640ad20ed0c41388b2ad52a4644e376c.ppt

- Количество слайдов: 38

Plasma Product Line 1

Plasma Product Line 1

Plasma Spray Systems 3710 Conventional Plasma Equipment: Ø Low end manual Model 3710 Controller with SG-100 Ø Semi-automatic Model 3620 Controller with SG-100 3620 2

Plasma Spray Systems 3710 Conventional Plasma Equipment: Ø Low end manual Model 3710 Controller with SG-100 Ø Semi-automatic Model 3620 Controller with SG-100 3620 2

Plasma Spray Systems New & Unique Technology: Ø Model 7700 Universal Plasma Closed loop - Net Energy Controlled plasma spray system Ø Global Tasking System (GTS) Universal thermal spray controller Ø Plaz. Jet high energy plasma Unique technology for rapid production of high density coatings Plaz. Jet 3

Plasma Spray Systems New & Unique Technology: Ø Model 7700 Universal Plasma Closed loop - Net Energy Controlled plasma spray system Ø Global Tasking System (GTS) Universal thermal spray controller Ø Plaz. Jet high energy plasma Unique technology for rapid production of high density coatings Plaz. Jet 3

Plasma Spray Systems Model 3710 Plasma Control Console: Ø Most economically priced l Ø Outstanding value ‘Jewel’ critical orifice gas flow control l l Highly accurate and repeatable gas flow control = consistency No need for routine calibration 4

Plasma Spray Systems Model 3710 Plasma Control Console: Ø Most economically priced l Ø Outstanding value ‘Jewel’ critical orifice gas flow control l l Highly accurate and repeatable gas flow control = consistency No need for routine calibration 4

Plasma Spray Systems Model 3710 Plasma Control Console: Ø Built-in PC-100 power supply controller with digital displays l Ø Easy to set and operate Two powder feeder control (either / or) l l Bond coat -- top coat changeover made easy Time consuming feeder cleanouts can be eliminated 5

Plasma Spray Systems Model 3710 Plasma Control Console: Ø Built-in PC-100 power supply controller with digital displays l Ø Easy to set and operate Two powder feeder control (either / or) l l Bond coat -- top coat changeover made easy Time consuming feeder cleanouts can be eliminated 5

Plasma Spray Systems Model 3620 Plasma Control Console: Ø Built-in PC-100 power supply controller with digital displays l Ø Easy to set and manipulate Two powder feeder control (either / or / both at the same time) l l Bond coat -- top coat application Graded coating application 6

Plasma Spray Systems Model 3620 Plasma Control Console: Ø Built-in PC-100 power supply controller with digital displays l Ø Easy to set and manipulate Two powder feeder control (either / or / both at the same time) l l Bond coat -- top coat application Graded coating application 6

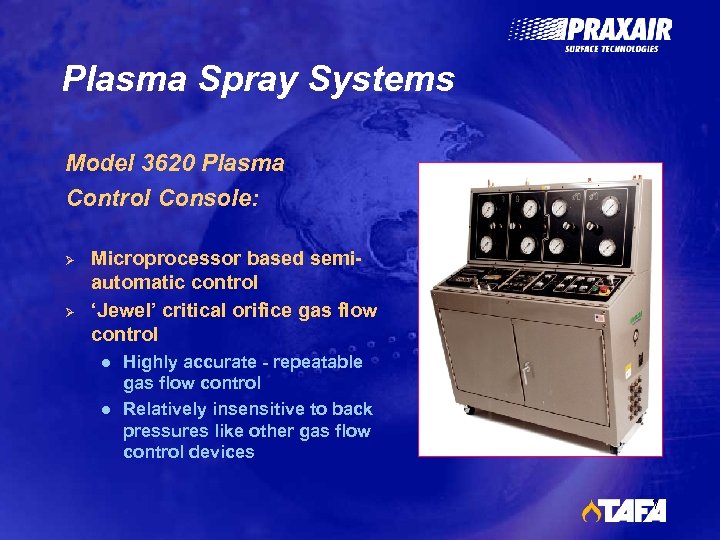

Plasma Spray Systems Model 3620 Plasma Control Console: Ø Ø Microprocessor based semiautomatic control ‘Jewel’ critical orifice gas flow control l l Highly accurate - repeatable gas flow control Relatively insensitive to back pressures like other gas flow control devices 7

Plasma Spray Systems Model 3620 Plasma Control Console: Ø Ø Microprocessor based semiautomatic control ‘Jewel’ critical orifice gas flow control l l Highly accurate - repeatable gas flow control Relatively insensitive to back pressures like other gas flow control devices 7

Plasma Spray Systems Model 3710 and 3620 Plasma Control Consoles: Ø Safety interlocks l Ø NFPA type “Z” purging with alarm in case of failure l Ø Ø Ø Prevent gun operation in case of other equipment failure Safe design 24 VDC purge circuit Remote E-stop box Stainless steel plumbing for flammable gas 8

Plasma Spray Systems Model 3710 and 3620 Plasma Control Consoles: Ø Safety interlocks l Ø NFPA type “Z” purging with alarm in case of failure l Ø Ø Ø Prevent gun operation in case of other equipment failure Safe design 24 VDC purge circuit Remote E-stop box Stainless steel plumbing for flammable gas 8

