Pipeline Process Calculations

Pipeline Process Calculations

Hydraulic Calculations of Pipe Flows Terms: pipe flows (pressure flows, pressurized pipelines) Parameters to be defined: • Initial pressure (р1) • Pipeline flow rate (Q) • Pipe diameter

Hydraulic Calculations of Pipe Flows Terms: pipe flows (pressure flows, pressurized pipelines) Parameters to be defined: • Initial pressure (р1) • Pipeline flow rate (Q) • Pipe diameter

Basic Equations to be Applied I. Mass flow rate should be always constant 1. Volumetric flow rate (Q, м 3/с): 2. Mass flow rate (G, kg/s): Round pipeline cross section, cross section is calculated as so the formula is as follows: 3. Continuity equation Material-balance equation is as follows:

Basic Equations to be Applied I. Mass flow rate should be always constant 1. Volumetric flow rate (Q, м 3/с): 2. Mass flow rate (G, kg/s): Round pipeline cross section, cross section is calculated as so the formula is as follows: 3. Continuity equation Material-balance equation is as follows:

Basic Equations to be Applied II. Mechanical Energy Change Total head at pipeline cross section consists of potential head, pressure head, and velocity head. 4. Bernoulli Equation The sum of three head types is referred to the total mechanical energy of flow at a given cross section, and it is called total head (H):

Basic Equations to be Applied II. Mechanical Energy Change Total head at pipeline cross section consists of potential head, pressure head, and velocity head. 4. Bernoulli Equation The sum of three head types is referred to the total mechanical energy of flow at a given cross section, and it is called total head (H):

Basic Equations to be Applied Assumptions made in deriving Bernoulli's equation: • Fluid is incompressible; • Fluid flow is 'steady state' – velocities are constant with respect to time, T = const; • Smoothly-changing flow within a given pipeline section.

Basic Equations to be Applied Assumptions made in deriving Bernoulli's equation: • Fluid is incompressible; • Fluid flow is 'steady state' – velocities are constant with respect to time, T = const; • Smoothly-changing flow within a given pipeline section.

Basic Equations to be Applied III. Momentum equation. Fluid viscosity. Newton’s 2 nd law. Two types of hydraulic resistance are distinguished: friction resistance (h. Т) and local resistance (h. М): when Z 1=Z 2 and ω1=ω2 obtain:

Basic Equations to be Applied III. Momentum equation. Fluid viscosity. Newton’s 2 nd law. Two types of hydraulic resistance are distinguished: friction resistance (h. Т) and local resistance (h. М): when Z 1=Z 2 and ω1=ω2 obtain:

Friction Loss Definition The friction resistance (pressure differential along the pipeline length) is calculated from Darcy's-Weisbach empirical formula (at any flow regime): As follows from equation , so the total pressure loss can be represented as: If velocity (ω) is expressed through volume flow rate and cross section area from equation , the equation will be as follows:

Friction Loss Definition The friction resistance (pressure differential along the pipeline length) is calculated from Darcy's-Weisbach empirical formula (at any flow regime): As follows from equation , so the total pressure loss can be represented as: If velocity (ω) is expressed through volume flow rate and cross section area from equation , the equation will be as follows:

Friction Loss Definition In sloping pipe flows head loss (h. T) caused by friction overcome along the length of pipeline must be calculated with regard to height differences: The value of hydraulic resistance factor depends on Reynold’s number (Re) and relative roughness of pipeline wall:

Friction Loss Definition In sloping pipe flows head loss (h. T) caused by friction overcome along the length of pipeline must be calculated with regard to height differences: The value of hydraulic resistance factor depends on Reynold’s number (Re) and relative roughness of pipeline wall:

Friction Loss Definition In a case of Laminar flow hydraulic resistance factor depends on Reynolds parameter only. If Reynolds number Rекр 2320, oil flow is laminar and the value of hydraulic resistance factor is calculated through Stocks formula: Taking into account that Reynolds number is calculated by the following formula: Then, if we substitute the equations (1. 20) (1. 19), we will have:

Friction Loss Definition In a case of Laminar flow hydraulic resistance factor depends on Reynolds parameter only. If Reynolds number Rекр 2320, oil flow is laminar and the value of hydraulic resistance factor is calculated through Stocks formula: Taking into account that Reynolds number is calculated by the following formula: Then, if we substitute the equations (1. 20) (1. 19), we will have:

Turbulent Flow Velocity Profile

Turbulent Flow Velocity Profile

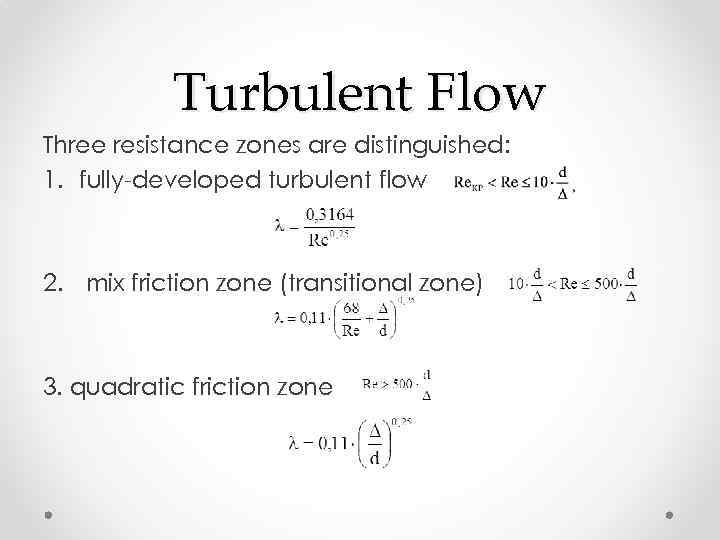

Turbulent Flow Three resistance zones are distinguished: 1. fully-developed turbulent flow 2. mix friction zone (transitional zone) 3. quadratic friction zone

Turbulent Flow Three resistance zones are distinguished: 1. fully-developed turbulent flow 2. mix friction zone (transitional zone) 3. quadratic friction zone

Resistance Local Loss Calculation Resistance Local Loss is calculated by Weisbach formula: Also, Darcy-Weisbach formula can be applied:

Resistance Local Loss Calculation Resistance Local Loss is calculated by Weisbach formula: Also, Darcy-Weisbach formula can be applied:

Formulas for Hydraulic Resistance Factor Calculation

Formulas for Hydraulic Resistance Factor Calculation

Problem What will be hydraulic resistance factor and head loss (pressure loss), when oil density is 840 kg/m 3, viscosity-9 c. St, pipeline diameter - 0, 361 mm (Δ = 0, 15 mm), pipeline length - 125 km and flow rate - 400 m 3/h.

Problem What will be hydraulic resistance factor and head loss (pressure loss), when oil density is 840 kg/m 3, viscosity-9 c. St, pipeline diameter - 0, 361 mm (Δ = 0, 15 mm), pipeline length - 125 km and flow rate - 400 m 3/h.