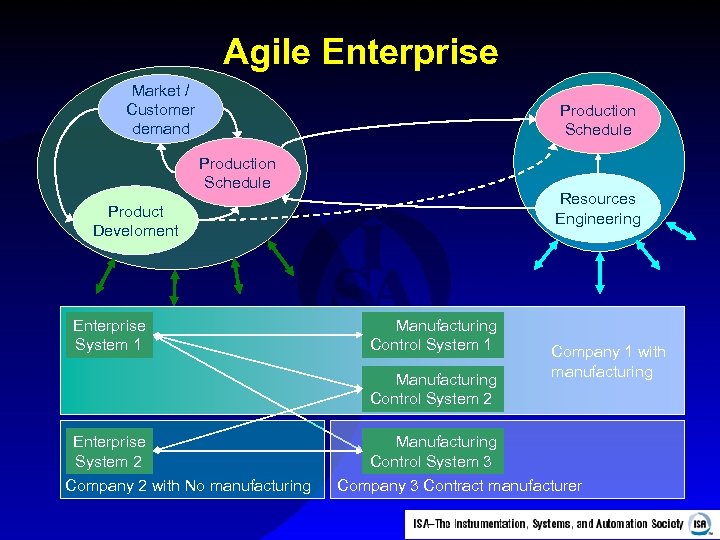

Agile Enterprise Market / Customer demand Production Schedule Resources Engineering Product Develoment Enterprise System 1 Manufacturing Control System 1 Manufacturing Control System 2 Enterprise System 2 Company 2 with No manufacturing Company 1 with manufacturing Manufacturing Control System 3 Company 3 Contract manufacturer

Agile Enterprise Market / Customer demand Production Schedule Resources Engineering Product Develoment Enterprise System 1 Manufacturing Control System 1 Manufacturing Control System 2 Enterprise System 2 Company 2 with No manufacturing Company 1 with manufacturing Manufacturing Control System 3 Company 3 Contract manufacturer

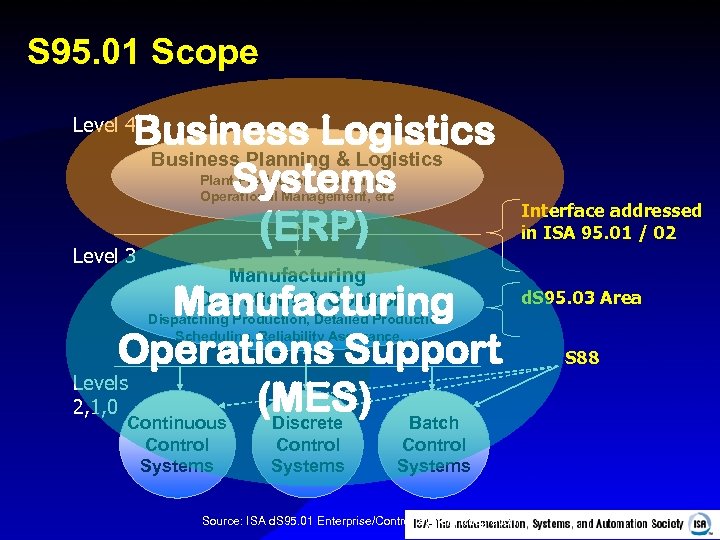

S 95. 01 Scope Business Logistics Business Planning & Logistics Systems (ERP) Level 4 Plant Production Scheduling, Operational Management, etc Level 3 Manufacturing Operations & Control Manufacturing Operations Support Levels (MES) Batch 2, 1, 0 Discrete Continuous Interface addressed in ISA 95. 01 / 02 d. S 95. 03 Area Dispatching Production, Detailed Production Scheduling, Reliability Assurance, . . . Control Systems Source: ISA d. S 95. 01 Enterprise/Control System Integration S 88

S 95. 01 Scope Business Logistics Business Planning & Logistics Systems (ERP) Level 4 Plant Production Scheduling, Operational Management, etc Level 3 Manufacturing Operations & Control Manufacturing Operations Support Levels (MES) Batch 2, 1, 0 Discrete Continuous Interface addressed in ISA 95. 01 / 02 d. S 95. 03 Area Dispatching Production, Detailed Production Scheduling, Reliability Assurance, . . . Control Systems Source: ISA d. S 95. 01 Enterprise/Control System Integration S 88

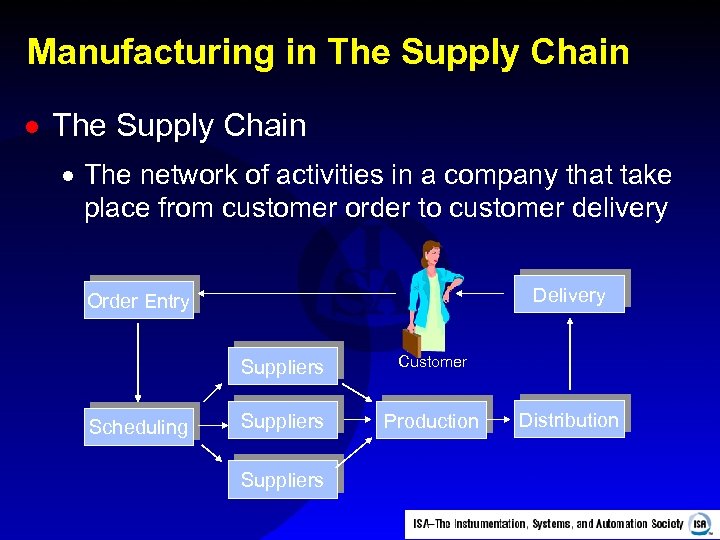

Manufacturing in The Supply Chain · The network of activities in a company that take place from customer order to customer delivery Delivery Order Entry Suppliers Scheduling Customer Suppliers Production Suppliers Distribution

Manufacturing in The Supply Chain · The network of activities in a company that take place from customer order to customer delivery Delivery Order Entry Suppliers Scheduling Customer Suppliers Production Suppliers Distribution

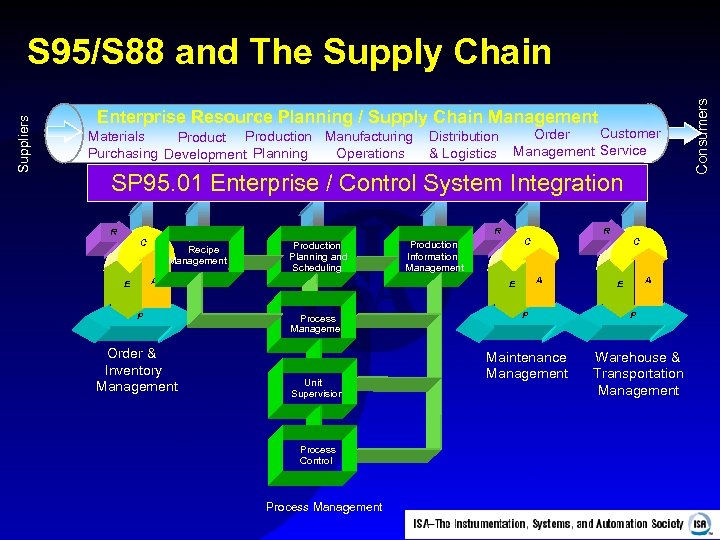

Enterprise Resource Planning / Supply Chain Management Materials Production Manufacturing Purchasing Development Planning Operations Distribution & Logistics Customer Management Service Order SP 95. 01 Enterprise / Control System Integration R R C Recipe Management Production Planning and Scheduling A E P Order & Inventory Management R Production Information Management A E Process Management Unit Supervision Process Control Process Management C C P Maintenance Management A E P Warehouse & Transportation Management Consumers Suppliers S 95/S 88 and The Supply Chain

Enterprise Resource Planning / Supply Chain Management Materials Production Manufacturing Purchasing Development Planning Operations Distribution & Logistics Customer Management Service Order SP 95. 01 Enterprise / Control System Integration R R C Recipe Management Production Planning and Scheduling A E P Order & Inventory Management R Production Information Management A E Process Management Unit Supervision Process Control Process Management C C P Maintenance Management A E P Warehouse & Transportation Management Consumers Suppliers S 95/S 88 and The Supply Chain

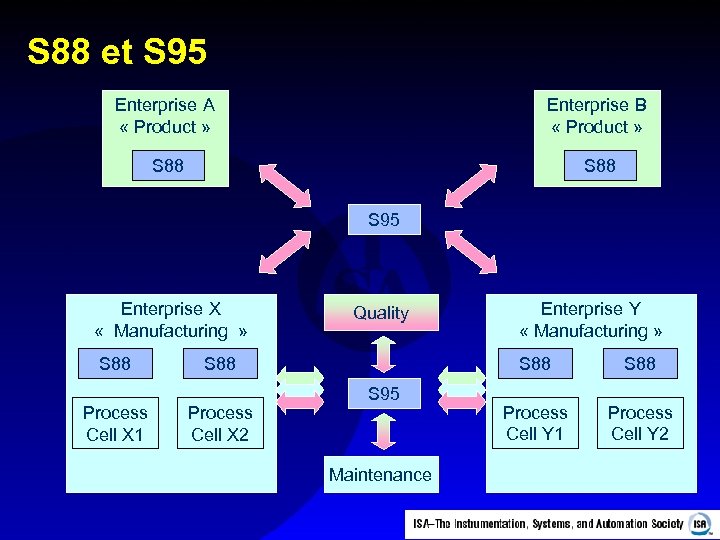

S 88 et S 95 Enterprise A « Product » Enterprise B « Product » S 88 S 95 Enterprise X « Manufacturing » S 88 Process Cell X 1 Quality S 88 Process Cell X 2 Enterprise Y « Manufacturing » S 88 S 95 Maintenance S 88 Process Cell Y 1 Process Cell Y 2

S 88 et S 95 Enterprise A « Product » Enterprise B « Product » S 88 S 95 Enterprise X « Manufacturing » S 88 Process Cell X 1 Quality S 88 Process Cell X 2 Enterprise Y « Manufacturing » S 88 S 95 Maintenance S 88 Process Cell Y 1 Process Cell Y 2

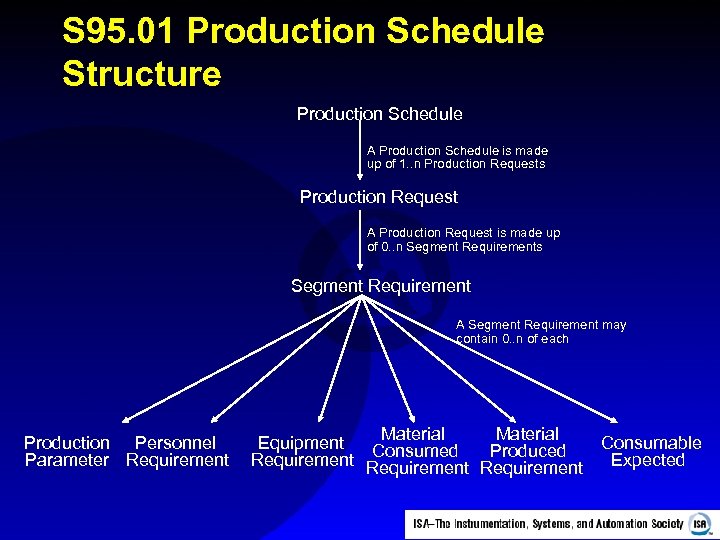

S 95. 01 Production Schedule Structure Production Schedule A Production Schedule is made up of 1. . n Production Requests Production Request A Production Request is made up of 0. . n Segment Requirements Segment Requirement A Segment Requirement may contain 0. . n of each Production Personnel Parameter Requirement Material Equipment Consumable Consumed Produced Requirement Expected

