b9af4775d784b4abb018ec08af9a03da.ppt

- Количество слайдов: 27

Plant Wide Controller (PWC) Overview Preferred Instruments a division of Preferred Utilities Mfg. Corp. PWC

Plant Wide Controller (PWC) Overview Preferred Instruments a division of Preferred Utilities Mfg. Corp. PWC

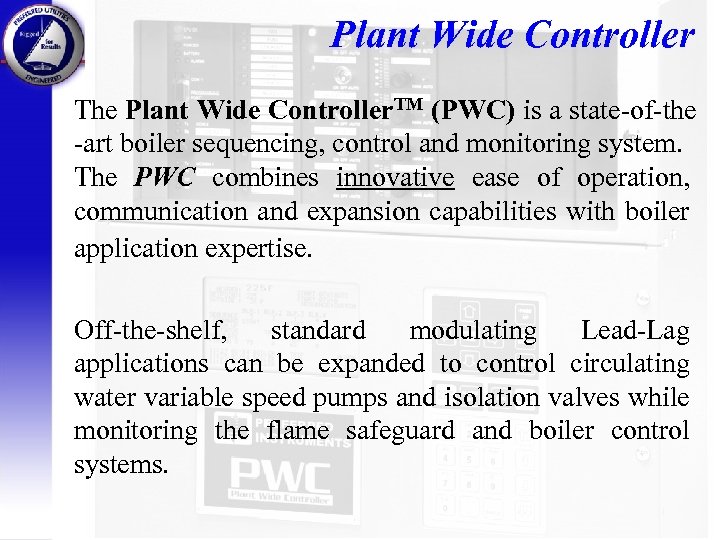

Plant Wide Controller The Plant Wide Controller. TM (PWC) is a state-of-the -art boiler sequencing, control and monitoring system. The PWC combines innovative ease of operation, communication and expansion capabilities with boiler application expertise. Off-the-shelf, standard modulating Lead-Lag applications can be expanded to control circulating water variable speed pumps and isolation valves while monitoring the flame safeguard and boiler control systems. PWC

Plant Wide Controller The Plant Wide Controller. TM (PWC) is a state-of-the -art boiler sequencing, control and monitoring system. The PWC combines innovative ease of operation, communication and expansion capabilities with boiler application expertise. Off-the-shelf, standard modulating Lead-Lag applications can be expanded to control circulating water variable speed pumps and isolation valves while monitoring the flame safeguard and boiler control systems. PWC

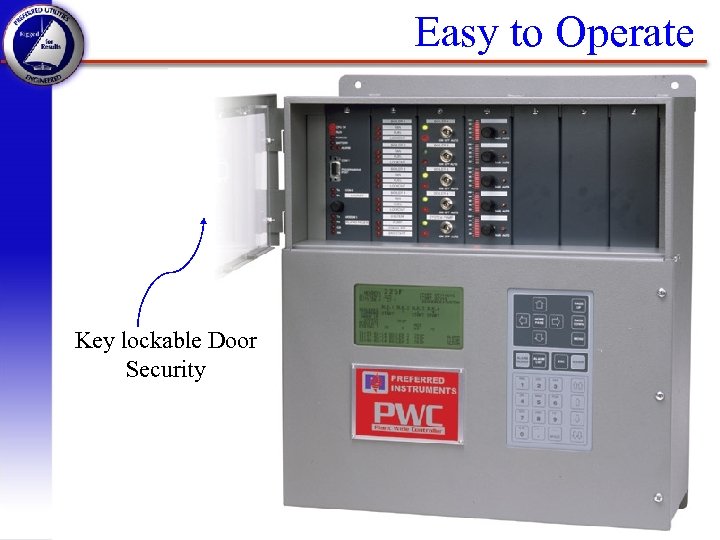

Easy to Operate Key lockable Door Security PWC

Easy to Operate Key lockable Door Security PWC

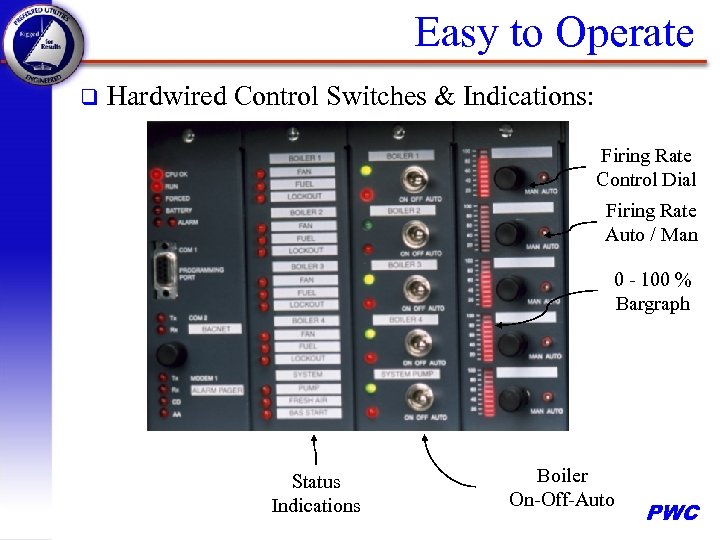

Easy to Operate q Hardwired Control Switches & Indications: Firing Rate Control Dial Firing Rate Auto / Man 0 - 100 % Bargraph Status Indications Boiler On-Off-Auto PWC

