4946aadbf4d801f42dadf78ef6dff4c8.ppt

- Количество слайдов: 95

Poolside Alarm Ø Jay Bombien – BSEE l Ø Darren Pallesen- BSEE l Ø Lead Presentation Manager Peter Brunner- BSEE l Ø Lead Project Integrator Louis Chatfield- BSEE l Ø Lead Report Manager Lead System Designer Milja Cumbo- BSEE l Lead Manufacturing Mgr 1

Major Functions and Features Ø Functions: l l Ø Monitor a pool for potential hazardous situations Loud audible alarms when a child falls in unnoticeably Features: l l l Outdoor unit will display water temp, air temp, and low battery indicator Solar cells on poolside unit to keep outdoor battery charged User Control On/Off 2

Poolside Alarm Ø The device will monitor a pool for potential hazardous situations. (i. e. child falling in) Ø Indoor unit will display water temp, air temp, and low battery indicator. Ø Wireless home receiver and display unit with loud audible signal. Ø Solar cells on poolside unit to keep outdoor battery charged. 3

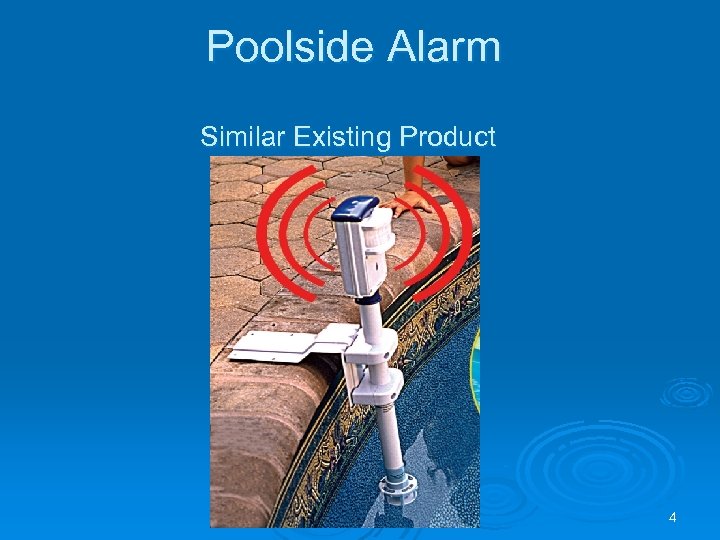

Poolside Alarm Similar Existing Product 4

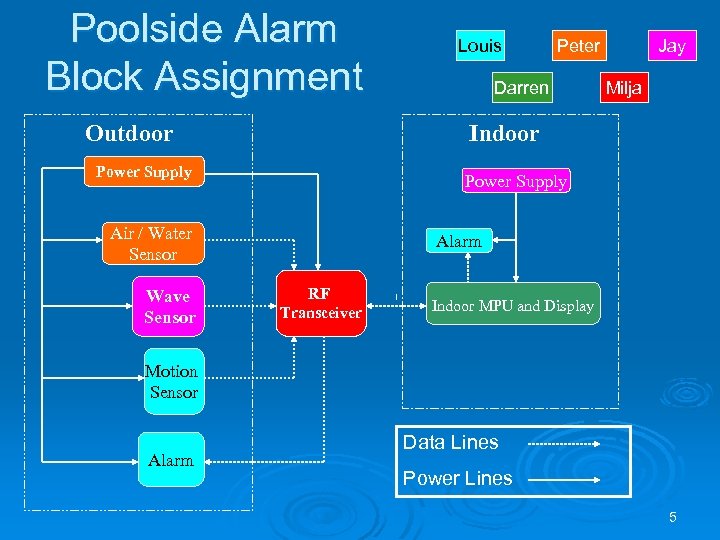

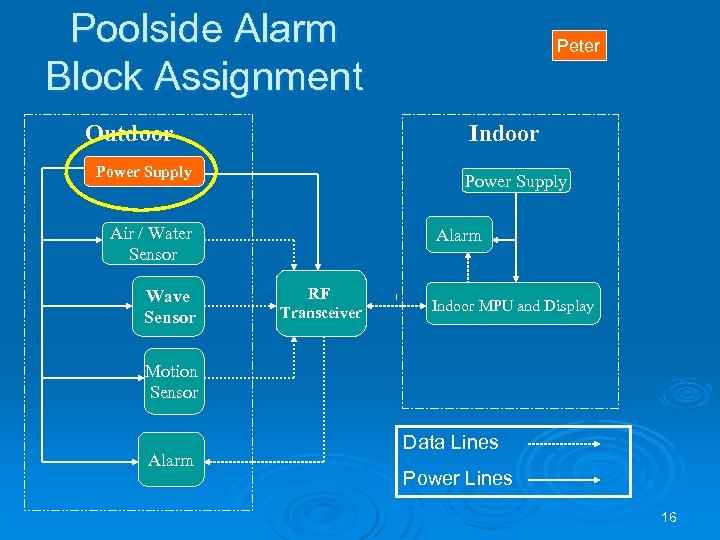

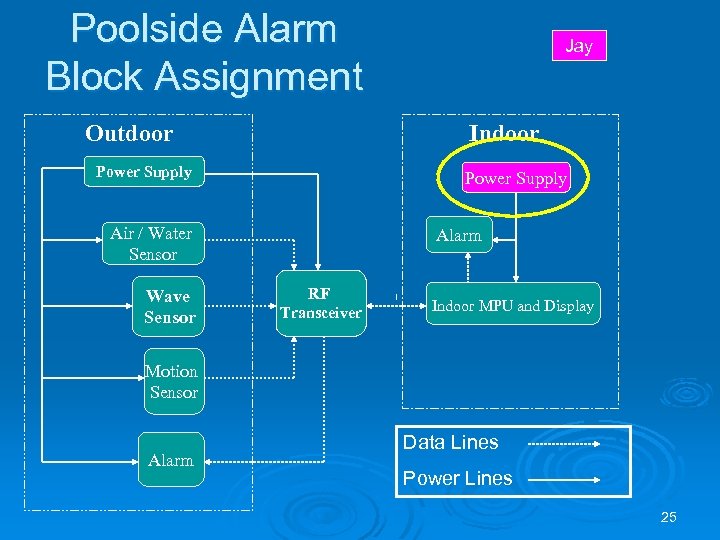

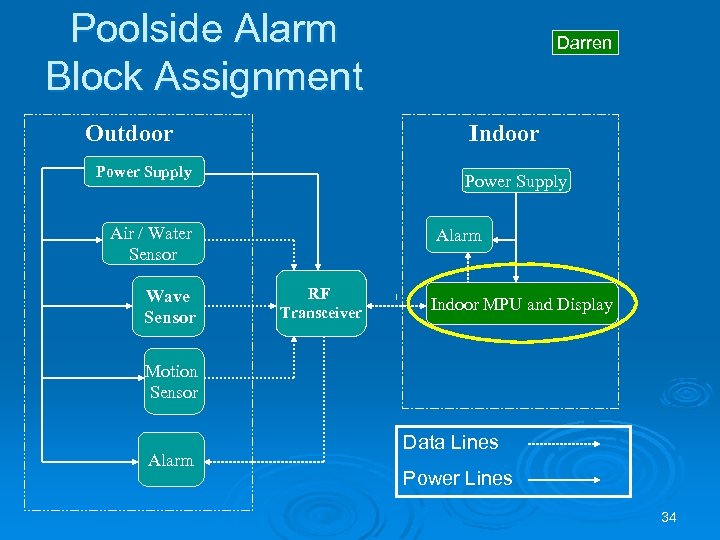

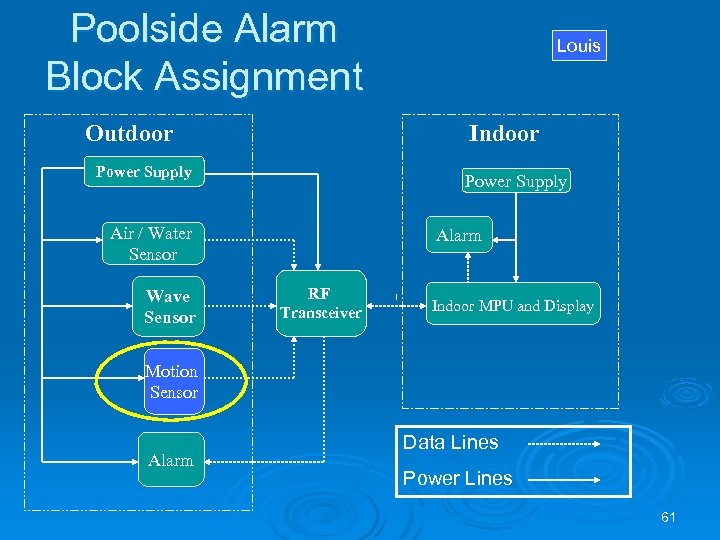

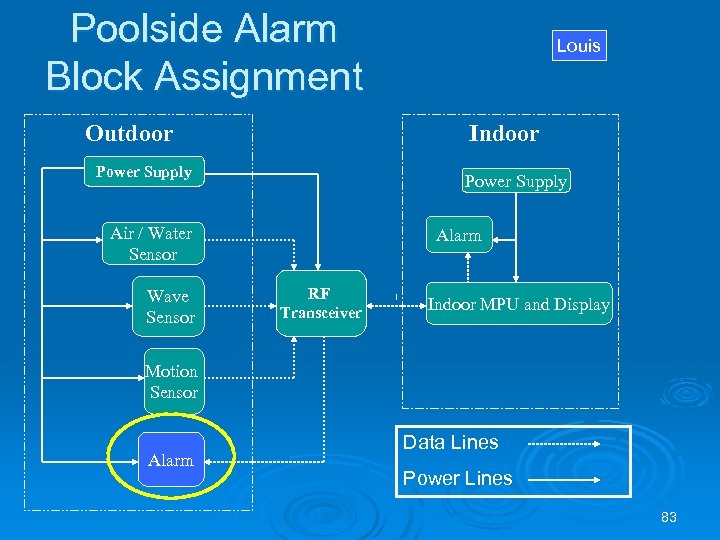

Poolside Alarm Block Assignment Outdoor Peter Darren Jay Milja Indoor Power Supply Air / Water Sensor Wave Sensor Louis Alarm RF Transceiver Indoor MPU and Display Motion Sensor Alarm Data Lines Power Lines 5

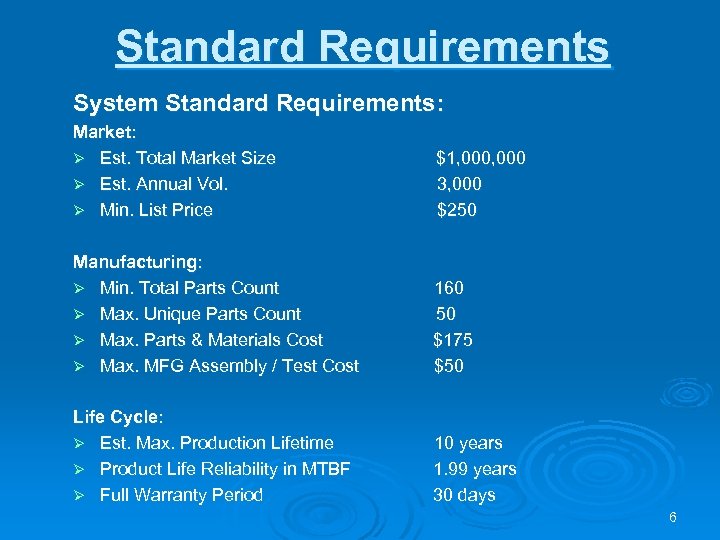

Standard Requirements System Standard Requirements: Market: Ø Est. Total Market Size $1, 000 Ø Est. Annual Vol. 3, 000 Ø Min. List Price $250 Manufacturing: Ø Min. Total Parts Count 160 Ø Max. Unique Parts Count 50 Ø Max. Parts & Materials Cost $175 Ø Max. MFG Assembly / Test Cost $50 Life Cycle: Ø Est. Max. Production Lifetime 10 years Ø Product Life Reliability in MTBF 1. 99 years Ø Full Warranty Period 30 days 6

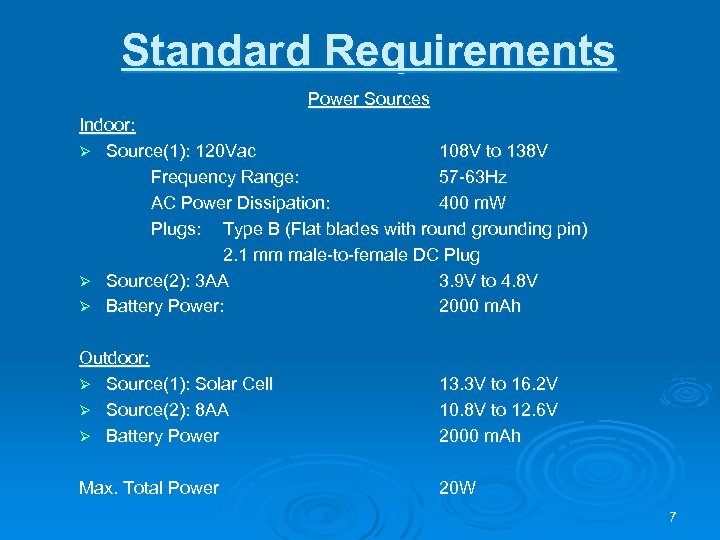

Standard Requirements Power Sources Indoor: Ø Source(1): 120 Vac 108 V to 138 V Frequency Range: 57 -63 Hz AC Power Dissipation: 400 m. W Plugs: Type B (Flat blades with round grounding pin) 2. 1 mm male-to-female DC Plug Ø Source(2): 3 AA 3. 9 V to 4. 8 V Ø Battery Power: 2000 m. Ah Outdoor: Ø Source(1): Solar Cell Ø Source(2): 8 AA Ø Battery Power 13. 3 V to 16. 2 V 10. 8 V to 12. 6 V 2000 m. Ah Max. Total Power 20 W 7

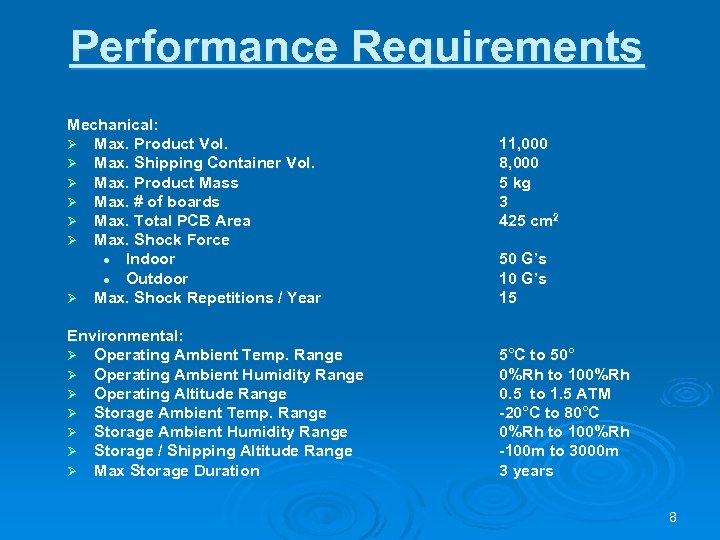

Performance Requirements Mechanical: Ø Max. Product Vol. Ø Max. Shipping Container Vol. Ø Max. Product Mass Ø Max. # of boards Ø Max. Total PCB Area Ø Max. Shock Force l Indoor l Outdoor Ø Max. Shock Repetitions / Year Environmental: Ø Operating Ambient Temp. Range Ø Operating Ambient Humidity Range Ø Operating Altitude Range Ø Storage Ambient Temp. Range Ø Storage Ambient Humidity Range Ø Storage / Shipping Altitude Range Ø Max Storage Duration 11, 000 8, 000 5 kg 3 425 cm 2 50 G’s 15 5°C to 50° 0%Rh to 100%Rh 0. 5 to 1. 5 ATM -20°C to 80°C 0%Rh to 100%Rh -100 m to 3000 m 3 years 8

