8ac019a77dbf8d2ee297e7b99db1be15.ppt

- Количество слайдов: 21

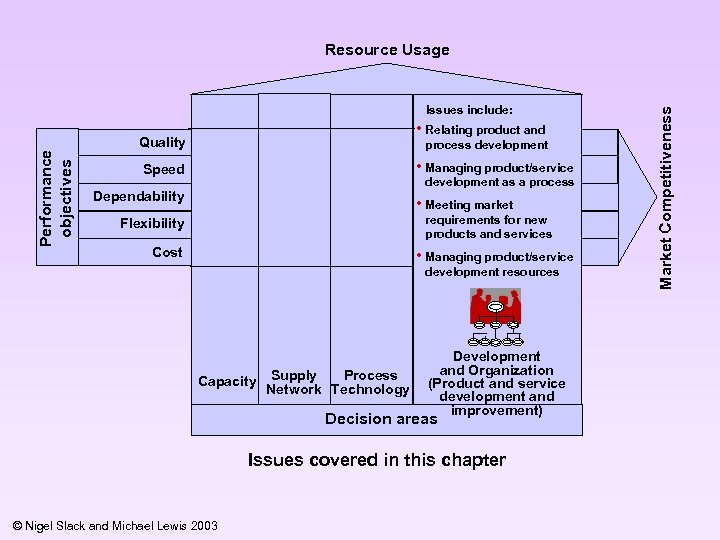

Performance objectives Issues include: • Relating product and Quality process development • Managing product/service Speed development as a process Dependability • Meeting market requirements for new products and services Flexibility Cost • Managing product/service development resources Capacity Supply Process Network Technology Development and Organization (Product and service development and improvement) Decision areas Issues covered in this chapter © Nigel Slack and Michael Lewis 2003 Market Competitiveness Resource Usage

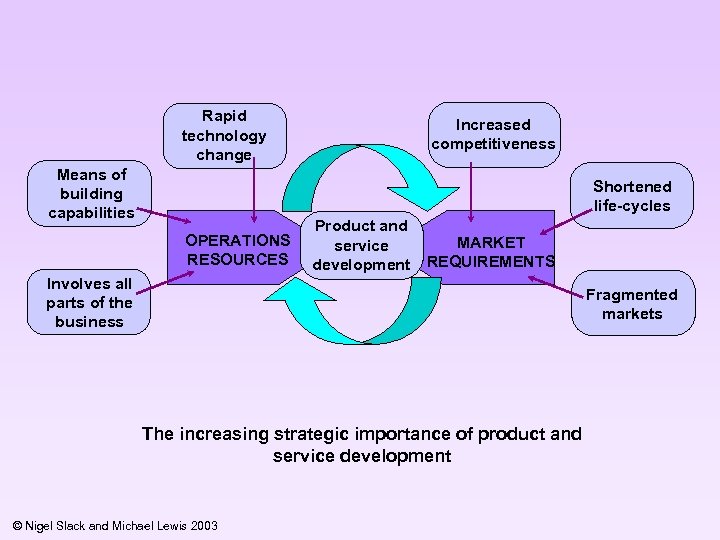

Rapid technology change Means of building capabilities Increased competitiveness Shortened life-cycles OPERATIONS RESOURCES Product and service development MARKET REQUIREMENTS Involves all parts of the business Fragmented markets The increasing strategic importance of product and service development © Nigel Slack and Michael Lewis 2003

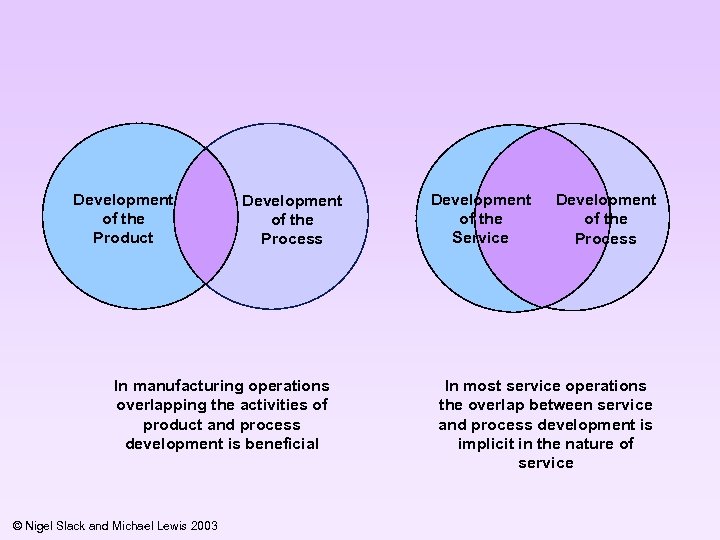

Development of the Product Development of the Process In manufacturing operations overlapping the activities of product and process development is beneficial © Nigel Slack and Michael Lewis 2003 Development of the Service Development of the Process In most service operations the overlap between service and process development is implicit in the nature of service