Easy to Operate q Hardwired Control Switches & Indications: Firing Rate Control Dial Firing Rate Auto / Man 0 - 100 % Bargraph Status Indications Boiler On-Off-Auto PWC

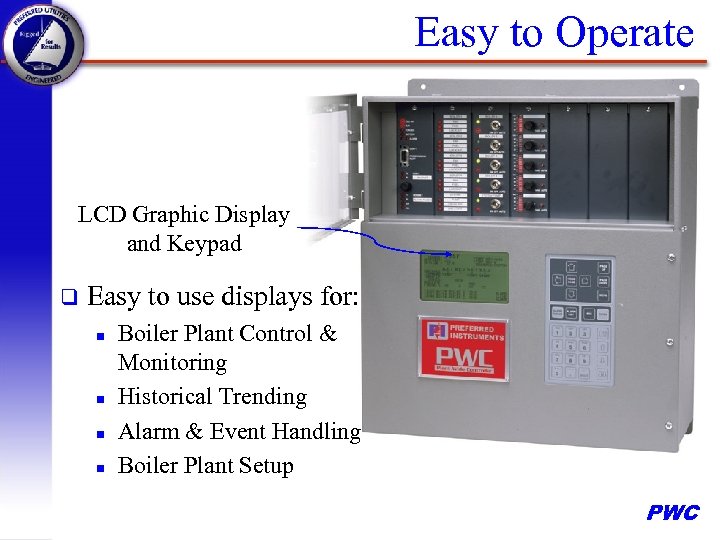

Easy to Operate LCD Graphic Display and Keypad q Easy to use displays for: n n Boiler Plant Control & Monitoring Historical Trending Alarm & Event Handling Boiler Plant Setup PWC

Easy to Operate LCD Graphic Display and Keypad q Easy to use displays for: n n Boiler Plant Control & Monitoring Historical Trending Alarm & Event Handling Boiler Plant Setup PWC

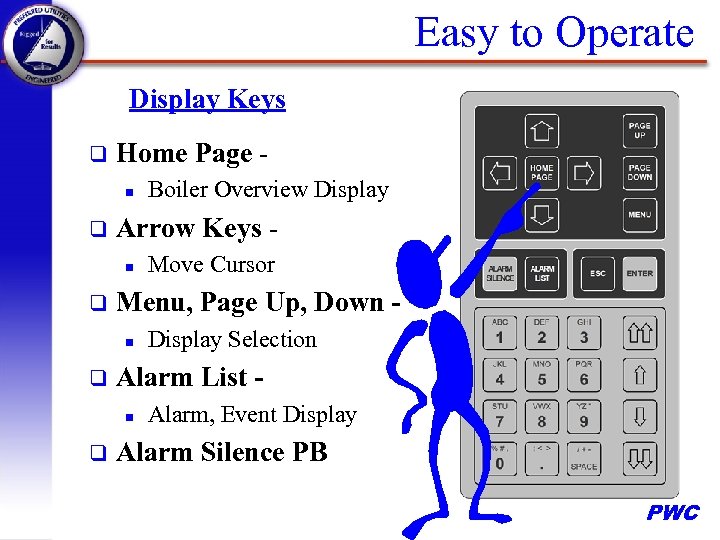

Easy to Operate Display Keys q Home Page n q Arrow Keys n q Display Selection Alarm List n q Move Cursor Menu, Page Up, Down n q Boiler Overview Display Alarm, Event Display Alarm Silence PB PWC

Easy to Operate Display Keys q Home Page n q Arrow Keys n q Display Selection Alarm List n q Move Cursor Menu, Page Up, Down n q Boiler Overview Display Alarm, Event Display Alarm Silence PB PWC

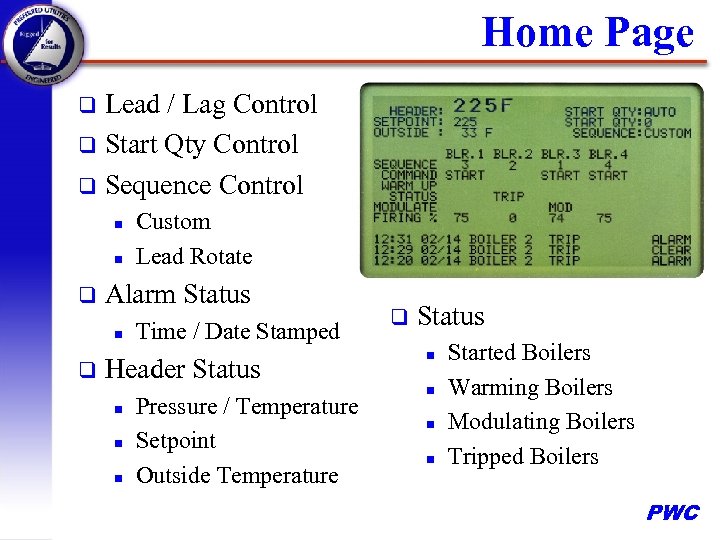

Home Page Lead / Lag Control q Start Qty Control q Sequence Control q n n q Alarm Status n q Custom Lead Rotate Time / Date Stamped Header Status n n n Pressure / Temperature Setpoint Outside Temperature q Status n n Started Boilers Warming Boilers Modulating Boilers Tripped Boilers PWC