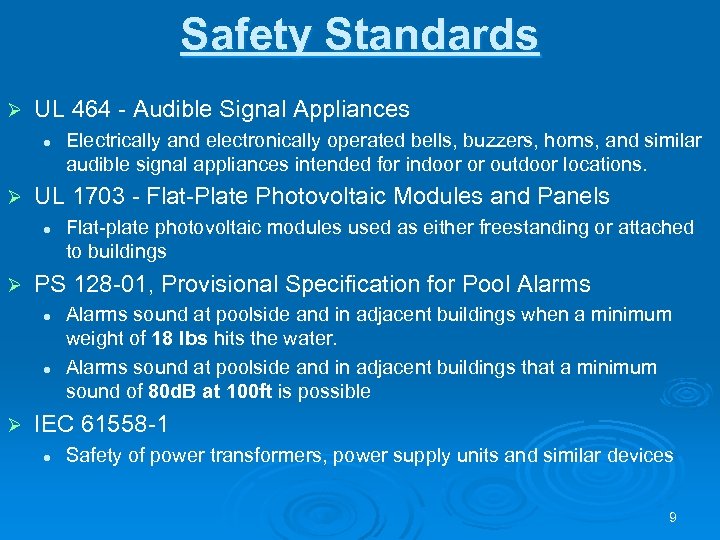

Safety Standards Ø UL 464 - Audible Signal Appliances l Ø UL 1703 - Flat-Plate Photovoltaic Modules and Panels l Ø Flat-plate photovoltaic modules used as either freestanding or attached to buildings PS 128 -01, Provisional Specification for Pool Alarms l l Ø Electrically and electronically operated bells, buzzers, horns, and similar audible signal appliances intended for indoor or outdoor locations. Alarms sound at poolside and in adjacent buildings when a minimum weight of 18 lbs hits the water. Alarms sound at poolside and in adjacent buildings that a minimum sound of 80 d. B at 100 ft is possible IEC 61558 -1 l Safety of power transformers, power supply units and similar devices 9

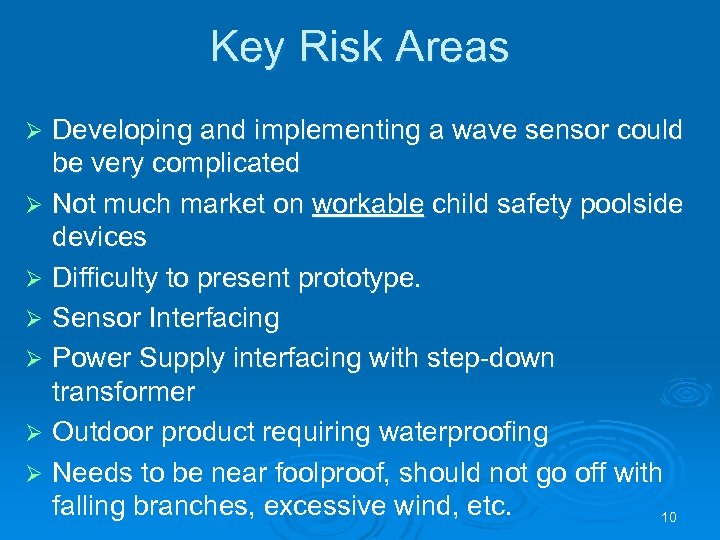

Key Risk Areas Developing and implementing a wave sensor could be very complicated Ø Not much market on workable child safety poolside devices Ø Difficulty to present prototype. Ø Sensor Interfacing Ø Power Supply interfacing with step-down transformer Ø Outdoor product requiring waterproofing Ø Needs to be near foolproof, should not go off with falling branches, excessive wind, etc. 10 Ø

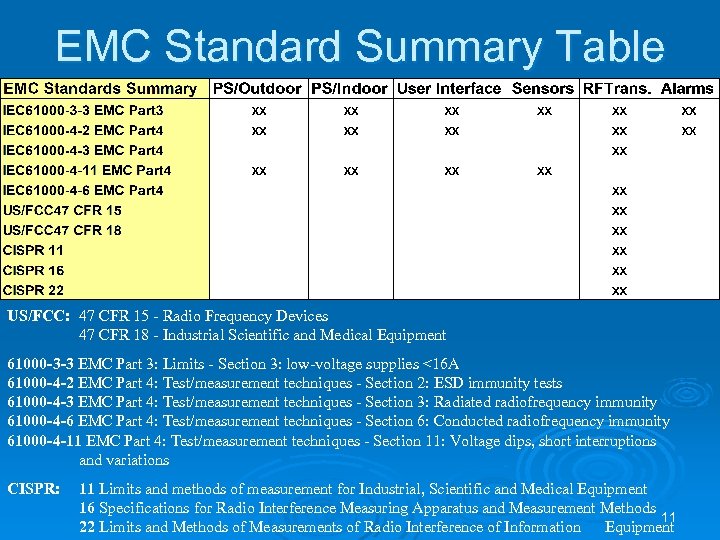

EMC Standard Summary Table US/FCC: 47 CFR 15 - Radio Frequency Devices 47 CFR 18 - Industrial Scientific and Medical Equipment 61000 -3 -3 EMC Part 3: Limits - Section 3: low-voltage supplies <16 A 61000 -4 -2 EMC Part 4: Test/measurement techniques - Section 2: ESD immunity tests 61000 -4 -3 EMC Part 4: Test/measurement techniques - Section 3: Radiated radiofrequency immunity 61000 -4 -6 EMC Part 4: Test/measurement techniques - Section 6: Conducted radiofrequency immunity 61000 -4 -11 EMC Part 4: Test/measurement techniques - Section 11: Voltage dips, short interruptions and variations CISPR: 11 Limits and methods of measurement for Industrial, Scientific and Medical Equipment 16 Specifications for Radio Interference Measuring Apparatus and Measurement Methods 11 22 Limits and Methods of Measurements of Radio Interference of Information Equipment

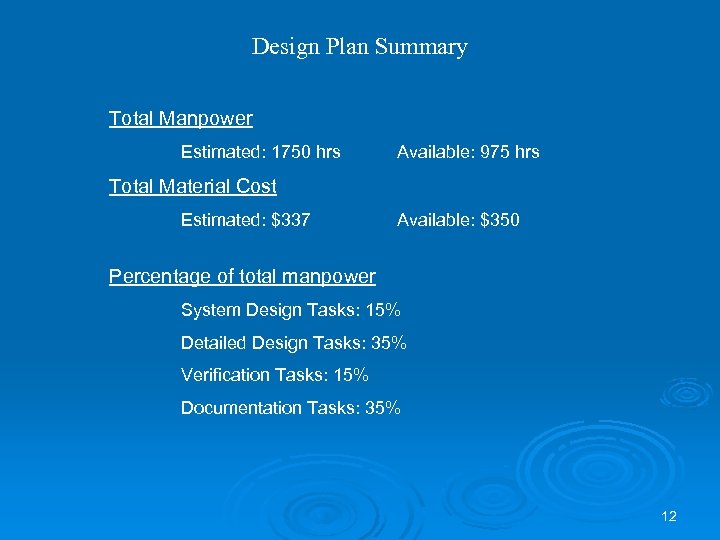

Design Plan Summary Total Manpower Estimated: 1750 hrs Available: 975 hrs Total Material Cost Estimated: $337 Available: $350 Percentage of total manpower System Design Tasks: 15% Detailed Design Tasks: 35% Verification Tasks: 15% Documentation Tasks: 35% 12

Prototype Summary Slide • Total # of bds • 8 bds – 1 for Each Block • Total PCB area (cm 2) • B 1(40), B 2(65), B 3(40), B 4(50), B 5(50), B 6(40), B 7(50), B 8(90) • Total = 425 • Technology: • Perfboard, PCB, Breadboard • Soldering & Wirewrap 13

Gantt Chart 14

Outdoor Power Supply Peter Brunner 15

Poolside Alarm Block Assignment Outdoor Indoor Power Supply Air / Water Sensor Wave Sensor Peter Alarm RF Transceiver Indoor MPU and Display Motion Sensor Alarm Data Lines Power Lines 16

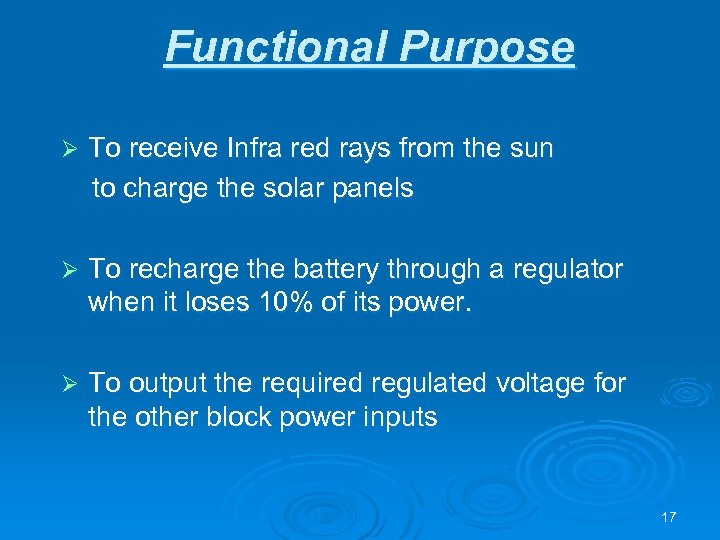

Functional Purpose To receive Infra red rays from the sun to charge the solar panels Ø Ø To recharge the battery through a regulator when it loses 10% of its power. Ø To output the required regulated voltage for the other block power inputs 17

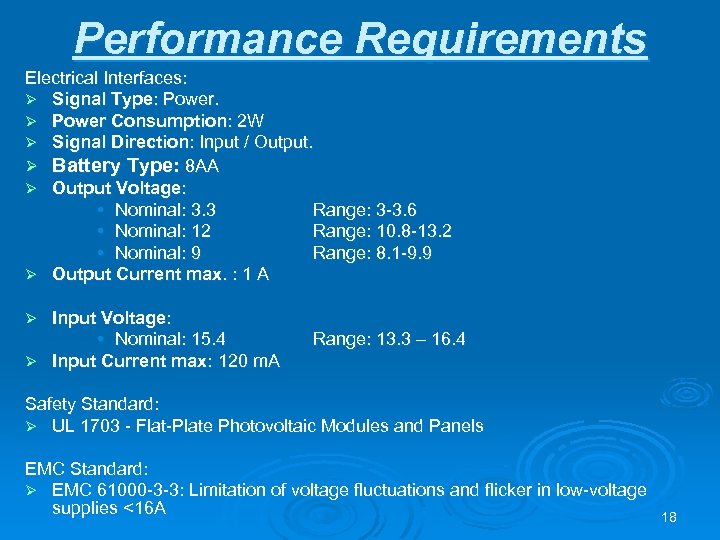

Performance Requirements Electrical Interfaces: Ø Signal Type: Power. Ø Power Consumption: 2 W Ø Signal Direction: Input / Output. Ø Battery Type: 8 AA Ø Output Voltage: • Nominal: 3. 3 Range: 3 -3. 6 • Nominal: 12 Range: 10. 8 -13. 2 • Nominal: 9 Range: 8. 1 -9. 9 Ø Output Current max. : 1 A Input Voltage: • Nominal: 15. 4 Ø Input Current max: 120 m. A Ø Range: 13. 3 – 16. 4 Safety Standard: Ø UL 1703 - Flat-Plate Photovoltaic Modules and Panels EMC Standard: Ø EMC 61000 -3 -3: Limitation of voltage fluctuations and flicker in low-voltage supplies <16 A 18

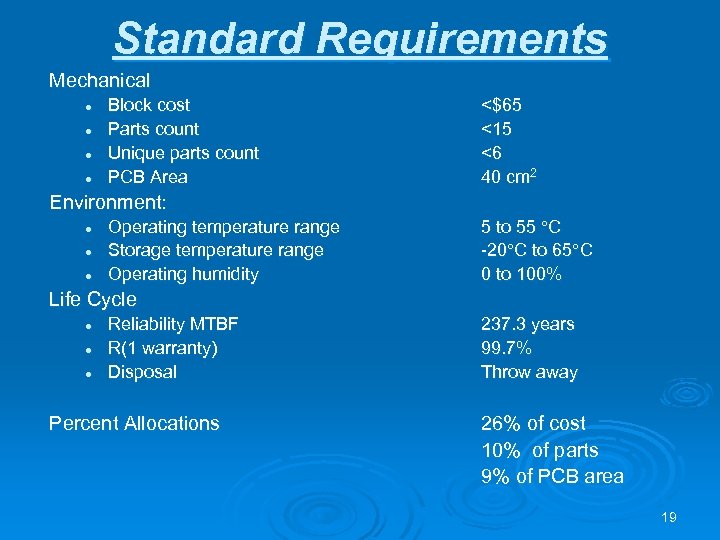

Standard Requirements Mechanical l l Block cost Parts count Unique parts count PCB Area <$65 <15 <6 40 cm 2 Environment: l l l Operating temperature range Storage temperature range Operating humidity 5 to 55 C -20 C to 65 C 0 to 100% Life Cycle l l l Reliability MTBF R(1 warranty) Disposal Percent Allocations 237. 3 years 99. 7% Throw away 26% of cost 10% of parts 9% of PCB area 19

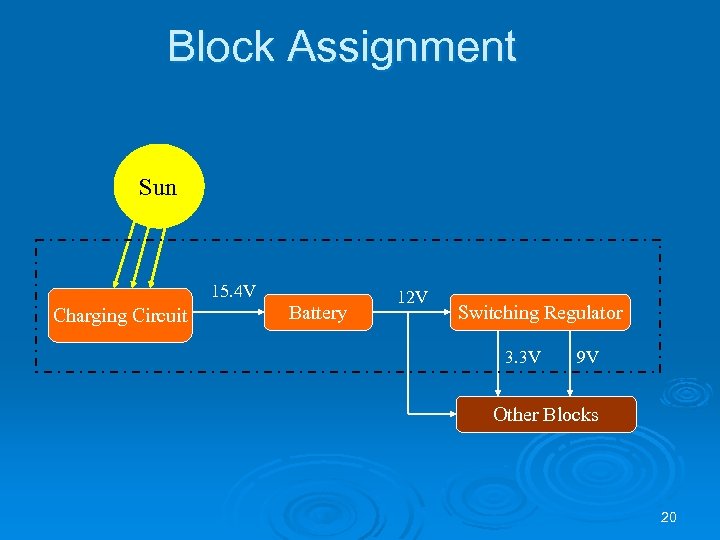

Block Assignment Sun 15. 4 V Charging Circuit Battery 12 V Switching Regulator 3. 3 V 9 V Other Blocks 20

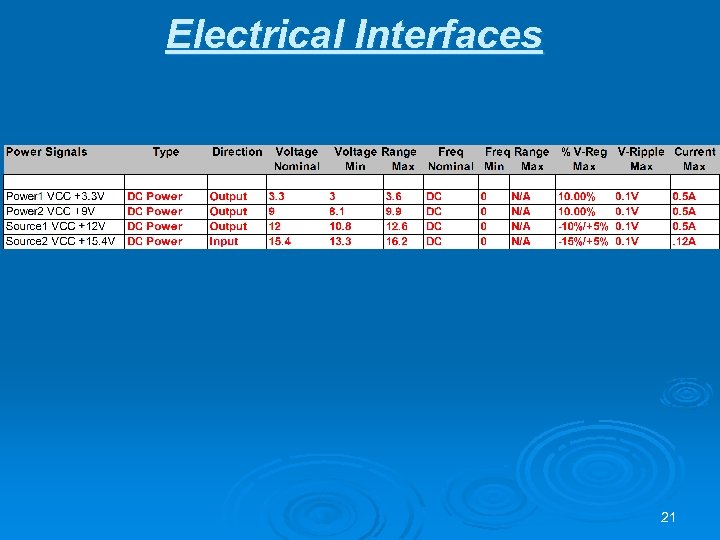

Electrical Interfaces 21

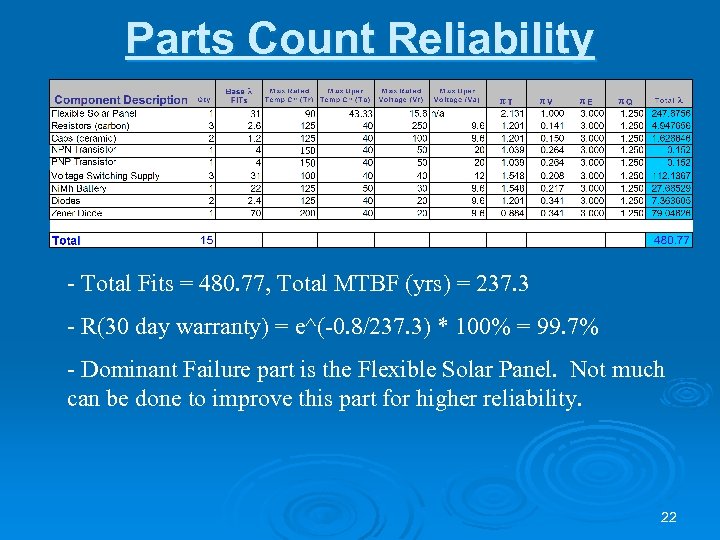

Parts Count Reliability - Total Fits = 480. 77, Total MTBF (yrs) = 237. 3 - R(30 day warranty) = e^(-0. 8/237. 3) * 100% = 99. 7% - Dominant Failure part is the Flexible Solar Panel. Not much can be done to improve this part for higher reliability. 22

