8b3deb1c71bc3ea5996e1d02ea75e2c6.ppt

- Количество слайдов: 18

Poster Handout CORBA & ASTM E 1989 -98—A NOVEL APPROACH TO DISTRIBUTED INSTRUMENT CONTROL Torsten Staab TSTAAB@LANL. GOV January 22 -26, 2000 Palm Springs, CA

Poster Outline • The Objective • The Technologies • ASTM E 1989 -98 LECIS • CORBA • The Result • The Benefits • The Prototype • Contact Information

The Objective The main objective of this hybrid approach is to provide an enabling software technology that allows for standardized, flexible, and hardware-independent instrument control. Today, most automated laboratory systems represent islands of automation. Although the instruments used in these systems may be highly integrated and able to communicate with each other, in most cases they are unable to communicate with the outside world (e. g. , other automation systems). Most automation systems are designed for one task only, which, due to a lack of data and control standards, considerably limits the reuse of system components. This poster describes a new approach for the automation and integration of laboratory systems that will foster the connectivity and reuse of laboratory automation system components.

The Technologies This hybrid approach to instrument control is based upon two standards—CORBA (Common Object Request Broker Architecture) and ASTM E 1989 -98, also know as LECIS (Laboratory Equipment Control Interface Specification). While CORBA is aimed at distributed, object-oriented computing, the ASTM E 198998 standard defines a generic control interface for laboratory equipment. The marriage of both technologies allows us to represent instruments and controllers in the form of objects that are able to interact over a network via standardized, ASTM E 1989 -98 compliant interfaces.

ASTM E 1989 -98 (LECIS) What is ASTM E 1989 -98? The ASTM E 1989 -98 standard (aka LECIS (Laboratory Equipment Control Interface Specification) defines a uniform remote control interface for laboratory equipment. LECIS is based on a core set of standard equipment behaviors, described in the form of interactions. ASTM E 1989 -98 Origins The ASTM E 1989 -98 standard is based upon the National Institute of Standards and Technology (NIST) Consortium for Automated Analytical Laboratory Systems (CAALS) Common Command Set and Sandia National Laboratory’s General Equipment Interface Specification.

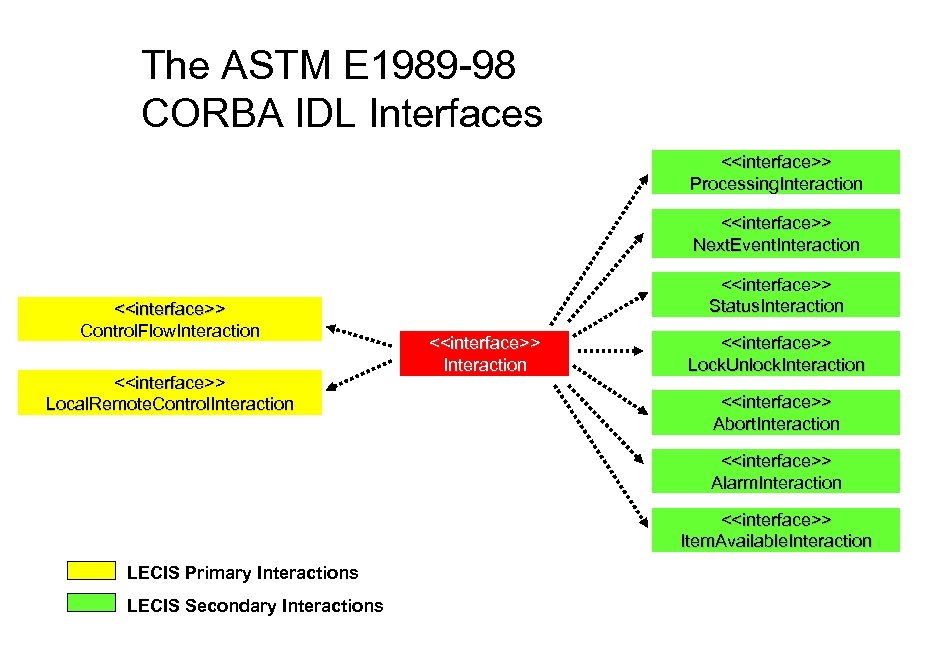

ASTM E 1989 -98 Primary Interactions ASTM E 1989 -98 defines the following primary interactions: w. Control Flow (regulates instrument initialization, configuration, and regular operations) w. Local/Remote Control Mode (manages instrument’s local/remote control mode transitions)

