CRANES.ppt

- Количество слайдов: 35

Портовое перегрузочное оборудование

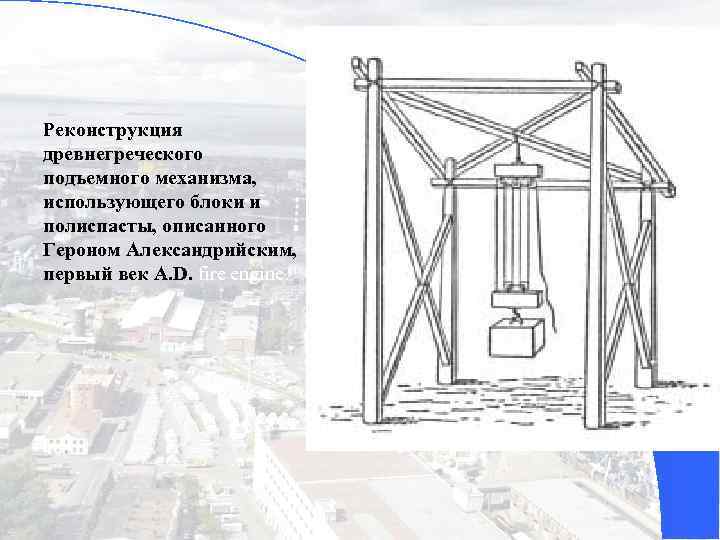

Реконструкция древнегреческого подъемного механизма, использующего блоки и полиспасты, описанного Героном Александрийским, первый век A. D. fire engine. 2

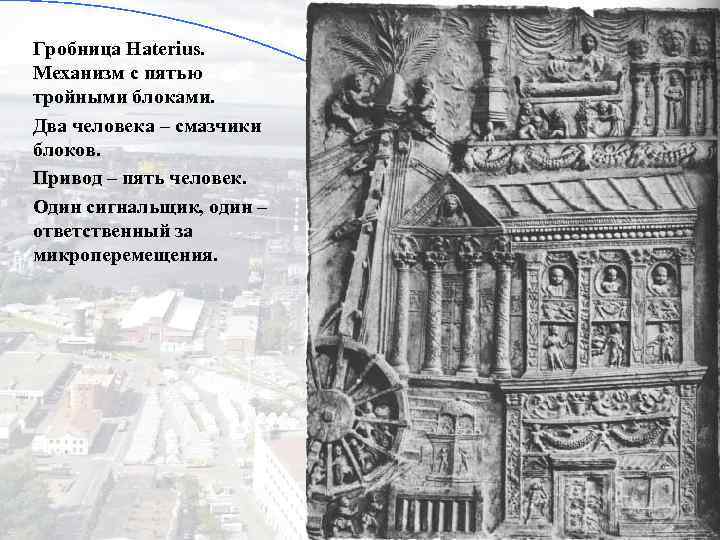

Гробница Haterius. Механизм с пятью тройными блоками. Два человека – смазчики блоков. Привод – пять человек. Один сигнальщик, один – ответственный за микроперемещения. 3

