4c940159550ac7cd8d34d40fc2df85f4.ppt

- Количество слайдов: 14

Performance Based Logistics 03 pm 52 -1

Performance-Based Logistics • Program Manager is responsible for life cycle support • PM manages integrated logistics chain • Do. D sustainment commands foster transparency and interoperability • Performance agreements negotiated with operational customers • PM builds performance agreements with industry and organic providers • National ownership of material and services to the point of consumption • Logistics and financial transactions transparent at the operational level • Outcome performance measured throughout the process 03 pm 52 -2

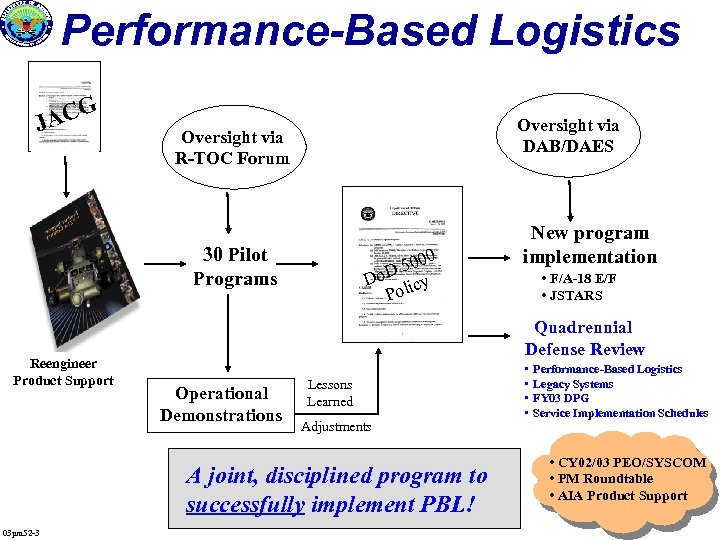

Performance-Based Logistics G JAC Oversight via DAB/DAES Oversight via R-TOC Forum 30 Pilot Programs Reengineer Product Support 0 500 Do. D licy Po • F/A-18 E/F • JSTARS Quadrennial Defense Review Operational Demonstrations Lessons Learned Adjustments A joint, disciplined program to successfully implement PBL! 03 pm 52 -3 New program implementation • • Performance-Based Logistics Legacy Systems FY 03 DPG Service Implementation Schedules • CY 02/03 PEO/SYSCOM • PM Roundtable • AIA Product Support

QDR Direction • Project and sustain the force with minimal footprint • Implement performance-based logistics to improve readiness for major weapon systems and availability of commodities • Reduce cycle times to industry standards Logistics Transformation to support Military Transformation 03 pm 42 -4 03 pm 52 -4

Performance-Based Logistics Do. D Directive 5000. 1 “The Defense Acquisition System” May 12, 2003 Performance-Based Logistics. PMs shall develop and implement performance based logistics strategies that optimize total system availability while minimizing cost and logistics footprint. Trade-off decisions involving cost, useful service, and effectiveness shall consider corrosion prevention and mitigation. Sustainment strategies shall include the best use of public and private sector capabilities through government/industry partnering initiatives, in accordance with statutory requirements. Total Systems Approach. The PM shall be the single point of accountability for accomplishing program objectives for total life cycle systems management, including sustainment 03 pm 52 -5