Home Page Lead / Lag Control q Start Qty Control q Sequence Control q n n q Alarm Status n q Custom Lead Rotate Time / Date Stamped Header Status n n n Pressure / Temperature Setpoint Outside Temperature q Status n n Started Boilers Warming Boilers Modulating Boilers Tripped Boilers PWC

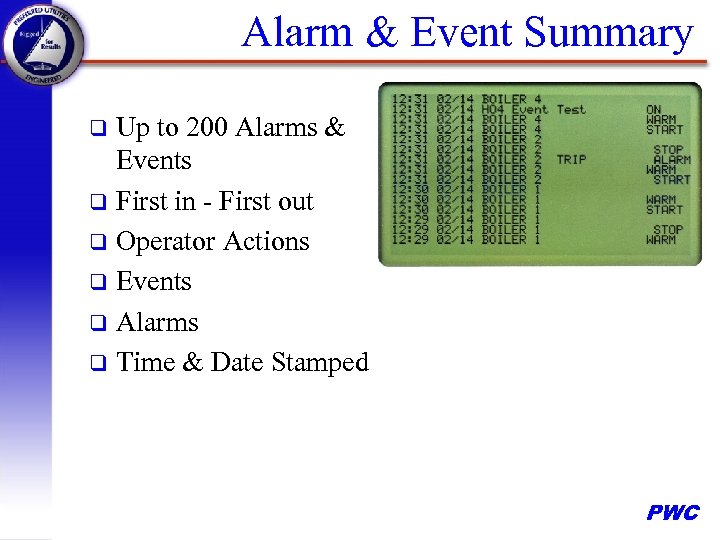

Alarm & Event Summary Up to 200 Alarms & Events q First in - First out q Operator Actions q Events q Alarms q Time & Date Stamped q PWC

Alarm & Event Summary Up to 200 Alarms & Events q First in - First out q Operator Actions q Events q Alarms q Time & Date Stamped q PWC

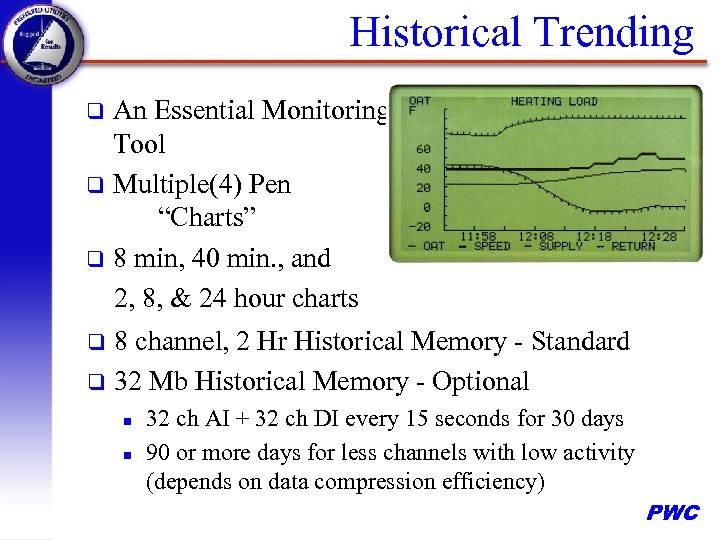

Historical Trending An Essential Monitoring Tool q Multiple(4) Pen “Charts” q 8 min, 40 min. , and 2, 8, & 24 hour charts q 8 channel, 2 Hr Historical Memory - Standard q 32 Mb Historical Memory - Optional q n n 32 ch AI + 32 ch DI every 15 seconds for 30 days 90 or more days for less channels with low activity (depends on data compression efficiency) PWC

Historical Trending An Essential Monitoring Tool q Multiple(4) Pen “Charts” q 8 min, 40 min. , and 2, 8, & 24 hour charts q 8 channel, 2 Hr Historical Memory - Standard q 32 Mb Historical Memory - Optional q n n 32 ch AI + 32 ch DI every 15 seconds for 30 days 90 or more days for less channels with low activity (depends on data compression efficiency) PWC

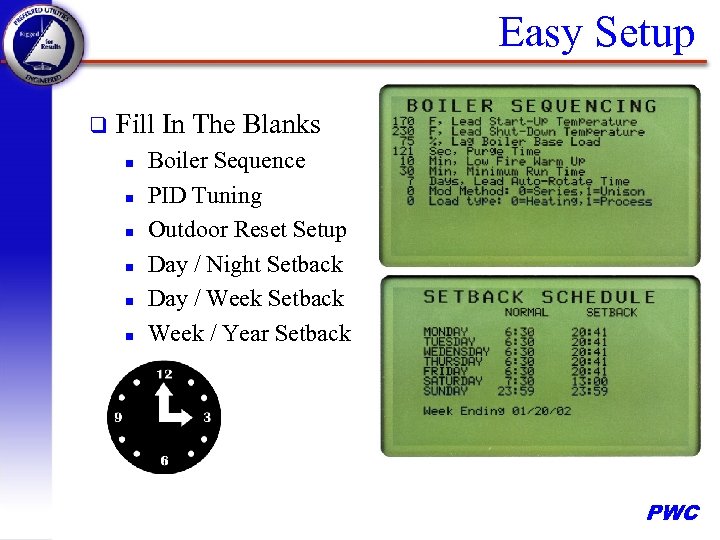

Easy Setup q Fill In The Blanks n n n Boiler Sequence PID Tuning Outdoor Reset Setup Day / Night Setback Day / Week Setback Week / Year Setback PWC

