82c6aae3087cc1da2f0d616ce5a2458e.ppt

- Количество слайдов: 54

PHASE II Rosemount Product Training Agenda: • RMT Sensor differentiation • Vol I & II RTDs and Thermocouple overview • Complete point solutions – Connections heads overview – Extensions overview – Thermowell overview • RTD calibration schedules • Ordering information RMT Sales Training 1/99 Phase II - Temperature Sensor

PHASE II Rosemount Product Training Agenda: • RMT Sensor differentiation • Vol I & II RTDs and Thermocouple overview • Complete point solutions – Connections heads overview – Extensions overview – Thermowell overview • RTD calibration schedules • Ordering information RMT Sales Training 1/99 Phase II - Temperature Sensor

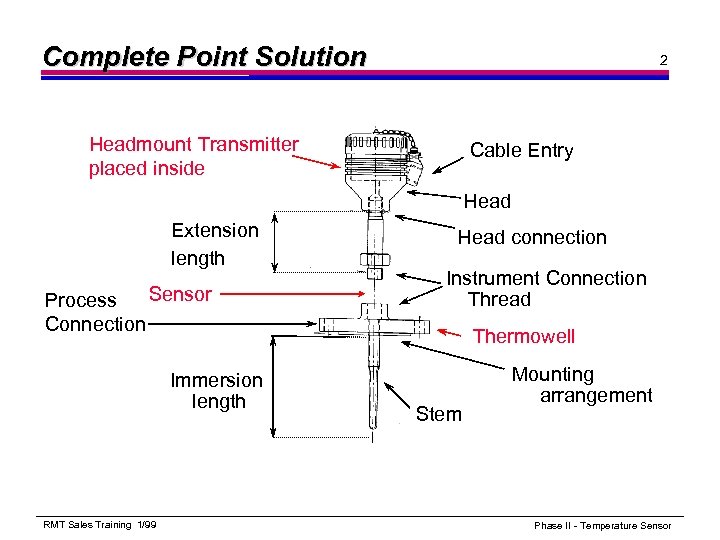

Complete Point Solution 2 Headmount Transmitter placed inside Cable Entry Head Extension length Sensor Process Connection Immersion length RMT Sales Training 1/99 Head connection Instrument Connection Thread Thermowell Stem Mounting arrangement Phase II - Temperature Sensor

Complete Point Solution 2 Headmount Transmitter placed inside Cable Entry Head Extension length Sensor Process Connection Immersion length RMT Sales Training 1/99 Head connection Instrument Connection Thread Thermowell Stem Mounting arrangement Phase II - Temperature Sensor

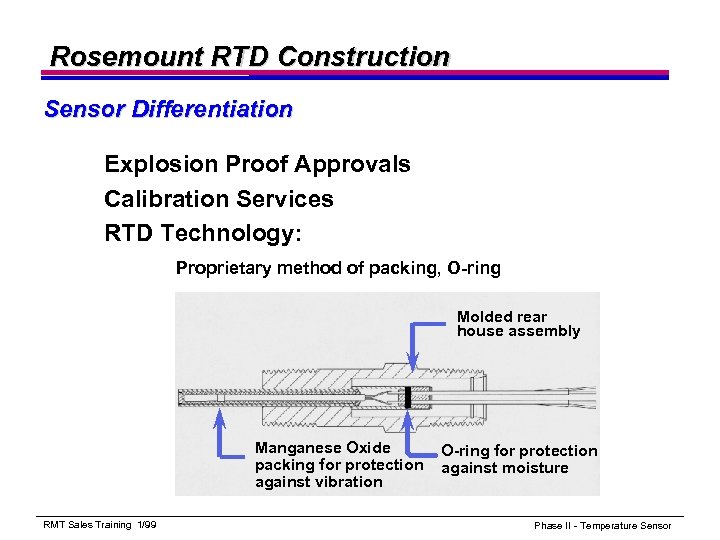

Rosemount RTD Construction Sensor Differentiation Explosion Proof Approvals Calibration Services RTD Technology: Proprietary method of packing, O-ring Molded rear house assembly Manganese Oxide packing for protection against vibration RMT Sales Training 1/99 O-ring for protection against moisture Phase II - Temperature Sensor

Rosemount RTD Construction Sensor Differentiation Explosion Proof Approvals Calibration Services RTD Technology: Proprietary method of packing, O-ring Molded rear house assembly Manganese Oxide packing for protection against vibration RMT Sales Training 1/99 O-ring for protection against moisture Phase II - Temperature Sensor

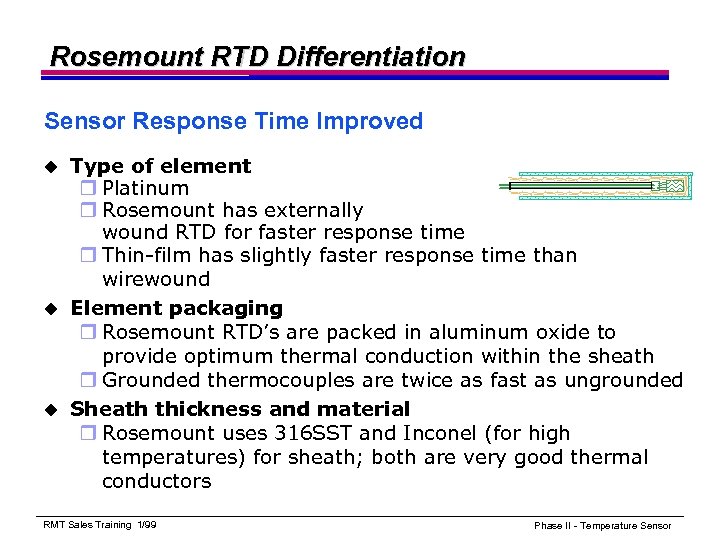

Rosemount RTD Differentiation Sensor Response Time Improved Type of element r Platinum r Rosemount has externally wound RTD for faster response time r Thin-film has slightly faster response time than wirewound u Element packaging r Rosemount RTD’s are packed in aluminum oxide to provide optimum thermal conduction within the sheath r Grounded thermocouples are twice as fast as ungrounded u Sheath thickness and material r Rosemount uses 316 SST and Inconel (for high temperatures) for sheath; both are very good thermal conductors u RMT Sales Training 1/99 Phase II - Temperature Sensor

Rosemount RTD Differentiation Sensor Response Time Improved Type of element r Platinum r Rosemount has externally wound RTD for faster response time r Thin-film has slightly faster response time than wirewound u Element packaging r Rosemount RTD’s are packed in aluminum oxide to provide optimum thermal conduction within the sheath r Grounded thermocouples are twice as fast as ungrounded u Sheath thickness and material r Rosemount uses 316 SST and Inconel (for high temperatures) for sheath; both are very good thermal conductors u RMT Sales Training 1/99 Phase II - Temperature Sensor

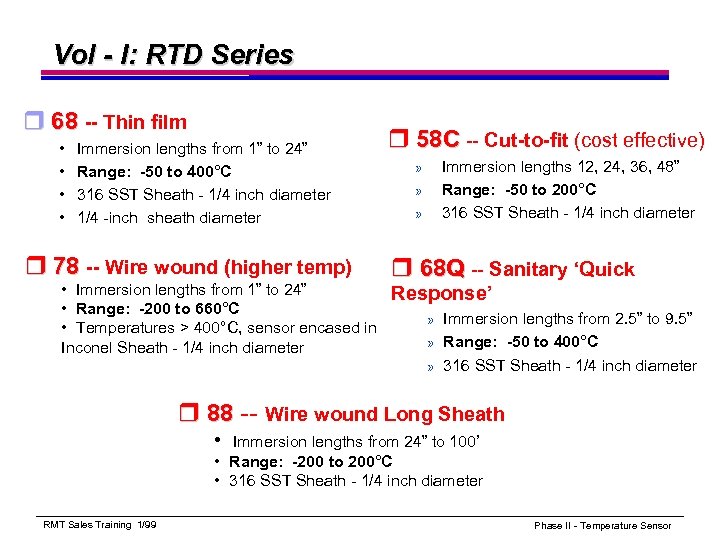

Vol - I: RTD Series r 68 -- Thin film • • Immersion lengths from 1” to 24” Range: -50 to 400°C 316 SST Sheath - 1/4 inch diameter 1/4 -inch sheath diameter r 78 -- Wire wound (higher temp) • Immersion lengths from 1” to 24” • Range: -200 to 660°C • Temperatures > 400°C, sensor encased in Inconel Sheath - 1/4 inch diameter r 58 C -- Cut-to-fit (cost effective) Immersion lengths 12, 24, 36, 48” Range: -50 to 200°C 316 SST Sheath - 1/4 inch diameter » » » r 68 Q -- Sanitary ‘Quick Response’ Immersion lengths from 2. 5” to 9. 5” » Range: -50 to 400°C » 316 SST Sheath - 1/4 inch diameter » r 88 -- Wire wound Long Sheath • Immersion lengths from 24” to 100’ • Range: -200 to 200°C • 316 SST Sheath - 1/4 inch diameter RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol - I: RTD Series r 68 -- Thin film • • Immersion lengths from 1” to 24” Range: -50 to 400°C 316 SST Sheath - 1/4 inch diameter 1/4 -inch sheath diameter r 78 -- Wire wound (higher temp) • Immersion lengths from 1” to 24” • Range: -200 to 660°C • Temperatures > 400°C, sensor encased in Inconel Sheath - 1/4 inch diameter r 58 C -- Cut-to-fit (cost effective) Immersion lengths 12, 24, 36, 48” Range: -50 to 200°C 316 SST Sheath - 1/4 inch diameter » » » r 68 Q -- Sanitary ‘Quick Response’ Immersion lengths from 2. 5” to 9. 5” » Range: -50 to 400°C » 316 SST Sheath - 1/4 inch diameter » r 88 -- Wire wound Long Sheath • Immersion lengths from 24” to 100’ • Range: -200 to 200°C • 316 SST Sheath - 1/4 inch diameter RMT Sales Training 1/99 Phase II - Temperature Sensor

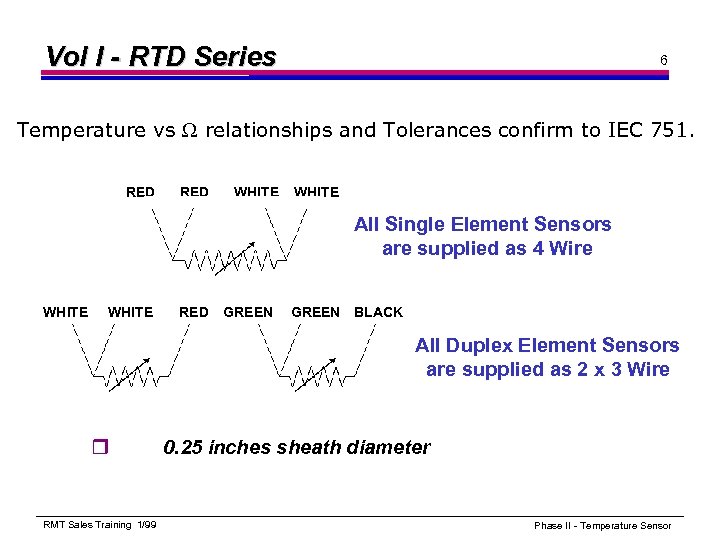

Vol I - RTD Series 6 Temperature vs relationships and Tolerances confirm to IEC 751. RED WHITE All Single Element Sensors are supplied as 4 Wire WHITE RED GREEN BLACK All Duplex Element Sensors are supplied as 2 x 3 Wire r RMT Sales Training 1/99 0. 25 inches sheath diameter Phase II - Temperature Sensor

Vol I - RTD Series 6 Temperature vs relationships and Tolerances confirm to IEC 751. RED WHITE All Single Element Sensors are supplied as 4 Wire WHITE RED GREEN BLACK All Duplex Element Sensors are supplied as 2 x 3 Wire r RMT Sales Training 1/99 0. 25 inches sheath diameter Phase II - Temperature Sensor

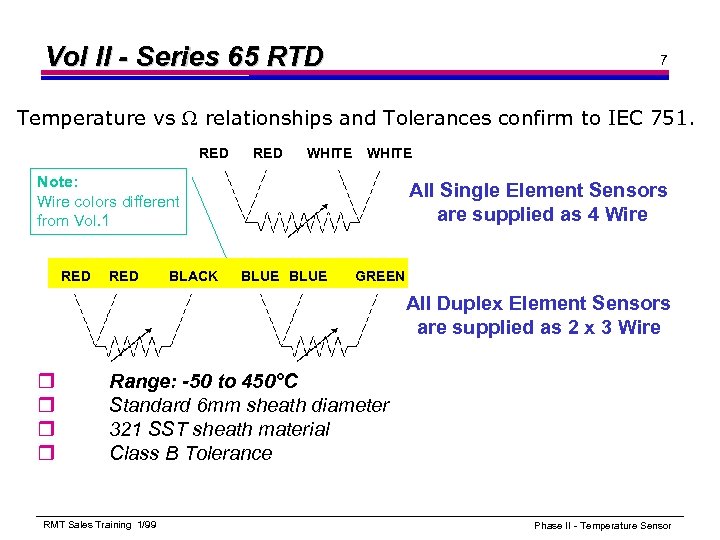

Vol II - Series 65 RTD 7 Temperature vs relationships and Tolerances confirm to IEC 751. RED WHITE Note: Wire colors different from Vol. 1 RED BLACK All Single Element Sensors are supplied as 4 Wire BLUE GREEN All Duplex Element Sensors are supplied as 2 x 3 Wire r r Range: -50 to 450°C Standard 6 mm sheath diameter 321 SST sheath material Class B Tolerance RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol II - Series 65 RTD 7 Temperature vs relationships and Tolerances confirm to IEC 751. RED WHITE Note: Wire colors different from Vol. 1 RED BLACK All Single Element Sensors are supplied as 4 Wire BLUE GREEN All Duplex Element Sensors are supplied as 2 x 3 Wire r r Range: -50 to 450°C Standard 6 mm sheath diameter 321 SST sheath material Class B Tolerance RMT Sales Training 1/99 Phase II - Temperature Sensor

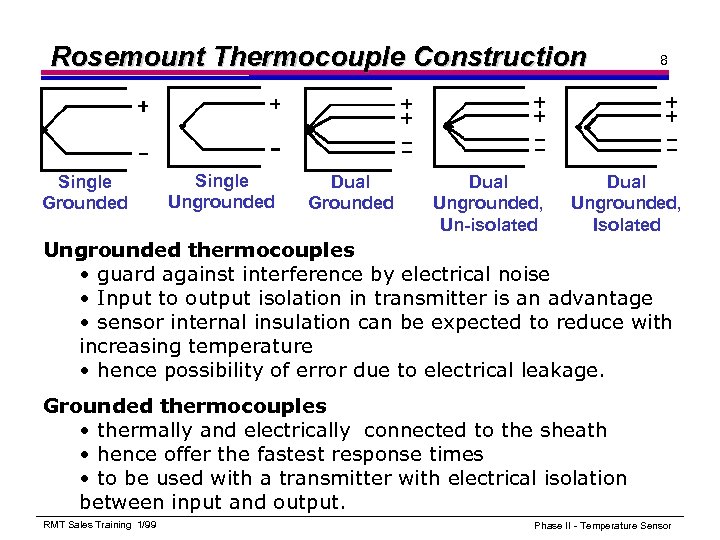

Rosemount Thermocouple Construction Single Grounded Single Ungrounded Dual Grounded Dual Ungrounded, Un-isolated 8 Dual Ungrounded, Isolated Ungrounded thermocouples • guard against interference by electrical noise • Input to output isolation in transmitter is an advantage • sensor internal insulation can be expected to reduce with increasing temperature • hence possibility of error due to electrical leakage. Grounded thermocouples • thermally and electrically connected to the sheath • hence offer the fastest response times • to be used with a transmitter with electrical isolation between input and output. RMT Sales Training 1/99 Phase II - Temperature Sensor