S 95. 01 Production Schedule Structure Production Schedule A Production Schedule is made up of 1. . n Production Requests Production Request A Production Request is made up of 0. . n Segment Requirements Segment Requirement A Segment Requirement may contain 0. . n of each Production Personnel Parameter Requirement Material Equipment Consumable Consumed Produced Requirement Expected

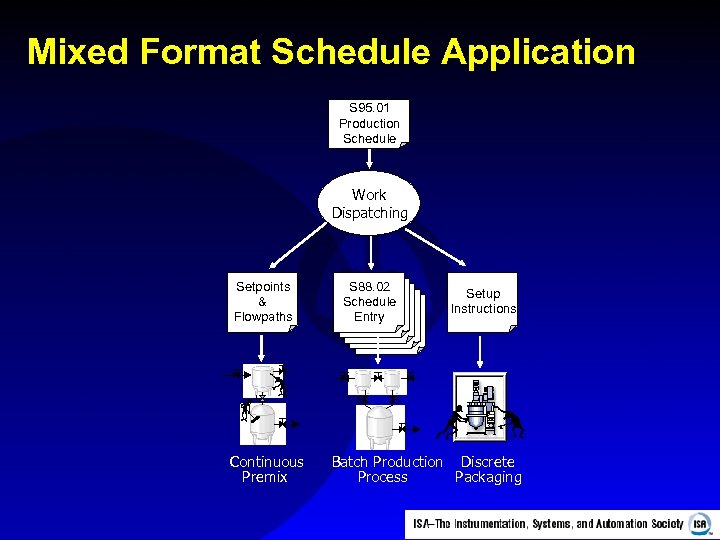

Mixed Format Schedule Application S 95. 01 Production Schedule Work Dispatching Setpoints & Flowpaths Continuous Premix S 88. 02 Schedule Entry Setup Instructions Batch Production Discrete Process Packaging

Mixed Format Schedule Application S 95. 01 Production Schedule Work Dispatching Setpoints & Flowpaths Continuous Premix S 88. 02 Schedule Entry Setup Instructions Batch Production Discrete Process Packaging

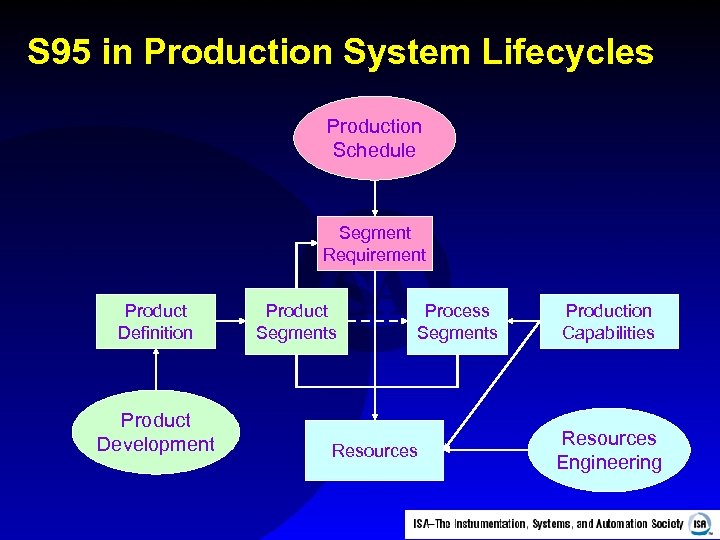

S 95 in Production System Lifecycles Production Schedule Segment Requirement Product Definition Product Development Product Segments Process Segments Resources Production Capabilities Resources Engineering

S 95 in Production System Lifecycles Production Schedule Segment Requirement Product Definition Product Development Product Segments Process Segments Resources Production Capabilities Resources Engineering

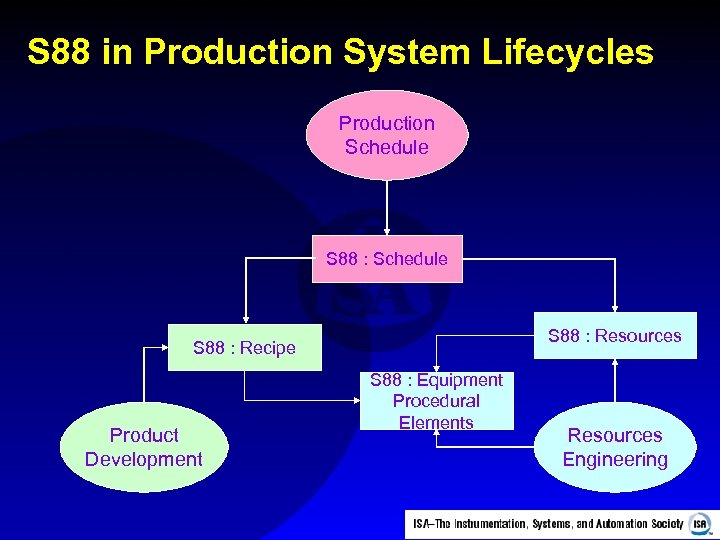

S 88 in Production System Lifecycles Production Schedule S 88 : Resources S 88 : Recipe Product Development S 88 : Equipment Procedural Elements Resources Engineering

S 88 in Production System Lifecycles Production Schedule S 88 : Resources S 88 : Recipe Product Development S 88 : Equipment Procedural Elements Resources Engineering

ISA 95 : Enterprise – Production Communication

ISA 95 : Enterprise – Production Communication

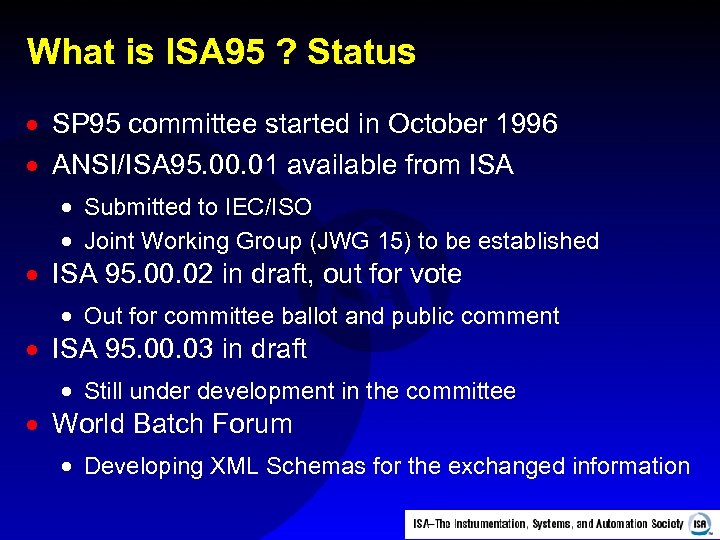

What is ISA 95 ? Status · SP 95 committee started in October 1996 · ANSI/ISA 95. 00. 01 available from ISA · Submitted to IEC/ISO · Joint Working Group (JWG 15) to be established · ISA 95. 00. 02 in draft, out for vote · Out for committee ballot and public comment · ISA 95. 00. 03 in draft · Still under development in the committee · World Batch Forum · Developing XML Schemas for the exchanged information

What is ISA 95 ? Status · SP 95 committee started in October 1996 · ANSI/ISA 95. 00. 01 available from ISA · Submitted to IEC/ISO · Joint Working Group (JWG 15) to be established · ISA 95. 00. 02 in draft, out for vote · Out for committee ballot and public comment · ISA 95. 00. 03 in draft · Still under development in the committee · World Batch Forum · Developing XML Schemas for the exchanged information

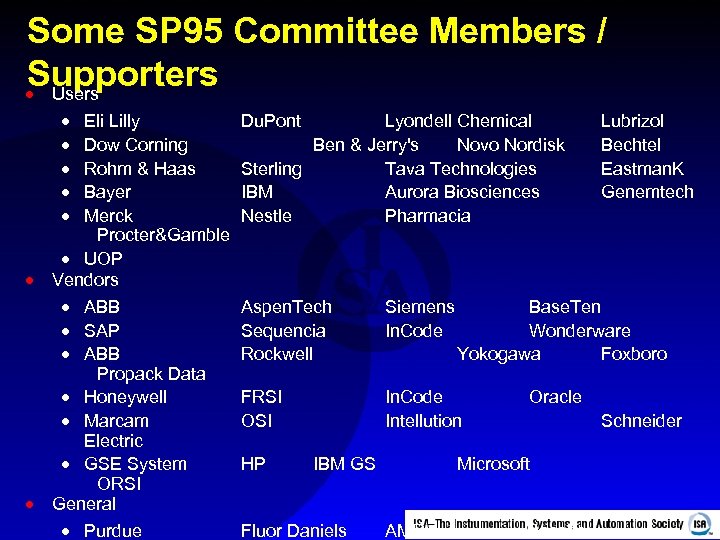

Some SP 95 Committee Members / Supporters · Users · · · · Eli Lilly Dow Corning Rohm & Haas Bayer Merck Procter&Gamble · UOP Vendors Du. Pont Lyondell Chemical Ben & Jerry's Novo Nordisk Sterling Tava Technologies IBM Aurora Biosciences Nestle Pharmacia · ABB · SAP · ABB Propack Data · Honeywell · Marcam Electric · GSE System ORSI General · Purdue Aspen. Tech Sequencia Rockwell Siemens In. Code FRSI OSI In. Code Intellution HP IBM GS Fluor Daniels Base. Ten Wonderware Yokogawa Foxboro Oracle Schneider Microsoft AMR Lubrizol Bechtel Eastman. K Genemtech Jacobs

Some SP 95 Committee Members / Supporters · Users · · · · Eli Lilly Dow Corning Rohm & Haas Bayer Merck Procter&Gamble · UOP Vendors Du. Pont Lyondell Chemical Ben & Jerry's Novo Nordisk Sterling Tava Technologies IBM Aurora Biosciences Nestle Pharmacia · ABB · SAP · ABB Propack Data · Honeywell · Marcam Electric · GSE System ORSI General · Purdue Aspen. Tech Sequencia Rockwell Siemens In. Code FRSI OSI In. Code Intellution HP IBM GS Fluor Daniels Base. Ten Wonderware Yokogawa Foxboro Oracle Schneider Microsoft AMR Lubrizol Bechtel Eastman. K Genemtech Jacobs

Why Did We Start SP 95 ? · Integration of business (logistics) systems to manufacturing is hard to do · Different systems, cultures, terminology. . . · Many benefits expected from standardization and documentation of “best practices” · Effective operation of manufacturing is hard to do · MES solutions are too related to processing methods and too industry-specific · Many benefits expected from standardization and documentation of “best practices”