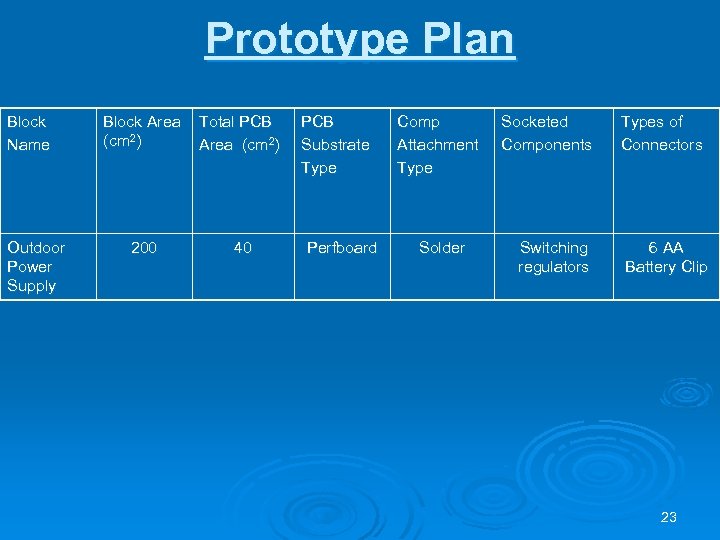

Prototype Plan Block Name Outdoor Power Supply Block Area Total PCB (cm 2) Area (cm 2) 200 40 PCB Substrate Type Perfboard Comp Attachment Type Solder Socketed Components Switching regulators Types of Connectors 6 AA Battery Clip 23

Indoor Power Supply Jay Bombien 24

Poolside Alarm Block Assignment Outdoor Indoor Power Supply Air / Water Sensor Wave Sensor Jay Alarm RF Transceiver Indoor MPU and Display Motion Sensor Alarm Data Lines Power Lines 25

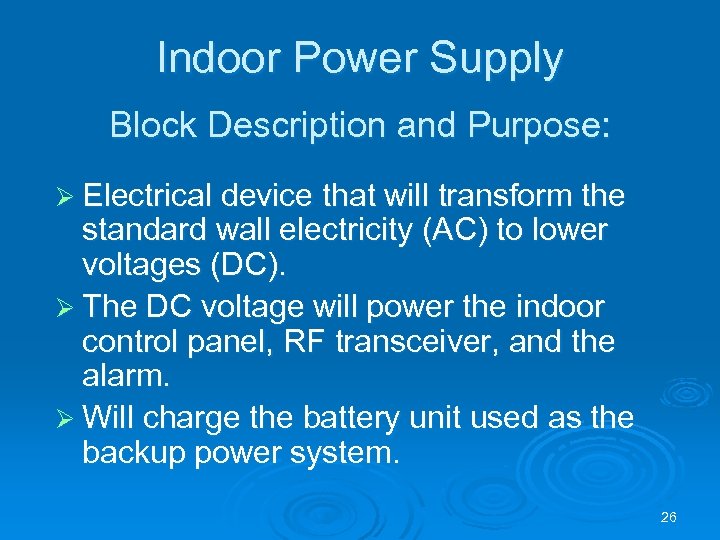

Indoor Power Supply Block Description and Purpose: Ø Electrical device that will transform the standard wall electricity (AC) to lower voltages (DC). Ø The DC voltage will power the indoor control panel, RF transceiver, and the alarm. Ø Will charge the battery unit used as the backup power system. 26

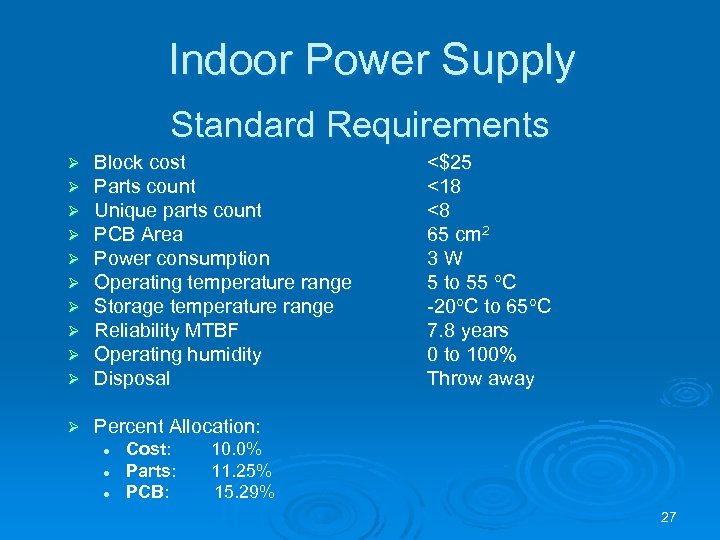

Indoor Power Supply Standard Requirements Ø Ø Ø Ø Ø Block cost Parts count Unique parts count PCB Area Power consumption Operating temperature range Storage temperature range Reliability MTBF Operating humidity Disposal Ø Percent Allocation: l l l <$25 <18 <8 65 cm 2 3 W 5 to 55 C -20 C to 65 C 7. 8 years 0 to 100% Throw away Cost: 10. 0% Parts: 11. 25% PCB: 15. 29% 27

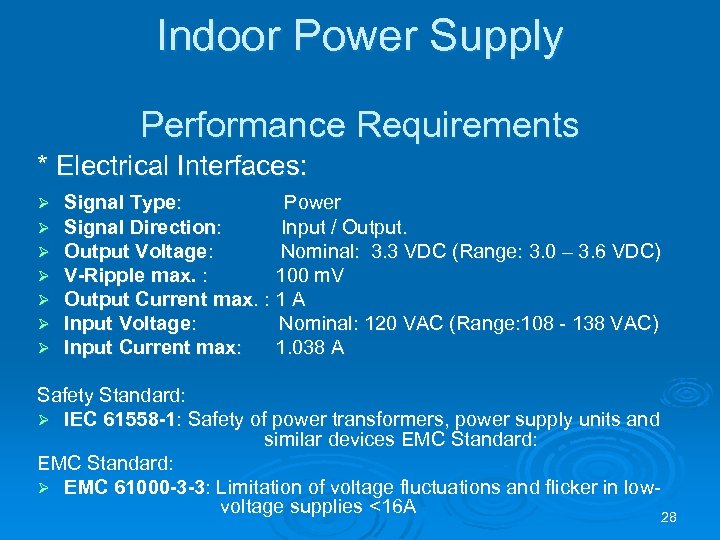

Indoor Power Supply Performance Requirements * Electrical Interfaces: Ø Signal Type: Power Ø Ø Ø Signal Direction: Input / Output Voltage: Nominal: 3. 3 VDC (Range: 3. 0 – 3. 6 VDC) V-Ripple max. : 100 m. V Output Current max. : 1 A Input Voltage: Nominal: 120 VAC (Range: 108 - 138 VAC) Input Current max: 1. 038 A Safety Standard: Ø IEC 61558 -1: Safety of power transformers, power supply units and similar devices EMC Standard: Ø EMC 61000 -3 -3: Limitation of voltage fluctuations and flicker in low voltage supplies <16 A 28

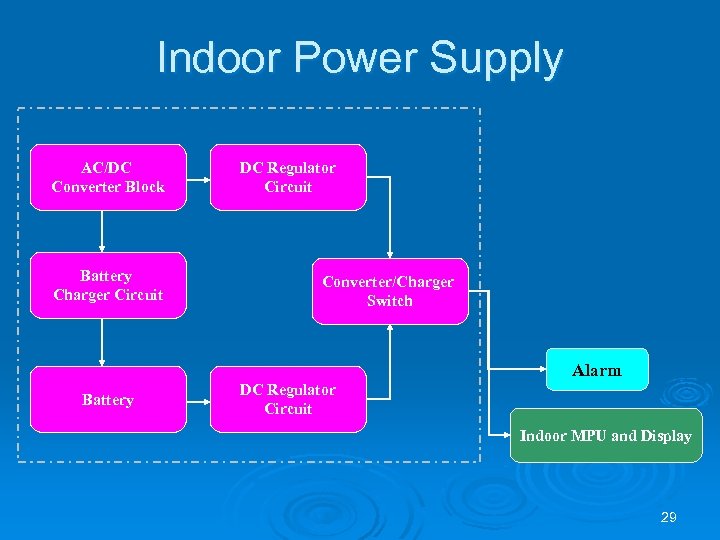

Indoor Power Supply AC/DC Converter Block Battery Charger Circuit DC Regulator Circuit Converter/Charger Switch Alarm Battery DC Regulator Circuit Indoor MPU and Display 29

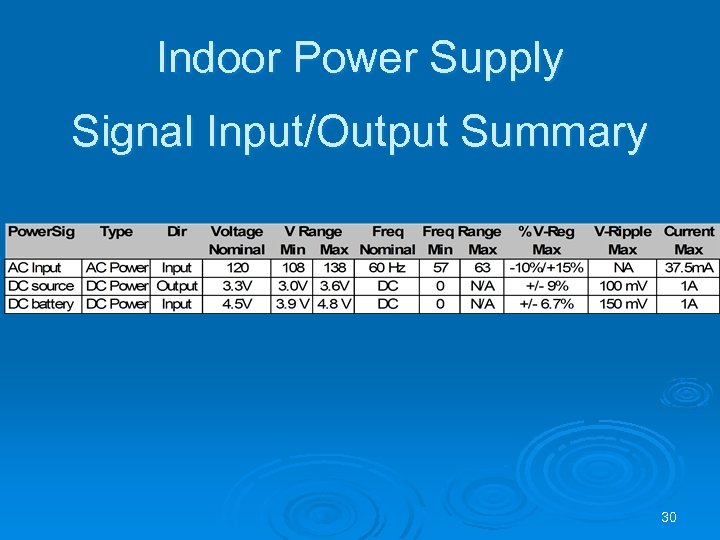

Indoor Power Supply Signal Input/Output Summary 30

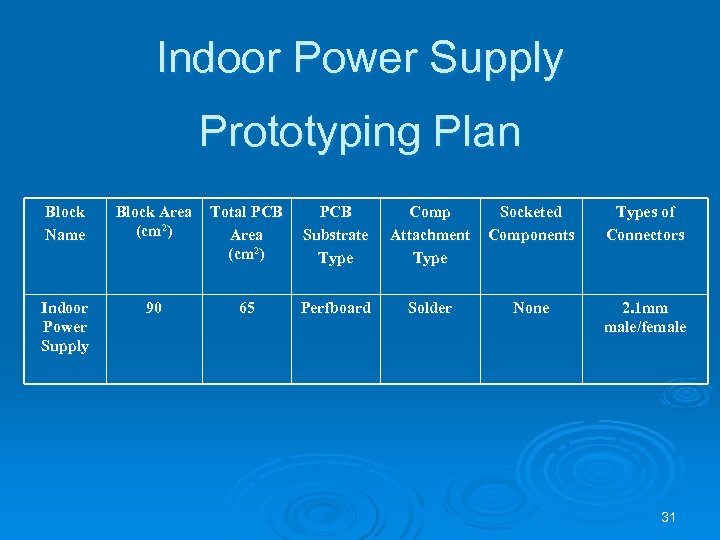

Indoor Power Supply Prototyping Plan Block Name Block Area (cm 2) Total PCB Area (cm 2) PCB Substrate Type Comp Attachment Type Socketed Components Types of Connectors Indoor Power Supply 90 65 Perfboard Solder None 2. 1 mm male/female 31

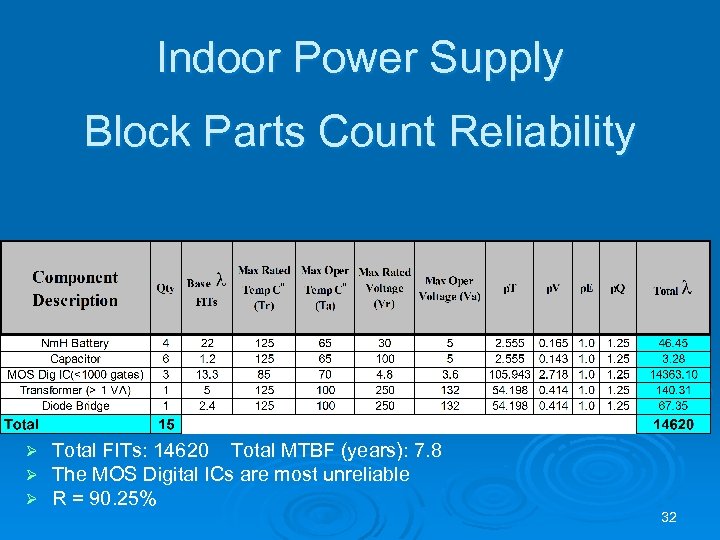

Indoor Power Supply Block Parts Count Reliability Ø Ø Ø Total FITs: 14620 Total MTBF (years): 7. 8 The MOS Digital ICs are most unreliable R = 90. 25% 32

Indoor MPU and Display Darren Pallesen 33

Poolside Alarm Block Assignment Outdoor Indoor Power Supply Air / Water Sensor Wave Sensor Darren Alarm RF Transceiver Indoor MPU and Display Motion Sensor Alarm Data Lines Power Lines 34

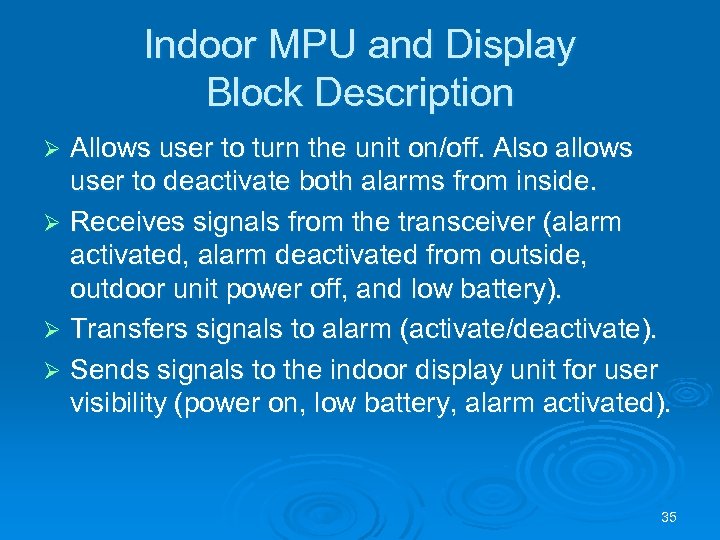

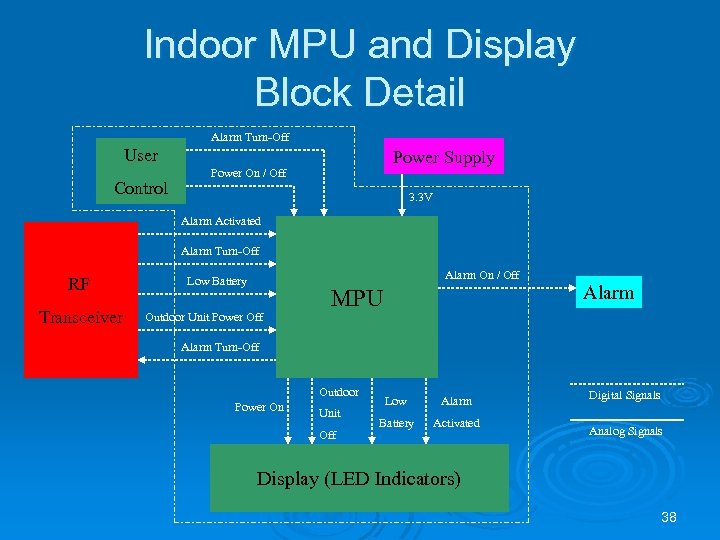

Indoor MPU and Display Block Description Allows user to turn the unit on/off. Also allows user to deactivate both alarms from inside. Ø Receives signals from the transceiver (alarm activated, alarm deactivated from outside, outdoor unit power off, and low battery). Ø Transfers signals to alarm (activate/deactivate). Ø Sends signals to the indoor display unit for user visibility (power on, low battery, alarm activated). Ø 35

