e0f70d0144806ccc9e4ccf4505e56a29.ppt

- Количество слайдов: 61

PERALATAN PENCAMPURAN (MIXING EQUIPMENT) Dr. Ir. Meika Syahbana Rusli, MSc

Tujuan Pencampuran: Bergabungnya bahan menjadi suatu campuran yang sedapat mungkin memiliki kesamaan penyebaran yang sempurna Jenis agregat komponen dalam suatu campuran : 1. Campuran gas ; 1. Contoh : udara 2. Campuran bahan cair; 1. Contoh : larutan, emulsi 3. Campuran bahan padat-bahan cair; 1. Contoh : suspensi, pasta 4. Campuran bahan cair-gas; Contoh : minuman yang mengandung CO 2

5. Campuran bahan padat; Contoh : pakan ternak, adukan semen pasir 6. Campuran gas-bahan padat; Contoh : asap • Homogenisasi campuran jenis 1 dan 6 dilakukan dengan bantuan aliran turbulen melalui pompa • Homogenisasi campuran jenis 2 s/d 5 dilakukan melalui : v A. pengadukan v B. pencampuran bahan viskous v C. pencampuran bahan padat

Pengadukan bahan cair Tujuan : a. Mensuspensikan bahan/partikel padat b. Menggabungkan bahan-bahan cair yang dapat saling bercampur c. Mendispersikan gas dalam bentuk gelembung gas halus d. Mendispersikan bahan cair lain yang tidak dapat bercampur e. Meningkatkan pindah panas antara bahan cair dan penukar panas Dalam suatu proses pengadukan, beberapa tujuan tersebut diatas dicapai secara sekaligus. Contoh : proses hidrogenasi katalitis minyak nabati

Rancangan alat pengauk (agitators) Secara umum agitator terdiri dari : 1. bejana (vessel) 2. sumbu berputar (As) 3. pengaduk (impeller) 4. penggerak (motor) 5. pemecah aliran (buffle)

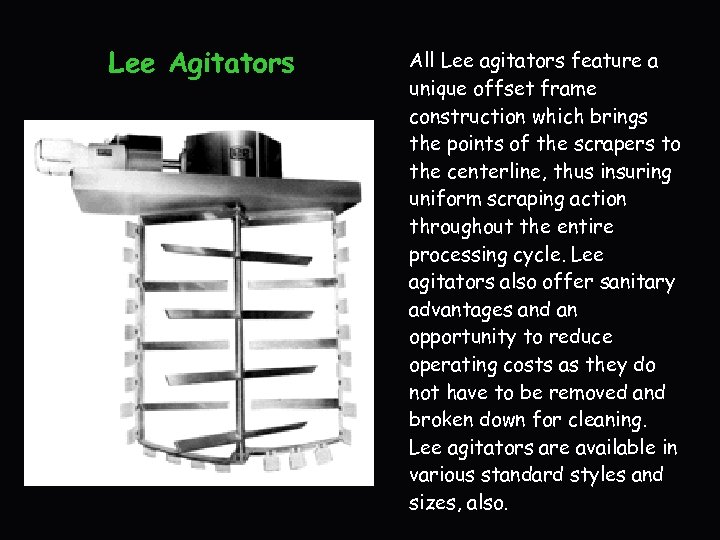

Lee Agitators All Lee agitators feature a unique offset frame construction which brings the points of the scrapers to the centerline, thus insuring uniform scraping action throughout the entire processing cycle. Lee agitators also offer sanitary advantages and an opportunity to reduce operating costs as they do not have to be removed and broken down for cleaning. Lee agitators are available in various standard styles and sizes, also.

Other features include: Exclusive centerline scraper assembly assures uniform scraping and complete mixing. Scrapers are hinged to the frame above and back of the center at a steep pitch, thus moving the heated film of the product continuously toward the center of the kettle. Option of fixed or variable speed, electric or hydraulic motors. Agitator drive mounted in a heavy stainless steel channel with special lip seal to prevent leakage into product. Choice of hydraulic cylinders for easy tilt-out of agitator. USDA approved scraper blades available in a choice of quality materials, including: molded nylon, nickel alloy castings, and Teflon. Fully-enclosed gear box with heavy-duty gears assures reliability and long life. Lee assembles, tests and runs all agitator assemblies before shipment. Standard agitator is supplied with a USDA approved bottom support bushing. All scraped-surface agitators can be installed at an incline in hemispherical bottom vessels.