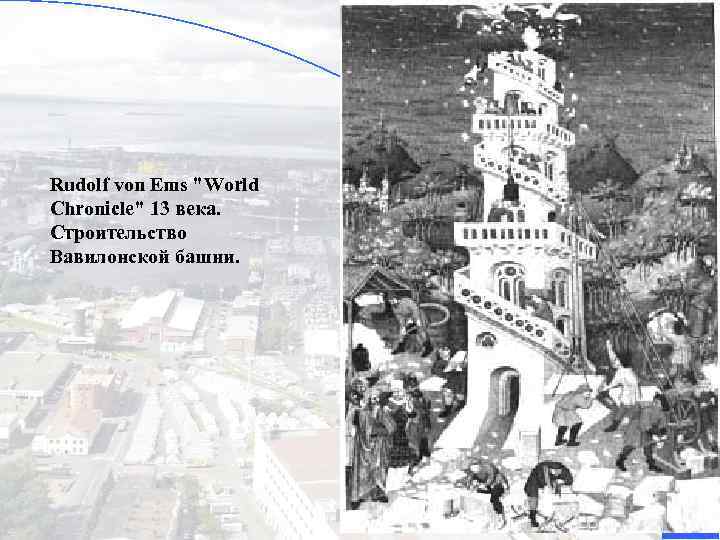

Rudolf von Ems "World Chronicle" 13 века. Строительство Вавилонской башни. 4

Leonardo's Codex Atlanticus Два мобильных крана для строительства каналов. Привод – ослы. Поворот обеспечивает использование и для дноуглубления, и берегообразования. 5

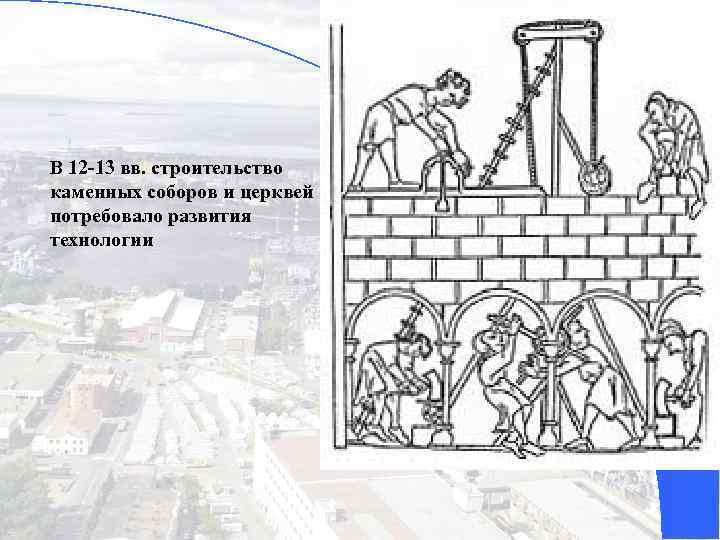

В 12 -13 вв. строительство каменных соборов и церквей потребовало развития технологии 6

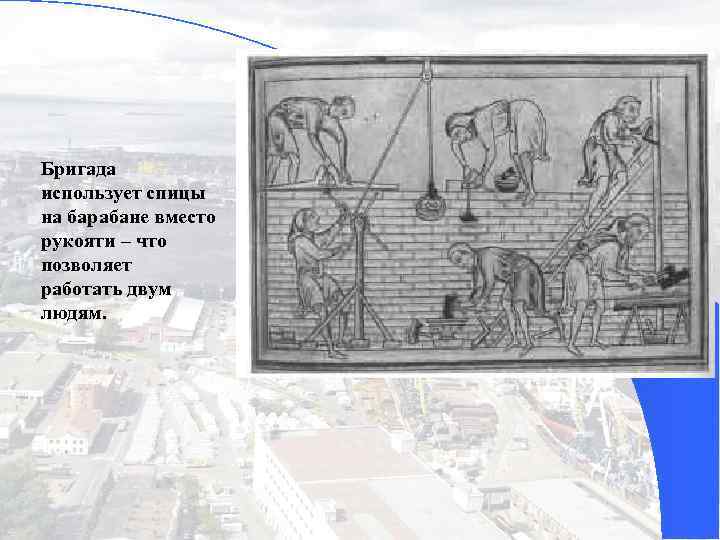

Бригада использует спицы на барабане вместо рукояти – что позволяет работать двум людям. 7

