ec5810104e8c26ae03bf33efb5e18c69.ppt

- Количество слайдов: 37

Plans and Preparations for the PST Energy Act Investigations Texas Commission on Environmental Quality Environmental Trade Fair May 5 -6, 2015

Plans and Preparations for the PST Energy Act Investigations Texas Commission on Environmental Quality Environmental Trade Fair May 5 -6, 2015

Small Business and Local Government Assistance Brian Christian Andy Gardner Division Director Section Manager

Small Business and Local Government Assistance Brian Christian Andy Gardner Division Director Section Manager

SBLGA Offers: • Technical Compliance Assistance • One on One Help • Compliance Tools • Free & Confidential

SBLGA Offers: • Technical Compliance Assistance • One on One Help • Compliance Tools • Free & Confidential

SBLGA Resources • • • Site Visit Program** Enviro. Mentor Program** Regional Staff Hotline number The Advocate

SBLGA Resources • • • Site Visit Program** Enviro. Mentor Program** Regional Staff Hotline number The Advocate

Site Visit Program • Free to small businesses • Conducted by contractor hired by the SBLGA Section • Completes a 62 point PST checklist • Owner receives a report – Enforcement does not

Site Visit Program • Free to small businesses • Conducted by contractor hired by the SBLGA Section • Completes a 62 point PST checklist • Owner receives a report – Enforcement does not

Enviro. Mentor Program • Technical Assistance • Volunteer Professionals – Consultants – Engineers – Lawyers – Operators

Enviro. Mentor Program • Technical Assistance • Volunteer Professionals – Consultants – Engineers – Lawyers – Operators

Today’s Topics • Update on 40 CFR Part 280 • 3 year Energy Act Investigations • SBLGA Project – Compliance checklists – SBLGA tools – Free PST compliance workshops

Today’s Topics • Update on 40 CFR Part 280 • 3 year Energy Act Investigations • SBLGA Project – Compliance checklists – SBLGA tools – Free PST compliance workshops

40 CFR Part 280 • Changes to federal UST rules will likely become effective soon • Watch EPA and TCEQ websites for updates • Participate in the rulemaking process

40 CFR Part 280 • Changes to federal UST rules will likely become effective soon • Watch EPA and TCEQ websites for updates • Participate in the rulemaking process

Federal Energy Act of 2005 • Requires states to inspect facilities with USTs every 3 years • There approximately 21, 000 active facilities with USTs in Texas • TCEQ and agency contractors have performed investigations the past 3+ years

Federal Energy Act of 2005 • Requires states to inspect facilities with USTs every 3 years • There approximately 21, 000 active facilities with USTs in Texas • TCEQ and agency contractors have performed investigations the past 3+ years

Federal Energy Act of 2005 • Best option is for facilities to be in compliance before an investigation • More than 680 administrative orders filed by TCEQ in Fiscal Year 2014 • Average penalty greater than $5, 500

Federal Energy Act of 2005 • Best option is for facilities to be in compliance before an investigation • More than 680 administrative orders filed by TCEQ in Fiscal Year 2014 • Average penalty greater than $5, 500

Compliance Checklists • Energy Act – 10 focused points • CEIMOD – Modified compliance evaluation investigation • Temporarily out of service

Compliance Checklists • Energy Act – 10 focused points • CEIMOD – Modified compliance evaluation investigation • Temporarily out of service

Preparing for a PST Focused Energy Act Investigation • Energy Act focused checklist citing mostly Category A violations – requires automatic initiation of formal enforcement action • TCEQ investigators are still looking for compliance with all applicable rules

Preparing for a PST Focused Energy Act Investigation • Energy Act focused checklist citing mostly Category A violations – requires automatic initiation of formal enforcement action • TCEQ investigators are still looking for compliance with all applicable rules

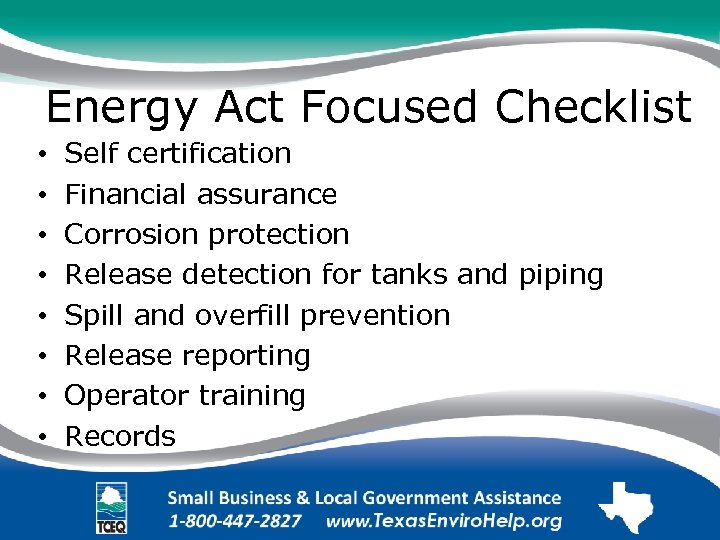

Energy Act Focused Checklist • • Self certification Financial assurance Corrosion protection Release detection for tanks and piping Spill and overfill prevention Release reporting Operator training Records