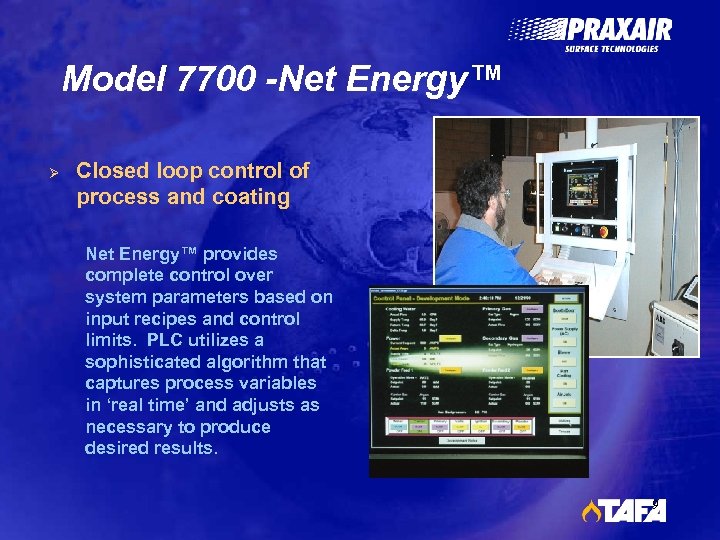

Model 7700 -Net Energy™ Ø Closed loop control of process and coating Net Energy™ provides complete control over system parameters based on input recipes and control limits. PLC utilizes a sophisticated algorithm that captures process variables in ‘real time’ and adjusts as necessary to produce desired results. 9

Model 7700 -Net Energy™ Ø Closed loop control of process and coating Net Energy™ provides complete control over system parameters based on input recipes and control limits. PLC utilizes a sophisticated algorithm that captures process variables in ‘real time’ and adjusts as necessary to produce desired results. 9

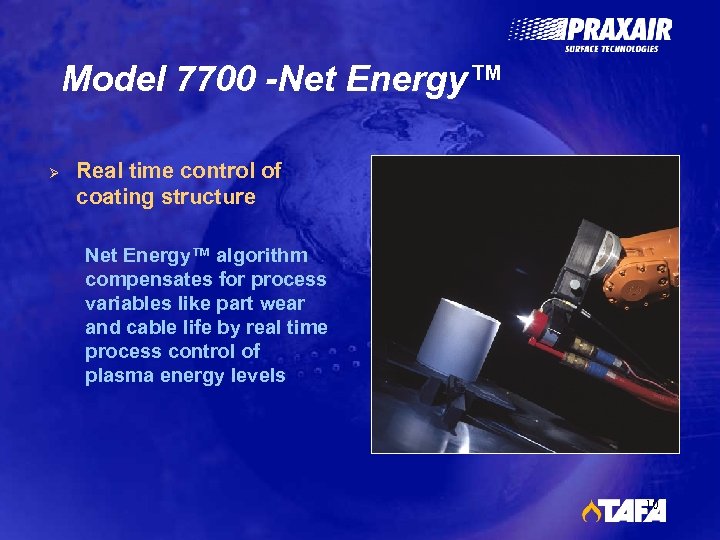

Model 7700 -Net Energy™ Ø Real time control of coating structure Net Energy™ algorithm compensates for process variables like part wear and cable life by real time process control of plasma energy levels 10

Model 7700 -Net Energy™ Ø Real time control of coating structure Net Energy™ algorithm compensates for process variables like part wear and cable life by real time process control of plasma energy levels 10

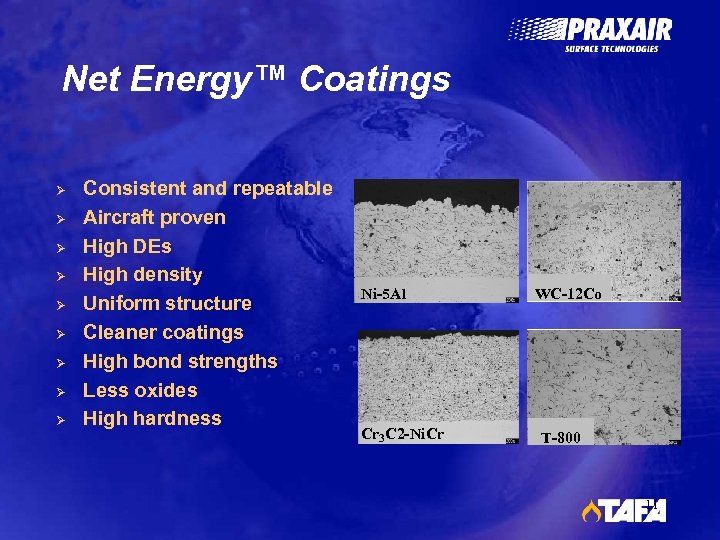

Net Energy™ Coatings Ø Ø Ø Ø Ø Consistent and repeatable Aircraft proven High DEs High density Uniform structure Cleaner coatings High bond strengths Less oxides High hardness Ni-5 Al Cr 3 C 2 -Ni. Cr WC-12 Co T-800 11

Net Energy™ Coatings Ø Ø Ø Ø Ø Consistent and repeatable Aircraft proven High DEs High density Uniform structure Cleaner coatings High bond strengths Less oxides High hardness Ni-5 Al Cr 3 C 2 -Ni. Cr WC-12 Co T-800 11

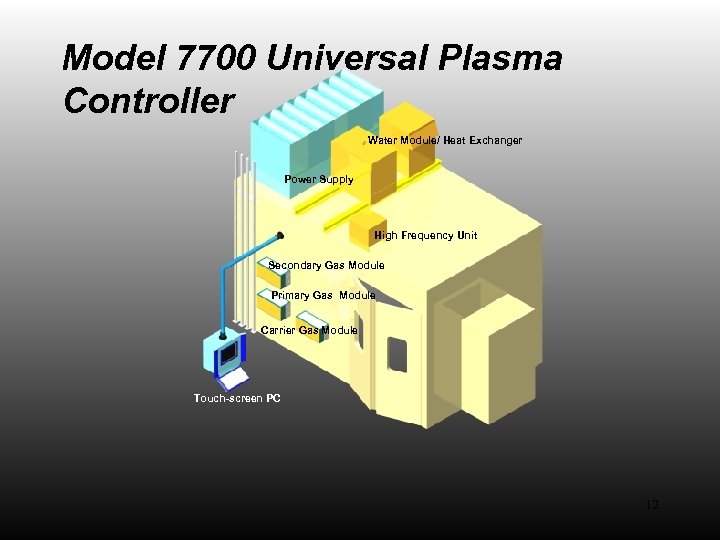

Model 7700 Universal Plasma Controller Water Module/ Heat Exchanger Power Supply High Frequency Unit Secondary Gas Module Primary Gas Module Carrier Gas Module Touch-screen PC 12