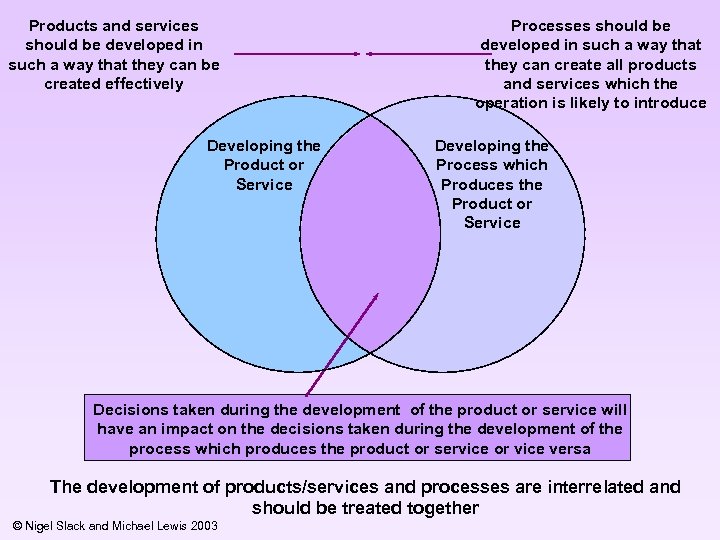

Products and services should be developed in such a way that they can be created effectively Developing the Product or Service Processes should be developed in such a way that they can create all products and services which the operation is likely to introduce Developing the Process which Produces the Product or Service Decisions taken during the development of the product or service will have an impact on the decisions taken during the development of the process which produces the product or service or vice versa The development of products/services and processes are interrelated and should be treated together © Nigel Slack and Michael Lewis 2003

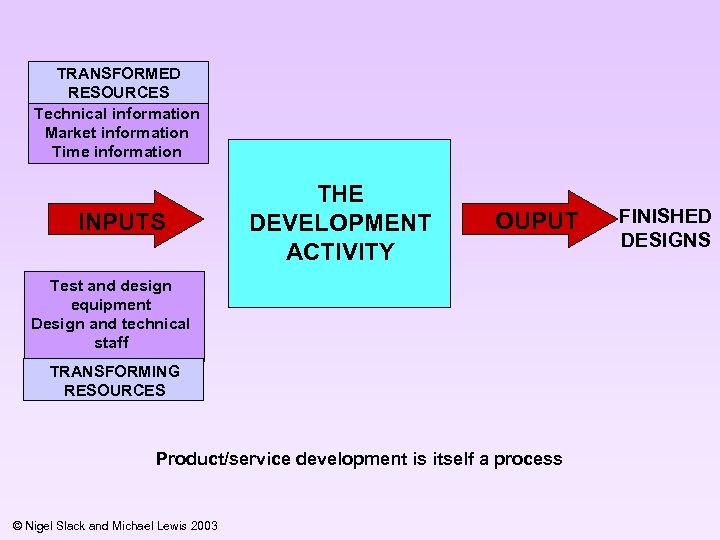

TRANSFORMED RESOURCES Technical information Market information Time information INPUTS THE DEVELOPMENT ACTIVITY OUPUT Test and design equipment Design and technical staff TRANSFORMING RESOURCES Product/service development is itself a process © Nigel Slack and Michael Lewis 2003 FINISHED DESIGNS