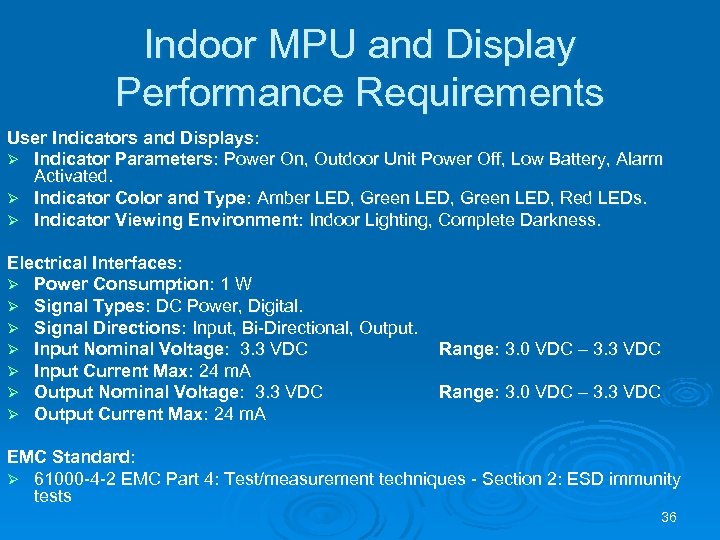

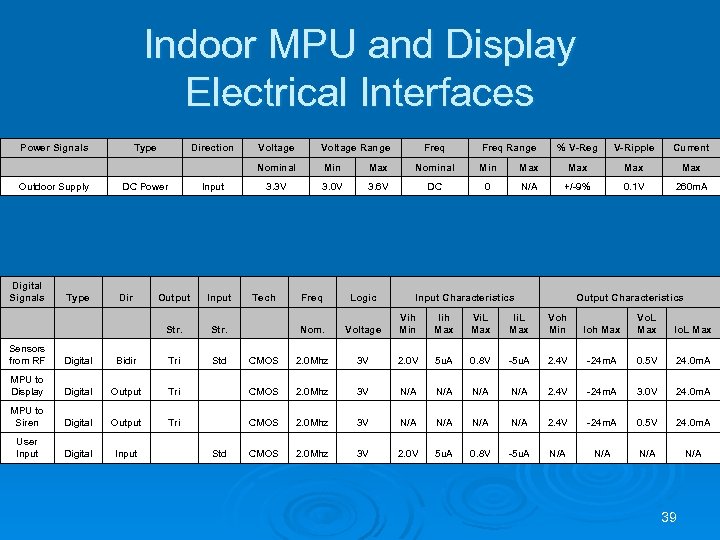

Indoor MPU and Display Performance Requirements User Indicators and Displays: Ø Indicator Parameters: Power On, Outdoor Unit Power Off, Low Battery, Alarm Activated. Ø Indicator Color and Type: Amber LED, Green LED, Red LEDs. Ø Indicator Viewing Environment: Indoor Lighting, Complete Darkness. Electrical Interfaces: Ø Power Consumption: 1 W Ø Signal Types: DC Power, Digital. Ø Signal Directions: Input, Bi-Directional, Output. Ø Input Nominal Voltage: 3. 3 VDC Ø Input Current Max: 24 m. A Ø Output Nominal Voltage: 3. 3 VDC Ø Output Current Max: 24 m. A Range: 3. 0 VDC – 3. 3 VDC EMC Standard: Ø 61000 -4 -2 EMC Part 4: Test/measurement techniques - Section 2: ESD immunity tests 36

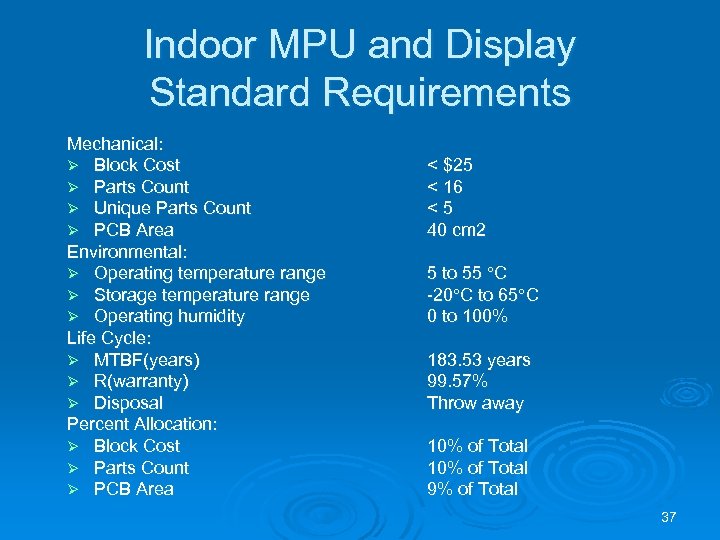

Indoor MPU and Display Standard Requirements Mechanical: Ø Block Cost Ø Parts Count Ø Unique Parts Count Ø PCB Area Environmental: Ø Operating temperature range Ø Storage temperature range Ø Operating humidity Life Cycle: Ø MTBF(years) Ø R(warranty) Ø Disposal Percent Allocation: Ø Block Cost Ø Parts Count Ø PCB Area < $25 < 16 < 5 40 cm 2 5 to 55 C -20 C to 65 C 0 to 100% 183. 53 years 99. 57% Throw away 10% of Total 9% of Total 37

Indoor MPU and Display Block Detail Alarm Turn-Off User Control Power Supply Power On / Off 3. 3 V Alarm Activated Alarm Turn-Off RF Transceiver Alarm On / Off Low Battery Outdoor Unit Power Off MPU Alarm Turn-Off Outdoor Power On Unit Off Low Alarm Battery Activated Digital Signals Analog Signals Display (LED Indicators) 38

Indoor MPU and Display Electrical Interfaces Power Signals Type Direction Voltage Range Freq Range Nominal Min Max Nominal Min Outdoor Supply DC Power Input 3. 3 V 3. 0 V 3. 6 V DC 0 % V-Reg V-Ripple Current Max Max N/A +/-9% 0. 1 V 260 m. A Digital Signals Type Dir Output Input Tech Freq Logic Str. Nom. Voltage Vih Min Iih Max Vi. L Max Ii. L Max Voh Min Ioh Max Vo. L Max Io. L Max Sensors from RF Digital Bidir Tri Std CMOS 2. 0 Mhz 3 V 2. 0 V 5 u. A 0. 8 V -5 u. A 2. 4 V -24 m. A 0. 5 V 24. 0 m. A MPU to Display Digital Output Tri CMOS 2. 0 Mhz 3 V N/A N/A 2. 4 V -24 m. A 3. 0 V 24. 0 m. A MPU to Siren Digital Output Tri CMOS 2. 0 Mhz 3 V N/A N/A 2. 4 V -24 m. A 0. 5 V 24. 0 m. A User Input Digital Input CMOS 2. 0 Mhz 3 V 2. 0 V 5 u. A 0. 8 V -5 u. A N/A N/A Std Input Characteristics Output Characteristics 39

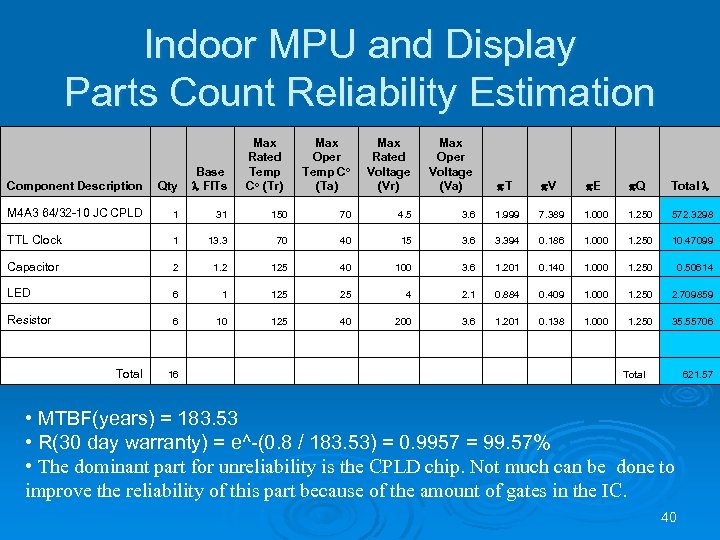

Indoor MPU and Display Parts Count Reliability Estimation Max Rated Temp Co (Tr) Max Oper Temp Co (Ta) Max Rated Voltage (Vr) Max Oper Voltage (Va) Component Description Qty Base l FITs M 4 A 3 64/32 -10 JC CPLD 1 31 150 70 4. 5 TTL Clock 1 13. 3 70 40 Capacitor 2 125 LED 6 1 Resistor 6 10 p. T p. V p. E p. Q Total l 3. 6 1. 999 7. 389 1. 000 1. 250 572. 3298 15 3. 6 3. 394 0. 186 1. 000 1. 250 10. 47099 40 100 3. 6 1. 201 0. 140 1. 000 1. 250 0. 50614 125 25 4 2. 1 0. 884 0. 409 1. 000 1. 250 2. 709859 125 40 200 3. 6 1. 201 0. 138 1. 000 1. 250 35. 55706 Total 16 Total 621. 57 • MTBF(years) = 183. 53 • R(30 day warranty) = e^-(0. 8 / 183. 53) = 0. 9957 = 99. 57% • The dominant part for unreliability is the CPLD chip. Not much can be done to improve the reliability of this part because of the amount of gates in the IC. 40

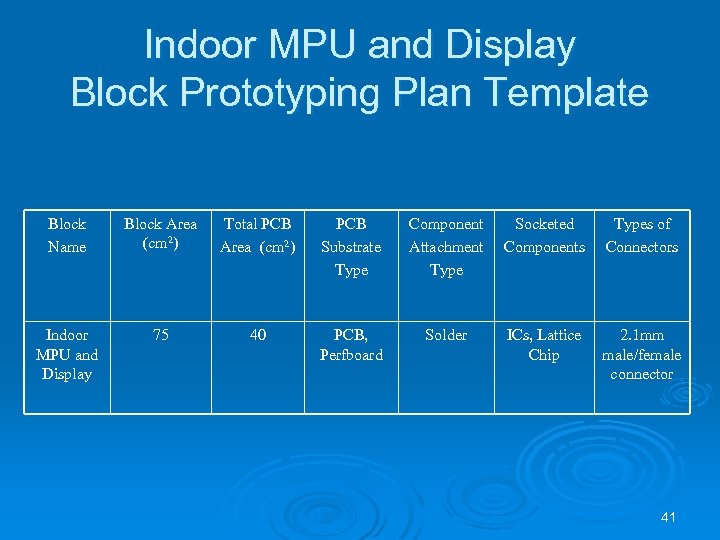

Indoor MPU and Display Block Prototyping Plan Template Block Name Block Area (cm 2) Total PCB Area (cm 2) PCB Substrate Type Component Attachment Type Socketed Components Types of Connectors Indoor MPU and Display 75 40 PCB, Perfboard Solder ICs, Lattice Chip 2. 1 mm male/female connector 41

Wave Sensor Jay Bombien 42

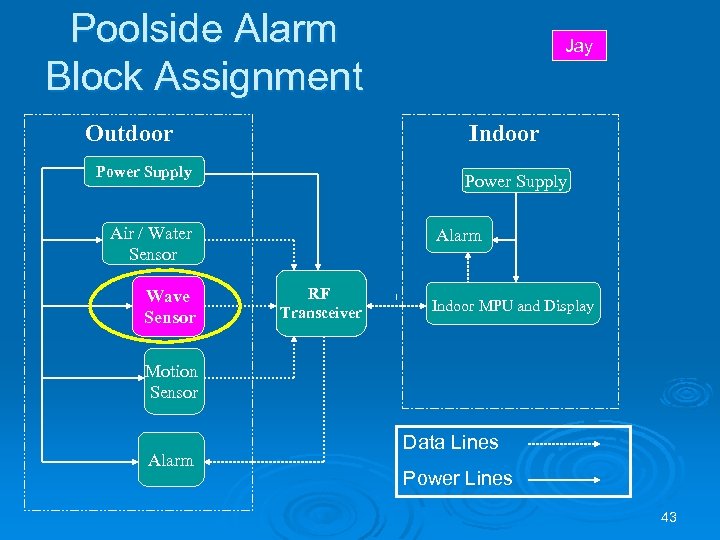

Poolside Alarm Block Assignment Outdoor Indoor Power Supply Air / Water Sensor Wave Sensor Jay Alarm RF Transceiver Indoor MPU and Display Motion Sensor Alarm Data Lines Power Lines 43

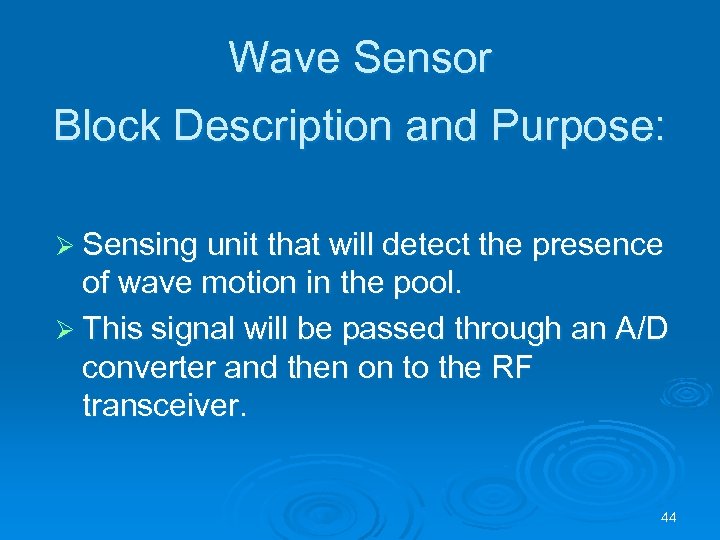

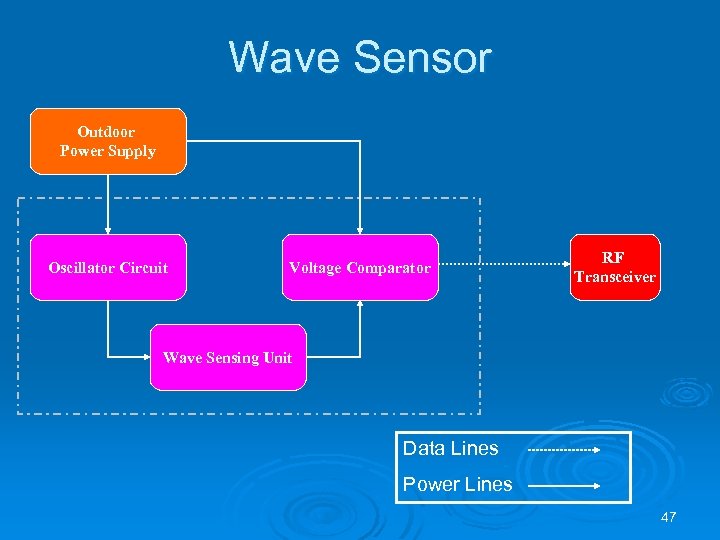

Wave Sensor Block Description and Purpose: Ø Sensing unit that will detect the presence of wave motion in the pool. Ø This signal will be passed through an A/D converter and then on to the RF transceiver. 44

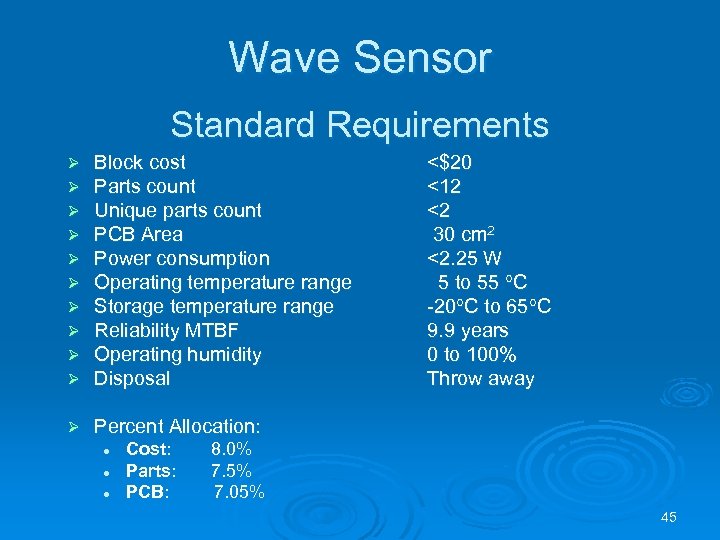

Wave Sensor Standard Requirements Ø Ø Ø Ø Ø Block cost Parts count Unique parts count PCB Area Power consumption Operating temperature range Storage temperature range Reliability MTBF Operating humidity Disposal Ø Percent Allocation: l l l <$20 <12 <2 30 cm 2 <2. 25 W 5 to 55 C -20 C to 65 C 9. 9 years 0 to 100% Throw away Cost: 8. 0% Parts: 7. 5% PCB: 7. 05% 45

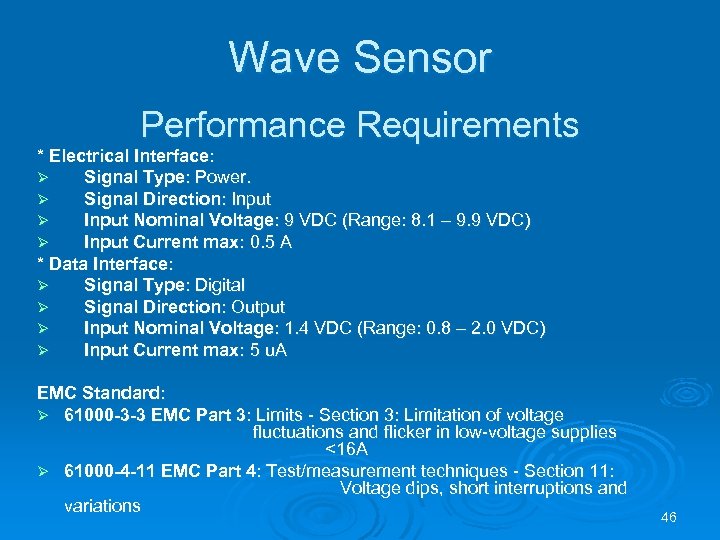

Wave Sensor Performance Requirements * Electrical Interface: Ø Signal Type: Power. Ø Signal Direction: Input Ø Input Nominal Voltage: 9 VDC (Range: 8. 1 – 9. 9 VDC) Ø Input Current max: 0. 5 A * Data Interface: Ø Signal Type: Digital Ø Signal Direction: Output Ø Input Nominal Voltage: 1. 4 VDC (Range: 0. 8 – 2. 0 VDC) Ø Input Current max: 5 u. A EMC Standard: Ø 61000 -3 -3 EMC Part 3: Limits - Section 3: Limitation of voltage fluctuations and flicker in low-voltage supplies <16 A Ø 61000 -4 -11 EMC Part 4: Test/measurement techniques - Section 11: Voltage dips, short interruptions and variations 46