Why Did We Start SP 95 ? · Integration of business (logistics) systems to manufacturing is hard to do · Different systems, cultures, terminology. . . · Many benefits expected from standardization and documentation of “best practices” · Effective operation of manufacturing is hard to do · MES solutions are too related to processing methods and too industry-specific · Many benefits expected from standardization and documentation of “best practices”

Business Defines the Need · There must always be a business need for information to be exchanged · Requirements for exchanged information are always driven by business needs & business processes · Typical Business Drivers: · · · Available To Promise Reduced Cycle Time Supply Chain Optimization Asset Efficiency Agile Manufacturing

Business Defines the Need · There must always be a business need for information to be exchanged · Requirements for exchanged information are always driven by business needs & business processes · Typical Business Drivers: · · · Available To Promise Reduced Cycle Time Supply Chain Optimization Asset Efficiency Agile Manufacturing

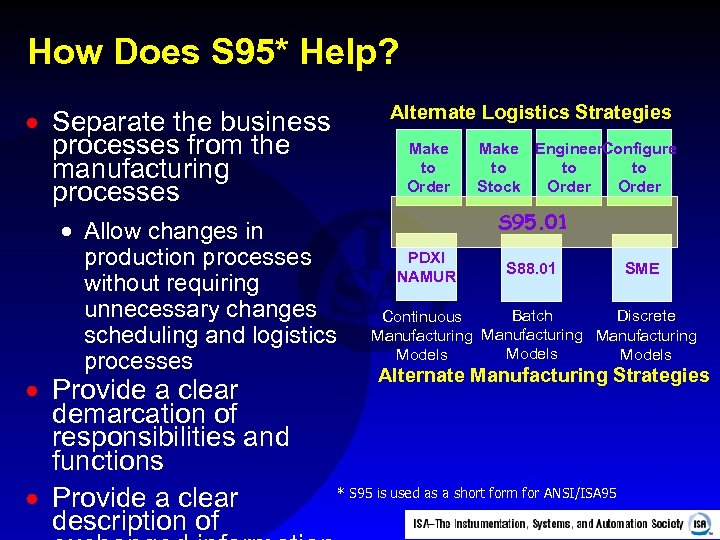

How Does S 95* Help? · Separate the business processes from the manufacturing processes · Allow changes in production processes without requiring unnecessary changes scheduling and logistics processes · Provide a clear demarcation of responsibilities and functions · Provide a clear description of Alternate Logistics Strategies Make to Order Make Engineer. Configure to to to Stock Order S 95. 01 PDXI NAMUR S 88. 01 SME Batch Discrete Continuous Manufacturing Models Alternate Manufacturing Strategies * S 95 is used as a short form for ANSI/ISA 95

How Does S 95* Help? · Separate the business processes from the manufacturing processes · Allow changes in production processes without requiring unnecessary changes scheduling and logistics processes · Provide a clear demarcation of responsibilities and functions · Provide a clear description of Alternate Logistics Strategies Make to Order Make Engineer. Configure to to to Stock Order S 95. 01 PDXI NAMUR S 88. 01 SME Batch Discrete Continuous Manufacturing Models Alternate Manufacturing Strategies * S 95 is used as a short form for ANSI/ISA 95

Scope of S 95. 01 · The definition of the scope of the manufacturing control domain · A definition of the functions associated with the interface between control functions and enterprise functions · A definition of the information which is shared between control functions and enterprise functions · Based on the Purdue Reference Model for CIM and MESA model

Scope of S 95. 01 · The definition of the scope of the manufacturing control domain · A definition of the functions associated with the interface between control functions and enterprise functions · A definition of the information which is shared between control functions and enterprise functions · Based on the Purdue Reference Model for CIM and MESA model

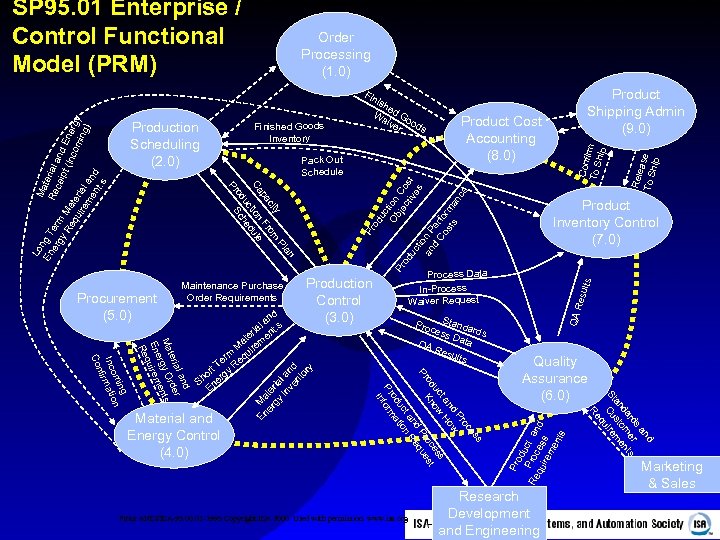

SP 95. 01 Enterprise / Control Functional Model (PRM) Order Processing (1. 0) od Pr Sta ces ndards s Da ta QA Res ults ts esul Pro From ANSI/ISA-95. 00. 01 -1995 Copyright ISA 2000. Used with permission. www. isa. org Pro du c Re Proc t an qu es d ire s me nts Quality Assurance (6. 0) Research Development and Engineering d an s rd er s da om nt an st me St Cu ire qu Re En Ma er te gy ria In l a ve nd nt or y Process Data In-Process Waiver Request ss ce ro P nd ow t a H ss uc ow ce t od Kn ro es Pr P qu nd e t a n R uc tio od a Pr form In Material and Energy Control (4. 0) Production Control (3. 0) QA R Pr od n la nd al a der r teri Ma y O ents erg En uirem q Re ing n om Inc rmatio nfi Co nd a al nt. s i er e at em M ir m u er Req T rt y ho erg S n E Product Inventory Control (7. 0) uc tio an n P d er Co fo sts rm an P y m cit ro pa F Ca tion dule uc he od Sc Pr Procurement (5. 0) Maintenance Purchase Order Requirements Product Cost Accounting (8. 0) Rele a To S se hip Pack Out Schedule Product Shipping Admin (9. 0) Con fi To S rm hip Finished Goods Inventory ce Production Scheduling (2. 0) nis he Wa d G ive ood s r uc Ob tion jec Co tiv st es Lo Ma n t En g T Re erial a er erm cei gy pt ( nd E R Ma Inc ner eq te om gy uir ria ing em l a ) en nd t. s Fi Marketing & Sales

SP 95. 01 Enterprise / Control Functional Model (PRM) Order Processing (1. 0) od Pr Sta ces ndards s Da ta QA Res ults ts esul Pro From ANSI/ISA-95. 00. 01 -1995 Copyright ISA 2000. Used with permission. www. isa. org Pro du c Re Proc t an qu es d ire s me nts Quality Assurance (6. 0) Research Development and Engineering d an s rd er s da om nt an st me St Cu ire qu Re En Ma er te gy ria In l a ve nd nt or y Process Data In-Process Waiver Request ss ce ro P nd ow t a H ss uc ow ce t od Kn ro es Pr P qu nd e t a n R uc tio od a Pr form In Material and Energy Control (4. 0) Production Control (3. 0) QA R Pr od n la nd al a der r teri Ma y O ents erg En uirem q Re ing n om Inc rmatio nfi Co nd a al nt. s i er e at em M ir m u er Req T rt y ho erg S n E Product Inventory Control (7. 0) uc tio an n P d er Co fo sts rm an P y m cit ro pa F Ca tion dule uc he od Sc Pr Procurement (5. 0) Maintenance Purchase Order Requirements Product Cost Accounting (8. 0) Rele a To S se hip Pack Out Schedule Product Shipping Admin (9. 0) Con fi To S rm hip Finished Goods Inventory ce Production Scheduling (2. 0) nis he Wa d G ive ood s r uc Ob tion jec Co tiv st es Lo Ma n t En g T Re erial a er erm cei gy pt ( nd E R Ma Inc ner eq te om gy uir ria ing em l a ) en nd t. s Fi Marketing & Sales

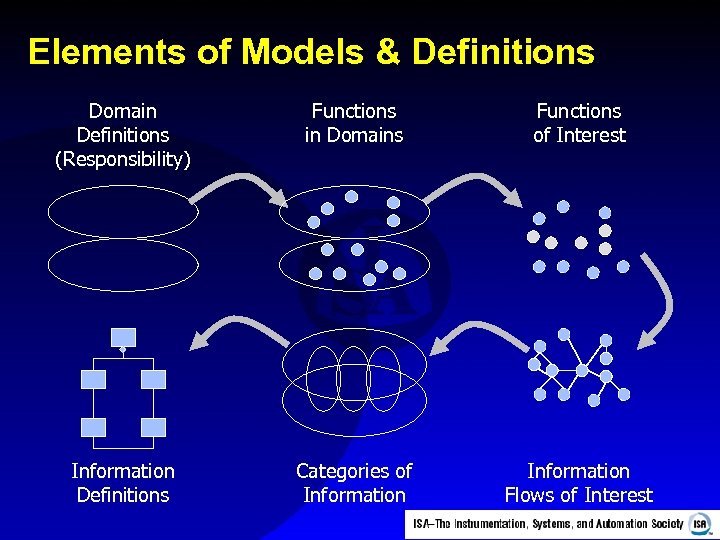

Elements of Models & Definitions Domain Definitions (Responsibility) Functions in Domains Functions of Interest Information Definitions Categories of Information Flows of Interest

Elements of Models & Definitions Domain Definitions (Responsibility) Functions in Domains Functions of Interest Information Definitions Categories of Information Flows of Interest

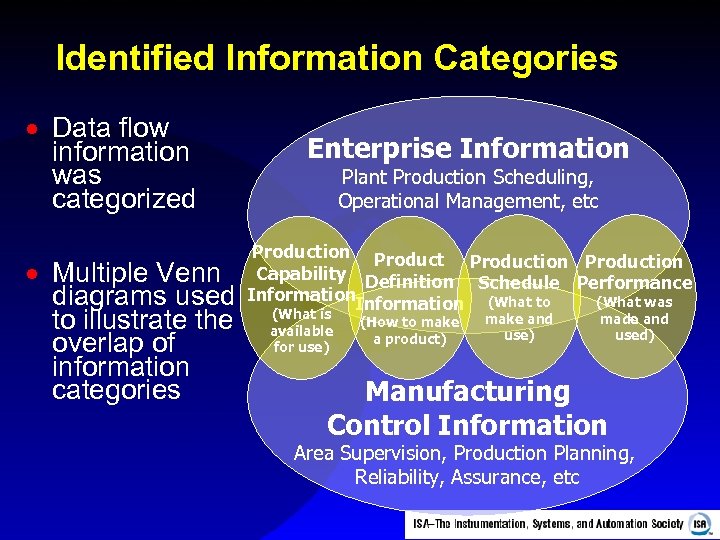

Identified Information Categories · Data flow information was categorized · Enterprise Information Plant Production Scheduling, Operational Management, etc Production Capability Definition Multiple Venn Schedule Performance Information (What to diagrams used (What was to illustrate the overlap of information categories (What is available for use) (How to make a product) make and use) made and used) Manufacturing Control Information Area Supervision, Production Planning, Reliability, Assurance, etc