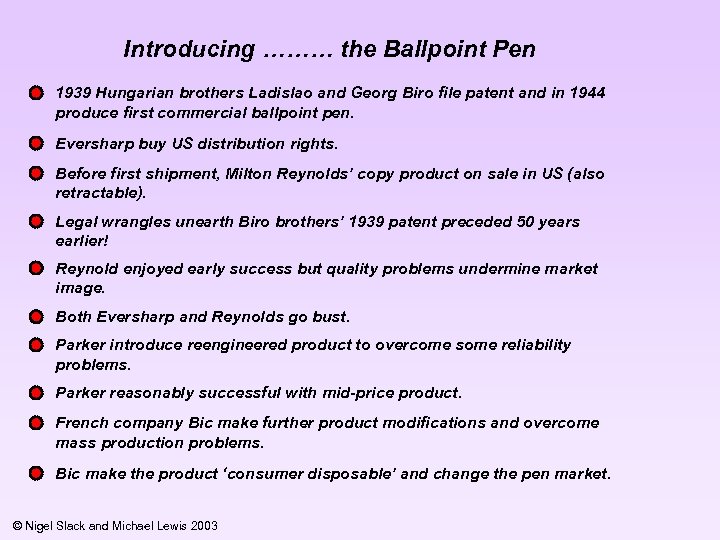

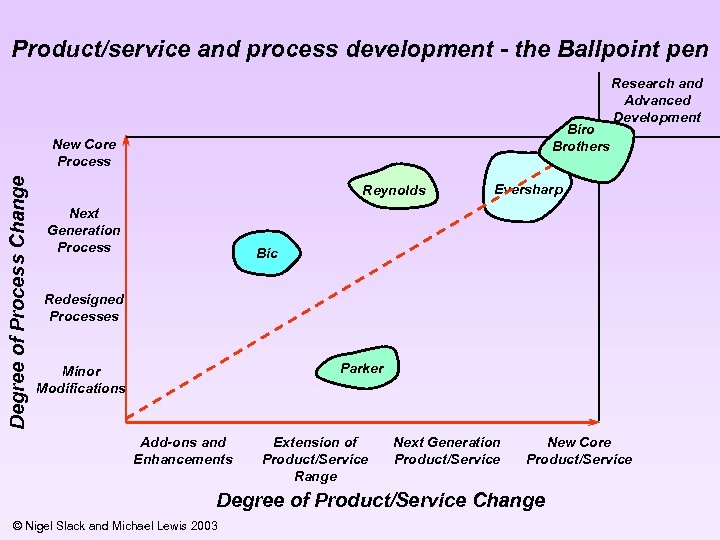

Introducing ……… the Ballpoint Pen 1939 Hungarian brothers Ladislao and Georg Biro file patent and in 1944 produce first commercial ballpoint pen. Eversharp buy US distribution rights. Before first shipment, Milton Reynolds’ copy product on sale in US (also retractable). Legal wrangles unearth Biro brothers’ 1939 patent preceded 50 years earlier! Reynold enjoyed early success but quality problems undermine market image. Both Eversharp and Reynolds go bust. Parker introduce reengineered product to overcome some reliability problems. Parker reasonably successful with mid-price product. French company Bic make further product modifications and overcome mass production problems. Bic make the product ‘consumer disposable’ and change the pen market. © Nigel Slack and Michael Lewis 2003

Product/service and process development - the Ballpoint pen Biro Brothers Degree of Process Change New Core Process Reynolds Next Generation Process Research and Advanced Development Eversharp Bic Redesigned Processes Parker Minor Modifications Add-ons and Enhancements Extension of Product/Service Range Next Generation Product/Service New Core Product/Service Degree of Product/Service Change © Nigel Slack and Michael Lewis 2003

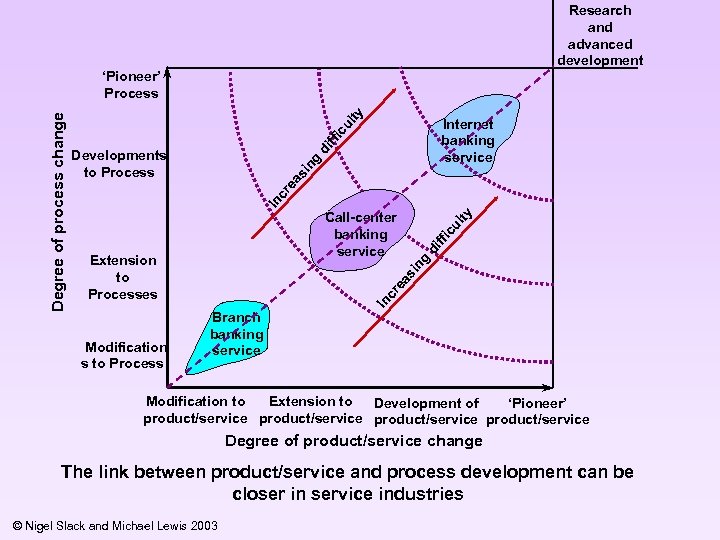

Research and advanced development lty di ffi cu Internet banking service cr e as i ng Developments to Process Modification s to Process cu ffi di In cr ea si Extension to Processes ng Call-center banking service lty In Degree of process change ‘Pioneer’ Process Branch banking service Modification to Extension to Development of ‘Pioneer’ product/service Degree of product/service change The link between product/service and process development can be closer in service industries © Nigel Slack and Michael Lewis 2003