Energy Act Focused Checklist • • Self certification Financial assurance Corrosion protection Release detection for tanks and piping Spill and overfill prevention Release reporting Operator training Records

Self Certification • Is the delivery certificate current, valid? • Applies to USTs containing motor fuel • Required annually • Fuel delivery prohibited without a current, valid delivery certificate

Self Certification • Is the delivery certificate current, valid? • Applies to USTs containing motor fuel • Required annually • Fuel delivery prohibited without a current, valid delivery certificate

Financial Assurance • Is the insurance current? • Facilities submit certificate of insurance with self certification form • Does the facility have documentation?

Financial Assurance • Is the insurance current? • Facilities submit certificate of insurance with self certification form • Does the facility have documentation?

Corrosion Protection • Are all underground and underwater metal components protected from corrosion? – Steel tanks and lines – Buried metal components – Metal components in contact with water

Corrosion Protection • Are all underground and underwater metal components protected from corrosion? – Steel tanks and lines – Buried metal components – Metal components in contact with water

Corrosion Protection • Cathodic protection systems must be tested at installation and every three years thereafter • For impressed current systems, rectifier should be read every 60 days and recorded in a log sheet

Corrosion Protection • Cathodic protection systems must be tested at installation and every three years thereafter • For impressed current systems, rectifier should be read every 60 days and recorded in a log sheet

Corrosion Protection • FRP Tanks and Composite Tanks don’t require a cathodic protection system • Does the facility have documentation? • What is acceptable documentation?

Corrosion Protection • FRP Tanks and Composite Tanks don’t require a cathodic protection system • Does the facility have documentation? • What is acceptable documentation?

Release Detection • Tanks – Monthly method capable of detecting a 0. 2 gph leak rate (ATG & SIR) – Inventory control required if retail or if the method requires it • Accurate, daily readings • Reconcile at the end of each month

Release Detection • Tanks – Monthly method capable of detecting a 0. 2 gph leak rate (ATG & SIR) – Inventory control required if retail or if the method requires it • Accurate, daily readings • Reconcile at the end of each month

Release Detection • Pressurized Piping – 2 methods required • Automatic line leak detector (3 gph) and be function tested annually and • Monthly release detection (0. 2 gph) or annual piping tightness test (0. 1 gph)

Release Detection • Pressurized Piping – 2 methods required • Automatic line leak detector (3 gph) and be function tested annually and • Monthly release detection (0. 2 gph) or annual piping tightness test (0. 1 gph)

Release Detection • Suction or Gravity Piping • Monthly or triennial test • Keep documentation to verify compliance

Release Detection • Suction or Gravity Piping • Monthly or triennial test • Keep documentation to verify compliance

Spill & Overfill Prevention • Tight fill fitting • Spill bucket -Inspect every 60 days to ensure they’re liquid tight • Overfill Device – Automatic shut-off valve – in fill port – Automatic flow restrictor – in vent line • Keep documentation

Spill & Overfill Prevention • Tight fill fitting • Spill bucket -Inspect every 60 days to ensure they’re liquid tight • Overfill Device – Automatic shut-off valve – in fill port – Automatic flow restrictor – in vent line • Keep documentation

Release Reporting • Were any suspected releases reported within 24 hours and investigated? – Exceeding inventory control reconciliation amount 2 months in a row – Inconclusive or failing SIR or ATG result • System tightness test within 30 days • Keep documentation

Release Reporting • Were any suspected releases reported within 24 hours and investigated? – Exceeding inventory control reconciliation amount 2 months in a row – Inconclusive or failing SIR or ATG result • System tightness test within 30 days • Keep documentation

Operator Training • Initial deadline was August 8 th 2012 • Re-train every 3 years • Completion certificate

Operator Training • Initial deadline was August 8 th 2012 • Re-train every 3 years • Completion certificate

Records • Facility should maintain records to determine compliance • It doesn’t count if you can’t prove it

Records • Facility should maintain records to determine compliance • It doesn’t count if you can’t prove it

Common Violations Cited • • • Not doing inventory control No proof of tank test results No 3 year cathodic protection test No documentation of tank material No overfill documentation Insufficient records

Common Violations Cited • • • Not doing inventory control No proof of tank test results No 3 year cathodic protection test No documentation of tank material No overfill documentation Insufficient records

What happens after an investigation? • Exit interview form given to facility • If violations are noted, get in compliance and submit documentation ASAP – it could save $$$$

