ccbc7432afb1e6d18a4778366a3b5b33.ppt

- Количество слайдов: 19

PILOT SCHEME ON NUTRIFARMS CENTRE OF EXCELLENCE ON MAIZE PROCESSING AND VALUE ADDITION Department of Dairy and Food Technology College of Dairy & Food Science Technology Maharana Pratap University of Agriculture & Technology Udaipur - 313 001

PILOT SCHEME ON NUTRIFARMS CENTRE OF EXCELLENCE ON MAIZE PROCESSING AND VALUE ADDITION Department of Dairy and Food Technology College of Dairy & Food Science Technology Maharana Pratap University of Agriculture & Technology Udaipur - 313 001

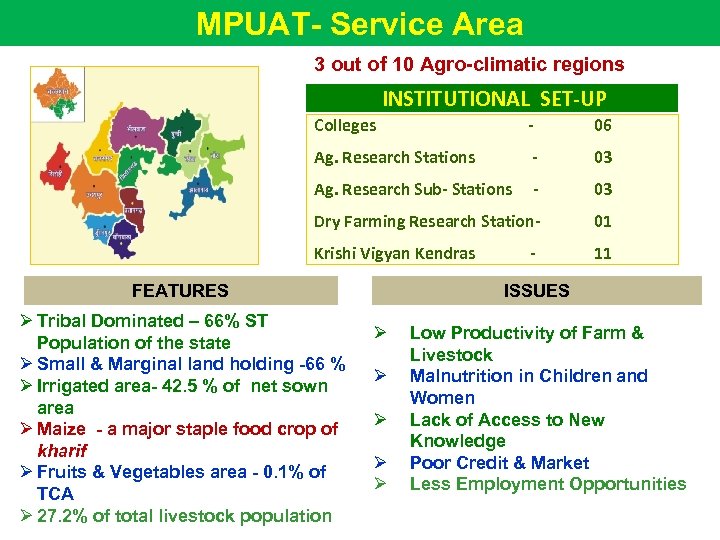

MPUAT- Service Area 3 out of 10 Agro-climatic regions INSTITUTIONAL SET-UP Colleges - 06 Ag. Research Stations - 03 Ag. Research Sub- Stations - 03 Dry Farming Research Station- 01 Krishi Vigyan Kendras 11 FEATURES Ø Tribal Dominated – 66% ST Population of the state Ø Small & Marginal land holding -66 % Ø Irrigated area- 42. 5 % of net sown area Ø Maize - a major staple food crop of kharif Ø Fruits & Vegetables area - 0. 1% of TCA Ø 27. 2% of total livestock population ISSUES Ø Ø Ø Low Productivity of Farm & Livestock Malnutrition in Children and Women Lack of Access to New Knowledge Poor Credit & Market Less Employment Opportunities

MPUAT- Service Area 3 out of 10 Agro-climatic regions INSTITUTIONAL SET-UP Colleges - 06 Ag. Research Stations - 03 Ag. Research Sub- Stations - 03 Dry Farming Research Station- 01 Krishi Vigyan Kendras 11 FEATURES Ø Tribal Dominated – 66% ST Population of the state Ø Small & Marginal land holding -66 % Ø Irrigated area- 42. 5 % of net sown area Ø Maize - a major staple food crop of kharif Ø Fruits & Vegetables area - 0. 1% of TCA Ø 27. 2% of total livestock population ISSUES Ø Ø Ø Low Productivity of Farm & Livestock Malnutrition in Children and Women Lack of Access to New Knowledge Poor Credit & Market Less Employment Opportunities

