bc56f0be78560fcaf0be9b107046bae7.ppt

- Количество слайдов: 51

PHASE II Rosemount Product Training RMT Sales Training 12/98 1 Agenda: • Features of various temperature transmitters models • Modular constructional description • RTD Sensor Matching • RTD Sensor Trim • RTD sensor Reference • General specification • Ordering Information • TPE calculation Phase II -Temperature Transmitter

PHASE II Rosemount Product Training RMT Sales Training 12/98 1 Agenda: • Features of various temperature transmitters models • Modular constructional description • RTD Sensor Matching • RTD Sensor Trim • RTD sensor Reference • General specification • Ordering Information • TPE calculation Phase II -Temperature Transmitter

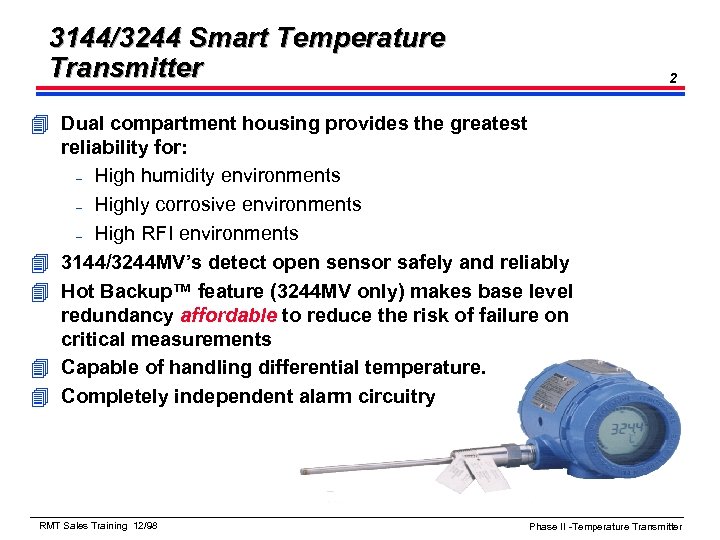

3144/3244 Smart Temperature Transmitter 2 4 Dual compartment housing provides the greatest reliability for: – High humidity environments – Highly corrosive environments – High RFI environments 4 3144/3244 MV’s detect open sensor safely and reliably 4 Hot Backup™ feature (3244 MV only) makes base level redundancy affordable to reduce the risk of failure on critical measurements 4 Capable of handling differential temperature. 4 Completely independent alarm circuitry RMT Sales Training 12/98 Phase II -Temperature Transmitter

3144/3244 Smart Temperature Transmitter 2 4 Dual compartment housing provides the greatest reliability for: – High humidity environments – Highly corrosive environments – High RFI environments 4 3144/3244 MV’s detect open sensor safely and reliably 4 Hot Backup™ feature (3244 MV only) makes base level redundancy affordable to reduce the risk of failure on critical measurements 4 Capable of handling differential temperature. 4 Completely independent alarm circuitry RMT Sales Training 12/98 Phase II -Temperature Transmitter

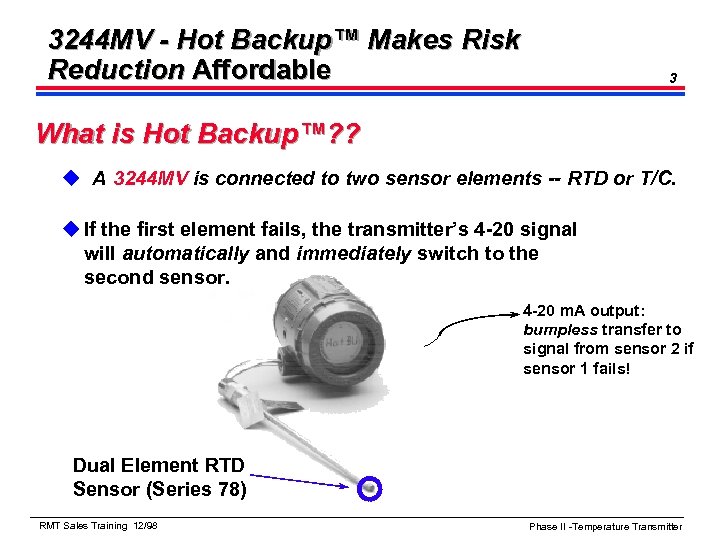

3244 MV - Hot Backup™ Makes Risk Reduction Affordable 3 What is Hot Backup™? ? u A 3244 MV is connected to two sensor elements -- RTD or T/C. u If the first element fails, the transmitter’s 4 -20 signal will automatically and immediately switch to the second sensor. 4 -20 m. A output: bumpless transfer to signal from sensor 2 if sensor 1 fails! Dual Element RTD Sensor (Series 78) RMT Sales Training 12/98 Phase II -Temperature Transmitter

3244 MV - Hot Backup™ Makes Risk Reduction Affordable 3 What is Hot Backup™? ? u A 3244 MV is connected to two sensor elements -- RTD or T/C. u If the first element fails, the transmitter’s 4 -20 signal will automatically and immediately switch to the second sensor. 4 -20 m. A output: bumpless transfer to signal from sensor 2 if sensor 1 fails! Dual Element RTD Sensor (Series 78) RMT Sales Training 12/98 Phase II -Temperature Transmitter

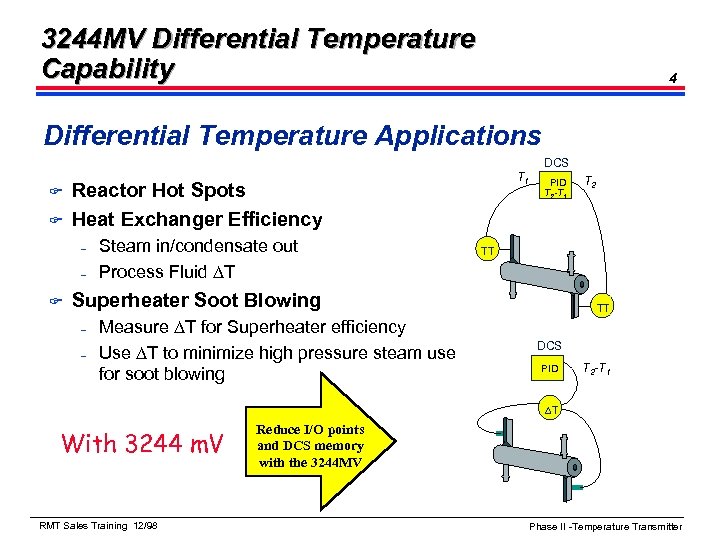

3244 MV Differential Temperature Capability 4 Differential Temperature Applications DCS F F Reactor Hot Spots Heat Exchanger Efficiency – – F T 1 Steam in/condensate out Process Fluid DT PID T 2 -T 1 TT Superheater Soot Blowing – – Measure DT for Superheater efficiency Use DT to minimize high pressure steam use for soot blowing T 2 TT DCS PID T 2 -T 1 DT With 3244 m. V RMT Sales Training 12/98 Reduce I/O points and DCS memory with the 3244 MV Phase II -Temperature Transmitter

3244 MV Differential Temperature Capability 4 Differential Temperature Applications DCS F F Reactor Hot Spots Heat Exchanger Efficiency – – F T 1 Steam in/condensate out Process Fluid DT PID T 2 -T 1 TT Superheater Soot Blowing – – Measure DT for Superheater efficiency Use DT to minimize high pressure steam use for soot blowing T 2 TT DCS PID T 2 -T 1 DT With 3244 m. V RMT Sales Training 12/98 Reduce I/O points and DCS memory with the 3244 MV Phase II -Temperature Transmitter

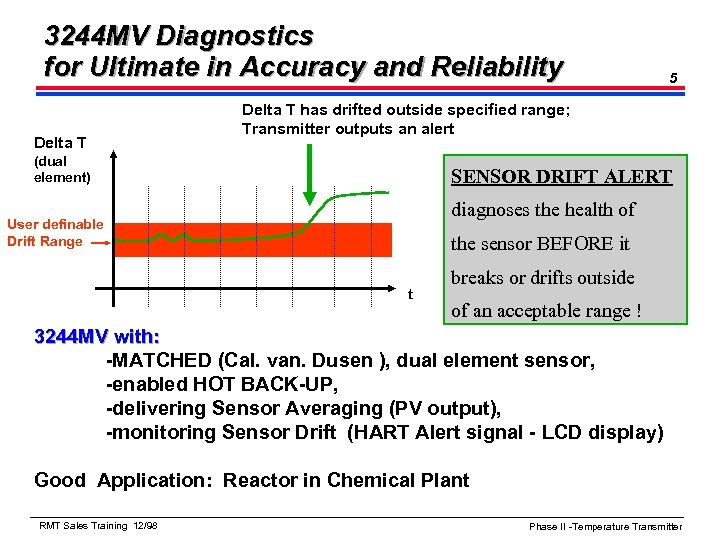

3244 MV Diagnostics for Ultimate in Accuracy and Reliability Delta T 5 Delta T has drifted outside specified range; Transmitter outputs an alert (dual element) SENSOR DRIFT ALERT diagnoses the health of User definable Drift Range the sensor BEFORE it t breaks or drifts outside of an acceptable range ! 3244 MV with: -MATCHED (Cal. van. Dusen ), dual element sensor, -enabled HOT BACK-UP, -delivering Sensor Averaging (PV output), -monitoring Sensor Drift (HART Alert signal - LCD display) Good Application: Reactor in Chemical Plant RMT Sales Training 12/98 Phase II -Temperature Transmitter

3244 MV Diagnostics for Ultimate in Accuracy and Reliability Delta T 5 Delta T has drifted outside specified range; Transmitter outputs an alert (dual element) SENSOR DRIFT ALERT diagnoses the health of User definable Drift Range the sensor BEFORE it t breaks or drifts outside of an acceptable range ! 3244 MV with: -MATCHED (Cal. van. Dusen ), dual element sensor, -enabled HOT BACK-UP, -delivering Sensor Averaging (PV output), -monitoring Sensor Drift (HART Alert signal - LCD display) Good Application: Reactor in Chemical Plant RMT Sales Training 12/98 Phase II -Temperature Transmitter

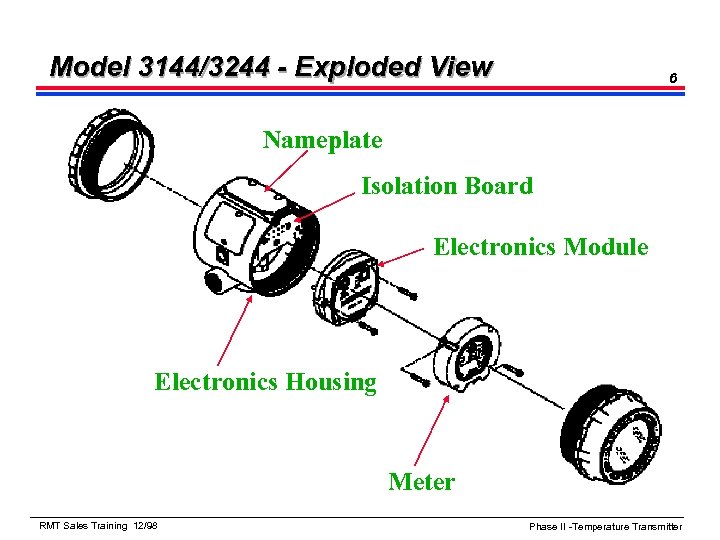

Model 3144/3244 - Exploded View 6 Nameplate Isolation Board Electronics Module Electronics Housing Meter RMT Sales Training 12/98 Phase II -Temperature Transmitter

Model 3144/3244 - Exploded View 6 Nameplate Isolation Board Electronics Module Electronics Housing Meter RMT Sales Training 12/98 Phase II -Temperature Transmitter

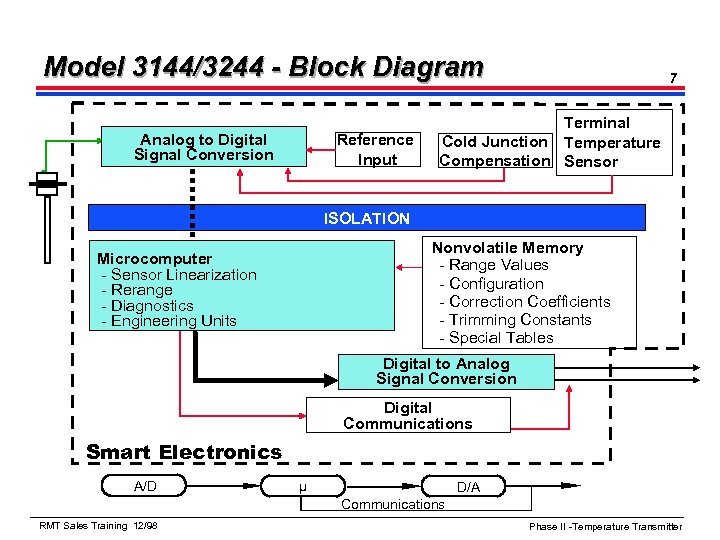

Model 3144/3244 - Block Diagram Analog to Digital Signal Conversion Reference Input 7 Terminal Cold Junction Temperature Compensation Sensor ISOLATION Nonvolatile Memory - Range Values - Configuration - Correction Coefficients - Trimming Constants - Special Tables Microcomputer - Sensor Linearization - Rerange - Diagnostics - Engineering Units Digital to Analog Signal Conversion Digital Communications Smart Electronics A/D µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

Model 3144/3244 - Block Diagram Analog to Digital Signal Conversion Reference Input 7 Terminal Cold Junction Temperature Compensation Sensor ISOLATION Nonvolatile Memory - Range Values - Configuration - Correction Coefficients - Trimming Constants - Special Tables Microcomputer - Sensor Linearization - Rerange - Diagnostics - Engineering Units Digital to Analog Signal Conversion Digital Communications Smart Electronics A/D µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

