73c4e48f91e493c70f5c15bc40c8f8f9.ppt

- Количество слайдов: 56

Pesticide Formulations Substitutes for Common Pesticide Formulations Kevin Fry Extension Educator, Agronomy 724 -548 -3447 CMEG PENN STATE Crop Management Extension Group

Instructions • Match household product substitute with its similar pesticide formulation type. • Write household product substitute name in the box next to the formulation it best represents.

Pesticide Formulations Household Products

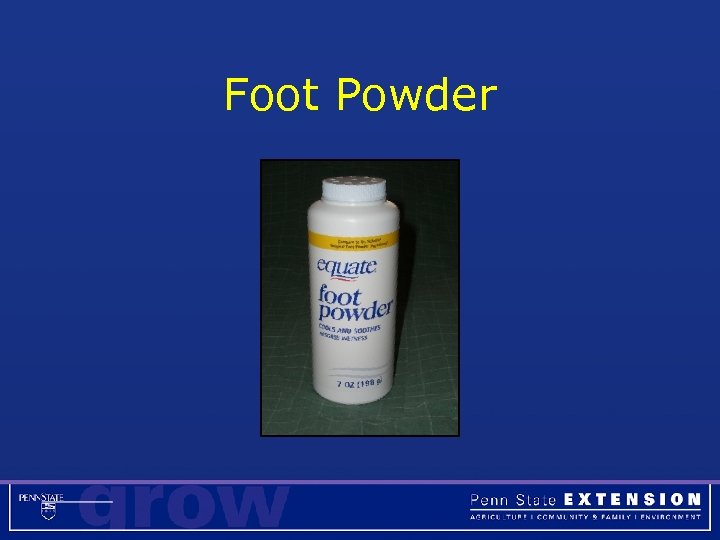

Foot Powder

Pepto-Bismal & V 8

Mayonnaise

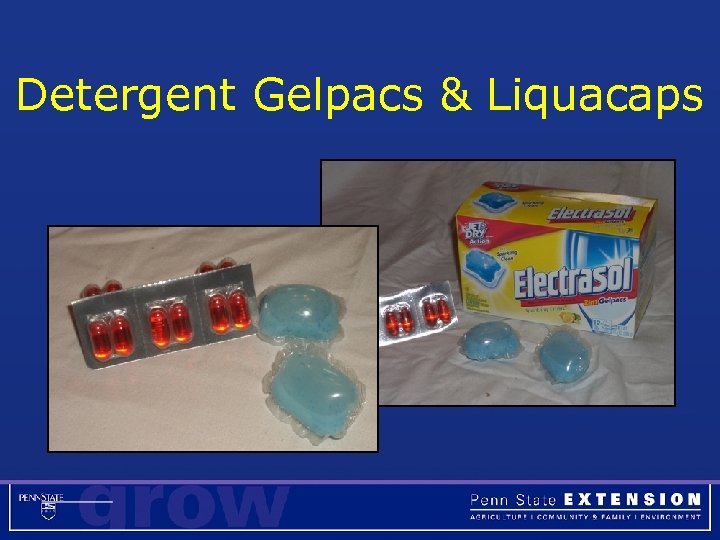

Detergent Gelpacs & Liquacaps

Pine-Sol

Cocoa & Flour

Cat Litter & Grape-nuts

Vicks Vapo. Rub & Air Freshener

Hair Spray

White Grape Juice

Drink Mix & Corn Starch

Glass Cleaner

Toothpaste & Granola Bar

Grits & Dry Milk

Contac Cold Medicine

Guinea Pig/Rabbit Food

Pesticide Formulations Answers

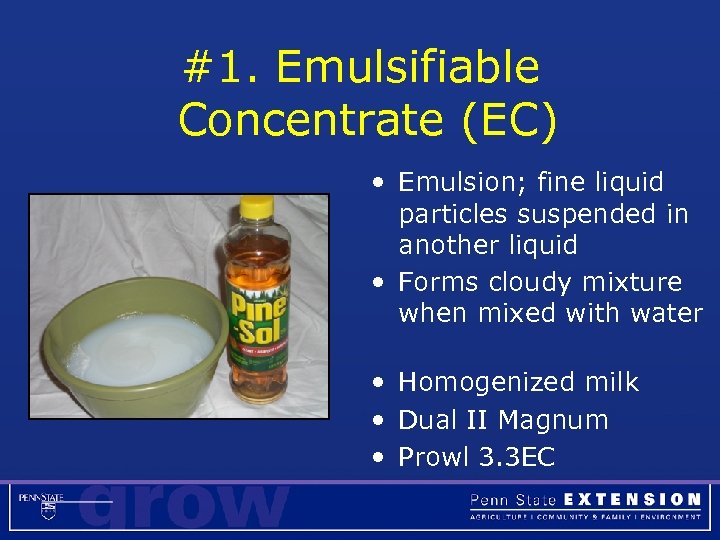

#1. Emulsifiable Concentrate (EC) • Emulsion; fine liquid particles suspended in another liquid • Forms cloudy mixture when mixed with water • Homogenized milk • Dual II Magnum • Prowl 3. 3 EC

#2. Solution (S) / Concentrated Solution (C or LC) • Liquid that will form a true aqueous solution • Banvel / Clarity 4 S • Roundup Pro Concentrate

#3. Flowable (F or L) • Fine solid particles dispersed (suspended) in a liquid • Atrazine 4 L • Princep 4 L

#4. Dust (D) • Fine solid particles • Ready to use • Not water-soluble • Delta Dust • Bug-B-Gon MAX Garden Insect Killer Dust

#5. Granule (G) • Small particles • Ready to use • Not water-soluble • Force 3 G • Lorsban 15 G • “Weed and Feed”