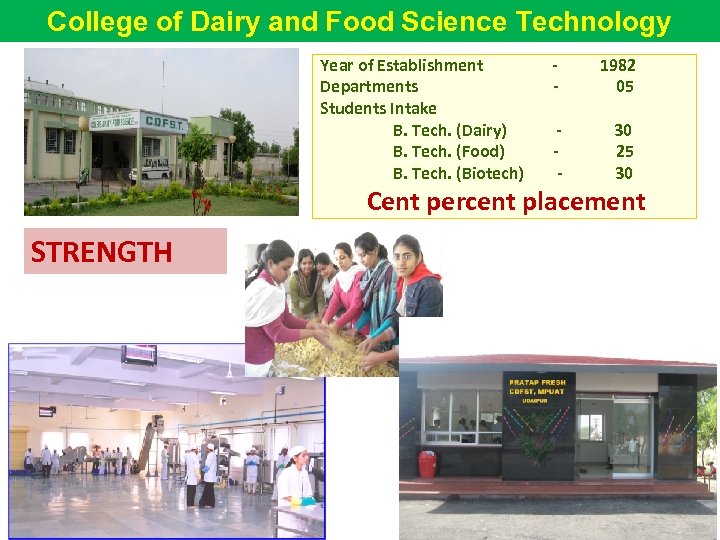

College of Dairy and Food Science Technology Year of Establishment Departments Students Intake B. Tech. (Dairy) B. Tech. (Food) B. Tech. (Biotech) - 1982 05 - 30 25 30 Cent percent placement STRENGTH

College of Dairy and Food Science Technology Year of Establishment Departments Students Intake B. Tech. (Dairy) B. Tech. (Food) B. Tech. (Biotech) - 1982 05 - 30 25 30 Cent percent placement STRENGTH

Infrastructure Facilities Available Ø Condensing & Drying Lab (93 sq. m. ) Ø Fat Rich Dairy Products Lab (93 sq. m. ) Ø Fruits & Vegetables Lab (93 sq. m. ) Ø Frozen Foods Products Lab (93 sq. m. ) Ø Indigenous Products Lab (70 sq. m. ) Ø Meat Products Lab (70 sq. m. ) Ø Experiential Learning Lab (280 sq. m. ) Ø Underutilized Fruit Lab (140 sq. m) Ø Unit Operation Lab (93 Sqmt) Ø Instrumentation Lab (93 Sqmt) Ø Workshop (93 Sqmt)

Infrastructure Facilities Available Ø Condensing & Drying Lab (93 sq. m. ) Ø Fat Rich Dairy Products Lab (93 sq. m. ) Ø Fruits & Vegetables Lab (93 sq. m. ) Ø Frozen Foods Products Lab (93 sq. m. ) Ø Indigenous Products Lab (70 sq. m. ) Ø Meat Products Lab (70 sq. m. ) Ø Experiential Learning Lab (280 sq. m. ) Ø Underutilized Fruit Lab (140 sq. m) Ø Unit Operation Lab (93 Sqmt) Ø Instrumentation Lab (93 Sqmt) Ø Workshop (93 Sqmt)

PILOT SCHEME ON NUTRIFARMS CENTRE OF EXCELLENCE ON PROCESSING AND VALUE ADDITION OF MAIZE Budget outlay : 75. 0 lakh Date of sanction : 06 March, 2014 GOAL Maize Processing and value addition technique - A step forward towards creation of employment and eradication of malnutrition in tribal dominated areas of Rajasthan

PILOT SCHEME ON NUTRIFARMS CENTRE OF EXCELLENCE ON PROCESSING AND VALUE ADDITION OF MAIZE Budget outlay : 75. 0 lakh Date of sanction : 06 March, 2014 GOAL Maize Processing and value addition technique - A step forward towards creation of employment and eradication of malnutrition in tribal dominated areas of Rajasthan