Rosemount Thermocouple Construction Single Grounded Single Ungrounded Dual Grounded Dual Ungrounded, Un-isolated 8 Dual Ungrounded, Isolated Ungrounded thermocouples • guard against interference by electrical noise • Input to output isolation in transmitter is an advantage • sensor internal insulation can be expected to reduce with increasing temperature • hence possibility of error due to electrical leakage. Grounded thermocouples • thermally and electrically connected to the sheath • hence offer the fastest response times • to be used with a transmitter with electrical isolation between input and output. RMT Sales Training 1/99 Phase II - Temperature Sensor

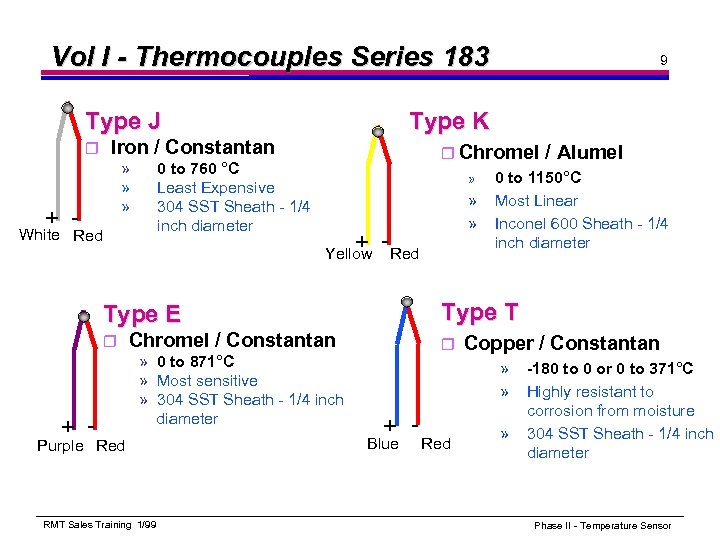

Vol I - Thermocouples Series 183 Type J r Type K Iron / Constantan » » » + - 0 to 760 °C Least Expensive 304 SST Sheath - 1/4 inch diameter White Red + -Red Yellow + - Chromel / Constantan » 0 to 871°C » Most sensitive » 304 SST Sheath - 1/4 inch diameter Purple Red RMT Sales Training 1/99 r Chromel / Alumel » 0 to 1150°C » Most Linear » Inconel 600 Sheath - 1/4 inch diameter Type T Type E r 9 r Copper / Constantan » » + - Blue Red » -180 to 0 or 0 to 371°C Highly resistant to corrosion from moisture 304 SST Sheath - 1/4 inch diameter Phase II - Temperature Sensor

Vol I - Thermocouples Series 183 Type J r Type K Iron / Constantan » » » + - 0 to 760 °C Least Expensive 304 SST Sheath - 1/4 inch diameter White Red + -Red Yellow + - Chromel / Constantan » 0 to 871°C » Most sensitive » 304 SST Sheath - 1/4 inch diameter Purple Red RMT Sales Training 1/99 r Chromel / Alumel » 0 to 1150°C » Most Linear » Inconel 600 Sheath - 1/4 inch diameter Type T Type E r 9 r Copper / Constantan » » + - Blue Red » -180 to 0 or 0 to 371°C Highly resistant to corrosion from moisture 304 SST Sheath - 1/4 inch diameter Phase II - Temperature Sensor

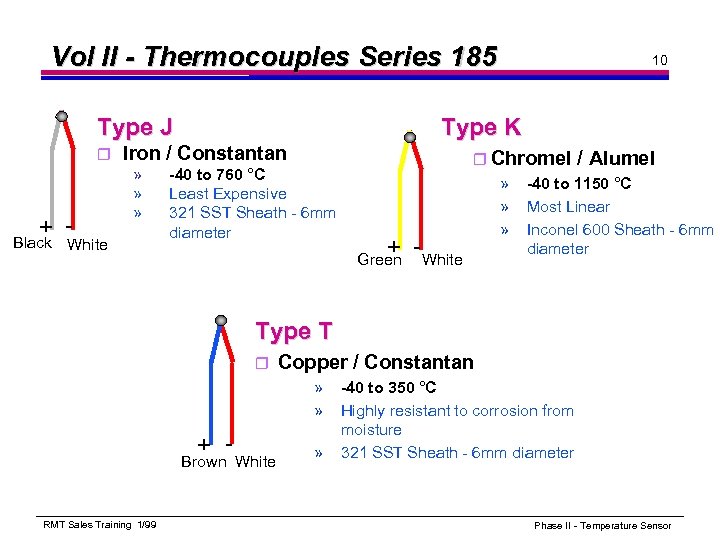

Vol II - Thermocouples Series 185 Type J r + - Type K Iron / Constantan » » » Black White 10 -40 to 760 °C Least Expensive 321 SST Sheath - 6 mm diameter + -White Green r Chromel / Alumel » -40 to 1150 °C » Most Linear » Inconel 600 Sheath - 6 mm diameter Type T r Copper / Constantan » » + - Brown White RMT Sales Training 1/99 » -40 to 350 °C Highly resistant to corrosion from moisture 321 SST Sheath - 6 mm diameter Phase II - Temperature Sensor

Vol II - Thermocouples Series 185 Type J r + - Type K Iron / Constantan » » » Black White 10 -40 to 760 °C Least Expensive 321 SST Sheath - 6 mm diameter + -White Green r Chromel / Alumel » -40 to 1150 °C » Most Linear » Inconel 600 Sheath - 6 mm diameter Type T r Copper / Constantan » » + - Brown White RMT Sales Training 1/99 » -40 to 350 °C Highly resistant to corrosion from moisture 321 SST Sheath - 6 mm diameter Phase II - Temperature Sensor

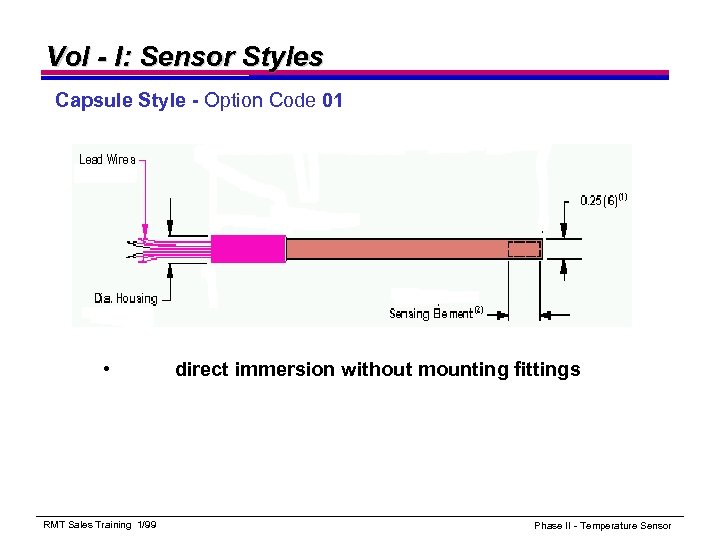

Vol - I: Sensor Styles Capsule Style - Option Code 01 • RMT Sales Training 1/99 direct immersion without mounting fittings Phase II - Temperature Sensor

Vol - I: Sensor Styles Capsule Style - Option Code 01 • RMT Sales Training 1/99 direct immersion without mounting fittings Phase II - Temperature Sensor

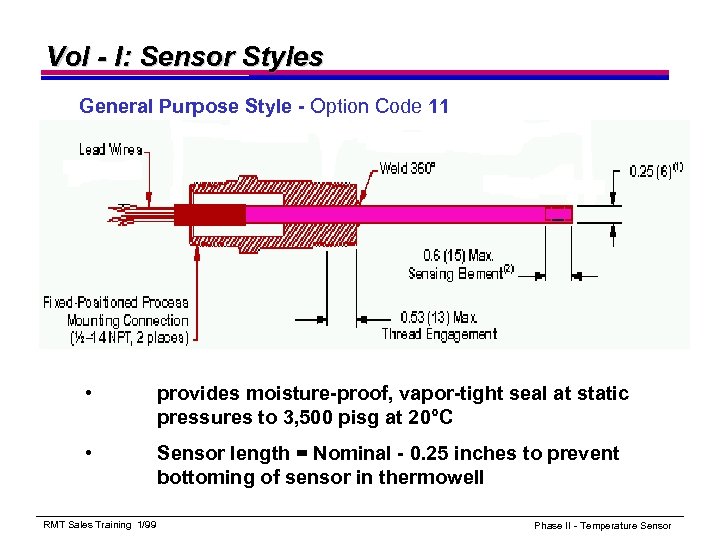

Vol - I: Sensor Styles General Purpose Style - Option Code 11 • provides moisture-proof, vapor-tight seal at static pressures to 3, 500 pisg at 20°C • Sensor length = Nominal - 0. 25 inches to prevent bottoming of sensor in thermowell RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol - I: Sensor Styles General Purpose Style - Option Code 11 • provides moisture-proof, vapor-tight seal at static pressures to 3, 500 pisg at 20°C • Sensor length = Nominal - 0. 25 inches to prevent bottoming of sensor in thermowell RMT Sales Training 1/99 Phase II - Temperature Sensor

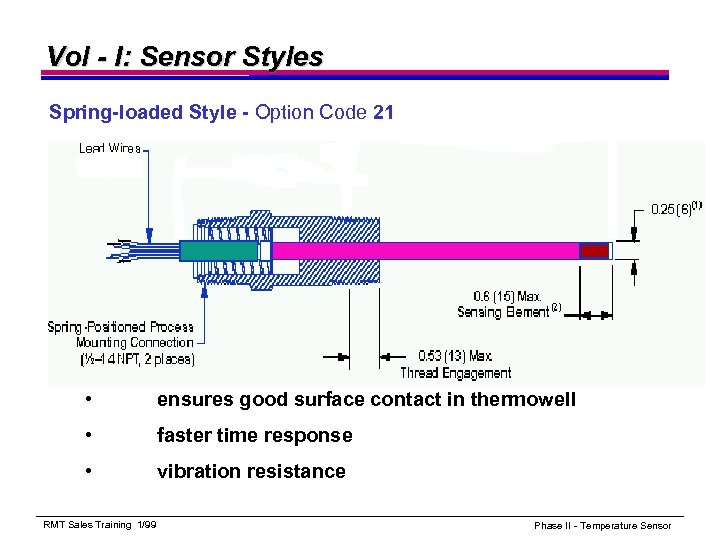

Vol - I: Sensor Styles Spring-loaded Style - Option Code 21 • ensures good surface contact in thermowell • faster time response • vibration resistance RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol - I: Sensor Styles Spring-loaded Style - Option Code 21 • ensures good surface contact in thermowell • faster time response • vibration resistance RMT Sales Training 1/99 Phase II - Temperature Sensor

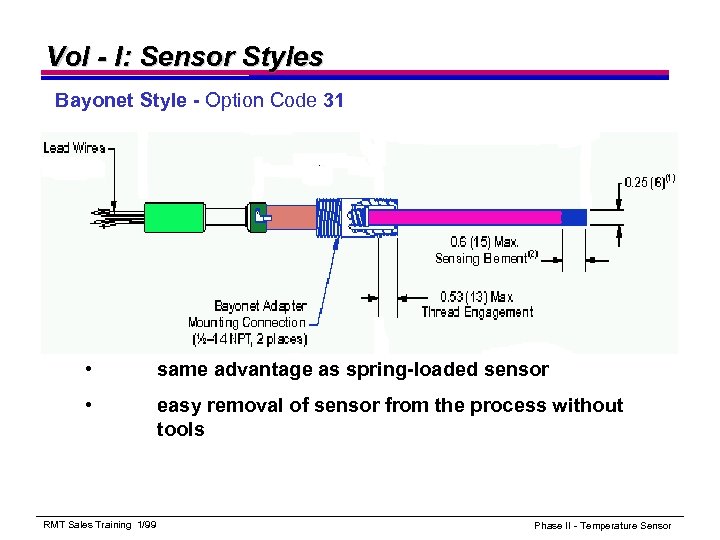

Vol - I: Sensor Styles Bayonet Style - Option Code 31 • same advantage as spring-loaded sensor • easy removal of sensor from the process without tools RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol - I: Sensor Styles Bayonet Style - Option Code 31 • same advantage as spring-loaded sensor • easy removal of sensor from the process without tools RMT Sales Training 1/99 Phase II - Temperature Sensor

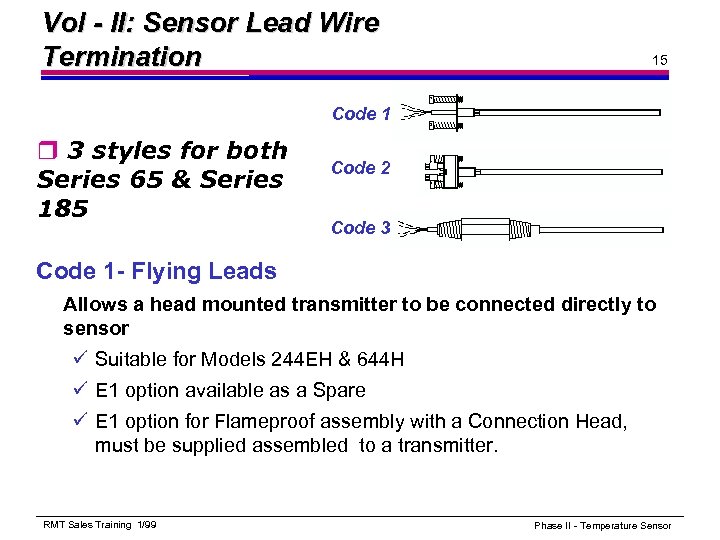

Vol - II: Sensor Lead Wire Termination 15 Code 1 r 3 styles for both Series 65 & Series 185 Code 2 Code 3 Code 1 - Flying Leads Allows a head mounted transmitter to be connected directly to sensor ü Suitable for Models 244 EH & 644 H ü E 1 option available as a Spare ü E 1 option for Flameproof assembly with a Connection Head, must be supplied assembled to a transmitter. RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol - II: Sensor Lead Wire Termination 15 Code 1 r 3 styles for both Series 65 & Series 185 Code 2 Code 3 Code 1 - Flying Leads Allows a head mounted transmitter to be connected directly to sensor ü Suitable for Models 244 EH & 644 H ü E 1 option available as a Spare ü E 1 option for Flameproof assembly with a Connection Head, must be supplied assembled to a transmitter. RMT Sales Training 1/99 Phase II - Temperature Sensor