Model 7700 Universal Plasma Controller Water Module/ Heat Exchanger Power Supply High Frequency Unit Secondary Gas Module Primary Gas Module Carrier Gas Module Touch-screen PC 12

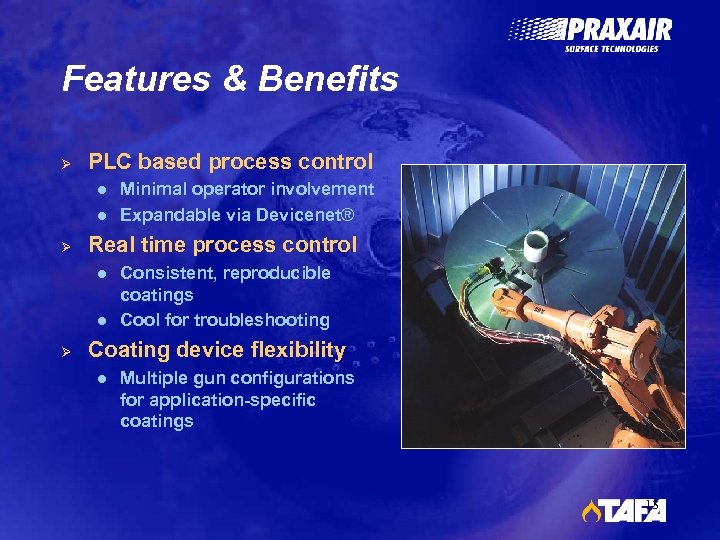

Features & Benefits Ø PLC based process control l l Ø Real time process control l l Ø Minimal operator involvement Expandable via Devicenet® Consistent, reproducible coatings Cool for troubleshooting Coating device flexibility l Multiple gun configurations for application-specific coatings 13

Features & Benefits Ø PLC based process control l l Ø Real time process control l l Ø Minimal operator involvement Expandable via Devicenet® Consistent, reproducible coatings Cool for troubleshooting Coating device flexibility l Multiple gun configurations for application-specific coatings 13

Features & Benefits Ø Ergonomic design l l Ø Safe design l Ø Minimum floor space required Module placement flexibility Minimizing process hazards Data acquisition l l l Records storage Process monitoring Quality control 14

Features & Benefits Ø Ergonomic design l l Ø Safe design l Ø Minimum floor space required Module placement flexibility Minimizing process hazards Data acquisition l l l Records storage Process monitoring Quality control 14

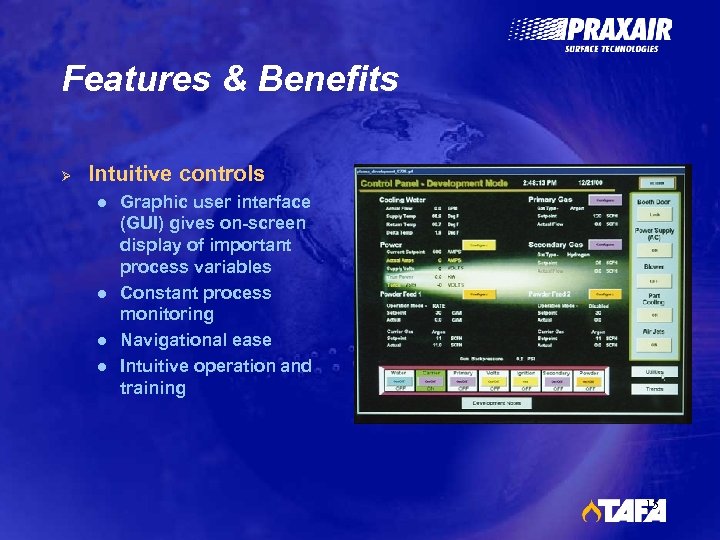

Features & Benefits Ø Intuitive controls l l Graphic user interface (GUI) gives on-screen display of important process variables Constant process monitoring Navigational ease Intuitive operation and training 15

Features & Benefits Ø Intuitive controls l l Graphic user interface (GUI) gives on-screen display of important process variables Constant process monitoring Navigational ease Intuitive operation and training 15

Net Energy™ Performance Ø Less downtime l l Ø Completely automated Recipe storage Real time monitoring helps schedule maintenance Multiple powder feeding options Longer production runs l l Longer hardware life Multiple feeding options w l Quick changeovers Multiple coating sequences w Preheat, bond coat, top coat, graded coatings 16

Net Energy™ Performance Ø Less downtime l l Ø Completely automated Recipe storage Real time monitoring helps schedule maintenance Multiple powder feeding options Longer production runs l l Longer hardware life Multiple feeding options w l Quick changeovers Multiple coating sequences w Preheat, bond coat, top coat, graded coatings 16

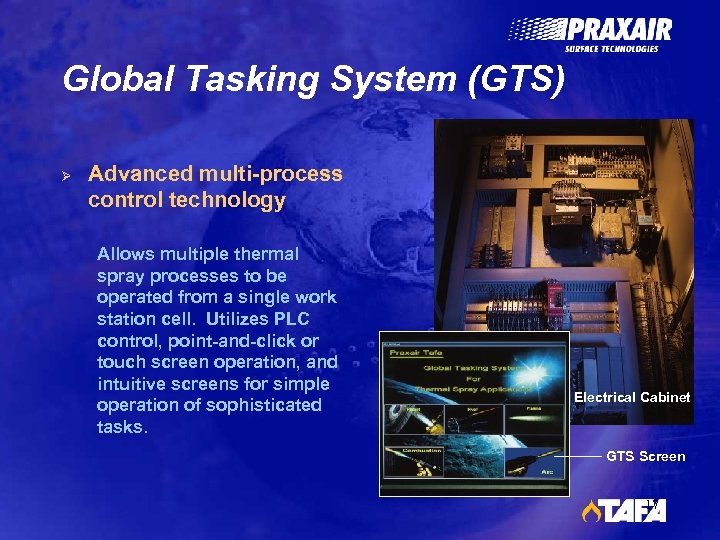

Global Tasking System (GTS) Ø Advanced multi-process control technology Allows multiple thermal spray processes to be operated from a single work station cell. Utilizes PLC control, point-and-click or touch screen operation, and intuitive screens for simple operation of sophisticated tasks. Electrical Cabinet GTS Screen 17