Easy Setup q Fill In The Blanks n n n Boiler Sequence PID Tuning Outdoor Reset Setup Day / Night Setback Day / Week Setback Week / Year Setback PWC

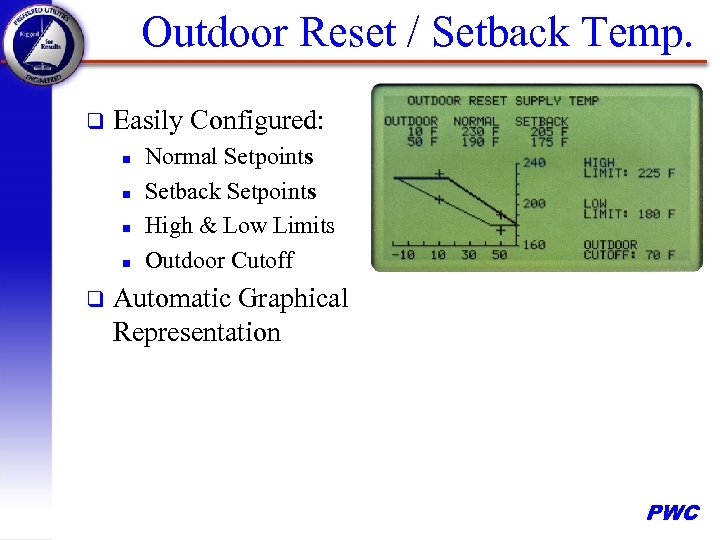

Outdoor Reset / Setback Temp. q Easily Configured: n n q Normal Setpoints Setback Setpoints High & Low Limits Outdoor Cutoff Automatic Graphical Representation PWC

Outdoor Reset / Setback Temp. q Easily Configured: n n q Normal Setpoints Setback Setpoints High & Low Limits Outdoor Cutoff Automatic Graphical Representation PWC

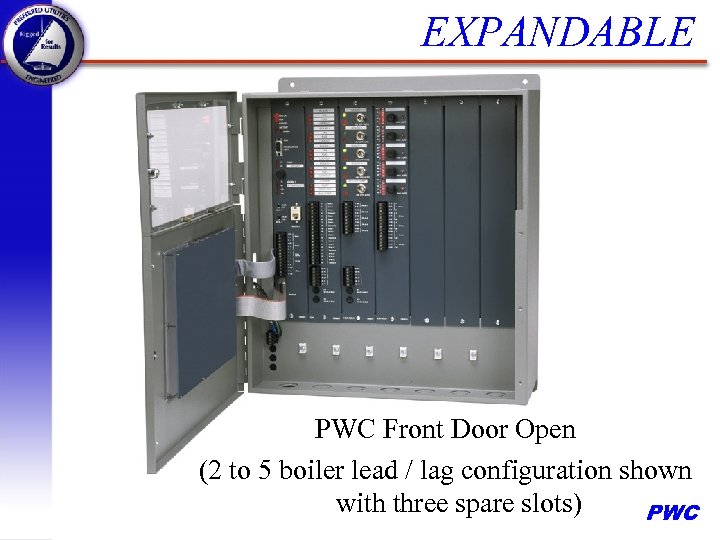

EXPANDABLE PWC Front Door Open (2 to 5 boiler lead / lag configuration shown with three spare slots) PWC

EXPANDABLE PWC Front Door Open (2 to 5 boiler lead / lag configuration shown with three spare slots) PWC

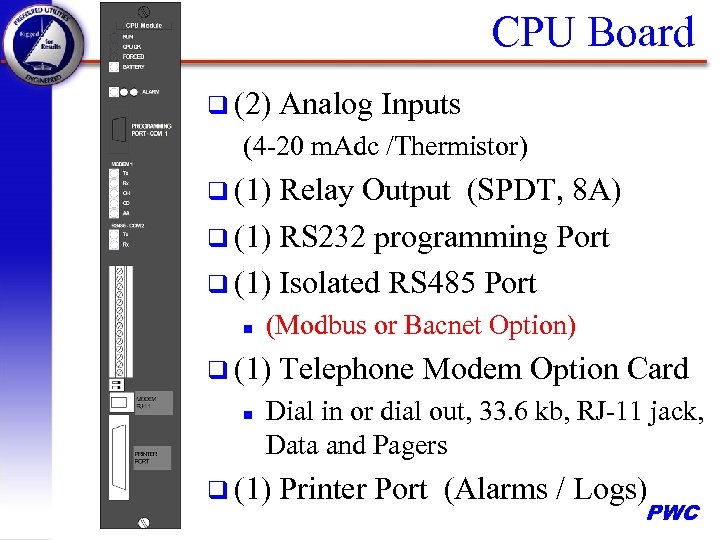

CPU Board q (2) Analog Inputs (4 -20 m. Adc /Thermistor) q (1) Relay Output (SPDT, 8 A) q (1) RS 232 programming Port q (1) Isolated RS 485 Port n (Modbus or Bacnet Option) q (1) n Telephone Modem Option Card Dial in or dial out, 33. 6 kb, RJ-11 jack, Data and Pagers q (1) Printer Port (Alarms / Logs) PWC