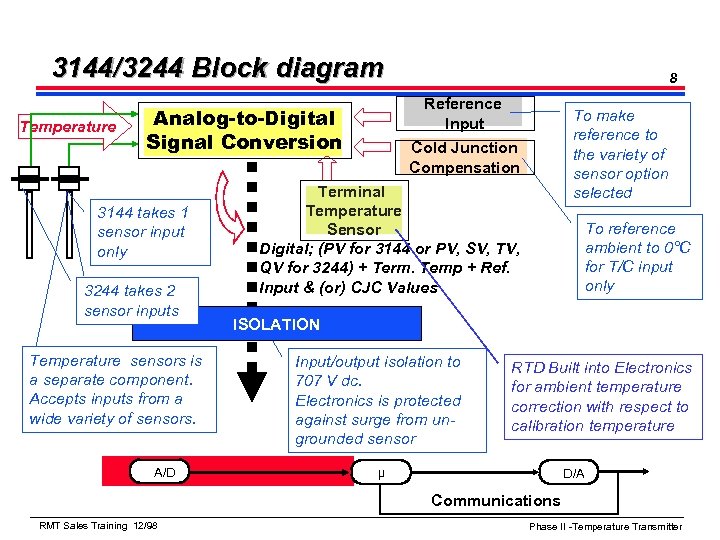

3144/3244 Block diagram Temperature Reference Input Analog-to-Digital Signal Conversion 3144 takes 1 sensor input only 3244 takes 2 sensor inputs Temperature sensors is a separate component. Accepts inputs from a wide variety of sensors. A/D 8 To make reference to the variety of sensor option selected Cold Junction Compensation Terminal Temperature Sensor Digital; (PV for 3144 or PV, SV, TV, QV for 3244) + Term. Temp + Ref. Input & (or) CJC Values To reference ambient to 0°C for T/C input only ISOLATION Input/output isolation to 707 V dc. Electronics is protected against surge from ungrounded sensor RTD Built into Electronics for ambient temperature correction with respect to calibration temperature µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

3144/3244 Block diagram Temperature Reference Input Analog-to-Digital Signal Conversion 3144 takes 1 sensor input only 3244 takes 2 sensor inputs Temperature sensors is a separate component. Accepts inputs from a wide variety of sensors. A/D 8 To make reference to the variety of sensor option selected Cold Junction Compensation Terminal Temperature Sensor Digital; (PV for 3144 or PV, SV, TV, QV for 3244) + Term. Temp + Ref. Input & (or) CJC Values To reference ambient to 0°C for T/C input only ISOLATION Input/output isolation to 707 V dc. Electronics is protected against surge from ungrounded sensor RTD Built into Electronics for ambient temperature correction with respect to calibration temperature µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

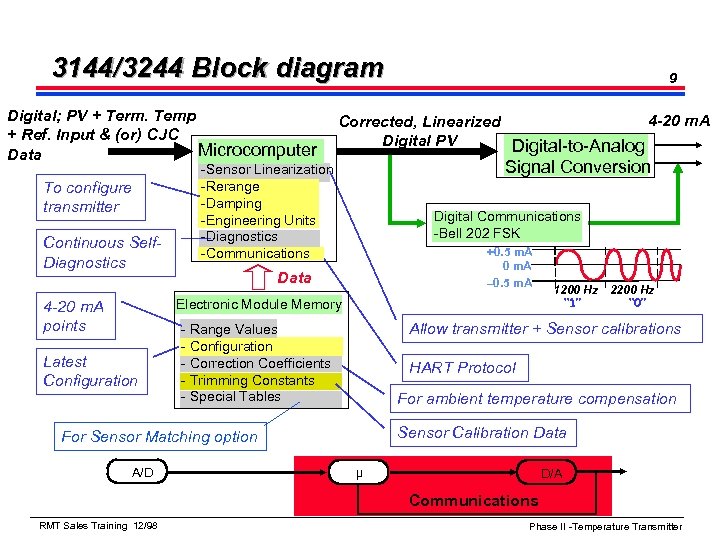

3144/3244 Block diagram Digital; PV + Term. Temp + Ref. Input & (or) CJC Microcomputer Data To configure transmitter Continuous Self. Diagnostics 9 4 -20 m. A Corrected, Linearized Digital PV Digital-to-Analog Signal Conversion -Sensor Linearization -Rerange -Damping -Engineering Units -Diagnostics -Communications Digital Communications -Bell 202 FSK +0. 5 m. A 0 m. A – 0. 5 m. A Data Electronic Module Memory 4 -20 m. A points Latest Configuration Allow transmitter + Sensor calibrations - Range Values - Configuration - Correction Coefficients - Trimming Constants - Special Tables HART Protocol For ambient temperature compensation Sensor Calibration Data For Sensor Matching option A/D 1200 Hz 2200 Hz “ 0” “ 1” µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

3144/3244 Block diagram Digital; PV + Term. Temp + Ref. Input & (or) CJC Microcomputer Data To configure transmitter Continuous Self. Diagnostics 9 4 -20 m. A Corrected, Linearized Digital PV Digital-to-Analog Signal Conversion -Sensor Linearization -Rerange -Damping -Engineering Units -Diagnostics -Communications Digital Communications -Bell 202 FSK +0. 5 m. A 0 m. A – 0. 5 m. A Data Electronic Module Memory 4 -20 m. A points Latest Configuration Allow transmitter + Sensor calibrations - Range Values - Configuration - Correction Coefficients - Trimming Constants - Special Tables HART Protocol For ambient temperature compensation Sensor Calibration Data For Sensor Matching option A/D 1200 Hz 2200 Hz “ 0” “ 1” µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

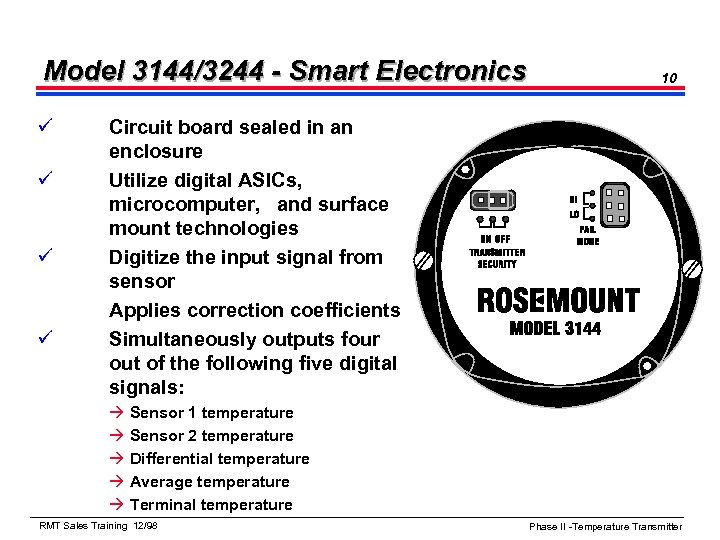

Model 3144/3244 - Smart Electronics ü ü 10 Circuit board sealed in an enclosure Utilize digital ASICs, microcomputer, and surface mount technologies Digitize the input signal from sensor Applies correction coefficients Simultaneously outputs four out of the following five digital signals: à Sensor 1 temperature à Sensor 2 temperature à Differential temperature à Average temperature à Terminal temperature RMT Sales Training 12/98 Phase II -Temperature Transmitter

Model 3144/3244 - Smart Electronics ü ü 10 Circuit board sealed in an enclosure Utilize digital ASICs, microcomputer, and surface mount technologies Digitize the input signal from sensor Applies correction coefficients Simultaneously outputs four out of the following five digital signals: à Sensor 1 temperature à Sensor 2 temperature à Differential temperature à Average temperature à Terminal temperature RMT Sales Training 12/98 Phase II -Temperature Transmitter

3144 & 3244 MV Product Overview Specification F F Digital HART communications superimposed on analog signal Wide variety of user-selectable inputs with 275 HART communicator – u F F F RTDs, T/Cs, m. Vs, Ohms Accuracy – F 11 D/A: ± 0. 02% of span, A/D: ± 0. 1°C for Pt 100 RTDs Turn-on time less than 5. 0 seconds Update time 0. 5 seconds Full approvals available (see PDS) Wide rangeability RMT Sales Training 12/98 Phase II -Temperature Transmitter

3144 & 3244 MV Product Overview Specification F F Digital HART communications superimposed on analog signal Wide variety of user-selectable inputs with 275 HART communicator – u F F F RTDs, T/Cs, m. Vs, Ohms Accuracy – F 11 D/A: ± 0. 02% of span, A/D: ± 0. 1°C for Pt 100 RTDs Turn-on time less than 5. 0 seconds Update time 0. 5 seconds Full approvals available (see PDS) Wide rangeability RMT Sales Training 12/98 Phase II -Temperature Transmitter

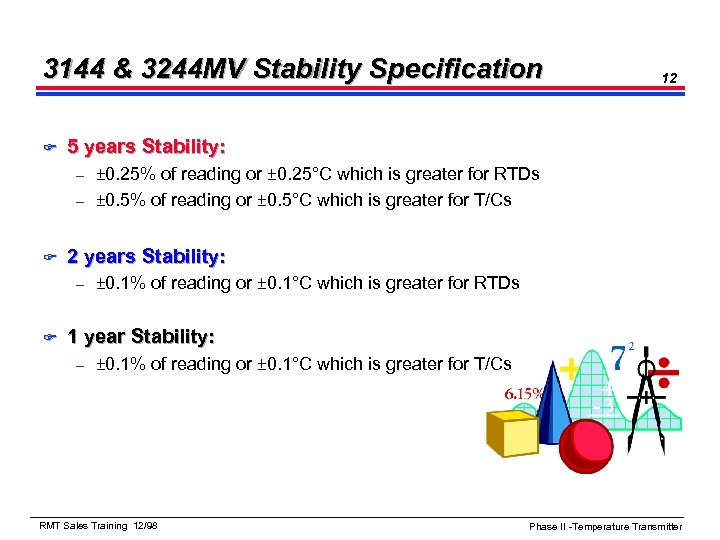

3144 & 3244 MV Stability Specification F 12 5 years Stability: ± 0. 25% of reading or ± 0. 25°C which is greater for RTDs – ± 0. 5% of reading or ± 0. 5°C which is greater for T/Cs – F 2 years Stability: – F ± 0. 1% of reading or ± 0. 1°C which is greater for RTDs 1 year Stability: – ± 0. 1% of reading or ± 0. 1°C which is greater for T/Cs RMT Sales Training 12/98 Phase II -Temperature Transmitter

3144 & 3244 MV Stability Specification F 12 5 years Stability: ± 0. 25% of reading or ± 0. 25°C which is greater for RTDs – ± 0. 5% of reading or ± 0. 5°C which is greater for T/Cs – F 2 years Stability: – F ± 0. 1% of reading or ± 0. 1°C which is greater for RTDs 1 year Stability: – ± 0. 1% of reading or ± 0. 1°C which is greater for T/Cs RMT Sales Training 12/98 Phase II -Temperature Transmitter

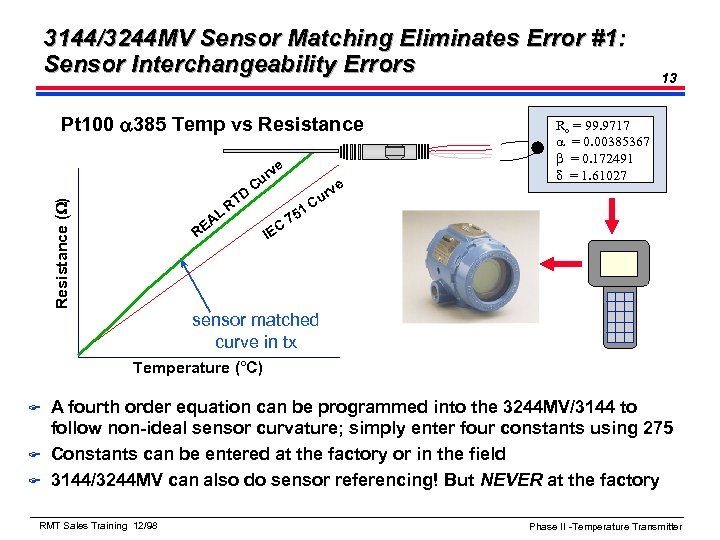

3144/3244 MV Sensor Matching Eliminates Error #1: Sensor Interchangeability Errors Pt 100 a 385 Temp vs Resistance (W) e AL TD v ur e C R RE C IE 1 75 v ur C 13 Ro = 99. 9717 a = 0. 00385367 b = 0. 172491 d = 1. 61027 sensor matched curve in tx Temperature (°C) F F F A fourth order equation can be programmed into the 3244 MV/3144 to follow non-ideal sensor curvature; simply enter four constants using 275 Constants can be entered at the factory or in the field 3144/3244 MV can also do sensor referencing! But NEVER at the factory RMT Sales Training 12/98 Phase II -Temperature Transmitter

3144/3244 MV Sensor Matching Eliminates Error #1: Sensor Interchangeability Errors Pt 100 a 385 Temp vs Resistance (W) e AL TD v ur e C R RE C IE 1 75 v ur C 13 Ro = 99. 9717 a = 0. 00385367 b = 0. 172491 d = 1. 61027 sensor matched curve in tx Temperature (°C) F F F A fourth order equation can be programmed into the 3244 MV/3144 to follow non-ideal sensor curvature; simply enter four constants using 275 Constants can be entered at the factory or in the field 3144/3244 MV can also do sensor referencing! But NEVER at the factory RMT Sales Training 12/98 Phase II -Temperature Transmitter

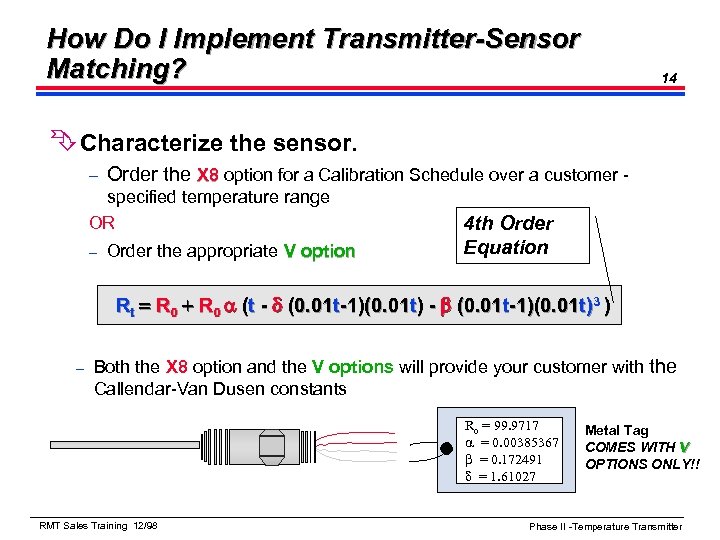

How Do I Implement Transmitter-Sensor Matching? 14 ÊCharacterize the sensor. – Order the X 8 option for a Calibration Schedule over a customer - specified temperature range OR – Order the appropriate V option 4 th Order Equation Rt = R 0 + R 0 a (t - d (0. 01 t-1)(0. 01 t) - b (0. 01 t-1)(0. 01 t)3 ) – Both the X 8 option and the V options will provide your customer with the Callendar-Van Dusen constants Ro = 99. 9717 a = 0. 00385367 b = 0. 172491 d = 1. 61027 RMT Sales Training 12/98 Metal Tag COMES WITH V OPTIONS ONLY!! Phase II -Temperature Transmitter