Global Tasking System (GTS) Ø Advanced multi-process control technology Allows multiple thermal spray processes to be operated from a single work station cell. Utilizes PLC control, point-and-click or touch screen operation, and intuitive screens for simple operation of sophisticated tasks. Electrical Cabinet GTS Screen 17

GTS Capabilities Ø One system runs: l l l GTS with JP-5000, 2700 I. D. gun and 9000 Plaz. Jet Net Energy 5500 -2000 JP-8000 HVOF 9000 Arc Spray Combustion Spray guns Automation And any othermal spray process you need or want 18

GTS Capabilities Ø One system runs: l l l GTS with JP-5000, 2700 I. D. gun and 9000 Plaz. Jet Net Energy 5500 -2000 JP-8000 HVOF 9000 Arc Spray Combustion Spray guns Automation And any othermal spray process you need or want 18

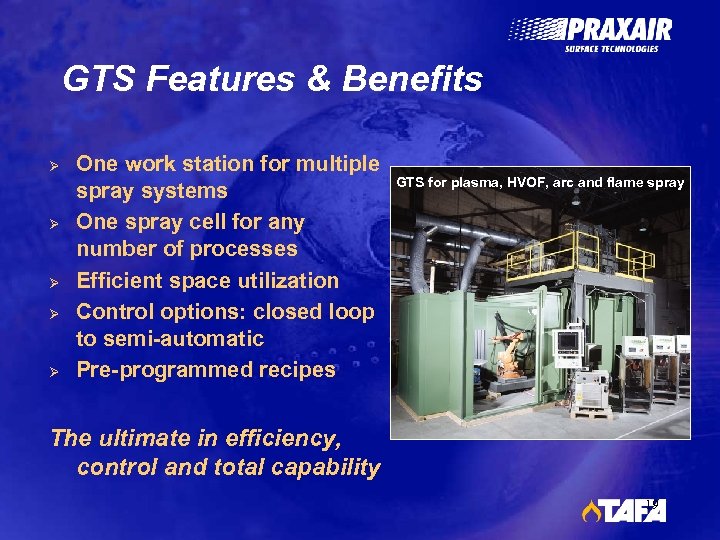

GTS Features & Benefits Ø Ø Ø One work station for multiple spray systems One spray cell for any number of processes Efficient space utilization Control options: closed loop to semi-automatic Pre-programmed recipes GTS for plasma, HVOF, arc and flame spray The ultimate in efficiency, control and total capability 19

GTS Features & Benefits Ø Ø Ø One work station for multiple spray systems One spray cell for any number of processes Efficient space utilization Control options: closed loop to semi-automatic Pre-programmed recipes GTS for plasma, HVOF, arc and flame spray The ultimate in efficiency, control and total capability 19

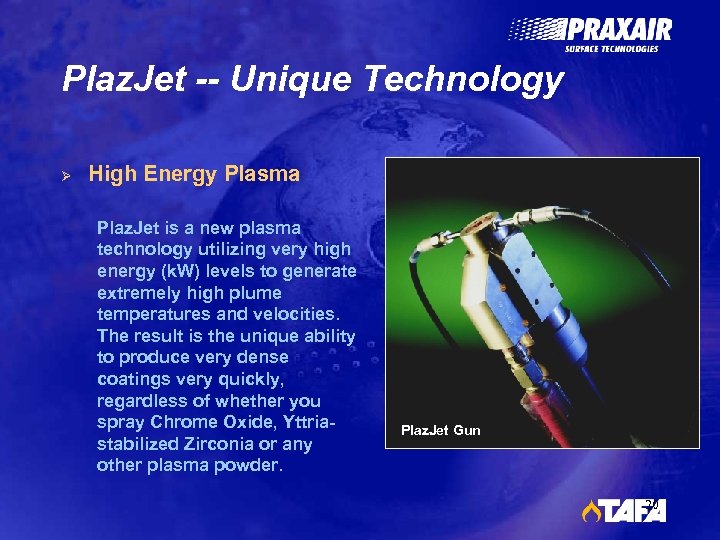

Plaz. Jet -- Unique Technology Ø High Energy Plasma Plaz. Jet is a new plasma technology utilizing very high energy (k. W) levels to generate extremely high plume temperatures and velocities. The result is the unique ability to produce very dense coatings very quickly, regardless of whether you spray Chrome Oxide, Yttriastabilized Zirconia or any other plasma powder. Plaz. Jet Gun 20

Plaz. Jet -- Unique Technology Ø High Energy Plasma Plaz. Jet is a new plasma technology utilizing very high energy (k. W) levels to generate extremely high plume temperatures and velocities. The result is the unique ability to produce very dense coatings very quickly, regardless of whether you spray Chrome Oxide, Yttriastabilized Zirconia or any other plasma powder. Plaz. Jet Gun 20