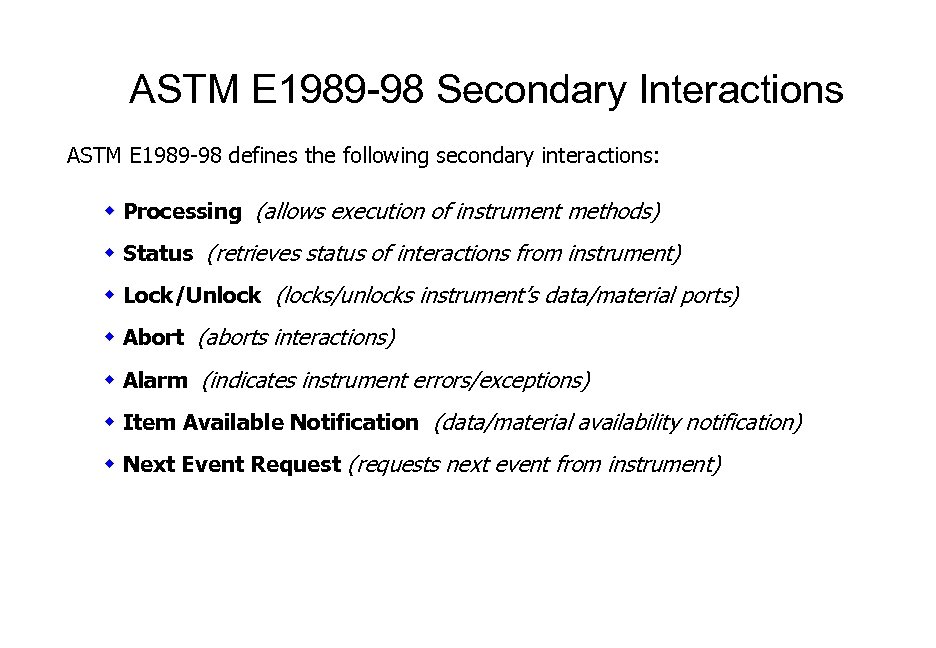

ASTM E 1989 -98 Secondary Interactions ASTM E 1989 -98 defines the following secondary interactions: w Processing (allows execution of instrument methods) w Status (retrieves status of interactions from instrument) w Lock/Unlock (locks/unlocks instrument’s data/material ports) w Abort (aborts interactions) w Alarm (indicates instrument errors/exceptions) w Item Available Notification (data/material availability notification) w Next Event Request (requests next event from instrument)

CORBA (Common Object Request Broker Architecture) What is CORBA? CORBA is an object-oriented middleware standard that enables objects (here: instruments and controllers) to discover each other and interoperate in an heterogeneous network environment. CORBA Origins CORBA was defined by the OMG (Object Management Group, www. omg. org), a consortium of over 800 software and hardware vendors.