Wave Sensor Outdoor Power Supply Oscillator Circuit Voltage Comparator RF Transceiver Wave Sensing Unit Data Lines Power Lines 47

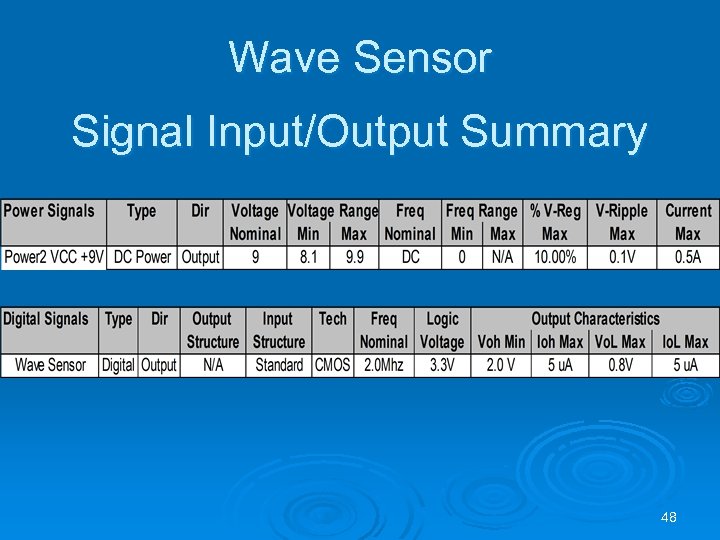

Wave Sensor Signal Input/Output Summary 48

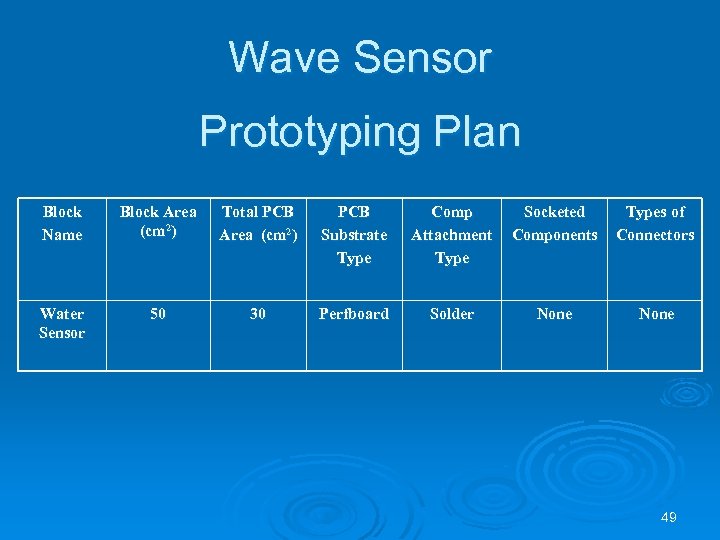

Wave Sensor Prototyping Plan Block Name Block Area (cm 2) Total PCB Area (cm 2) PCB Substrate Type Comp Attachment Type Socketed Components Types of Connectors Water Sensor 50 30 Perfboard Solder None 49

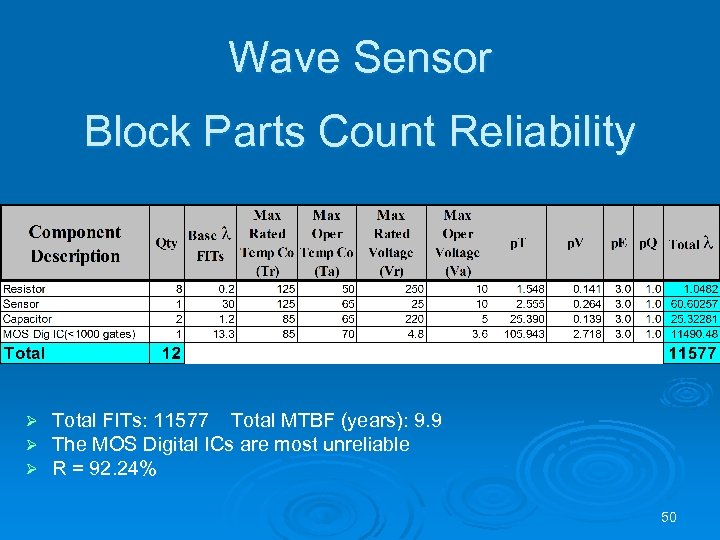

Wave Sensor Block Parts Count Reliability Ø Ø Ø Total FITs: 11577 Total MTBF (years): 9. 9 The MOS Digital ICs are most unreliable R = 92. 24% 50

Air & Water Temp Sensor Peter Brunner 51

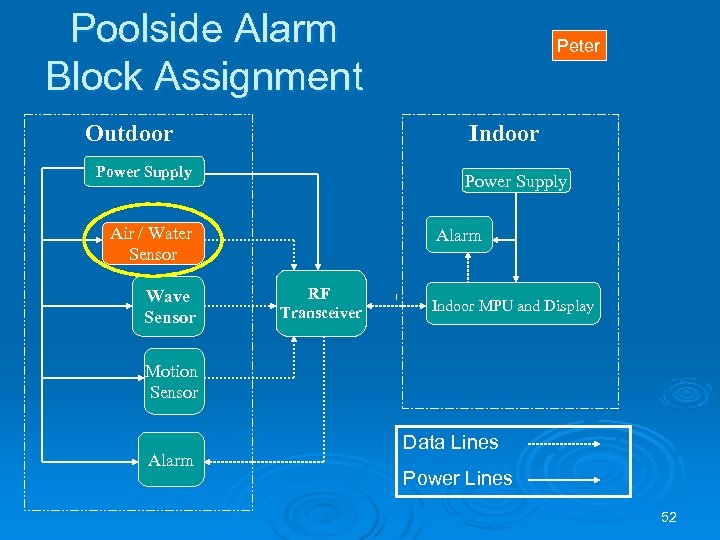

Poolside Alarm Block Assignment Outdoor Indoor Power Supply Air / Water Sensor Wave Sensor Peter Alarm RF Transceiver Indoor MPU and Display Motion Sensor Alarm Data Lines Power Lines 52

Function Ø To measure the current pool water and outdoor air temperature Ø To convert the temperature into a positive digital voltage to be sent to the MPU with an accuracy of ± 3 C (max) over a range of 5 C to 55 C 53

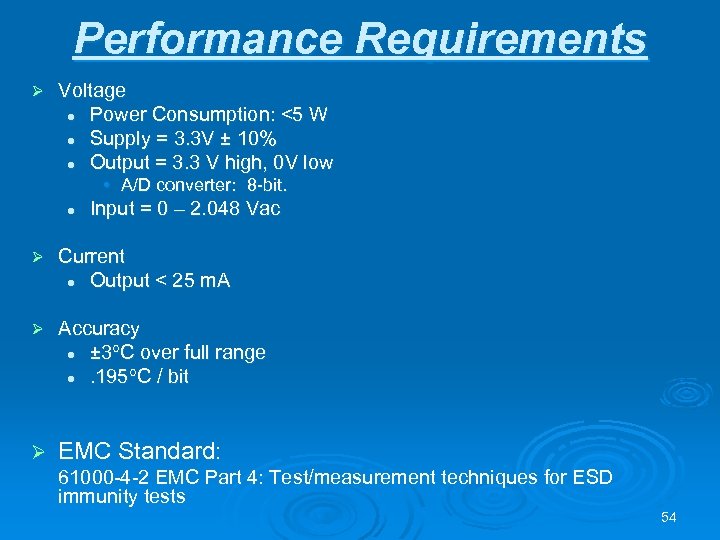

Performance Requirements Ø Voltage l Power Consumption: <5 W l Supply = 3. 3 V ± 10% l Output = 3. 3 V high, 0 V low • A/D converter: 8 -bit. l Input = 0 – 2. 048 Vac Ø Current l Output < 25 m. A Ø Accuracy l ± 3 C over full range l. 195 C / bit Ø EMC Standard: 61000 -4 -2 EMC Part 4: Test/measurement techniques for ESD immunity tests 54

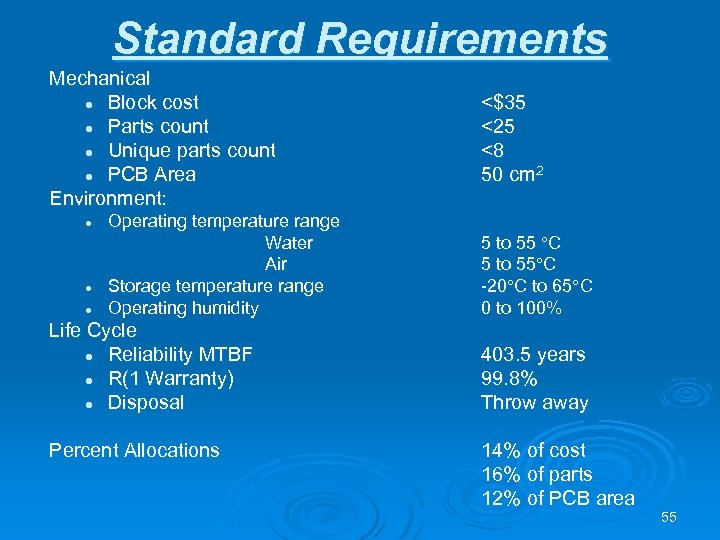

Standard Requirements Mechanical l Block cost l Parts count l Unique parts count l PCB Area Environment: l l l Operating temperature range Water Air Storage temperature range Operating humidity Life Cycle l Reliability MTBF l R(1 Warranty) l Disposal Percent Allocations <$35 <25 <8 50 cm 2 5 to 55 C -20 C to 65 C 0 to 100% 403. 5 years 99. 8% Throw away 14% of cost 16% of parts 12% of PCB area 55

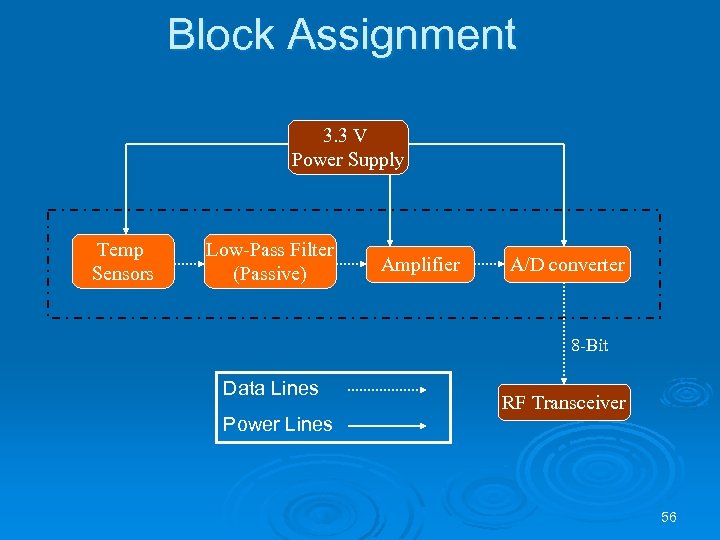

Block Assignment 3. 3 V Power Supply Temp Sensors Low-Pass Filter (Passive) Amplifier A/D converter 8 -Bit Data Lines Power Lines RF Transceiver 56

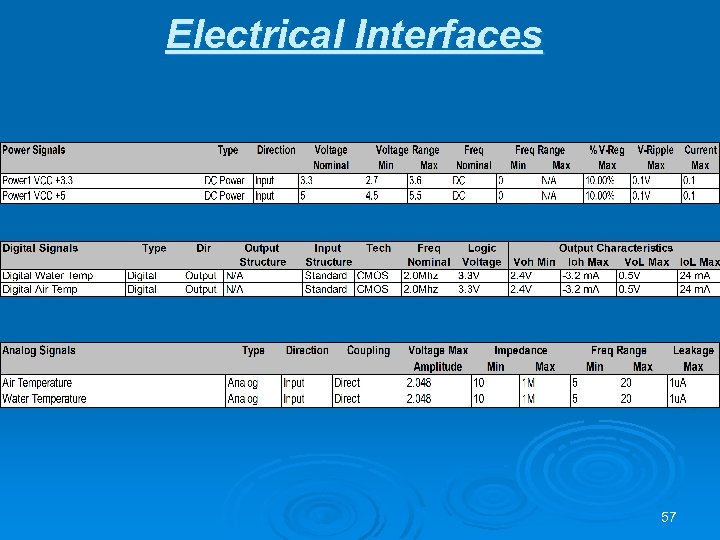

Electrical Interfaces 57

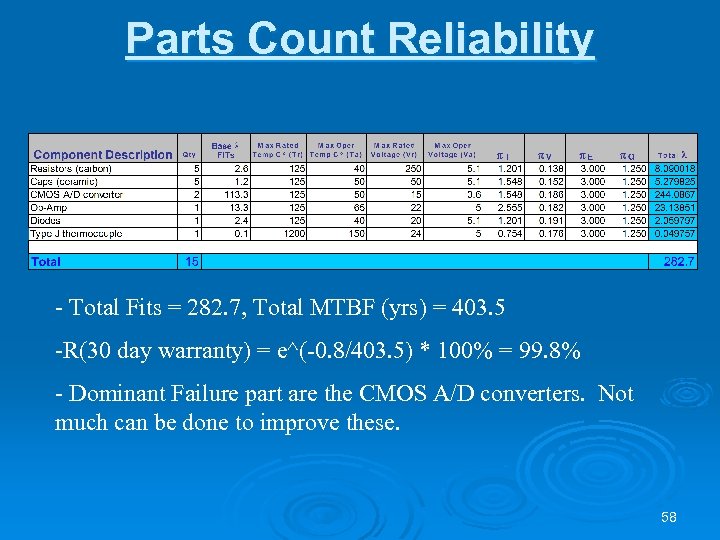

Parts Count Reliability - Total Fits = 282. 7, Total MTBF (yrs) = 403. 5 -R(30 day warranty) = e^(-0. 8/403. 5) * 100% = 99. 8% - Dominant Failure part are the CMOS A/D converters. Not much can be done to improve these. 58

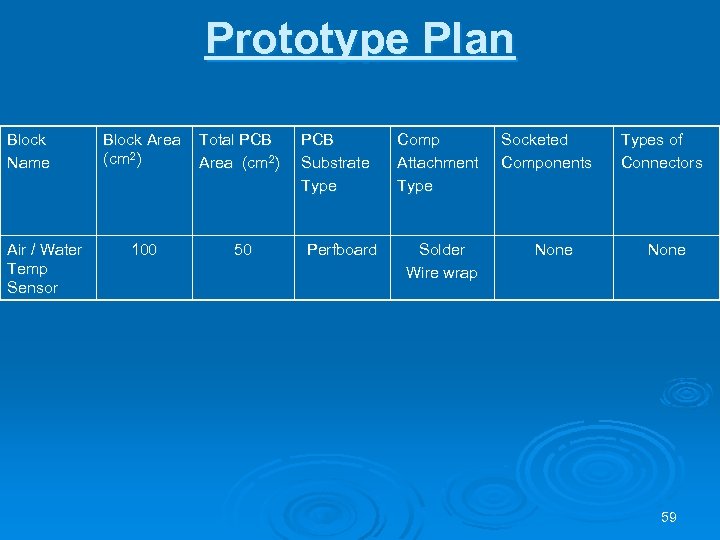

Prototype Plan Block Name Air / Water Temp Sensor Block Area Total PCB (cm 2) Area (cm 2) 100 50 PCB Substrate Type Perfboard Comp Attachment Type Solder Wire wrap Socketed Components None Types of Connectors None 59

Motion Sensor Louis Chatfield 60

Poolside Alarm Block Assignment Outdoor Indoor Power Supply Air / Water Sensor Wave Sensor Louis Alarm RF Transceiver Indoor MPU and Display Motion Sensor Alarm Data Lines Power Lines 61

