b5d55d7a0cfe12ec29a66438880e99d6.ppt

- Количество слайдов: 25

Photo Gallery Standardprecastwalls. com

Photo Gallery Standardprecastwalls. com

Introduction • Standard Precast Walls (SPW) are custom prefabricated concrete panels for residential and light commercial construction. Our walls are finished on both the exterior and interior side, eliminating the need for drywall, insulation, and stucco. Our detailed casting and installation techniques produce buildings that are strong, attractive, environmental, and affordable. • Our panels are can be adapted and engineered for almost any floor plan. They are manufactured under strict quality control guidelines at our plants in Tampa, Florida and Savannah, Georgia. Once the foundation has been set, our panels are trucked vertically to the jobsite where they can be erected by one of our experienced crews in just one or two days. • SPW is the front-runner in the prefabricated building revolution. From mold, to hurricanes, to energy efficiency, our walls offer the best building envelope available in today’s market. They are, quite simply, building science at its best. Standardprecastwalls. com

Introduction • Standard Precast Walls (SPW) are custom prefabricated concrete panels for residential and light commercial construction. Our walls are finished on both the exterior and interior side, eliminating the need for drywall, insulation, and stucco. Our detailed casting and installation techniques produce buildings that are strong, attractive, environmental, and affordable. • Our panels are can be adapted and engineered for almost any floor plan. They are manufactured under strict quality control guidelines at our plants in Tampa, Florida and Savannah, Georgia. Once the foundation has been set, our panels are trucked vertically to the jobsite where they can be erected by one of our experienced crews in just one or two days. • SPW is the front-runner in the prefabricated building revolution. From mold, to hurricanes, to energy efficiency, our walls offer the best building envelope available in today’s market. They are, quite simply, building science at its best. Standardprecastwalls. com

The Benefits of Precast • Increase Building Cycle Time • Extremely Energy Efficient • Better Protection from Mold, Fire, Rot, and Termites • Easily withstands hurricane force winds • Environmentally Responsible • Applicable to almost any floor plan or design • Panels can be customized to almost aesthetic demand. Standardprecastwalls. com

The Benefits of Precast • Increase Building Cycle Time • Extremely Energy Efficient • Better Protection from Mold, Fire, Rot, and Termites • Easily withstands hurricane force winds • Environmentally Responsible • Applicable to almost any floor plan or design • Panels can be customized to almost aesthetic demand. Standardprecastwalls. com

The Cost • For a small premium, you get the best building that money can buy. • For budget purposes, building a house using our walls as your envelope will cost you between 3 to 5% more than traditional framing methods (CMU or Wood). So if the finished hard costs (including architect and engineering) of your home cost you $100 per square foot, that same house would cost you approximately $105 psf. • The difference is that you can be moving in months earlier to an environmentally friendly home that is stronger and far more resistant to mold, hurricanes, fire, termites, and rot than any other building on the market today. Your energy savings alone usually more than make up the difference. Standardprecastwalls. com

The Cost • For a small premium, you get the best building that money can buy. • For budget purposes, building a house using our walls as your envelope will cost you between 3 to 5% more than traditional framing methods (CMU or Wood). So if the finished hard costs (including architect and engineering) of your home cost you $100 per square foot, that same house would cost you approximately $105 psf. • The difference is that you can be moving in months earlier to an environmentally friendly home that is stronger and far more resistant to mold, hurricanes, fire, termites, and rot than any other building on the market today. Your energy savings alone usually more than make up the difference. Standardprecastwalls. com

The “Sandwich” Panel • • • Our panels are often called a “sandwich” wall because it consists of two layers of concrete sandwiching insulation. The interior layer of concrete is the structural layer. It is typically 4” thick. This layer is extremely smooth and eliminates the need for drywall. Electrical boxes with conduit are easily cast into the panel. The exterior layer is architectural layer and is usually 2” thick. This layer has a smooth to medium textured “stucco” finish that is ready for paint. For insulation we use Dow’s Styrofoam Brand “blue board” that is 2” thick. Our panels can have dimensions as large as 30’ x 13. 5’. Window and door openings are incorporated into the panel during production. Standardprecastwalls. com