Identified Information Categories · Data flow information was categorized · Enterprise Information Plant Production Scheduling, Operational Management, etc Production Capability Definition Multiple Venn Schedule Performance Information (What to diagrams used (What was to illustrate the overlap of information categories (What is available for use) (How to make a product) make and use) made and used) Manufacturing Control Information Area Supervision, Production Planning, Reliability, Assurance, etc

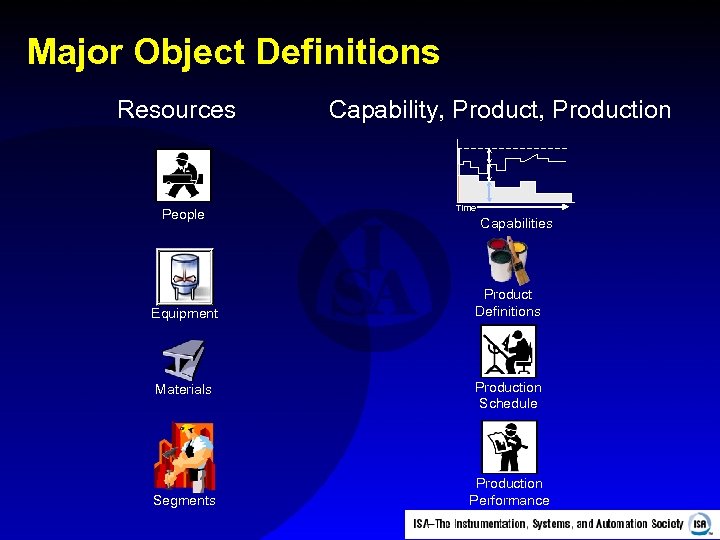

Major Object Definitions Resources Capability, Production Product People Equipment Materials Segments Time Capabilities Product Definitions Production Schedule Production Performance

Major Object Definitions Resources Capability, Production Product People Equipment Materials Segments Time Capabilities Product Definitions Production Schedule Production Performance

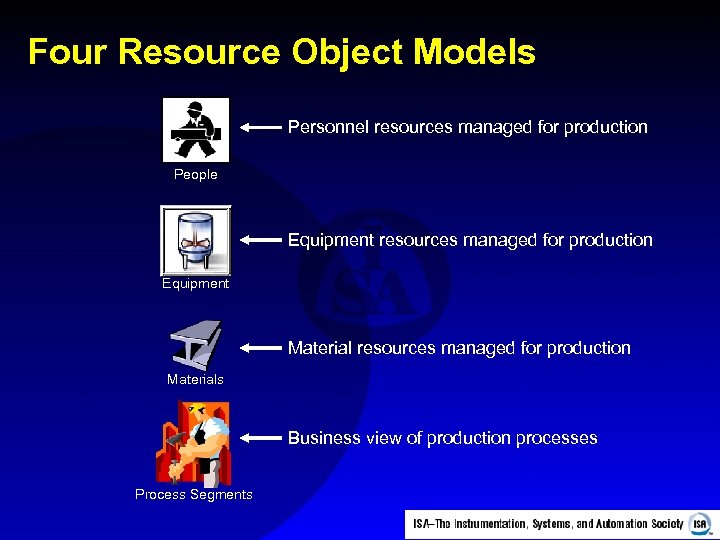

Four Resource Object Models Personnel resources managed for production People Equipment resources managed for production Equipment Material resources managed for production Materials Business view of production processes Process Segments

Four Resource Object Models Personnel resources managed for production People Equipment resources managed for production Equipment Material resources managed for production Materials Business view of production processes Process Segments

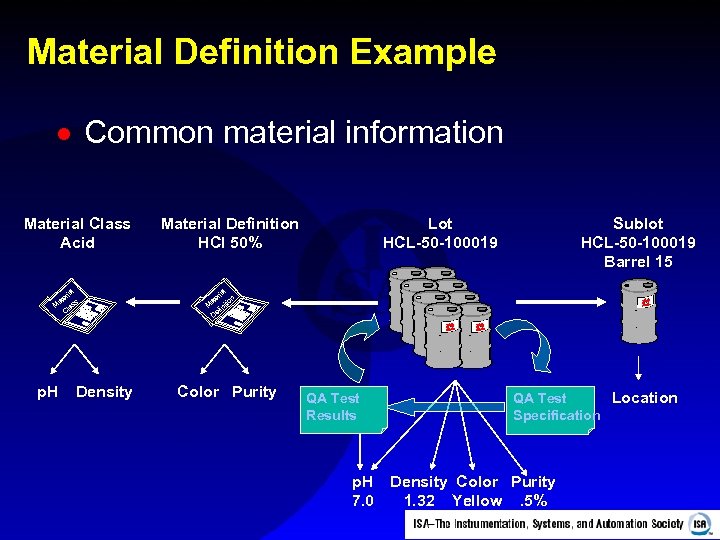

Material Definition Example · Common material information Material Class Acid l ia er at ss M la C p. H Density Material Definition HCl 50% Lot HCL-50 -100019 Sublot HCL-50 -100019 Barrel 15 l ia er at ition M in f De Color Purity QA Test Results p. H 7. 0 Location QA Test Specification Density Color Purity 1. 32 Yellow. 5%

Material Definition Example · Common material information Material Class Acid l ia er at ss M la C p. H Density Material Definition HCl 50% Lot HCL-50 -100019 Sublot HCL-50 -100019 Barrel 15 l ia er at ition M in f De Color Purity QA Test Results p. H 7. 0 Location QA Test Specification Density Color Purity 1. 32 Yellow. 5%

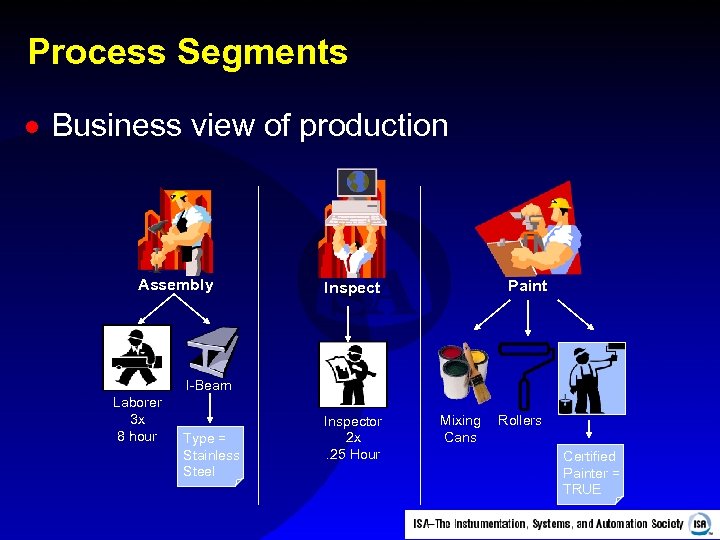

Process Segments · Business view of production Assembly Paint Inspect I-Beam Laborer 3 x 8 hour Type = Stainless Steel Inspector 2 x. 25 Hour Mixing Cans Rollers Certified Painter = TRUE

Process Segments · Business view of production Assembly Paint Inspect I-Beam Laborer 3 x 8 hour Type = Stainless Steel Inspector 2 x. 25 Hour Mixing Cans Rollers Certified Painter = TRUE

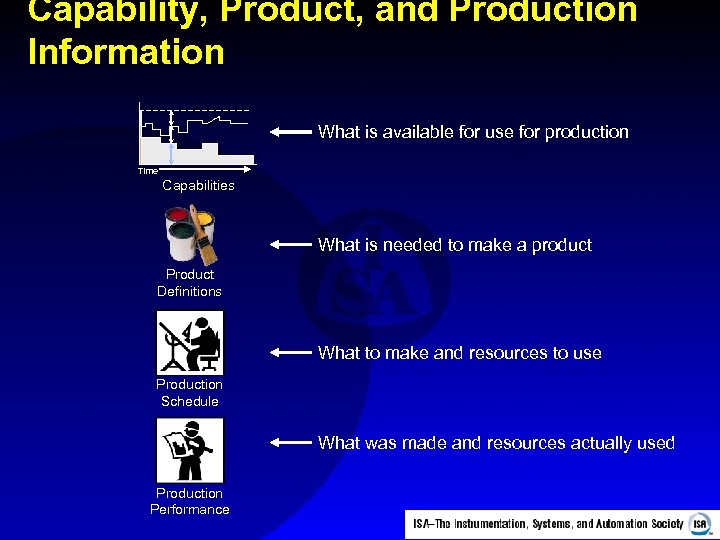

Capability, Product, and Production Information What is available for use for production Product Time Capabilities What is needed to make a product Product Definitions What to make and resources to use Production Schedule What was made and resources actually used Production Performance

Capability, Product, and Production Information What is available for use for production Product Time Capabilities What is needed to make a product Product Definitions What to make and resources to use Production Schedule What was made and resources actually used Production Performance

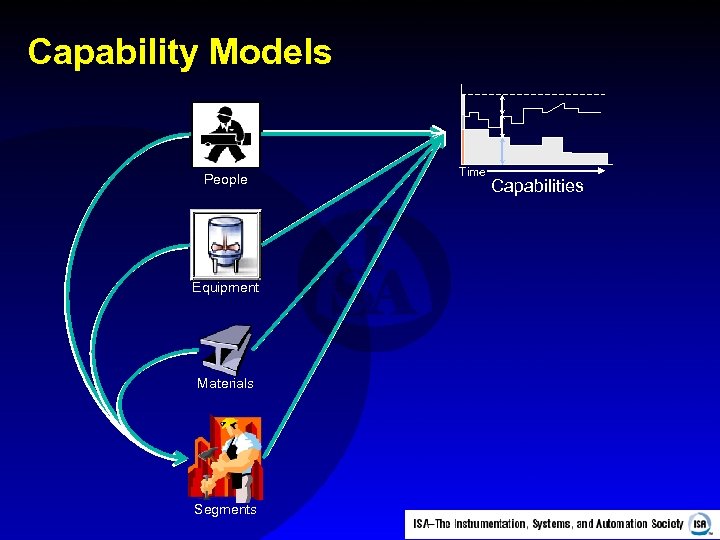

Capability Models Product People Equipment Materials Segments Time Capabilities

Capability Models Product People Equipment Materials Segments Time Capabilities

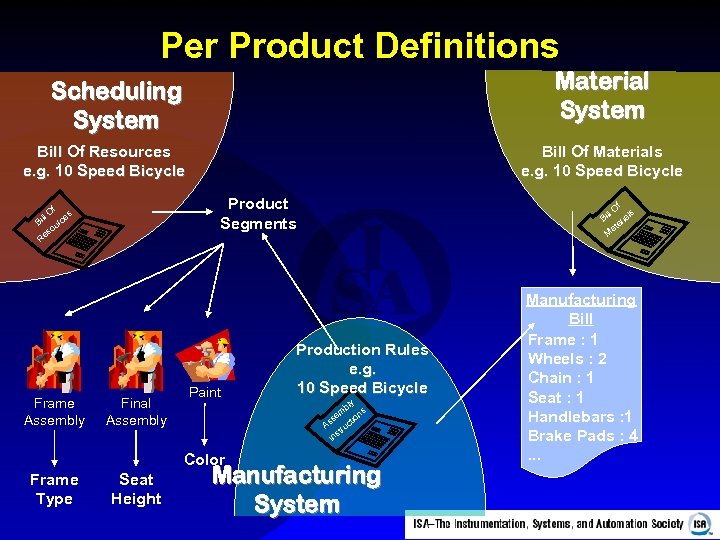

Per Product Definitions Material System Scheduling System Bill Of Resources e. g. 10 Speed Bicycle Product Segments f O s ill rce B u so Re Frame Assembly Bill Of Materials e. g. 10 Speed Bicycle Final Assembly Paint Color Frame Type Seat Height f ll O als i er at M Bi Production Rules e. g. 10 Speed Bicycle y bl em ions s t As ruc t s In Manufacturing System Manufacturing Bill Frame : 1 Wheels : 2 Chain : 1 Seat : 1 Handlebars : 1 Brake Pads : 4. . .