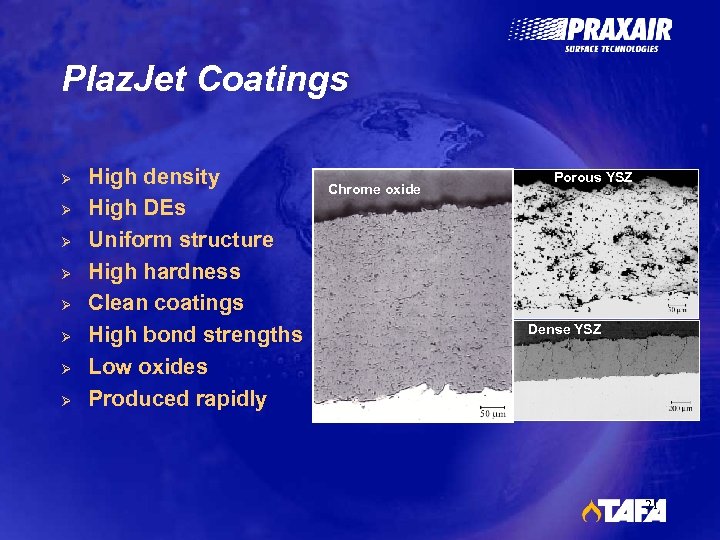

Plaz. Jet Coatings Ø Ø Ø Ø High density High DEs Uniform structure High hardness Clean coatings High bond strengths Low oxides Produced rapidly Chrome oxide Porous YSZ Dense YSZ 21

Plaz. Jet Coatings Ø Ø Ø Ø High density High DEs Uniform structure High hardness Clean coatings High bond strengths Low oxides Produced rapidly Chrome oxide Porous YSZ Dense YSZ 21

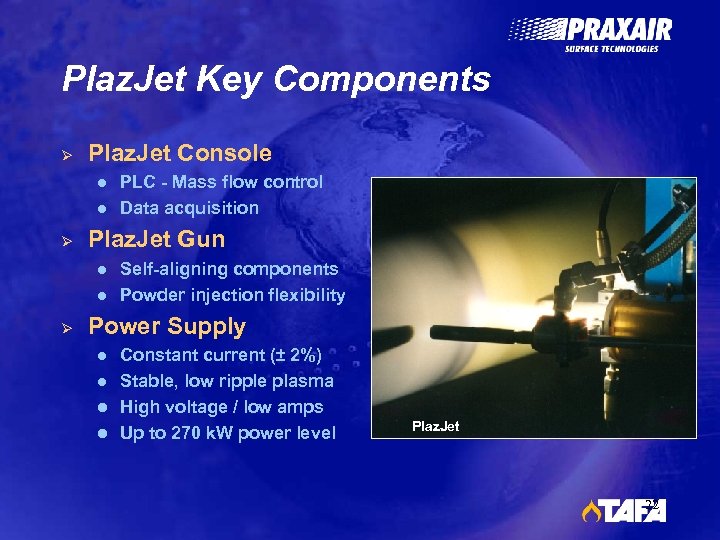

Plaz. Jet Key Components Ø Plaz. Jet Console l l Ø Plaz. Jet Gun l l Ø PLC - Mass flow control Data acquisition Self-aligning components Powder injection flexibility Power Supply Constant current (± 2%) l Stable, low ripple plasma l High voltage / low amps l Up to 270 k. W power level l Plaz. Jet 22

Plaz. Jet Key Components Ø Plaz. Jet Console l l Ø Plaz. Jet Gun l l Ø PLC - Mass flow control Data acquisition Self-aligning components Powder injection flexibility Power Supply Constant current (± 2%) l Stable, low ripple plasma l High voltage / low amps l Up to 270 k. W power level l Plaz. Jet 22

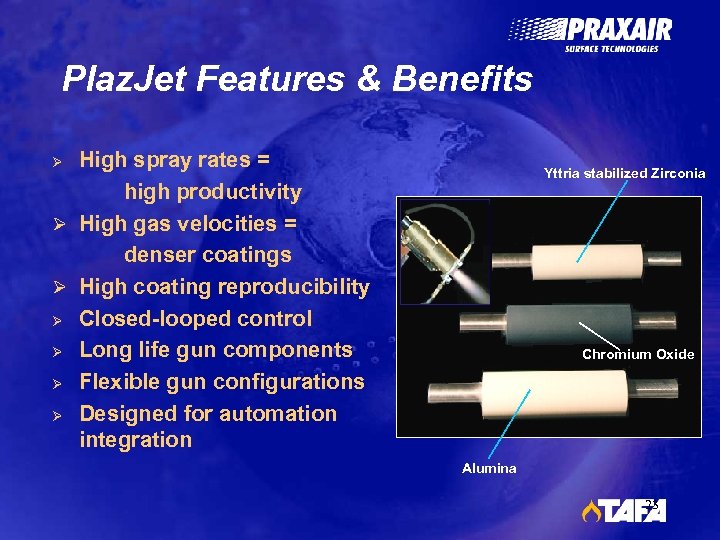

Plaz. Jet Features & Benefits High spray rates = high productivity Ø High gas velocities = denser coatings Ø High coating reproducibility Ø Closed-looped control Ø Long life gun components Ø Flexible gun configurations Ø Designed for automation integration Ø Yttria stabilized Zirconia Chromium Oxide Alumina 23

Plaz. Jet Features & Benefits High spray rates = high productivity Ø High gas velocities = denser coatings Ø High coating reproducibility Ø Closed-looped control Ø Long life gun components Ø Flexible gun configurations Ø Designed for automation integration Ø Yttria stabilized Zirconia Chromium Oxide Alumina 23

Plasma Spray Guns SG-100 Power: 80 k. W SG-200 Power: 40 k. W Plaz. Jet Power: 270 k. W 24

Plasma Spray Guns SG-100 Power: 80 k. W SG-200 Power: 40 k. W Plaz. Jet Power: 270 k. W 24