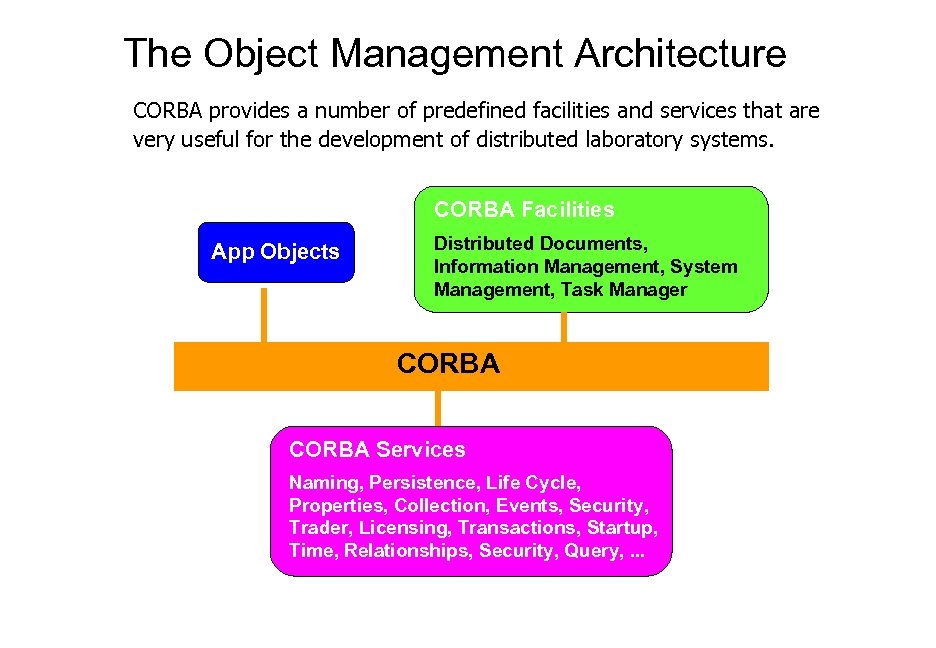

The Object Management Architecture CORBA provides a number of predefined facilities and services that are very useful for the development of distributed laboratory systems. CORBA Facilities App Objects Distributed Documents, Information Management, System Management, Task Manager CORBA Services Naming, Persistence, Life Cycle, Properties, Collection, Events, Security, Trader, Licensing, Transactions, Startup, Time, Relationships, Security, Query, . . .

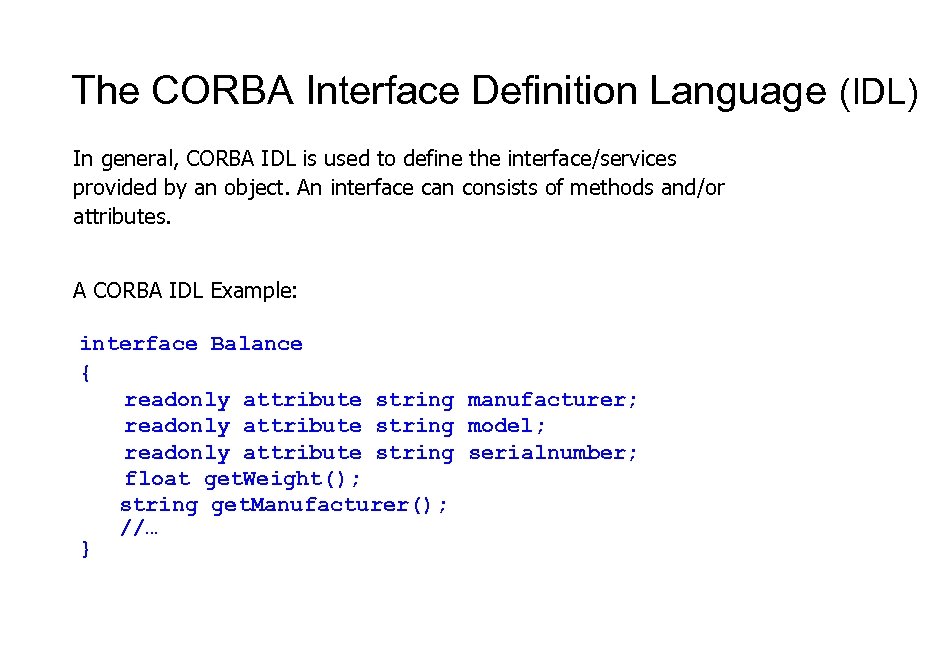

The CORBA Interface Definition Language (IDL) In general, CORBA IDL is used to define the interface/services provided by an object. An interface can consists of methods and/or attributes. A CORBA IDL Example: interface Balance { readonly attribute string manufacturer; readonly attribute string model; readonly attribute string serialnumber; float get. Weight(); string get. Manufacturer(); //… }