How Do I Implement Transmitter-Sensor Matching? 14 ÊCharacterize the sensor. – Order the X 8 option for a Calibration Schedule over a customer - specified temperature range OR – Order the appropriate V option 4 th Order Equation Rt = R 0 + R 0 a (t - d (0. 01 t-1)(0. 01 t) - b (0. 01 t-1)(0. 01 t)3 ) – Both the X 8 option and the V options will provide your customer with the Callendar-Van Dusen constants Ro = 99. 9717 a = 0. 00385367 b = 0. 172491 d = 1. 61027 RMT Sales Training 12/98 Metal Tag COMES WITH V OPTIONS ONLY!! Phase II -Temperature Transmitter

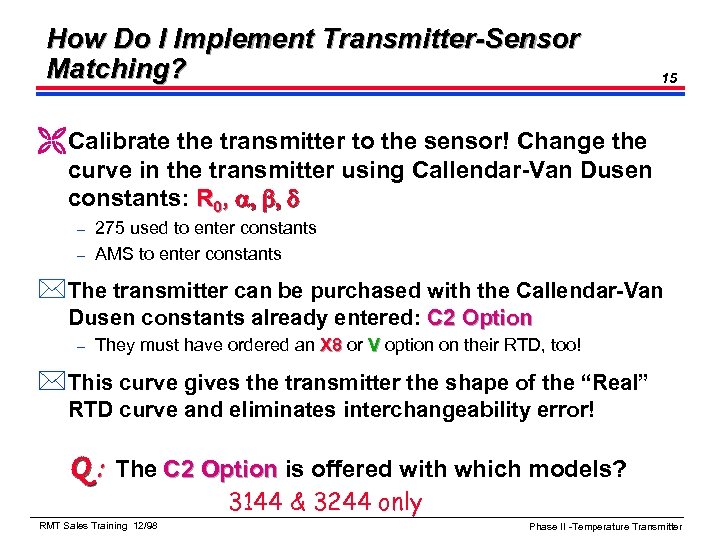

How Do I Implement Transmitter-Sensor Matching? 15 Ë Calibrate the transmitter to the sensor! Change the curve in the transmitter using Callendar-Van Dusen constants: R 0, a, b, d 275 used to enter constants – AMS to enter constants – * The transmitter can be purchased with the Callendar-Van Dusen constants already entered: C 2 Option – They must have ordered an X 8 or V option on their RTD, too! * This curve gives the transmitter the shape of the “Real” RTD curve and eliminates interchangeability error! Q: The C 2 Option is offered with which models? 3144 & 3244 only RMT Sales Training 12/98 Phase II -Temperature Transmitter

How Do I Implement Transmitter-Sensor Matching? 15 Ë Calibrate the transmitter to the sensor! Change the curve in the transmitter using Callendar-Van Dusen constants: R 0, a, b, d 275 used to enter constants – AMS to enter constants – * The transmitter can be purchased with the Callendar-Van Dusen constants already entered: C 2 Option – They must have ordered an X 8 or V option on their RTD, too! * This curve gives the transmitter the shape of the “Real” RTD curve and eliminates interchangeability error! Q: The C 2 Option is offered with which models? 3144 & 3244 only RMT Sales Training 12/98 Phase II -Temperature Transmitter

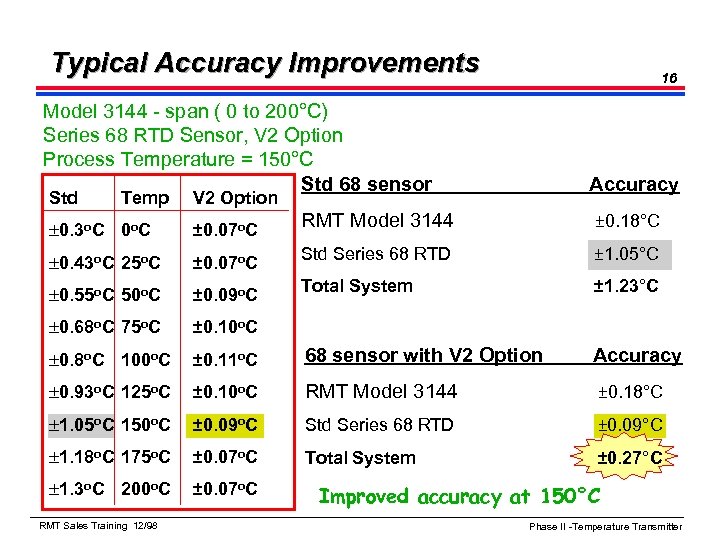

Typical Accuracy Improvements 16 Model 3144 - span ( 0 to 200°C) Series 68 RTD Sensor, V 2 Option Process Temperature = 150°C Std 68 sensor Std Temp Accuracy V 2 Option ± 0. 3 o. C 0 o. C ± 0. 07 o. C RMT Model 3144 ± 0. 18°C ± 0. 43 o. C 25 o. C ± 0. 07 o. C Std Series 68 RTD ± 1. 05°C ± 0. 55 o. C 50 o. C ± 0. 09 o. C Total System ± 1. 23°C ± 0. 68 o. C 75 o. C ± 0. 10 o. C ± 0. 8 o. C 100 o. C ± 0. 11 o. C 68 sensor with V 2 Option Accuracy ± 0. 93 o. C 125 o. C ± 0. 10 o. C RMT Model 3144 ± 0. 18°C ± 1. 05 o. C 150 o. C ± 0. 09 o. C Std Series 68 RTD ± 0. 09°C ± 1. 18 o. C 175 o. C ± 0. 07 o. C Total System ± 0. 27°C ± 1. 3 o. C 200 o. C ± 0. 07 o. C RMT Sales Training 12/98 Improved accuracy at 150°C Phase II -Temperature Transmitter

Typical Accuracy Improvements 16 Model 3144 - span ( 0 to 200°C) Series 68 RTD Sensor, V 2 Option Process Temperature = 150°C Std 68 sensor Std Temp Accuracy V 2 Option ± 0. 3 o. C 0 o. C ± 0. 07 o. C RMT Model 3144 ± 0. 18°C ± 0. 43 o. C 25 o. C ± 0. 07 o. C Std Series 68 RTD ± 1. 05°C ± 0. 55 o. C 50 o. C ± 0. 09 o. C Total System ± 1. 23°C ± 0. 68 o. C 75 o. C ± 0. 10 o. C ± 0. 8 o. C 100 o. C ± 0. 11 o. C 68 sensor with V 2 Option Accuracy ± 0. 93 o. C 125 o. C ± 0. 10 o. C RMT Model 3144 ± 0. 18°C ± 1. 05 o. C 150 o. C ± 0. 09 o. C Std Series 68 RTD ± 0. 09°C ± 1. 18 o. C 175 o. C ± 0. 07 o. C Total System ± 0. 27°C ± 1. 3 o. C 200 o. C ± 0. 07 o. C RMT Sales Training 12/98 Improved accuracy at 150°C Phase II -Temperature Transmitter

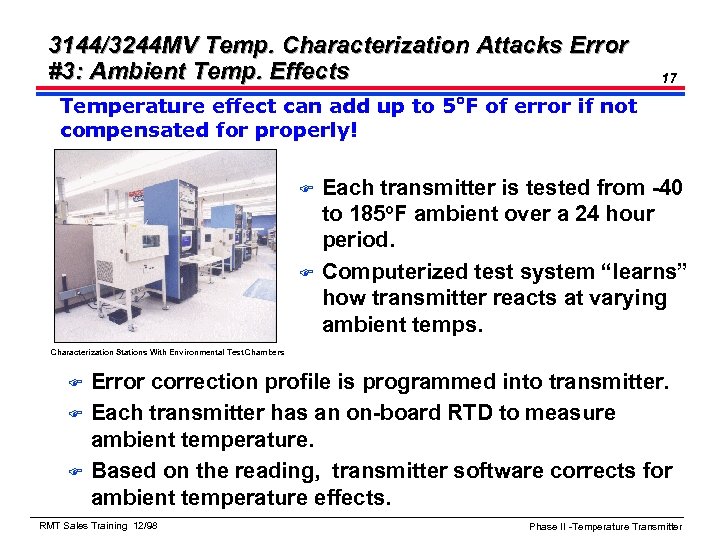

3144/3244 MV Temp. Characterization Attacks Error #3: Ambient Temp. Effects 17 Temperature effect can add up to 5 o. F of error if not compensated for properly! F F Each transmitter is tested from -40 to 185 o. F ambient over a 24 hour period. Computerized test system “learns” how transmitter reacts at varying ambient temps. Characterization Stations With Environmental Test Chambers F F F Error correction profile is programmed into transmitter. Each transmitter has an on-board RTD to measure ambient temperature. Based on the reading, transmitter software corrects for ambient temperature effects. RMT Sales Training 12/98 Phase II -Temperature Transmitter

3144/3244 MV Temp. Characterization Attacks Error #3: Ambient Temp. Effects 17 Temperature effect can add up to 5 o. F of error if not compensated for properly! F F Each transmitter is tested from -40 to 185 o. F ambient over a 24 hour period. Computerized test system “learns” how transmitter reacts at varying ambient temps. Characterization Stations With Environmental Test Chambers F F F Error correction profile is programmed into transmitter. Each transmitter has an on-board RTD to measure ambient temperature. Based on the reading, transmitter software corrects for ambient temperature effects. RMT Sales Training 12/98 Phase II -Temperature Transmitter

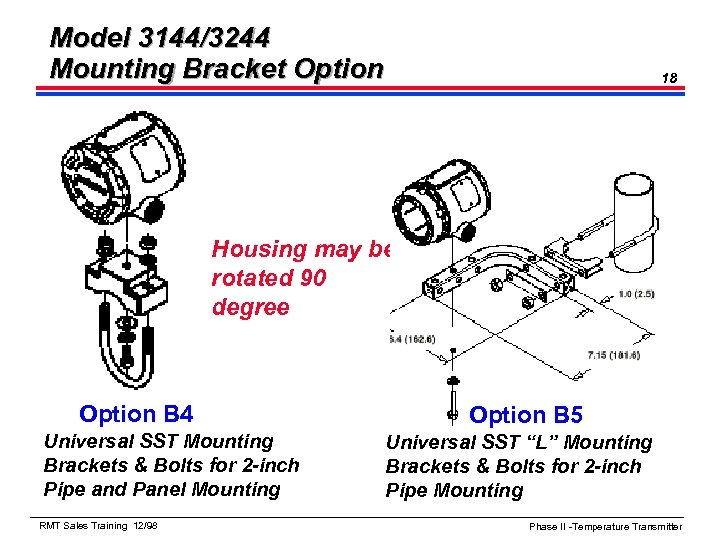

Model 3144/3244 Mounting Bracket Option 18 Housing may be rotated 90 degree Option B 4 Universal SST Mounting Brackets & Bolts for 2 -inch Pipe and Panel Mounting RMT Sales Training 12/98 Option B 5 Universal SST “L” Mounting Brackets & Bolts for 2 -inch Pipe Mounting Phase II -Temperature Transmitter

Model 3144/3244 Mounting Bracket Option 18 Housing may be rotated 90 degree Option B 4 Universal SST Mounting Brackets & Bolts for 2 -inch Pipe and Panel Mounting RMT Sales Training 12/98 Option B 5 Universal SST “L” Mounting Brackets & Bolts for 2 -inch Pipe Mounting Phase II -Temperature Transmitter

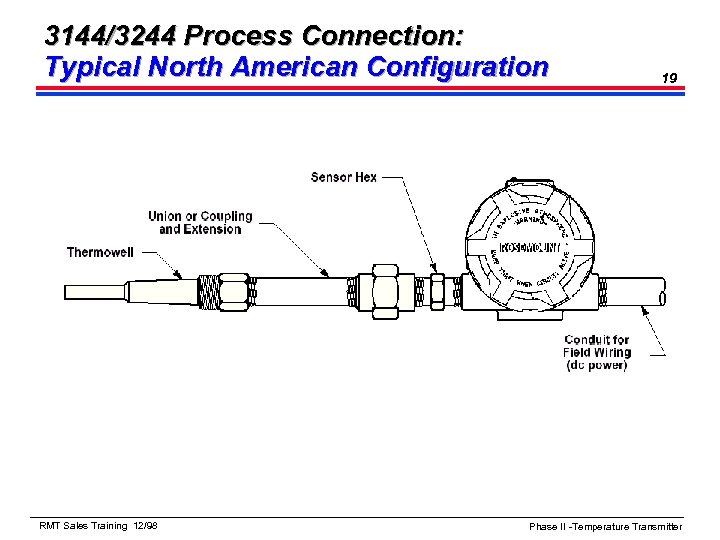

3144/3244 Process Connection: Typical North American Configuration RMT Sales Training 12/98 19 Phase II -Temperature Transmitter

3144/3244 Process Connection: Typical North American Configuration RMT Sales Training 12/98 19 Phase II -Temperature Transmitter

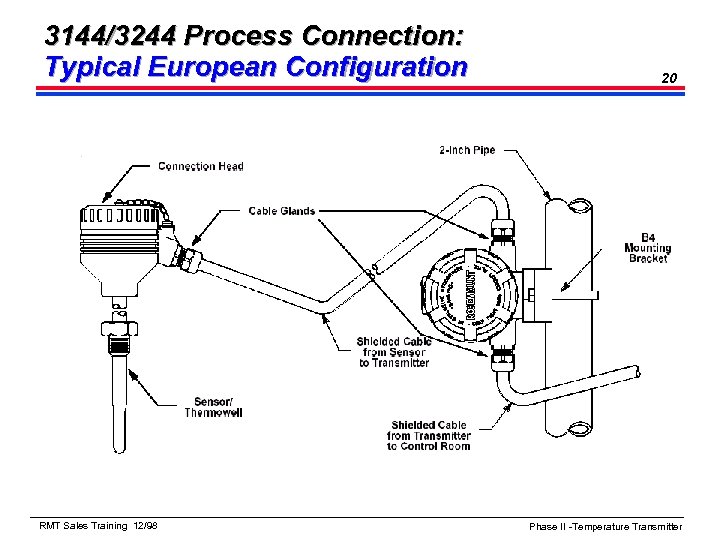

3144/3244 Process Connection: Typical European Configuration RMT Sales Training 12/98 20 Phase II -Temperature Transmitter

3144/3244 Process Connection: Typical European Configuration RMT Sales Training 12/98 20 Phase II -Temperature Transmitter