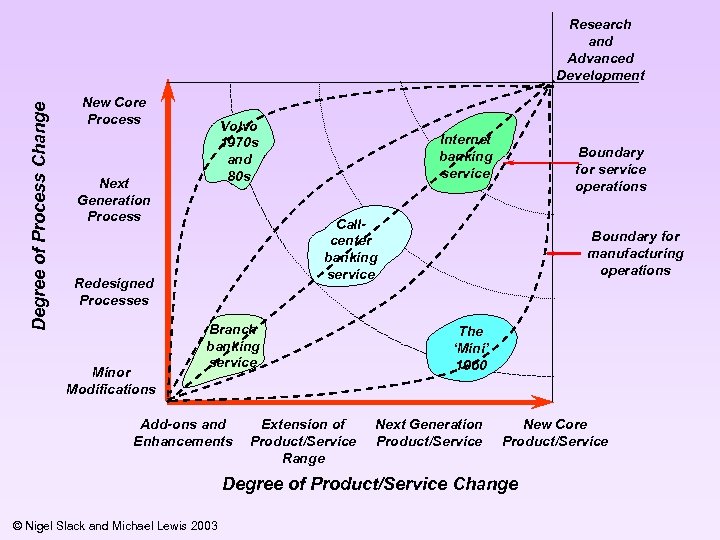

Degree of Process Change Research and Advanced Development New Core Process Volvo 1970 s and 80 s Next Generation Process Boundary for service operations Callcenter banking service Redesigned Processes Minor Modifications Internet banking service Branch banking service Add-ons and Enhancements Extension of Product/Service Range Boundary for manufacturing operations The ‘Mini’ 1960 Next Generation Product/Service New Core Product/Service Degree of Product/Service Change © Nigel Slack and Michael Lewis 2003

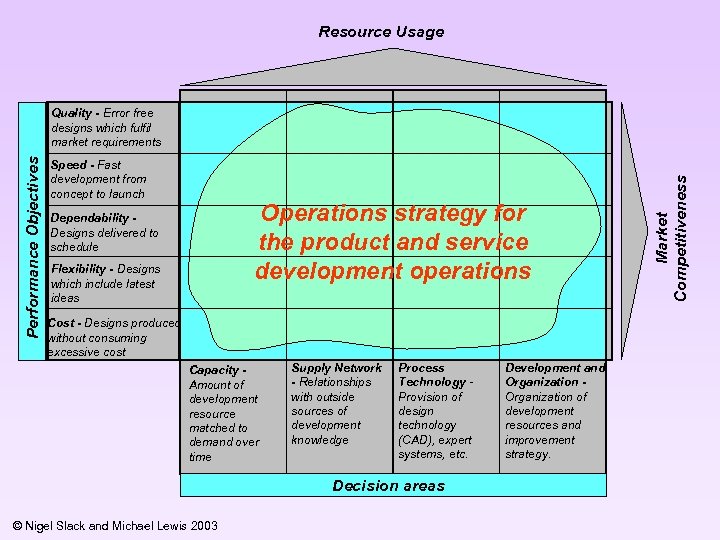

Resource Usage Speed - Fast development from concept to launch Operations strategy for the product and service development operations Dependability Designs delivered to schedule Flexibility - Designs which include latest ideas Cost - Designs produced without consuming excessive cost Capacity Amount of development resource matched to demand over time Supply Network - Relationships with outside sources of development knowledge Process Technology Provision of design technology (CAD), expert systems, etc. Decision areas © Nigel Slack and Michael Lewis 2003 Development and Organization of development resources and improvement strategy. Market Competitiveness Performance Objectives Quality - Error free designs which fulfil market requirements

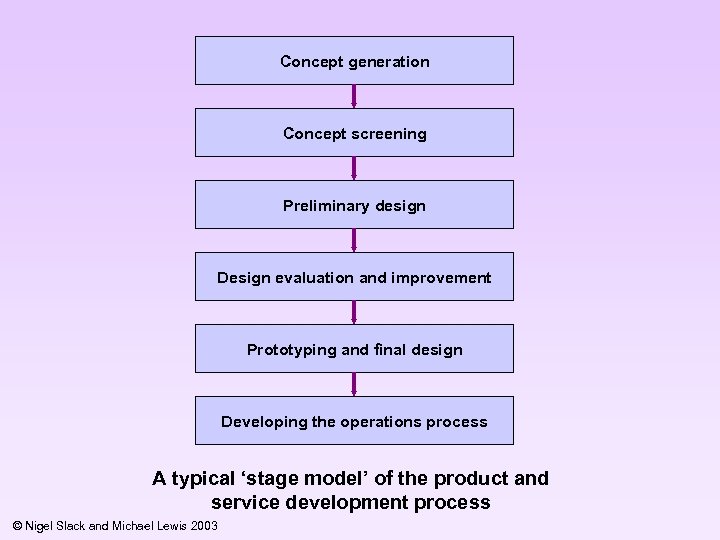

Concept generation Concept screening Preliminary design Design evaluation and improvement Prototyping and final design Developing the operations process A typical ‘stage model’ of the product and service development process © Nigel Slack and Michael Lewis 2003