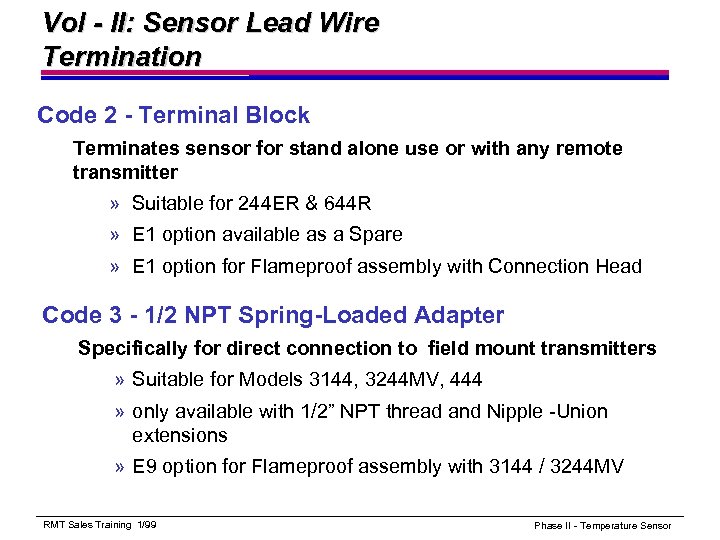

Vol - II: Sensor Lead Wire Termination Code 2 - Terminal Block Terminates sensor for stand alone use or with any remote transmitter » Suitable for 244 ER & 644 R » E 1 option available as a Spare » E 1 option for Flameproof assembly with Connection Head Code 3 - 1/2 NPT Spring-Loaded Adapter Specifically for direct connection to field mount transmitters » Suitable for Models 3144, 3244 MV, 444 » only available with 1/2” NPT thread and Nipple -Union extensions » E 9 option for Flameproof assembly with 3144 / 3244 MV RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol - II: Sensor Lead Wire Termination Code 2 - Terminal Block Terminates sensor for stand alone use or with any remote transmitter » Suitable for 244 ER & 644 R » E 1 option available as a Spare » E 1 option for Flameproof assembly with Connection Head Code 3 - 1/2 NPT Spring-Loaded Adapter Specifically for direct connection to field mount transmitters » Suitable for Models 3144, 3244 MV, 444 » only available with 1/2” NPT thread and Nipple -Union extensions » E 9 option for Flameproof assembly with 3144 / 3244 MV RMT Sales Training 1/99 Phase II - Temperature Sensor

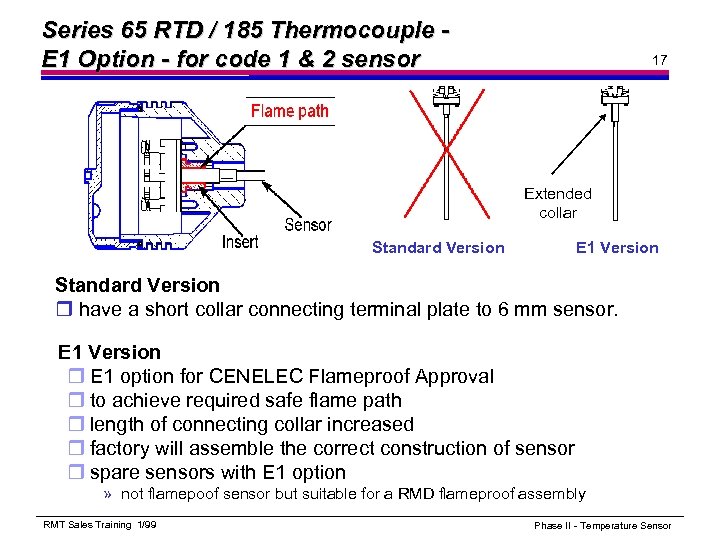

Series 65 RTD / 185 Thermocouple E 1 Option - for code 1 & 2 sensor 17 Extended collar Standard Version E 1 Version Standard Version r have a short collar connecting terminal plate to 6 mm sensor. E 1 Version r E 1 option for CENELEC Flameproof Approval r to achieve required safe flame path r length of connecting collar increased r factory will assemble the correct construction of sensor r spare sensors with E 1 option » not flamepoof sensor but suitable for a RMD flameproof assembly RMT Sales Training 1/99 Phase II - Temperature Sensor

Series 65 RTD / 185 Thermocouple E 1 Option - for code 1 & 2 sensor 17 Extended collar Standard Version E 1 Version Standard Version r have a short collar connecting terminal plate to 6 mm sensor. E 1 Version r E 1 option for CENELEC Flameproof Approval r to achieve required safe flame path r length of connecting collar increased r factory will assemble the correct construction of sensor r spare sensors with E 1 option » not flamepoof sensor but suitable for a RMD flameproof assembly RMT Sales Training 1/99 Phase II - Temperature Sensor

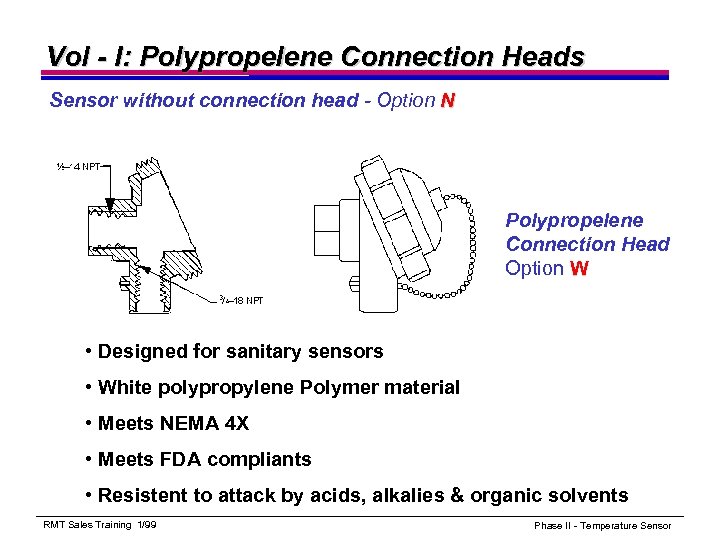

Vol - I: Polypropelene Connection Heads Sensor without connection head - Option N Polypropelene Connection Head Option W • Designed for sanitary sensors • White polypropylene Polymer material • Meets NEMA 4 X • Meets FDA compliants • Resistent to attack by acids, alkalies & organic solvents RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol - I: Polypropelene Connection Heads Sensor without connection head - Option N Polypropelene Connection Head Option W • Designed for sanitary sensors • White polypropylene Polymer material • Meets NEMA 4 X • Meets FDA compliants • Resistent to attack by acids, alkalies & organic solvents RMT Sales Training 1/99 Phase II - Temperature Sensor

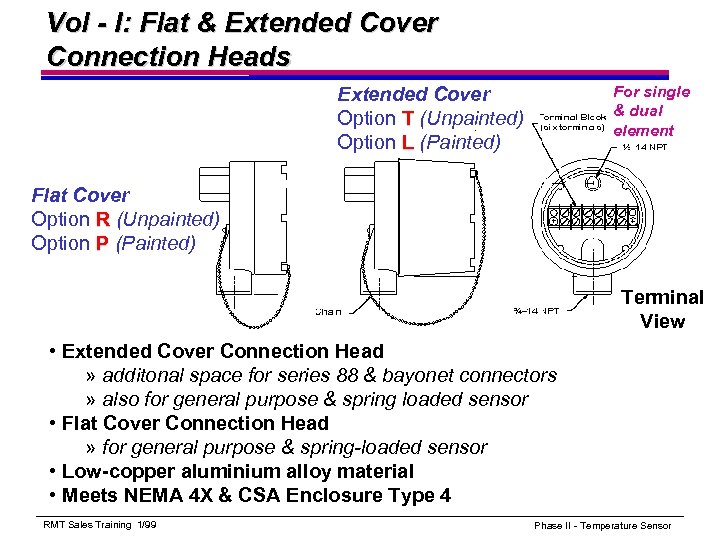

Vol - I: Flat & Extended Cover Connection Heads For single & dual element Extended Cover Option T (Unpainted) Option L (Painted) Flat Cover Option R (Unpainted) Option P (Painted) Terminal View • Extended Cover Connection Head » additonal space for series 88 & bayonet connectors » also for general purpose & spring loaded sensor • Flat Cover Connection Head » for general purpose & spring-loaded sensor • Low-copper aluminium alloy material • Meets NEMA 4 X & CSA Enclosure Type 4 RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol - I: Flat & Extended Cover Connection Heads For single & dual element Extended Cover Option T (Unpainted) Option L (Painted) Flat Cover Option R (Unpainted) Option P (Painted) Terminal View • Extended Cover Connection Head » additonal space for series 88 & bayonet connectors » also for general purpose & spring loaded sensor • Flat Cover Connection Head » for general purpose & spring-loaded sensor • Low-copper aluminium alloy material • Meets NEMA 4 X & CSA Enclosure Type 4 RMT Sales Training 1/99 Phase II - Temperature Sensor

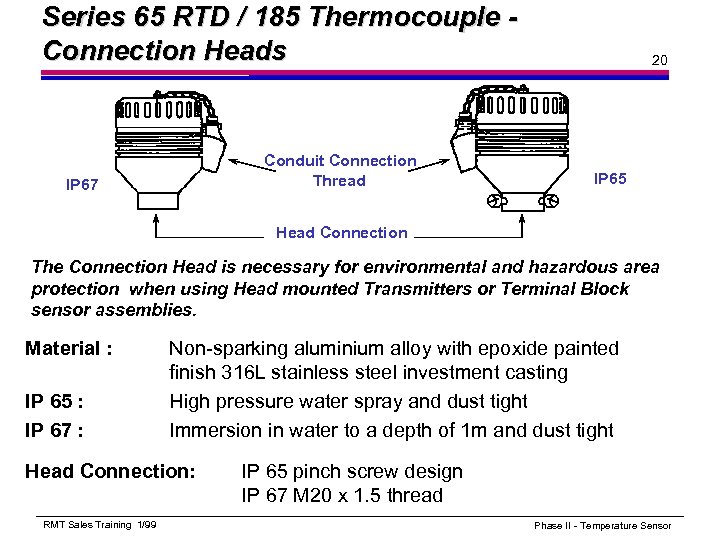

Series 65 RTD / 185 Thermocouple Connection Heads Conduit Connection Thread IP 67 20 IP 65 Head Connection The Connection Head is necessary for environmental and hazardous area protection when using Head mounted Transmitters or Terminal Block sensor assemblies. Material : IP 65 : IP 67 : Non-sparking aluminium alloy with epoxide painted finish 316 L stainless steel investment casting High pressure water spray and dust tight Immersion in water to a depth of 1 m and dust tight Head Connection: RMT Sales Training 1/99 IP 65 pinch screw design IP 67 M 20 x 1. 5 thread Phase II - Temperature Sensor

Series 65 RTD / 185 Thermocouple Connection Heads Conduit Connection Thread IP 67 20 IP 65 Head Connection The Connection Head is necessary for environmental and hazardous area protection when using Head mounted Transmitters or Terminal Block sensor assemblies. Material : IP 65 : IP 67 : Non-sparking aluminium alloy with epoxide painted finish 316 L stainless steel investment casting High pressure water spray and dust tight Immersion in water to a depth of 1 m and dust tight Head Connection: RMT Sales Training 1/99 IP 65 pinch screw design IP 67 M 20 x 1. 5 thread Phase II - Temperature Sensor

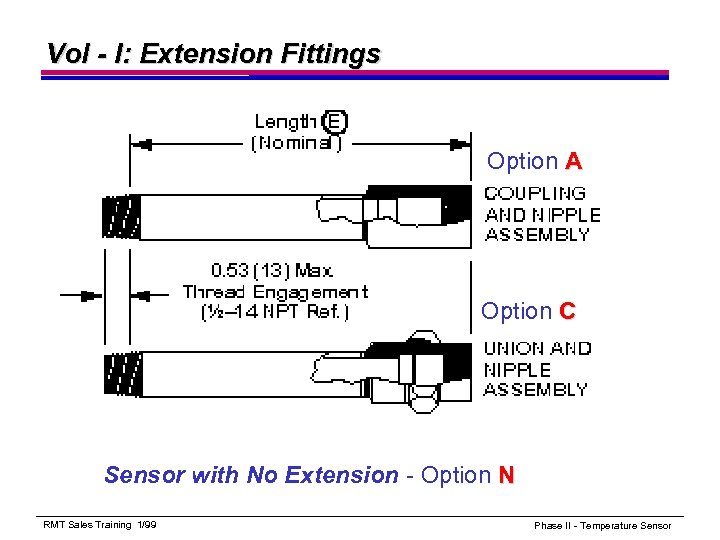

Vol - I: Extension Fittings Option A Option C Sensor with No Extension - Option N RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol - I: Extension Fittings Option A Option C Sensor with No Extension - Option N RMT Sales Training 1/99 Phase II - Temperature Sensor

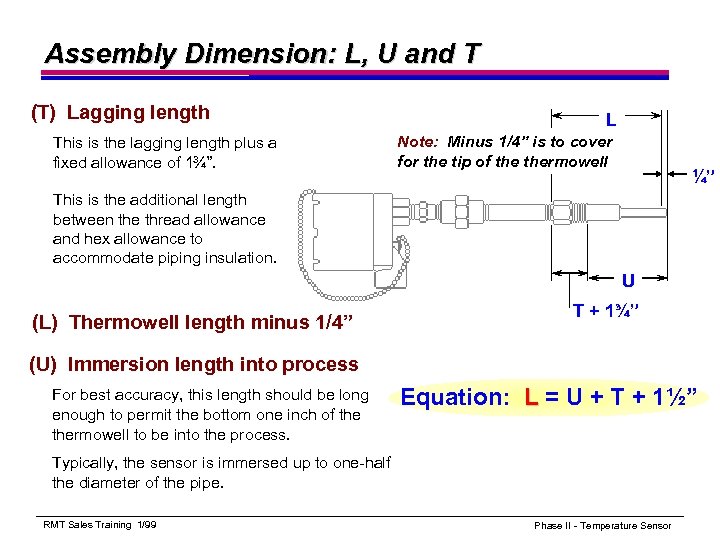

Assembly Dimension: L, U and T (T) Lagging length This is the lagging length plus a fixed allowance of 1¾”. L Note: Minus 1/4” is to cover for the tip of thermowell ¼” This is the additional length between the thread allowance and hex allowance to accommodate piping insulation. U (L) Thermowell length minus 1/4” T + 1¾” (U) Immersion length into process For best accuracy, this length should be long enough to permit the bottom one inch of thermowell to be into the process. Equation: L = U + T + 1½” Typically, the sensor is immersed up to one-half the diameter of the pipe. RMT Sales Training 1/99 Phase II - Temperature Sensor

