d545657d36e731692368b9759a8269ab.ppt

- Количество слайдов: 50

POC Leadership Forum Update on the Regulations CLIA, CAP, JCAHO and COLA Ronald H. Laessig, Ph. D. University of Wisconsin Madison, Wisconsin www. cms. hhs. gov/clia

POC Leadership Forum Update on the Regulations CLIA, CAP, JCAHO and COLA Ronald H. Laessig, Ph. D. University of Wisconsin Madison, Wisconsin www. cms. hhs. gov/clia

Purpose of U. S. Lab Regulations … quality standards for all laboratory testing to ensure accuracy reliability timeliness of patient test results regardless of where the test is performed… www. cms. hhs. gov/clia

Purpose of U. S. Lab Regulations … quality standards for all laboratory testing to ensure accuracy reliability timeliness of patient test results regardless of where the test is performed… www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #1 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #1 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #2 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #2 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #3 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #3 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #4 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #4 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #5 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #5 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #6 www. cms. hhs. gov/clia

Series of six slides from Glamour Magazine The latest information on test quality Believe it or not #6 www. cms. hhs. gov/clia

Quality POCT: What drives the system? According to Glamour Magazine: …. (we always go right to the source) If Regulations are not followed…. . . Human error follows J. Yost, the “CLIA Lady”

Quality POCT: What drives the system? According to Glamour Magazine: …. (we always go right to the source) If Regulations are not followed…. . . Human error follows J. Yost, the “CLIA Lady”

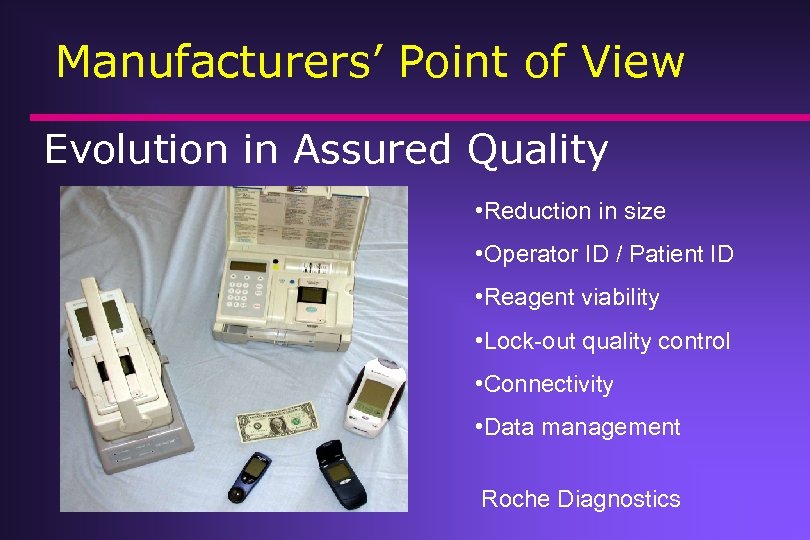

Manufacturers’ Point of View Evolution in Assured Quality • Reduction in size • Operator ID / Patient ID • Reagent viability • Lock-out quality control • Connectivity • Data management Roche Diagnostics

Manufacturers’ Point of View Evolution in Assured Quality • Reduction in size • Operator ID / Patient ID • Reagent viability • Lock-out quality control • Connectivity • Data management Roche Diagnostics

Regulator’s Point of View U. S. Regulations = CLIA C = Clinical L = Laboratory I = Improvement A = Amendments Regulates ~180, 000 U. S. test sites http: //www. cms. hhs. gov/clia/

Regulator’s Point of View U. S. Regulations = CLIA C = Clinical L = Laboratory I = Improvement A = Amendments Regulates ~180, 000 U. S. test sites http: //www. cms. hhs. gov/clia/

Regulator’s Point of View CLIA’ 88 (February 28, 1992) CLIA’ 03 (January 24, 2003)

Regulator’s Point of View CLIA’ 88 (February 28, 1992) CLIA’ 03 (January 24, 2003)

Linking Quality and Regulations CLIA’s working premise: CLIA’s mandated quality practices will improve quality of test results

Linking Quality and Regulations CLIA’s working premise: CLIA’s mandated quality practices will improve quality of test results

CLIA Regulations and the Director The laboratory director is responsible for the overall operation and administration of the laboratory … [the] testing systems … used [must] provide quality laboratory services for all aspects of test performance … including the preanalytic, and post-analytic phases of testing

CLIA Regulations and the Director The laboratory director is responsible for the overall operation and administration of the laboratory … [the] testing systems … used [must] provide quality laboratory services for all aspects of test performance … including the preanalytic, and post-analytic phases of testing

Quality POCT Challenge – March 2004 Dilemma for today: q With the manufacturer buildingin/assuring quality, Ø Where is the professional input from the laboratory director? Ø Does the director just buy the technology and use it?