The “Sandwich” Panel • • • Our panels are often called a “sandwich” wall because it consists of two layers of concrete sandwiching insulation. The interior layer of concrete is the structural layer. It is typically 4” thick. This layer is extremely smooth and eliminates the need for drywall. Electrical boxes with conduit are easily cast into the panel. The exterior layer is architectural layer and is usually 2” thick. This layer has a smooth to medium textured “stucco” finish that is ready for paint. For insulation we use Dow’s Styrofoam Brand “blue board” that is 2” thick. Our panels can have dimensions as large as 30’ x 13. 5’. Window and door openings are incorporated into the panel during production. Standardprecastwalls. com

T-Mass Connector • • This composite connector is a critical part of the patented design of the T-Mass Wall. This connector is 3 X stronger than steel and prevents any sort of thermal or moisture bridge in the wall. These connectors are the “toothpick” that holds the “sandwich panel” together. They provide sheer strength for the wall, and on most designs they are placed every 16” OC. We are the only licensed manufacturer of the Styrofoam Brand T-Mass Wall Panel by Dow in Florida and Georgia. For more information on our T-Mass product visit our website. Standardprecastwalls. com

T-Mass Connector • • This composite connector is a critical part of the patented design of the T-Mass Wall. This connector is 3 X stronger than steel and prevents any sort of thermal or moisture bridge in the wall. These connectors are the “toothpick” that holds the “sandwich panel” together. They provide sheer strength for the wall, and on most designs they are placed every 16” OC. We are the only licensed manufacturer of the Styrofoam Brand T-Mass Wall Panel by Dow in Florida and Georgia. For more information on our T-Mass product visit our website. Standardprecastwalls. com

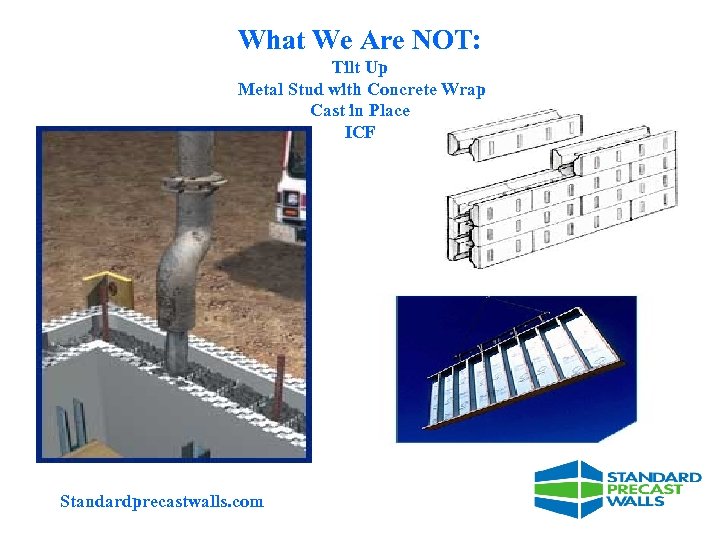

What We Are NOT: Tilt Up Metal Stud with Concrete Wrap Cast in Place ICF Standardprecastwalls. com

What We Are NOT: Tilt Up Metal Stud with Concrete Wrap Cast in Place ICF Standardprecastwalls. com

THE PROCESS After an initial design, schedule, and budget consultation, a set of house plans will be structurally engineered (complete with foundation design) for our panels. “Shop tickets” are then produced by our engineers at sent to one of our plants for production. Each panel is laid out on a steel casting table. Standardprecastwalls. com

THE PROCESS After an initial design, schedule, and budget consultation, a set of house plans will be structurally engineered (complete with foundation design) for our panels. “Shop tickets” are then produced by our engineers at sent to one of our plants for production. Each panel is laid out on a steel casting table. Standardprecastwalls. com