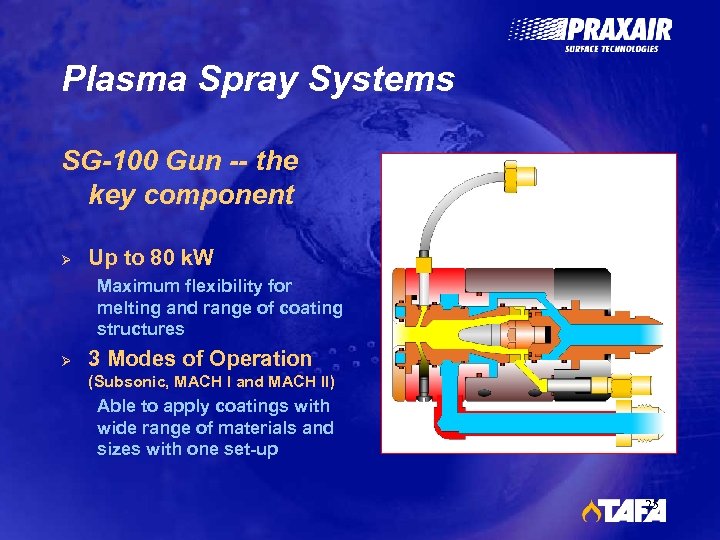

Plasma Spray Systems SG-100 Gun -- the key component Ø Up to 80 k. W Maximum flexibility for melting and range of coating structures Ø 3 Modes of Operation (Subsonic, MACH I and MACH II) Able to apply coatings with wide range of materials and sizes with one set-up 25

Plasma Spray Systems SG-100 Gun -- the key component Ø Up to 80 k. W Maximum flexibility for melting and range of coating structures Ø 3 Modes of Operation (Subsonic, MACH I and MACH II) Able to apply coatings with wide range of materials and sizes with one set-up 25

Plasma Equipment Ø Thermal source Plasma arc Ø Key elements Anode, cathode, gas injector D. C. rectifiers, water cooling, gas supply, material feed, Ø Material delivery powder feeder, carrier gas Ø Controls net energy, DC current, water cooling, arc gas flows, powder feed rate, manipulation 26

Plasma Equipment Ø Thermal source Plasma arc Ø Key elements Anode, cathode, gas injector D. C. rectifiers, water cooling, gas supply, material feed, Ø Material delivery powder feeder, carrier gas Ø Controls net energy, DC current, water cooling, arc gas flows, powder feed rate, manipulation 26

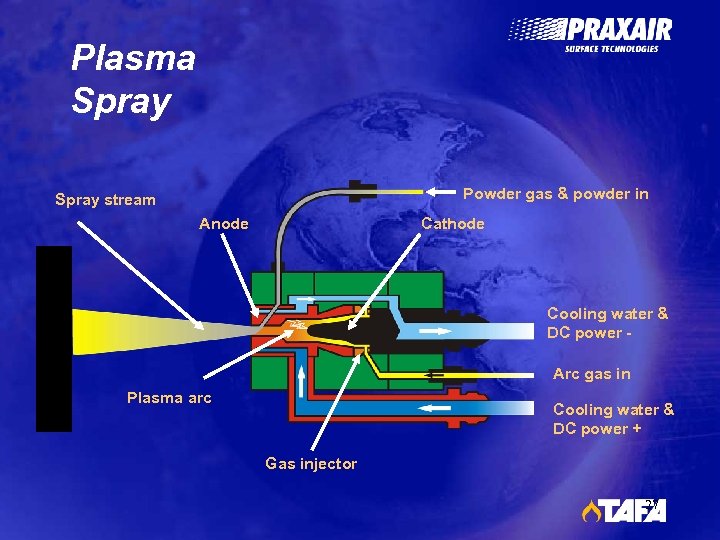

Plasma Spray Powder gas & powder in Spray stream Anode Cathode Cooling water & DC power Arc gas in Plasma arc Cooling water & DC power + Gas injector 27

Plasma Spray Powder gas & powder in Spray stream Anode Cathode Cooling water & DC power Arc gas in Plasma arc Cooling water & DC power + Gas injector 27

SG-100 -- the key component Features and benefits Ø Powder injection flexibility l l Ø Air jet assembly l Ø Internal and/or external -- flexibility for optimized coating structure Forward, 90º, backward -- flexibility for optimized coating structure No coating contamination from over spray Self-aligning components l l Easy and quick hardware changes Proper geometric spacing for assured gun performance 28

SG-100 -- the key component Features and benefits Ø Powder injection flexibility l l Ø Air jet assembly l Ø Internal and/or external -- flexibility for optimized coating structure Forward, 90º, backward -- flexibility for optimized coating structure No coating contamination from over spray Self-aligning components l l Easy and quick hardware changes Proper geometric spacing for assured gun performance 28

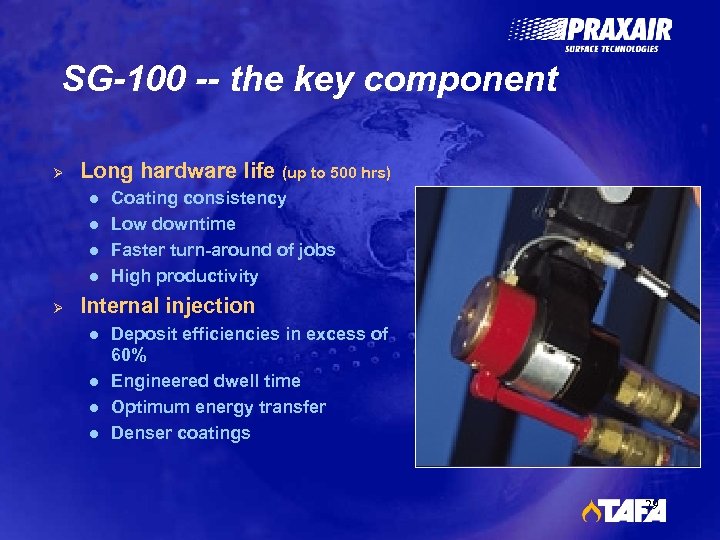

SG-100 -- the key component Ø Long hardware life (up to 500 hrs) l l Ø Coating consistency Low downtime Faster turn-around of jobs High productivity Internal injection l l Deposit efficiencies in excess of 60% Engineered dwell time Optimum energy transfer Denser coatings 29