Quality POCT Challenge – March 2004 Dilemma for today: q With the manufacturer buildingin/assuring quality, Ø Where is the professional input from the laboratory director? Ø Does the director just buy the technology and use it?

What do we know today about CLIA and Quality Requirements? CLIA’ 03 takes a Quality Systems approach like ISO documents q The quality requirements follow the route of the specimen q Ø Ø Ø pre-analytical post-analytical issues

What do we know today about CLIA and Quality Requirements? CLIA’ 03 takes a Quality Systems approach like ISO documents q The quality requirements follow the route of the specimen q Ø Ø Ø pre-analytical post-analytical issues

CLIA and Quality Requirements? q The old CLIA covered the analytical requirements in one section and quality assurance in another. q The new CLIA groups the quality requirements under a new term “Quality Assessment” q Quality Assessment = Quality Control + Quality Assurance q CLIA wants to consider the testing process start to finish-hence “pre, post and analytical assessment”

CLIA and Quality Requirements? q The old CLIA covered the analytical requirements in one section and quality assurance in another. q The new CLIA groups the quality requirements under a new term “Quality Assessment” q Quality Assessment = Quality Control + Quality Assurance q CLIA wants to consider the testing process start to finish-hence “pre, post and analytical assessment”

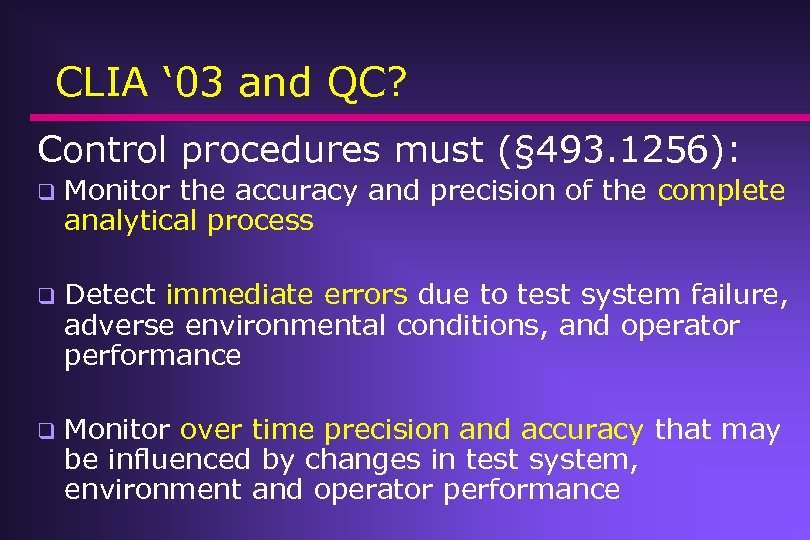

CLIA ‘ 03 and QC? Control procedures must (§ 493. 1256): q Monitor the accuracy and precision of the complete analytical process q Detect immediate errors due to test system failure, adverse environmental conditions, and operator performance q Monitor over time precision and accuracy that may be influenced by changes in test system, environment and operator performance

CLIA ‘ 03 and QC? Control procedures must (§ 493. 1256): q Monitor the accuracy and precision of the complete analytical process q Detect immediate errors due to test system failure, adverse environmental conditions, and operator performance q Monitor over time precision and accuracy that may be influenced by changes in test system, environment and operator performance

CLIA’ 03 and QC? Control procedures must (§ 493. 1256): Monitor complete analytical process q Detect immediate errors q Monitor over time precision and accuracy q Conceptually, meeting the requirements sounds easy, But ---