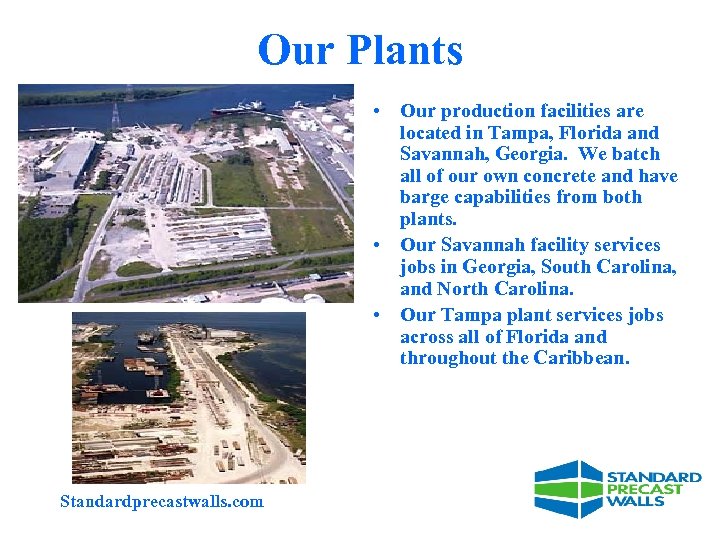

Our Plants • Our production facilities are located in Tampa, Florida and Savannah, Georgia. We batch all of our own concrete and have barge capabilities from both plants. • Our Savannah facility services jobs in Georgia, South Carolina, and North Carolina. • Our Tampa plant services jobs across all of Florida and throughout the Caribbean. Standardprecastwalls. com

Our Plants • Our production facilities are located in Tampa, Florida and Savannah, Georgia. We batch all of our own concrete and have barge capabilities from both plants. • Our Savannah facility services jobs in Georgia, South Carolina, and North Carolina. • Our Tampa plant services jobs across all of Florida and throughout the Caribbean. Standardprecastwalls. com

Tilting Steel Casting Table Standardprecastwalls. com

Tilting Steel Casting Table Standardprecastwalls. com

Set Up and Layout Standardprecastwalls. com

Set Up and Layout Standardprecastwalls. com

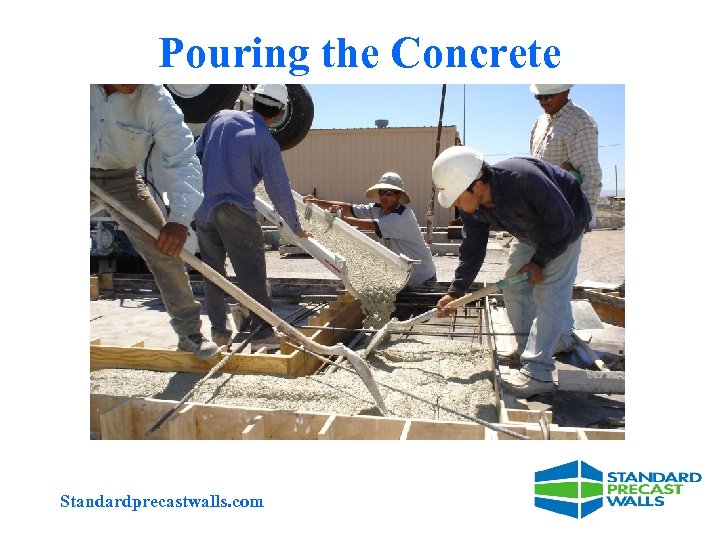

Pouring the Concrete Standardprecastwalls. com

Pouring the Concrete Standardprecastwalls. com

Insulation and Connectors Standardprecastwalls. com

Insulation and Connectors Standardprecastwalls. com

Finishing The exterior of our panels come with a medium to fine stucco finish that is ready for the color of your choice. Our walls can also be wrapped in wood, shingles, or stone. Multiple brick finishes are also available. Standardprecastwalls. com

Finishing The exterior of our panels come with a medium to fine stucco finish that is ready for the color of your choice. Our walls can also be wrapped in wood, shingles, or stone. Multiple brick finishes are also available. Standardprecastwalls. com