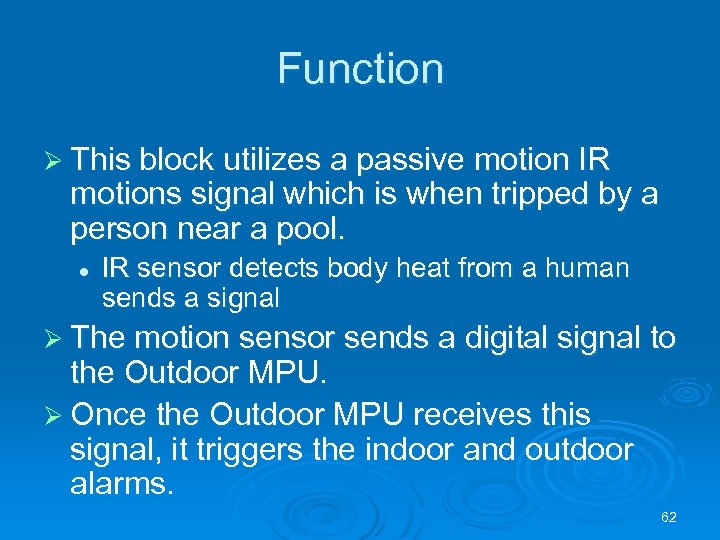

Function Ø This block utilizes a passive motion IR motions signal which is when tripped by a person near a pool. l IR sensor detects body heat from a human sends a signal Ø The motion sensor sends a digital signal to the Outdoor MPU. Ø Once the Outdoor MPU receives this signal, it triggers the indoor and outdoor alarms. 62

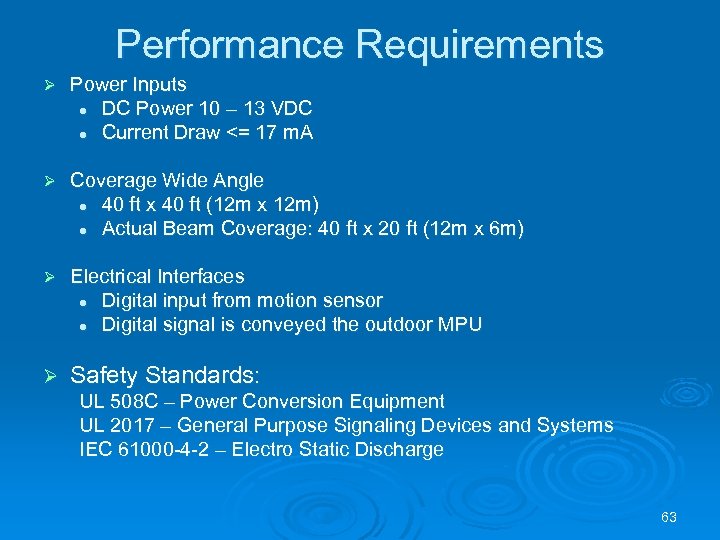

Performance Requirements Ø Power Inputs l DC Power 10 – 13 VDC l Current Draw <= 17 m. A Ø Coverage Wide Angle l 40 ft x 40 ft (12 m x 12 m) l Actual Beam Coverage: 40 ft x 20 ft (12 m x 6 m) Ø Electrical Interfaces l Digital input from motion sensor l Digital signal is conveyed the outdoor MPU Ø Safety Standards: UL 508 C – Power Conversion Equipment UL 2017 – General Purpose Signaling Devices and Systems IEC 61000 -4 -2 – Electro Static Discharge 63

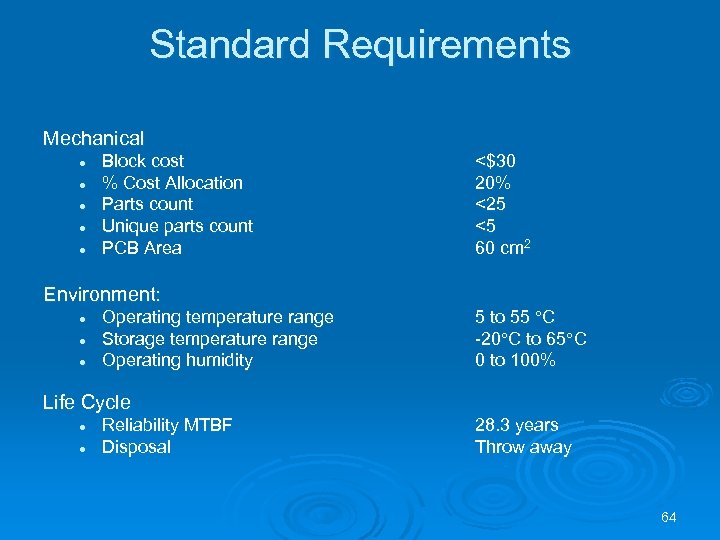

Standard Requirements Mechanical l l Block cost % Cost Allocation Parts count Unique parts count PCB Area Environment: l l l Operating temperature range Storage temperature range Operating humidity <$30 20% <25 <5 60 cm 2 5 to 55 C -20 C to 65 C 0 to 100% Life Cycle l l Reliability MTBF Disposal 28. 3 years Throw away 64

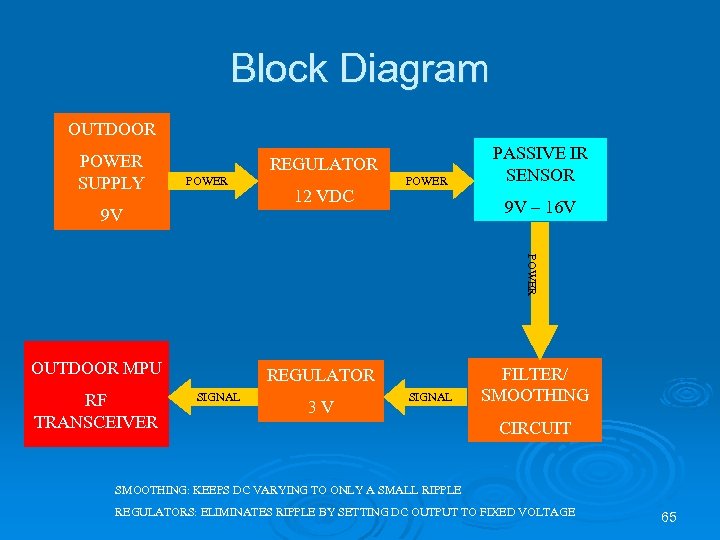

Block Diagram OUTDOOR POWER SUPPLY REGULATOR POWER 9 V 12 VDC POWER PASSIVE IR SENSOR 9 V – 16 V POWER OUTDOOR MPU RF TRANSCEIVER REGULATOR SIGNAL 3 V SIGNAL FILTER/ SMOOTHING CIRCUIT SMOOTHING: KEEPS DC VARYING TO ONLY A SMALL RIPPLE REGULATORS: ELIMINATES RIPPLE BY SETTING DC OUTPUT TO FIXED VOLTAGE 65

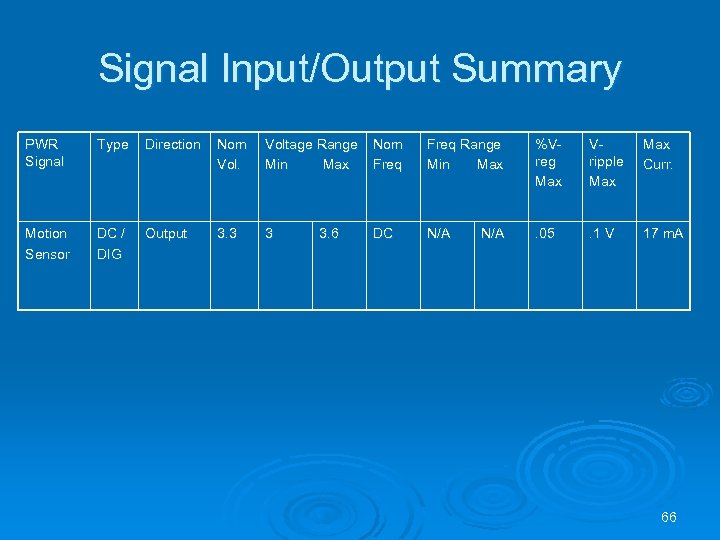

Signal Input/Output Summary PWR Signal Type Direction Nom Voltage Range Vol. Min Max Nom Freq Range Min Max %Vreg Max Vripple Max Curr. Motion Sensor DC / DIG Output 3. 3 DC N/A . 05 . 1 V 17 m. A 3 3. 6 N/A 66

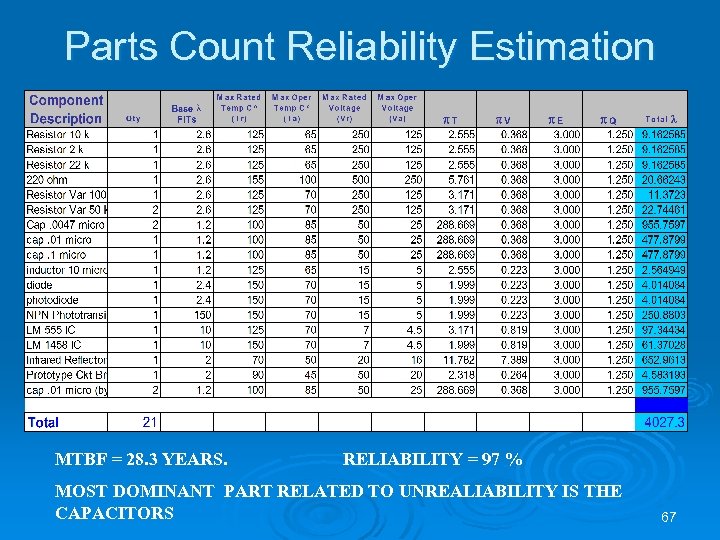

Parts Count Reliability Estimation MTBF = 28. 3 YEARS. RELIABILITY = 97 % MOST DOMINANT PART RELATED TO UNREALIABILITY IS THE CAPACITORS 67

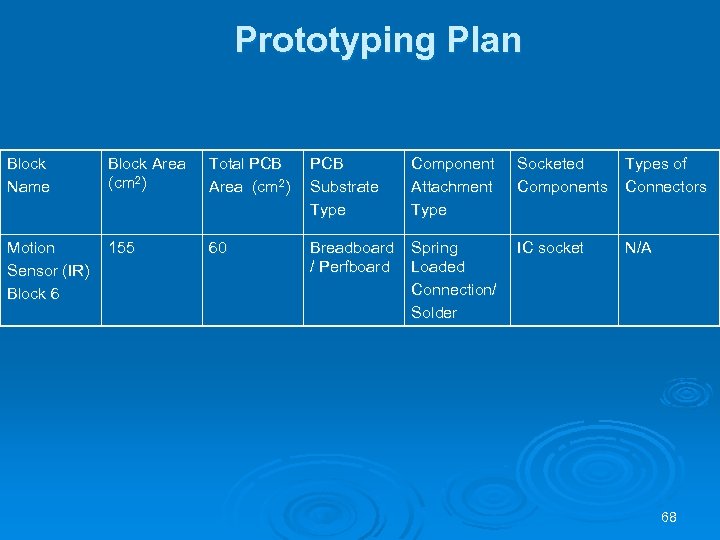

Prototyping Plan Block Name Block Area (cm 2) Total PCB Area (cm 2) PCB Substrate Type Component Attachment Type Socketed Components Types of Connectors Motion Sensor (IR) Block 6 155 60 Breadboard / Perfboard Spring Loaded Connection/ Solder IC socket N/A 68

RF Transceiver Milja Cumbo 69

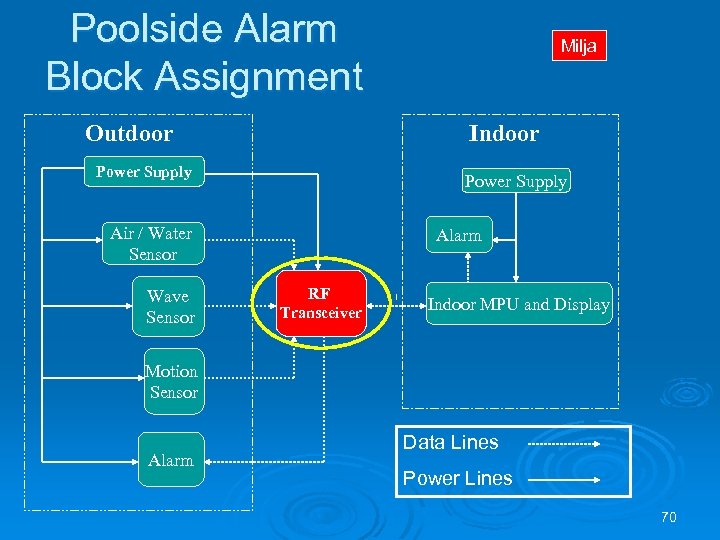

Poolside Alarm Block Assignment Outdoor Indoor Power Supply Air / Water Sensor Wave Sensor Milja Alarm RF Transceiver Indoor MPU and Display Motion Sensor Alarm Data Lines Power Lines 70

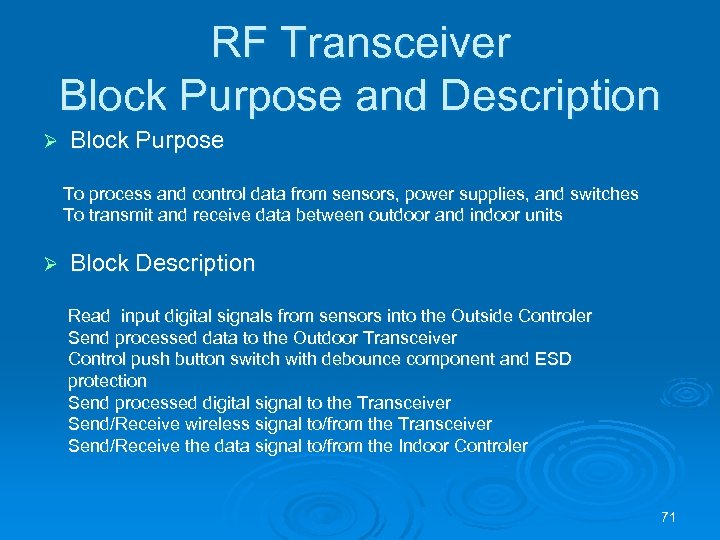

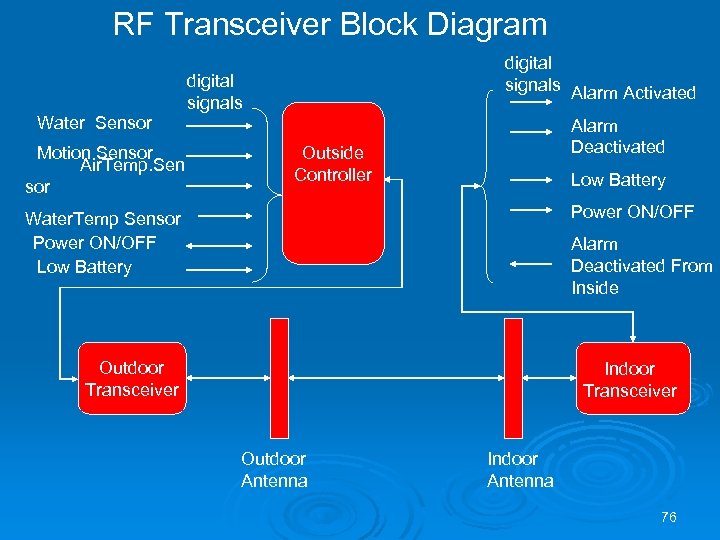

RF Transceiver Block Purpose and Description Ø Block Purpose To process and control data from sensors, power supplies, and switches To transmit and receive data between outdoor and indoor units Ø Block Description Read input digital signals from sensors into the Outside Controler Send processed data to the Outdoor Transceiver Control push button switch with debounce component and ESD protection Send processed digital signal to the Transceiver Send/Receive wireless signal to/from the Transceiver Send/Receive the data signal to/from the Indoor Controler 71

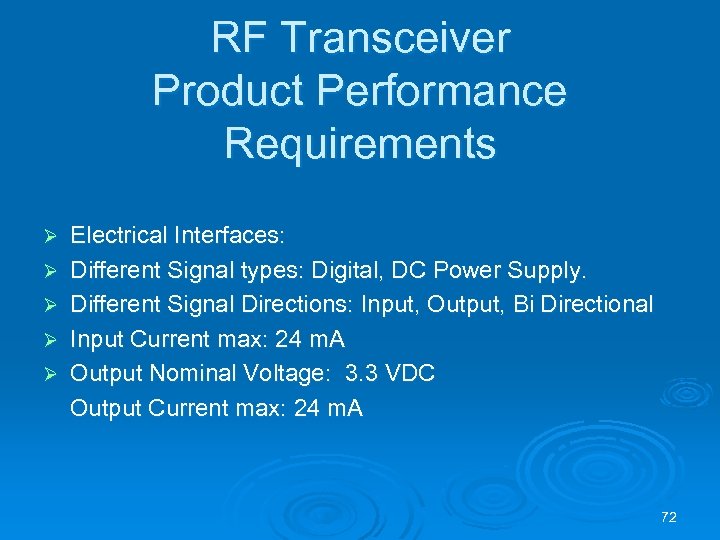

RF Transceiver Product Performance Requirements Electrical Interfaces: Ø Different Signal types: Digital, DC Power Supply. Ø Different Signal Directions: Input, Output, Bi Directional Ø Input Current max: 24 m. A Ø Output Nominal Voltage: 3. 3 VDC Output Current max: 24 m. A Ø 72