CLIA’ 03 and QC? Control procedures must (§ 493. 1256): Monitor complete analytical process q Detect immediate errors q Monitor over time precision and accuracy q Conceptually, meeting the requirements sounds easy, But ---

CLIA’ 03 and QC? Control procedures must (§ 493. 1256): Monitor complete analytical process q Detect immediate errors q Monitor over time precision and accuracy q Conceptually, meeting the requirements sounds easy, But ---

CLIA’ 03 and QC? Control procedures must (§ 493. 1256): Monitor complete analytical process q Detect immediate errors q Monitor over time precision and accuracy q Conceptually, meeting the requirements sounds easy, But ---

CLIA ’ 03 and Q C The Devil is in the Details

CLIA ’ 03 and Q C The Devil is in the Details

CLIA’ 03 – The details! q What about Ø Ø Ø q Electronic QC? Process controls? Internal controls? Do these a) b) c) d) evaluate complete analytical process detect immediate errors monitor accuracy and precision over time none of the above

CLIA’ 03 – The details! q What about Ø Ø Ø q Electronic QC? Process controls? Internal controls? Do these a) b) c) d) evaluate complete analytical process detect immediate errors monitor accuracy and precision over time none of the above

Details - 12 January 2004 Interpretive Guidelines for CLIA – 300+ pages NEW and More http: //www. cms. hhs. gov/clia/appendc. asp

Details - 12 January 2004 Interpretive Guidelines for CLIA – 300+ pages NEW and More http: //www. cms. hhs. gov/clia/appendc. asp

New Concept for QC? EQC Equivalent Quality Control

New Concept for QC? EQC Equivalent Quality Control

New Concept for QC? EQC = Electronic Quality Control

New Concept for QC? EQC = Electronic Quality Control

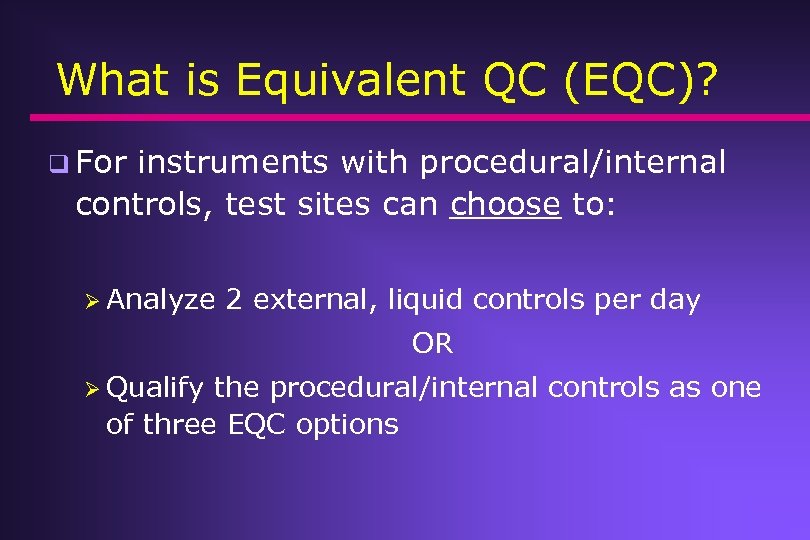

What is Equivalent QC (EQC)? q For instruments with procedural/internal controls, test sites can choose to: Ø Analyze 2 external, liquid controls per day OR Ø Qualify the procedural/internal controls as one of three EQC options

What is Equivalent QC (EQC)? q For instruments with procedural/internal controls, test sites can choose to: Ø Analyze 2 external, liquid controls per day OR Ø Qualify the procedural/internal controls as one of three EQC options