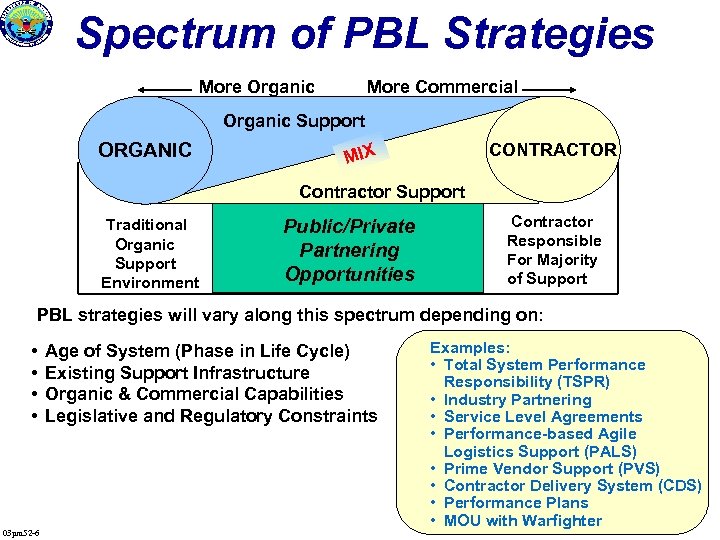

Spectrum of PBL Strategies More Organic More Commercial Organic Support ORGANIC CONTRACTOR MIX Contractor Support Traditional Organic Support Environment Public/Private Partnering Opportunities Contractor Responsible For Majority of Support PBL strategies will vary along this spectrum depending on: • • 03 pm 52 -6 Age of System (Phase in Life Cycle) Existing Support Infrastructure Organic & Commercial Capabilities Legislative and Regulatory Constraints Examples: • Total System Performance Responsibility (TSPR) • Industry Partnering • Service Level Agreements • Performance-based Agile Logistics Support (PALS) • Prime Vendor Support (PVS) • Contractor Delivery System (CDS) • Performance Plans • MOU with Warfighter

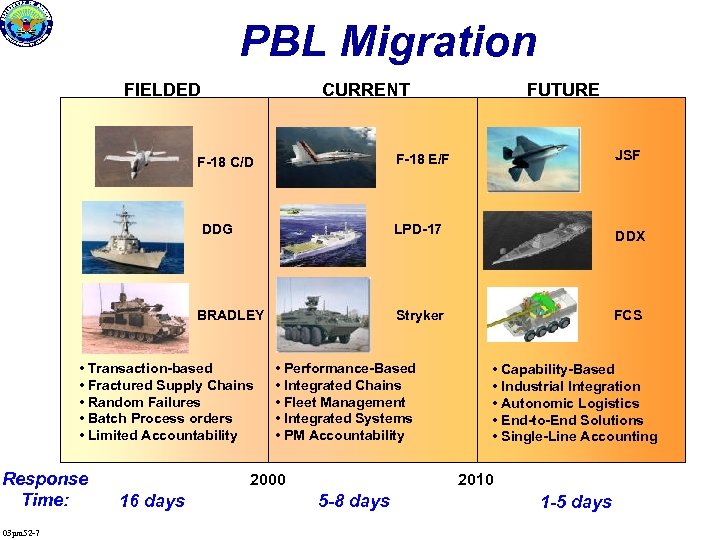

PBL Migration FIELDED CURRENT DDG LPD-17 BRADLEY • Transaction-based • Fractured Supply Chains • Random Failures • Batch Process orders • Limited Accountability 03 pm 52 -7 DDX FCS Stryker • Performance-Based • Integrated Chains • Fleet Management • Integrated Systems • PM Accountability 2000 16 days JSF F-18 E/F F-18 C/D Response Time: FUTURE • Capability-Based • Industrial Integration • Autonomic Logistics • End-to-End Solutions • Single-Line Accounting 2010 5 -8 days 1 -5 days

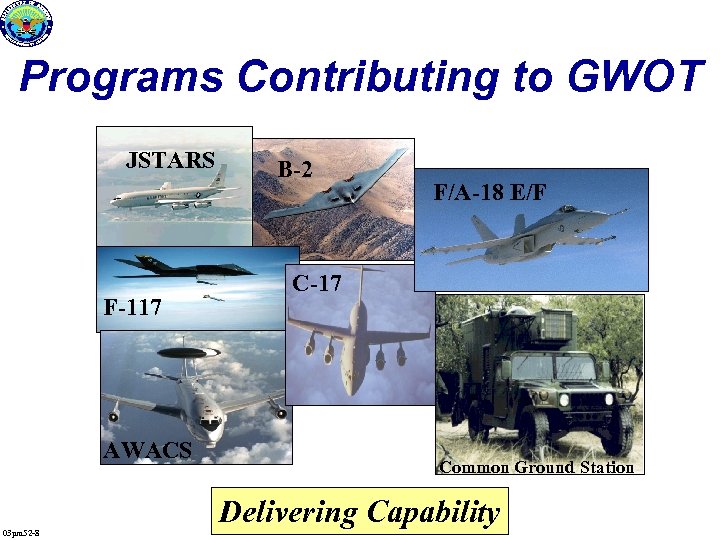

Programs Contributing to GWOT JSTARS F-117 AWACS 03 pm 52 -8 B-2 F/A-18 E/F C-17 Common Ground Station Delivering Capability