CPU Board q (2) Analog Inputs (4 -20 m. Adc /Thermistor) q (1) Relay Output (SPDT, 8 A) q (1) RS 232 programming Port q (1) Isolated RS 485 Port n (Modbus or Bacnet Option) q (1) n Telephone Modem Option Card Dial in or dial out, 33. 6 kb, RJ-11 jack, Data and Pagers q (1) Printer Port (Alarms / Logs) PWC

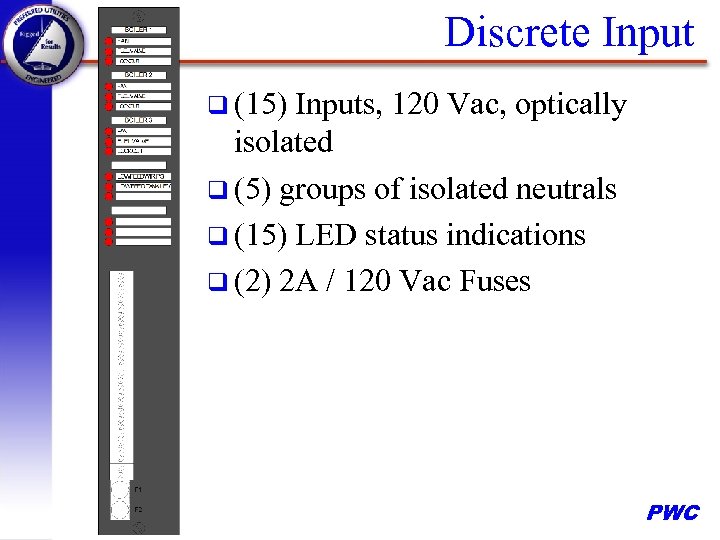

Discrete Input q (15) Inputs, 120 Vac, optically isolated q (5) groups of isolated neutrals q (15) LED status indications q (2) 2 A / 120 Vac Fuses PWC

Discrete Input q (15) Inputs, 120 Vac, optically isolated q (5) groups of isolated neutrals q (15) LED status indications q (2) 2 A / 120 Vac Fuses PWC

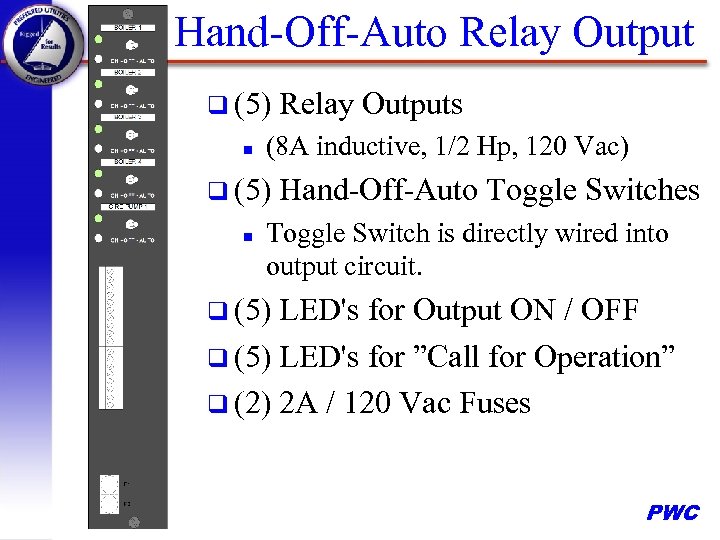

Hand-Off-Auto Relay Output q (5) n (8 A inductive, 1/2 Hp, 120 Vac) q (5) n Relay Outputs Hand-Off-Auto Toggle Switches Toggle Switch is directly wired into output circuit. q (5) LED's for Output ON / OFF q (5) LED's for ”Call for Operation” q (2) 2 A / 120 Vac Fuses PWC

Hand-Off-Auto Relay Output q (5) n (8 A inductive, 1/2 Hp, 120 Vac) q (5) n Relay Outputs Hand-Off-Auto Toggle Switches Toggle Switch is directly wired into output circuit. q (5) LED's for Output ON / OFF q (5) LED's for ”Call for Operation” q (2) 2 A / 120 Vac Fuses PWC

