297cdad0cbde57b1ab40bd0eaac329e5.ppt

- Количество слайдов: 17

Post Consumption Water Use The Hidden Waste Presented at: Great Lakes Craft Brewers & Water Conservation Conference October 26, 2009 Thomas E. Pape Alliance for Water Efficiency 1 Copyright 2009 – Thomas Pape

Post Consumption Water Use The Hidden Waste Presented at: Great Lakes Craft Brewers & Water Conservation Conference October 26, 2009 Thomas E. Pape Alliance for Water Efficiency 1 Copyright 2009 – Thomas Pape

Sustainability • Environmental impacts of the total life cycle of products • Product disposal often has the most severe long-term impact on the environment • “Green” consciousness accepts responsibility for the entire lifecycle impacts 2 Copyright 2009 – Thomas Pape

Sustainability • Environmental impacts of the total life cycle of products • Product disposal often has the most severe long-term impact on the environment • “Green” consciousness accepts responsibility for the entire lifecycle impacts 2 Copyright 2009 – Thomas Pape

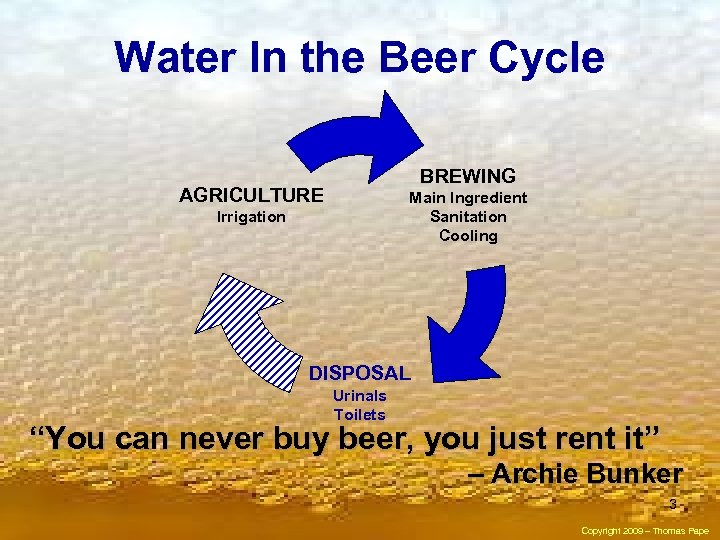

Water In the Beer Cycle BREWING AGRICULTURE Main Ingredient Sanitation Cooling Irrigation DISPOSAL Urinals Toilets “You can never buy beer, you just rent it” – Archie Bunker 3 Copyright 2009 – Thomas Pape

Water In the Beer Cycle BREWING AGRICULTURE Main Ingredient Sanitation Cooling Irrigation DISPOSAL Urinals Toilets “You can never buy beer, you just rent it” – Archie Bunker 3 Copyright 2009 – Thomas Pape

Water Efficiency in Brewing • Measured in pints of water used to produce pints of beer. • Best water saving brewery strategies achieve water use ratios of less than 4 pints of water to produce 1 pint of beer. 4: 1 • Theoretical perfection of 1: 1 (not feasible) • Additional brewing efficiencies likely allows for less than 2 pints additional potential savings for each pint of beer produced. 4 Copyright 2009 – Thomas Pape

Water Efficiency in Brewing • Measured in pints of water used to produce pints of beer. • Best water saving brewery strategies achieve water use ratios of less than 4 pints of water to produce 1 pint of beer. 4: 1 • Theoretical perfection of 1: 1 (not feasible) • Additional brewing efficiencies likely allows for less than 2 pints additional potential savings for each pint of beer produced. 4 Copyright 2009 – Thomas Pape

The Hidden Water Waste • Current disposal practices use an average of more than 19 pints of water for every 1 pint of beer – 19: 1 efficiency ratio • Worst case scenarios use 40 pints of water to dispose of 1 pint of beer – 40: 1 • More than 10 gallons of water savings are easily available in disposing of every 1 gallon of beer served. 5 Copyright 2009 – Thomas Pape

The Hidden Water Waste • Current disposal practices use an average of more than 19 pints of water for every 1 pint of beer – 19: 1 efficiency ratio • Worst case scenarios use 40 pints of water to dispose of 1 pint of beer – 40: 1 • More than 10 gallons of water savings are easily available in disposing of every 1 gallon of beer served. 5 Copyright 2009 – Thomas Pape

Water Efficiency in Beer Disposal • The water saving potential is more than 20 times greater in disposal cycle compared to brewing cycle 6 Copyright 2009 – Thomas Pape

Water Efficiency in Beer Disposal • The water saving potential is more than 20 times greater in disposal cycle compared to brewing cycle 6 Copyright 2009 – Thomas Pape