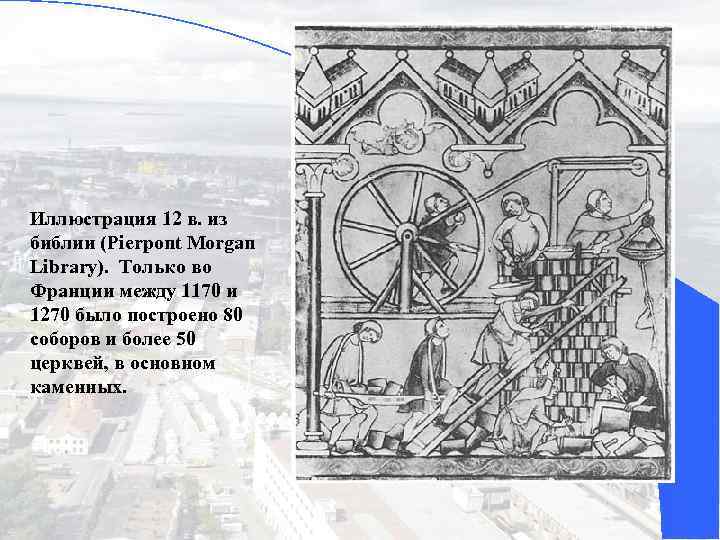

Иллюстрация 12 в. из библии (Pierpont Morgan Library). Только во Франции между 1170 и 1270 было построено 80 соборов и более 50 церквей, в основном каменных. 8

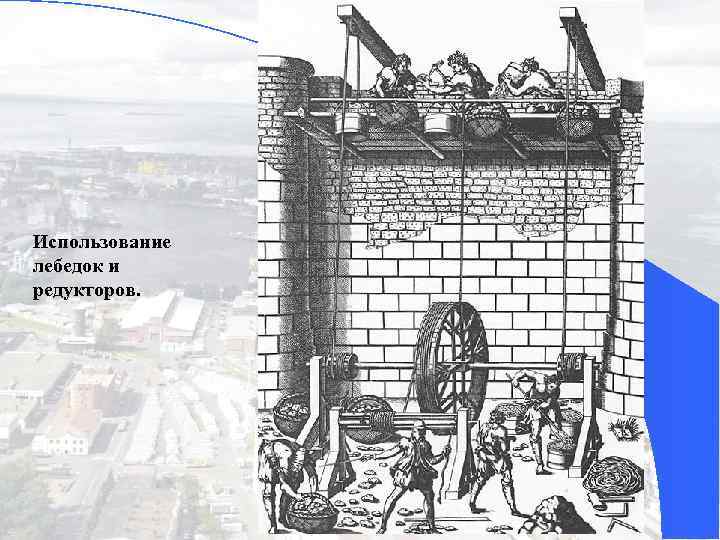

Использование лебедок и редукторов. 9

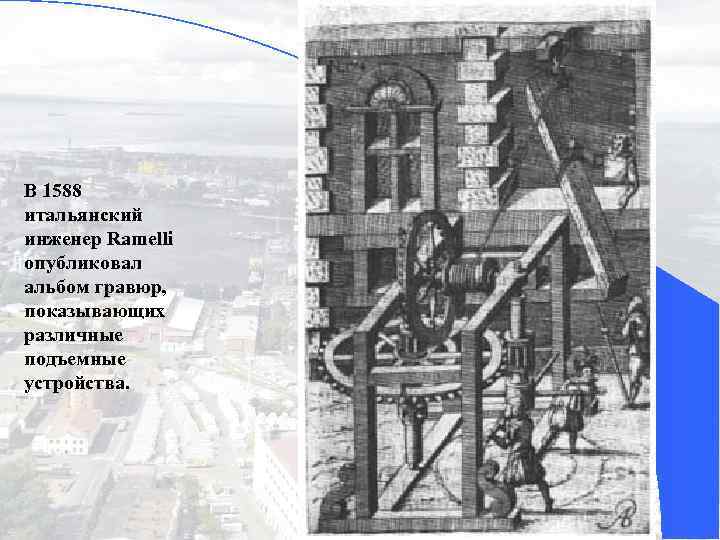

В 1588 итальянский инженер Ramelli опубликовал альбом гравюр, показывающих различные подъемные устройства. 10