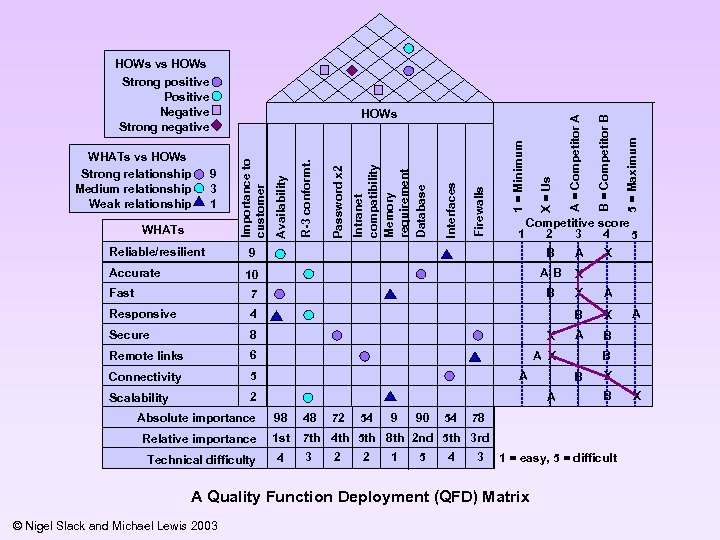

Reliable/resilient 1 5 = Maximum B = Competitor B X = Us 1 = Minimum Firewalls Interfaces Intranet compatibility Memory requirement Database Password x 2 R-3 conformt. WHATs Availability 9 3 1 Importance to customer WHATs vs HOWs Strong relationship Medium relationship Weak relationship HOWs A = Competitor A HOWs vs HOWs Strong positive Positive Negative Strong negative Competitive score 2 3 4 5 9 B A 10 AB X Fast 7 B X A Responsive 4 B X Secure 8 X A B Remote links 6 A X Connectivity 5 Scalability 2 Accurate A Absolute importance 98 48 Relative importance 1 st Technical difficulty 4 2 54 2 9 1 90 5 54 X B 7 th 4 th 5 th 8 th 2 nd 5 th 3 rd 3 72 4 78 3 1 = easy, 5 = difficult A Quality Function Deployment (QFD) Matrix © Nigel Slack and Michael Lewis 2003 A B B A X X

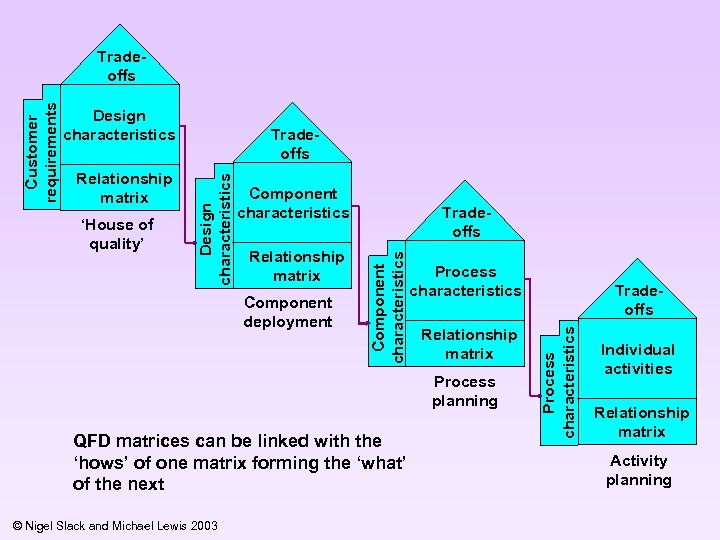

Design characteristics Relationship matrix Component deployment Tradeoffs Process characteristics Relationship matrix Process planning QFD matrices can be linked with the ‘hows’ of one matrix forming the ‘what’ of the next © Nigel Slack and Michael Lewis 2003 Tradeoffs Process characteristics ‘House of quality’ Component characteristics Relationship matrix Tradeoffs Design characteristics Customer requirements Tradeoffs Individual activities Relationship matrix Activity planning