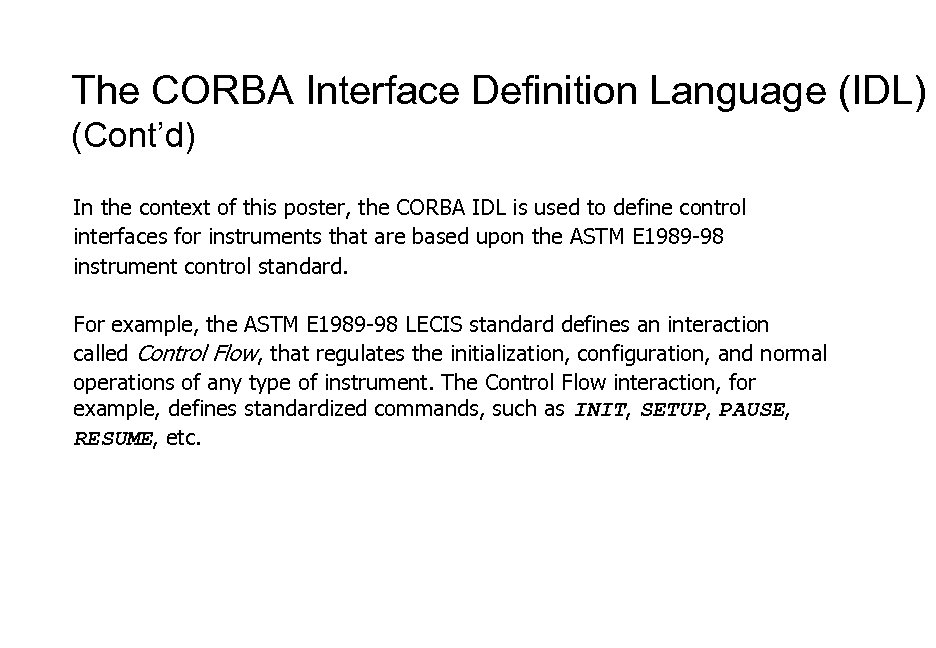

The CORBA Interface Definition Language (IDL) (Cont’d) In the context of this poster, the CORBA IDL is used to define control interfaces for instruments that are based upon the ASTM E 1989 -98 instrument control standard. For example, the ASTM E 1989 -98 LECIS standard defines an interaction called Control Flow, that regulates the initialization, configuration, and normal operations of any type of instrument. The Control Flow interaction, for example, defines standardized commands, such as INIT, SETUP, PAUSE, RESUME, etc.

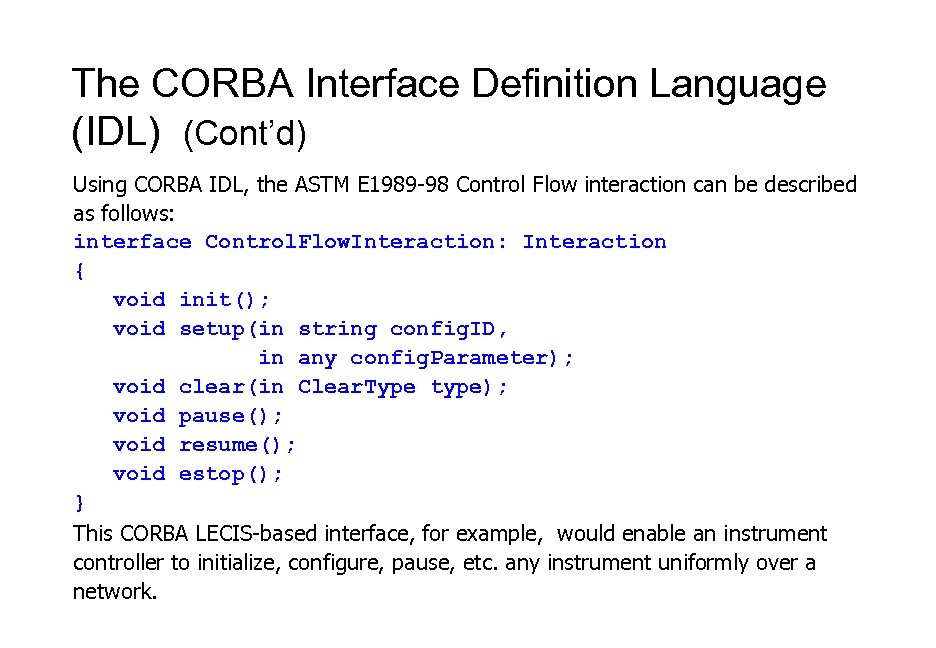

The CORBA Interface Definition Language (IDL) (Cont’d) Using CORBA IDL, the ASTM E 1989 -98 Control Flow interaction can be described as follows: interface Control. Flow. Interaction: Interaction { void init(); void setup(in string config. ID, in any config. Parameter); void clear(in Clear. Type type); void pause(); void resume(); void estop(); } This CORBA LECIS-based interface, for example, would enable an instrument controller to initialize, configure, pause, etc. any instrument uniformly over a network.