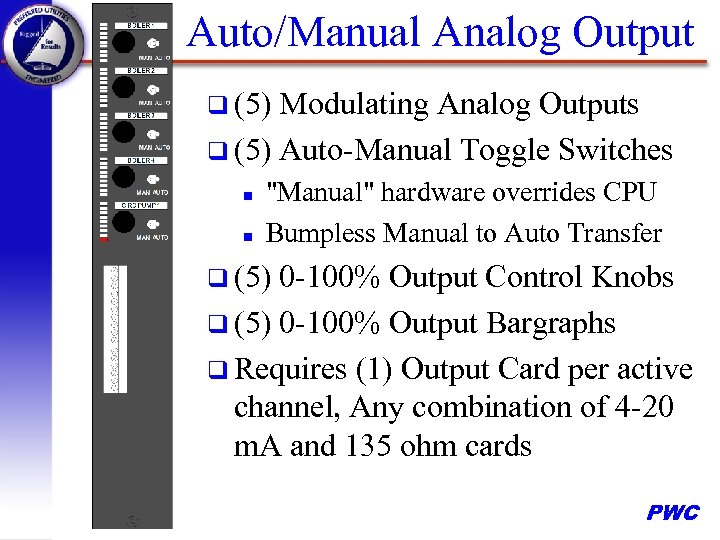

Auto/Manual Analog Output q (5) Modulating Analog Outputs q (5) Auto-Manual Toggle Switches n n "Manual" hardware overrides CPU Bumpless Manual to Auto Transfer q (5) 0 -100% Output Control Knobs q (5) 0 -100% Output Bargraphs q Requires (1) Output Card per active channel, Any combination of 4 -20 m. A and 135 ohm cards PWC

Auto/Manual Analog Output q (5) Modulating Analog Outputs q (5) Auto-Manual Toggle Switches n n "Manual" hardware overrides CPU Bumpless Manual to Auto Transfer q (5) 0 -100% Output Control Knobs q (5) 0 -100% Output Bargraphs q Requires (1) Output Card per active channel, Any combination of 4 -20 m. A and 135 ohm cards PWC

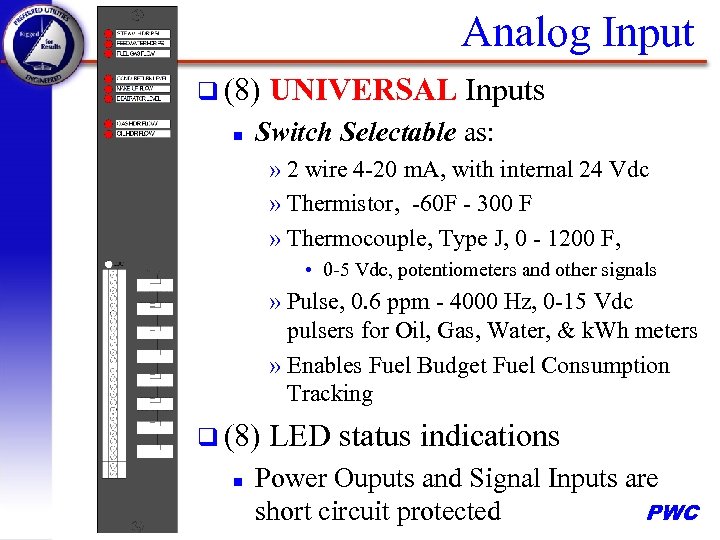

Analog Input q (8) n UNIVERSAL Inputs Switch Selectable as: » 2 wire 4 -20 m. A, with internal 24 Vdc » Thermistor, -60 F - 300 F » Thermocouple, Type J, 0 - 1200 F, • 0 -5 Vdc, potentiometers and other signals » Pulse, 0. 6 ppm - 4000 Hz, 0 -15 Vdc pulsers for Oil, Gas, Water, & k. Wh meters » Enables Fuel Budget Fuel Consumption Tracking q (8) n LED status indications Power Ouputs and Signal Inputs are PWC short circuit protected

Analog Input q (8) n UNIVERSAL Inputs Switch Selectable as: » 2 wire 4 -20 m. A, with internal 24 Vdc » Thermistor, -60 F - 300 F » Thermocouple, Type J, 0 - 1200 F, • 0 -5 Vdc, potentiometers and other signals » Pulse, 0. 6 ppm - 4000 Hz, 0 -15 Vdc pulsers for Oil, Gas, Water, & k. Wh meters » Enables Fuel Budget Fuel Consumption Tracking q (8) n LED status indications Power Ouputs and Signal Inputs are PWC short circuit protected

Relay Output q (8) n n Isolated Relay Outputs ( 8 A inductive, ½ Hp, 120 Vac) (2) SPDT, (6) NO-SPST q (8) LED status indications q (2) 2 A / 120 Vac Fuses PWC

Relay Output q (8) n n Isolated Relay Outputs ( 8 A inductive, ½ Hp, 120 Vac) (2) SPDT, (6) NO-SPST q (8) LED status indications q (2) 2 A / 120 Vac Fuses PWC

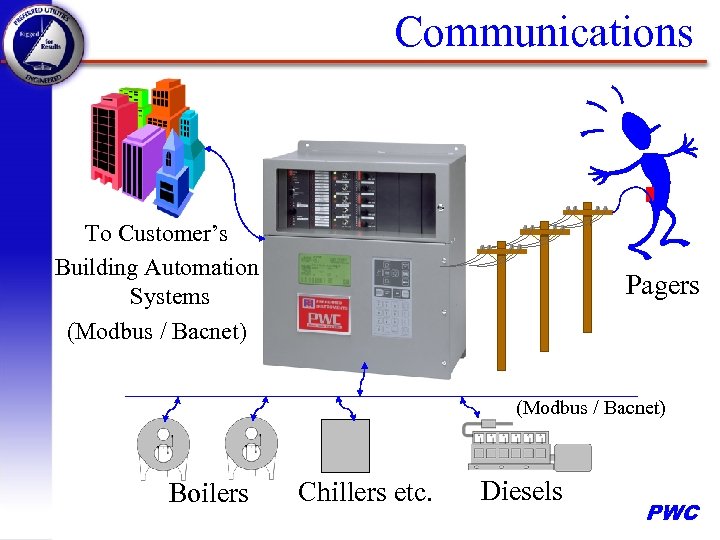

Communications To Customer’s Building Automation Systems (Modbus / Bacnet) Pagers (Modbus / Bacnet) Boilers Chillers etc. Diesels PWC