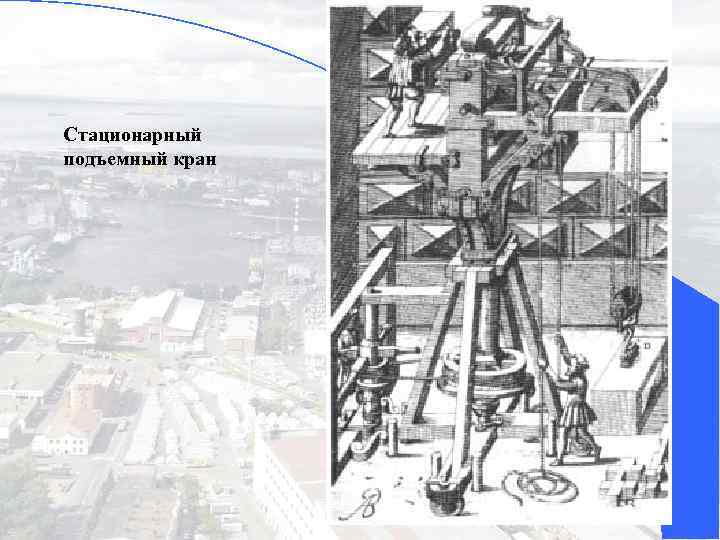

Стационарный подъемный кран 11

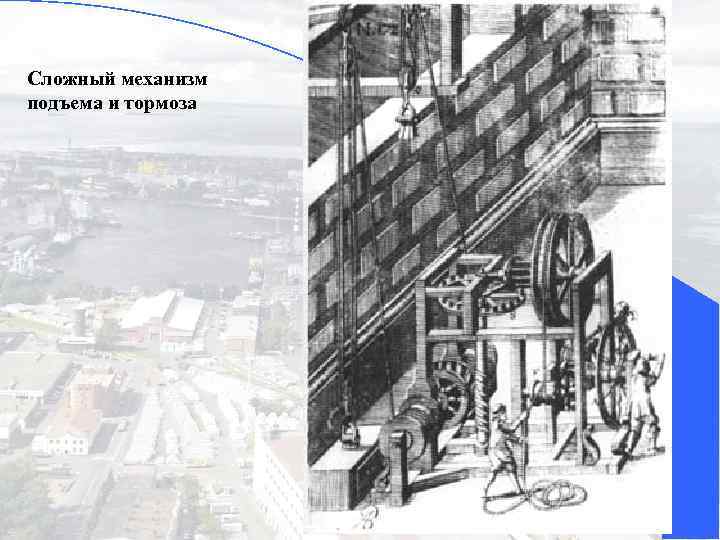

Сложный механизм подъема и тормоза 12

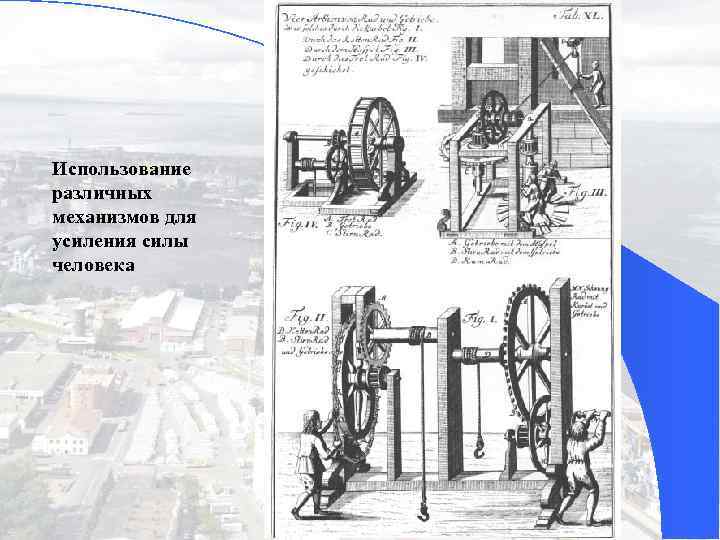

Использование различных механизмов для усиления силы человека 13

Two main trends in port cargo operations: – cargo handling with equipment specialized for concrete cargo type; q – handling with general equipment, allowing for different types of cargo. q Specialization and generalization are two extreme poles, a balance between those provides optimal variant of technology for a particular operator In many ports ХХ century went under the domination of general-purposed electrical portal slewing cranes mounted on rails.