SG-100 -- the key component Ø Long hardware life (up to 500 hrs) l l Ø Coating consistency Low downtime Faster turn-around of jobs High productivity Internal injection l l Deposit efficiencies in excess of 60% Engineered dwell time Optimum energy transfer Denser coatings 29

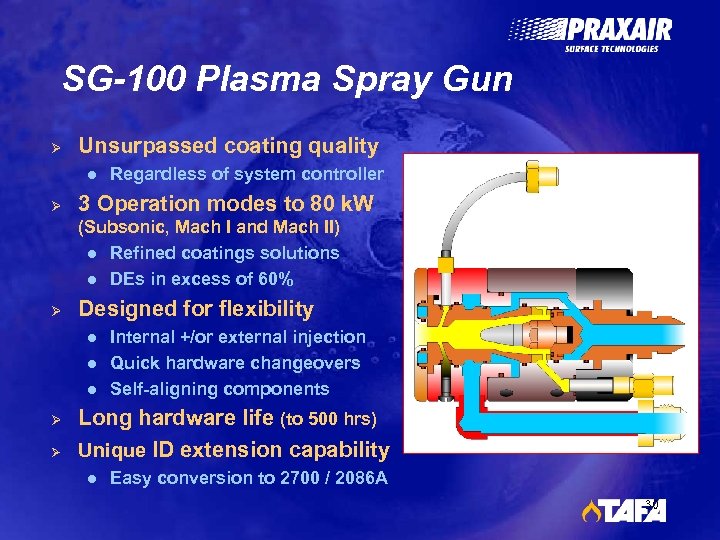

SG-100 Plasma Spray Gun Ø Unsurpassed coating quality l Ø Regardless of system controller 3 Operation modes to 80 k. W (Subsonic, Mach I and Mach II) l Refined coatings solutions l DEs in excess of 60% Ø Designed for flexibility l l l Ø Ø Internal +/or external injection Quick hardware changeovers Self-aligning components Long hardware life (to 500 hrs) Unique ID extension capability l Easy conversion to 2700 / 2086 A 30

SG-100 Plasma Spray Gun Ø Unsurpassed coating quality l Ø Regardless of system controller 3 Operation modes to 80 k. W (Subsonic, Mach I and Mach II) l Refined coatings solutions l DEs in excess of 60% Ø Designed for flexibility l l l Ø Ø Internal +/or external injection Quick hardware changeovers Self-aligning components Long hardware life (to 500 hrs) Unique ID extension capability l Easy conversion to 2700 / 2086 A 30

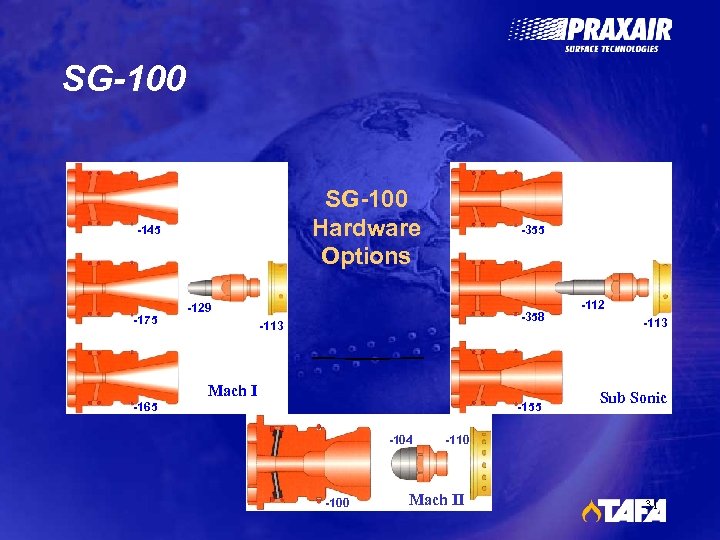

SG-100 Hardware Options -145 -175 -355 -129 -358 -113 Mach I -165 -155 -104 -100 -112 -113 Sub Sonic -110 Mach II 31

SG-100 Hardware Options -145 -175 -355 -129 -358 -113 Mach I -165 -155 -104 -100 -112 -113 Sub Sonic -110 Mach II 31

SG-100 -- a versatile tool SG-100 Accessories ID Extensions Model 2086 -A External Feed Plate ID size > 2. 5” (62. 5 mm) Model 2700 Air-Jet Assembly ID size > 1. 5” (37. 5 mm) 32

SG-100 -- a versatile tool SG-100 Accessories ID Extensions Model 2086 -A External Feed Plate ID size > 2. 5” (62. 5 mm) Model 2700 Air-Jet Assembly ID size > 1. 5” (37. 5 mm) 32

ID Extension Guns Ø l l ID Extensions Easy adaptability with the SG-100 Gun Robust designs Self-aligning components 45º, 60º, Straight-ahead spraying Model 2086 -A ID size > 3” (75 mm) Model 2700 ID size > 1. 5” (37. 5 mm) 33

ID Extension Guns Ø l l ID Extensions Easy adaptability with the SG-100 Gun Robust designs Self-aligning components 45º, 60º, Straight-ahead spraying Model 2086 -A ID size > 3” (75 mm) Model 2700 ID size > 1. 5” (37. 5 mm) 33

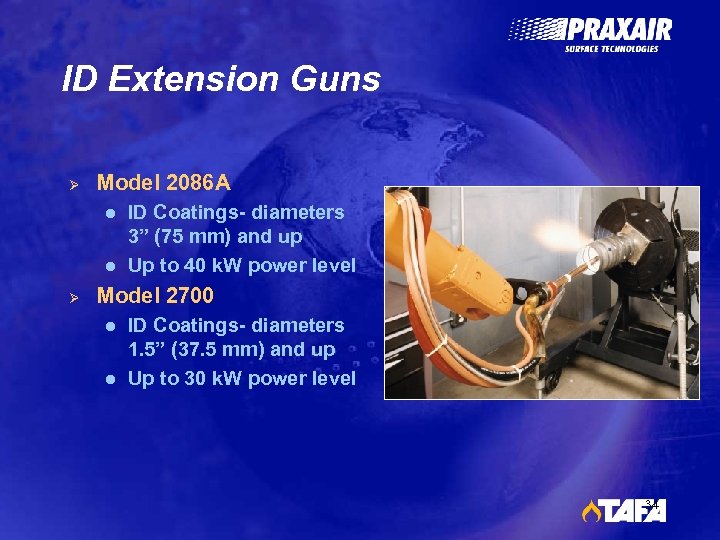

ID Extension Guns Ø Model 2086 A l l Ø ID Coatings- diameters 3” (75 mm) and up Up to 40 k. W power level Model 2700 l l ID Coatings- diameters 1. 5” (37. 5 mm) and up Up to 30 k. W power level 34