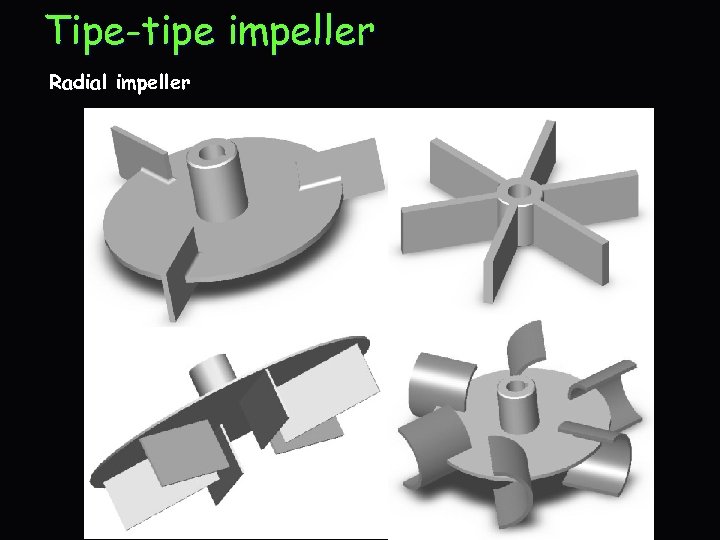

Tipe-tipe impeller Radial impeller

Axial impeller

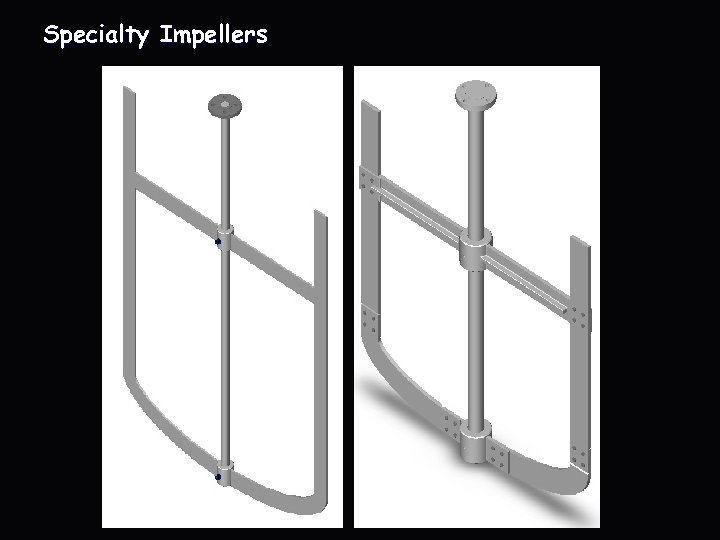

Specialty Impellers

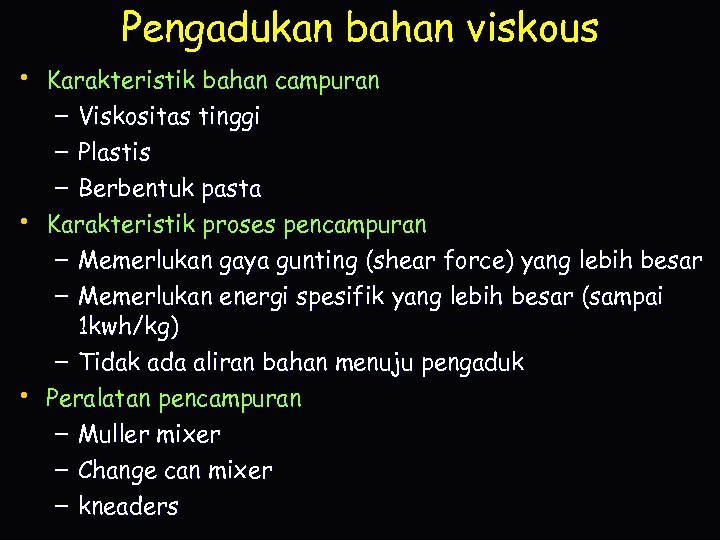

Pengadukan bahan viskous • Karakteristik bahan campuran – Viskositas tinggi – Plastis – Berbentuk pasta • Karakteristik proses pencampuran – Memerlukan gaya gunting (shear force) yang lebih besar – Memerlukan energi spesifik yang lebih besar (sampai 1 kwh/kg) – Tidak ada aliran bahan menuju pengaduk • Peralatan pencampuran – Muller mixer – Change can mixer – kneaders