Main criteria of crane selection for universal port complexes: терминалов можно выделить следующие основные q - universality, or ability to handle different cargo types q - efficiency, or amplitudes of working movements with safe weight and velocities providing sufficient speed of handling typical ships, rail sections, trucks or stacks q - mobility, or amplitudes to move operatively between cargo fronts (berth, rail, truck) and stack working areas

q. Demands for foundation and pavement. For mobile cranes they are different whet working and travelling q. Environmental impact q. Purchase price q. Operation costs q. Economic efficiency and competitiveness of cargo handling operations could be achieved by harmonization of all features of the port cranes

Rail mounted portal slewing cranes q Universal q Efficient at all fronts q Low mobile q Low utilization in time

Mobile cranes l Mobility l Mobile cranes include: tends to be a priority for insuring competitiveness in port cargo handling operations q Mobile harbor cranes with cargo runner (MHC) q Manipulators q Balance (equilibrium) cranes

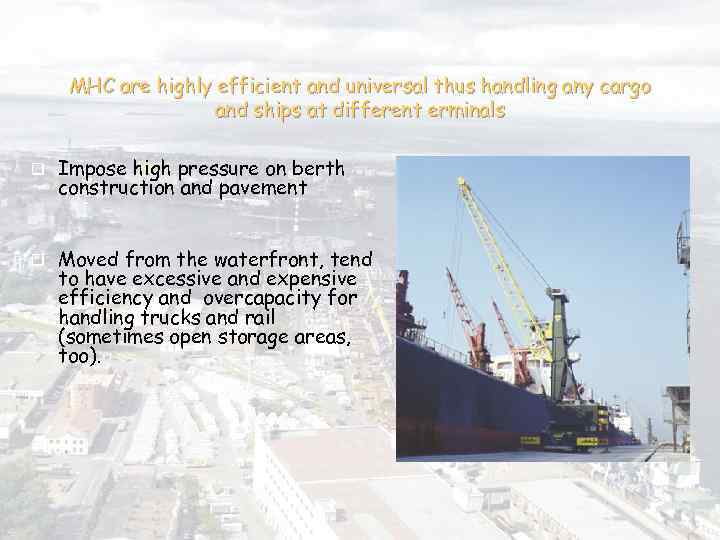

MHC are highly efficient and universal thus handling any cargo and ships at different erminals q Impose high pressure on berth construction and pavement q Moved from the waterfront, tend to have excessive and expensive efficiency and overcapacity for handling trucks and rail (sometimes open storage areas, too).

Hydraulic manipulators on self-propelling chassyes Developed from excavators with accurate and precise movement typical for robots. к l Main manufacturers MANTSINEN (Finland); FUCHS (Germany); SENNEBOGEN (Germany); HITACHI (Japan). l

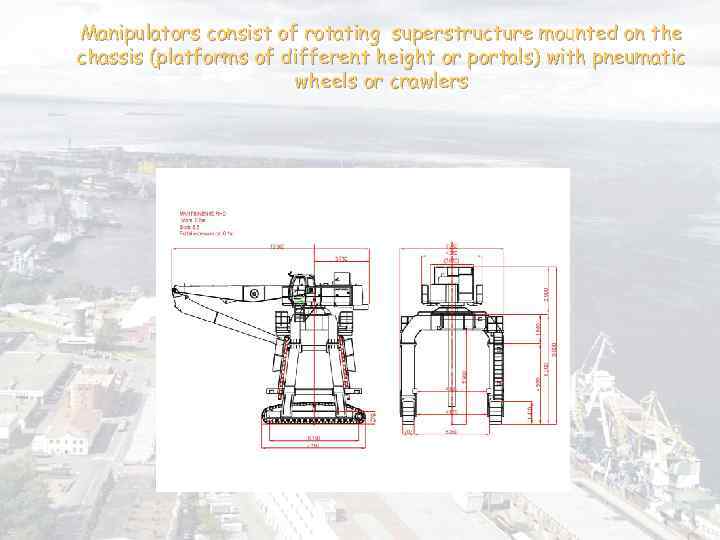

Manipulators consist of rotating superstructure mounted on the chassis (platforms of different height or portals) with pneumatic wheels or crawlers