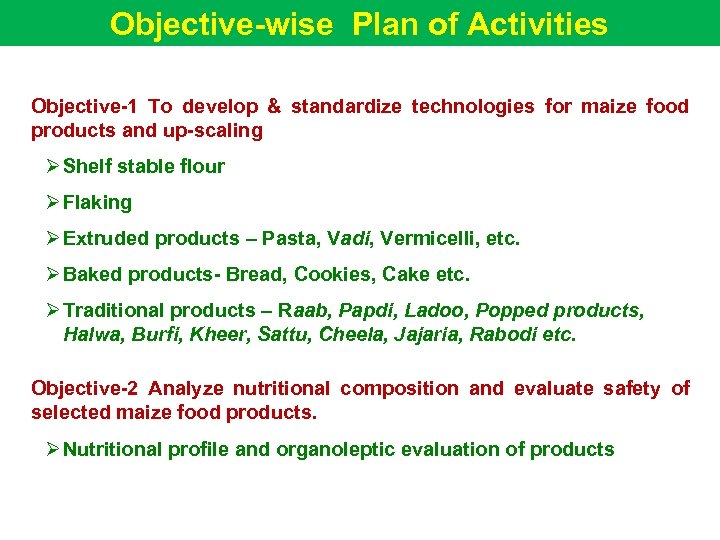

Objective-wise Plan of Activities Objective-1 To develop & standardize technologies for maize food products and up-scaling Ø Shelf stable flour Ø Flaking Ø Extruded products – Pasta, Vadi, Vermicelli, etc. Ø Baked products- Bread, Cookies, Cake etc. Ø Traditional products – Raab, Papdi, Ladoo, Popped products, Halwa, Burfi, Kheer, Sattu, Cheela, Jajaria, Rabodi etc. Objective-2 Analyze nutritional composition and evaluate safety of selected maize food products. Ø Nutritional profile and organoleptic evaluation of products

Objective-wise Plan of Activities Objective-1 To develop & standardize technologies for maize food products and up-scaling Ø Shelf stable flour Ø Flaking Ø Extruded products – Pasta, Vadi, Vermicelli, etc. Ø Baked products- Bread, Cookies, Cake etc. Ø Traditional products – Raab, Papdi, Ladoo, Popped products, Halwa, Burfi, Kheer, Sattu, Cheela, Jajaria, Rabodi etc. Objective-2 Analyze nutritional composition and evaluate safety of selected maize food products. Ø Nutritional profile and organoleptic evaluation of products

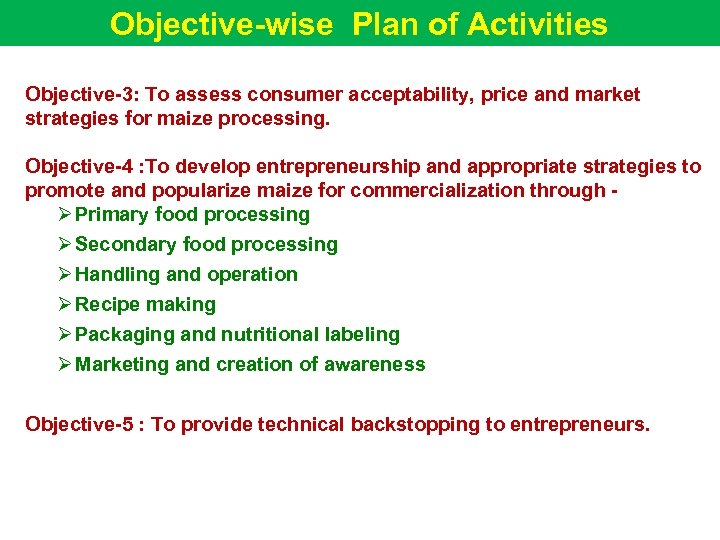

Objective-wise Plan of Activities Objective-3: To assess consumer acceptability, price and market strategies for maize processing. Objective-4 : To develop entrepreneurship and appropriate strategies to promote and popularize maize for commercialization through Ø Primary food processing Ø Secondary food processing Ø Handling and operation Ø Recipe making Ø Packaging and nutritional labeling Ø Marketing and creation of awareness Objective-5 : To provide technical backstopping to entrepreneurs.

Objective-wise Plan of Activities Objective-3: To assess consumer acceptability, price and market strategies for maize processing. Objective-4 : To develop entrepreneurship and appropriate strategies to promote and popularize maize for commercialization through Ø Primary food processing Ø Secondary food processing Ø Handling and operation Ø Recipe making Ø Packaging and nutritional labeling Ø Marketing and creation of awareness Objective-5 : To provide technical backstopping to entrepreneurs.