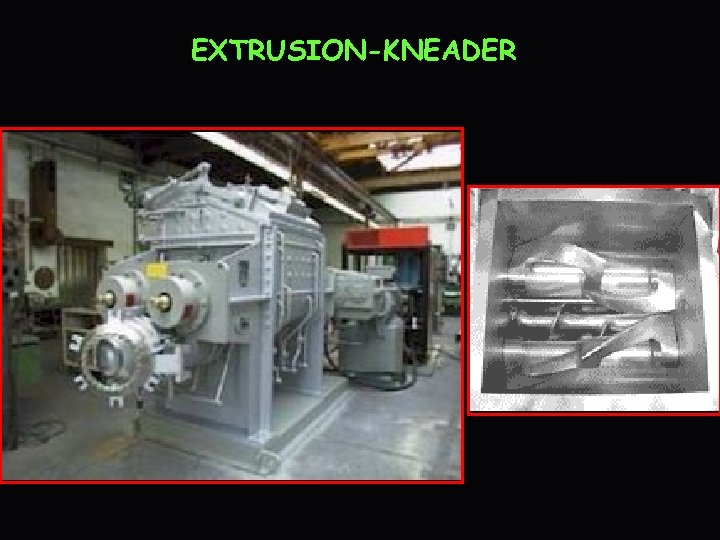

EXTRUSION-KNEADER

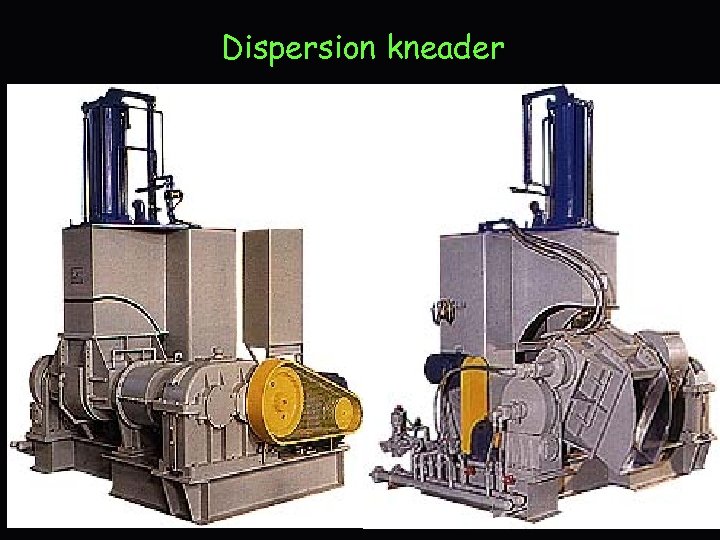

Dispersion kneader

FEATURE FOR DISPERSION KNEADER: 1. It has an automatic temperature and time control system to provide a 100% mixing effect. 2. Easy to clean chamber and changing colours. 3. It mixes compounds in 6~10 minutes per batch equivalent to 2 units of mixing Roller. 4. Pressurized and sealing mixing chamber to provide high mixing performance and prevented environmental pollution. 5. Easy to installation, operation and maintenance to lower the running cost.

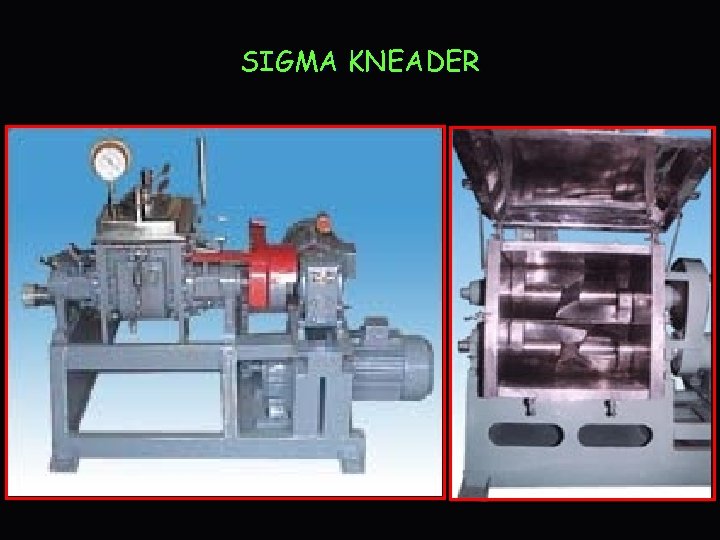

SIGMA KNEADER

Excellent for kneading and mixing of highly viscous materials like dough, putty, rubber solutions, adhesives, polymers etc. The mixing action is a combination of smearing, stretching, folding, dividing and recombining as the material is processed between the sigma blades and the container walls. Jacket arrangement is provided for heating or cooling application. In bigger models the container is tilted by a hydraulic cylinder to ensure complete discharge of mass.