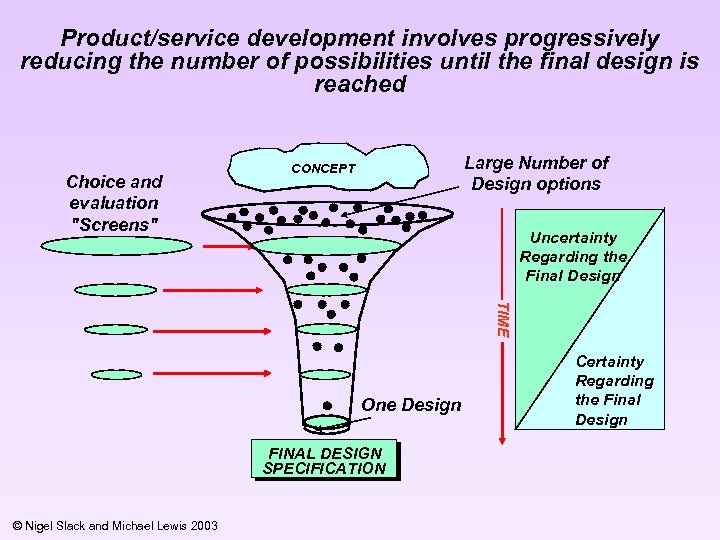

Product/service development involves progressively reducing the number of possibilities until the final design is reached Choice and evaluation "Screens" Large Number of Design options CONCEPT Uncertainty Regarding the Final Design TIME One Design FINAL DESIGN SPECIFICATION © Nigel Slack and Michael Lewis 2003 Certainty Regarding the Final Design

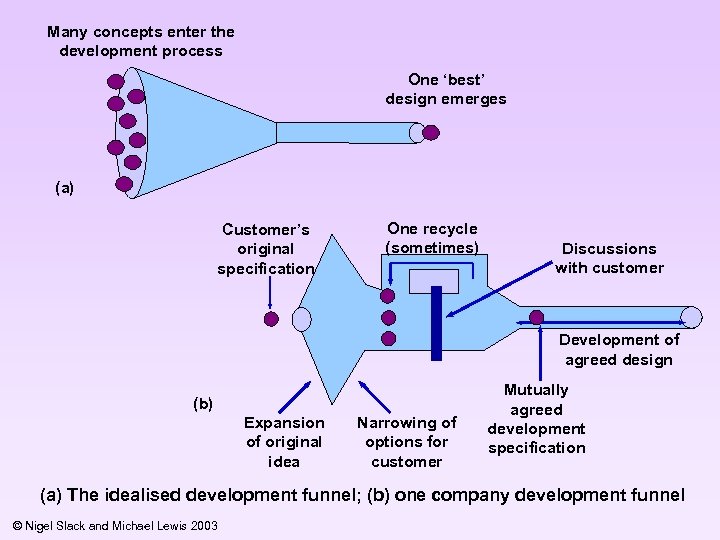

Many concepts enter the development process One ‘best’ design emerges (a) Customer’s original specification One recycle (sometimes) Discussions with customer Development of agreed design (b) Expansion of original idea Narrowing of options for customer Mutually agreed development specification (a) The idealised development funnel; (b) one company development funnel © Nigel Slack and Michael Lewis 2003

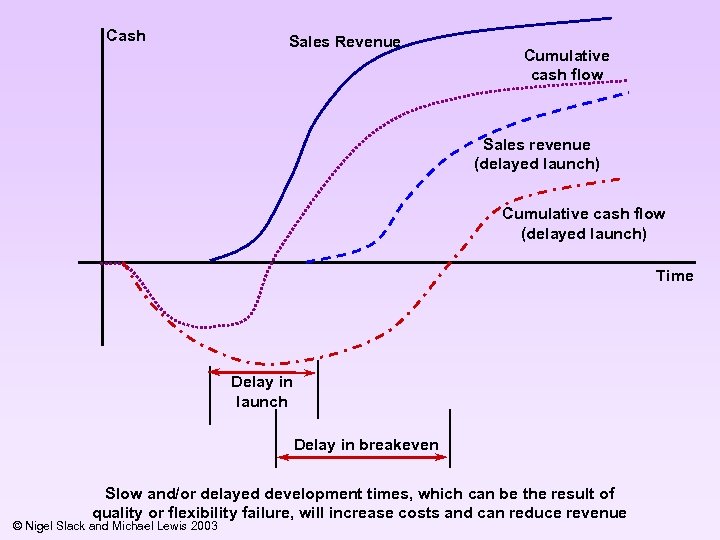

Cash Sales Revenue Cumulative cash flow Sales revenue (delayed launch) Cumulative cash flow (delayed launch) Time Delay in launch Delay in breakeven Slow and/or delayed development times, which can be the result of quality or flexibility failure, will increase costs and can reduce revenue © Nigel Slack and Michael Lewis 2003