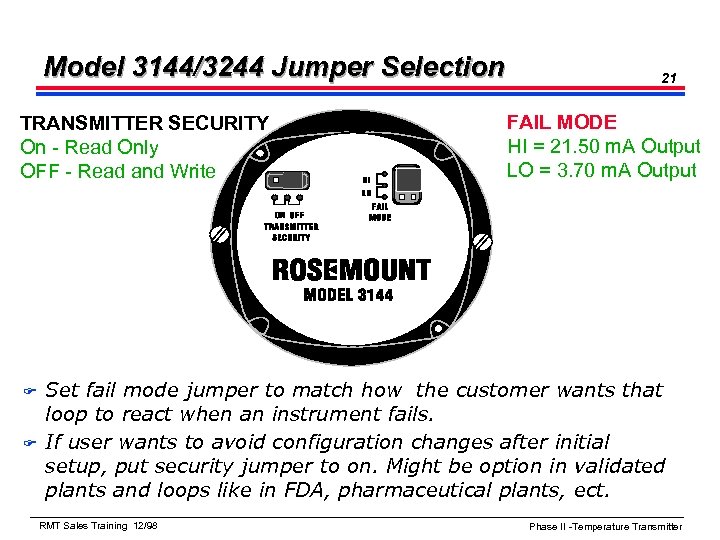

Model 3144/3244 Jumper Selection TRANSMITTER SECURITY On - Read Only OFF - Read and Write F F 21 FAIL MODE HI = 21. 50 m. A Output LO = 3. 70 m. A Output Set fail mode jumper to match how the customer wants that loop to react when an instrument fails. If user wants to avoid configuration changes after initial setup, put security jumper to on. Might be option in validated plants and loops like in FDA, pharmaceutical plants, ect. RMT Sales Training 12/98 Phase II -Temperature Transmitter

Model 3144/3244 Jumper Selection TRANSMITTER SECURITY On - Read Only OFF - Read and Write F F 21 FAIL MODE HI = 21. 50 m. A Output LO = 3. 70 m. A Output Set fail mode jumper to match how the customer wants that loop to react when an instrument fails. If user wants to avoid configuration changes after initial setup, put security jumper to on. Might be option in validated plants and loops like in FDA, pharmaceutical plants, ect. RMT Sales Training 12/98 Phase II -Temperature Transmitter

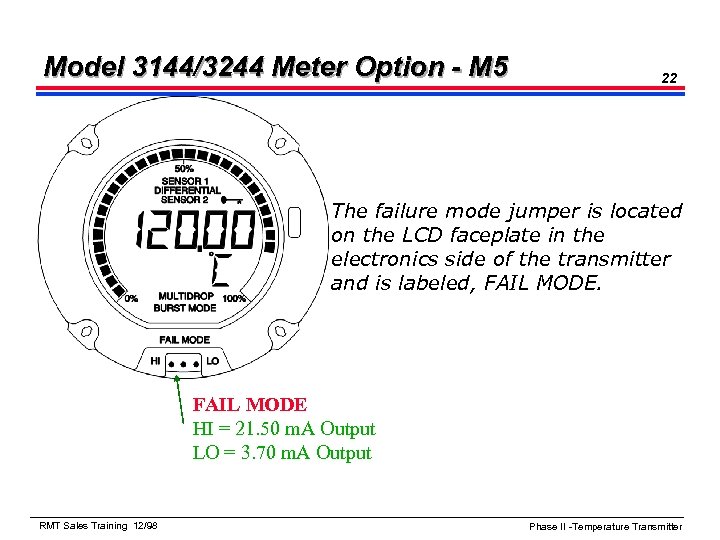

Model 3144/3244 Meter Option - M 5 22 The failure mode jumper is located on the LCD faceplate in the electronics side of the transmitter and is labeled, FAIL MODE HI = 21. 50 m. A Output LO = 3. 70 m. A Output RMT Sales Training 12/98 Phase II -Temperature Transmitter

Model 3144/3244 Meter Option - M 5 22 The failure mode jumper is located on the LCD faceplate in the electronics side of the transmitter and is labeled, FAIL MODE HI = 21. 50 m. A Output LO = 3. 70 m. A Output RMT Sales Training 12/98 Phase II -Temperature Transmitter

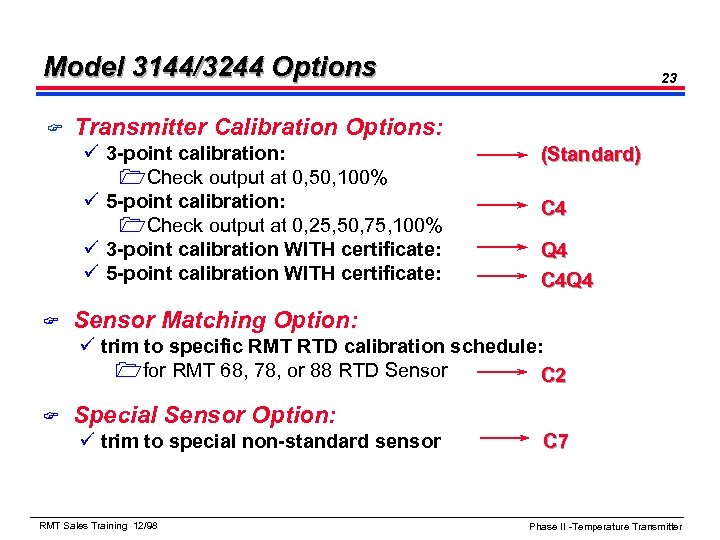

Model 3144/3244 Options F Transmitter Calibration Options: ü 3 -point calibration: 1 Check output at 0, 50, 100% ü 5 -point calibration: 1 Check output at 0, 25, 50, 75, 100% ü 3 -point calibration WITH certificate: ü 5 -point calibration WITH certificate: F 23 (Standard) C 4 Q 4 C 4 Q 4 Sensor Matching Option: ü trim to specific RMT RTD calibration schedule: 1 for RMT 68, 78, or 88 RTD Sensor C 2 F Special Sensor Option: ü trim to special non-standard sensor RMT Sales Training 12/98 C 7 Phase II -Temperature Transmitter

Model 3144/3244 Options F Transmitter Calibration Options: ü 3 -point calibration: 1 Check output at 0, 50, 100% ü 5 -point calibration: 1 Check output at 0, 25, 50, 75, 100% ü 3 -point calibration WITH certificate: ü 5 -point calibration WITH certificate: F 23 (Standard) C 4 Q 4 C 4 Q 4 Sensor Matching Option: ü trim to specific RMT RTD calibration schedule: 1 for RMT 68, 78, or 88 RTD Sensor C 2 F Special Sensor Option: ü trim to special non-standard sensor RMT Sales Training 12/98 C 7 Phase II -Temperature Transmitter

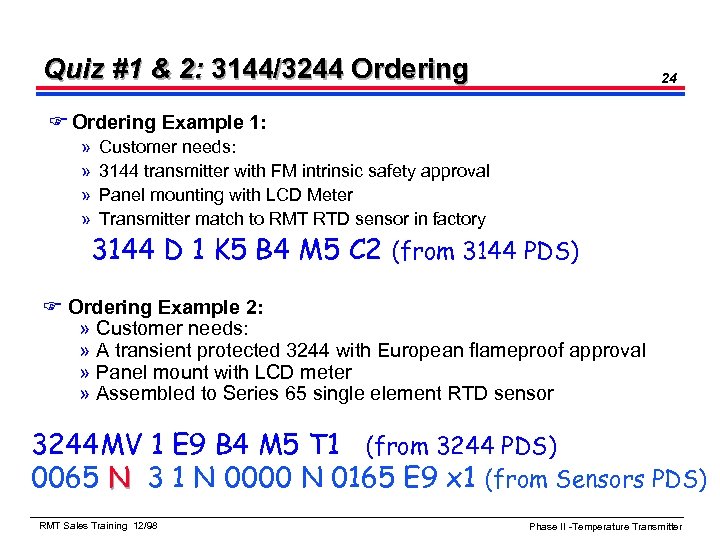

Quiz #1 & 2: 3144/3244 Ordering 24 F Ordering Example 1: » » Customer needs: 3144 transmitter with FM intrinsic safety approval Panel mounting with LCD Meter Transmitter match to RMT RTD sensor in factory 3144 D 1 K 5 B 4 M 5 C 2 (from 3144 PDS) F Ordering Example 2: » Customer needs: » A transient protected 3244 with European flameproof approval » Panel mount with LCD meter » Assembled to Series 65 single element RTD sensor 3244 MV 1 E 9 B 4 M 5 T 1 (from 3244 PDS) 0065 N 3 1 N 0000 N 0165 E 9 x 1 (from Sensors PDS) RMT Sales Training 12/98 Phase II -Temperature Transmitter

Quiz #1 & 2: 3144/3244 Ordering 24 F Ordering Example 1: » » Customer needs: 3144 transmitter with FM intrinsic safety approval Panel mounting with LCD Meter Transmitter match to RMT RTD sensor in factory 3144 D 1 K 5 B 4 M 5 C 2 (from 3144 PDS) F Ordering Example 2: » Customer needs: » A transient protected 3244 with European flameproof approval » Panel mount with LCD meter » Assembled to Series 65 single element RTD sensor 3244 MV 1 E 9 B 4 M 5 T 1 (from 3244 PDS) 0065 N 3 1 N 0000 N 0165 E 9 x 1 (from Sensors PDS) RMT Sales Training 12/98 Phase II -Temperature Transmitter

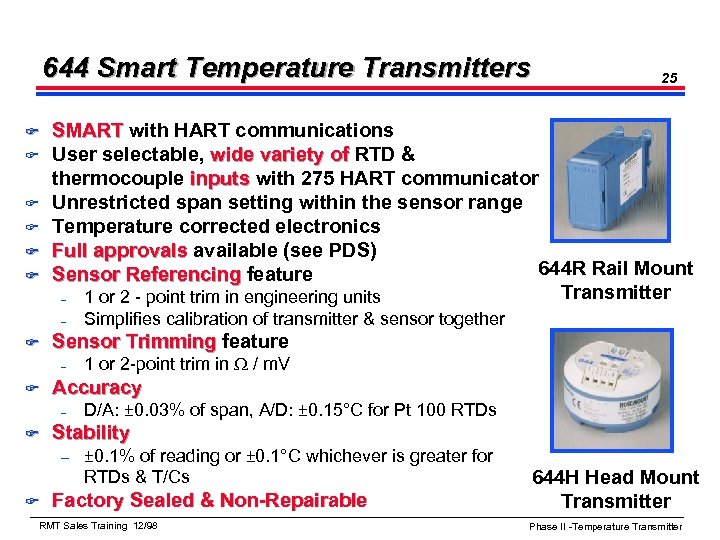

644 Smart Temperature Transmitters F F F SMART with HART communications User selectable, wide variety of RTD & thermocouple inputs with 275 HART communicator Unrestricted span setting within the sensor range Temperature corrected electronics Full approvals available (see PDS) 644 R Rail Mount Sensor Referencing feature Transmitter – 1 or 2 - point trim in engineering units – F D/A: ± 0. 03% of span, A/D: ± 0. 15°C for Pt 100 RTDs Stability – F 1 or 2 -point trim in / m. V Accuracy – F Simplifies calibration of transmitter & sensor together Sensor Trimming feature – F 25 ± 0. 1% of reading or ± 0. 1°C whichever is greater for RTDs & T/Cs Factory Sealed & Non-Repairable RMT Sales Training 12/98 644 H Head Mount Transmitter Phase II -Temperature Transmitter

644 Smart Temperature Transmitters F F F SMART with HART communications User selectable, wide variety of RTD & thermocouple inputs with 275 HART communicator Unrestricted span setting within the sensor range Temperature corrected electronics Full approvals available (see PDS) 644 R Rail Mount Sensor Referencing feature Transmitter – 1 or 2 - point trim in engineering units – F D/A: ± 0. 03% of span, A/D: ± 0. 15°C for Pt 100 RTDs Stability – F 1 or 2 -point trim in / m. V Accuracy – F Simplifies calibration of transmitter & sensor together Sensor Trimming feature – F 25 ± 0. 1% of reading or ± 0. 1°C whichever is greater for RTDs & T/Cs Factory Sealed & Non-Repairable RMT Sales Training 12/98 644 H Head Mount Transmitter Phase II -Temperature Transmitter

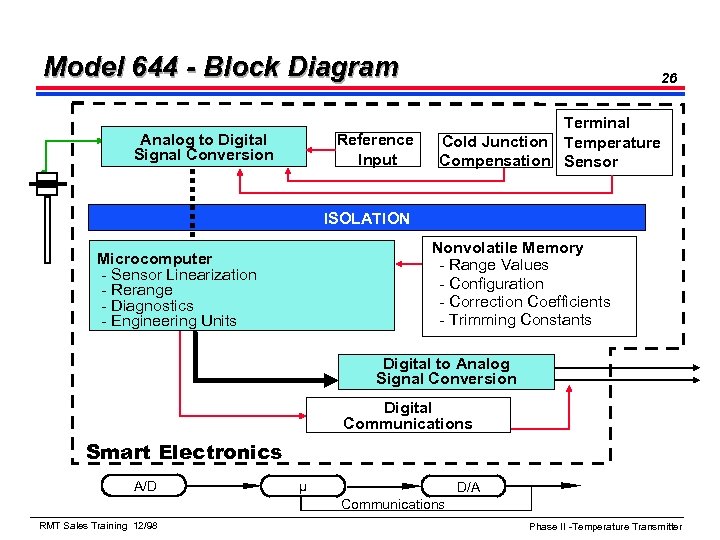

Model 644 - Block Diagram Analog to Digital Signal Conversion Reference Input 26 Terminal Cold Junction Temperature Compensation Sensor ISOLATION Nonvolatile Memory - Range Values - Configuration - Correction Coefficients - Trimming Constants Microcomputer - Sensor Linearization - Rerange - Diagnostics - Engineering Units Digital to Analog Signal Conversion Digital Communications Smart Electronics A/D µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

Model 644 - Block Diagram Analog to Digital Signal Conversion Reference Input 26 Terminal Cold Junction Temperature Compensation Sensor ISOLATION Nonvolatile Memory - Range Values - Configuration - Correction Coefficients - Trimming Constants Microcomputer - Sensor Linearization - Rerange - Diagnostics - Engineering Units Digital to Analog Signal Conversion Digital Communications Smart Electronics A/D µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

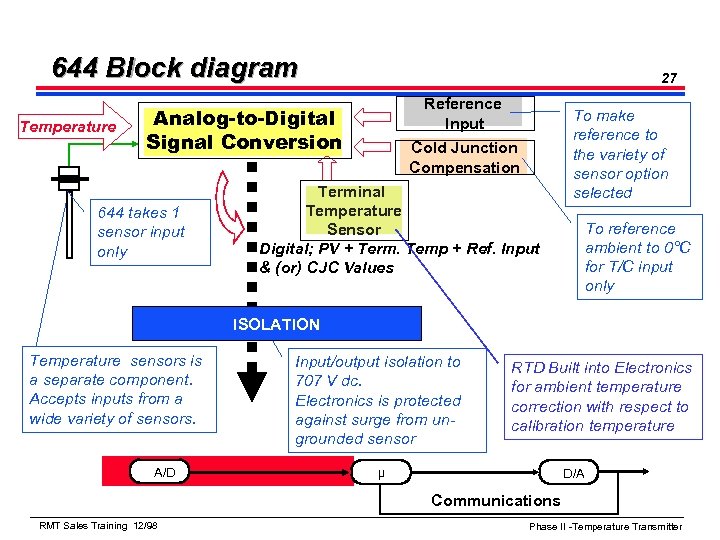

644 Block diagram Temperature 27 Reference Input Analog-to-Digital Signal Conversion 644 takes 1 sensor input only Cold Junction Compensation Terminal Temperature Sensor Digital; PV + Term. Temp + Ref. Input & (or) CJC Values To make reference to the variety of sensor option selected To reference ambient to 0°C for T/C input only ISOLATION Temperature sensors is a separate component. Accepts inputs from a wide variety of sensors. A/D Input/output isolation to 707 V dc. Electronics is protected against surge from ungrounded sensor RTD Built into Electronics for ambient temperature correction with respect to calibration temperature µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