What happens after an investigation? • Exit interview form given to facility • If violations are noted, get in compliance and submit documentation ASAP – it could save $$$$

Penalty Calculations • Many factors – Amount of throughput – Compliance History – Avoided Costs (not doing a tightness test) – Good faith reduction (25%) – Deferral for agreed order (20%)

Penalty Calculations • Many factors – Amount of throughput – Compliance History – Avoided Costs (not doing a tightness test) – Good faith reduction (25%) – Deferral for agreed order (20%)

SBLGA’s PST Tools • Free, confidential site visit (if facility is a small business and not in enforcement)* • PST Super Guide (RG-475) • Petroleum Storage Tanks (PST): Compliance Resources webpage

SBLGA’s PST Tools • Free, confidential site visit (if facility is a small business and not in enforcement)* • PST Super Guide (RG-475) • Petroleum Storage Tanks (PST): Compliance Resources webpage

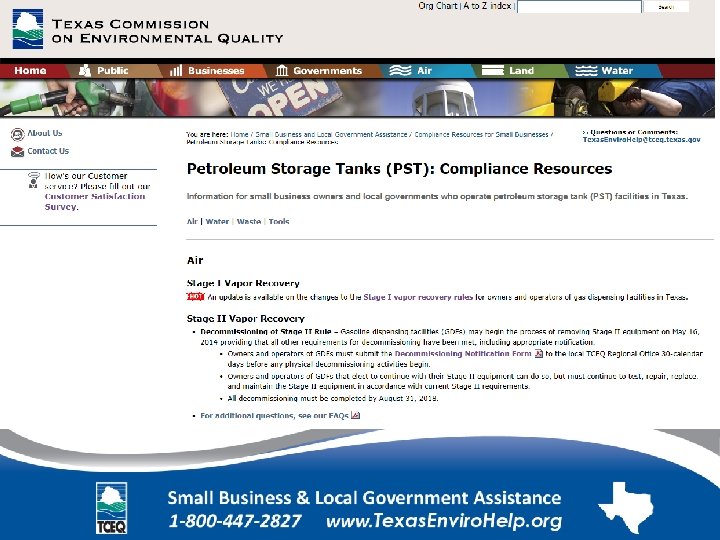

PST Compliance Resources web page

PST Compliance Resources web page

SBLGA’s PST Tools • Compliance Notebook NEW!! – Example records – Blank log sheets – Place to put necessary records – Follows CEIMOD compliance checklist

SBLGA’s PST Tools • Compliance Notebook NEW!! – Example records – Blank log sheets – Place to put necessary records – Follows CEIMOD compliance checklist

Compliance Notebook Content • • Self-Certification & Registration Financial Assurance Corrosion Protection Tank Release Detection Piping Release Detection Spill and Overfill Prevention Release Reporting

Compliance Notebook Content • • Self-Certification & Registration Financial Assurance Corrosion Protection Tank Release Detection Piping Release Detection Spill and Overfill Prevention Release Reporting

Compliance Notebook Content • • Miscellaneous Records Operator Training Shear Valves Equipment installed after January 1, 2009 Texas Department of Agriculture Temporarily out of service USTs Stage I and II

Compliance Notebook Content • • Miscellaneous Records Operator Training Shear Valves Equipment installed after January 1, 2009 Texas Department of Agriculture Temporarily out of service USTs Stage I and II

Free PST Workshops • Owners and operators of facilities with USTs invited • Participants receive compliance notebook and discuss content • SBLGA staff present to answer compliance questions

Free PST Workshops • Owners and operators of facilities with USTs invited • Participants receive compliance notebook and discuss content • SBLGA staff present to answer compliance questions

Free PST Workshops • Austin workshop – May 19, 2015 • Waco workshop – June 11, 2015 • Conducted statewide in Fiscal Year 2016

Free PST Workshops • Austin workshop – May 19, 2015 • Waco workshop – June 11, 2015 • Conducted statewide in Fiscal Year 2016

For More Information… • www. texasenvirohelp. org • Contact regional SBLGA staff • 1 -800 -447 -2827 - hotline

For More Information… • www. texasenvirohelp. org • Contact regional SBLGA staff • 1 -800 -447 -2827 - hotline

• Danielle Cochran – TCEQ Region 4 – Fort Worth – Phone: (817) 588 -5927 – E-Mail: danielle. cochran@tceq. texas. gov • Nathan Weiss – TCEQ Region 13 – San Antonio – Phone: (210) 403 -4092 – E-Mail: nathan. weiss@tceq. texas. gov

• Danielle Cochran – TCEQ Region 4 – Fort Worth – Phone: (817) 588 -5927 – E-Mail: danielle. cochran@tceq. texas. gov • Nathan Weiss – TCEQ Region 13 – San Antonio – Phone: (210) 403 -4092 – E-Mail: nathan. weiss@tceq. texas. gov