Per Product Definitions Material System Scheduling System Bill Of Resources e. g. 10 Speed Bicycle Product Segments f O s ill rce B u so Re Frame Assembly Bill Of Materials e. g. 10 Speed Bicycle Final Assembly Paint Color Frame Type Seat Height f ll O als i er at M Bi Production Rules e. g. 10 Speed Bicycle y bl em ions s t As ruc t s In Manufacturing System Manufacturing Bill Frame : 1 Wheels : 2 Chain : 1 Seat : 1 Handlebars : 1 Brake Pads : 4. . .

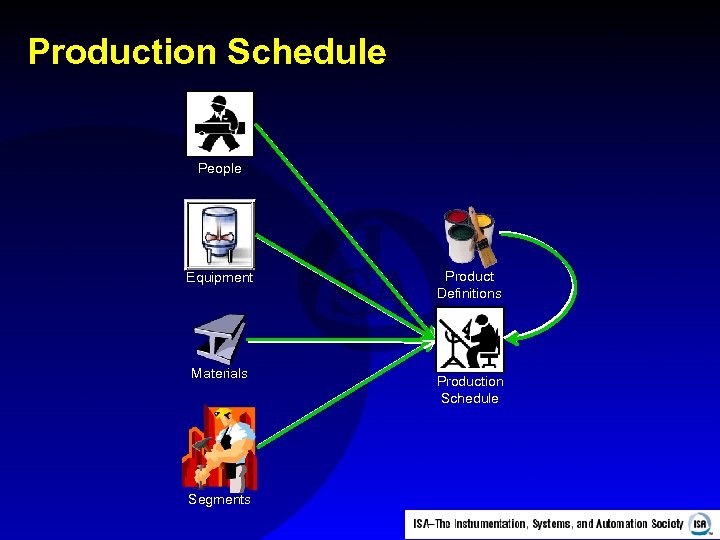

Production Schedule People Equipment Materials Segments Product Definitions Production Schedule

Production Schedule People Equipment Materials Segments Product Definitions Production Schedule

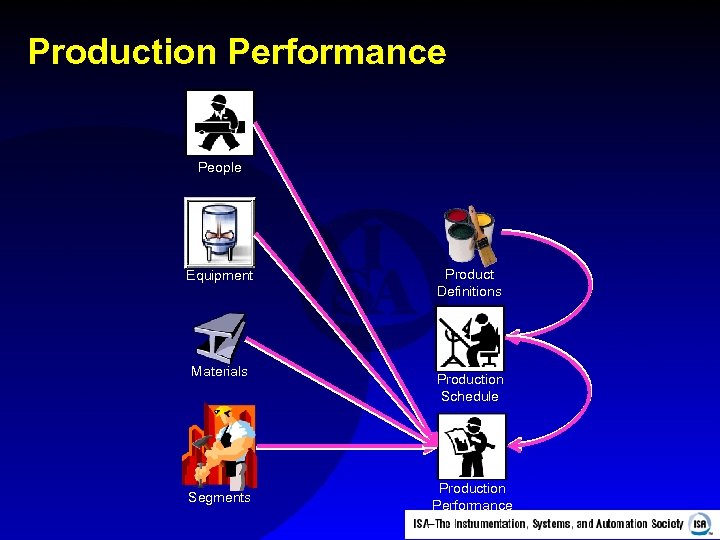

Production Performance People Equipment Materials Segments Product Definitions Production Schedule Production Performance

Production Performance People Equipment Materials Segments Product Definitions Production Schedule Production Performance

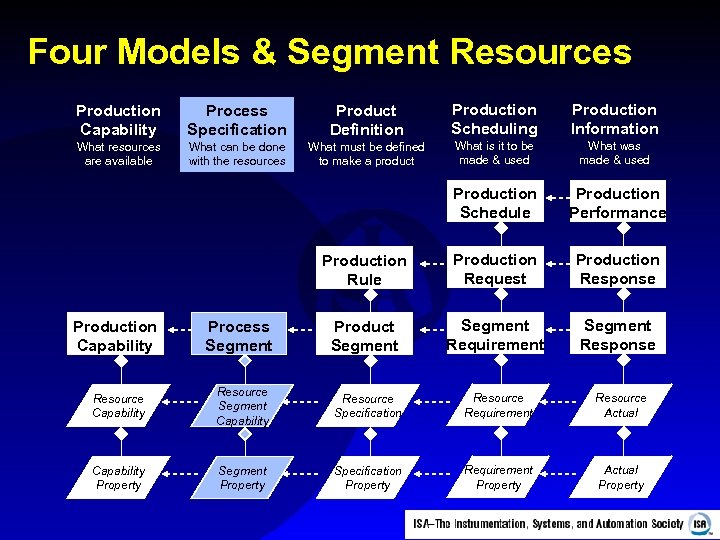

Four Models & Segment Resources Production Capability Process Specification Product Definition Production Scheduling Production Information What resources are available What can be done with the resources What must be defined to make a product What is it to be made & used What was made & used Production Schedule Production Performance Production Rule Production Request Production Response Production Capability Process Segment Product Segment Requirement Segment Response Resource Capability Resource Segment Capability Resource Specification Resource Requirement Resource Actual Capability Property Segment Property Specification Property Requirement Property Actual Property

Four Models & Segment Resources Production Capability Process Specification Product Definition Production Scheduling Production Information What resources are available What can be done with the resources What must be defined to make a product What is it to be made & used What was made & used Production Schedule Production Performance Production Rule Production Request Production Response Production Capability Process Segment Product Segment Requirement Segment Response Resource Capability Resource Segment Capability Resource Specification Resource Requirement Resource Actual Capability Property Segment Property Specification Property Requirement Property Actual Property

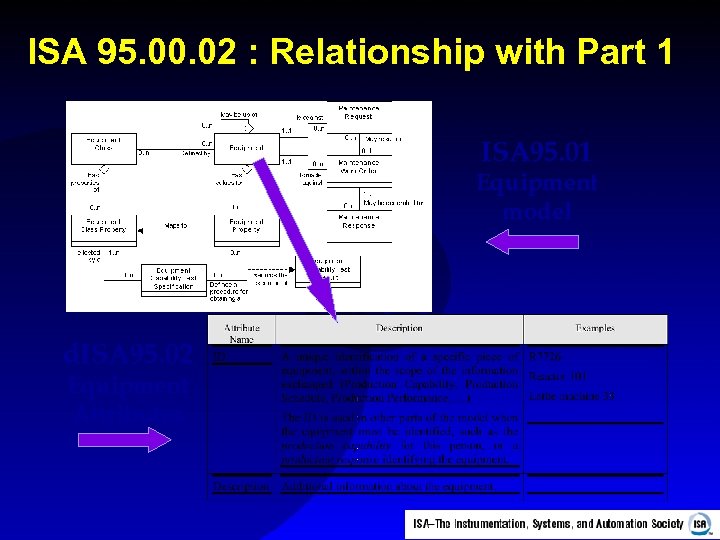

ISA 95. 00. 02 : Relationship with Part 1 ISA 95. 01 Equipment model d. ISA 95. 02 Equipment Attributes

ISA 95. 00. 02 : Relationship with Part 1 ISA 95. 01 Equipment model d. ISA 95. 02 Equipment Attributes

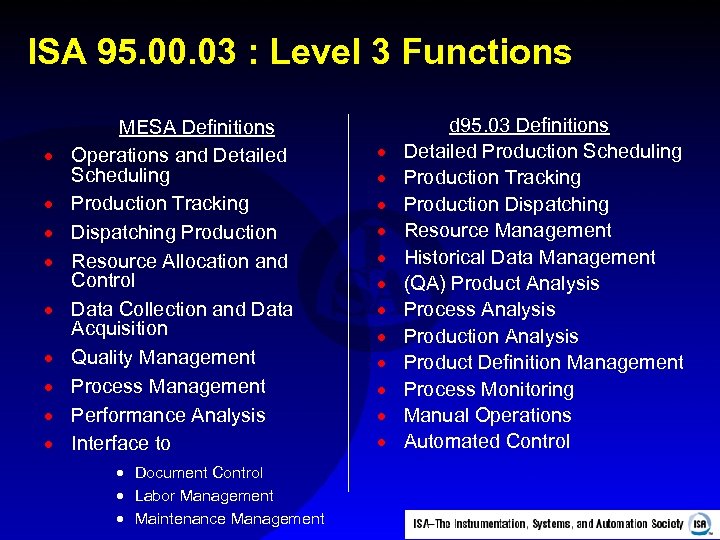

ISA 95. 00. 03 : Level 3 Functions · · · · · MESA Definitions Operations and Detailed Scheduling Production Tracking Dispatching Production Resource Allocation and Control Data Collection and Data Acquisition Quality Management Process Management Performance Analysis Interface to · Document Control · Labor Management · Maintenance Management · · · d 95. 03 Definitions Detailed Production Scheduling Production Tracking Production Dispatching Resource Management Historical Data Management (QA) Product Analysis Process Analysis Production Analysis Product Definition Management Process Monitoring Manual Operations Automated Control

ISA 95. 00. 03 : Level 3 Functions · · · · · MESA Definitions Operations and Detailed Scheduling Production Tracking Dispatching Production Resource Allocation and Control Data Collection and Data Acquisition Quality Management Process Management Performance Analysis Interface to · Document Control · Labor Management · Maintenance Management · · · d 95. 03 Definitions Detailed Production Scheduling Production Tracking Production Dispatching Resource Management Historical Data Management (QA) Product Analysis Process Analysis Production Analysis Product Definition Management Process Monitoring Manual Operations Automated Control