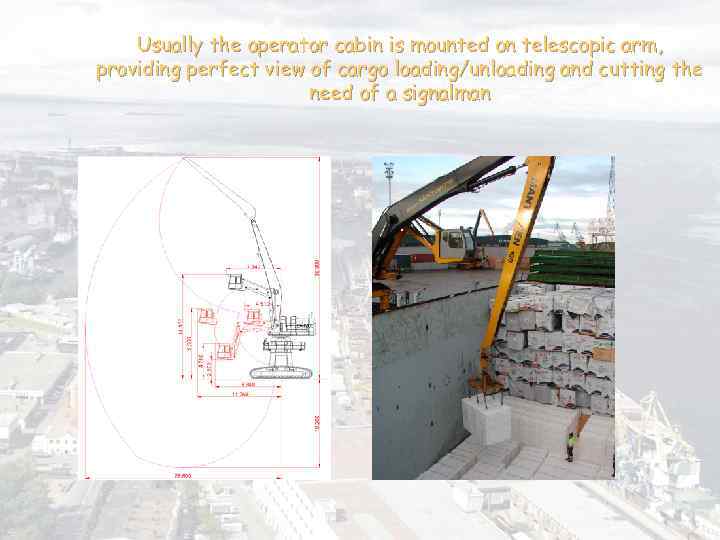

Usually the operator cabin is mounted on telescopic arm , providing perfect view of cargo loading/unloading and cutting the need of a signalman

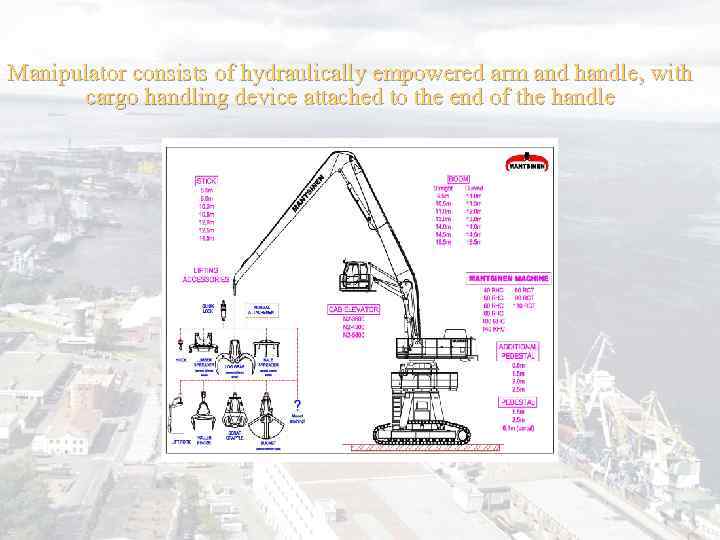

Manipulator consists of hydraulically empowered arm and handle, with cargo handling device attached to the end of the handle

This type of the boom system provides: q q q Precision positioning of the cargo handling device on the cargo or place of discharge, Elimination of sway, Operation in any wind conditions Possibility to expose vertical pressure on the cargo surface, which is very serious advantage Delivery of hydraulic or electric power to cargo handling device, which opens wide opportunities for automation (intellectual handling devices)