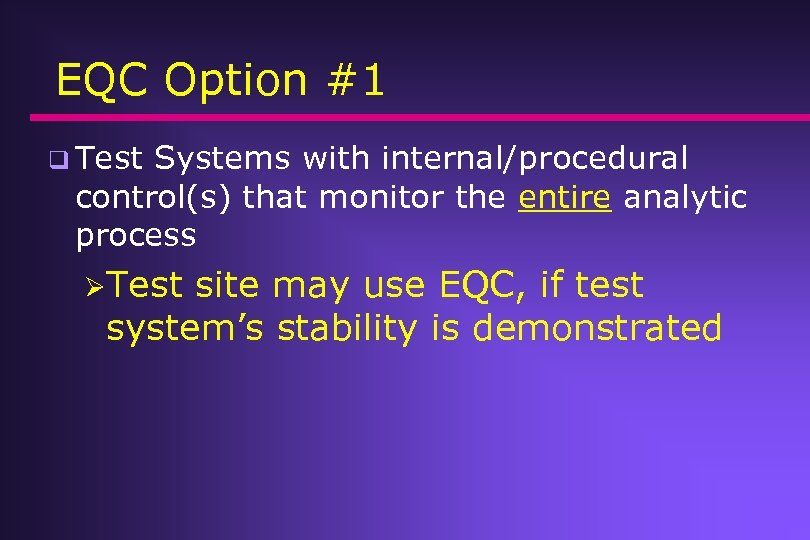

EQC Option #1 q Test Systems with internal/procedural control(s) that monitor the entire analytic process ØTest site may use EQC, if test system’s stability is demonstrated

EQC Option #1 q Test Systems with internal/procedural control(s) that monitor the entire analytic process ØTest site may use EQC, if test system’s stability is demonstrated

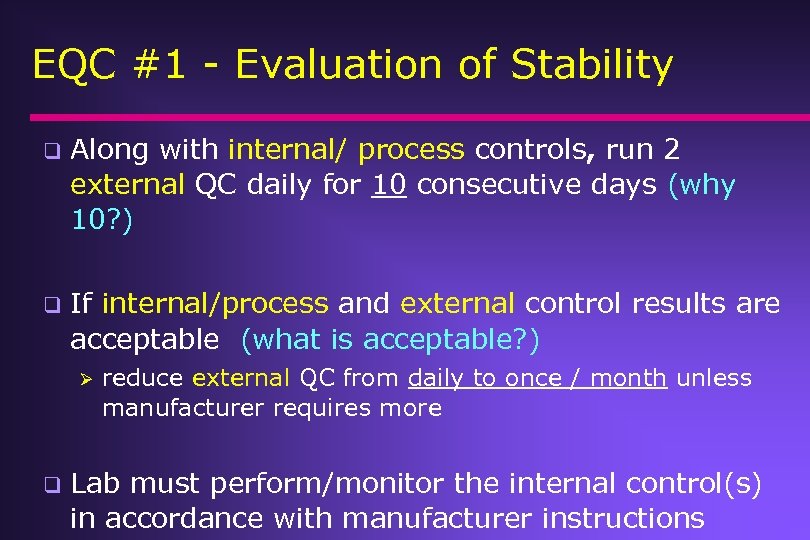

EQC #1 - Evaluation of Stability q Along with internal/ process controls, run 2 external QC daily for 10 consecutive days (why 10? ) q If internal/process and external control results are acceptable (what is acceptable? ) Ø q reduce external QC from daily to once / month unless manufacturer requires more Lab must perform/monitor the internal control(s) in accordance with manufacturer instructions

EQC #1 - Evaluation of Stability q Along with internal/ process controls, run 2 external QC daily for 10 consecutive days (why 10? ) q If internal/process and external control results are acceptable (what is acceptable? ) Ø q reduce external QC from daily to once / month unless manufacturer requires more Lab must perform/monitor the internal control(s) in accordance with manufacturer instructions

Option #1 Instrument with manufacturer supplied on board controls, run automatically.

Option #1 Instrument with manufacturer supplied on board controls, run automatically.