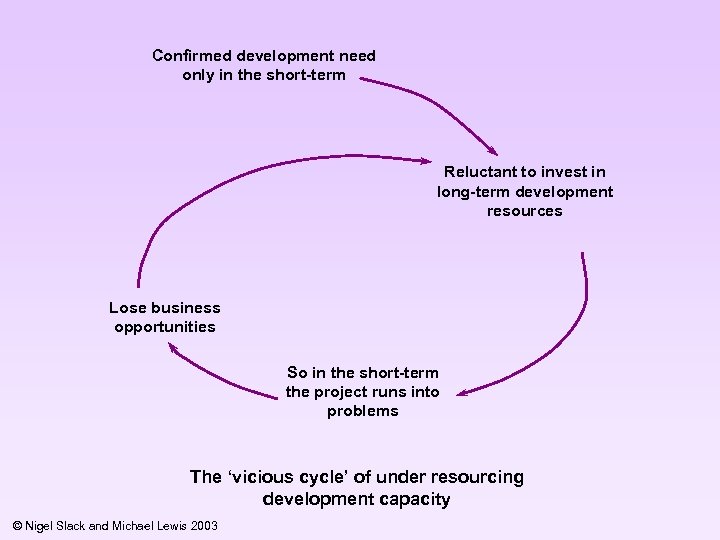

Confirmed development need only in the short-term Reluctant to invest in long-term development resources Lose business opportunities So in the short-term the project runs into problems The ‘vicious cycle’ of under resourcing development capacity © Nigel Slack and Michael Lewis 2003

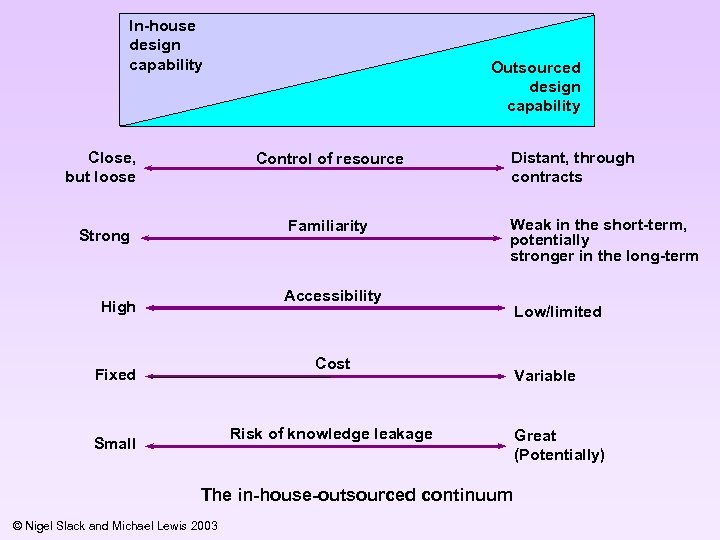

In-house design capability Close, but loose Outsourced design capability Control of resource Familiarity Strong Distant, through contracts Weak in the short-term, potentially stronger in the long-term Accessibility High Cost Fixed Risk of knowledge leakage Small The in-house-outsourced continuum © Nigel Slack and Michael Lewis 2003 Low/limited Variable Great (Potentially)

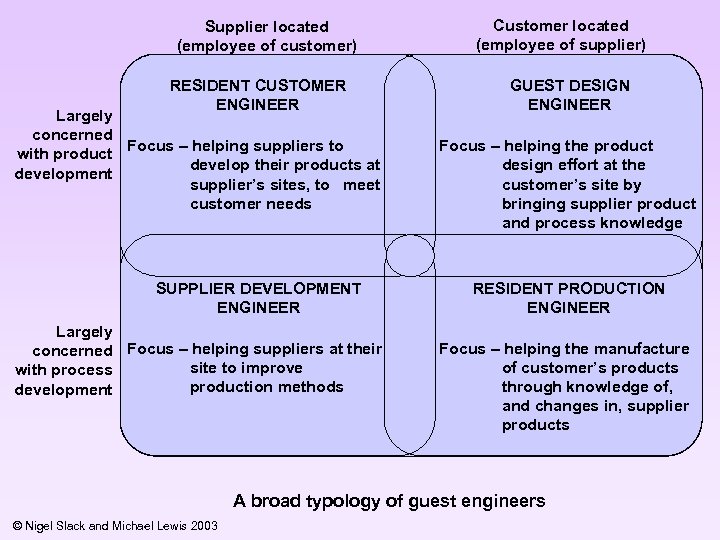

Supplier located (employee of customer) RESIDENT CUSTOMER ENGINEER Largely concerned Focus – helping suppliers to with product develop their products at development supplier’s sites, to meet customer needs SUPPLIER DEVELOPMENT ENGINEER Largely concerned Focus – helping suppliers at their site to improve with process production methods development Customer located (employee of supplier) GUEST DESIGN ENGINEER Focus – helping the product design effort at the customer’s site by bringing supplier product and process knowledge RESIDENT PRODUCTION ENGINEER Focus – helping the manufacture of customer’s products through knowledge of, and changes in, supplier products A broad typology of guest engineers © Nigel Slack and Michael Lewis 2003