RF Transceiver Product Safety Requirements Ø UL 464 - Audible Signal Appliances l Electrically and electronically operated bells, buzzers, horns, and similar audible signal appliances intended for indoor or outdoor locations. 73

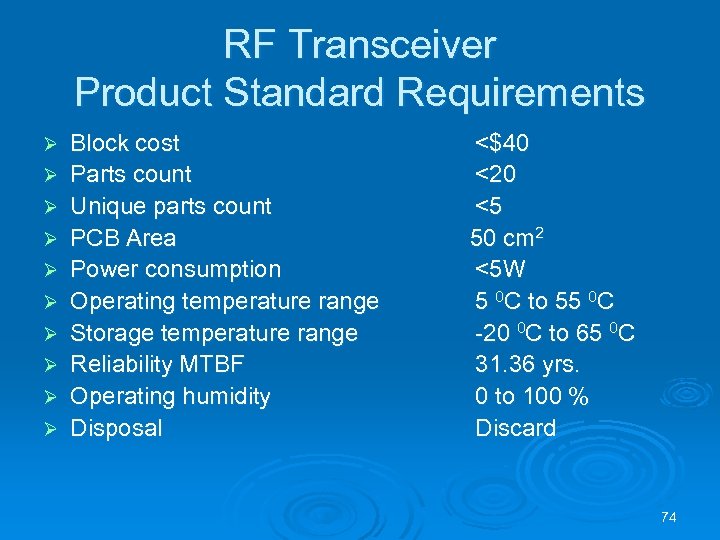

RF Transceiver Product Standard Requirements Ø Ø Ø Ø Ø Block cost <$40 Parts count <20 Unique parts count <5 PCB Area 50 cm 2 Power consumption <5 W Operating temperature range 5 0 C to 55 0 C Storage temperature range -20 0 C to 65 0 C Reliability MTBF 31. 36 yrs. Operating humidity 0 to 100 % Disposal Discard 74

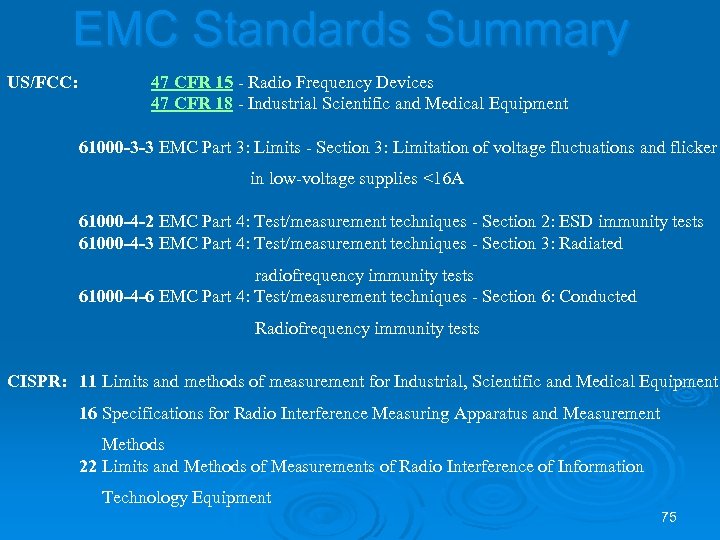

EMC Standards Summary US/FCC: 47 CFR 15 - Radio Frequency Devices 47 CFR 18 - Industrial Scientific and Medical Equipment 61000 -3 -3 EMC Part 3: Limits - Section 3: Limitation of voltage fluctuations and flicker in low-voltage supplies <16 A 61000 -4 -2 EMC Part 4: Test/measurement techniques - Section 2: ESD immunity tests 61000 -4 -3 EMC Part 4: Test/measurement techniques - Section 3: Radiated radiofrequency immunity tests 61000 -4 -6 EMC Part 4: Test/measurement techniques - Section 6: Conducted Radiofrequency immunity tests CISPR: 11 Limits and methods of measurement for Industrial, Scientific and Medical Equipment 16 Specifications for Radio Interference Measuring Apparatus and Measurement Methods 22 Limits and Methods of Measurements of Radio Interference of Information Technology Equipment 75

RF Transceiver Block Diagram digital signals Alarm Activated digital signals Water Sensor Motion Sensor Air. Temp. Sen sor Alarm Deactivated Outside Controller Low Battery Power ON/OFF Water. Temp Sensor Power ON/OFF Low Battery Alarm Deactivated From Inside Outdoor Transceiver Indoor Transceiver Outdoor Antenna Indoor Antenna 76

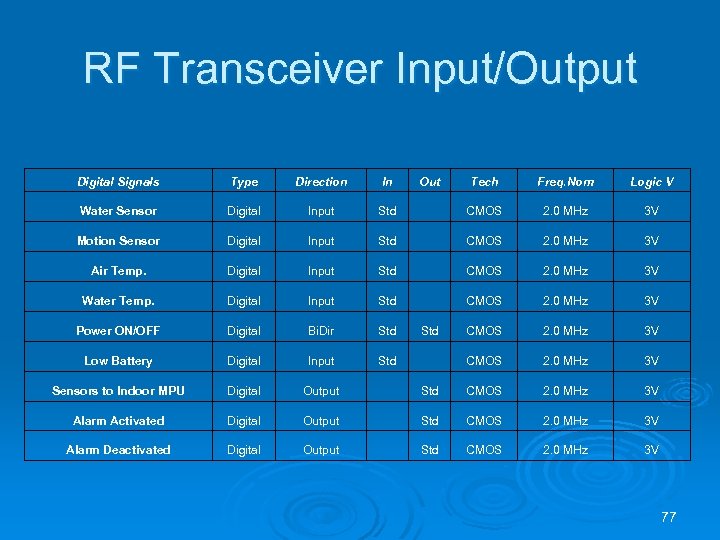

RF Transceiver Input/Output Digital Signals Type Direction In Out Tech Freq. Nom Logic V Water Sensor Digital Input Std CMOS 2. 0 MHz 3 V Motion Sensor Digital Input Std CMOS 2. 0 MHz 3 V Air Temp. Digital Input Std CMOS 2. 0 MHz 3 V Water Temp. Digital Input Std CMOS 2. 0 MHz 3 V Power ON/OFF Digital Bi. Dir Std CMOS 2. 0 MHz 3 V Low Battery Digital Input Std CMOS 2. 0 MHz 3 V Sensors to Indoor MPU Digital Output Std CMOS 2. 0 MHz 3 V Alarm Activated Digital Output Std CMOS 2. 0 MHz 3 V Alarm Deactivated Digital Output Std CMOS 2. 0 MHz 3 V 77

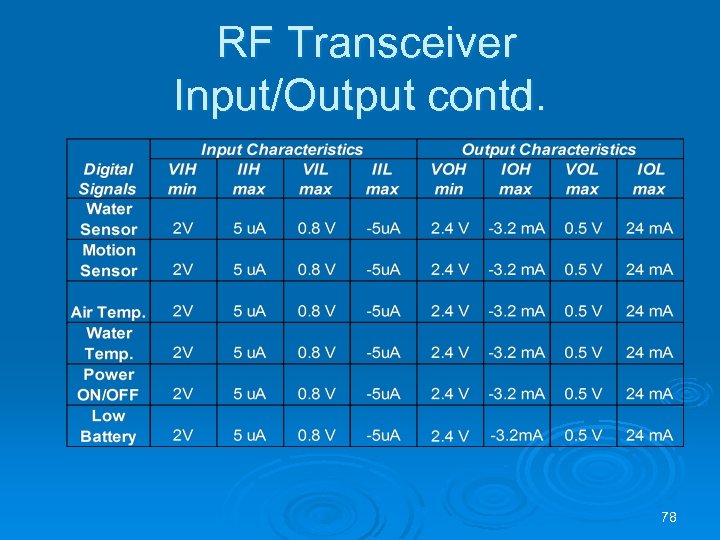

RF Transceiver Input/Output contd. 78

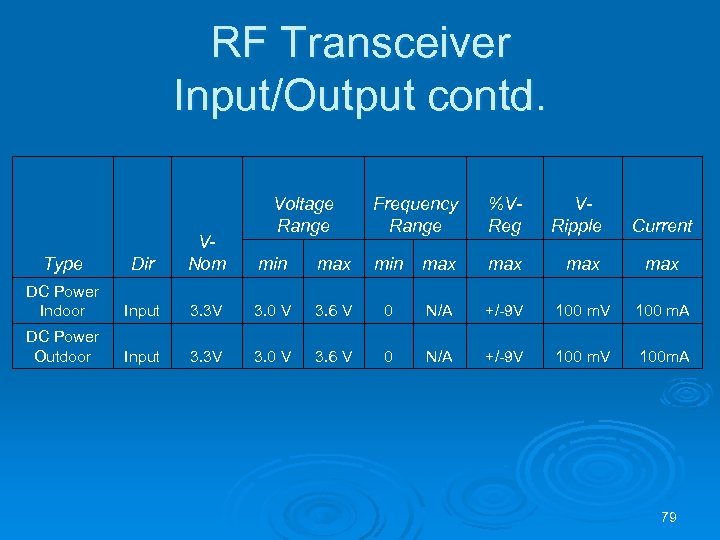

RF Transceiver Input/Output contd. Voltage Range Frequency Range %VReg VRipple Current Type Dir VNom DC Power Indoor Input 3. 3 V 3. 0 V 3. 6 V 0 N/A +/-9 V 100 m. A DC Power Outdoor Input 3. 3 V 3. 0 V 3. 6 V 0 N/A +/-9 V 100 m. V 100 m. A min max max max 79

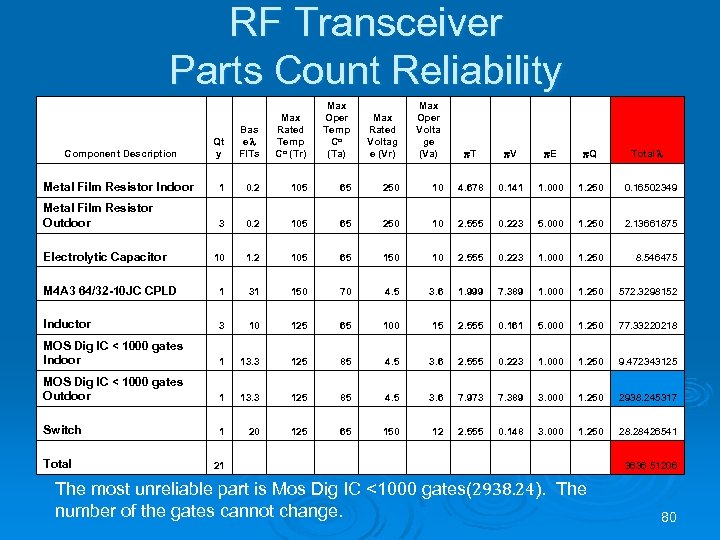

RF Transceiver Parts Count Reliability Max Oper Temp Co (Ta) Max Rated Voltag e (Vr) Max Oper Volta ge (Va) Qt y Bas e l FITs Max Rated Temp Co (Tr) Metal Film Resistor Indoor 1 0. 2 105 65 250 Metal Film Resistor Outdoor 3 0. 2 105 65 10 1. 2 105 M 4 A 3 64/32 -10 JC CPLD 1 31 Inductor 3 MOS Dig IC < 1000 gates Indoor p. T p. V p. E p. Q Total l 10 4. 678 0. 141 1. 000 1. 250 0. 16502349 250 10 2. 555 0. 223 5. 000 1. 250 2. 13661875 65 150 10 2. 555 0. 223 1. 000 1. 250 8. 546475 150 70 4. 5 3. 6 1. 999 7. 389 1. 000 1. 250 572. 3298152 10 125 65 100 15 2. 555 0. 161 5. 000 1. 250 77. 33220218 1 13. 3 125 85 4. 5 3. 6 2. 555 0. 223 1. 000 1. 250 9. 472343125 MOS Dig IC < 1000 gates Outdoor 1 13. 3 125 85 4. 5 3. 6 7. 973 7. 389 3. 000 1. 250 2938. 245317 Switch 1 20 125 65 150 12 2. 555 0. 148 3. 000 1. 250 28. 28426541 Component Description Electrolytic Capacitor Total 21 The most unreliable part is Mos Dig IC <1000 gates(2938. 24). The number of the gates cannot change. 3636. 51206 80

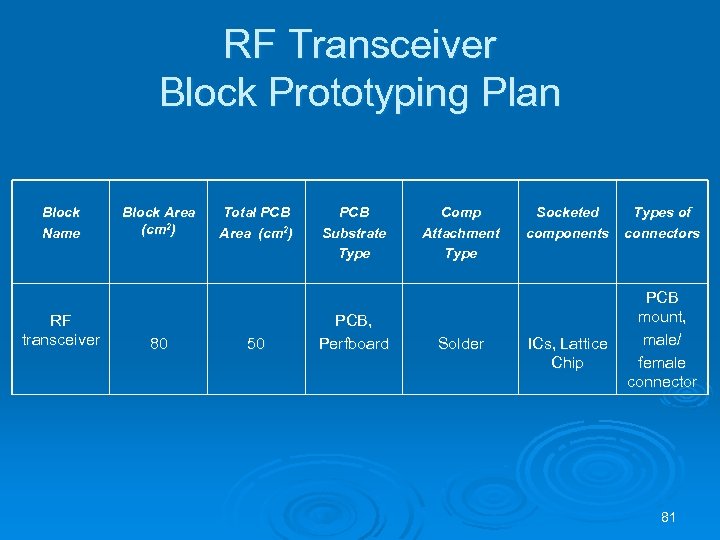

RF Transceiver Block Prototyping Plan Block Name RF transceiver Block Area (cm 2) 80 Total PCB Area (cm 2) 50 PCB Substrate Type PCB, Perfboard Comp Attachment Type Solder Socketed components Types of connectors PCB mount, male/ ICs, Lattice Chip female connector 81

Alarms Louis Chatfield 82

Poolside Alarm Block Assignment Outdoor Indoor Power Supply Air / Water Sensor Wave Sensor Louis Alarm RF Transceiver Indoor MPU and Display Motion Sensor Alarm Data Lines Power Lines 83

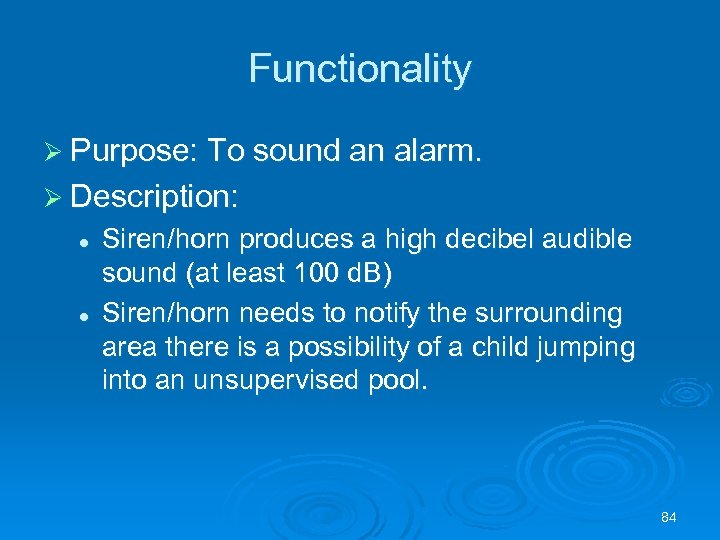

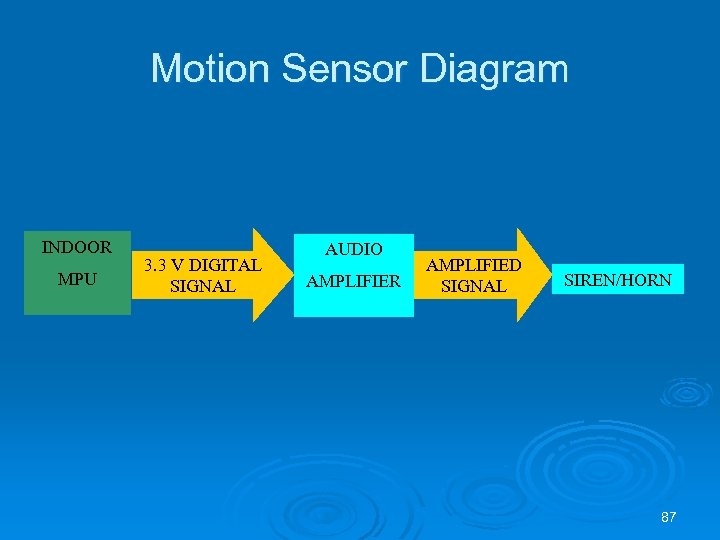

Functionality Ø Purpose: To sound an alarm. Ø Description: l l Siren/horn produces a high decibel audible sound (at least 100 d. B) Siren/horn needs to notify the surrounding area there is a possibility of a child jumping into an unsupervised pool. 84