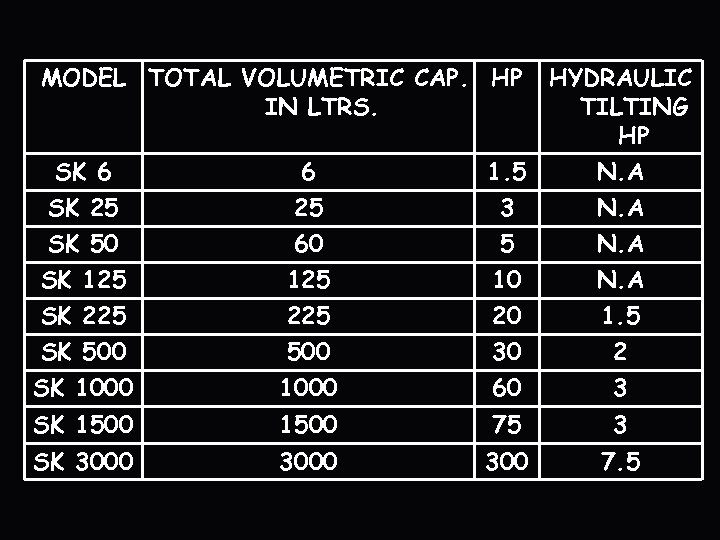

MODEL TOTAL VOLUMETRIC CAP. HP IN LTRS. HYDRAULIC TILTING HP 1. 5 N. A SK 6 6 SK 25 SK 50 SK 125 SK 225 SK 500 SK 1000 25 60 125 225 500 1000 3 5 10 20 30 60 N. A 1. 5 2 3 SK 1500 75 3 SK 3000 300 7. 5

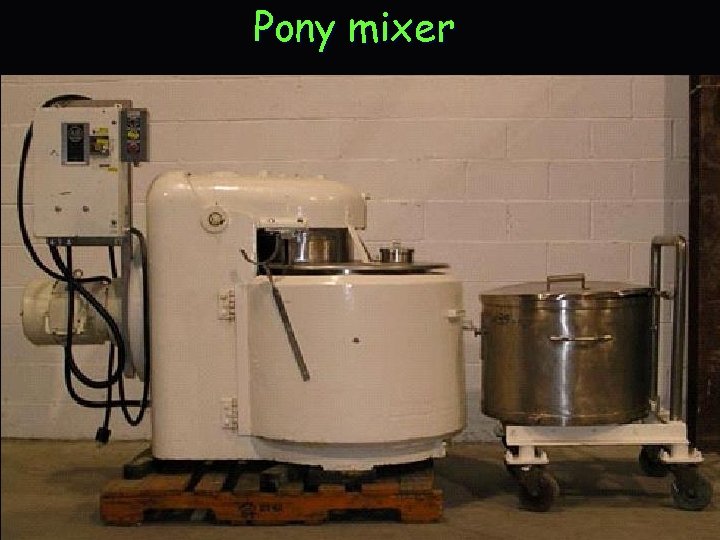

Pony mixer

Pencampuran partikel padat • Karakteristik proses pencampuran – Bahan padat datat mengalir – Prinsip hampir sama dengan pencampuran bahan viskous – Membutuhkan tenaga yang lebih ringan/kecil dari pada pencampuran bahan pasta – Tidak ada aliran bahan ke pengaduk dengan sendirinya – Cara kerja : kocokan mekanik, angkat dan jatuhkan dan menggelindingkan bahan

Jenis-jenis mesin pencampur bahan padat antara lain : 1. Ribbon blender 2. Vertical screw mixer 3. Double cone mixer 4. Twin shell blender