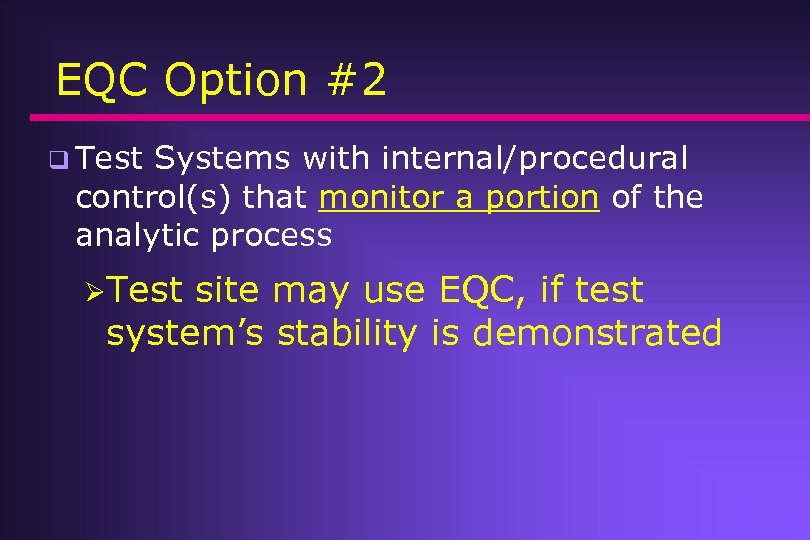

EQC Option #2 q Test Systems with internal/procedural control(s) that monitor a portion of the analytic process ØTest site may use EQC, if test system’s stability is demonstrated

EQC Option #2 q Test Systems with internal/procedural control(s) that monitor a portion of the analytic process ØTest site may use EQC, if test system’s stability is demonstrated

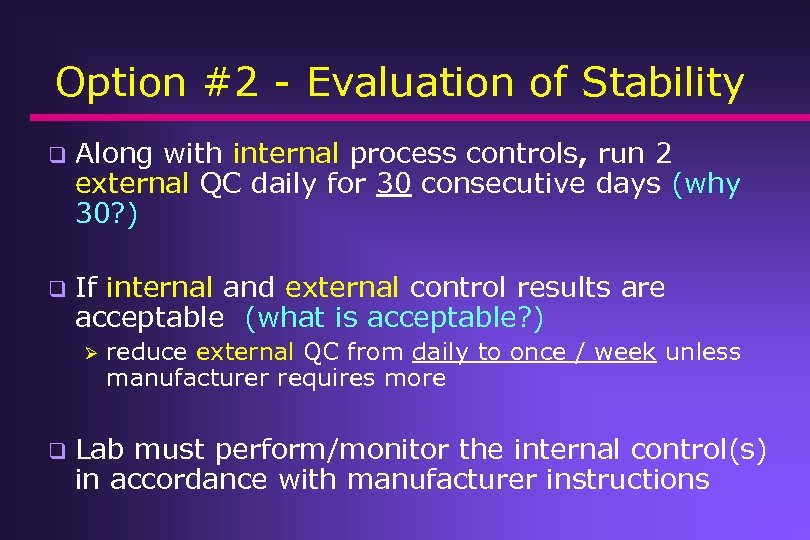

Option #2 - Evaluation of Stability q Along with internal process controls, run 2 external QC daily for 30 consecutive days (why 30? ) q If internal and external control results are acceptable (what is acceptable? ) Ø q reduce external QC from daily to once / week unless manufacturer requires more Lab must perform/monitor the internal control(s) in accordance with manufacturer instructions

Option #2 - Evaluation of Stability q Along with internal process controls, run 2 external QC daily for 30 consecutive days (why 30? ) q If internal and external control results are acceptable (what is acceptable? ) Ø q reduce external QC from daily to once / week unless manufacturer requires more Lab must perform/monitor the internal control(s) in accordance with manufacturer instructions

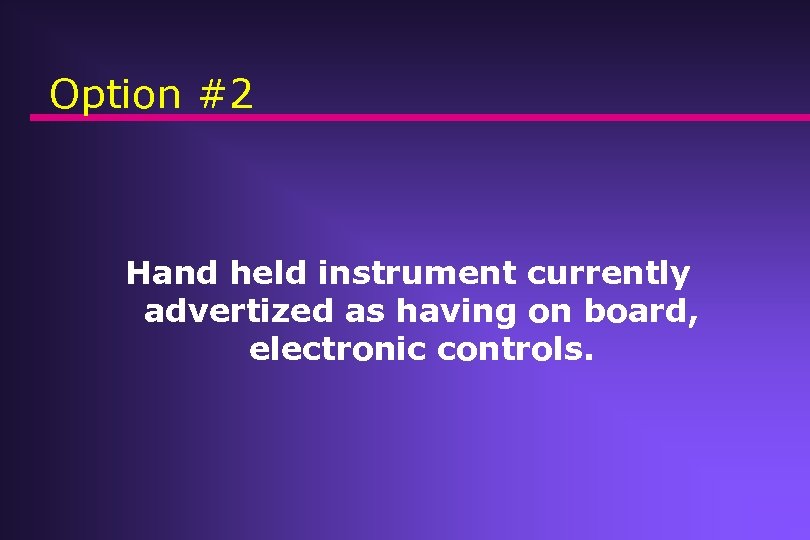

Option #2 Hand held instrument currently advertized as having on board, electronic controls.