644 Block diagram Temperature 27 Reference Input Analog-to-Digital Signal Conversion 644 takes 1 sensor input only Cold Junction Compensation Terminal Temperature Sensor Digital; PV + Term. Temp + Ref. Input & (or) CJC Values To make reference to the variety of sensor option selected To reference ambient to 0°C for T/C input only ISOLATION Temperature sensors is a separate component. Accepts inputs from a wide variety of sensors. A/D Input/output isolation to 707 V dc. Electronics is protected against surge from ungrounded sensor RTD Built into Electronics for ambient temperature correction with respect to calibration temperature µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

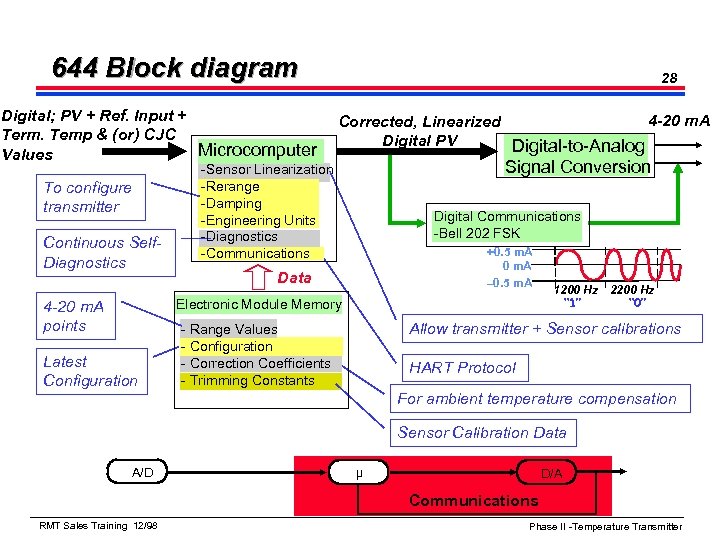

644 Block diagram Digital; PV + Ref. Input + Term. Temp & (or) CJC Microcomputer Values To configure transmitter Continuous Self. Diagnostics 28 4 -20 m. A Corrected, Linearized Digital PV Digital-to-Analog Signal Conversion -Sensor Linearization -Rerange -Damping -Engineering Units -Diagnostics -Communications Digital Communications -Bell 202 FSK +0. 5 m. A 0 m. A – 0. 5 m. A Data Electronic Module Memory 4 -20 m. A points Latest Configuration 1200 Hz 2200 Hz “ 0” “ 1” Allow transmitter + Sensor calibrations - Range Values - Configuration - Correction Coefficients - Trimming Constants HART Protocol For ambient temperature compensation Sensor Calibration Data A/D µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

644 Block diagram Digital; PV + Ref. Input + Term. Temp & (or) CJC Microcomputer Values To configure transmitter Continuous Self. Diagnostics 28 4 -20 m. A Corrected, Linearized Digital PV Digital-to-Analog Signal Conversion -Sensor Linearization -Rerange -Damping -Engineering Units -Diagnostics -Communications Digital Communications -Bell 202 FSK +0. 5 m. A 0 m. A – 0. 5 m. A Data Electronic Module Memory 4 -20 m. A points Latest Configuration 1200 Hz 2200 Hz “ 0” “ 1” Allow transmitter + Sensor calibrations - Range Values - Configuration - Correction Coefficients - Trimming Constants HART Protocol For ambient temperature compensation Sensor Calibration Data A/D µ D/A Communications RMT Sales Training 12/98 Phase II -Temperature Transmitter

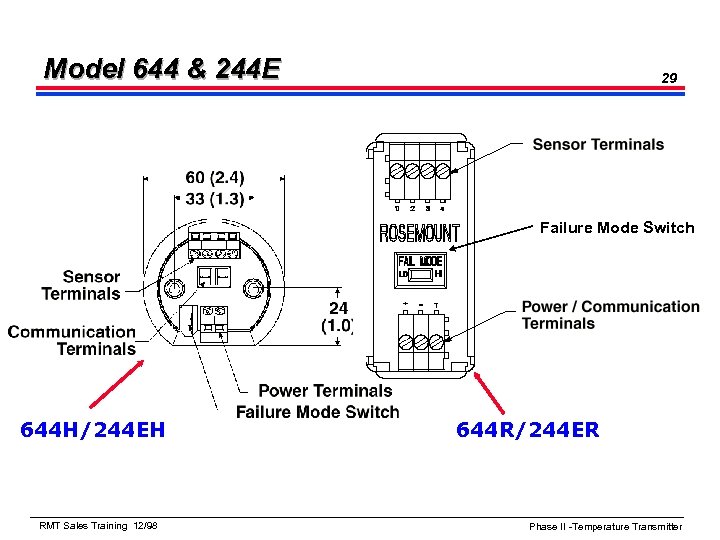

Model 644 & 244 E 29 Failure Mode Switch 644 H/244 EH RMT Sales Training 12/98 644 R/244 ER Phase II -Temperature Transmitter

Model 644 & 244 E 29 Failure Mode Switch 644 H/244 EH RMT Sales Training 12/98 644 R/244 ER Phase II -Temperature Transmitter

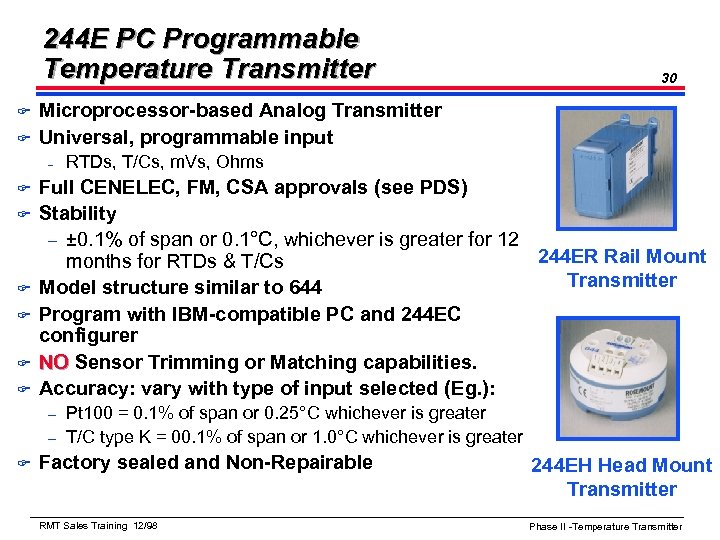

244 E PC Programmable Temperature Transmitter F F Microprocessor-based Analog Transmitter Universal, programmable input – F F F 30 RTDs, T/Cs, m. Vs, Ohms Full CENELEC, FM, CSA approvals (see PDS) Stability – ± 0. 1% of span or 0. 1°C, whichever is greater for 12 244 ER Rail Mount months for RTDs & T/Cs Transmitter Model structure similar to 644 Program with IBM-compatible PC and 244 EC configurer NO Sensor Trimming or Matching capabilities. Accuracy: vary with type of input selected (Eg. ): Pt 100 = 0. 1% of span or 0. 25°C whichever is greater – T/C type K = 00. 1% of span or 1. 0°C whichever is greater – F Factory sealed and Non-Repairable 244 EH Head Mount Transmitter RMT Sales Training 12/98 Phase II -Temperature Transmitter

244 E PC Programmable Temperature Transmitter F F Microprocessor-based Analog Transmitter Universal, programmable input – F F F 30 RTDs, T/Cs, m. Vs, Ohms Full CENELEC, FM, CSA approvals (see PDS) Stability – ± 0. 1% of span or 0. 1°C, whichever is greater for 12 244 ER Rail Mount months for RTDs & T/Cs Transmitter Model structure similar to 644 Program with IBM-compatible PC and 244 EC configurer NO Sensor Trimming or Matching capabilities. Accuracy: vary with type of input selected (Eg. ): Pt 100 = 0. 1% of span or 0. 25°C whichever is greater – T/C type K = 00. 1% of span or 1. 0°C whichever is greater – F Factory sealed and Non-Repairable 244 EH Head Mount Transmitter RMT Sales Training 12/98 Phase II -Temperature Transmitter

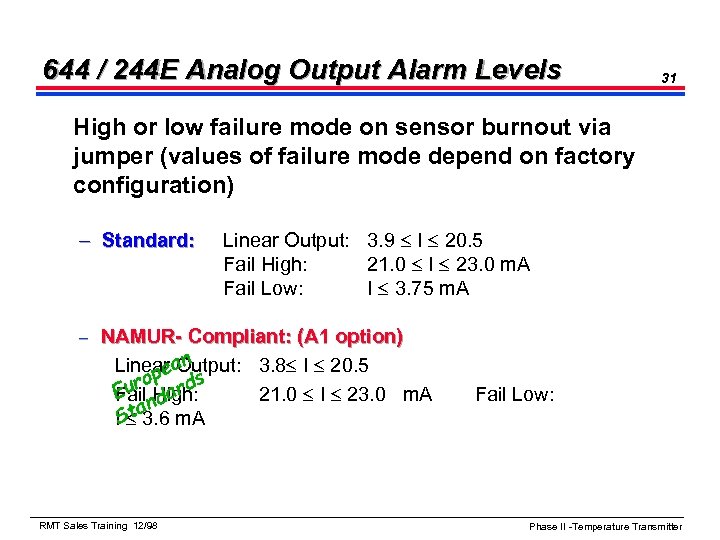

644 / 244 E Analog Output Alarm Levels 31 High or low failure mode on sensor burnout via jumper (values of failure mode depend on factory configuration) – Standard: – Linear Output: 3. 9 I 20. 5 Fail High: 21. 0 I 23. 0 m. A Fail Low: I 3. 75 m. A NAMUR- Compliant: (A 1 option) Linear an pe Output: 3. 8 I 20. 5 ro rds Eu High: Fail nda 21. 0 I 23. 0 m. A a m. A ISt 3. 6 RMT Sales Training 12/98 Fail Low: Phase II -Temperature Transmitter

644 / 244 E Analog Output Alarm Levels 31 High or low failure mode on sensor burnout via jumper (values of failure mode depend on factory configuration) – Standard: – Linear Output: 3. 9 I 20. 5 Fail High: 21. 0 I 23. 0 m. A Fail Low: I 3. 75 m. A NAMUR- Compliant: (A 1 option) Linear an pe Output: 3. 8 I 20. 5 ro rds Eu High: Fail nda 21. 0 I 23. 0 m. A a m. A ISt 3. 6 RMT Sales Training 12/98 Fail Low: Phase II -Temperature Transmitter

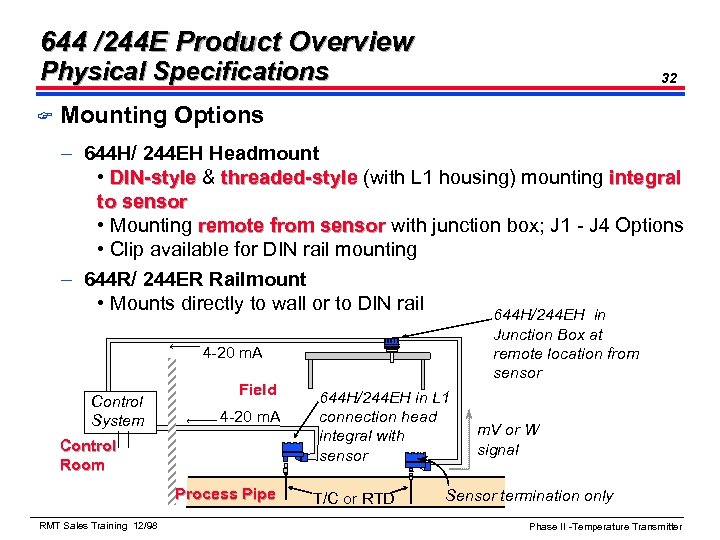

644 /244 E Product Overview Physical Specifications F 32 Mounting Options – 644 H/ 244 EH Headmount • DIN-style & threaded-style (with L 1 housing) mounting integral to sensor • Mounting remote from sensor with junction box; J 1 - J 4 Options • Clip available for DIN rail mounting – 644 R/ 244 ER Railmount • Mounts directly to wall or to DIN rail 644 H/244 EH in Junction Box at remote location from sensor 4 -20 m. A Control System Field 4 -20 m. A Control Room Process Pipe RMT Sales Training 12/98 644 H/244 EH in L 1 connection head integral with sensor T/C or RTD m. V or W signal Sensor termination only Phase II -Temperature Transmitter

644 /244 E Product Overview Physical Specifications F 32 Mounting Options – 644 H/ 244 EH Headmount • DIN-style & threaded-style (with L 1 housing) mounting integral to sensor • Mounting remote from sensor with junction box; J 1 - J 4 Options • Clip available for DIN rail mounting – 644 R/ 244 ER Railmount • Mounts directly to wall or to DIN rail 644 H/244 EH in Junction Box at remote location from sensor 4 -20 m. A Control System Field 4 -20 m. A Control Room Process Pipe RMT Sales Training 12/98 644 H/244 EH in L 1 connection head integral with sensor T/C or RTD m. V or W signal Sensor termination only Phase II -Temperature Transmitter