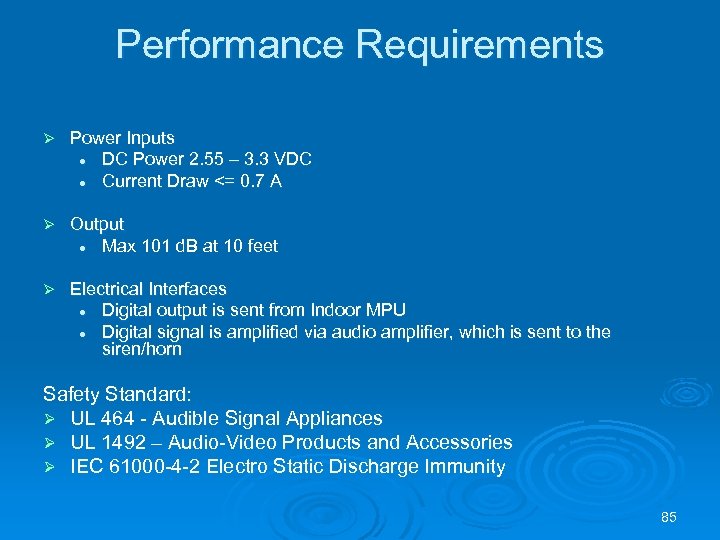

Performance Requirements Ø Power Inputs l DC Power 2. 55 – 3. 3 VDC l Current Draw <= 0. 7 A Ø Output l Max 101 d. B at 10 feet Ø Electrical Interfaces l Digital output is sent from Indoor MPU l Digital signal is amplified via audio amplifier, which is sent to the siren/horn Safety Standard: Ø UL 464 - Audible Signal Appliances Ø UL 1492 – Audio-Video Products and Accessories Ø IEC 61000 -4 -2 Electro Static Discharge Immunity 85

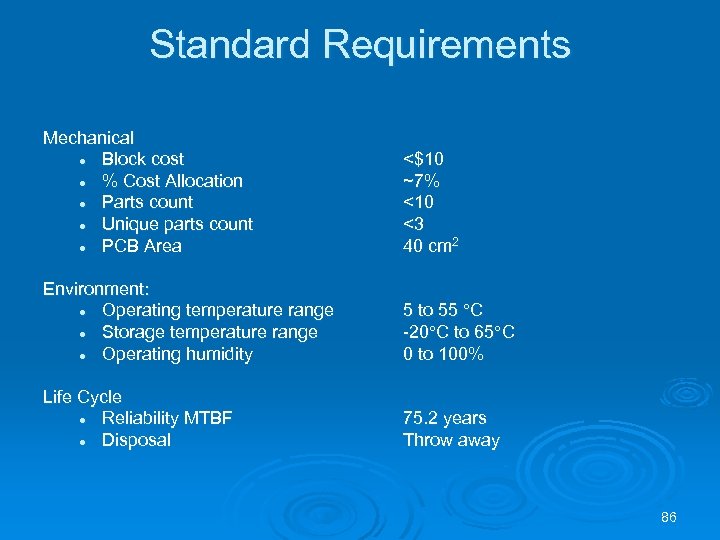

Standard Requirements Mechanical l Block cost l % Cost Allocation l Parts count l Unique parts count l PCB Area Environment: l Operating temperature range l Storage temperature range l Operating humidity Life Cycle l Reliability MTBF l Disposal <$10 ~7% <10 <3 40 cm 2 5 to 55 C -20 C to 65 C 0 to 100% 75. 2 years Throw away 86

Motion Sensor Diagram INDOOR MPU 3. 3 V DIGITAL SIGNAL AUDIO AMPLIFIER AMPLIFIED SIGNAL SIREN/HORN 87

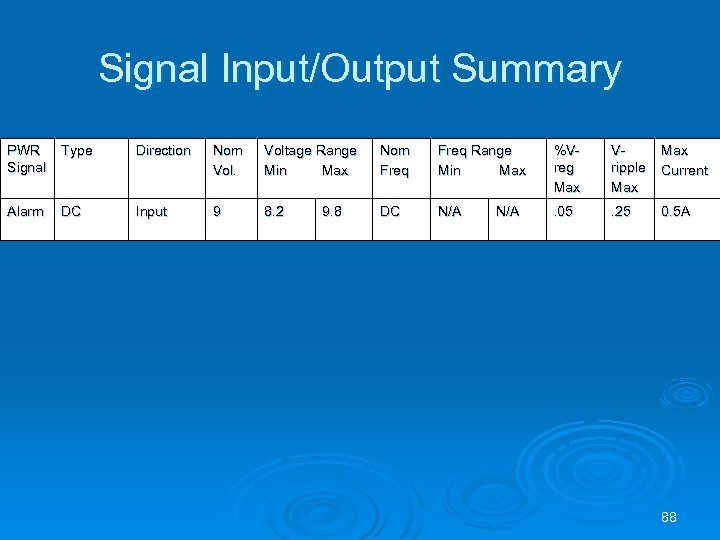

Signal Input/Output Summary PWR Signal Type Direction Nom Voltage Range Min Max Nom Freq Range Min Max %Vreg Max Vripple Max Current Alarm DC Input 9 8. 2 DC N/A . 05 . 25 0. 5 A 9. 8 N/A 88

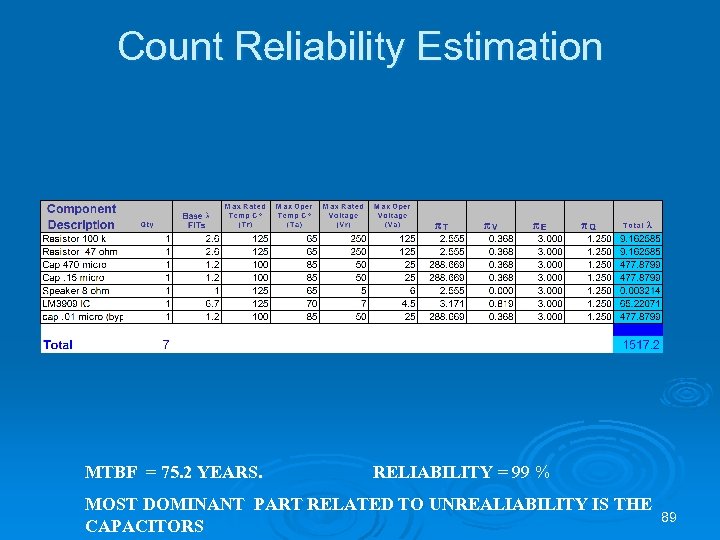

Count Reliability Estimation MTBF = 75. 2 YEARS. RELIABILITY = 99 % MOST DOMINANT PART RELATED TO UNREALIABILITY IS THE CAPACITORS 89

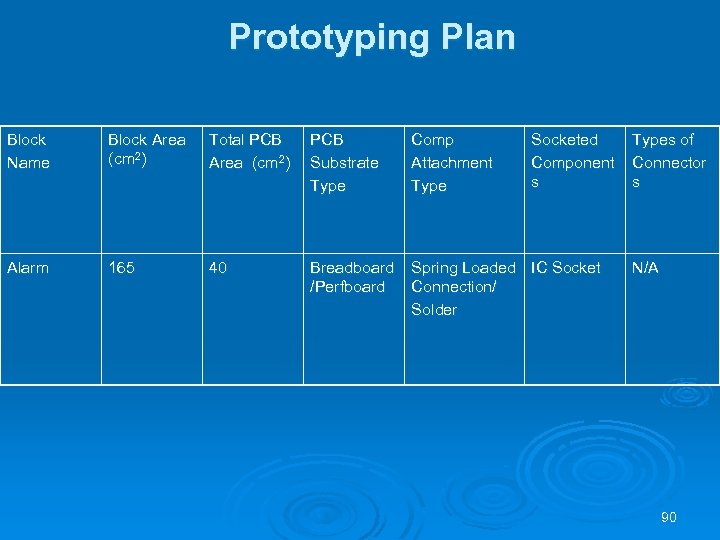

Prototyping Plan Block Name Block Area (cm 2) Total PCB Area (cm 2) PCB Substrate Type Comp Attachment Type Socketed Component s Alarm 165 40 Breadboard /Perfboard Spring Loaded IC Socket Connection/ Solder Types of Connector s N/A 90

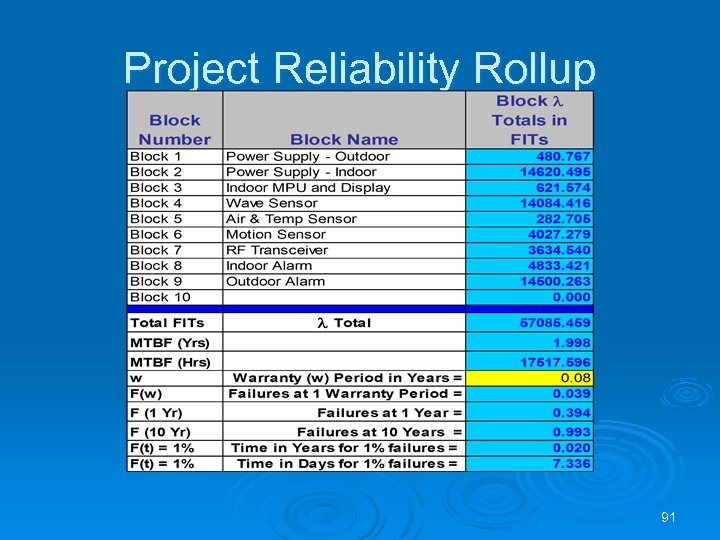

Project Reliability Rollup 91

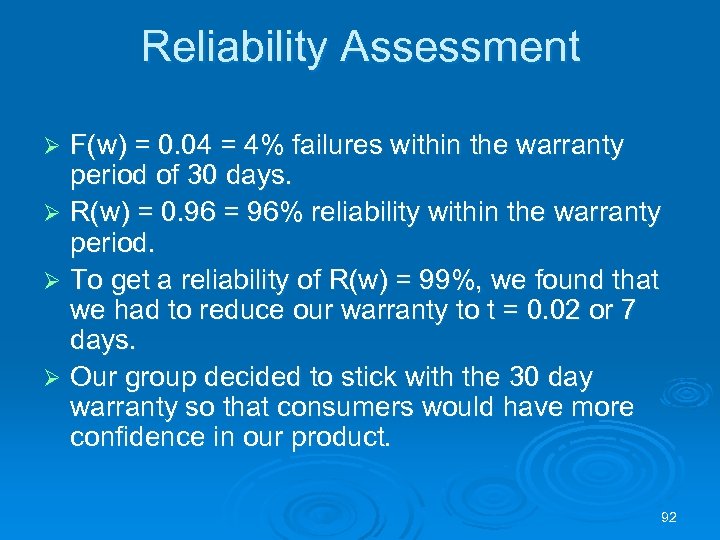

Reliability Assessment F(w) = 0. 04 = 4% failures within the warranty period of 30 days. Ø R(w) = 0. 96 = 96% reliability within the warranty period. Ø To get a reliability of R(w) = 99%, we found that we had to reduce our warranty to t = 0. 02 or 7 days. Ø Our group decided to stick with the 30 day warranty so that consumers would have more confidence in our product. Ø 92

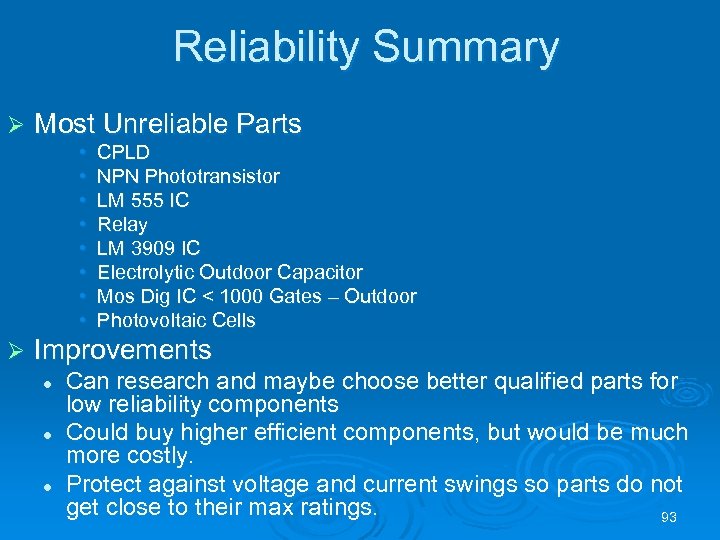

Reliability Summary Ø Most Unreliable Parts • • Ø CPLD NPN Phototransistor LM 555 IC Relay LM 3909 IC Electrolytic Outdoor Capacitor Mos Dig IC < 1000 Gates – Outdoor Photovoltaic Cells Improvements l l l Can research and maybe choose better qualified parts for low reliability components Could buy higher efficient components, but would be much more costly. Protect against voltage and current swings so parts do not get close to their max ratings. 93

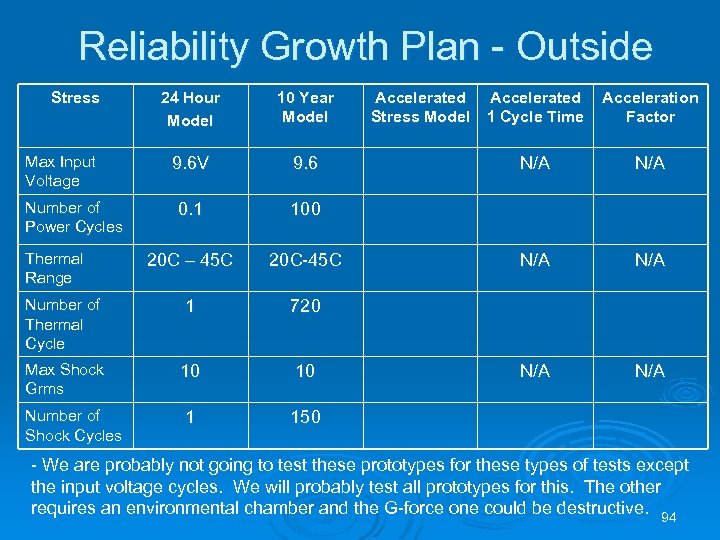

Reliability Growth Plan - Outside Stress 24 Hour Model 10 Year Model 9. 6 V 9. 6 0. 1 100 20 C – 45 C 20 C-45 C Number of Thermal Cycle 1 720 Max Shock Grms 10 10 1 150 Max Input Voltage Number of Power Cycles Thermal Range Number of Shock Cycles Accelerated Stress Model 1 Cycle Time Acceleration Factor N/A N/A N/A - We are probably not going to test these prototypes for these types of tests except the input voltage cycles. We will probably test all prototypes for this. The other requires an environmental chamber and the G-force one could be destructive. 94

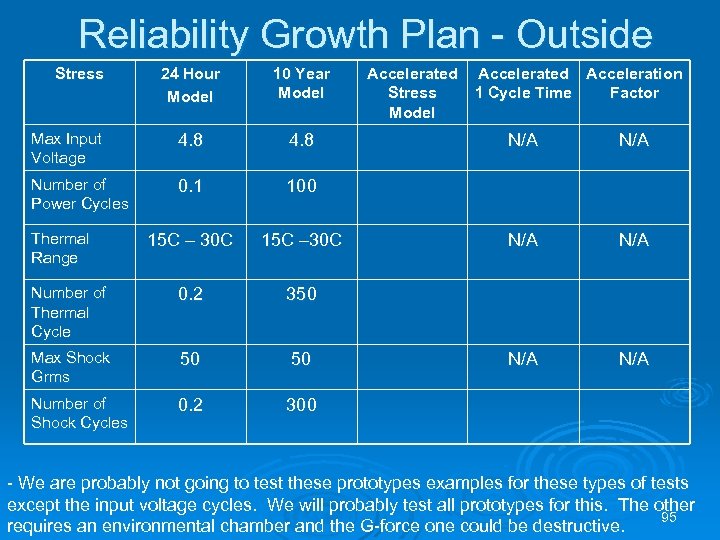

Reliability Growth Plan - Outside Stress 24 Hour Model 10 Year Model Accelerated Acceleration Stress 1 Cycle Time Factor Model Max Input Voltage 4. 8 N/A Number of Power Cycles 0. 1 100 15 C – 30 C N/A Number of Thermal Cycle 0. 2 350 Max Shock Grms 50 50 N/A Number of Shock Cycles 0. 2 300 Thermal Range - We are probably not going to test these prototypes examples for these types of tests except the input voltage cycles. We will probably test all prototypes for this. The other 95 requires an environmental chamber and the G-force one could be destructive.

4946aadbf4d801f42dadf78ef6dff4c8.ppt