Option #2 Hand held instrument currently advertized as having on board, electronic controls.

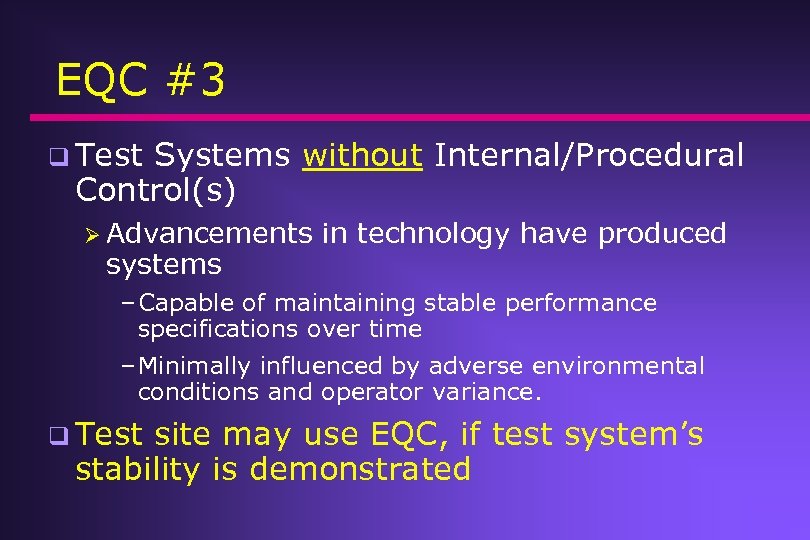

EQC #3 q Test Systems without Internal/Procedural Control(s) Ø Advancements systems in technology have produced – Capable of maintaining stable performance specifications over time – Minimally influenced by adverse environmental conditions and operator variance. q Test site may use EQC, if test system’s stability is demonstrated

EQC #3 q Test Systems without Internal/Procedural Control(s) Ø Advancements systems in technology have produced – Capable of maintaining stable performance specifications over time – Minimally influenced by adverse environmental conditions and operator variance. q Test site may use EQC, if test system’s stability is demonstrated

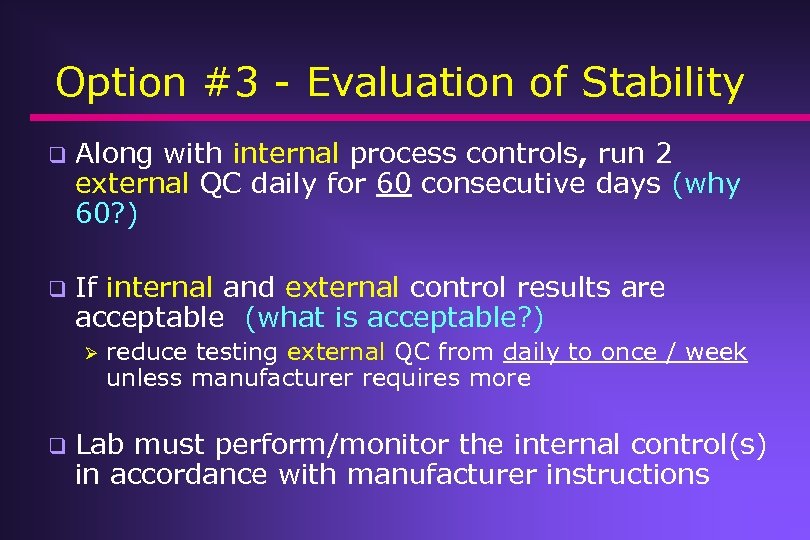

Option #3 - Evaluation of Stability q Along with internal process controls, run 2 external QC daily for 60 consecutive days (why 60? ) q If internal and external control results are acceptable (what is acceptable? ) Ø q reduce testing external QC from daily to once / week unless manufacturer requires more Lab must perform/monitor the internal control(s) in accordance with manufacturer instructions

Option #3 - Evaluation of Stability q Along with internal process controls, run 2 external QC daily for 60 consecutive days (why 60? ) q If internal and external control results are acceptable (what is acceptable? ) Ø q reduce testing external QC from daily to once / week unless manufacturer requires more Lab must perform/monitor the internal control(s) in accordance with manufacturer instructions

Option #3? What belongs in this picture?