#6. Pellet (P or PS) • Formed small- to medium-sized particles • Ready to use • Not water-soluble • Pramitol 5 PS • Spike 20 P

#7. Wettable Powder (W or WP) • Relatively insoluble fine-particle solid that forms a suspension • Not a true solution • Fore 80 WP • Pounce 25 WP

#8. Water-Dispersible Granules (WDG) / Dry Flowables (DF) • Small particles of a wettable powder • Will form a suspension • Not a true solution • Drive 75 DF • Escort XP

#9. Soluble Powder (SP or WSP) • Fine- or mediumparticle sized solid that will dissolve in water to form a true solution • Roundup Pro Dry

#10. Water Soluble Packaging (Gel Pack) • A semi-solid colloid (jelly) packaged in water-soluble film. • Topsin M WSB • Brigade WSB • “Toss and go” packaging

#11. Aerosol (A) • Fine airborne particles/droplets plus a propellant • D-Con House and Garden • Bug repellent – DEET

#12. Bait (B) • Attractant/feeding stimulant + food + pesticide • Maxforce FC Ant Killer Bait Gel • Hotshot Max. Attrax Ant Bait • Dcon or Tomcat Bait Blocks

#13. Invert Emulsion (IE) • An emulsion in which the active ingredient is dispersed in oil rather than in water • Usually a thick mixture • Certain roadside non -crop products

#14. Microencapsulated (ME) • Coated or encased units – time release • Prowl H 2 O • Penncap-M • Bio. Barrier

#15. Ready-to-Use (RTU) • Solution or suspension diluted to use rate • Roundup RTU

#16. ULV/Fog/Smoke • Fine particles/ droplets suspended in air • Raid concentrated fogger

So what!? • Why are formulations important? • Storage – dry vs. liquid; concentrated? • Handling – dry vs. liquid, do you have preference? • Mixing and Loading