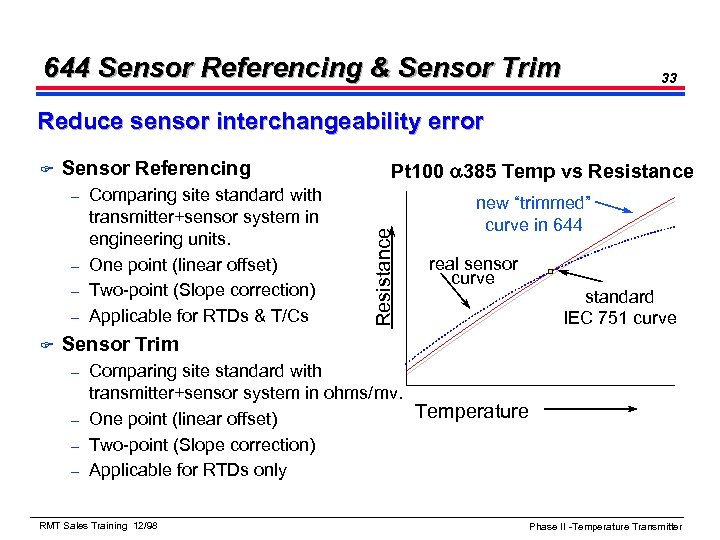

644 Sensor Referencing & Sensor Trim 33 Reduce sensor interchangeability error F Sensor Referencing Comparing site standard with transmitter+sensor system in engineering units. – One point (linear offset) – Two-point (Slope correction) – Applicable for RTDs & T/Cs Pt 100 a 385 Temp vs Resistance F Resistance – new “trimmed” curve in 644 real sensor curve standard IEC 751 curve Sensor Trim Comparing site standard with transmitter+sensor system in ohms/mv. Temperature – One point (linear offset) – Two-point (Slope correction) – Applicable for RTDs only – RMT Sales Training 12/98 Phase II -Temperature Transmitter

644 Sensor Referencing & Sensor Trim 33 Reduce sensor interchangeability error F Sensor Referencing Comparing site standard with transmitter+sensor system in engineering units. – One point (linear offset) – Two-point (Slope correction) – Applicable for RTDs & T/Cs Pt 100 a 385 Temp vs Resistance F Resistance – new “trimmed” curve in 644 real sensor curve standard IEC 751 curve Sensor Trim Comparing site standard with transmitter+sensor system in ohms/mv. Temperature – One point (linear offset) – Two-point (Slope correction) – Applicable for RTDs only – RMT Sales Training 12/98 Phase II -Temperature Transmitter

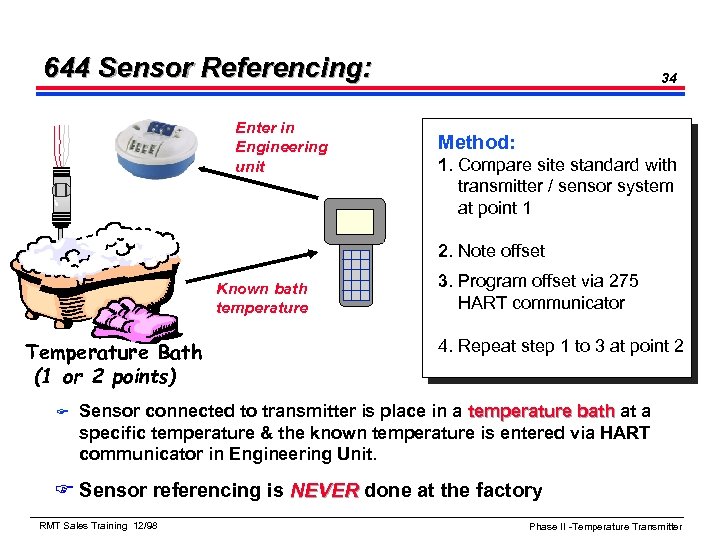

644 Sensor Referencing: Enter in Engineering unit 34 Method: 1. Compare site standard with transmitter / sensor system at point 1 2. Note offset Known bath temperature Temperature Bath (1 or 2 points) F 3. Program offset via 275 HART communicator 4. Repeat step 1 to 3 at point 2 Sensor connected to transmitter is place in a temperature bath at a specific temperature & the known temperature is entered via HART communicator in Engineering Unit. F Sensor referencing is NEVER done at the factory RMT Sales Training 12/98 Phase II -Temperature Transmitter

644 Sensor Referencing: Enter in Engineering unit 34 Method: 1. Compare site standard with transmitter / sensor system at point 1 2. Note offset Known bath temperature Temperature Bath (1 or 2 points) F 3. Program offset via 275 HART communicator 4. Repeat step 1 to 3 at point 2 Sensor connected to transmitter is place in a temperature bath at a specific temperature & the known temperature is entered via HART communicator in Engineering Unit. F Sensor referencing is NEVER done at the factory RMT Sales Training 12/98 Phase II -Temperature Transmitter

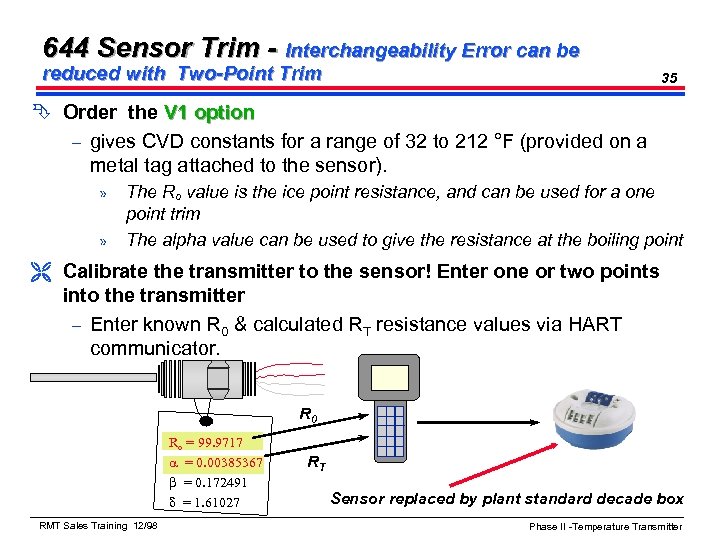

644 Sensor Trim - Interchangeability Error can be reduced with Two-Point Trim 35 Ê Order the V 1 option – gives CVD constants for a range of 32 to 212 °F (provided on a metal tag attached to the sensor). » » The Ro value is the ice point resistance, and can be used for a one point trim The alpha value can be used to give the resistance at the boiling point Ë Calibrate the transmitter to the sensor! Enter one or two points into the transmitter – Enter known R 0 & calculated RT resistance values via HART communicator. R 0 Ro = 99. 9717 a = 0. 00385367 b = 0. 172491 d = 1. 61027 RMT Sales Training 12/98 RT Sensor replaced by plant standard decade box Phase II -Temperature Transmitter

644 Sensor Trim - Interchangeability Error can be reduced with Two-Point Trim 35 Ê Order the V 1 option – gives CVD constants for a range of 32 to 212 °F (provided on a metal tag attached to the sensor). » » The Ro value is the ice point resistance, and can be used for a one point trim The alpha value can be used to give the resistance at the boiling point Ë Calibrate the transmitter to the sensor! Enter one or two points into the transmitter – Enter known R 0 & calculated RT resistance values via HART communicator. R 0 Ro = 99. 9717 a = 0. 00385367 b = 0. 172491 d = 1. 61027 RMT Sales Training 12/98 RT Sensor replaced by plant standard decade box Phase II -Temperature Transmitter

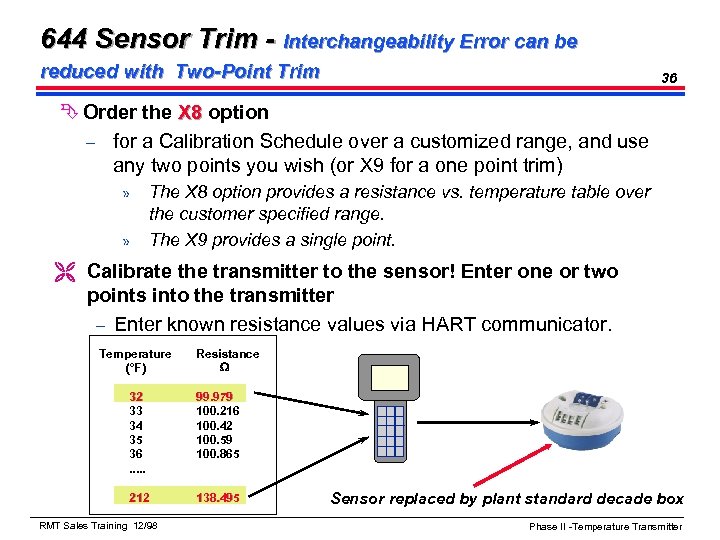

644 Sensor Trim - Interchangeability Error can be reduced with Two-Point Trim 36 Ê Order the X 8 option – for a Calibration Schedule over a customized range, and use any two points you wish (or X 9 for a one point trim) » » The X 8 option provides a resistance vs. temperature table over the customer specified range. The X 9 provides a single point. Ë Calibrate the transmitter to the sensor! Enter one or two points into the transmitter – Enter known resistance values via HART communicator. Temperature (°F) Resistance W 32 33 34 35 36. . . 99. 979 100. 216 100. 42 100. 59 100. 865 212 138. 495 RMT Sales Training 12/98 Sensor replaced by plant standard decade box Phase II -Temperature Transmitter

644 Sensor Trim - Interchangeability Error can be reduced with Two-Point Trim 36 Ê Order the X 8 option – for a Calibration Schedule over a customized range, and use any two points you wish (or X 9 for a one point trim) » » The X 8 option provides a resistance vs. temperature table over the customer specified range. The X 9 provides a single point. Ë Calibrate the transmitter to the sensor! Enter one or two points into the transmitter – Enter known resistance values via HART communicator. Temperature (°F) Resistance W 32 33 34 35 36. . . 99. 979 100. 216 100. 42 100. 59 100. 865 212 138. 495 RMT Sales Training 12/98 Sensor replaced by plant standard decade box Phase II -Temperature Transmitter

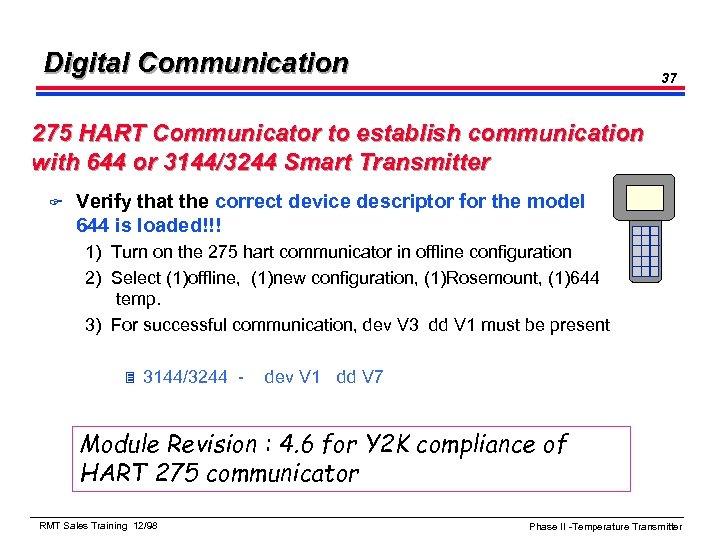

Digital Communication 37 275 HART Communicator to establish communication with 644 or 3144/3244 Smart Transmitter F Verify that the correct device descriptor for the model 644 is loaded!!! 1) Turn on the 275 hart communicator in offline configuration 2) Select (1)offline, (1)new configuration, (1)Rosemount, (1)644 temp. 3) For successful communication, dev V 3 dd V 1 must be present 3 3144/3244 - dev V 1 dd V 7 Module Revision : 4. 6 for Y 2 K compliance of HART 275 communicator RMT Sales Training 12/98 Phase II -Temperature Transmitter

Digital Communication 37 275 HART Communicator to establish communication with 644 or 3144/3244 Smart Transmitter F Verify that the correct device descriptor for the model 644 is loaded!!! 1) Turn on the 275 hart communicator in offline configuration 2) Select (1)offline, (1)new configuration, (1)Rosemount, (1)644 temp. 3) For successful communication, dev V 3 dd V 1 must be present 3 3144/3244 - dev V 1 dd V 7 Module Revision : 4. 6 for Y 2 K compliance of HART 275 communicator RMT Sales Training 12/98 Phase II -Temperature Transmitter

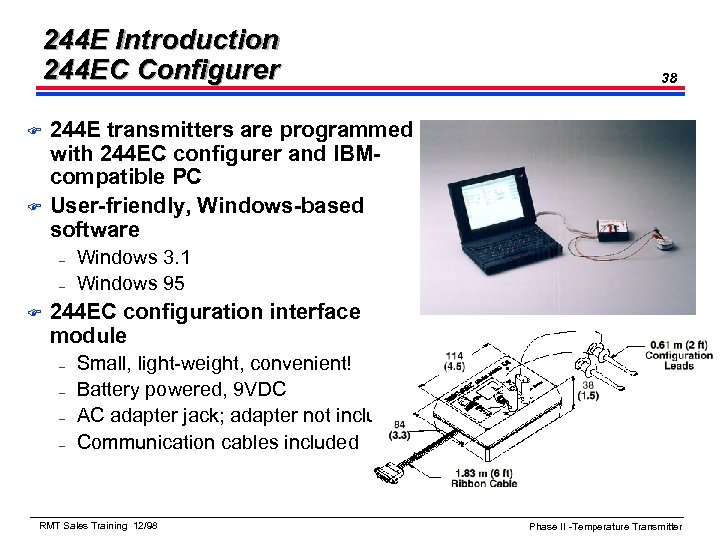

244 E Introduction 244 EC Configurer F F 244 E transmitters are programmed with 244 EC configurer and IBMcompatible PC User-friendly, Windows-based software – – F 38 Windows 3. 1 Windows 95 244 EC configuration interface module – – Small, light-weight, convenient! Battery powered, 9 VDC AC adapter jack; adapter not included Communication cables included RMT Sales Training 12/98 Phase II -Temperature Transmitter

244 E Introduction 244 EC Configurer F F 244 E transmitters are programmed with 244 EC configurer and IBMcompatible PC User-friendly, Windows-based software – – F 38 Windows 3. 1 Windows 95 244 EC configuration interface module – – Small, light-weight, convenient! Battery powered, 9 VDC AC adapter jack; adapter not included Communication cables included RMT Sales Training 12/98 Phase II -Temperature Transmitter

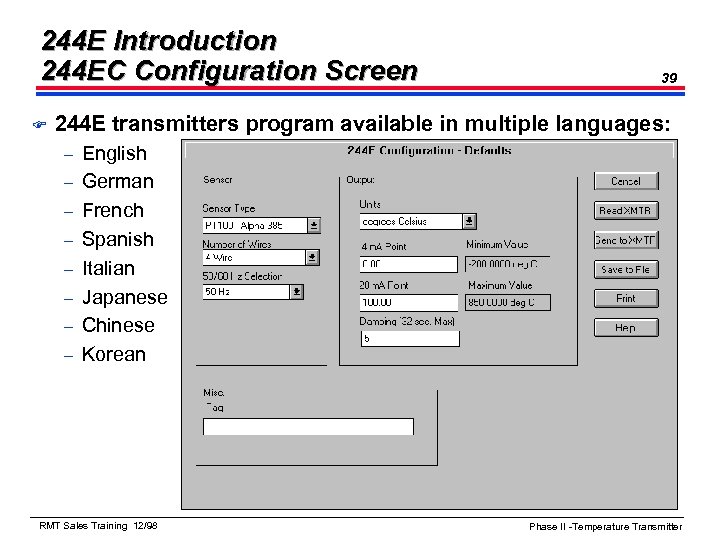

244 E Introduction 244 EC Configuration Screen F 39 244 E transmitters program available in multiple languages: – – – – English German French Spanish Italian Japanese Chinese Korean RMT Sales Training 12/98 Phase II -Temperature Transmitter