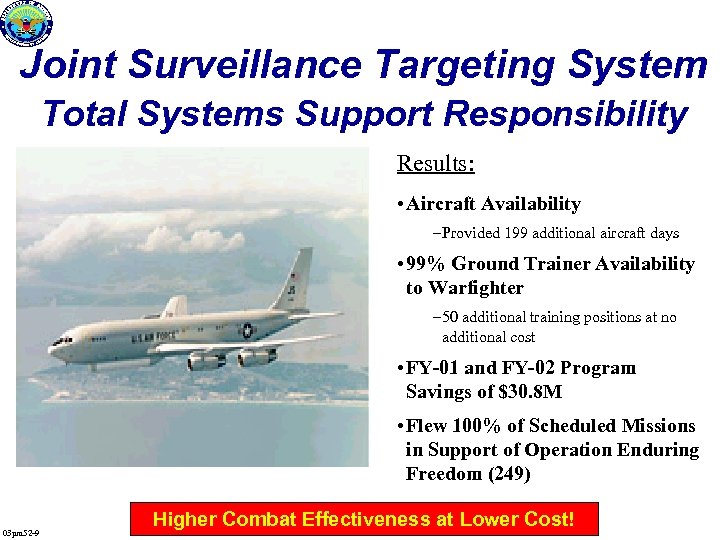

Joint Surveillance Targeting System Total Systems Support Responsibility Results: • Aircraft Availability – Provided 199 additional aircraft days • 99% Ground Trainer Availability to Warfighter – 50 additional training positions at no additional cost • FY-01 and FY-02 Program Savings of $30. 8 M • Flew 100% of Scheduled Missions in Support of Operation Enduring Freedom (249) 03 pm 52 -9 Higher Combat Effectiveness at Lower Cost!

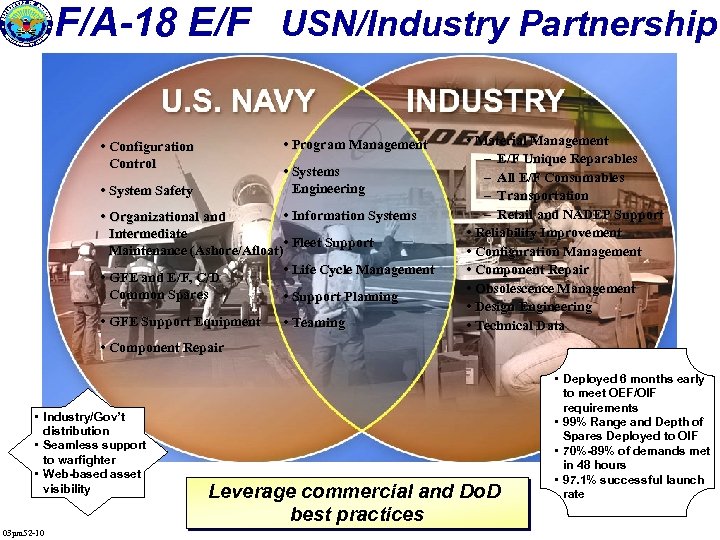

F/A-18 E/F USN/Industry Partnership • Program Management • Configuration Control • Systems Engineering • System Safety • Information Systems • Organizational and Intermediate • Fleet Support Maintenance (Ashore/Afloat) • Life Cycle Management • GFE and E/F, C/D Common Spares • Support Planning • GFE Support Equipment • Teaming • Material Management – E/F Unique Reparables – All E/F Consumables – Transportation – Retail and NADEP Support • Reliability Improvement • Configuration Management • Component Repair • Obsolescence Management • Design Engineering • Technical Data • Component Repair • Industry/Gov’t distribution • Seamless support to warfighter • Web-based asset visibility 03 pm 52 -10 Leverage commercial and Do. D best practices • Deployed 6 months early to meet OEF/OIF requirements • 99% Range and Depth of Spares Deployed to OIF • 70%-89% of demands met in 48 hours • 97. 1% successful launch rate