Option #3? What belongs in this picture?

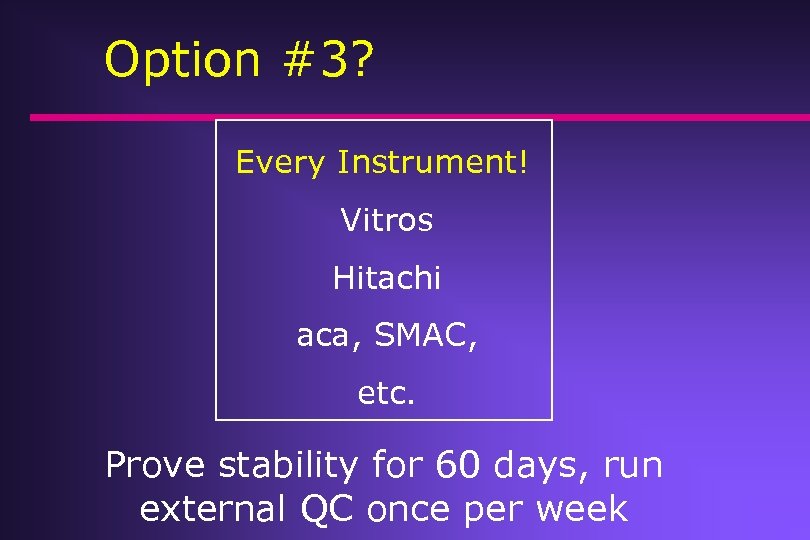

Option #3? Every Instrument! Vitros Hitachi aca, SMAC, etc. Prove stability for 60 days, run external QC once per week

Option #3? Every Instrument! Vitros Hitachi aca, SMAC, etc. Prove stability for 60 days, run external QC once per week

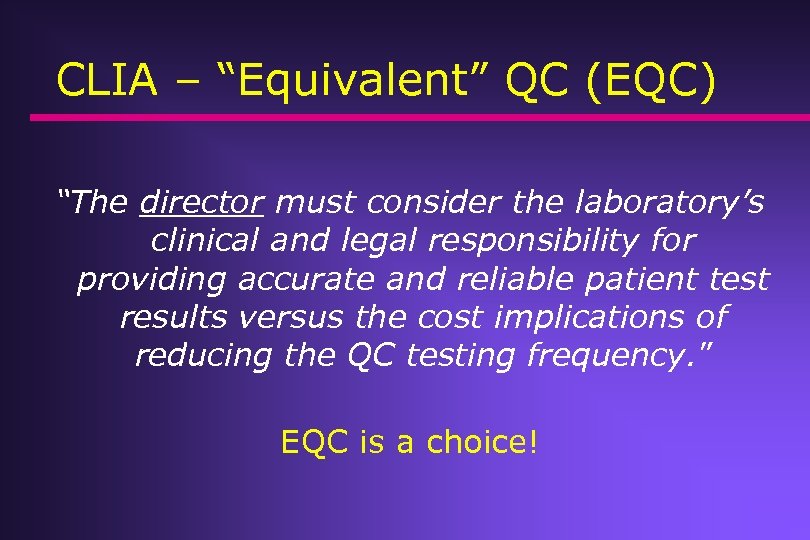

CLIA – “Equivalent” QC (EQC) “The director must consider the laboratory’s clinical and legal responsibility for providing accurate and reliable patient test results versus the cost implications of reducing the QC testing frequency. ” EQC is a choice!

CLIA – “Equivalent” QC (EQC) “The director must consider the laboratory’s clinical and legal responsibility for providing accurate and reliable patient test results versus the cost implications of reducing the QC testing frequency. ” EQC is a choice!

Uncle Sam Has Uncle Sam gone Crazy?

Uncle Sam Has Uncle Sam gone Crazy?

Uncle Sam Has Uncle Sam gone Crazy? q Maybe or Maybe Not!