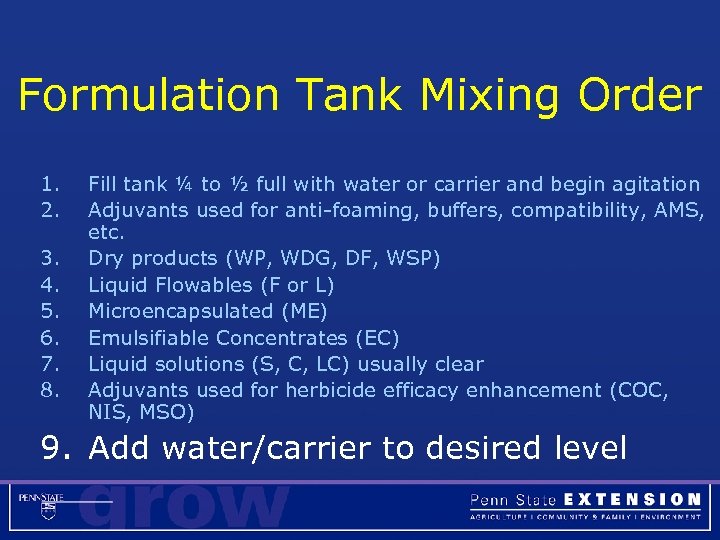

Mixing and Loading • Mixing and loading order can be determined by the formulation if not specified on the label.

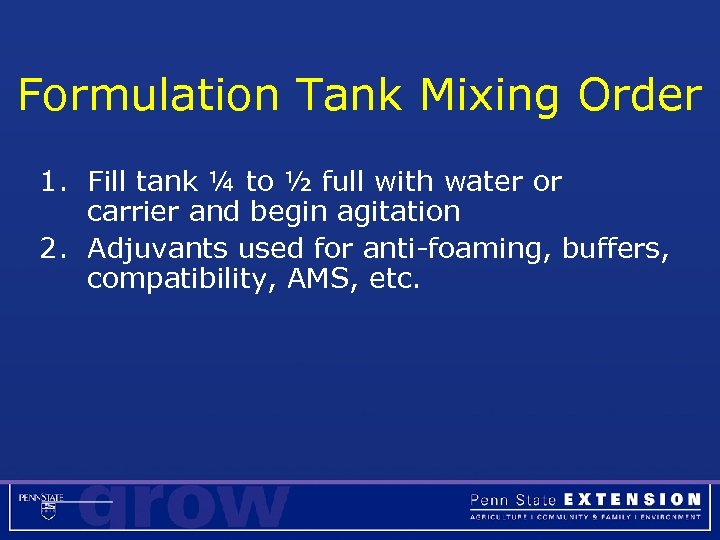

Formulation Tank Mixing Order 1. Fill tank ¼ to ½ full with water or carrier and begin agitation 2. Adjuvants used for anti-foaming, buffers, compatibility, AMS, etc.

Formulation Tank Mixing Order 1. Fill tank ¼ to ½ full with water or carrier and begin agitation 2. Adjuvants used for anti-foaming, buffers, compatibility, AMS, etc. 3. Dry products (WP, WDG, DF, WSP) 4. Liquid Flowables (F or L)

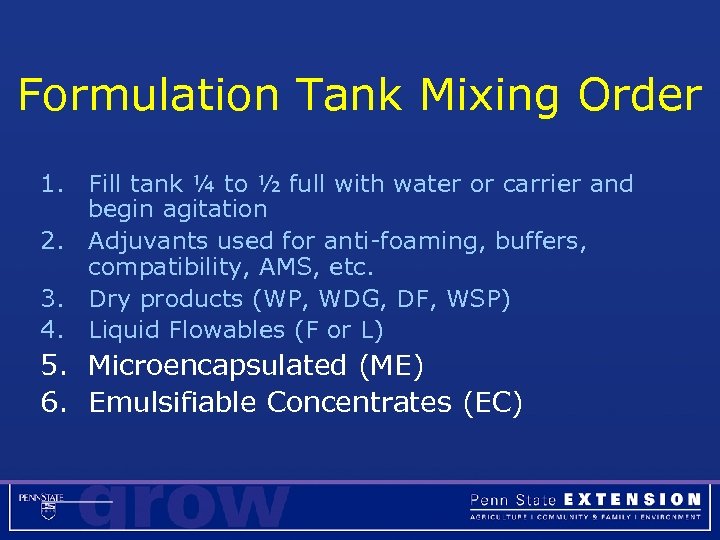

Formulation Tank Mixing Order 1. Fill tank ¼ to ½ full with water or carrier and begin agitation 2. Adjuvants used for anti-foaming, buffers, compatibility, AMS, etc. 3. Dry products (WP, WDG, DF, WSP) 4. Liquid Flowables (F or L) 5. Microencapsulated (ME) 6. Emulsifiable Concentrates (EC)