Assembly Dimension: L, U and T (T) Lagging length This is the lagging length plus a fixed allowance of 1¾”. L Note: Minus 1/4” is to cover for the tip of thermowell ¼” This is the additional length between the thread allowance and hex allowance to accommodate piping insulation. U (L) Thermowell length minus 1/4” T + 1¾” (U) Immersion length into process For best accuracy, this length should be long enough to permit the bottom one inch of thermowell to be into the process. Equation: L = U + T + 1½” Typically, the sensor is immersed up to one-half the diameter of the pipe. RMT Sales Training 1/99 Phase II - Temperature Sensor

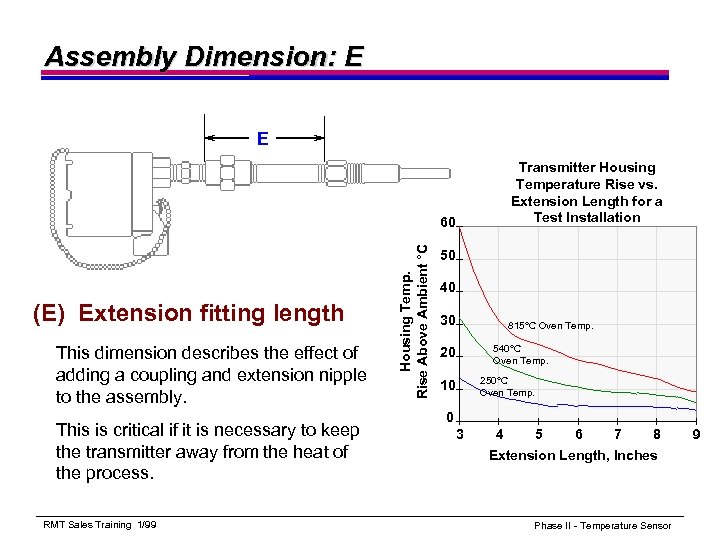

Assembly Dimension: E E Transmitter Housing Temperature Rise vs. Extension Length for a Test Installation (E) Extension fitting length This dimension describes the effect of adding a coupling and extension nipple to the assembly. This is critical if it is necessary to keep the transmitter away from the heat of the process. RMT Sales Training 1/99 Housing Temp. Rise Above Ambient °C 60 50 40 30 815°C Oven Temp. 540°C Oven Temp. 20 250°C Oven Temp. 10 0 3 4 5 6 7 8 Extension Length, Inches Phase II - Temperature Sensor 9

Assembly Dimension: E E Transmitter Housing Temperature Rise vs. Extension Length for a Test Installation (E) Extension fitting length This dimension describes the effect of adding a coupling and extension nipple to the assembly. This is critical if it is necessary to keep the transmitter away from the heat of the process. RMT Sales Training 1/99 Housing Temp. Rise Above Ambient °C 60 50 40 30 815°C Oven Temp. 540°C Oven Temp. 20 250°C Oven Temp. 10 0 3 4 5 6 7 8 Extension Length, Inches Phase II - Temperature Sensor 9

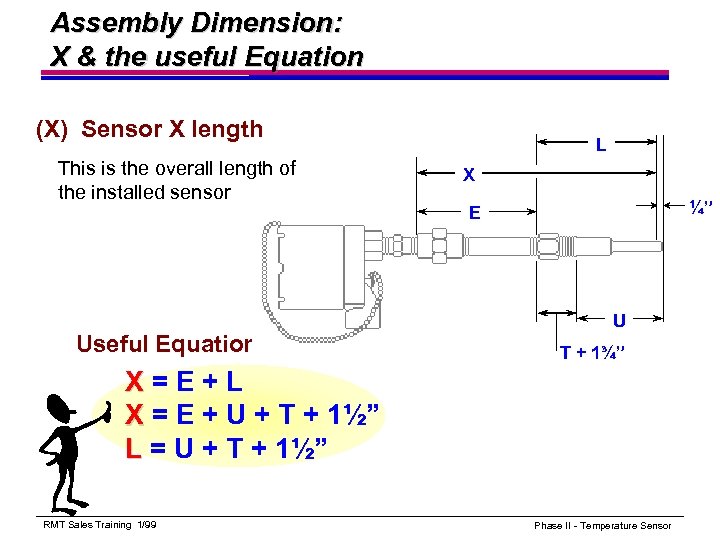

Assembly Dimension: X & the useful Equation (X) Sensor X length This is the overall length of the installed sensor L X ¼” E U Useful Equations T + 1¾” X=E+L X = E + U + T + 1½” L = U + T + 1½” RMT Sales Training 1/99 Phase II - Temperature Sensor

Assembly Dimension: X & the useful Equation (X) Sensor X length This is the overall length of the installed sensor L X ¼” E U Useful Equations T + 1¾” X=E+L X = E + U + T + 1½” L = U + T + 1½” RMT Sales Training 1/99 Phase II - Temperature Sensor

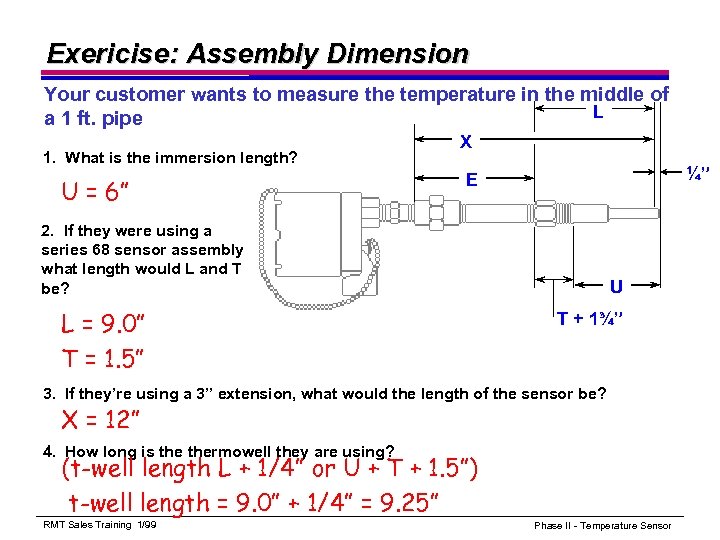

Exericise: Assembly Dimension Your customer wants to measure the temperature in the middle of L a 1 ft. pipe 1. What is the immersion length? U = 6” X ¼” E 2. If they were using a series 68 sensor assembly what length would L and T be? L = 9. 0” T = 1. 5” U T + 1¾” 3. If they’re using a 3” extension, what would the length of the sensor be? X = 12” 4. How long is thermowell they are using? (t-well length L + 1/4” or U + T + 1. 5”) t-well length = 9. 0” + 1/4” = 9. 25” RMT Sales Training 1/99 Phase II - Temperature Sensor

Exericise: Assembly Dimension Your customer wants to measure the temperature in the middle of L a 1 ft. pipe 1. What is the immersion length? U = 6” X ¼” E 2. If they were using a series 68 sensor assembly what length would L and T be? L = 9. 0” T = 1. 5” U T + 1¾” 3. If they’re using a 3” extension, what would the length of the sensor be? X = 12” 4. How long is thermowell they are using? (t-well length L + 1/4” or U + T + 1. 5”) t-well length = 9. 0” + 1/4” = 9. 25” RMT Sales Training 1/99 Phase II - Temperature Sensor

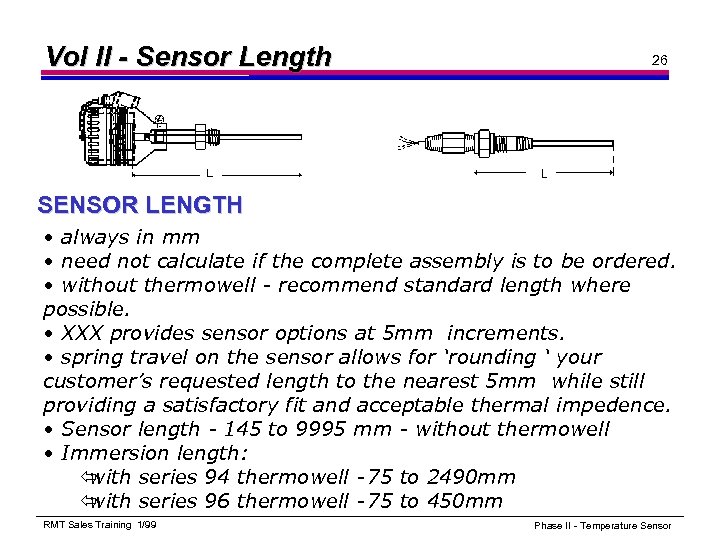

Vol II - Sensor Length 26 SENSOR LENGTH • always in mm • need not calculate if the complete assembly is to be ordered. • without thermowell - recommend standard length where possible. • XXX provides sensor options at 5 mm increments. • spring travel on the sensor allows for ‘rounding ‘ your customer’s requested length to the nearest 5 mm while still providing a satisfactory fit and acceptable thermal impedence. • Sensor length - 145 to 9995 mm - without thermowell • Immersion length: ï with series 94 thermowell - 75 to 2490 mm ï with series 96 thermowell - 75 to 450 mm RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol II - Sensor Length 26 SENSOR LENGTH • always in mm • need not calculate if the complete assembly is to be ordered. • without thermowell - recommend standard length where possible. • XXX provides sensor options at 5 mm increments. • spring travel on the sensor allows for ‘rounding ‘ your customer’s requested length to the nearest 5 mm while still providing a satisfactory fit and acceptable thermal impedence. • Sensor length - 145 to 9995 mm - without thermowell • Immersion length: ï with series 94 thermowell - 75 to 2490 mm ï with series 96 thermowell - 75 to 450 mm RMT Sales Training 1/99 Phase II - Temperature Sensor

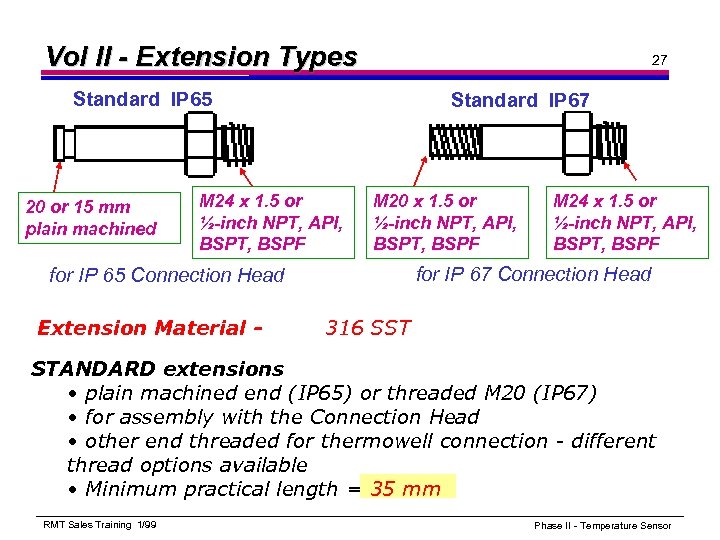

Vol II - Extension Types 27 Standard IP 65 20 or 15 mm plain machined Standard IP 67 M 24 x 1. 5 or ½-inch NPT, API, BSPT, BSPF M 20 x 1. 5 or ½-inch NPT, API, BSPT, BSPF for IP 67 Connection Head for IP 65 Connection Head Extension Material - M 24 x 1. 5 or ½-inch NPT, API, BSPT, BSPF 316 SST STANDARD extensions • plain machined end (IP 65) or threaded M 20 (IP 67) • for assembly with the Connection Head • other end threaded for thermowell connection - different thread options available • Minimum practical length = 35 mm RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol II - Extension Types 27 Standard IP 65 20 or 15 mm plain machined Standard IP 67 M 24 x 1. 5 or ½-inch NPT, API, BSPT, BSPF M 20 x 1. 5 or ½-inch NPT, API, BSPT, BSPF for IP 67 Connection Head for IP 65 Connection Head Extension Material - M 24 x 1. 5 or ½-inch NPT, API, BSPT, BSPF 316 SST STANDARD extensions • plain machined end (IP 65) or threaded M 20 (IP 67) • for assembly with the Connection Head • other end threaded for thermowell connection - different thread options available • Minimum practical length = 35 mm RMT Sales Training 1/99 Phase II - Temperature Sensor

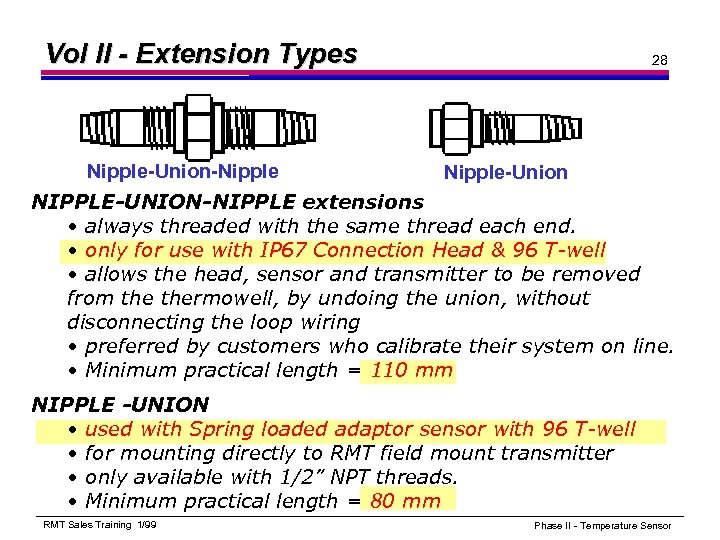

Vol II - Extension Types Nipple-Union-Nipple 28 Nipple-Union NIPPLE-UNION-NIPPLE extensions • always threaded with the same thread each end. • only for use with IP 67 Connection Head & 96 T-well • allows the head, sensor and transmitter to be removed from thermowell, by undoing the union, without disconnecting the loop wiring • preferred by customers who calibrate their system on line. • Minimum practical length = 110 mm NIPPLE -UNION • used with Spring loaded adaptor sensor with 96 T-well • for mounting directly to RMT field mount transmitter • only available with 1/2” NPT threads. • Minimum practical length = 80 mm RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol II - Extension Types Nipple-Union-Nipple 28 Nipple-Union NIPPLE-UNION-NIPPLE extensions • always threaded with the same thread each end. • only for use with IP 67 Connection Head & 96 T-well • allows the head, sensor and transmitter to be removed from thermowell, by undoing the union, without disconnecting the loop wiring • preferred by customers who calibrate their system on line. • Minimum practical length = 110 mm NIPPLE -UNION • used with Spring loaded adaptor sensor with 96 T-well • for mounting directly to RMT field mount transmitter • only available with 1/2” NPT threads. • Minimum practical length = 80 mm RMT Sales Training 1/99 Phase II - Temperature Sensor