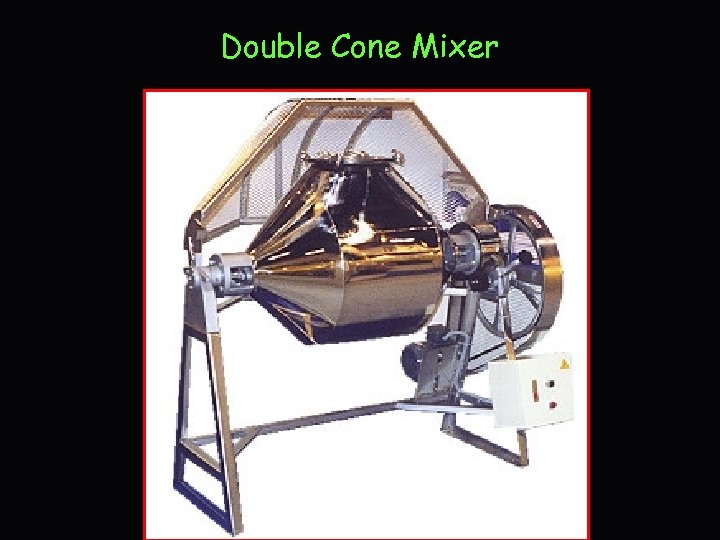

Double Cone Mixer

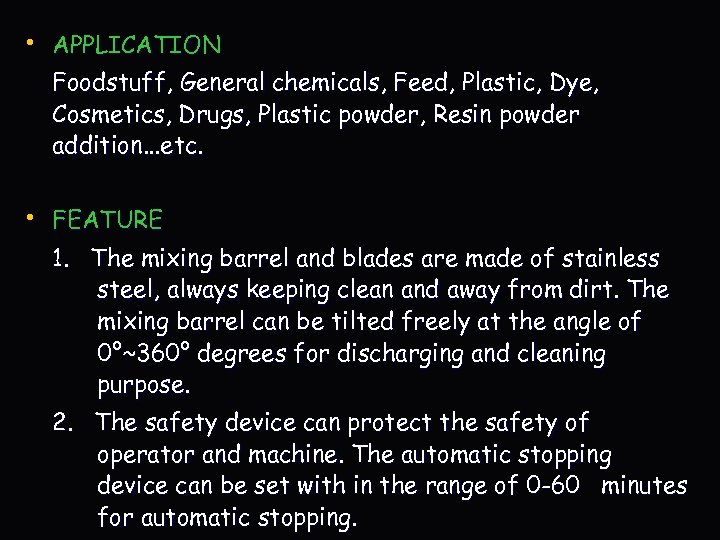

• APPLICATION Foodstuff, General chemicals, Feed, Plastic, Dye, Cosmetics, Drugs, Plastic powder, Resin powder addition. . . etc. • FEATURE 1. The mixing barrel and blades are made of stainless steel, always keeping clean and away from dirt. The mixing barrel can be tilted freely at the angle of 0°~360° degrees for discharging and cleaning purpose. 2. The safety device can protect the safety of operator and machine. The automatic stopping device can be set with in the range of 0 -60 minutes for automatic stopping.

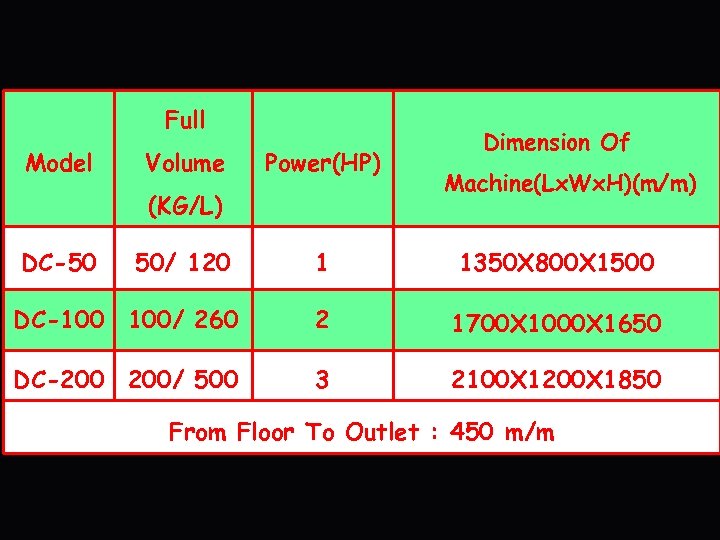

Full Model Volume Power(HP) (KG/L) DC-50 50/ 120 Dimension Of Machine(Lx. Wx. H)(m/m) 1 1350 X 800 X 1500 DC-100 100/ 260 2 1700 X 1000 X 1650 DC-200 200/ 500 3 2100 X 1200 X 1850 From Floor To Outlet : 450 m/m

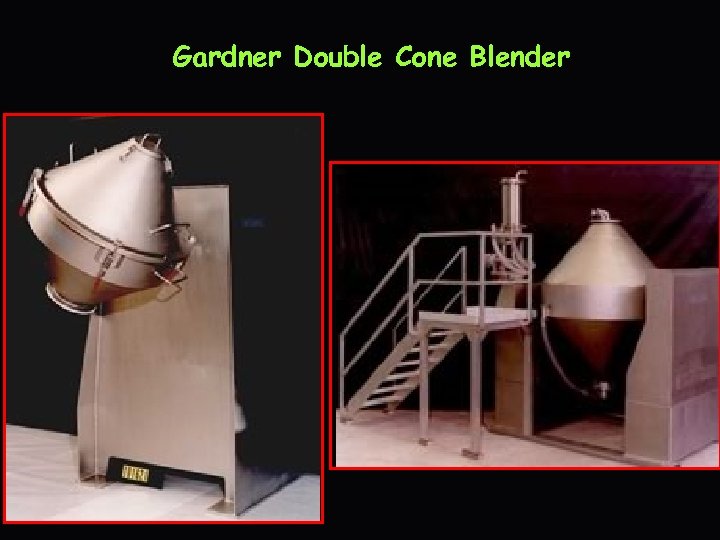

Gardner Double Cone Blender

Gardner Double Cone Blender GARDNER Double Cone Blenders incorporate a gentle, low energy tumbling action, ideal for blending the most delicate and fragile products. It is also the best way to mix very heavy and abrasive products. Features • Capacities range from 2 to 100, 000 litres. • Hygienic design with no internal seals. • Automated loading option via pneumatic conveying system. • Custom built to suit customer requirements.