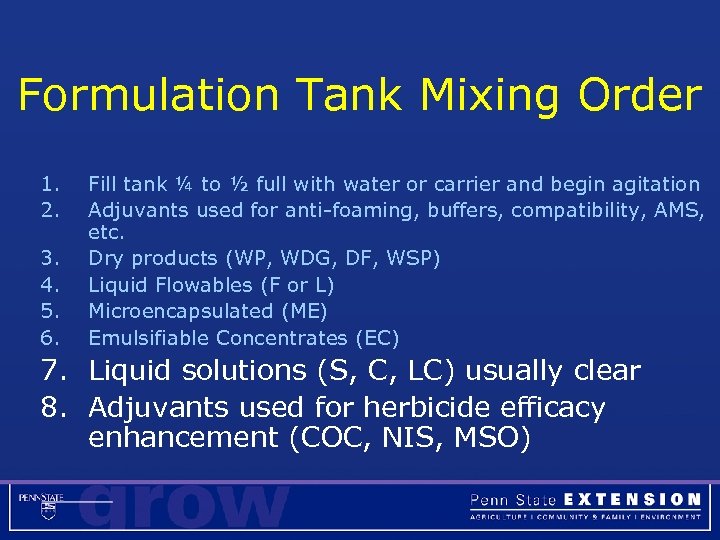

Formulation Tank Mixing Order 1. 2. 3. 4. 5. 6. Fill tank ¼ to ½ full with water or carrier and begin agitation Adjuvants used for anti-foaming, buffers, compatibility, AMS, etc. Dry products (WP, WDG, DF, WSP) Liquid Flowables (F or L) Microencapsulated (ME) Emulsifiable Concentrates (EC) 7. Liquid solutions (S, C, LC) usually clear 8. Adjuvants used for herbicide efficacy enhancement (COC, NIS, MSO)

Formulation Tank Mixing Order 1. 2. 3. 4. 5. 6. 7. 8. Fill tank ¼ to ½ full with water or carrier and begin agitation Adjuvants used for anti-foaming, buffers, compatibility, AMS, etc. Dry products (WP, WDG, DF, WSP) Liquid Flowables (F or L) Microencapsulated (ME) Emulsifiable Concentrates (EC) Liquid solutions (S, C, LC) usually clear Adjuvants used for herbicide efficacy enhancement (COC, NIS, MSO) 9. Add water/carrier to desired level

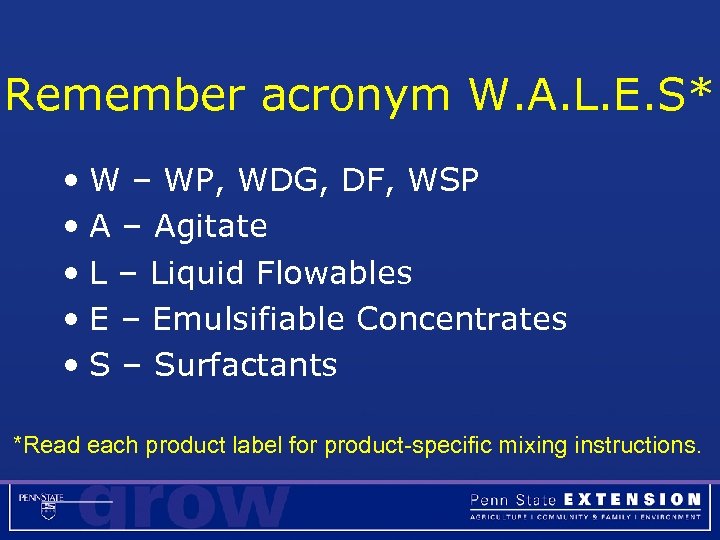

Remember acronym W. A. L. E. S* • W – WP, WDG, DF, WSP • A – Agitate • L – Liquid Flowables • E – Emulsifiable Concentrates • S – Surfactants *Read each product label for product-specific mixing instructions.