Uncle Sam Has Uncle Sam gone Crazy? q Maybe or Maybe Not!

March 2004 Does EQC and the U. S. regulations open a new era for new technologies or does EQC just cause confusion?

March 2004 Does EQC and the U. S. regulations open a new era for new technologies or does EQC just cause confusion?

Quality POCT: What Drives the System? q To me, CLIA QC regulations say – Ø Continue the “old” way – 2 external QC/day Ø Qualify the test system under EQC options and reduce frequency of external QC

Quality POCT: What Drives the System? q To me, CLIA QC regulations say – Ø Continue the “old” way – 2 external QC/day Ø Qualify the test system under EQC options and reduce frequency of external QC

Quality POCT: What Drives the System? q To me, CLIA QC regulations say – Ø Continue the “old” way – 2 external QC/day Ø Qualify the test system under EQC options and reduce frequency of external QC q EQC Option #3 ( for a test system with no internal/process controls) Ø Do you want your testing done on a system that qualifies under this option?

Quality POCT: What Drives the System? q To me, CLIA QC regulations say – Ø Continue the “old” way – 2 external QC/day Ø Qualify the test system under EQC options and reduce frequency of external QC q EQC Option #3 ( for a test system with no internal/process controls) Ø Do you want your testing done on a system that qualifies under this option?

The Devil is in the details q EQC Qualified System – External QC analyzed once per month or once per week. q EQC-1 EQC-2&3

The Devil is in the details q EQC Qualified System – External QC analyzed once per month or once per week. q EQC-1 EQC-2&3

![“The Devil is in the Details” § 493. 1282 Standard: Corrective actions …[if] external “The Devil is in the Details” § 493. 1282 Standard: Corrective actions …[if] external](https://present5.com/presentation/d545657d36e731692368b9759a8269ab/image-44.jpg) “The Devil is in the Details” § 493. 1282 Standard: Corrective actions …[if] external QC [results]…fail to meet the laboratory's established criteria for acceptability, all patient test results obtained…since the last acceptable test run must be evaluated to determine if patient test results have been adversely affected…

“The Devil is in the Details” § 493. 1282 Standard: Corrective actions …[if] external QC [results]…fail to meet the laboratory's established criteria for acceptability, all patient test results obtained…since the last acceptable test run must be evaluated to determine if patient test results have been adversely affected…

Quality POCT: Drivers? q Manufacturers – Building the perfect instrument to meet the needs of the testing environment

Quality POCT: Drivers? q Manufacturers – Building the perfect instrument to meet the needs of the testing environment

CLIA’s new QC/EQC Requirements q Have a two-year phase in Ø Inspection Ø Citations Ø NO punitive activities

CLIA’s new QC/EQC Requirements q Have a two-year phase in Ø Inspection Ø Citations Ø NO punitive activities

Manufacturers have “EQ” Options #1, 2, & 3 To be competitive in the marketplace, options #2 and #3 DON’T count

Manufacturers have “EQ” Options #1, 2, & 3 To be competitive in the marketplace, options #2 and #3 DON’T count

The bottom line…. . the “Regs” q We are in a two year phase in q We are all trying to figure out what they mean q At the end of the day, the laboratory director must make the call -- QC or EQC (1, 2, or 3) q We are after all in the patient care business q Legally, Morally, ethically, technically, the patients (must) always come first.

The bottom line…. . the “Regs” q We are in a two year phase in q We are all trying to figure out what they mean q At the end of the day, the laboratory director must make the call -- QC or EQC (1, 2, or 3) q We are after all in the patient care business q Legally, Morally, ethically, technically, the patients (must) always come first.

CLIA Regulations and the Director The laboratory director is responsible for the overall operation and administration of the laboratory … [the] testing systems … used [must] provide quality laboratory services for all aspects of test performance … including the preanalytic, and post-analytic phases of testing

CLIA Regulations and the Director The laboratory director is responsible for the overall operation and administration of the laboratory … [the] testing systems … used [must] provide quality laboratory services for all aspects of test performance … including the preanalytic, and post-analytic phases of testing

…. . and q. Speaking of Lab Directors, q. Heerrrrrs Fritz !!!!!

…. . and q. Speaking of Lab Directors, q. Heerrrrrs Fritz !!!!!