244 E Introduction 244 EC Configuration Screen F 39 244 E transmitters program available in multiple languages: – – – – English German French Spanish Italian Japanese Chinese Korean RMT Sales Training 12/98 Phase II -Temperature Transmitter

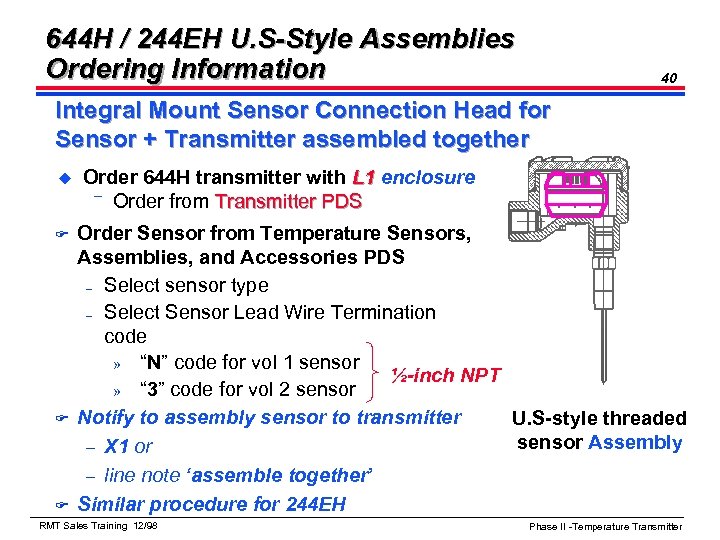

644 H / 244 EH U. S-Style Assemblies Ordering Information 40 Integral Mount Sensor Connection Head for Sensor + Transmitter assembled together u F F F Order 644 H transmitter with L 1 enclosure ¯ Order from Transmitter PDS Order Sensor from Temperature Sensors, Assemblies, and Accessories PDS – Select sensor type – Select Sensor Lead Wire Termination code » “N” code for vol 1 sensor ½-inch NPT » “ 3” code for vol 2 sensor Notify to assembly sensor to transmitter U. S-style threaded sensor Assembly – X 1 or – line note ‘assemble together’ Similar procedure for 244 EH RMT Sales Training 12/98 Phase II -Temperature Transmitter

644 H / 244 EH U. S-Style Assemblies Ordering Information 40 Integral Mount Sensor Connection Head for Sensor + Transmitter assembled together u F F F Order 644 H transmitter with L 1 enclosure ¯ Order from Transmitter PDS Order Sensor from Temperature Sensors, Assemblies, and Accessories PDS – Select sensor type – Select Sensor Lead Wire Termination code » “N” code for vol 1 sensor ½-inch NPT » “ 3” code for vol 2 sensor Notify to assembly sensor to transmitter U. S-style threaded sensor Assembly – X 1 or – line note ‘assemble together’ Similar procedure for 244 EH RMT Sales Training 12/98 Phase II -Temperature Transmitter

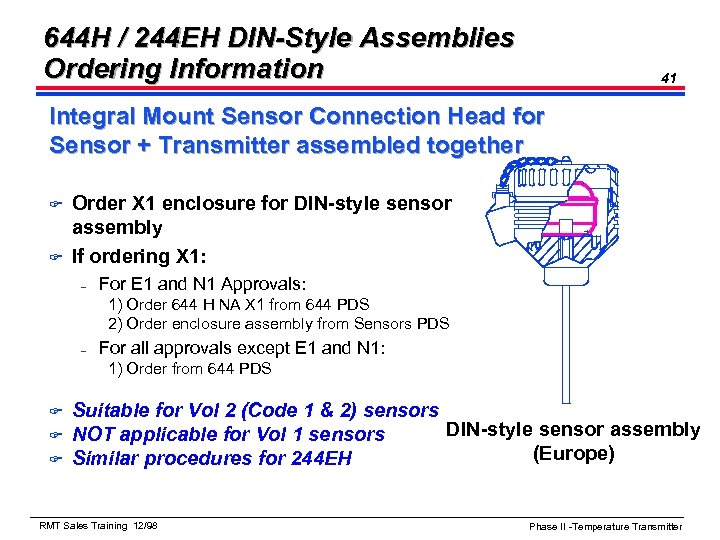

644 H / 244 EH DIN-Style Assemblies Ordering Information 41 Integral Mount Sensor Connection Head for Sensor + Transmitter assembled together F F Order X 1 enclosure for DIN-style sensor assembly If ordering X 1: – For E 1 and N 1 Approvals: 1) Order 644 H NA X 1 from 644 PDS 2) Order enclosure assembly from Sensors PDS – For all approvals except E 1 and N 1: 1) Order from 644 PDS F F F Suitable for Vol 2 (Code 1 & 2) sensors DIN-style sensor assembly NOT applicable for Vol 1 sensors (Europe) Similar procedures for 244 EH RMT Sales Training 12/98 Phase II -Temperature Transmitter

644 H / 244 EH DIN-Style Assemblies Ordering Information 41 Integral Mount Sensor Connection Head for Sensor + Transmitter assembled together F F Order X 1 enclosure for DIN-style sensor assembly If ordering X 1: – For E 1 and N 1 Approvals: 1) Order 644 H NA X 1 from 644 PDS 2) Order enclosure assembly from Sensors PDS – For all approvals except E 1 and N 1: 1) Order from 644 PDS F F F Suitable for Vol 2 (Code 1 & 2) sensors DIN-style sensor assembly NOT applicable for Vol 1 sensors (Europe) Similar procedures for 244 EH RMT Sales Training 12/98 Phase II -Temperature Transmitter

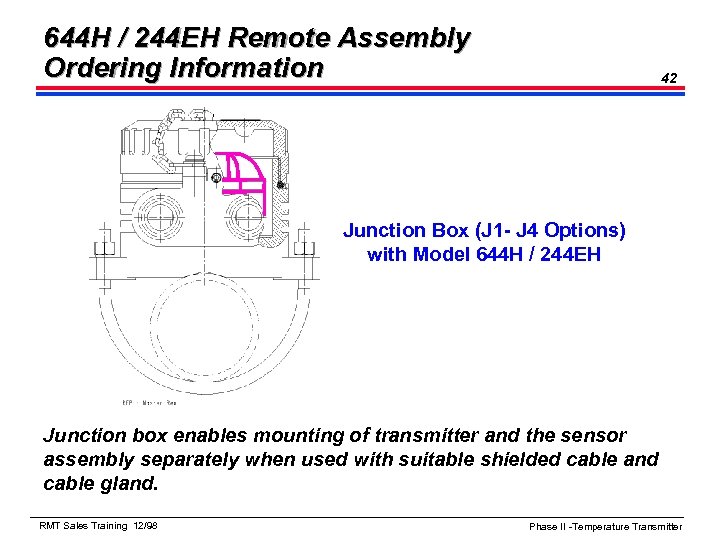

644 H / 244 EH Remote Assembly Ordering Information 42 Junction Box (J 1 - J 4 Options) with Model 644 H / 244 EH Junction box enables mounting of transmitter and the sensor assembly separately when used with suitable shielded cable and cable gland. RMT Sales Training 12/98 Phase II -Temperature Transmitter

644 H / 244 EH Remote Assembly Ordering Information 42 Junction Box (J 1 - J 4 Options) with Model 644 H / 244 EH Junction box enables mounting of transmitter and the sensor assembly separately when used with suitable shielded cable and cable gland. RMT Sales Training 12/98 Phase II -Temperature Transmitter

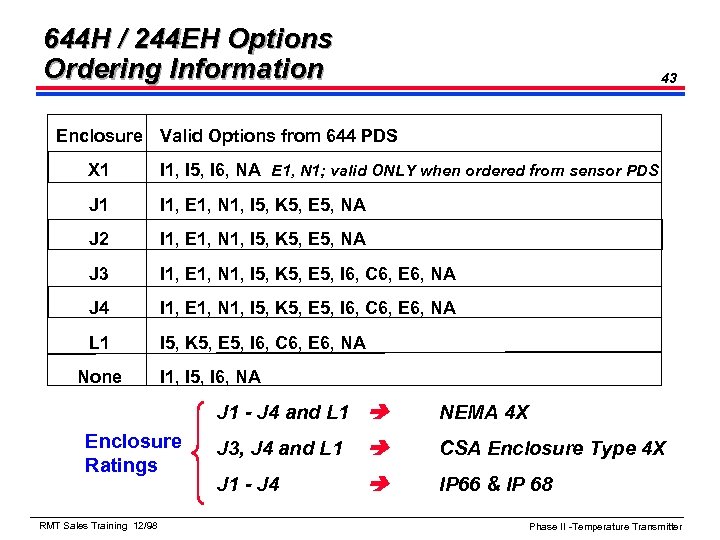

644 H / 244 EH Options Ordering Information 43 Enclosure Valid Options from 644 PDS X 1 I 1, I 5, I 6, NA E 1, N 1; valid ONLY when ordered from sensor PDS J 1 I 1, E 1, N 1, I 5, K 5, E 5, NA J 2 I 1, E 1, N 1, I 5, K 5, E 5, NA J 3 I 1, E 1, N 1, I 5, K 5, E 5, I 6, C 6, E 6, NA J 4 I 1, E 1, N 1, I 5, K 5, E 5, I 6, C 6, E 6, NA L 1 I 5, K 5, E 5, I 6, C 6, E 6, NA None I 1, I 5, I 6, NA J 1 - J 4 and L 1 Enclosure Ratings RMT Sales Training 12/98 NEMA 4 X J 3, J 4 and L 1 CSA Enclosure Type 4 X J 1 - J 4 IP 66 & IP 68 Phase II -Temperature Transmitter

644 H / 244 EH Options Ordering Information 43 Enclosure Valid Options from 644 PDS X 1 I 1, I 5, I 6, NA E 1, N 1; valid ONLY when ordered from sensor PDS J 1 I 1, E 1, N 1, I 5, K 5, E 5, NA J 2 I 1, E 1, N 1, I 5, K 5, E 5, NA J 3 I 1, E 1, N 1, I 5, K 5, E 5, I 6, C 6, E 6, NA J 4 I 1, E 1, N 1, I 5, K 5, E 5, I 6, C 6, E 6, NA L 1 I 5, K 5, E 5, I 6, C 6, E 6, NA None I 1, I 5, I 6, NA J 1 - J 4 and L 1 Enclosure Ratings RMT Sales Training 12/98 NEMA 4 X J 3, J 4 and L 1 CSA Enclosure Type 4 X J 1 - J 4 IP 66 & IP 68 Phase II -Temperature Transmitter

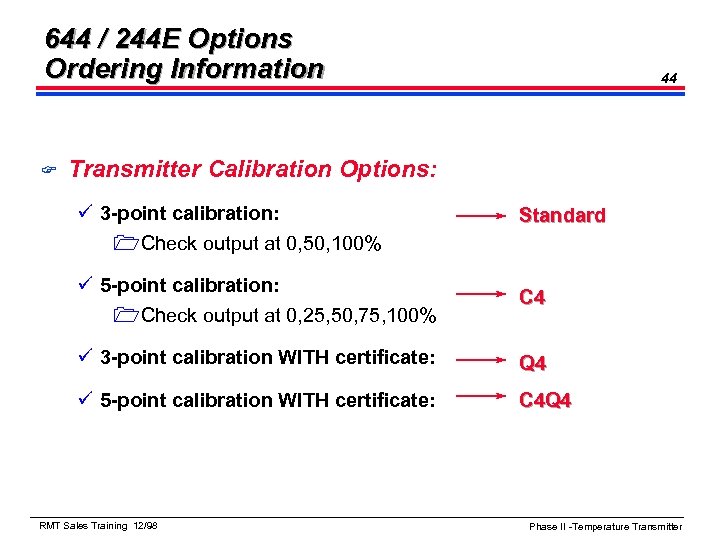

644 / 244 E Options Ordering Information F 44 Transmitter Calibration Options: ü 3 -point calibration: 1 Check output at 0, 50, 100% Standard ü 5 -point calibration: 1 Check output at 0, 25, 50, 75, 100% C 4 ü 3 -point calibration WITH certificate: Q 4 ü 5 -point calibration WITH certificate: C 4 Q 4 RMT Sales Training 12/98 Phase II -Temperature Transmitter

644 / 244 E Options Ordering Information F 44 Transmitter Calibration Options: ü 3 -point calibration: 1 Check output at 0, 50, 100% Standard ü 5 -point calibration: 1 Check output at 0, 25, 50, 75, 100% C 4 ü 3 -point calibration WITH certificate: Q 4 ü 5 -point calibration WITH certificate: C 4 Q 4 RMT Sales Training 12/98 Phase II -Temperature Transmitter

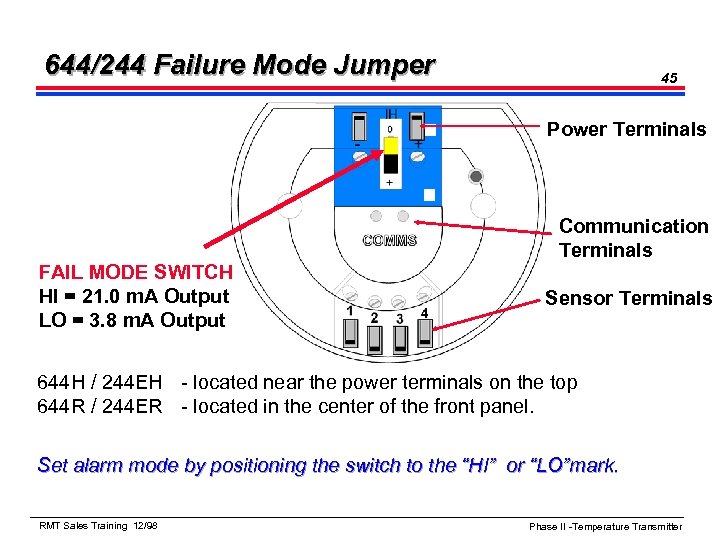

644/244 Failure Mode Jumper 45 Power Terminals Communication Terminals FAIL MODE SWITCH HI = 21. 0 m. A Output LO = 3. 8 m. A Output Sensor Terminals 644 H / 244 EH - located near the power terminals on the top 644 R / 244 ER - located in the center of the front panel. Set alarm mode by positioning the switch to the “HI” or “LO”mark. RMT Sales Training 12/98 Phase II -Temperature Transmitter