Trucking the Panels Standardprecastwalls. com

Trucking the Panels Standardprecastwalls. com

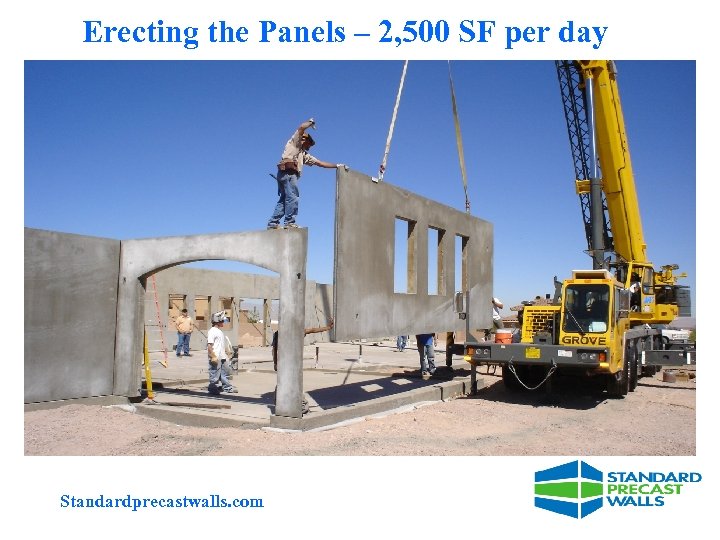

Erecting the Panels – 2, 500 SF per day Standardprecastwalls. com

Erecting the Panels – 2, 500 SF per day Standardprecastwalls. com

DETAILS Standardprecastwalls. com

DETAILS Standardprecastwalls. com

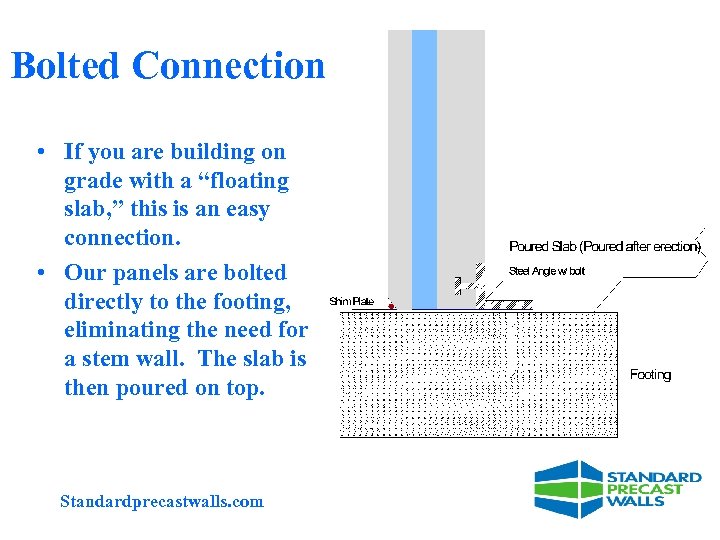

Bolted Connection • If you are building on grade with a “floating slab, ” this is an easy connection. • Our panels are bolted directly to the footing, eliminating the need for a stem wall. The slab is then poured on top. Standardprecastwalls. com

Bolted Connection • If you are building on grade with a “floating slab, ” this is an easy connection. • Our panels are bolted directly to the footing, eliminating the need for a stem wall. The slab is then poured on top. Standardprecastwalls. com

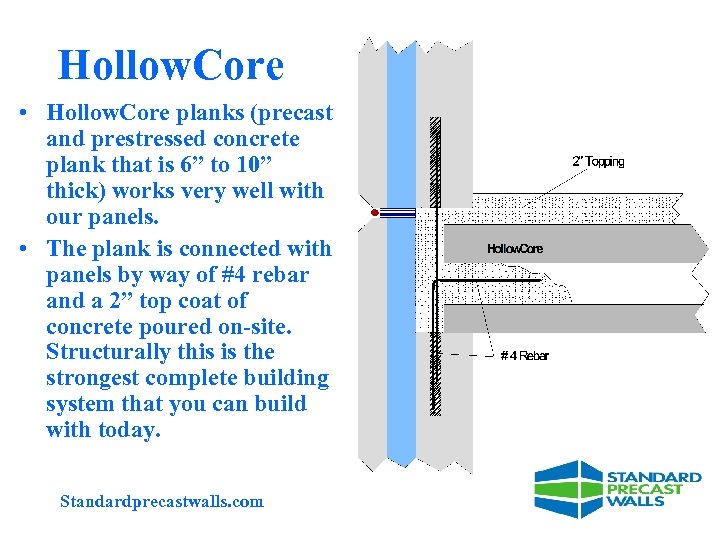

Hollow. Core • Hollow. Core planks (precast and prestressed concrete plank that is 6” to 10” thick) works very well with our panels. • The plank is connected with panels by way of #4 rebar and a 2” top coat of concrete poured on-site. Structurally this is the strongest complete building system that you can build with today. Standardprecastwalls. com

Hollow. Core • Hollow. Core planks (precast and prestressed concrete plank that is 6” to 10” thick) works very well with our panels. • The plank is connected with panels by way of #4 rebar and a 2” top coat of concrete poured on-site. Structurally this is the strongest complete building system that you can build with today. Standardprecastwalls. com