The Technology • High Efficiency Urinals (HEU) • One pint per flush urinal provide 1: 1 efficiency • Beware: Sensor flush valves INCREASE water use! 7 Copyright 2009 – Thomas Pape

The Technology • High Efficiency Urinals (HEU) • One pint per flush urinal provide 1: 1 efficiency • Beware: Sensor flush valves INCREASE water use! 7 Copyright 2009 – Thomas Pape

The Technology • High Efficiency Toilet (HET) • 1. 28 GPF = 10: 1 efficiency • Available in gravity flush, flusho-meter valve, and pressureassist technology • Beware: Sensor flush valves INCREASE water use! 8 Copyright 2009 – Thomas Pape

The Technology • High Efficiency Toilet (HET) • 1. 28 GPF = 10: 1 efficiency • Available in gravity flush, flusho-meter valve, and pressureassist technology • Beware: Sensor flush valves INCREASE water use! 8 Copyright 2009 – Thomas Pape

The Technology • Dual-Flush Toilet • 0. 9 Gallon/flush for liquid waste – 1. 6 GPF for solid waste • 7. 2: 1 Efficiency If used properly 9 Copyright 2009 – Thomas Pape

The Technology • Dual-Flush Toilet • 0. 9 Gallon/flush for liquid waste – 1. 6 GPF for solid waste • 7. 2: 1 Efficiency If used properly 9 Copyright 2009 – Thomas Pape

The Technology • • Non-water urinals 0: 1 Efficiency Vandal resistance Performance varies by make & model 10 Copyright 2009 – Thomas Pape

The Technology • • Non-water urinals 0: 1 Efficiency Vandal resistance Performance varies by make & model 10 Copyright 2009 – Thomas Pape

Future Technology? • Pee-and-go • She-inal • Urine diverting toilets 11 Copyright 2009 – Thomas Pape

Future Technology? • Pee-and-go • She-inal • Urine diverting toilets 11 Copyright 2009 – Thomas Pape

Green Codes Coming Soon • Applicable Green Code Provisions – – – – Require high efficiency urinals and toilets Require 1 FU upstream of of non-water urinals Requires sub-metering (major uses & spaces) Cooling Tower efficiency standards Require low-flow wash basin faucets PRSVs, connectionless steamers in kitchens Rain water harvesting Allows alternative water sources: stormwater, condensate, graywater, reuse, recycle, etc. • What are your code change needs? 12

Green Codes Coming Soon • Applicable Green Code Provisions – – – – Require high efficiency urinals and toilets Require 1 FU upstream of of non-water urinals Requires sub-metering (major uses & spaces) Cooling Tower efficiency standards Require low-flow wash basin faucets PRSVs, connectionless steamers in kitchens Rain water harvesting Allows alternative water sources: stormwater, condensate, graywater, reuse, recycle, etc. • What are your code change needs? 12

The Economics Estimated urinal usage: – Beerjoint = 200 flushes/day = 72, 000/yr – Brewpub = 100 flushes/day = 36, 000/yr – Bar & grill = 75 flushes/day = 27, 000/yr – Grill & bar = 50 flushes/day = 18, 000/yr • Estimated women toilet usage – Beerjoint = 100 flushes/day = 36, 000/yr – Brewpub = 75 flushes/day = 27, 000/yr – Bar & grill = 50 flushes/day = 18, 000/yr – Grill & bar = 50 flushes/day = 18, 000/yr 13 Copyright 2009 – Thomas Pape

The Economics Estimated urinal usage: – Beerjoint = 200 flushes/day = 72, 000/yr – Brewpub = 100 flushes/day = 36, 000/yr – Bar & grill = 75 flushes/day = 27, 000/yr – Grill & bar = 50 flushes/day = 18, 000/yr • Estimated women toilet usage – Beerjoint = 100 flushes/day = 36, 000/yr – Brewpub = 75 flushes/day = 27, 000/yr – Bar & grill = 50 flushes/day = 18, 000/yr – Grill & bar = 50 flushes/day = 18, 000/yr 13 Copyright 2009 – Thomas Pape