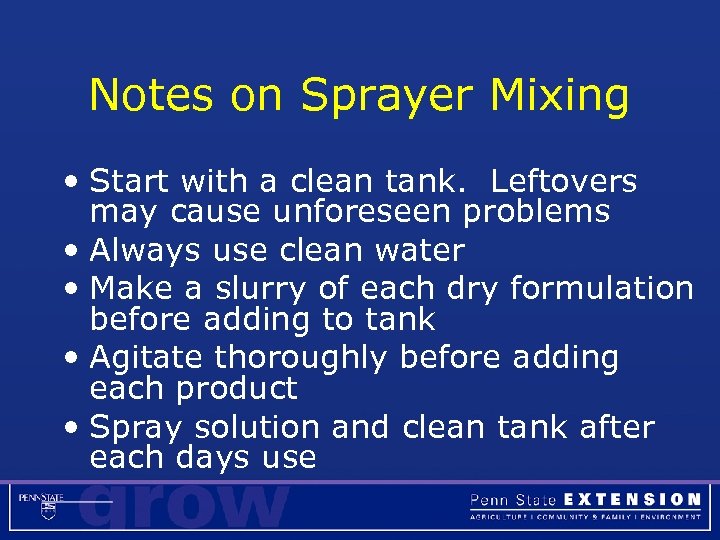

Notes on Sprayer Mixing • Start with a clean tank. Leftovers may cause unforeseen problems • Always use clean water • Make a slurry of each dry formulation before adding to tank • Agitate thoroughly before adding each product • Spray solution and clean tank after each days use

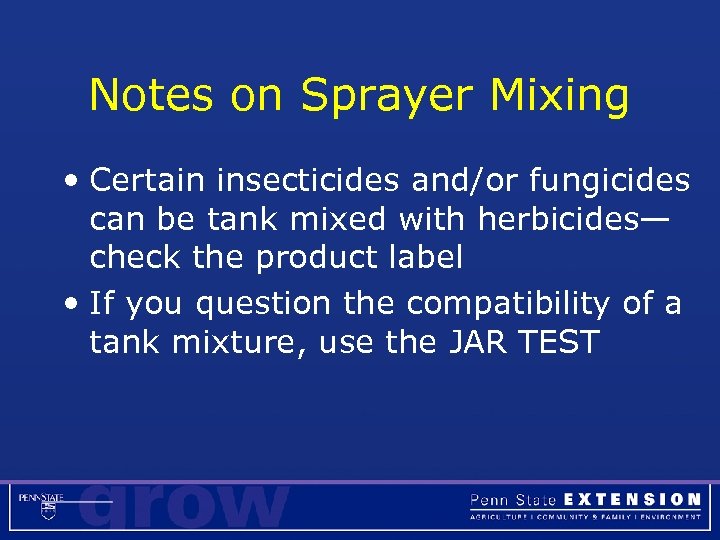

Notes on Sprayer Mixing • Certain insecticides and/or fungicides can be tank mixed with herbicides— check the product label • If you question the compatibility of a tank mixture, use the JAR TEST

Jar Test • Better to have gel, precipitate, sludge, or concrete in a jar rather than in your sprayer, hoses, pumps, and tips.

Jar Test • Labeled combinations of herbicides with fertilizers, insecticides, and fungicides are difficult to find.

Jar Test Safety • Always wear PPE when pouring or mixing pesticides. • Perform this test in a safe area away from food and sources of ignition. • Pesticide used in this test should be put into the spray tank when completed and applied to a labeled site. • Rinse all utensils and jars, and pour rinse water into spray tank.