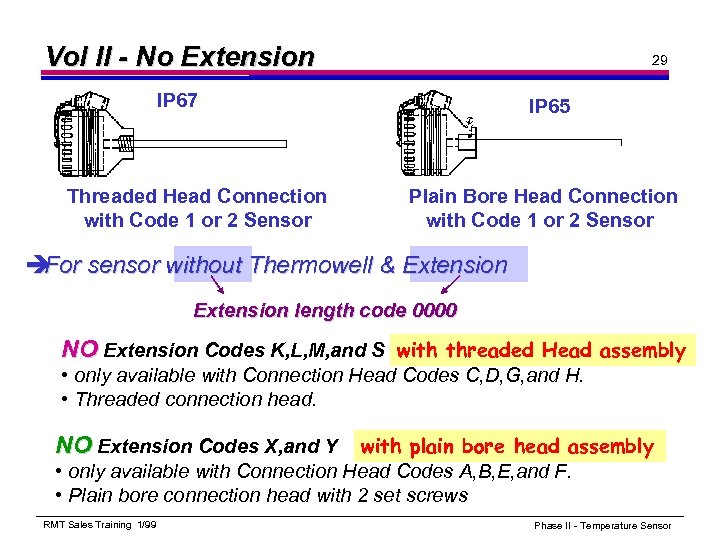

Vol II - No Extension 29 IP 67 Threaded Head Connection with Code 1 or 2 Sensor IP 65 Plain Bore Head Connection with Code 1 or 2 Sensor è sensor without Thermowell & Extension For Extension length code 0000 NO Extension Codes K, L, M, and S with threaded Head assembly • only available with Connection Head Codes C, D, G, and H. • Threaded connection head. NO Extension Codes X, and Y with plain bore head assembly • only available with Connection Head Codes A, B, E, and F. • Plain bore connection head with 2 set screws RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol II - No Extension 29 IP 67 Threaded Head Connection with Code 1 or 2 Sensor IP 65 Plain Bore Head Connection with Code 1 or 2 Sensor è sensor without Thermowell & Extension For Extension length code 0000 NO Extension Codes K, L, M, and S with threaded Head assembly • only available with Connection Head Codes C, D, G, and H. • Threaded connection head. NO Extension Codes X, and Y with plain bore head assembly • only available with Connection Head Codes A, B, E, and F. • Plain bore connection head with 2 set screws RMT Sales Training 1/99 Phase II - Temperature Sensor

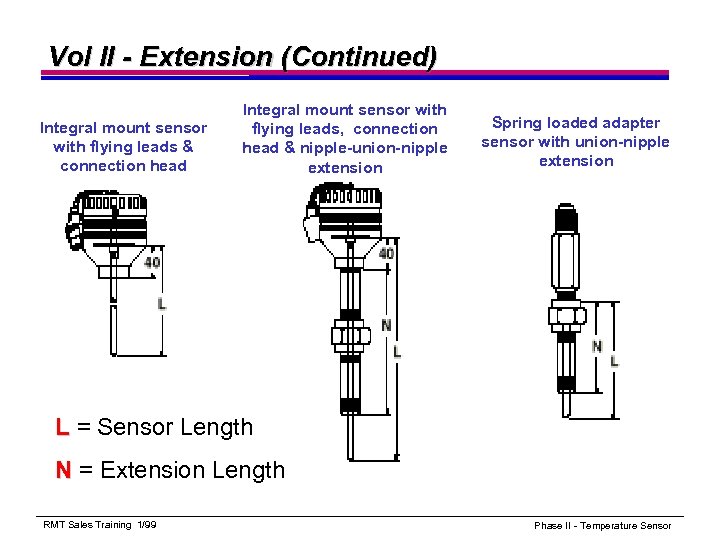

Vol II - Extension (Continued) Integral mount sensor with flying leads & connection head Integral mount sensor with flying leads, connection head & nipple-union-nipple extension Spring loaded adapter sensor with union-nipple extension L = Sensor Length N = Extension Length RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol II - Extension (Continued) Integral mount sensor with flying leads & connection head Integral mount sensor with flying leads, connection head & nipple-union-nipple extension Spring loaded adapter sensor with union-nipple extension L = Sensor Length N = Extension Length RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol I - Thermowell Series r Series 79 & Series 81 3 Identical design 3 Series 81 only offered with flange type-full penetration welds. r Series 80 3 Has internal tapered threads 3 For use in CSA applications. 3 Full penetration weld is a standard for the flange mount. Materials: Standard - 316 SST, 304 SST or C 1018 Carbon Steel. For corrosive environment, there are options: Monel, Hastelloy & Inconel 600. RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol I - Thermowell Series r Series 79 & Series 81 3 Identical design 3 Series 81 only offered with flange type-full penetration welds. r Series 80 3 Has internal tapered threads 3 For use in CSA applications. 3 Full penetration weld is a standard for the flange mount. Materials: Standard - 316 SST, 304 SST or C 1018 Carbon Steel. For corrosive environment, there are options: Monel, Hastelloy & Inconel 600. RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol I - Thermowells Thermowell Stems styles r Straight - All series r Tapered - All series r Stepped - All series Thermowell Mounting Styles r. Threaded - series 79 & 80 only » NPT= National (US) Pipe Taper (1/2 -14 up to 1 -11. 5 NPT) r. Welded - series 79 & 80 only » (3/4 -1 inch pipe) r. Flanged - All series » Rating: RMT Sales Training 1/99 1 inch - up to Class 600 1. 5 inch - up to Class 2500 2 inch - up to 1500 3 inch - up to 150 Phase II - Temperature Sensor

Vol I - Thermowells Thermowell Stems styles r Straight - All series r Tapered - All series r Stepped - All series Thermowell Mounting Styles r. Threaded - series 79 & 80 only » NPT= National (US) Pipe Taper (1/2 -14 up to 1 -11. 5 NPT) r. Welded - series 79 & 80 only » (3/4 -1 inch pipe) r. Flanged - All series » Rating: RMT Sales Training 1/99 1 inch - up to Class 600 1. 5 inch - up to Class 2500 2 inch - up to 1500 3 inch - up to 150 Phase II - Temperature Sensor

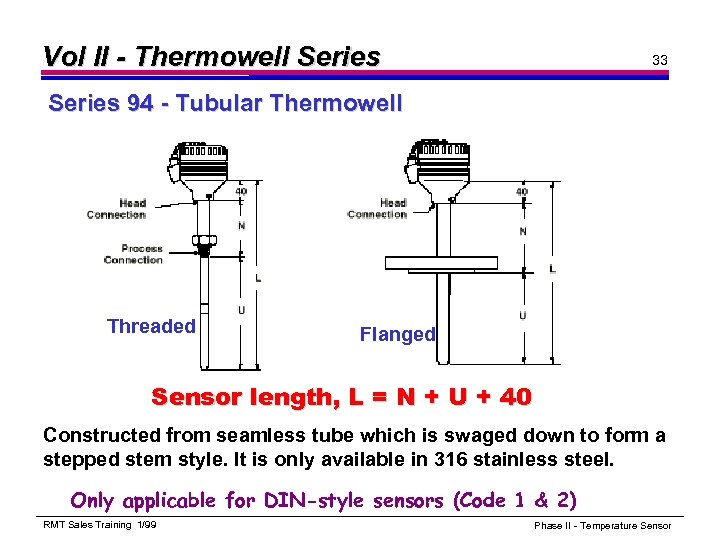

Vol II - Thermowell Series 33 Series 94 - Tubular Thermowell Threaded Flanged Sensor length, L = N + U + 40 Constructed from seamless tube which is swaged down to form a stepped stem style. It is only available in 316 stainless steel. Only applicable for DIN-style sensors (Code 1 & 2) RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol II - Thermowell Series 33 Series 94 - Tubular Thermowell Threaded Flanged Sensor length, L = N + U + 40 Constructed from seamless tube which is swaged down to form a stepped stem style. It is only available in 316 stainless steel. Only applicable for DIN-style sensors (Code 1 & 2) RMT Sales Training 1/99 Phase II - Temperature Sensor

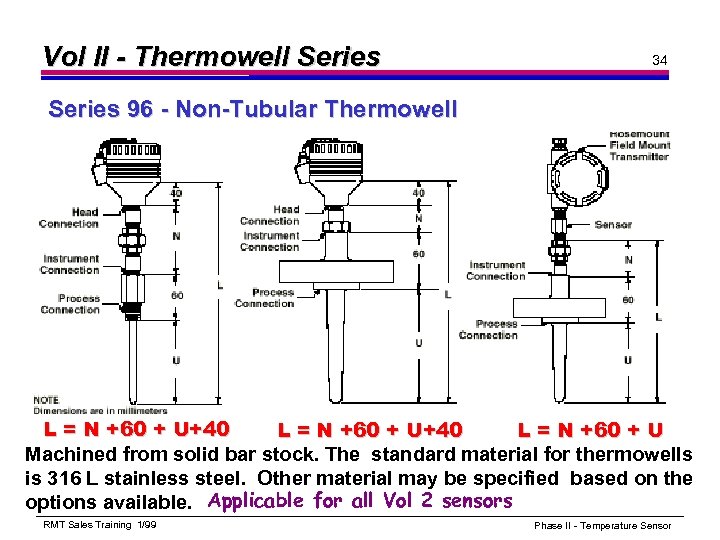

Vol II - Thermowell Series 34 Series 96 - Non-Tubular Thermowell L = N +60 + U+40 L = N +60 + U Machined from solid bar stock. The standard material for thermowells is 316 L stainless steel. Other material may be specified based on the options available. Applicable for all Vol 2 sensors RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol II - Thermowell Series 34 Series 96 - Non-Tubular Thermowell L = N +60 + U+40 L = N +60 + U Machined from solid bar stock. The standard material for thermowells is 316 L stainless steel. Other material may be specified based on the options available. Applicable for all Vol 2 sensors RMT Sales Training 1/99 Phase II - Temperature Sensor

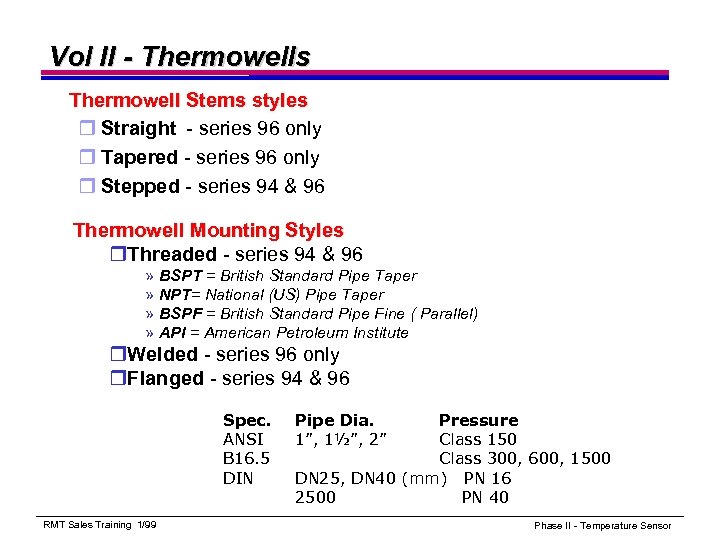

Vol II - Thermowells Thermowell Stems styles r Straight - series 96 only r Tapered - series 96 only r Stepped - series 94 & 96 Thermowell Mounting Styles r. Threaded - series 94 & 96 » BSPT = British Standard Pipe Taper » NPT= National (US) Pipe Taper » BSPF = British Standard Pipe Fine ( Parallel) » API = American Petroleum Institute r. Welded - series 96 only r. Flanged - series 94 & 96 Spec. ANSI B 16. 5 DIN RMT Sales Training 1/99 Pipe Dia. 1”, 1½”, 2” Pressure Class 150 Class 300, 600, 1500 DN 25, DN 40 (mm) PN 16 2500 PN 40 Phase II - Temperature Sensor

Vol II - Thermowells Thermowell Stems styles r Straight - series 96 only r Tapered - series 96 only r Stepped - series 94 & 96 Thermowell Mounting Styles r. Threaded - series 94 & 96 » BSPT = British Standard Pipe Taper » NPT= National (US) Pipe Taper » BSPF = British Standard Pipe Fine ( Parallel) » API = American Petroleum Institute r. Welded - series 96 only r. Flanged - series 94 & 96 Spec. ANSI B 16. 5 DIN RMT Sales Training 1/99 Pipe Dia. 1”, 1½”, 2” Pressure Class 150 Class 300, 600, 1500 DN 25, DN 40 (mm) PN 16 2500 PN 40 Phase II - Temperature Sensor

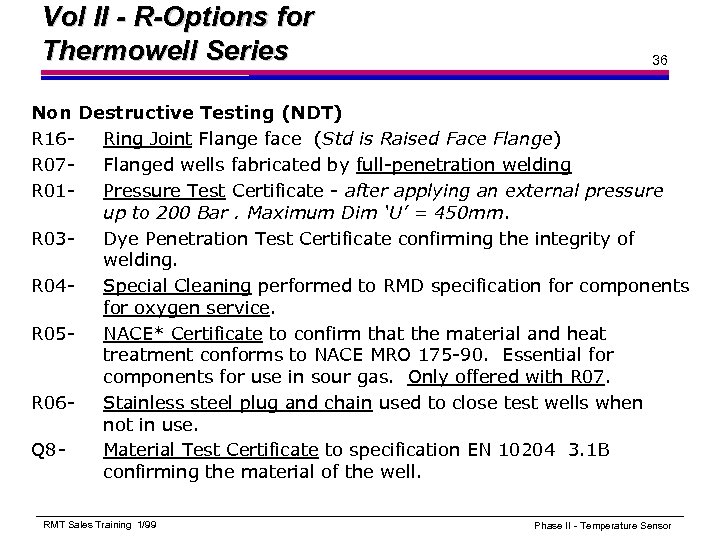

Vol II - R-Options for Thermowell Series 36 Non Destructive Testing (NDT) R 16 Ring Joint Flange face (Std is Raised Face Flange) R 07 Flanged wells fabricated by full-penetration welding R 01 Pressure Test Certificate - after applying an external pressure up to 200 Bar. Maximum Dim ‘U’ = 450 mm. R 03 Dye Penetration Test Certificate confirming the integrity of welding. R 04 Special Cleaning performed to RMD specification for components for oxygen service. R 05 NACE* Certificate to confirm that the material and heat treatment conforms to NACE MRO 175 -90. Essential for components for use in sour gas. Only offered with R 07. R 06 Stainless steel plug and chain used to close test wells when not in use. Q 8 Material Test Certificate to specification EN 10204 3. 1 B confirming the material of the well. RMT Sales Training 1/99 Phase II - Temperature Sensor

Vol II - R-Options for Thermowell Series 36 Non Destructive Testing (NDT) R 16 Ring Joint Flange face (Std is Raised Face Flange) R 07 Flanged wells fabricated by full-penetration welding R 01 Pressure Test Certificate - after applying an external pressure up to 200 Bar. Maximum Dim ‘U’ = 450 mm. R 03 Dye Penetration Test Certificate confirming the integrity of welding. R 04 Special Cleaning performed to RMD specification for components for oxygen service. R 05 NACE* Certificate to confirm that the material and heat treatment conforms to NACE MRO 175 -90. Essential for components for use in sour gas. Only offered with R 07. R 06 Stainless steel plug and chain used to close test wells when not in use. Q 8 Material Test Certificate to specification EN 10204 3. 1 B confirming the material of the well. RMT Sales Training 1/99 Phase II - Temperature Sensor

