Performance Evaluation of Warehousing Units

Performance Evaluation of Warehousing Units

Some general remarks • In general, a difficult problem due the – large number of operational issues that must be introduced in the model – stochastic nature of the system operations – unique aspects of the various environments – etc. • Therefore, simulation is the most extensively used tool • Analytical models exist mainly for some automated modules, because – they present some better defined structure and behavior (therefore, easier to justify the modeling assumptions) – the need for good performance estimates for these modules is more critical, due to their high investment cost and inflexibility to modifications – modeling and analyzing automated (production) systems is a prevailing trend in the scientific community

Some general remarks • In general, a difficult problem due the – large number of operational issues that must be introduced in the model – stochastic nature of the system operations – unique aspects of the various environments – etc. • Therefore, simulation is the most extensively used tool • Analytical models exist mainly for some automated modules, because – they present some better defined structure and behavior (therefore, easier to justify the modeling assumptions) – the need for good performance estimates for these modules is more critical, due to their high investment cost and inflexibility to modifications – modeling and analyzing automated (production) systems is a prevailing trend in the scientific community

An example application: “Travel-Time Models for AS/RS” (Y. Bozer and J. White, IIE Trans. , pgs 329 -338, 1984) Modeling assumptions: • The S/R machine operates either on a single or a dual command basis. • The S/R machine travels simultaneously in the horizontal and vertical directions with constant velocities. • Pick-up and deposit times associated with load handling can be ignored. In general, this is a deterministic component of the overall cycle time which can be added to it at the end, if it is deemed significant. • Randomized storage is used; thus, any location in the pick face is equally likely to be selected for storage or retrieval. Quantities to be evaluated: • Expected cycle time and throughput, under SC and DC operation

An example application: “Travel-Time Models for AS/RS” (Y. Bozer and J. White, IIE Trans. , pgs 329 -338, 1984) Modeling assumptions: • The S/R machine operates either on a single or a dual command basis. • The S/R machine travels simultaneously in the horizontal and vertical directions with constant velocities. • Pick-up and deposit times associated with load handling can be ignored. In general, this is a deterministic component of the overall cycle time which can be added to it at the end, if it is deemed significant. • Randomized storage is used; thus, any location in the pick face is equally likely to be selected for storage or retrieval. Quantities to be evaluated: • Expected cycle time and throughput, under SC and DC operation

A “brute force” calculation Assuming that: • the total number of storage locations is N • one-way travel time from I/O point to location i is t_oi = t_io • one-way travel time between locations i and j is t_ij = t_ji we have: • E(SC) = (2/N) * _{i=1}^N t_oi • E(DC) = (2 / (N * (N-1))) * * _{i=1}^{N-1} _{j=i+1}^N [t_oi+ t_ij + t_jo]

A “brute force” calculation Assuming that: • the total number of storage locations is N • one-way travel time from I/O point to location i is t_oi = t_io • one-way travel time between locations i and j is t_ij = t_ji we have: • E(SC) = (2/N) * _{i=1}^N t_oi • E(DC) = (2 / (N * (N-1))) * * _{i=1}^{N-1} _{j=i+1}^N [t_oi+ t_ij + t_jo]

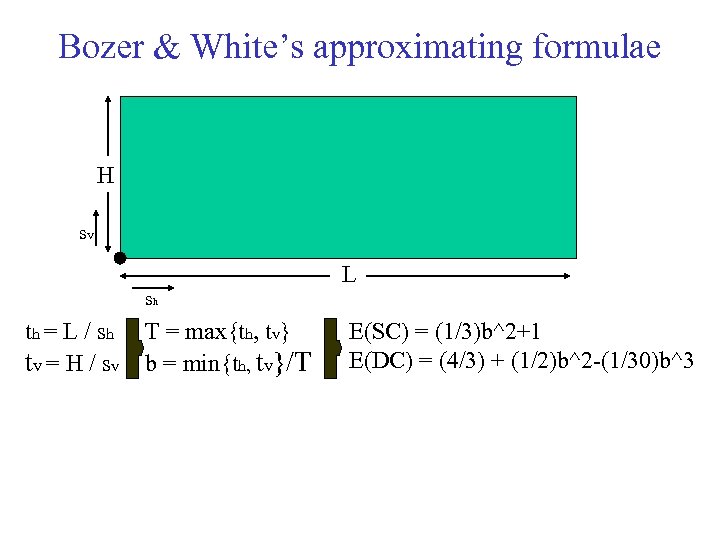

Bozer & White’s approximating formulae H sv sh t h = L / sh t v = H / sv T = max{th, tv} b = min{th, tv}/T L E(SC) = (1/3)b^2+1 E(DC) = (4/3) + (1/2)b^2 -(1/30)b^3

Bozer & White’s approximating formulae H sv sh t h = L / sh t v = H / sv T = max{th, tv} b = min{th, tv}/T L E(SC) = (1/3)b^2+1 E(DC) = (4/3) + (1/2)b^2 -(1/30)b^3

Some interesting follow-up works • Y. Bozer and J. White, “Design and Performance Models for End-of-Aisle order picking systems” Management Science, Vol. 36, No. 7, pgs 852 -866, 1990 • Y. Bozer and J. White, “A generalized design and performance analysis model for end-of-aisle order-picking systems”, IIE Trans. , Vol. 28, pgs 271 -280, 1996 • R. Foley and E. Frazelle, “Analytical results for miniload throughput and the distribution of dual command travel time”, IIE Trans. , Vol. 23, No. 3, pgs 273 -281, 1991 • R. Foley, S. Hackman and B. C. Park, “Back-of-the envelope miniload throughput bounds and approximations”, working paper, ISy. E, Georgia Tech, 2001

Some interesting follow-up works • Y. Bozer and J. White, “Design and Performance Models for End-of-Aisle order picking systems” Management Science, Vol. 36, No. 7, pgs 852 -866, 1990 • Y. Bozer and J. White, “A generalized design and performance analysis model for end-of-aisle order-picking systems”, IIE Trans. , Vol. 28, pgs 271 -280, 1996 • R. Foley and E. Frazelle, “Analytical results for miniload throughput and the distribution of dual command travel time”, IIE Trans. , Vol. 23, No. 3, pgs 273 -281, 1991 • R. Foley, S. Hackman and B. C. Park, “Back-of-the envelope miniload throughput bounds and approximations”, working paper, ISy. E, Georgia Tech, 2001