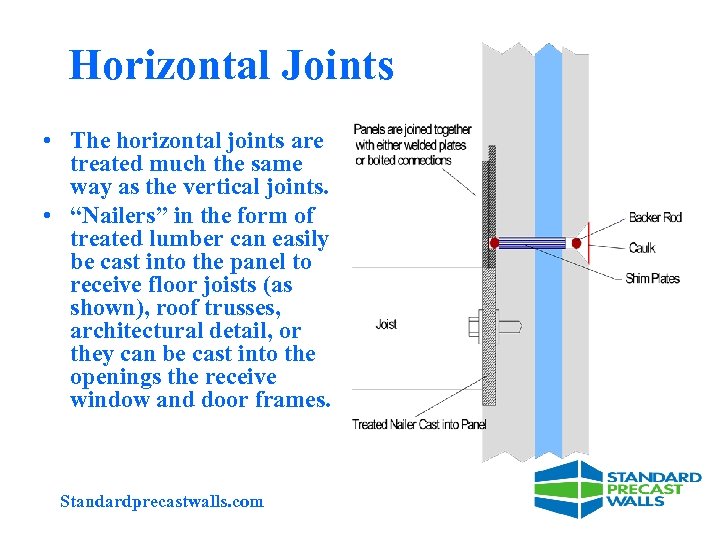

Horizontal Joints • The horizontal joints are treated much the same way as the vertical joints. • “Nailers” in the form of treated lumber can easily be cast into the panel to receive floor joists (as shown), roof trusses, architectural detail, or they can be cast into the openings the receive window and door frames. Standardprecastwalls. com

Horizontal Joints • The horizontal joints are treated much the same way as the vertical joints. • “Nailers” in the form of treated lumber can easily be cast into the panel to receive floor joists (as shown), roof trusses, architectural detail, or they can be cast into the openings the receive window and door frames. Standardprecastwalls. com

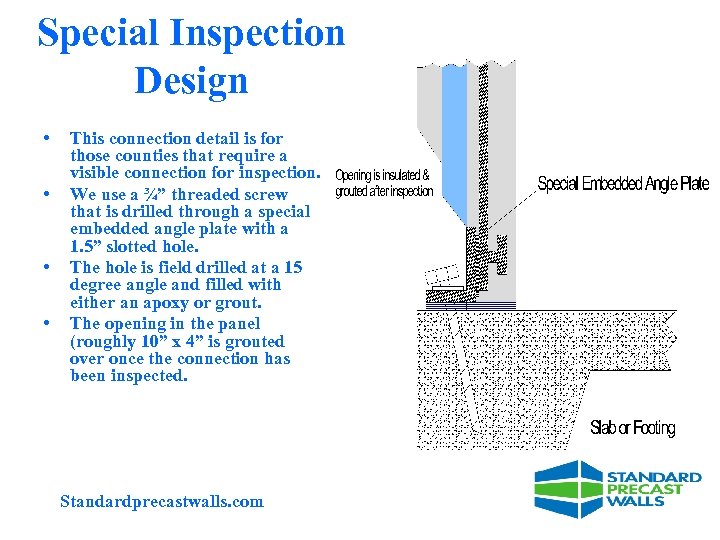

Special Inspection Design • • This connection detail is for those counties that require a visible connection for inspection. We use a ¾” threaded screw that is drilled through a special embedded angle plate with a 1. 5” slotted hole. The hole is field drilled at a 15 degree angle and filled with either an apoxy or grout. The opening in the panel (roughly 10” x 4” is grouted over once the connection has been inspected. Standardprecastwalls. com

Special Inspection Design • • This connection detail is for those counties that require a visible connection for inspection. We use a ¾” threaded screw that is drilled through a special embedded angle plate with a 1. 5” slotted hole. The hole is field drilled at a 15 degree angle and filled with either an apoxy or grout. The opening in the panel (roughly 10” x 4” is grouted over once the connection has been inspected. Standardprecastwalls. com