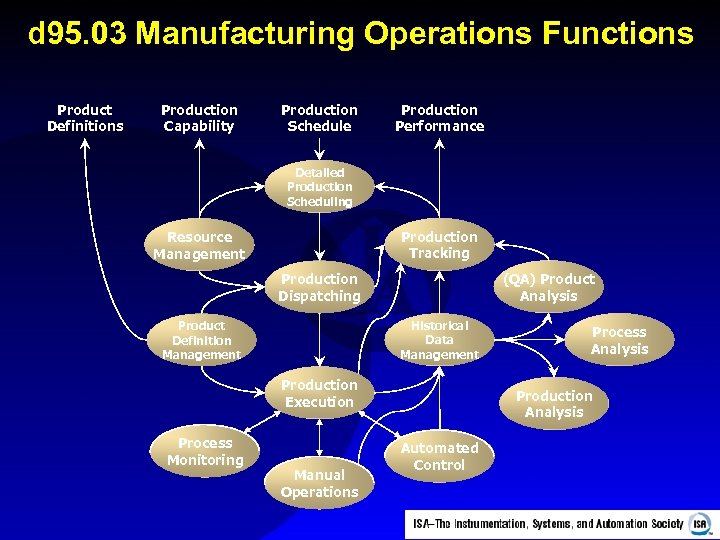

d 95. 03 Manufacturing Operations Functions Product Definitions Production Capability Production Schedule Production Performance Detailed Production Scheduling Production Tracking Resource Management (QA) Product Analysis Production Dispatching Historical Data Management Product Definition Management Production Execution Process Monitoring Manual Operations Process Analysis Production Analysis Automated Control

d 95. 03 Manufacturing Operations Functions Product Definitions Production Capability Production Schedule Production Performance Detailed Production Scheduling Production Tracking Resource Management (QA) Product Analysis Production Dispatching Historical Data Management Product Definition Management Production Execution Process Monitoring Manual Operations Process Analysis Production Analysis Automated Control

ISA 88 : Modular control

ISA 88 : Modular control

What is ISA 88 ? - Status · Standard ANSI/ISA 88 « Batch Control » · Comité SP 88 lancé en 1988 · Partie 1 – ISA 88. 00. 01 · Publiée et disponible à l’ISA et à l’ANSI · IEC 61512 -1 bilingue disponible auprès de l’IEC, l’UTE et l’AFNOR · Partie 2 – ISA 88. 00. 02 · Publication imminente · Version IEC (61512 -2) bilingue pour 2001? · Partie 3 – ISA 88. 00. 03 · Début des travaux

What is ISA 88 ? - Status · Standard ANSI/ISA 88 « Batch Control » · Comité SP 88 lancé en 1988 · Partie 1 – ISA 88. 00. 01 · Publiée et disponible à l’ISA et à l’ANSI · IEC 61512 -1 bilingue disponible auprès de l’IEC, l’UTE et l’AFNOR · Partie 2 – ISA 88. 00. 02 · Publication imminente · Version IEC (61512 -2) bilingue pour 2001? · Partie 3 – ISA 88. 00. 03 · Début des travaux

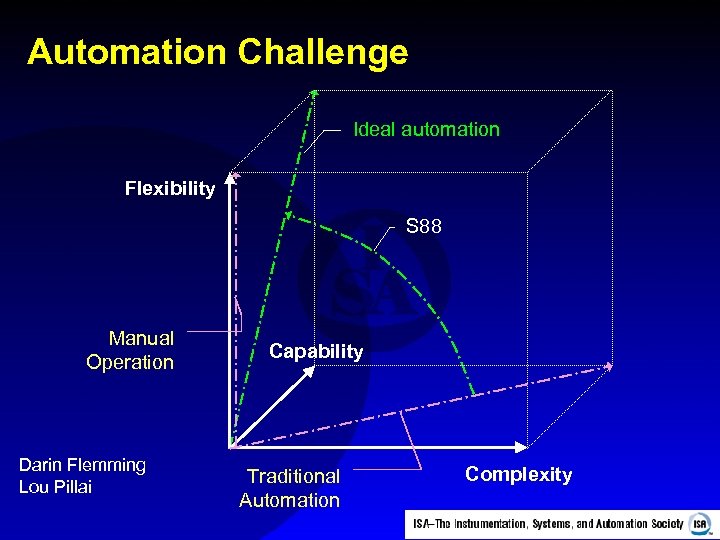

Automation Challenge Ideal automation Flexibility S 88 Manual Operation Darin Flemming Lou Pillai Capability Traditional Automation Complexity

Automation Challenge Ideal automation Flexibility S 88 Manual Operation Darin Flemming Lou Pillai Capability Traditional Automation Complexity

The Powerful Tyrex… · Big brain · Centralized design · OK for steady / slow changing environment · Shortcomings · Agility · Availability · Refer to first computerized systems

The Powerful Tyrex… · Big brain · Centralized design · OK for steady / slow changing environment · Shortcomings · Agility · Availability · Refer to first computerized systems

…vs Stupid Bird · Limited intelligence · Mostly decentralized design · Local decision making at feather level · Cope well with unexpected situations · Inherently adaptative structure

…vs Stupid Bird · Limited intelligence · Mostly decentralized design · Local decision making at feather level · Cope well with unexpected situations · Inherently adaptative structure

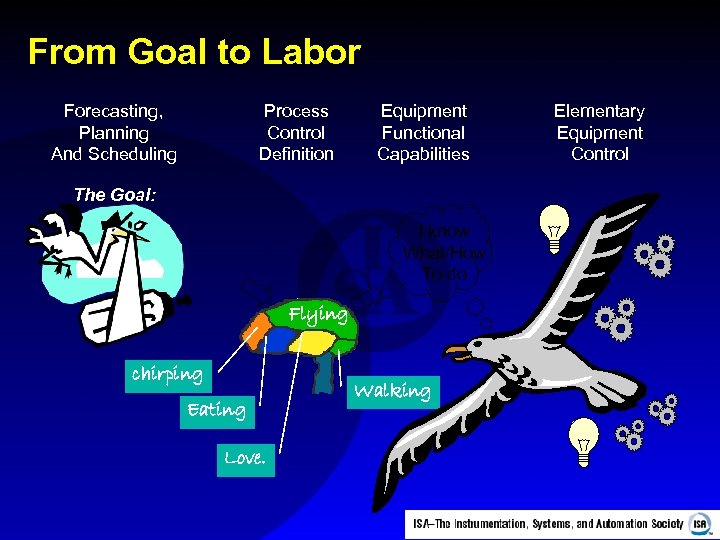

From Goal to Labor Forecasting, Planning And Scheduling Process Control Definition Equipment Functional Capabilities The Goal: I know What/How To do Flying chirping Eating Love. Walking Elementary Equipment Control

From Goal to Labor Forecasting, Planning And Scheduling Process Control Definition Equipment Functional Capabilities The Goal: I know What/How To do Flying chirping Eating Love. Walking Elementary Equipment Control

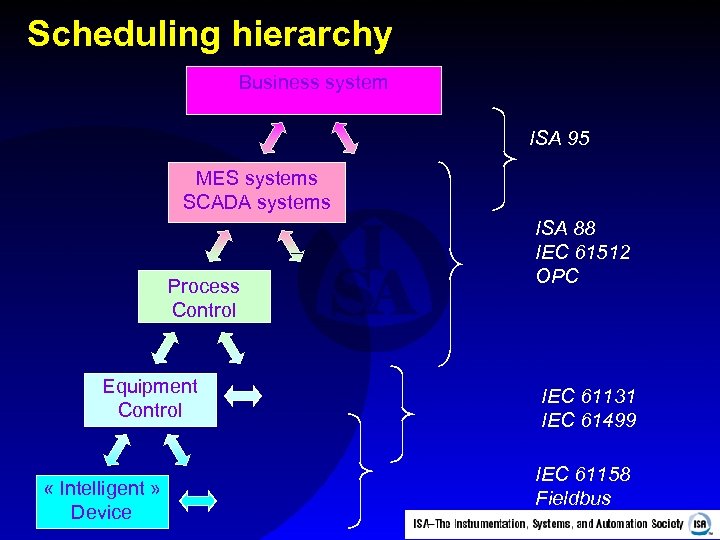

Scheduling hierarchy Business system ISA 95 MES systems SCADA systems Process Control Equipment Control « Intelligent » Device ISA 88 IEC 61512 OPC IEC 61131 IEC 61499 IEC 61158 Fieldbus

Scheduling hierarchy Business system ISA 95 MES systems SCADA systems Process Control Equipment Control « Intelligent » Device ISA 88 IEC 61512 OPC IEC 61131 IEC 61499 IEC 61158 Fieldbus

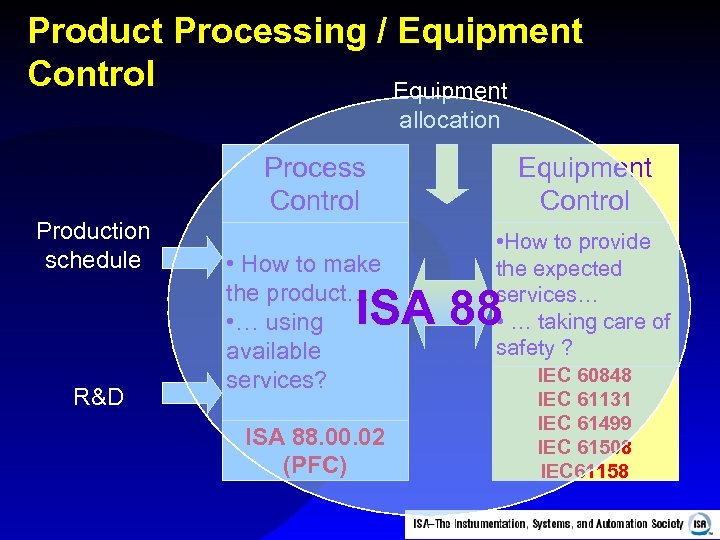

Product Processing / Equipment Control Equipment allocation Process Control Production schedule • How to make the product… • … using available services? Equipment Control • How to provide the expected services… • … taking care of safety ? ISA 88 R&D ISA 88. 00. 02 (PFC) IEC 60848 IEC 61131 IEC 61499 IEC 61508 IEC 61158

Product Processing / Equipment Control Equipment allocation Process Control Production schedule • How to make the product… • … using available services? Equipment Control • How to provide the expected services… • … taking care of safety ? ISA 88 R&D ISA 88. 00. 02 (PFC) IEC 60848 IEC 61131 IEC 61499 IEC 61508 IEC 61158

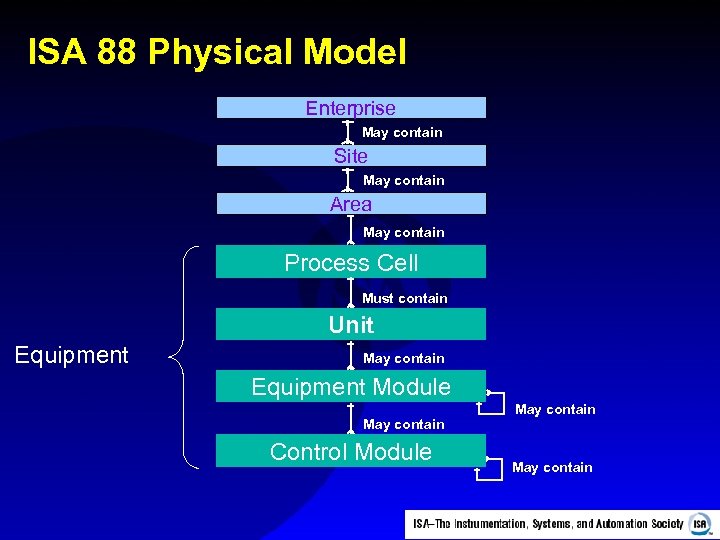

ISA 88 Physical Model Enterprise May contain Site May contain Area May contain Process Cell Must contain Unit Equipment May contain Equipment Module May contain Control Module May contain