ID Extension Guns Ø Model 2086 A l l Ø ID Coatings- diameters 3” (75 mm) and up Up to 40 k. W power level Model 2700 l l ID Coatings- diameters 1. 5” (37. 5 mm) and up Up to 30 k. W power level 34

SG-200 Ø SG-200 l l l 40 k. W Machine mount applications True 90 degree ID coatings 35

SG-200 Ø SG-200 l l l 40 k. W Machine mount applications True 90 degree ID coatings 35

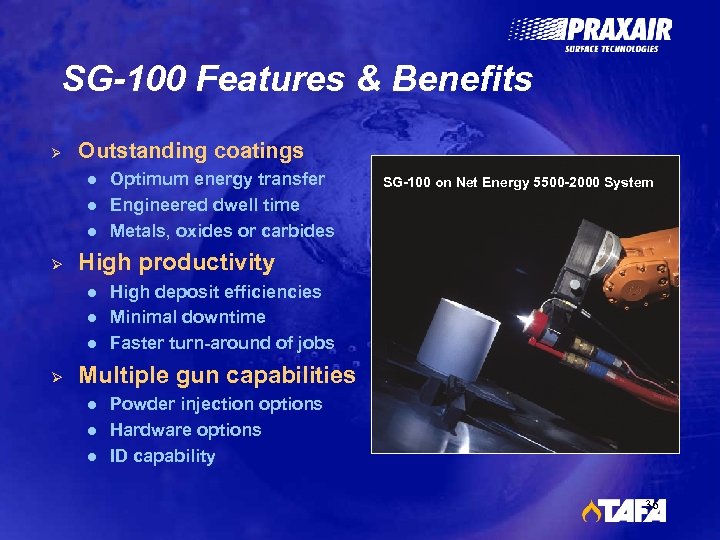

SG-100 Features & Benefits Ø Outstanding coatings l l l Ø SG-100 on Net Energy 5500 -2000 System High productivity l l l Ø Optimum energy transfer Engineered dwell time Metals, oxides or carbides High deposit efficiencies Minimal downtime Faster turn-around of jobs Multiple gun capabilities l l l Powder injection options Hardware options ID capability 36

SG-100 Features & Benefits Ø Outstanding coatings l l l Ø SG-100 on Net Energy 5500 -2000 System High productivity l l l Ø Optimum energy transfer Engineered dwell time Metals, oxides or carbides High deposit efficiencies Minimal downtime Faster turn-around of jobs Multiple gun capabilities l l l Powder injection options Hardware options ID capability 36

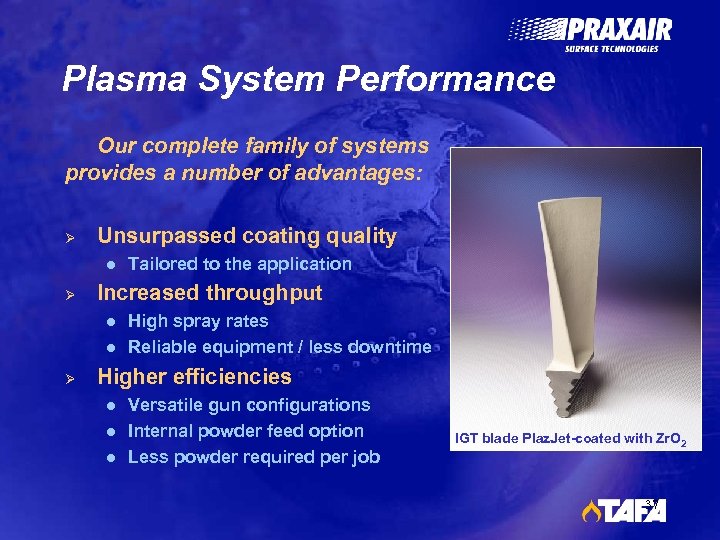

Plasma System Performance Our complete family of systems provides a number of advantages: Ø Unsurpassed coating quality l Ø Increased throughput l l Ø Tailored to the application High spray rates Reliable equipment / less downtime Higher efficiencies l l l Versatile gun configurations Internal powder feed option Less powder required per job IGT blade Plaz. Jet-coated with Zr. O 2 37

Plasma System Performance Our complete family of systems provides a number of advantages: Ø Unsurpassed coating quality l Ø Increased throughput l l Ø Tailored to the application High spray rates Reliable equipment / less downtime Higher efficiencies l l l Versatile gun configurations Internal powder feed option Less powder required per job IGT blade Plaz. Jet-coated with Zr. O 2 37

Plasma System Performance Ø Advanced system controls l l l Ø 2086 A I. D. gun spraying liner Engineered for consistency l l Ø Mass flow gas controls Closed loop feedback control Net Energy™ Critical orifice options Automation compatibility Recipe storage Real time monitoring Diagnostic capabilities Longer production runs l l Longer hardware life Multiple feeding options 38

Plasma System Performance Ø Advanced system controls l l l Ø 2086 A I. D. gun spraying liner Engineered for consistency l l Ø Mass flow gas controls Closed loop feedback control Net Energy™ Critical orifice options Automation compatibility Recipe storage Real time monitoring Diagnostic capabilities Longer production runs l l Longer hardware life Multiple feeding options 38