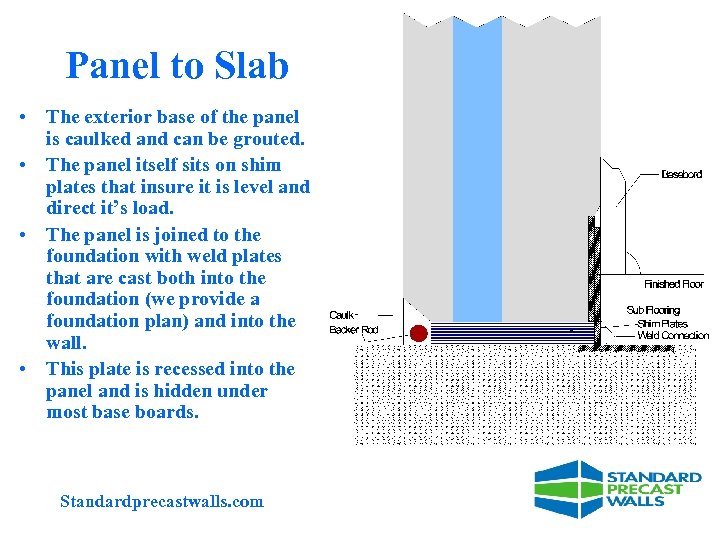

Panel to Slab • The exterior base of the panel is caulked and can be grouted. • The panel itself sits on shim plates that insure it is level and direct it’s load. • The panel is joined to the foundation with weld plates that are cast both into the foundation (we provide a foundation plan) and into the wall. • This plate is recessed into the panel and is hidden under most base boards. Standardprecastwalls. com

Panel to Slab • The exterior base of the panel is caulked and can be grouted. • The panel itself sits on shim plates that insure it is level and direct it’s load. • The panel is joined to the foundation with weld plates that are cast both into the foundation (we provide a foundation plan) and into the wall. • This plate is recessed into the panel and is hidden under most base boards. Standardprecastwalls. com

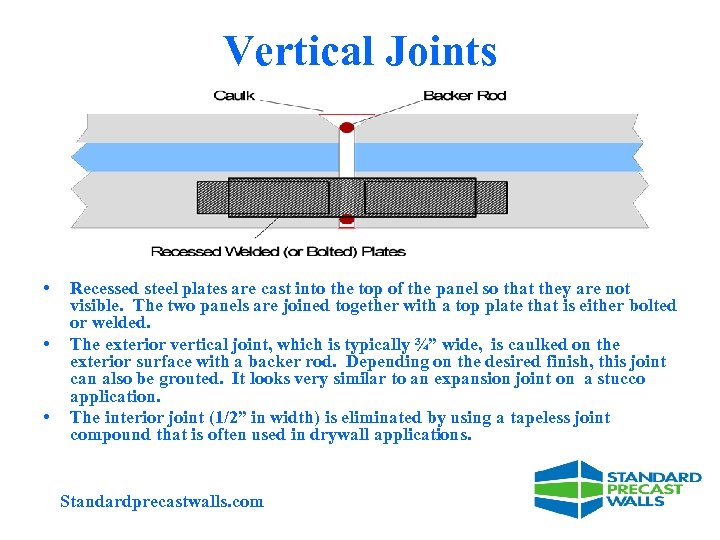

Vertical Joints • • • Recessed steel plates are cast into the top of the panel so that they are not visible. The two panels are joined together with a top plate that is either bolted or welded. The exterior vertical joint, which is typically ¾” wide, is caulked on the exterior surface with a backer rod. Depending on the desired finish, this joint can also be grouted. It looks very similar to an expansion joint on a stucco application. The interior joint (1/2” in width) is eliminated by using a tapeless joint compound that is often used in drywall applications. Standardprecastwalls. com

Vertical Joints • • • Recessed steel plates are cast into the top of the panel so that they are not visible. The two panels are joined together with a top plate that is either bolted or welded. The exterior vertical joint, which is typically ¾” wide, is caulked on the exterior surface with a backer rod. Depending on the desired finish, this joint can also be grouted. It looks very similar to an expansion joint on a stucco application. The interior joint (1/2” in width) is eliminated by using a tapeless joint compound that is often used in drywall applications. Standardprecastwalls. com

Halfon C-Channel Connection • The Halfon C-Channel is cast into the top of the panel. It has 6” studs that anchor it into the structural layer of concrete. A brace like the one shown above is attached to either side of each roof truss. The result is an incredibly strong roof connection. Standardprecastwalls. com

Halfon C-Channel Connection • The Halfon C-Channel is cast into the top of the panel. It has 6” studs that anchor it into the structural layer of concrete. A brace like the one shown above is attached to either side of each roof truss. The result is an incredibly strong roof connection. Standardprecastwalls. com

THE END Please call us at 706. 576. 2661 with any questions, or visit our website: standardprecastwalls. com Standardprecastwalls. com

THE END Please call us at 706. 576. 2661 with any questions, or visit our website: standardprecastwalls. com Standardprecastwalls. com