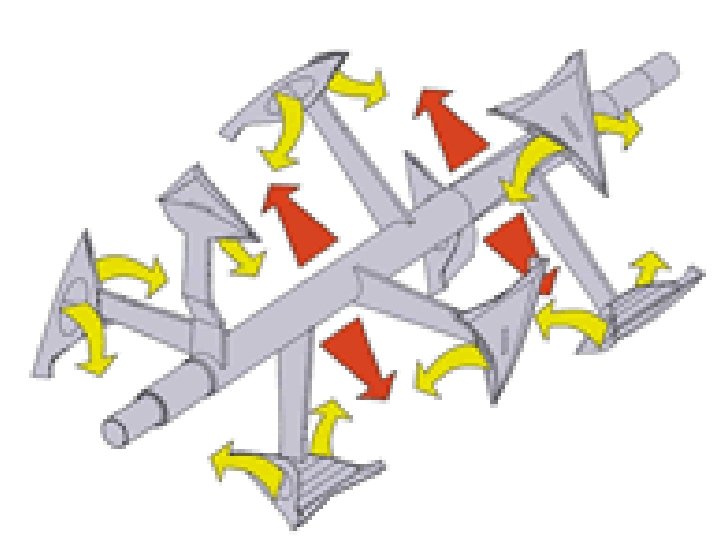

Benefits – Gentle blending of delicate materials. – Hygienic and easy to clean. – Each blender features KEMUTEC's unique multi shear deflector plates for the improved blending efficiency of free flowing powders and granules. – Minimal attrition when blending abrasive materials. – Total discharge of product with minimal retention

Plough Mixers

Gardner Plough Mixers are high energy, high shear, and high-speed mixers with cylindrical short aspect ratio mixing chambers. Extra shear can be achieved by adding side cutters or intensifiers. Gardner Plough Mixers are available with 'Easy Clean' cantilevered shaft, subject to application. Features • Hygienic design • Capacities in the range of 50 to 20, 000 litres • Custom built to suit customer requirements

Benefits – Alternative trough shapes are available to suit specific application requirements – Rapid mix times – High-energy mixes

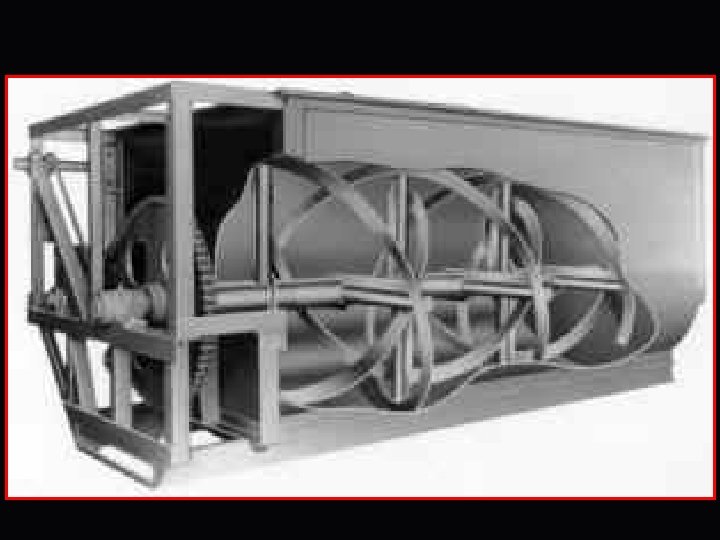

Ribbon Mixer

With Oil Spraying Device

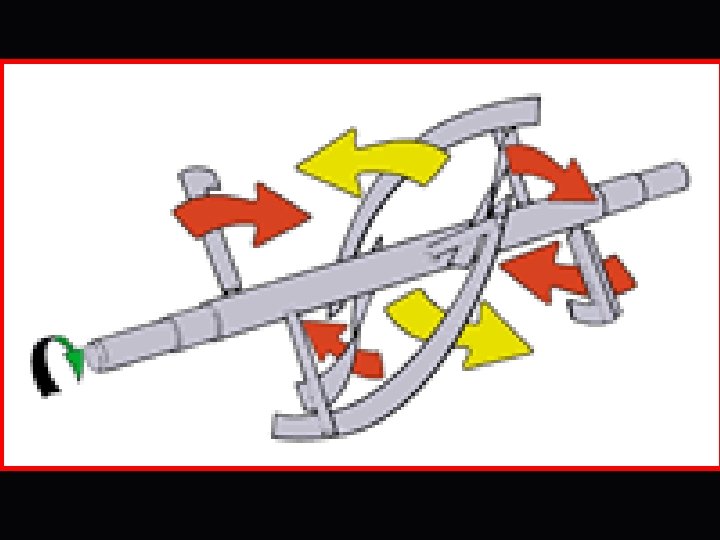

APPLICATION Foodstuff, Feed, Dye, Pigment, Chemical, Spice, Fertilizer. . . etc. FEATURE 1. The inner and outer layers dual-spiral "S" sign crossing of upper and lower mixing type is adopted. Mixing effectiveness is good. Speed is fast. Powder dust will not fly in operation. 2. Complete and through blending of raw materials by ribbon agitator which create two layers and counter movement of flows.