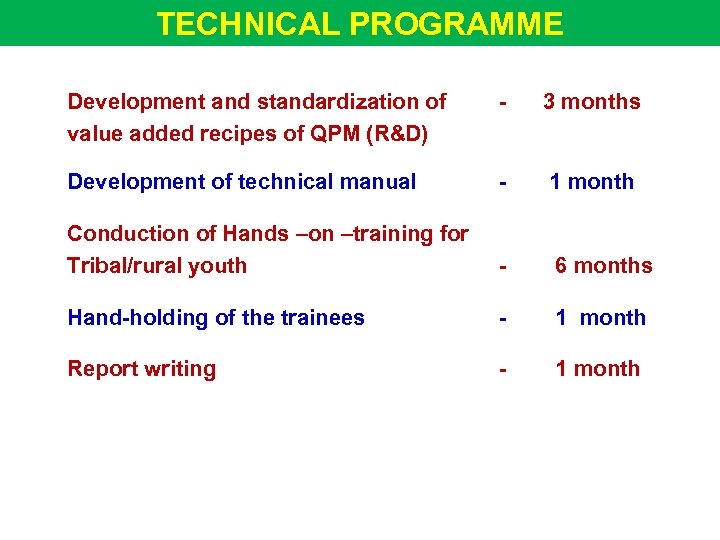

TECHNICAL PROGRAMME Development and standardization of value added recipes of QPM (R&D) - 3 months Development of technical manual - 1 month Conduction of Hands –on –training for Tribal/rural youth - 6 months Hand-holding of the trainees - 1 month Report writing - 1 month

TECHNICAL PROGRAMME Development and standardization of value added recipes of QPM (R&D) - 3 months Development of technical manual - 1 month Conduction of Hands –on –training for Tribal/rural youth - 6 months Hand-holding of the trainees - 1 month Report writing - 1 month

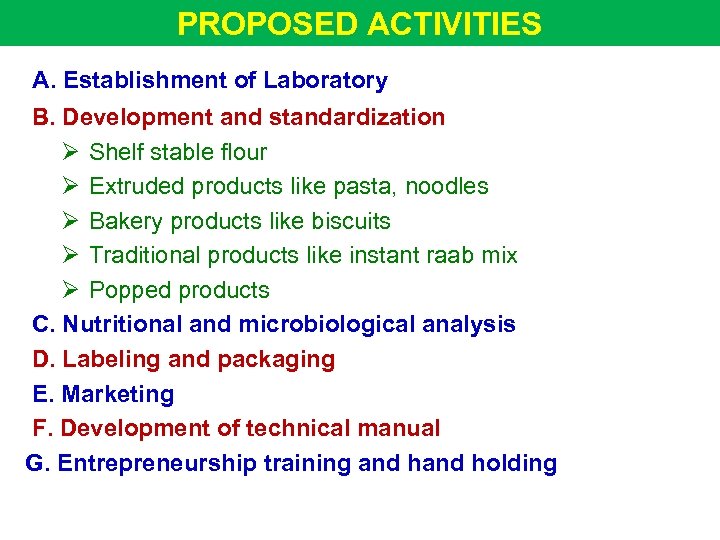

PROPOSED ACTIVITIES A. Establishment of Laboratory B. Development and standardization Ø Shelf stable flour Ø Extruded products like pasta, noodles Ø Bakery products like biscuits Ø Traditional products like instant raab mix Ø Popped products C. Nutritional and microbiological analysis D. Labeling and packaging E. Marketing F. Development of technical manual G. Entrepreneurship training and holding

PROPOSED ACTIVITIES A. Establishment of Laboratory B. Development and standardization Ø Shelf stable flour Ø Extruded products like pasta, noodles Ø Bakery products like biscuits Ø Traditional products like instant raab mix Ø Popped products C. Nutritional and microbiological analysis D. Labeling and packaging E. Marketing F. Development of technical manual G. Entrepreneurship training and holding

Essential Equipments Available Ø Ø Ø Ø Tray drier Pasta machine (5 Kg/hr. capacity) Kneader Baking Oven (Small) Sealing machine (Packaging) Shrink Wrapper Batch roaster Micro wave oven & OTG Major Equipments and Facilities Required Process for procurement initiated 1. Hammer Mill 2. Extruder (Hot) 3. Baking Oven 4. Packaging Machine 5. Weighing balance 6. Flour mill 7. Vacuum packaging 8. Aging Vat (100 L) 9. 10. 11. 12. 13. 14. 15. 16. Plastic crates Popcorn machine Batch roster Kneader (dough) Baking furnace Tray drier Shrink wrapper Grain storage bin