644/244 Failure Mode Jumper 45 Power Terminals Communication Terminals FAIL MODE SWITCH HI = 21. 0 m. A Output LO = 3. 8 m. A Output Sensor Terminals 644 H / 244 EH - located near the power terminals on the top 644 R / 244 ER - located in the center of the front panel. Set alarm mode by positioning the switch to the “HI” or “LO”mark. RMT Sales Training 12/98 Phase II -Temperature Transmitter

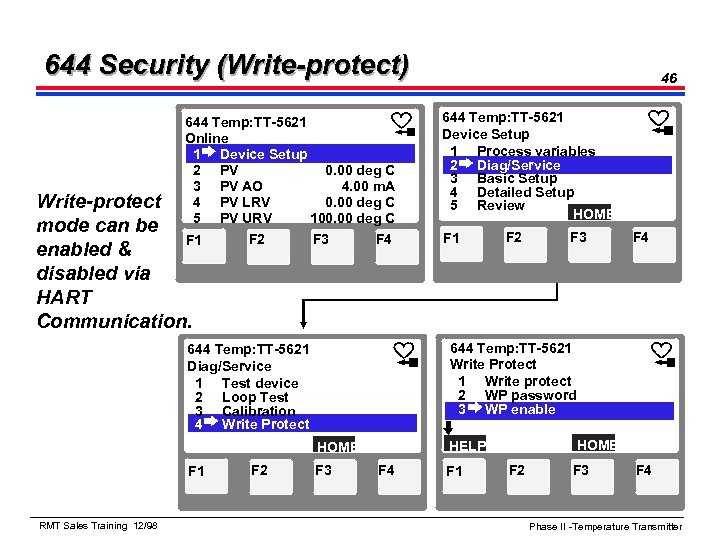

644 Security (Write-protect) 644 Temp: TT-5621 Online 1 Device Setup 2 PV 0. 00 deg C 3 PV AO 4. 00 m. A 4 PV LRV 0. 00 deg C 5 PV URV 100. 00 deg C Write-protect mode can be F 1 enabled & disabled via HART Communication. F 2 F 3 F 4 RMT Sales Training 12/98 F 1 F 2 F 3 F 4 F 3 HOME HELP HOME F 2 644 Temp: TT-5621 Device Setup 1 Process variables 2 Diag/Service 3 Basic Setup 4 Detailed Setup 5 Review HOME 644 Temp: TT-5621 Write Protect 1 Write protect 2 WP password 3 WP enable 644 Temp: TT-5621 Diag/Service 1 Test device 2 Loop Test 3 Calibration 4 Write Protect F 1 46 F 4 F 1 F 2 F 3 F 4 Phase II -Temperature Transmitter

644 Security (Write-protect) 644 Temp: TT-5621 Online 1 Device Setup 2 PV 0. 00 deg C 3 PV AO 4. 00 m. A 4 PV LRV 0. 00 deg C 5 PV URV 100. 00 deg C Write-protect mode can be F 1 enabled & disabled via HART Communication. F 2 F 3 F 4 RMT Sales Training 12/98 F 1 F 2 F 3 F 4 F 3 HOME HELP HOME F 2 644 Temp: TT-5621 Device Setup 1 Process variables 2 Diag/Service 3 Basic Setup 4 Detailed Setup 5 Review HOME 644 Temp: TT-5621 Write Protect 1 Write protect 2 WP password 3 WP enable 644 Temp: TT-5621 Diag/Service 1 Test device 2 Loop Test 3 Calibration 4 Write Protect F 1 46 F 4 F 1 F 2 F 3 F 4 Phase II -Temperature Transmitter

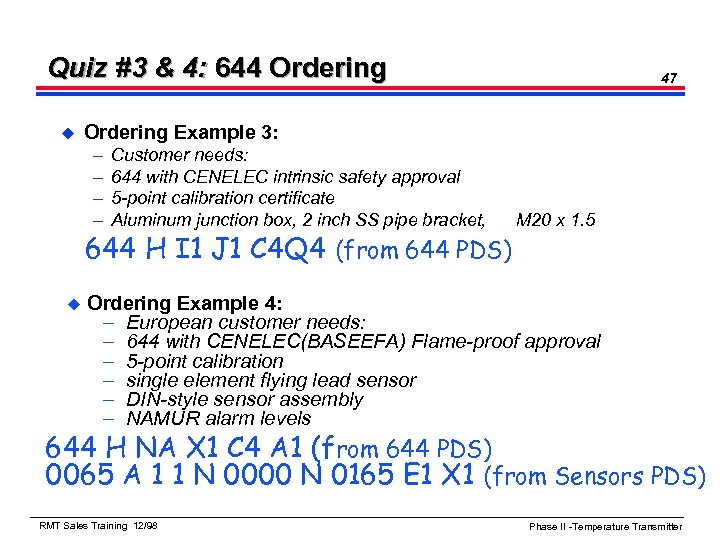

Quiz #3 & 4: 644 Ordering u Ordering Example 3: – – Customer needs: 644 with CENELEC intrinsic safety approval 5 -point calibration certificate Aluminum junction box, 2 inch SS pipe bracket, 644 H I 1 J 1 C 4 Q 4 (from 644 PDS) u 47 M 20 x 1. 5 Ordering Example 4: – European customer needs: – 644 with CENELEC(BASEEFA) Flame-proof approval – 5 -point calibration – single element flying lead sensor – DIN-style sensor assembly – NAMUR alarm levels 644 H NA X 1 C 4 A 1 (from 644 PDS) 0065 A 1 1 N 0000 N 0165 E 1 X 1 (from Sensors PDS) RMT Sales Training 12/98 Phase II -Temperature Transmitter

Quiz #3 & 4: 644 Ordering u Ordering Example 3: – – Customer needs: 644 with CENELEC intrinsic safety approval 5 -point calibration certificate Aluminum junction box, 2 inch SS pipe bracket, 644 H I 1 J 1 C 4 Q 4 (from 644 PDS) u 47 M 20 x 1. 5 Ordering Example 4: – European customer needs: – 644 with CENELEC(BASEEFA) Flame-proof approval – 5 -point calibration – single element flying lead sensor – DIN-style sensor assembly – NAMUR alarm levels 644 H NA X 1 C 4 A 1 (from 644 PDS) 0065 A 1 1 N 0000 N 0165 E 1 X 1 (from Sensors PDS) RMT Sales Training 12/98 Phase II -Temperature Transmitter

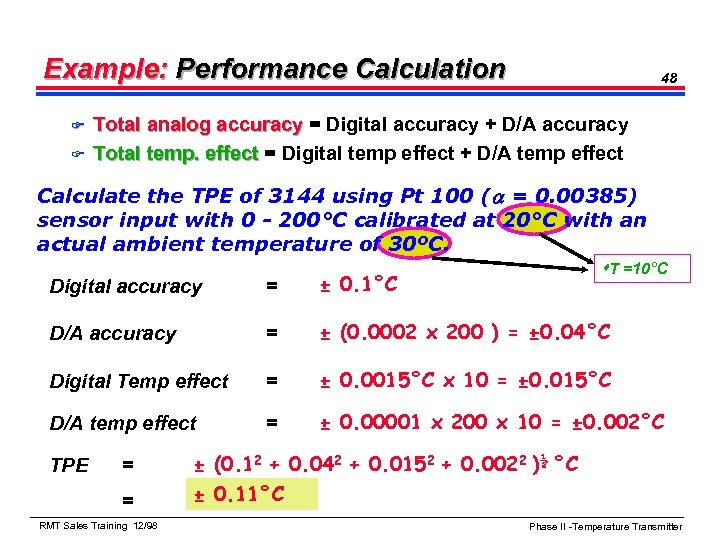

Example: Performance Calculation F F 48 Total analog accuracy = Digital accuracy + D/A accuracy Total temp. effect = Digital temp effect + D/A temp effect Calculate the TPE of 3144 using Pt 100 ( = 0. 00385) sensor input with 0 - 200°C calibrated at 20°C with an actual ambient temperature of 30ºC. T =10°C Digital accuracy = ± 0. 1°C D/A accuracy = ± (0. 0002 x 200 ) = ± 0. 04°C Digital Temp effect = ± 0. 0015°C x 10 = ± 0. 015°C D/A temp effect = ± 0. 00001 x 200 x 10 = ± 0. 002°C TPE = = RMT Sales Training 12/98 ± (0. 12 + 0. 042 + 0. 0152 + 0. 0022 )½ °C ± 0. 11°C Phase II -Temperature Transmitter

Example: Performance Calculation F F 48 Total analog accuracy = Digital accuracy + D/A accuracy Total temp. effect = Digital temp effect + D/A temp effect Calculate the TPE of 3144 using Pt 100 ( = 0. 00385) sensor input with 0 - 200°C calibrated at 20°C with an actual ambient temperature of 30ºC. T =10°C Digital accuracy = ± 0. 1°C D/A accuracy = ± (0. 0002 x 200 ) = ± 0. 04°C Digital Temp effect = ± 0. 0015°C x 10 = ± 0. 015°C D/A temp effect = ± 0. 00001 x 200 x 10 = ± 0. 002°C TPE = = RMT Sales Training 12/98 ± (0. 12 + 0. 042 + 0. 0152 + 0. 0022 )½ °C ± 0. 11°C Phase II -Temperature Transmitter

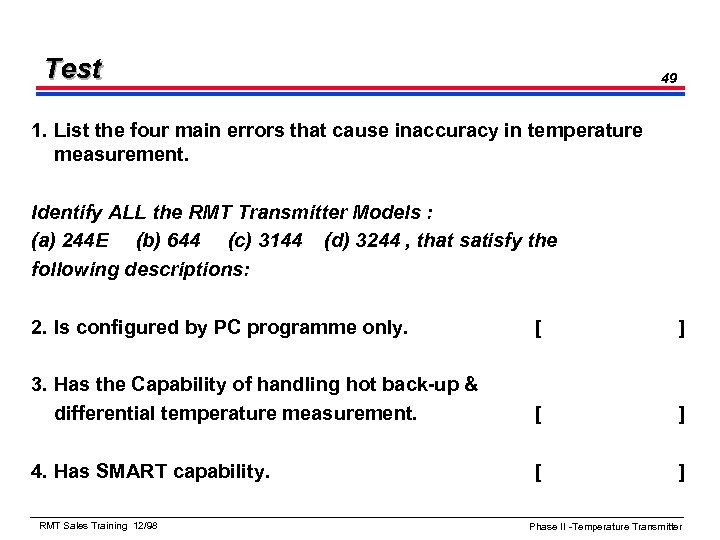

Test 49 1. List the four main errors that cause inaccuracy in temperature measurement. Identify ALL the RMT Transmitter Models : (a) 244 E (b) 644 (c) 3144 (d) 3244 , that satisfy the following descriptions: 2. Is configured by PC programme only. [ ] 3. Has the Capability of handling hot back-up & differential temperature measurement. [ ] 4. Has SMART capability. [ ] RMT Sales Training 12/98 Phase II -Temperature Transmitter

Test 49 1. List the four main errors that cause inaccuracy in temperature measurement. Identify ALL the RMT Transmitter Models : (a) 244 E (b) 644 (c) 3144 (d) 3244 , that satisfy the following descriptions: 2. Is configured by PC programme only. [ ] 3. Has the Capability of handling hot back-up & differential temperature measurement. [ ] 4. Has SMART capability. [ ] RMT Sales Training 12/98 Phase II -Temperature Transmitter

![Test 50 5. Has Sensor Matching capability. [ ] 6. Has Sensor Trim capability. Test 50 5. Has Sensor Matching capability. [ ] 6. Has Sensor Trim capability.](https://present5.com/presentation/bc56f0be78560fcaf0be9b107046bae7/image-50.jpg) Test 50 5. Has Sensor Matching capability. [ ] 6. Has Sensor Trim capability. [ ] 7. Outputs only analog signal. [ ] 8. Write protect is enabled via HART 275 communicator. [ ] 9. How many digital variable can a 3244 MV output ] 10. [ 3144 was calibrated in the factory at 20°C to a span 0 to 400°C. In the field this transmitter have to be connected to Pt 100 RTD sensor at 70°C ambient temperature. Calculate the operating accuracy (TPE) and express it in °C. RMT Sales Training 12/98 Phase II -Temperature Transmitter

Test 50 5. Has Sensor Matching capability. [ ] 6. Has Sensor Trim capability. [ ] 7. Outputs only analog signal. [ ] 8. Write protect is enabled via HART 275 communicator. [ ] 9. How many digital variable can a 3244 MV output ] 10. [ 3144 was calibrated in the factory at 20°C to a span 0 to 400°C. In the field this transmitter have to be connected to Pt 100 RTD sensor at 70°C ambient temperature. Calculate the operating accuracy (TPE) and express it in °C. RMT Sales Training 12/98 Phase II -Temperature Transmitter

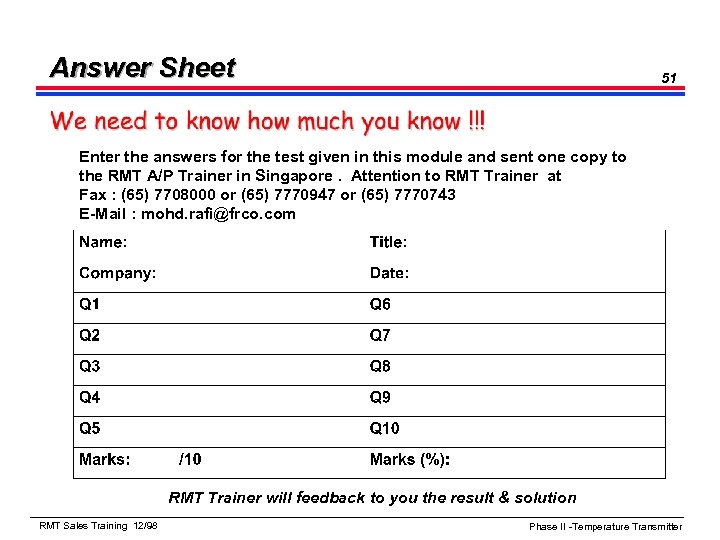

Answer Sheet 51 Enter the answers for the test given in this module and sent one copy to the RMT A/P Trainer in Singapore. Attention to RMT Trainer at Fax : (65) 7708000 or (65) 7770947 or (65) 7770743 E-Mail : mohd. rafi@frco. com RMT Trainer will feedback to you the result & solution RMT Sales Training 12/98 Phase II -Temperature Transmitter

Answer Sheet 51 Enter the answers for the test given in this module and sent one copy to the RMT A/P Trainer in Singapore. Attention to RMT Trainer at Fax : (65) 7708000 or (65) 7770947 or (65) 7770743 E-Mail : mohd. rafi@frco. com RMT Trainer will feedback to you the result & solution RMT Sales Training 12/98 Phase II -Temperature Transmitter