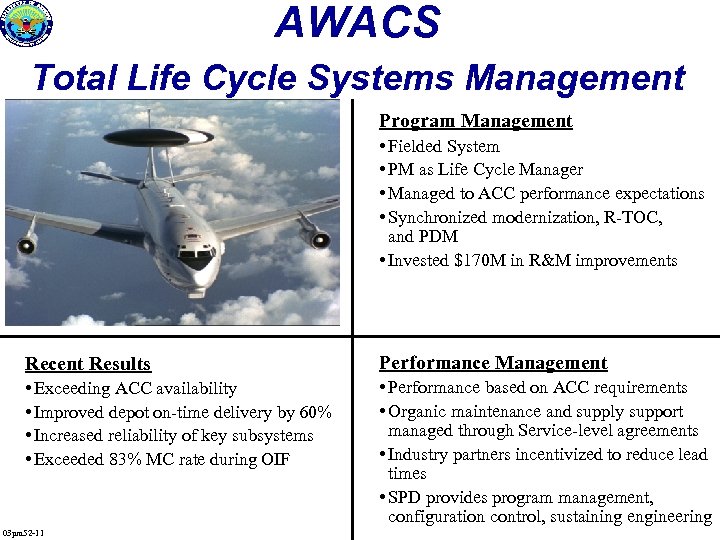

AWACS Total Life Cycle Systems Management Program Management • Fielded System • PM as Life Cycle Manager • Managed to ACC performance expectations • Synchronized modernization, R-TOC, and PDM • Invested $170 M in R&M improvements Recent Results Performance Management • Exceeding ACC availability • Improved depot on-time delivery by 60% • Increased reliability of key subsystems • Exceeded 83% MC rate during OIF • Performance based on ACC requirements • Organic maintenance and supply support managed through Service-level agreements • Industry partners incentivized to reduce lead times • SPD provides program management, configuration control, sustaining engineering 03 pm 52 -11

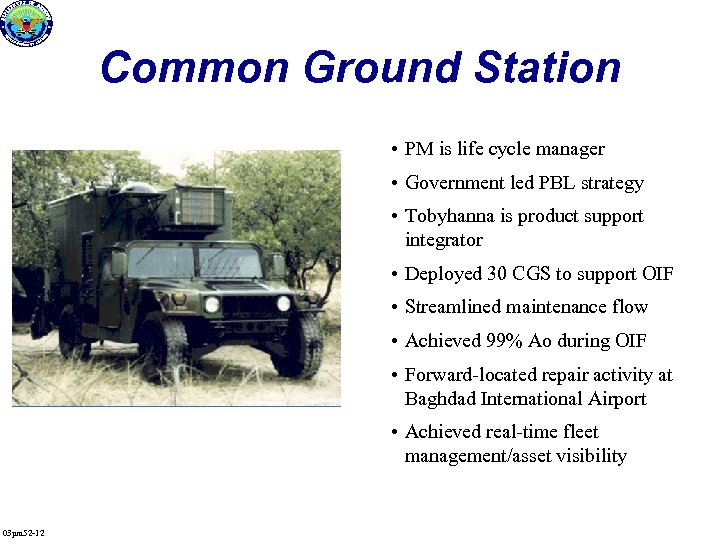

Common Ground Station • PM is life cycle manager • Government led PBL strategy • Tobyhanna is product support integrator • Deployed 30 CGS to support OIF • Streamlined maintenance flow • Achieved 99% Ao during OIF • Forward-located repair activity at Baghdad International Airport • Achieved real-time fleet management/asset visibility 03 pm 52 -12

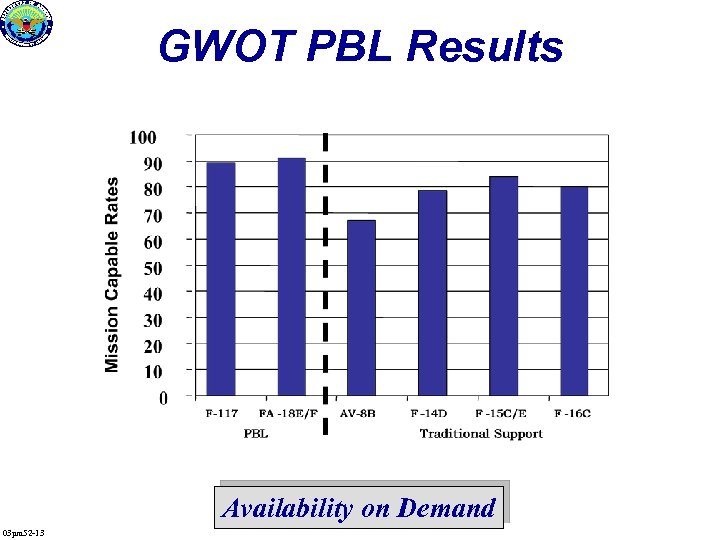

GWOT PBL Results Availability on Demand 03 pm 52 -13

Summary • Program Managers are Total Life Cycle Systems Managers • PBL is the preferred sustainment strategy – Applied based upon business case • Recent results confirm operational and cost benefits of PBL – Structural enablers continue to be addressed • We need your input to improve implementation process 03 pm 52 -14

4c940159550ac7cd8d34d40fc2df85f4.ppt