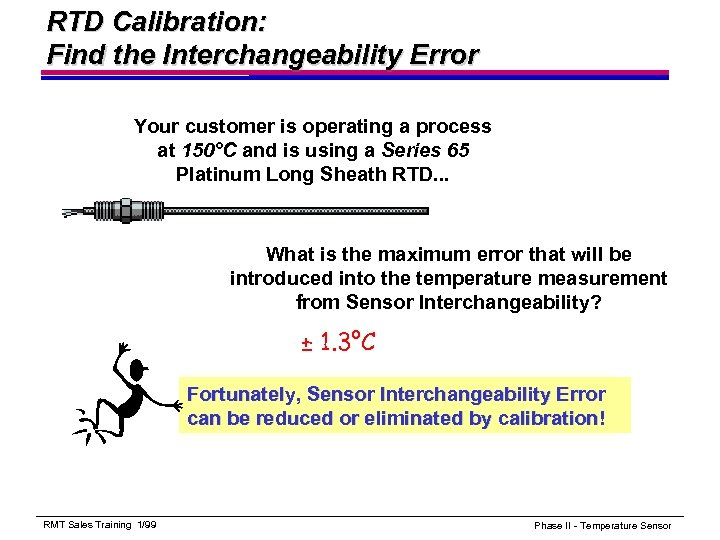

RTD Calibration: Find the Interchangeability Error Your customer is operating a process at 150°C and is using a Series 65 Platinum Long Sheath RTD. . . What is the maximum error that will be introduced into the temperature measurement from Sensor Interchangeability? ± 1. 3°C Fortunately, Sensor Interchangeability Error can be reduced or eliminated by calibration! RMT Sales Training 1/99 Phase II - Temperature Sensor

RTD Calibration: Find the Interchangeability Error Your customer is operating a process at 150°C and is using a Series 65 Platinum Long Sheath RTD. . . What is the maximum error that will be introduced into the temperature measurement from Sensor Interchangeability? ± 1. 3°C Fortunately, Sensor Interchangeability Error can be reduced or eliminated by calibration! RMT Sales Training 1/99 Phase II - Temperature Sensor

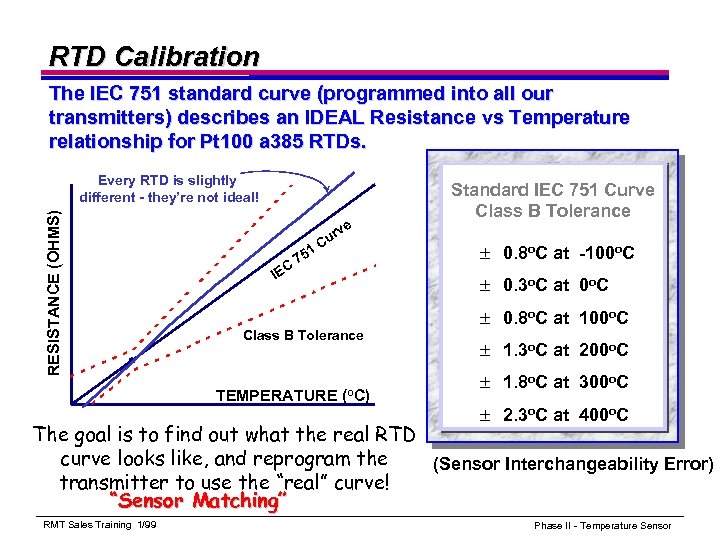

RTD Calibration The IEC 751 standard curve (programmed into all our transmitters) describes an IDEAL Resistance vs Temperature relationship for Pt 100 a 385 RTDs. RESISTANCE (OHMS) Every RTD is slightly different - they’re not ideal! ve C IE 1 75 r Cu ± 0. 8 o. C at -100 o. C ± 0. 3 o. C at 0 o. C Class B Tolerance TEMPERATURE Standard IEC 751 Curve Class B Tolerance (o. C) ± 0. 8 o. C at 100 o. C ± 1. 3 o. C at 200 o. C ± 1. 8 o. C at 300 o. C ± 2. 3 o. C at 400 o. C The goal is to find out what the real RTD curve looks like, and reprogram the (Sensor Interchangeability Error) transmitter to use the “real” curve! “Sensor Matching” RMT Sales Training 1/99 Phase II - Temperature Sensor

RTD Calibration The IEC 751 standard curve (programmed into all our transmitters) describes an IDEAL Resistance vs Temperature relationship for Pt 100 a 385 RTDs. RESISTANCE (OHMS) Every RTD is slightly different - they’re not ideal! ve C IE 1 75 r Cu ± 0. 8 o. C at -100 o. C ± 0. 3 o. C at 0 o. C Class B Tolerance TEMPERATURE Standard IEC 751 Curve Class B Tolerance (o. C) ± 0. 8 o. C at 100 o. C ± 1. 3 o. C at 200 o. C ± 1. 8 o. C at 300 o. C ± 2. 3 o. C at 400 o. C The goal is to find out what the real RTD curve looks like, and reprogram the (Sensor Interchangeability Error) transmitter to use the “real” curve! “Sensor Matching” RMT Sales Training 1/99 Phase II - Temperature Sensor

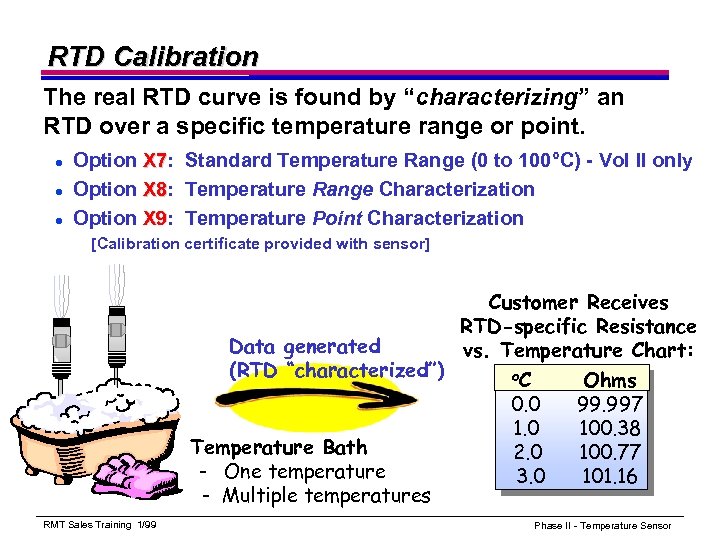

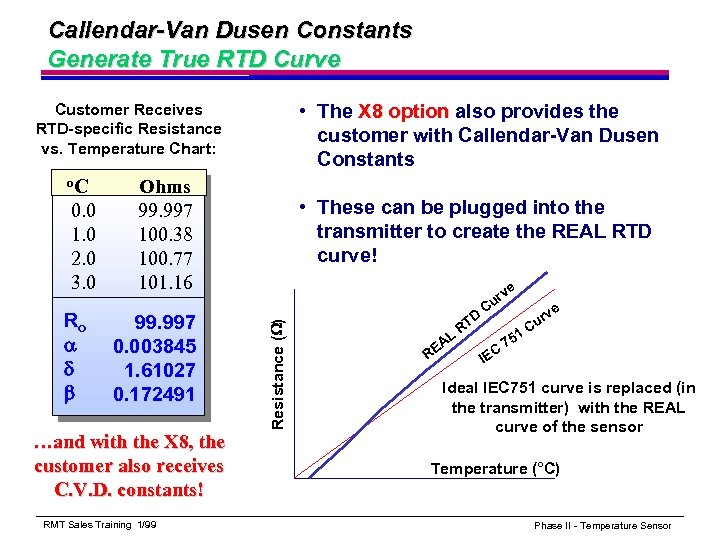

RTD Calibration The real RTD curve is found by “characterizing” an RTD over a specific temperature range or point. l l l Option X 7: Standard Temperature Range (0 to 100°C) - Vol II only X 7 Option X 8: Temperature Range Characterization X 8 Option X 9: Temperature Point Characterization X 9 [Calibration certificate provided with sensor] Data generated (RTD “characterized”) Temperature Bath - One temperature - Multiple temperatures RMT Sales Training 1/99 Customer Receives RTD-specific Resistance vs. Temperature Chart: o. C 0. 0 1. 0 2. 0 3. 0 Ohms 99. 997 100. 38 100. 77 101. 16 Phase II - Temperature Sensor

RTD Calibration The real RTD curve is found by “characterizing” an RTD over a specific temperature range or point. l l l Option X 7: Standard Temperature Range (0 to 100°C) - Vol II only X 7 Option X 8: Temperature Range Characterization X 8 Option X 9: Temperature Point Characterization X 9 [Calibration certificate provided with sensor] Data generated (RTD “characterized”) Temperature Bath - One temperature - Multiple temperatures RMT Sales Training 1/99 Customer Receives RTD-specific Resistance vs. Temperature Chart: o. C 0. 0 1. 0 2. 0 3. 0 Ohms 99. 997 100. 38 100. 77 101. 16 Phase II - Temperature Sensor

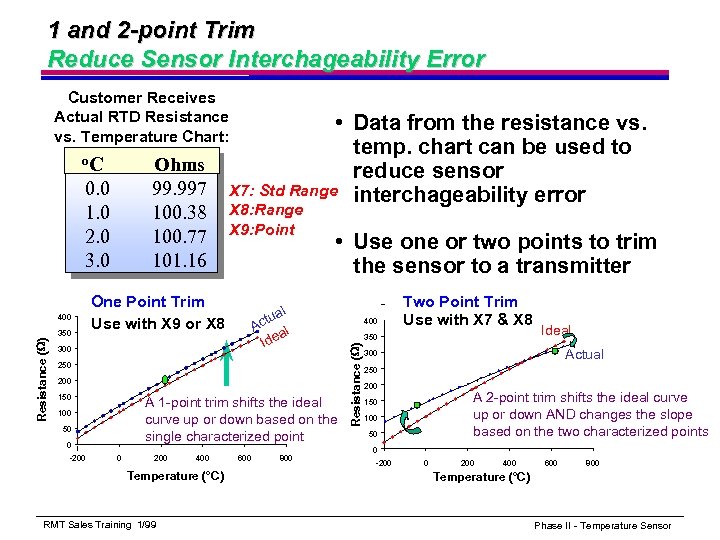

1 and 2 -point Trim Reduce Sensor Interchageability Error Customer Receives Actual RTD Resistance vs. Temperature Chart: • Data from the resistance vs. temp. chart can be used to Ohms reduce sensor 99. 997 X 7: Std Range interchageability error 0. 0 1. 0 2. 0 3. 0 400 Resistance (W) 350 100. 38 100. 77 101. 16 X 8: Range X 9: Point One Point Trim Use with X 9 or X 8 • Use one or two points to trim the sensor to a transmitter al ctu A al Ide 300 250 200 150 A 1 -point trim shifts the ideal curve up or down based on the single characterized point 100 50 0 -200 0 200 400 Temperature (°C) RMT Sales Training 1/99 600 800 400 Two Point Trim Use with X 7 & X 8 350 Resistance (W) o. C Ideal Actual 300 250 200 A 2 -point trim shifts the ideal curve up or down AND changes the slope based on the two characterized points 150 100 50 0 -200 0 200 400 600 800 Temperature (°C) Phase II - Temperature Sensor

1 and 2 -point Trim Reduce Sensor Interchageability Error Customer Receives Actual RTD Resistance vs. Temperature Chart: • Data from the resistance vs. temp. chart can be used to Ohms reduce sensor 99. 997 X 7: Std Range interchageability error 0. 0 1. 0 2. 0 3. 0 400 Resistance (W) 350 100. 38 100. 77 101. 16 X 8: Range X 9: Point One Point Trim Use with X 9 or X 8 • Use one or two points to trim the sensor to a transmitter al ctu A al Ide 300 250 200 150 A 1 -point trim shifts the ideal curve up or down based on the single characterized point 100 50 0 -200 0 200 400 Temperature (°C) RMT Sales Training 1/99 600 800 400 Two Point Trim Use with X 7 & X 8 350 Resistance (W) o. C Ideal Actual 300 250 200 A 2 -point trim shifts the ideal curve up or down AND changes the slope based on the two characterized points 150 100 50 0 -200 0 200 400 600 800 Temperature (°C) Phase II - Temperature Sensor

Callendar-Van Dusen Constants Generate True RTD Curve • The X 8 option also provides the customer with Callendar-Van Dusen Constants Customer Receives RTD-specific Resistance vs. Temperature Chart: 0. 0 1. 0 2. 0 3. 0 Ro a d b Ohms 99. 997 100. 38 100. 77 101. 16 99. 997 0. 003845 1. 61027 0. 172491 …and with the X 8, the customer also receives C. V. D. constants! RMT Sales Training 1/99 • These can be plugged into the transmitter to create the REAL RTD curve! ve Resistance (W) o. C L EA R D RT r Cu 1 C IE 75 r Cu ve Ideal IEC 751 curve is replaced (in the transmitter) with the REAL curve of the sensor Temperature (°C) Phase II - Temperature Sensor

Callendar-Van Dusen Constants Generate True RTD Curve • The X 8 option also provides the customer with Callendar-Van Dusen Constants Customer Receives RTD-specific Resistance vs. Temperature Chart: 0. 0 1. 0 2. 0 3. 0 Ro a d b Ohms 99. 997 100. 38 100. 77 101. 16 99. 997 0. 003845 1. 61027 0. 172491 …and with the X 8, the customer also receives C. V. D. constants! RMT Sales Training 1/99 • These can be plugged into the transmitter to create the REAL RTD curve! ve Resistance (W) o. C L EA R D RT r Cu 1 C IE 75 r Cu ve Ideal IEC 751 curve is replaced (in the transmitter) with the REAL curve of the sensor Temperature (°C) Phase II - Temperature Sensor

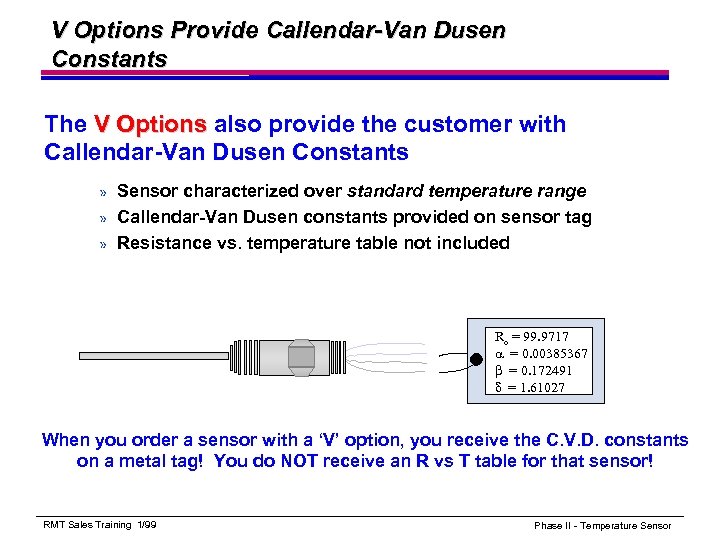

V Options Provide Callendar-Van Dusen Constants The V Options also provide the customer with Callendar-Van Dusen Constants Sensor characterized over standard temperature range » Callendar-Van Dusen constants provided on sensor tag » Resistance vs. temperature table not included » Ro = 99. 9717 a = 0. 00385367 b = 0. 172491 d = 1. 61027 When you order a sensor with a ‘V’ option, you receive the C. V. D. constants on a metal tag! You do NOT receive an R vs T table for that sensor! RMT Sales Training 1/99 Phase II - Temperature Sensor