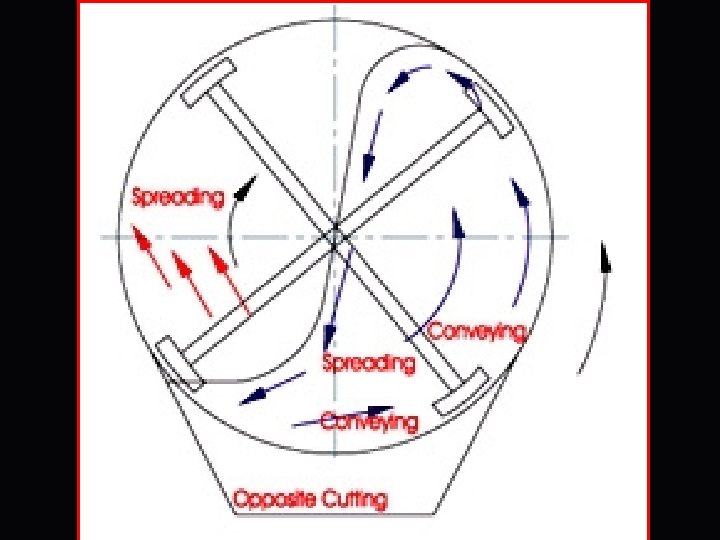

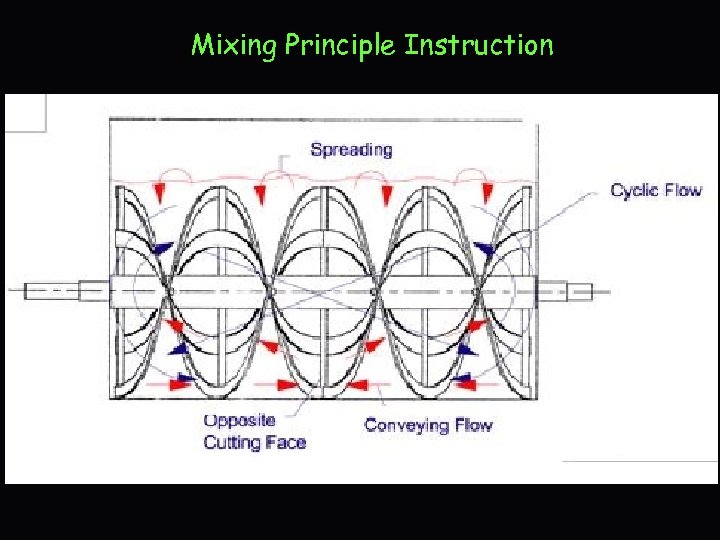

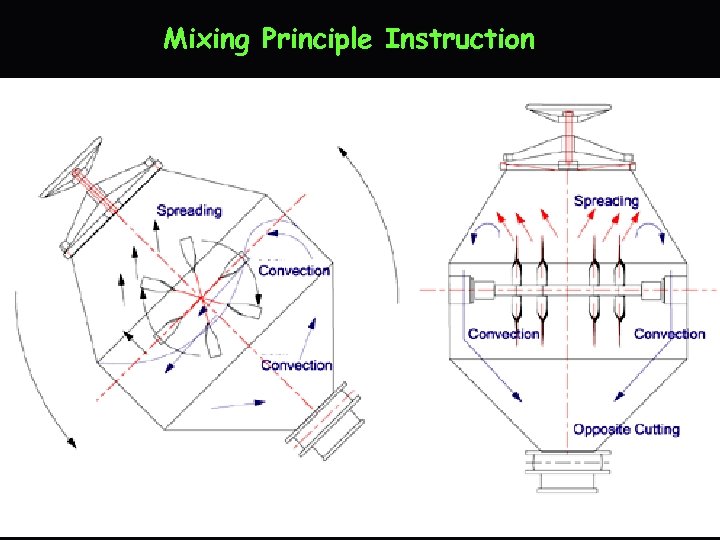

Mixing Principle Instruction

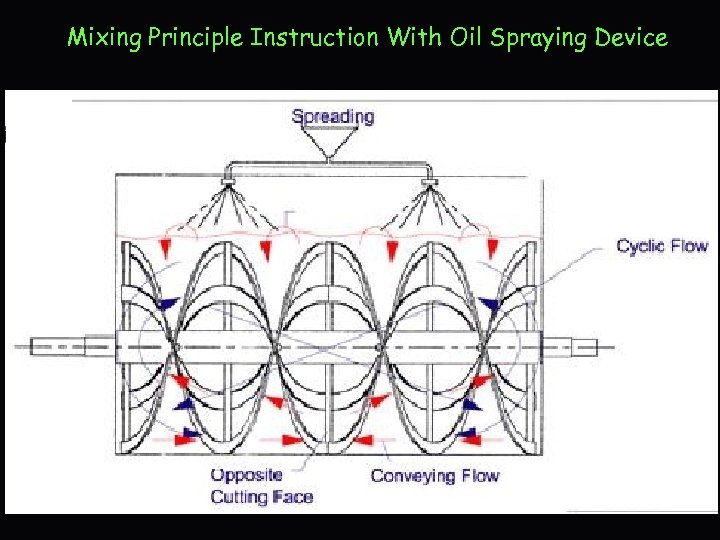

Mixing Principle Instruction With Oil Spraying Device

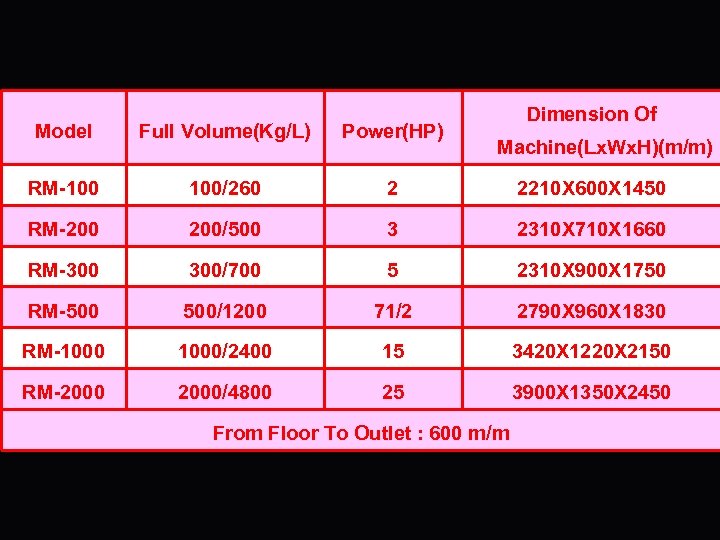

Dimension Of Model Power(HP) RM-100 100/260 2 2210 X 600 X 1450 RM-200 200/500 3 2310 X 710 X 1660 RM-300 300/700 5 2310 X 900 X 1750 RM-500 Full Volume(Kg/L) 500/1200 71/2 2790 X 960 X 1830 RM-1000/2400 15 3420 X 1220 X 2150 RM-2000/4800 25 3900 X 1350 X 2450 Machine(Lx. Wx. H)(m/m) From Floor To Outlet : 600 m/m