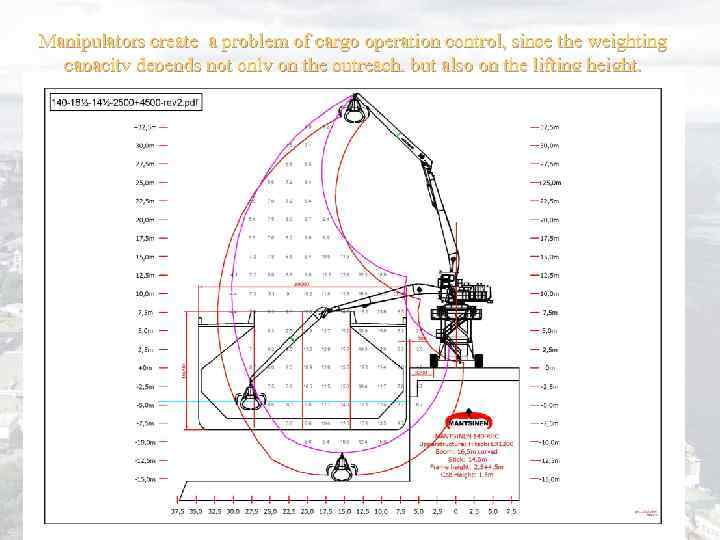

Manipulators create a problem of cargo operation control, since the weighting capacity depends not only on the outreach, but also on the lifting height.

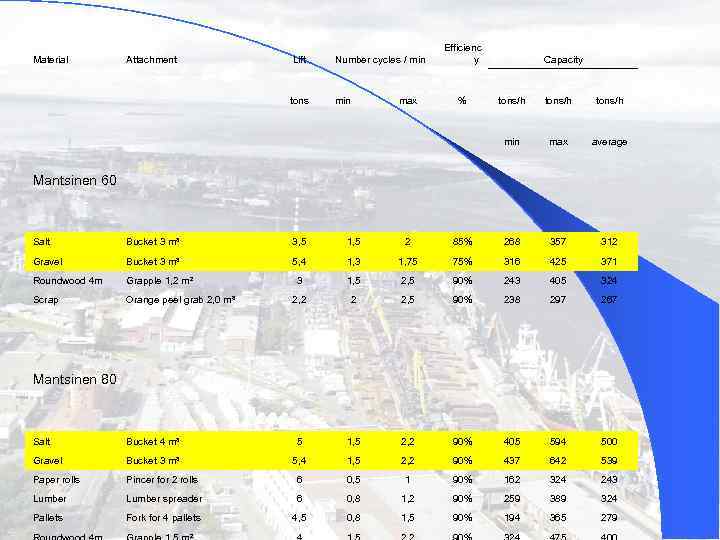

Material Attachment Lift Number cycles / min tons min max Efficienc y % Capacity tons/h min max average Mantsinen 60 Salt Bucket 3 m³ 3, 5 1, 5 2 85% 268 357 312 Gravel Bucket 3 m³ 5, 4 1, 3 1, 75 75% 316 425 371 Roundwood 4 m Grapple 1, 2 m² 3 1, 5 2, 5 90% 243 405 324 Scrap Orange peel grab 2, 0 m³ 2, 2 2 2, 5 90% 238 297 267 Mantsinen 80 Salt Bucket 4 m³ 5 1, 5 2, 2 90% 405 594 500 Gravel Bucket 3 m³ 5, 4 1, 5 2, 2 90% 437 642 539 Paper rolls Pincer for 2 rolls 6 0, 5 1 90% 162 324 243 Lumber spreader 6 0, 8 1, 2 90% 259 389 324 Pallets Fork for 4 pallets 4, 5 0, 8 1, 5 90% 194 365 279 27