Communications To Customer’s Building Automation Systems (Modbus / Bacnet) Pagers (Modbus / Bacnet) Boilers Chillers etc. Diesels PWC

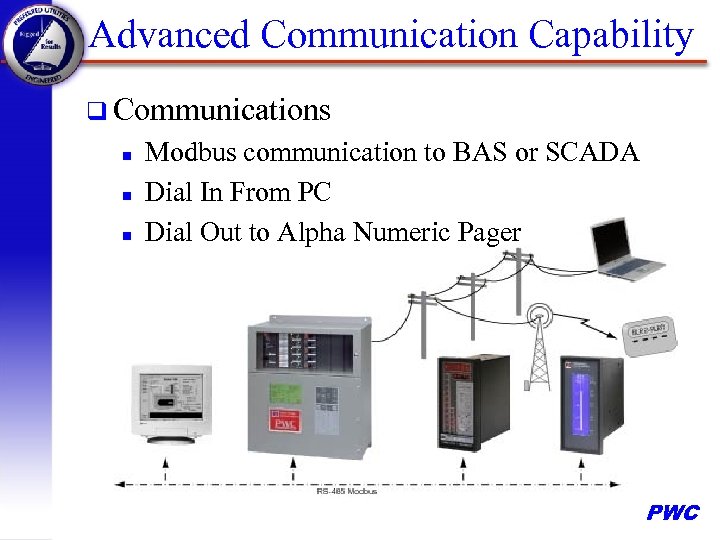

Advanced Communication Capability q Communications n n n Modbus communication to BAS or SCADA Dial In From PC Dial Out to Alpha Numeric Pager PWC

Advanced Communication Capability q Communications n n n Modbus communication to BAS or SCADA Dial In From PC Dial Out to Alpha Numeric Pager PWC

Dial In From PC PWC

Dial In From PC PWC

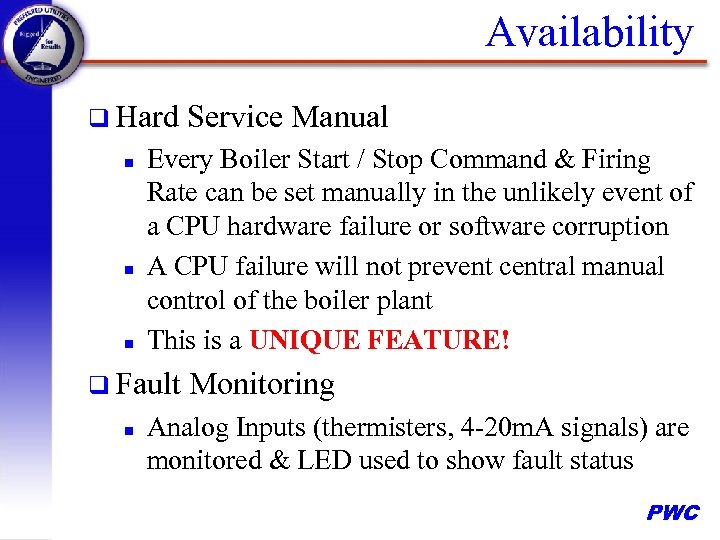

Availability q Hard n n n Every Boiler Start / Stop Command & Firing Rate can be set manually in the unlikely event of a CPU hardware failure or software corruption A CPU failure will not prevent central manual control of the boiler plant This is a UNIQUE FEATURE! q Fault n Service Manual Monitoring Analog Inputs (thermisters, 4 -20 m. A signals) are monitored & LED used to show fault status PWC

Availability q Hard n n n Every Boiler Start / Stop Command & Firing Rate can be set manually in the unlikely event of a CPU hardware failure or software corruption A CPU failure will not prevent central manual control of the boiler plant This is a UNIQUE FEATURE! q Fault n Service Manual Monitoring Analog Inputs (thermisters, 4 -20 m. A signals) are monitored & LED used to show fault status PWC

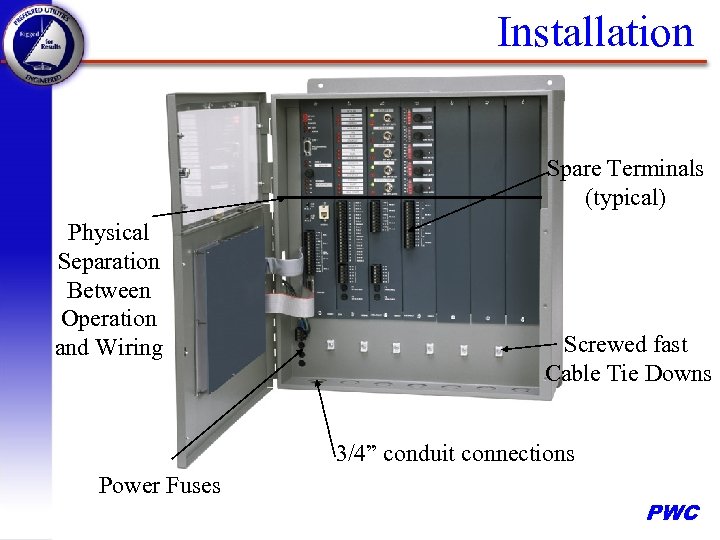

Installation Spare Terminals (typical) Physical Separation Between Operation and Wiring Screwed fast Cable Tie Downs 3/4” conduit connections Power Fuses PWC