The Result This effort resulted in a set of CORBA IDL and ASTM E 1989 -98 -based interface definitions that can be used for distributed, uniform, computing platform-, programming language-, and device-independent control of any type of laboratory instrument. A draft document of these ASTM E 1989 -98 IDL definitions can be downloaded at http: //www. lecis. org.

The ASTM E 1989 -98 CORBA IDL Interfaces <<interface>> Processing. Interaction <<interface>> Next. Event. Interaction <<interface>> Control. Flow. Interaction <<interface>> Local. Remote. Control. Interaction <<interface>> Status. Interaction <<interface>> Lock. Unlock. Interaction <<interface>> Abort. Interaction <<interface>> Alarm. Interaction <<interface>> Item. Available. Interaction LECIS Primary Interactions LECIS Secondary Interactions

The Benefits of using CORBA and ASTM E 1989 -98 w is low-level communication protocol-independent w is computing platform-independent w is programming language-independent w allows device-independent remote control w allows the control of instruments regardless of their location w defines instrument control interfaces independently of implementations w fosters plug-and-play of instruments w allows for hot swappable instruments, thereby reducing system downtimes w reduces vendor dependence w reduces instrument interfacing costs and efforts

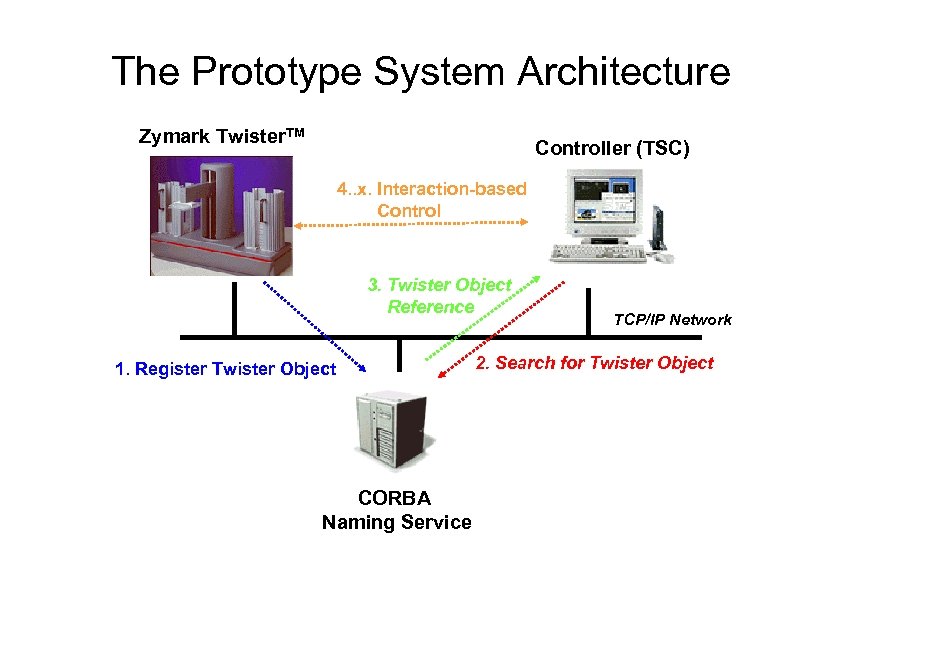

The Prototype System The ASTM E 1989 -98 CORBA IDL prototype system consists of two components (CORBA objects)—an instrument controller (Task Sequence Controller) and an instrument (Zymark’s universal plate handling robot Twister. TM). The Task Sequence Controller and the Zymark Twister. TM CORBA objects are both implemented in 100% pure Java. This prototype system demonstrates how to build a fully distributed, plug-and-play based laboratory automation system with the new ASTM E 1989 -98 CORBA IDL specification.

The Prototype System Architecture Zymark Twister. TM Controller (TSC) 4. . x. Interaction-based Control 3. Twister Object Reference 1. Register Twister Object CORBA Naming Service TCP/IP Network 2. Search for Twister Object

Contact Information For more information on the ASTM E 1989 -98 standard and CORBA/DCOM/TCPIP/RS-232 related commercial activities visit http: //www. lecis. org

8b3deb1c71bc3ea5996e1d02ea75e2c6.ppt