Balance (equilibrium) cranes

Balanced boom system

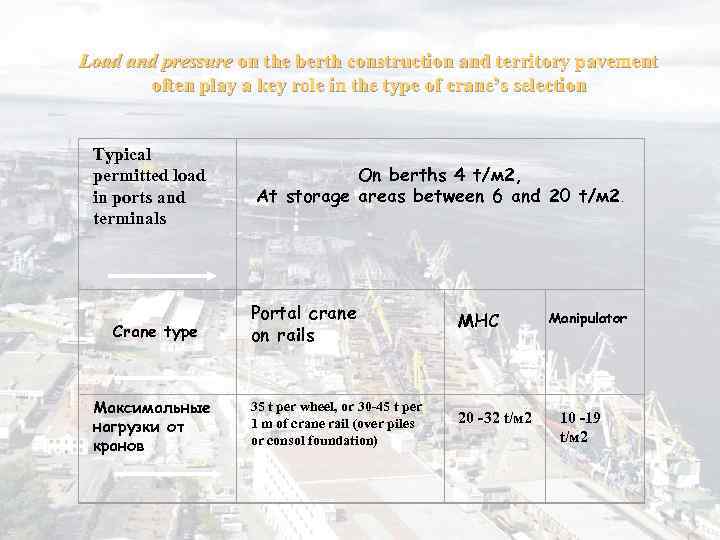

Load and pressure on the berth construction and territory pavement often play a key role in the type of crane’s selection On berths 4 t/м 2, At storage areas between 6 and 20 t/м 2. Typical permitted load in ports and terminals Crane type Максимальные нагрузки от кранов Portal crane on rails 35 t per wheel, or 30 -45 t per 1 m of crane rail (over piles or consol foundation) MHC Manipulator 20 -32 t/м 2 10 -19 t/м 2

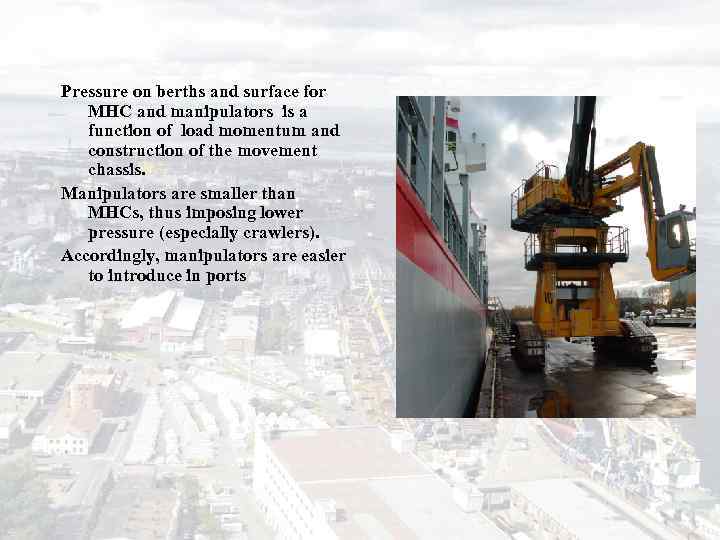

Pressure on berths and surface for MHC and manipulators is a function of load momentum and construction of the movement chassis. Manipulators are smaller than MHCs, thus imposing lower pressure (especially crawlers). Accordingly, manipulators are easier to introduce in ports

Сравнение основных технико-эксплуатационных характеристик универсальных портовых кранов Indicator (in points) Portal crane MHC Manipulator Universality High (5) Medium (4) (no containers) Mobility Low (3) High(5) Efficiency Medium (4) Very high (6) Low at berth, (3) Load surface demands High(3) High((3) Medium (4) Environment impact Low (5) Medium(4) Price Medium(4) High (3) Medium(4) Operating costs Medium (4) High (3) Total 28 29 27

Conclusions 1. Mobility of crane today is one of the most important feature 2. Mobility for a port user is the ability to move not father than between different cargo fronts and terminal zones. 3. In this case MHC and manipulators possess slightly excessive mobility for port applications.

4. Solving a problem of increasing the mobility of portal slewing cranes to the level permitting easy movement between cargo fronts could effectively increase the competiveness of the equipment. 5. Use of manipulators in ports today is restricted by the handling of relatively small ships (less then 9000 DWT). The sizes and construction of holds of river ships and short sea vessels make possible to handle them much more efficiently than with portal cranes. 6. This information is useful but not sufficient for the professional selection of the equipment. The decision should be based on thorough technical and economical analyses and qualitative characteristics of the complex project with mandatory study of civilian engineering aspects.

CRANES.ppt