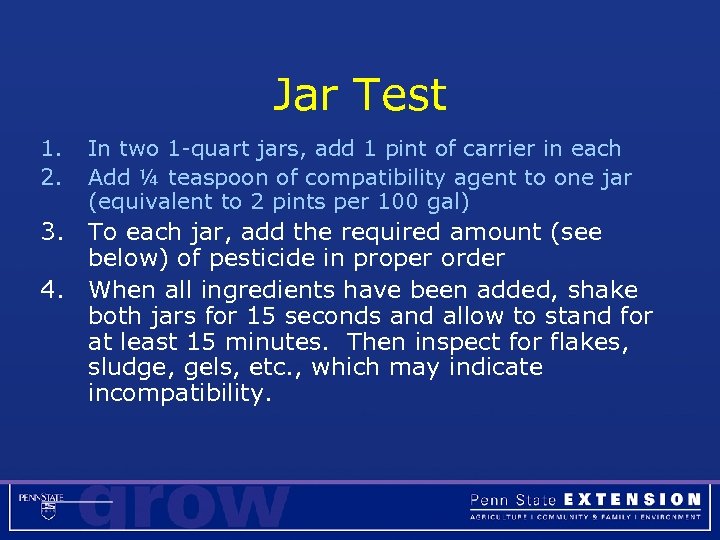

Jar Test 1. In two 1 -quart jars, add 1 pint of carrier in each 2. Add ¼ teaspoon of compatibility agent to one jar (equivalent to 2 pints per 100 gal)

Jar Test 1. 2. In two 1 -quart jars, add 1 pint of carrier in each Add ¼ teaspoon of compatibility agent to one jar (equivalent to 2 pints per 100 gal) 3. To each jar, add the required amount (see below) of pesticide in proper order 4. When all ingredients have been added, shake both jars for 15 seconds and allow to stand for at least 15 minutes. Then inspect for flakes, sludge, gels, etc. , which may indicate incompatibility.

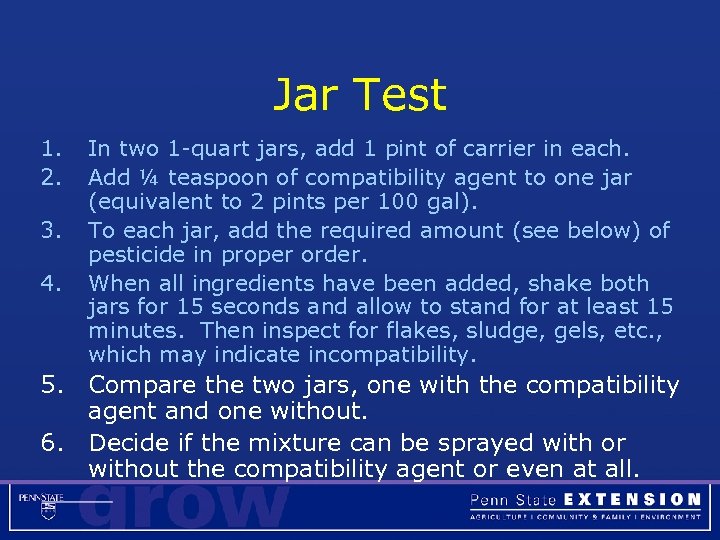

Jar Test 1. 2. 3. 4. In two 1 -quart jars, add 1 pint of carrier in each. Add ¼ teaspoon of compatibility agent to one jar (equivalent to 2 pints per 100 gal). To each jar, add the required amount (see below) of pesticide in proper order. When all ingredients have been added, shake both jars for 15 seconds and allow to stand for at least 15 minutes. Then inspect for flakes, sludge, gels, etc. , which may indicate incompatibility. 5. Compare the two jars, one with the compatibility agent and one without. 6. Decide if the mixture can be sprayed with or without the compatibility agent or even at all.