Installation Spare Terminals (typical) Physical Separation Between Operation and Wiring Screwed fast Cable Tie Downs 3/4” conduit connections Power Fuses PWC

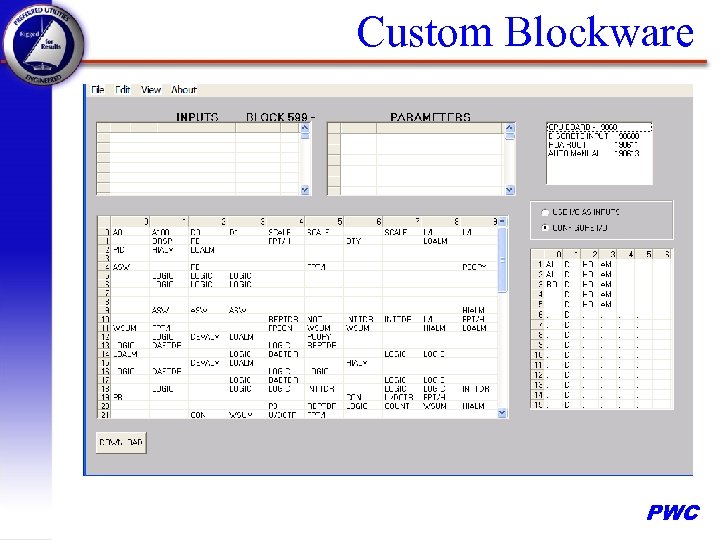

Custom Blockware PWC

Custom Blockware PWC

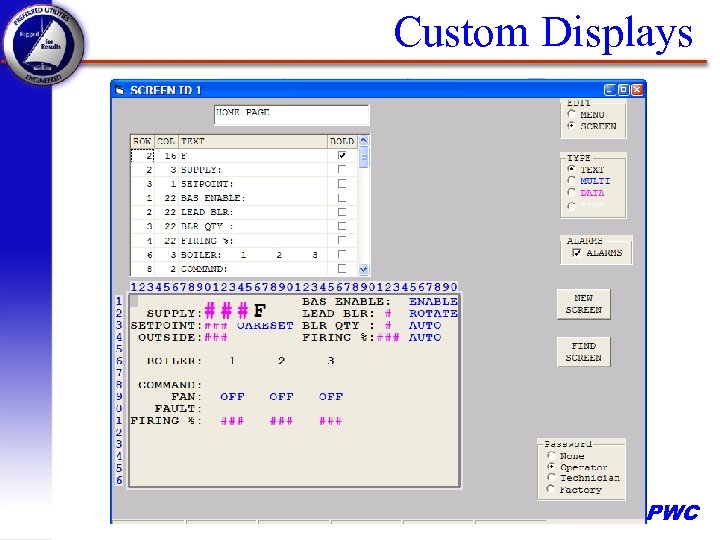

Custom Displays PWC

Custom Displays PWC

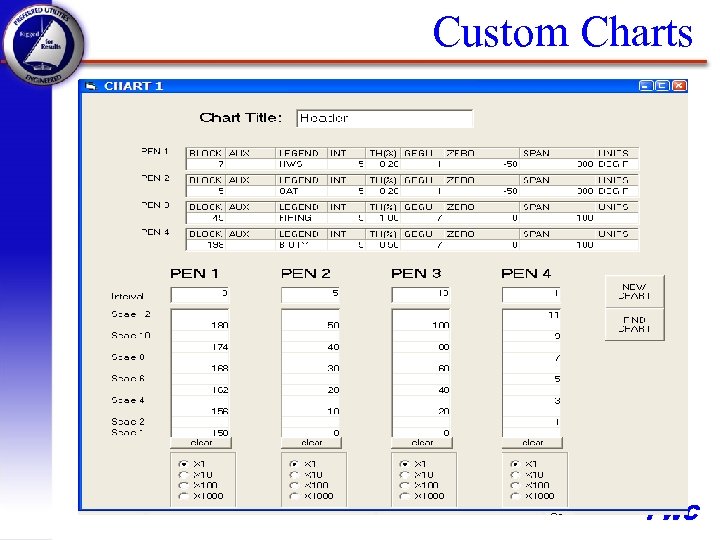

Custom Charts PWC

Custom Charts PWC

Preferred Instruments 31 -35 South Street • Danbury • CT T: (203) 743 -6741 • F: (203) 798 -7313 www. preferred-mfg. com PWC

Preferred Instruments 31 -35 South Street • Danbury • CT T: (203) 743 -6741 • F: (203) 798 -7313 www. preferred-mfg. com PWC