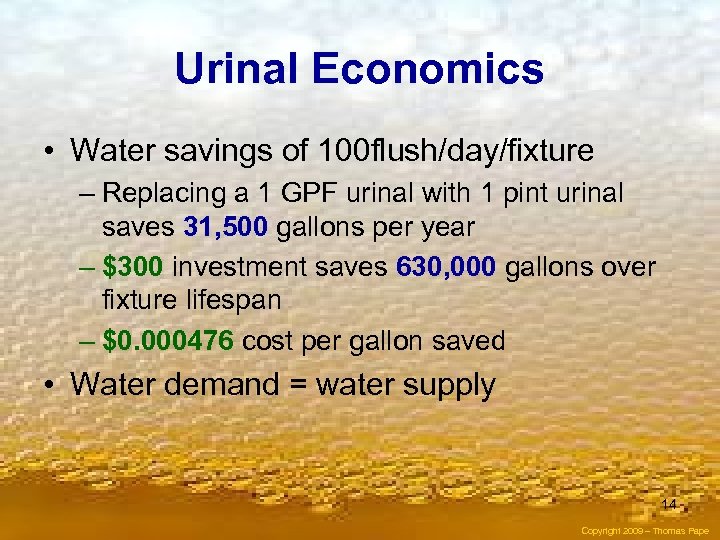

Urinal Economics • Water savings of 100 flush/day/fixture – Replacing a 1 GPF urinal with 1 pint urinal saves 31, 500 gallons per year – $300 investment saves 630, 000 gallons over fixture lifespan – $0. 000476 cost per gallon saved • Water demand = water supply 14 Copyright 2009 – Thomas Pape

Urinal Economics • Water savings of 100 flush/day/fixture – Replacing a 1 GPF urinal with 1 pint urinal saves 31, 500 gallons per year – $300 investment saves 630, 000 gallons over fixture lifespan – $0. 000476 cost per gallon saved • Water demand = water supply 14 Copyright 2009 – Thomas Pape

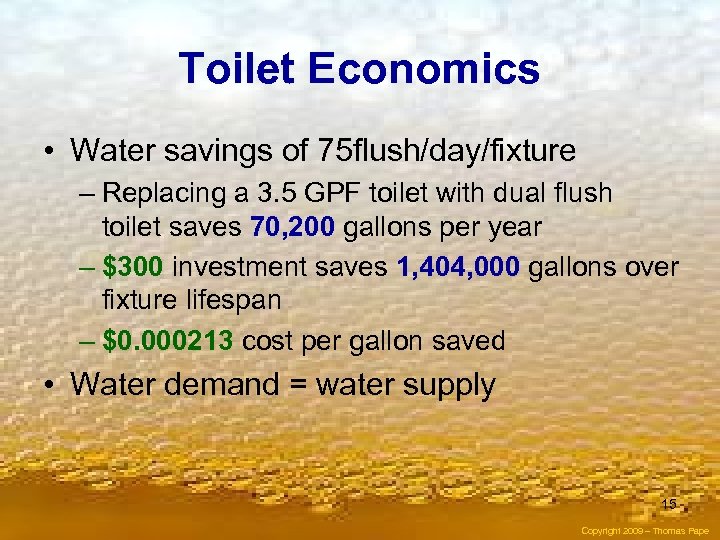

Toilet Economics • Water savings of 75 flush/day/fixture – Replacing a 3. 5 GPF toilet with dual flush toilet saves 70, 200 gallons per year – $300 investment saves 1, 404, 000 gallons over fixture lifespan – $0. 000213 cost per gallon saved • Water demand = water supply 15 Copyright 2009 – Thomas Pape

Toilet Economics • Water savings of 75 flush/day/fixture – Replacing a 3. 5 GPF toilet with dual flush toilet saves 70, 200 gallons per year – $300 investment saves 1, 404, 000 gallons over fixture lifespan – $0. 000213 cost per gallon saved • Water demand = water supply 15 Copyright 2009 – Thomas Pape

Implementation • Retrofit Own Brewpubs • Gather Stakeholders – Brewers, Water Suppliers, Wastewater Service Providers, Retailers, etc/ • Share Costs Based on Benefits • Provide Incentives for Retrofits – Rebates, Vouchers, Direct Installations • Exchange water savings for water rights • Join the Alliance for Water Efficiency 16 Copyright 2009 – Thomas Pape

Implementation • Retrofit Own Brewpubs • Gather Stakeholders – Brewers, Water Suppliers, Wastewater Service Providers, Retailers, etc/ • Share Costs Based on Benefits • Provide Incentives for Retrofits – Rebates, Vouchers, Direct Installations • Exchange water savings for water rights • Join the Alliance for Water Efficiency 16 Copyright 2009 – Thomas Pape

Alliance for Water Efficiency a 4 we. org Thomas Pape Technical Advisor Alliance for Water Efficiency tom@a 4 we. org bmp 4 h 2 o@aol. com 17 Copyright 2009 – Thomas Pape

Alliance for Water Efficiency a 4 we. org Thomas Pape Technical Advisor Alliance for Water Efficiency tom@a 4 we. org bmp 4 h 2 o@aol. com 17 Copyright 2009 – Thomas Pape