ISA 88 Physical Model Enterprise May contain Site May contain Area May contain Process Cell Must contain Unit Equipment May contain Equipment Module May contain Control Module May contain

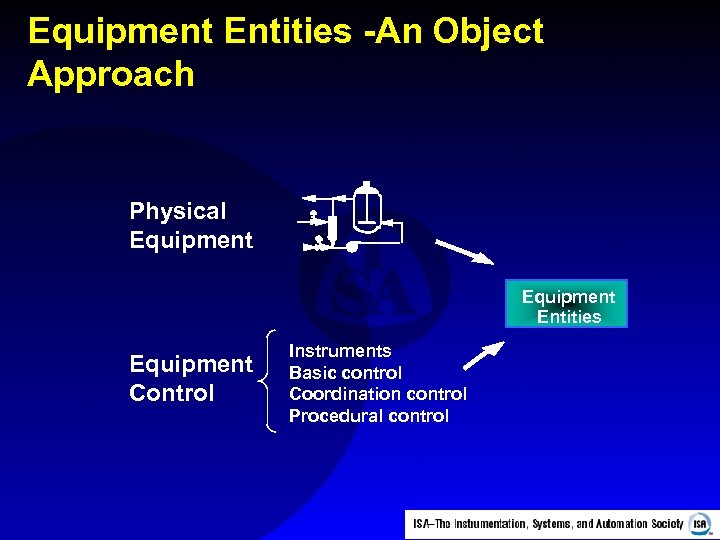

Equipment Entities -An Object Approach Physical Equipment Entities Equipment Control Instruments Basic control Coordination control Procedural control

Equipment Entities -An Object Approach Physical Equipment Entities Equipment Control Instruments Basic control Coordination control Procedural control

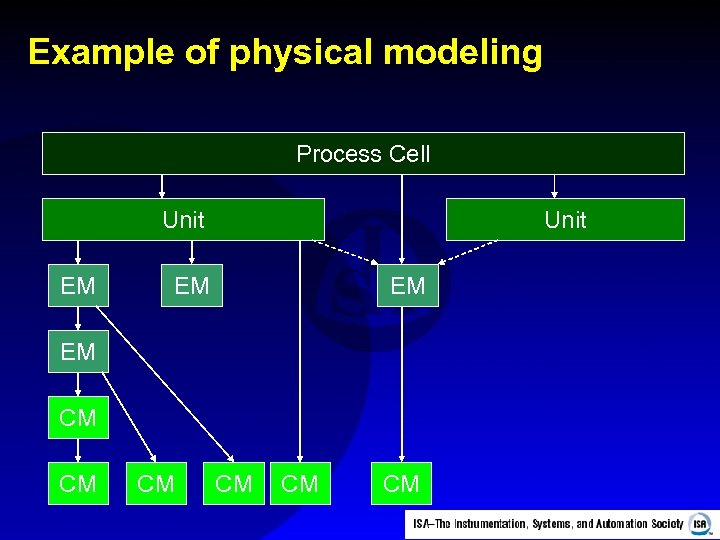

Example of physical modeling Process Cell Unit EM EM EM CM CM CM

Example of physical modeling Process Cell Unit EM EM EM CM CM CM

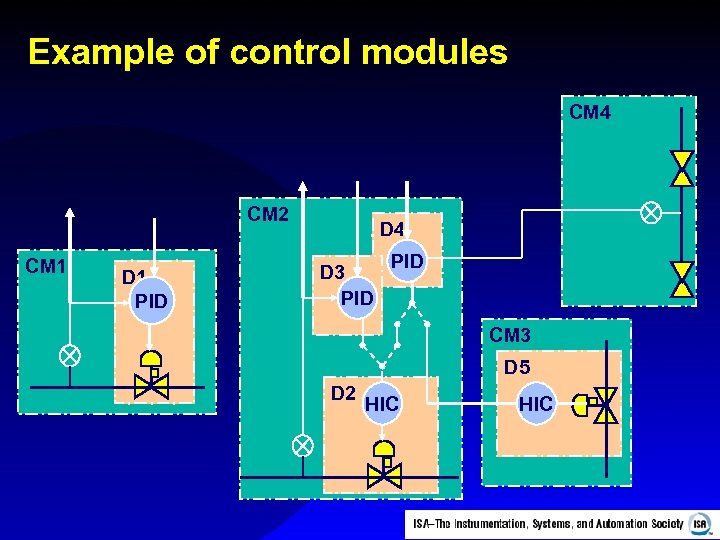

Example of control modules CM 4 CM 2 CM 1 D 1 PID D 4 D 3 PID CM 3 D 5 D 2 HIC

Example of control modules CM 4 CM 2 CM 1 D 1 PID D 4 D 3 PID CM 3 D 5 D 2 HIC

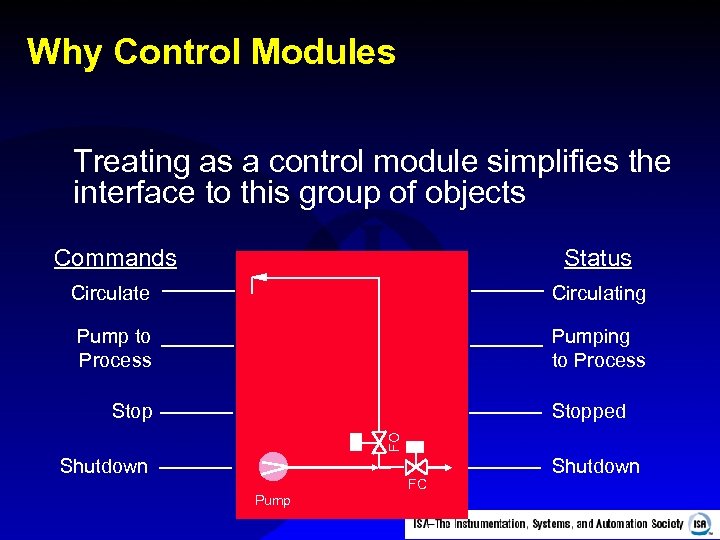

Why Control Modules Treating as a control module simplifies the interface to this group of objects Commands Status Circulate Circulating Pump to Process Pumping to Process Stopped FO Stop Shutdown FC Pump Shutdown

Why Control Modules Treating as a control module simplifies the interface to this group of objects Commands Status Circulate Circulating Pump to Process Pumping to Process Stopped FO Stop Shutdown FC Pump Shutdown

![Recipe/Equipment Control Separation Equipment Control Recipe Procedure [Must Always Exist] Procedure is an ordered Recipe/Equipment Control Separation Equipment Control Recipe Procedure [Must Always Exist] Procedure is an ordered](https://present5.com/presentation/c91d241d2d892e760a674f62ab5c08d8/image-50.jpg) Recipe/Equipment Control Separation Equipment Control Recipe Procedure [Must Always Exist] Procedure is an ordered set of Unit Procedure is an ordered set of Operation is an ordered set of Phase Equipment Phase

Recipe/Equipment Control Separation Equipment Control Recipe Procedure [Must Always Exist] Procedure is an ordered set of Unit Procedure is an ordered set of Operation is an ordered set of Phase Equipment Phase

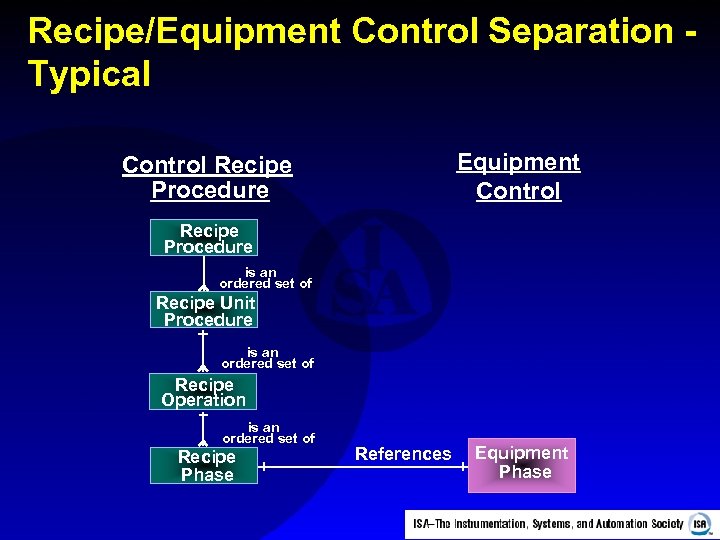

Recipe/Equipment Control Separation Typical Equipment Control Recipe Procedure is an ordered set of Recipe Unit Procedure is an ordered set of Recipe Operation is an ordered set of Recipe Phase References Equipment Phase

Recipe/Equipment Control Separation Typical Equipment Control Recipe Procedure is an ordered set of Recipe Unit Procedure is an ordered set of Recipe Operation is an ordered set of Recipe Phase References Equipment Phase

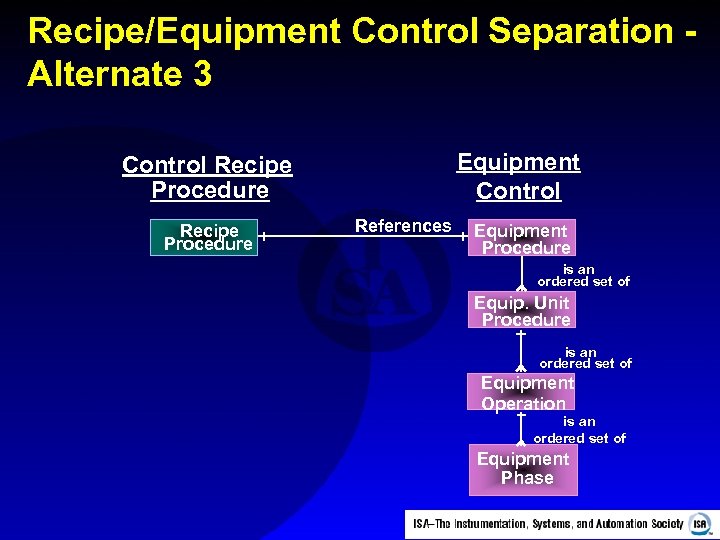

Recipe/Equipment Control Separation Alternate 3 Equipment Control Recipe Procedure References Equipment Procedure is an ordered set of Equip. Unit Procedure is an ordered set of Equipment Operation is an ordered set of Equipment Phase

Recipe/Equipment Control Separation Alternate 3 Equipment Control Recipe Procedure References Equipment Procedure is an ordered set of Equip. Unit Procedure is an ordered set of Equipment Operation is an ordered set of Equipment Phase