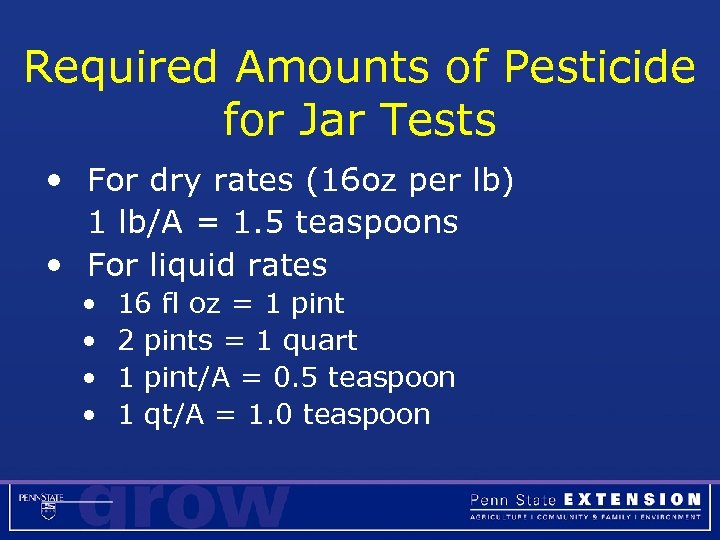

Required Amounts of Pesticide for Jar Tests • For dry rates (16 oz per lb) 1 lb/A = 1. 5 teaspoons • For liquid rates • • 16 fl oz = 1 pint 2 pints = 1 quart 1 pint/A = 0. 5 teaspoon 1 qt/A = 1. 0 teaspoon

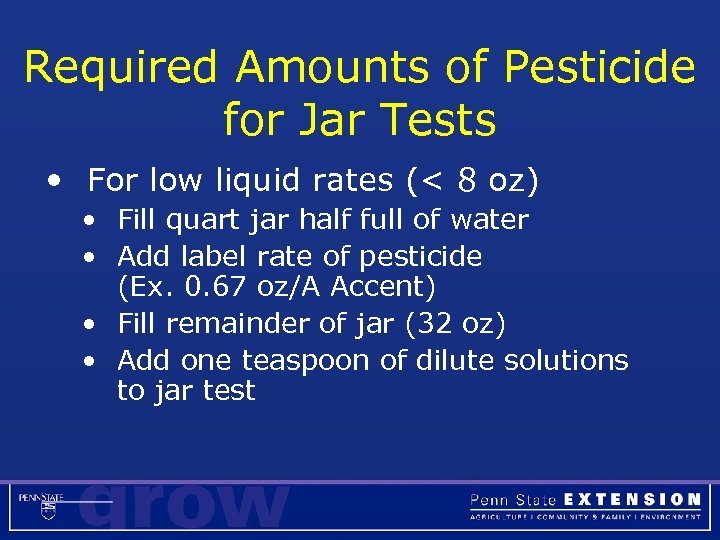

Required Amounts of Pesticide for Jar Tests • For low liquid rates (< 8 oz) • Fill quart jar half full of water • Add label rate of pesticide (Ex. 0. 67 oz/A Accent) • Fill remainder of jar (32 oz) • Add one teaspoon of dilute solutions to jar test

Sample Jar Test Questions?

This presentation was developed by Kevin Fry, Penn State Extension Educator in Armstrong County. Use of this presentation or parts of this presentation is encouraged as long as this credit slide is included. This presentation was adapted from a hands-on presentation and handouts given by Pat Hipkins, Senior Research Associate and Assistant Coordinator of the Virginia Tech Pesticide Programs, at the Northeastern Region Pesticide Safety Education Center Workshop in September 2005. All product photographs in this presentation were taken by Kevin Fry, Penn State Extension Educator in Armstrong County. The mixing and loading photographs in this presentation were taken from pesticidepics. com, the National Pesticide Media Database on the Virginia Tech Pesticide Programs web site. Where trade names appear, no discrimination is intended, and no endorsement by the Penn State College of Agricultural Sciences is implied. “Penn State is committed to affirmative action, equal opportunity, and the diversity of its workforce. ” © The Pennsylvania State University 2006 February 2006

73c4e48f91e493c70f5c15bc40c8f8f9.ppt