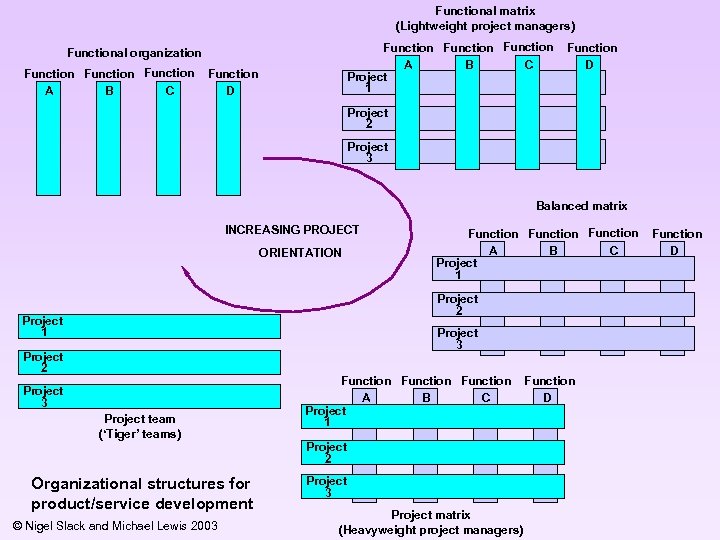

Functional matrix (Lightweight project managers) Function A B C Project 1 Functional organization Function A B C Function D Project 2 Project 3 Balanced matrix INCREASING PROJECT ORIENTATION Function A B C Project 1 Project 2 Project 1 Project 3 Project 2 Project 3 Project team (‘Tiger’ teams) Function A B C Project 1 Project 2 Organizational structures for product/service development © Nigel Slack and Michael Lewis 2003 Project matrix (Heavyweight project managers) Function D

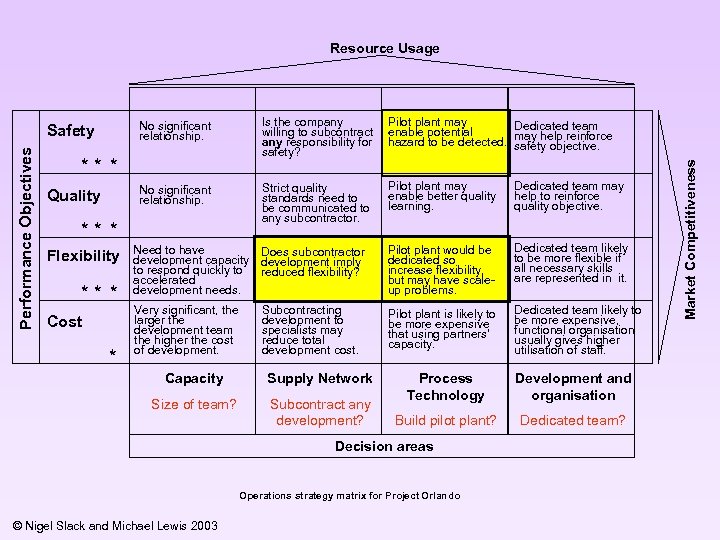

Resource Usage Performance Objectives Is the company willing to subcontract any responsibility for safety? Pilot plant may Dedicated team enable potential hazard to be detected. may help reinforce safety objective. No significant relationship. Strict quality standards need to be communicated to any subcontractor. Pilot plant may enable better quality learning. Dedicated team may help to reinforce quality objective. Need to have Does subcontractor development capacity development imply to respond quickly to reduced flexibility? accelerated development needs. Pilot plant would be dedicated so increase flexibility, but may have scaleup problems. Dedicated team likely to be more flexible if all necessary skills are represented in it. Very significant, the larger the development team the higher the cost of development. Pilot plant is likely to be more expensive that using partners’ capacity. Dedicated team likely to be more expensive, functional organisation usually gives higher utilisation of staff. ** * Quality ** * Flexibility ** * Cost * Subcontracting development to specialists may reduce total development cost. Capacity Supply Network Size of team? Subcontract any development? Process Technology Development and organisation Build pilot plant? Dedicated team? Decision areas Operations strategy matrix for Project Orlando © Nigel Slack and Michael Lewis 2003 Market Competitiveness No significant relationship. Safety

8ac019a77dbf8d2ee297e7b99db1be15.ppt