V Options Provide Callendar-Van Dusen Constants The V Options also provide the customer with Callendar-Van Dusen Constants Sensor characterized over standard temperature range » Callendar-Van Dusen constants provided on sensor tag » Resistance vs. temperature table not included » Ro = 99. 9717 a = 0. 00385367 b = 0. 172491 d = 1. 61027 When you order a sensor with a ‘V’ option, you receive the C. V. D. constants on a metal tag! You do NOT receive an R vs T table for that sensor! RMT Sales Training 1/99 Phase II - Temperature Sensor

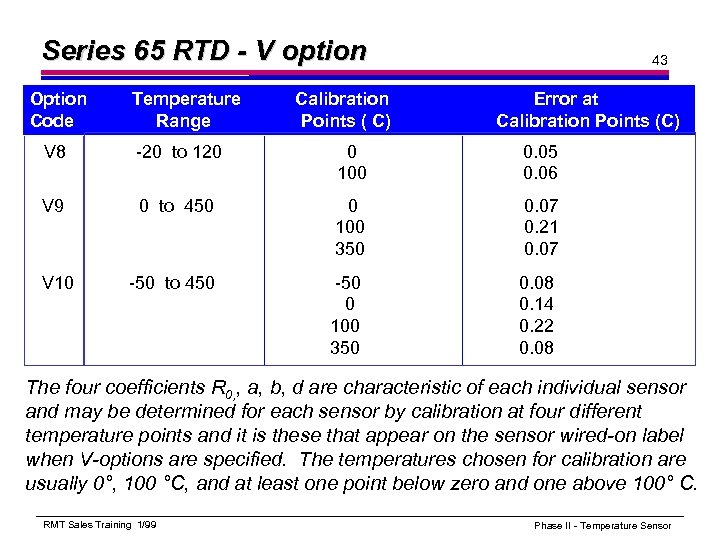

Series 65 RTD - V option Option Code Temperature Range Calibration Points ( C) 43 Error at Calibration Points (C) V 8 -20 to 120 0 100 0. 05 0. 06 V 9 0 to 450 0 100 350 0. 07 0. 21 0. 07 V 10 -50 to 450 -50 0 100 350 0. 08 0. 14 0. 22 0. 08 The four coefficients R 0, , a, b, d are characteristic of each individual sensor and may be determined for each sensor by calibration at four different temperature points and it is these that appear on the sensor wired-on label when V-options are specified. The temperatures chosen for calibration are usually 0°, 100 °C, and at least one point below zero and one above 100° C. RMT Sales Training 1/99 Phase II - Temperature Sensor

Series 65 RTD - V option Option Code Temperature Range Calibration Points ( C) 43 Error at Calibration Points (C) V 8 -20 to 120 0 100 0. 05 0. 06 V 9 0 to 450 0 100 350 0. 07 0. 21 0. 07 V 10 -50 to 450 -50 0 100 350 0. 08 0. 14 0. 22 0. 08 The four coefficients R 0, , a, b, d are characteristic of each individual sensor and may be determined for each sensor by calibration at four different temperature points and it is these that appear on the sensor wired-on label when V-options are specified. The temperatures chosen for calibration are usually 0°, 100 °C, and at least one point below zero and one above 100° C. RMT Sales Training 1/99 Phase II - Temperature Sensor

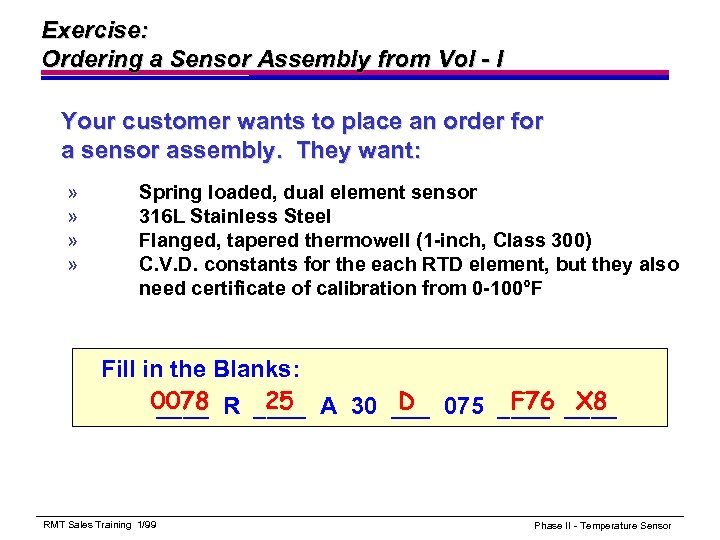

Exercise: Ordering a Sensor Assembly from Vol - I Your customer wants to place an order for a sensor assembly. They want: » » Spring loaded, dual element sensor 316 L Stainless Steel Flanged, tapered thermowell (1 -inch, Class 300) C. V. D. constants for the each RTD element, but they also need certificate of calibration from 0 -100°F Fill in the Blanks: 0078 R ____ A 30 ___ 075 ____ 25 D F 76 X 8 ____ RMT Sales Training 1/99 Phase II - Temperature Sensor

Exercise: Ordering a Sensor Assembly from Vol - I Your customer wants to place an order for a sensor assembly. They want: » » Spring loaded, dual element sensor 316 L Stainless Steel Flanged, tapered thermowell (1 -inch, Class 300) C. V. D. constants for the each RTD element, but they also need certificate of calibration from 0 -100°F Fill in the Blanks: 0078 R ____ A 30 ___ 075 ____ 25 D F 76 X 8 ____ RMT Sales Training 1/99 Phase II - Temperature Sensor

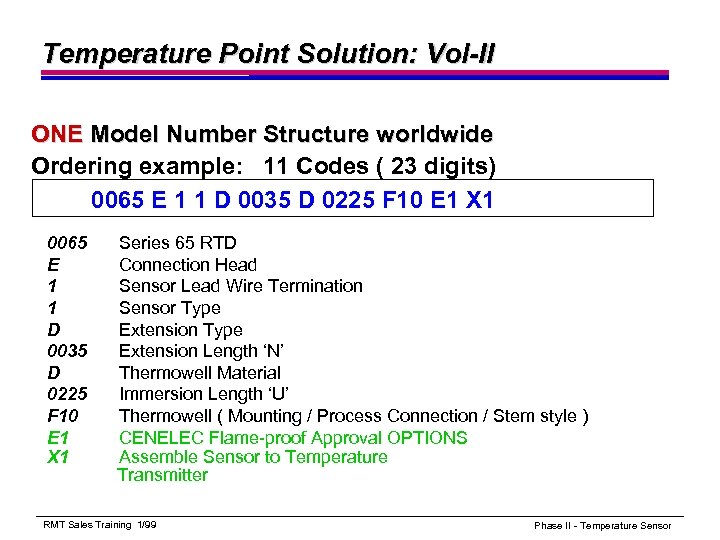

Temperature Point Solution: Vol-II ONE Model Number Structure worldwide Ordering example: 11 Codes ( 23 digits) 0065 E 1 1 D 0035 D 0225 F 10 E 1 X 1 Series 65 RTD Connection Head Sensor Lead Wire Termination Sensor Type Extension Length ‘N’ Thermowell Material Immersion Length ‘U’ Thermowell ( Mounting / Process Connection / Stem style ) CENELEC Flame-proof Approval OPTIONS Assemble Sensor to Temperature Transmitter RMT Sales Training 1/99 Phase II - Temperature Sensor

Temperature Point Solution: Vol-II ONE Model Number Structure worldwide Ordering example: 11 Codes ( 23 digits) 0065 E 1 1 D 0035 D 0225 F 10 E 1 X 1 Series 65 RTD Connection Head Sensor Lead Wire Termination Sensor Type Extension Length ‘N’ Thermowell Material Immersion Length ‘U’ Thermowell ( Mounting / Process Connection / Stem style ) CENELEC Flame-proof Approval OPTIONS Assemble Sensor to Temperature Transmitter RMT Sales Training 1/99 Phase II - Temperature Sensor

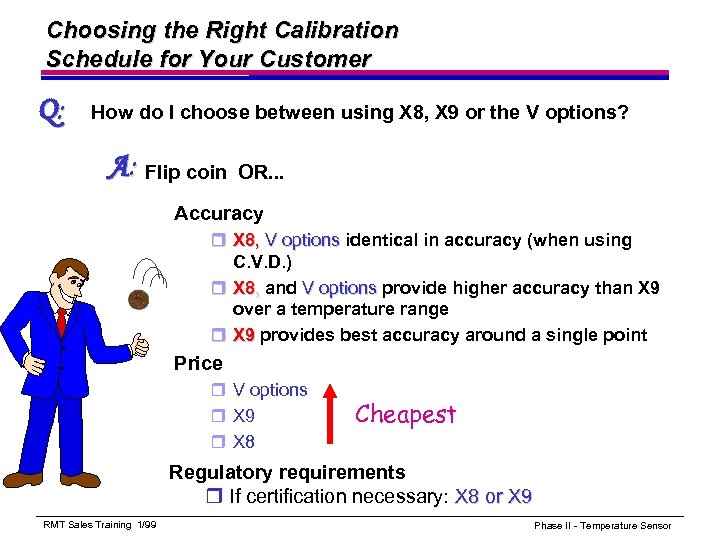

Choosing the Right Calibration Schedule for Your Customer Q: How do I choose between using X 8, X 9 or the V options? A: Flip coin OR. . . Accuracy r X 8, V options identical in accuracy (when using C. V. D. ) r X 8, and V options provide higher accuracy than X 9 over a temperature range r X 9 provides best accuracy around a single point Price r V options r X 9 r X 8 Cheapest Regulatory requirements r If certification necessary: X 8 or X 9 RMT Sales Training 1/99 Phase II - Temperature Sensor

Choosing the Right Calibration Schedule for Your Customer Q: How do I choose between using X 8, X 9 or the V options? A: Flip coin OR. . . Accuracy r X 8, V options identical in accuracy (when using C. V. D. ) r X 8, and V options provide higher accuracy than X 9 over a temperature range r X 9 provides best accuracy around a single point Price r V options r X 9 r X 8 Cheapest Regulatory requirements r If certification necessary: X 8 or X 9 RMT Sales Training 1/99 Phase II - Temperature Sensor

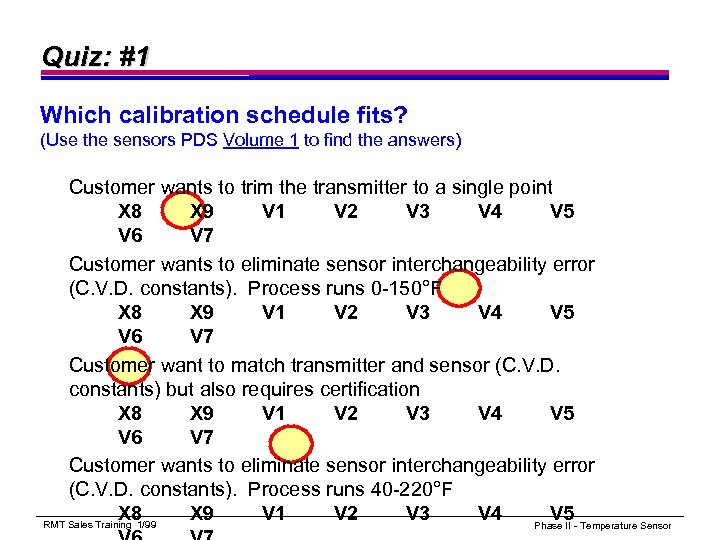

Quiz: #1 Which calibration schedule fits? (Use the sensors PDS Volume 1 to find the answers) Customer wants to trim the transmitter to a single point X 8 X 9 V 1 V 2 V 3 V 4 V 5 V 6 V 7 Customer wants to eliminate sensor interchangeability error (C. V. D. constants). Process runs 0 -150°F X 8 X 9 V 1 V 2 V 3 V 4 V 5 V 6 V 7 Customer want to match transmitter and sensor (C. V. D. constants) but also requires certification X 8 X 9 V 1 V 2 V 3 V 4 V 5 V 6 V 7 Customer wants to eliminate sensor interchangeability error (C. V. D. constants). Process runs 40 -220°F X 8 X 9 V 1 V 2 V 3 V 4 V 5 RMT Sales Training 1/99 Phase II - Temperature Sensor

Quiz: #1 Which calibration schedule fits? (Use the sensors PDS Volume 1 to find the answers) Customer wants to trim the transmitter to a single point X 8 X 9 V 1 V 2 V 3 V 4 V 5 V 6 V 7 Customer wants to eliminate sensor interchangeability error (C. V. D. constants). Process runs 0 -150°F X 8 X 9 V 1 V 2 V 3 V 4 V 5 V 6 V 7 Customer want to match transmitter and sensor (C. V. D. constants) but also requires certification X 8 X 9 V 1 V 2 V 3 V 4 V 5 V 6 V 7 Customer wants to eliminate sensor interchangeability error (C. V. D. constants). Process runs 40 -220°F X 8 X 9 V 1 V 2 V 3 V 4 V 5 RMT Sales Training 1/99 Phase II - Temperature Sensor

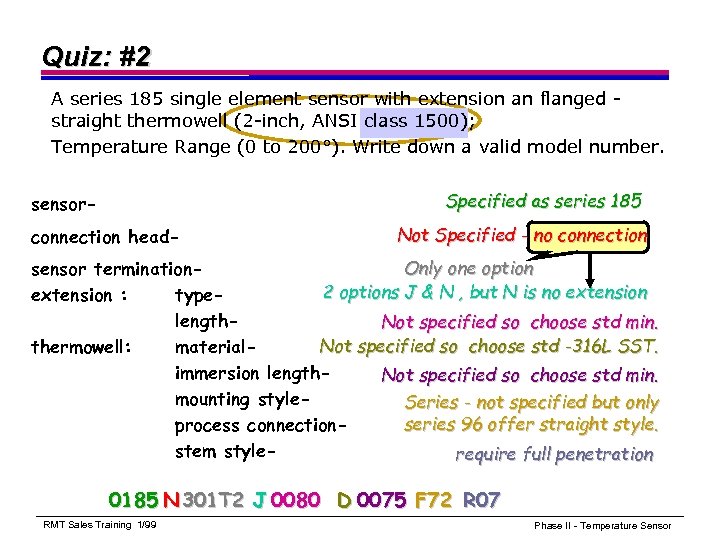

Quiz: #2 A series 185 single element sensor with extension an flanged straight thermowell (2 -inch, ANSI class 1500); Temperature Range (0 to 200°). Write down a valid model number. Specified as series 185 sensorconnection head- Not Specified - no connection Only one option sensor termination 2 options J & N , but N is no extension : typelength. Not specified so choose std min. Not specified so choose std -316 L SST. thermowell: materialimmersion length. Not specified so choose std min. mounting style. Series - not specified but only series 96 offer straight style. process connectionstem stylerequire full penetration 0185 N 301 T 2 J 0080 D 0075 F 72 R 07 RMT Sales Training 1/99 Phase II - Temperature Sensor