Essential Equipments Available Ø Ø Ø Ø Tray drier Pasta machine (5 Kg/hr. capacity) Kneader Baking Oven (Small) Sealing machine (Packaging) Shrink Wrapper Batch roaster Micro wave oven & OTG Major Equipments and Facilities Required Process for procurement initiated 1. Hammer Mill 2. Extruder (Hot) 3. Baking Oven 4. Packaging Machine 5. Weighing balance 6. Flour mill 7. Vacuum packaging 8. Aging Vat (100 L) 9. 10. 11. 12. 13. 14. 15. 16. Plastic crates Popcorn machine Batch roster Kneader (dough) Baking furnace Tray drier Shrink wrapper Grain storage bin

Progress A. Facilities Developed Smart Class Room

Progress A. Facilities Developed Smart Class Room

Progress A. Facilities Developed Laboratory

Progress A. Facilities Developed Laboratory

Progress A. Facilities Developed Equipments for Processing of Maize

Progress A. Facilities Developed Equipments for Processing of Maize

Progress B. Products initiated Pastine (butter milk based Maize product)

Progress B. Products initiated Pastine (butter milk based Maize product)

Progress B. Products initiated Pop corn (Enriched)

Progress B. Products initiated Pop corn (Enriched)

Progress B. Products initiated Nutritive Laddu

Progress B. Products initiated Nutritive Laddu

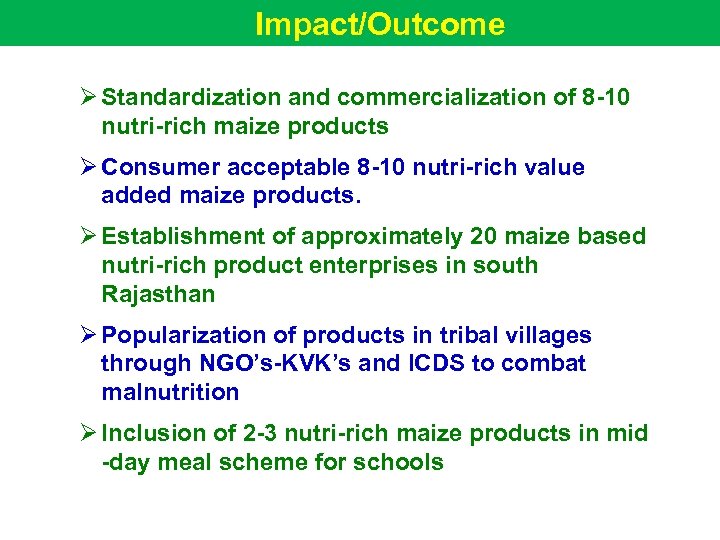

Impact/Outcome Ø Standardization and commercialization of 8 -10 nutri-rich maize products Ø Consumer acceptable 8 -10 nutri-rich value added maize products. Ø Establishment of approximately 20 maize based nutri-rich product enterprises in south Rajasthan Ø Popularization of products in tribal villages through NGO’s-KVK’s and ICDS to combat malnutrition Ø Inclusion of 2 -3 nutri-rich maize products in mid -day meal scheme for schools

Impact/Outcome Ø Standardization and commercialization of 8 -10 nutri-rich maize products Ø Consumer acceptable 8 -10 nutri-rich value added maize products. Ø Establishment of approximately 20 maize based nutri-rich product enterprises in south Rajasthan Ø Popularization of products in tribal villages through NGO’s-KVK’s and ICDS to combat malnutrition Ø Inclusion of 2 -3 nutri-rich maize products in mid -day meal scheme for schools

Sustainability ØBranding and Patenting of nutri-rich maize products. ØConsultancy. ØSale of nutri-rich products at CDFST PRATAP Fresh outlet. ØMore proposals to government for sustaining the activities. ØProcessing and packaging of sweet corn and baby corn.

Sustainability ØBranding and Patenting of nutri-rich maize products. ØConsultancy. ØSale of nutri-rich products at CDFST PRATAP Fresh outlet. ØMore proposals to government for sustaining the activities. ØProcessing and packaging of sweet corn and baby corn.

THANK YOU

THANK YOU