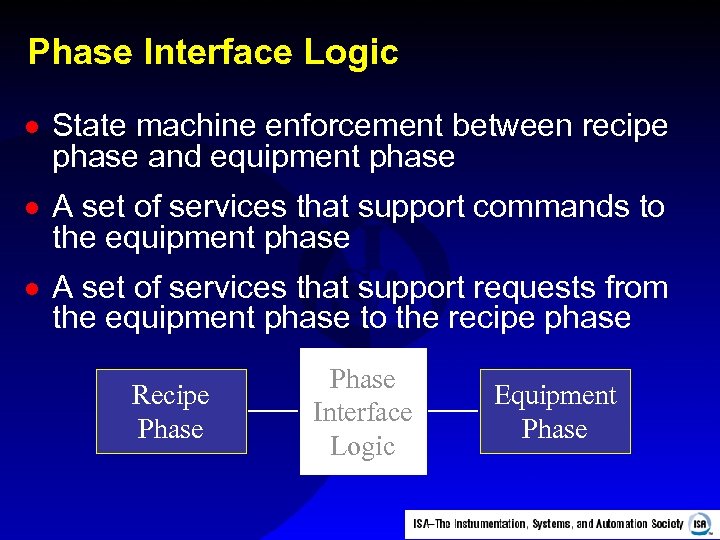

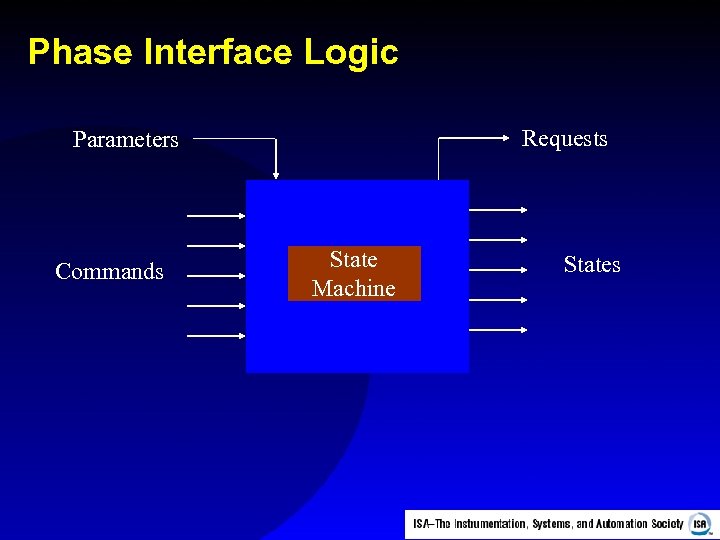

Phase Interface Logic · State machine enforcement between recipe phase and equipment phase · A set of services that support commands to the equipment phase · A set of services that support requests from the equipment phase to the recipe phase Recipe Phase Interface Logic Equipment Phase

Phase Interface Logic · State machine enforcement between recipe phase and equipment phase · A set of services that support commands to the equipment phase · A set of services that support requests from the equipment phase to the recipe phase Recipe Phase Interface Logic Equipment Phase

Phase Interface Logic Requests Parameters Commands State Machine States

Phase Interface Logic Requests Parameters Commands State Machine States

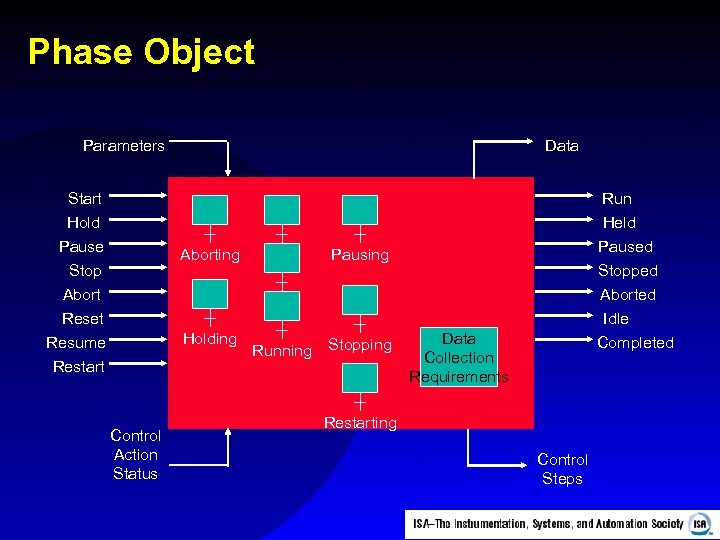

Phase Object Parameters Start Hold Pause Data Aborting Stop Abort Reset Resume Restart Holding Control Action Status Run Held Paused Pausing Running Stopped Aborted Idle Completed Data Collection Requirements Restarting Control Steps

Phase Object Parameters Start Hold Pause Data Aborting Stop Abort Reset Resume Restart Holding Control Action Status Run Held Paused Pausing Running Stopped Aborted Idle Completed Data Collection Requirements Restarting Control Steps

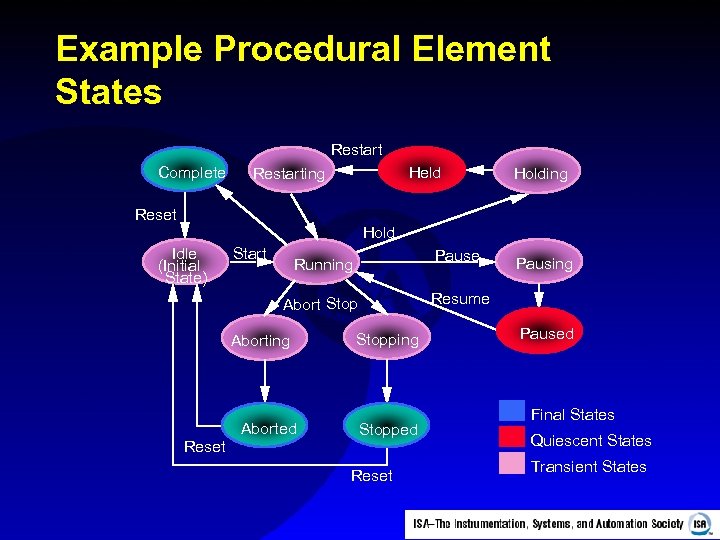

Example Procedural Element States Restart Complete Held Restarting Holding Reset Hold Idle Start (Initial State) Pause Running Resume Abort Stop Aborting Aborted Reset Pausing Stopped Reset Paused Final States Quiescent States Transient States

Example Procedural Element States Restart Complete Held Restarting Holding Reset Hold Idle Start (Initial State) Pause Running Resume Abort Stop Aborting Aborted Reset Pausing Stopped Reset Paused Final States Quiescent States Transient States

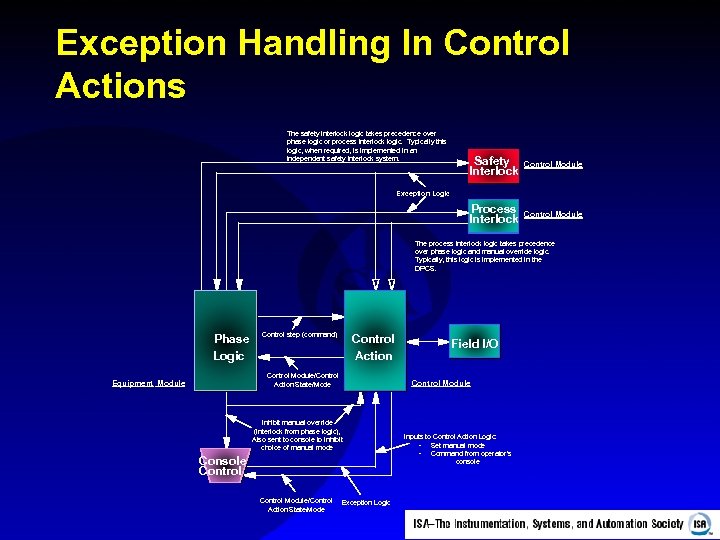

Exception Handling In Control Actions The safety interlock logic takes precedence over phase logic or process interlock logic. Typically this logic, when required, is implemented in an independent safety interlock system. Safety Interlock Control Module Process Interlock Control Module Exception Logic The process interlock logic takes precedence over phase logic and manual override logic. Typically, this logic is implemented in the DPCS. Phase Logic Control step (command) Control Action Control Module/Control Action State/Mode Equipment Module Control Module Inhibit manual override (Interlock from phase logic), Also sent to console to inhibit choice of manual mode Console Control Module/Control Action State/Mode Field I/O Exception Logic Inputs to Control Action Logic: - Set manual mode - Command from operator's console

Exception Handling In Control Actions The safety interlock logic takes precedence over phase logic or process interlock logic. Typically this logic, when required, is implemented in an independent safety interlock system. Safety Interlock Control Module Process Interlock Control Module Exception Logic The process interlock logic takes precedence over phase logic and manual override logic. Typically, this logic is implemented in the DPCS. Phase Logic Control step (command) Control Action Control Module/Control Action State/Mode Equipment Module Control Module Inhibit manual override (Interlock from phase logic), Also sent to console to inhibit choice of manual mode Console Control Module/Control Action State/Mode Field I/O Exception Logic Inputs to Control Action Logic: - Set manual mode - Command from operator's console

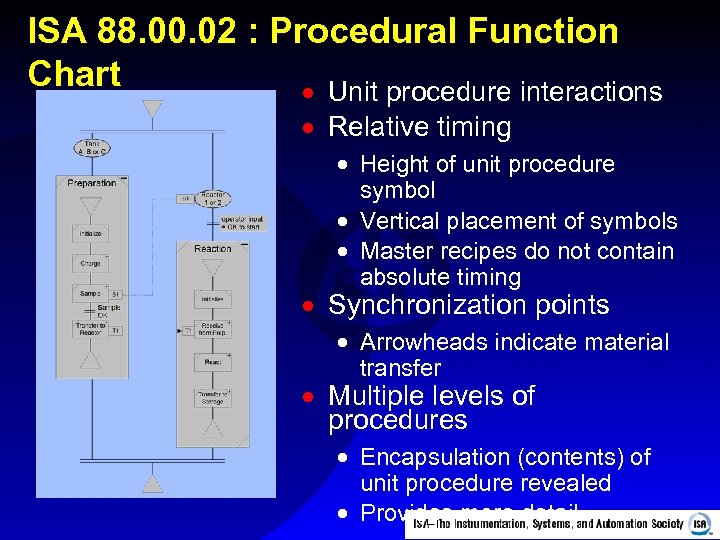

ISA 88. 00. 02 : Procedural Function Chart · Unit procedure interactions · Relative timing · Height of unit procedure symbol · Vertical placement of symbols · Master recipes do not contain absolute timing · Synchronization points · Arrowheads indicate material transfer · Multiple levels of procedures · Encapsulation (contents) of unit procedure revealed · Provides more detail

ISA 88. 00. 02 : Procedural Function Chart · Unit procedure interactions · Relative timing · Height of unit procedure symbol · Vertical placement of symbols · Master recipes do not contain absolute timing · Synchronization points · Arrowheads indicate material transfer · Multiple levels of procedures · Encapsulation (contents) of unit procedure revealed · Provides more detail

THANK YOU

THANK YOU