Quiz: #2 A series 185 single element sensor with extension an flanged straight thermowell (2 -inch, ANSI class 1500); Temperature Range (0 to 200°). Write down a valid model number. Specified as series 185 sensorconnection head- Not Specified - no connection Only one option sensor termination 2 options J & N , but N is no extension : typelength. Not specified so choose std min. Not specified so choose std -316 L SST. thermowell: materialimmersion length. Not specified so choose std min. mounting style. Series - not specified but only series 96 offer straight style. process connectionstem stylerequire full penetration 0185 N 301 T 2 J 0080 D 0075 F 72 R 07 RMT Sales Training 1/99 Phase II - Temperature Sensor

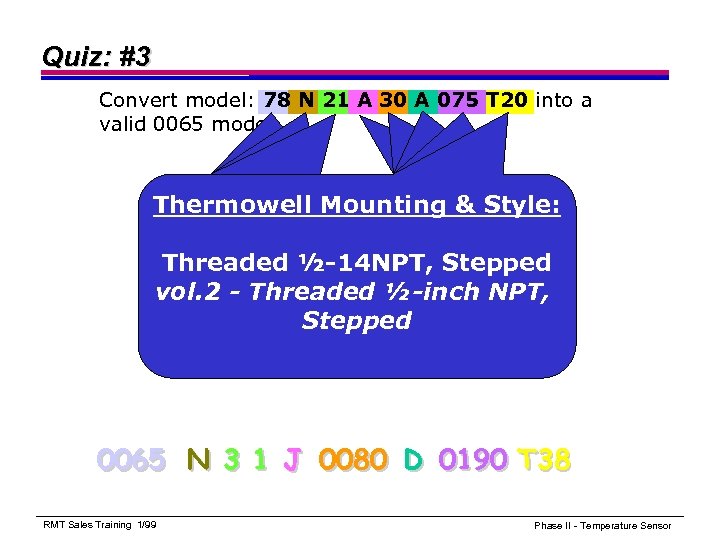

Quiz: #3 Convert model: 78 N 21 A 30 A 075 T 20 into a valid 0065 model. Thermowell Mounting & Style: Extension Length: Extension Type: Thermowell material: Immersion Length: Sensor Series: Sensor Nipple 76. 2 mm Connection Head: Lead Wire Termination 3” = Coupling Threaded ½-14 NPT, Stepped Series 78= 190. 5 mm 1 7. 5” 316 SST from volume Sensor vol. 2 codeconnection but. In& ext. we. Style: vol. 2 for Sensor choose ONLY, no J in vol. 2 to series 65 from In In vol. 2 - 316 L 190 mm convert we select SST NPT, - Threaded ½-inch spring-loaded, single 80 mm Nipple Union which element minimum length = is the head volume 2 Stepped only choice for 0065 N 31 0065 N 3 1 J 0080 D 0190 T 38 RMT Sales Training 1/99 Phase II - Temperature Sensor

Quiz: #3 Convert model: 78 N 21 A 30 A 075 T 20 into a valid 0065 model. Thermowell Mounting & Style: Extension Length: Extension Type: Thermowell material: Immersion Length: Sensor Series: Sensor Nipple 76. 2 mm Connection Head: Lead Wire Termination 3” = Coupling Threaded ½-14 NPT, Stepped Series 78= 190. 5 mm 1 7. 5” 316 SST from volume Sensor vol. 2 codeconnection but. In& ext. we. Style: vol. 2 for Sensor choose ONLY, no J in vol. 2 to series 65 from In In vol. 2 - 316 L 190 mm convert we select SST NPT, - Threaded ½-inch spring-loaded, single 80 mm Nipple Union which element minimum length = is the head volume 2 Stepped only choice for 0065 N 31 0065 N 3 1 J 0080 D 0190 T 38 RMT Sales Training 1/99 Phase II - Temperature Sensor

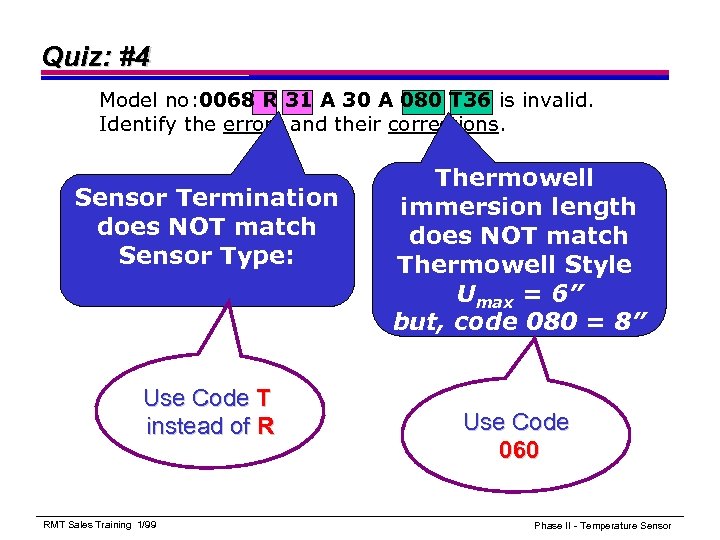

Quiz: #4 Model no: 0068 R 31 A 30 A 080 T 36 is invalid. Identify the errors and their corrections. Sensor Termination does NOT match Sensor Type: Use Code T instead of R RMT Sales Training 1/99 Thermowell immersion length does NOT match Thermowell Style Umax = 6” but, code 080 = 8” Use Code 060 Phase II - Temperature Sensor

Quiz: #4 Model no: 0068 R 31 A 30 A 080 T 36 is invalid. Identify the errors and their corrections. Sensor Termination does NOT match Sensor Type: Use Code T instead of R RMT Sales Training 1/99 Thermowell immersion length does NOT match Thermowell Style Umax = 6” but, code 080 = 8” Use Code 060 Phase II - Temperature Sensor

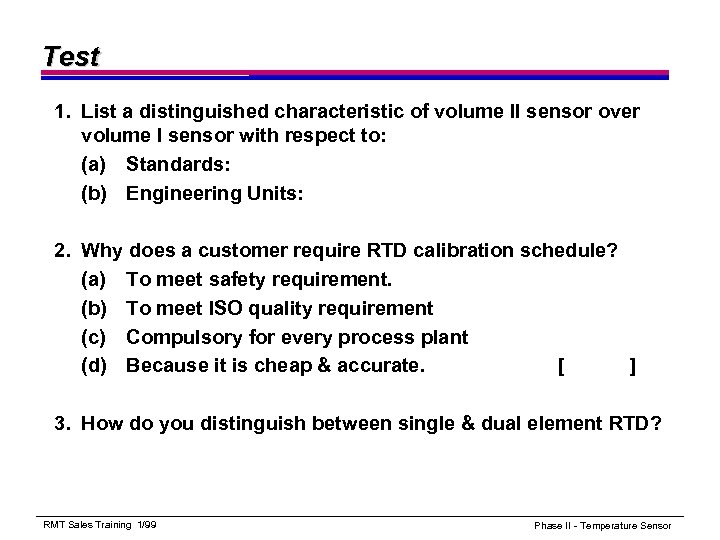

Test 1. List a distinguished characteristic of volume II sensor over volume I sensor with respect to: (a) Standards: (b) Engineering Units: 2. Why does a customer require RTD calibration schedule? (a) To meet safety requirement. (b) To meet ISO quality requirement (c) Compulsory for every process plant (d) Because it is cheap & accurate. [ ] 3. How do you distinguish between single & dual element RTD? RMT Sales Training 1/99 Phase II - Temperature Sensor

Test 1. List a distinguished characteristic of volume II sensor over volume I sensor with respect to: (a) Standards: (b) Engineering Units: 2. Why does a customer require RTD calibration schedule? (a) To meet safety requirement. (b) To meet ISO quality requirement (c) Compulsory for every process plant (d) Because it is cheap & accurate. [ ] 3. How do you distinguish between single & dual element RTD? RMT Sales Training 1/99 Phase II - Temperature Sensor

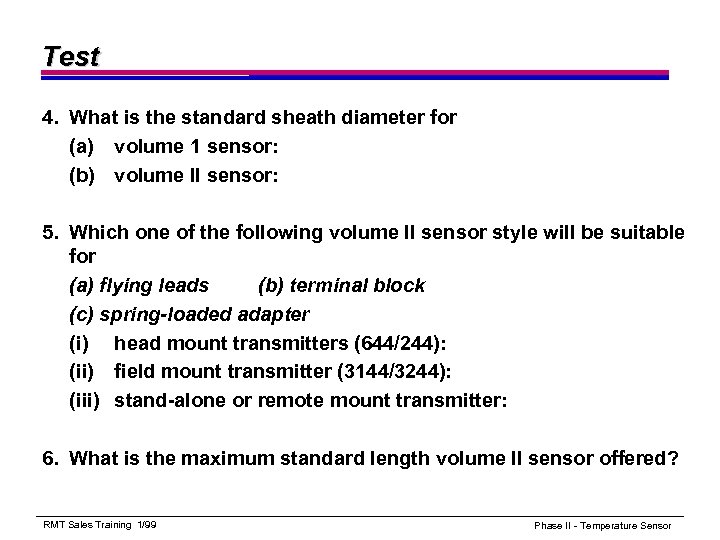

Test 4. What is the standard sheath diameter for (a) volume 1 sensor: (b) volume II sensor: 5. Which one of the following volume II sensor style will be suitable for (a) flying leads (b) terminal block (c) spring-loaded adapter (i) head mount transmitters (644/244): (ii) field mount transmitter (3144/3244): (iii) stand-alone or remote mount transmitter: 6. What is the maximum standard length volume II sensor offered? RMT Sales Training 1/99 Phase II - Temperature Sensor

Test 4. What is the standard sheath diameter for (a) volume 1 sensor: (b) volume II sensor: 5. Which one of the following volume II sensor style will be suitable for (a) flying leads (b) terminal block (c) spring-loaded adapter (i) head mount transmitters (644/244): (ii) field mount transmitter (3144/3244): (iii) stand-alone or remote mount transmitter: 6. What is the maximum standard length volume II sensor offered? RMT Sales Training 1/99 Phase II - Temperature Sensor

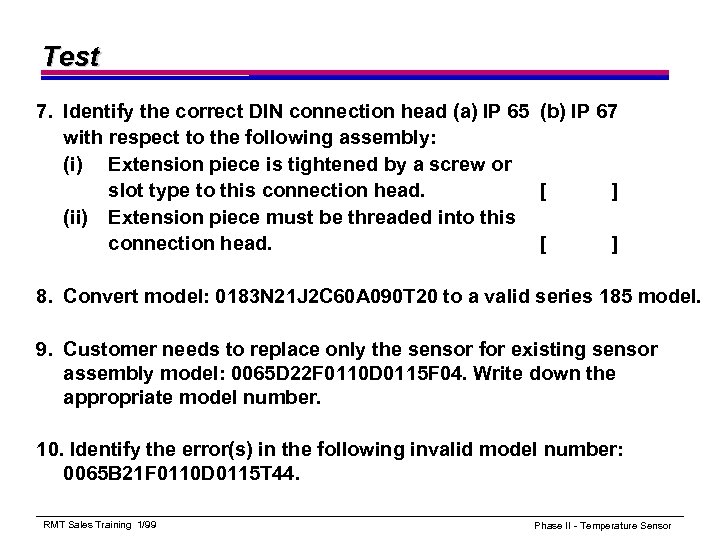

Test 7. Identify the correct DIN connection head (a) IP 65 (b) IP 67 with respect to the following assembly: (i) Extension piece is tightened by a screw or slot type to this connection head. [ ] (ii) Extension piece must be threaded into this connection head. [ ] 8. Convert model: 0183 N 21 J 2 C 60 A 090 T 20 to a valid series 185 model. 9. Customer needs to replace only the sensor for existing sensor assembly model: 0065 D 22 F 0110 D 0115 F 04. Write down the appropriate model number. 10. Identify the error(s) in the following invalid model number: 0065 B 21 F 0110 D 0115 T 44. RMT Sales Training 1/99 Phase II - Temperature Sensor

Test 7. Identify the correct DIN connection head (a) IP 65 (b) IP 67 with respect to the following assembly: (i) Extension piece is tightened by a screw or slot type to this connection head. [ ] (ii) Extension piece must be threaded into this connection head. [ ] 8. Convert model: 0183 N 21 J 2 C 60 A 090 T 20 to a valid series 185 model. 9. Customer needs to replace only the sensor for existing sensor assembly model: 0065 D 22 F 0110 D 0115 F 04. Write down the appropriate model number. 10. Identify the error(s) in the following invalid model number: 0065 B 21 F 0110 D 0115 T 44. RMT Sales Training 1/99 Phase II - Temperature Sensor

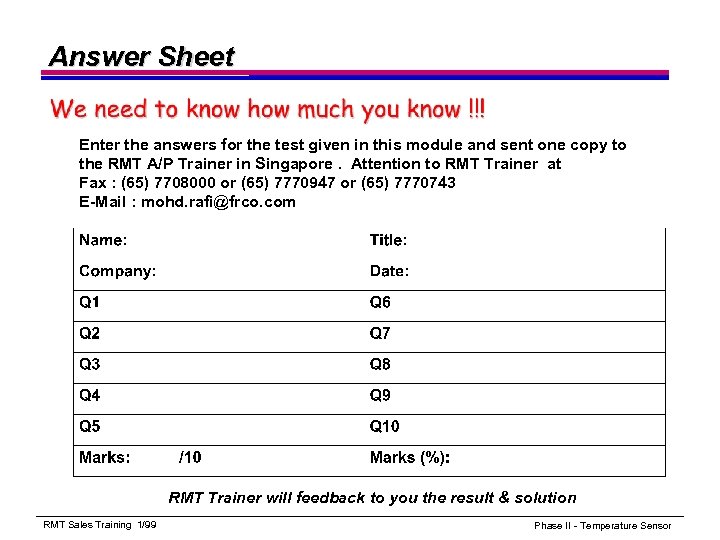

Answer Sheet Enter the answers for the test given in this module and sent one copy to the RMT A/P Trainer in Singapore. Attention to RMT Trainer at Fax : (65) 7708000 or (65) 7770947 or (65) 7770743 E-Mail : mohd. rafi@frco. com RMT Trainer will feedback to you the result & solution RMT Sales Training 1/99 Phase II - Temperature Sensor

Answer Sheet Enter the answers for the test given in this module and sent one copy to the RMT A/P Trainer in Singapore. Attention to RMT Trainer at Fax : (65) 7708000 or (65) 7770947 or (65) 7770743 E-Mail : mohd. rafi@frco. com RMT Trainer will feedback to you the result & solution RMT Sales Training 1/99 Phase II - Temperature Sensor