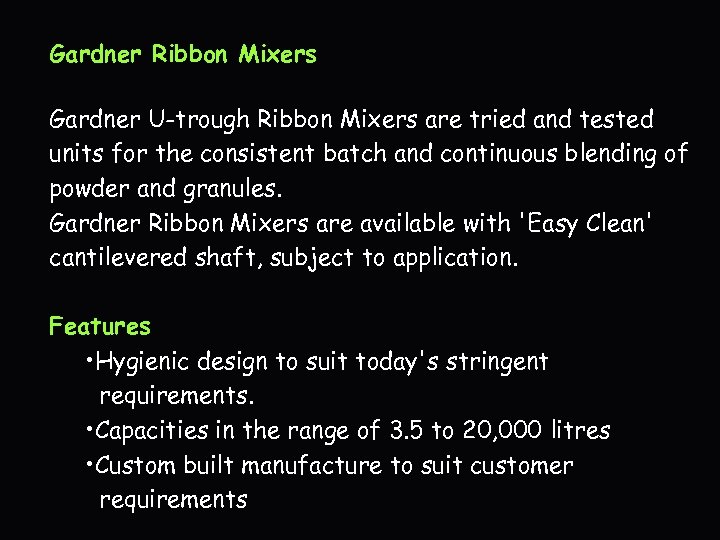

Gardner Ribbon Mixers

Gardner Ribbon Mixers Gardner U-trough Ribbon Mixers are tried and tested units for the consistent batch and continuous blending of powder and granules. Gardner Ribbon Mixers are available with 'Easy Clean' cantilevered shaft, subject to application. Features • Hygienic design to suit today's stringent requirements. • Capacities in the range of 3. 5 to 20, 000 litres • Custom built manufacture to suit customer requirements

Benefits – Mixing times are rapid whilst maintaining a gentle action – Minor ingredients are dispersed homogeneously without the need for premixing

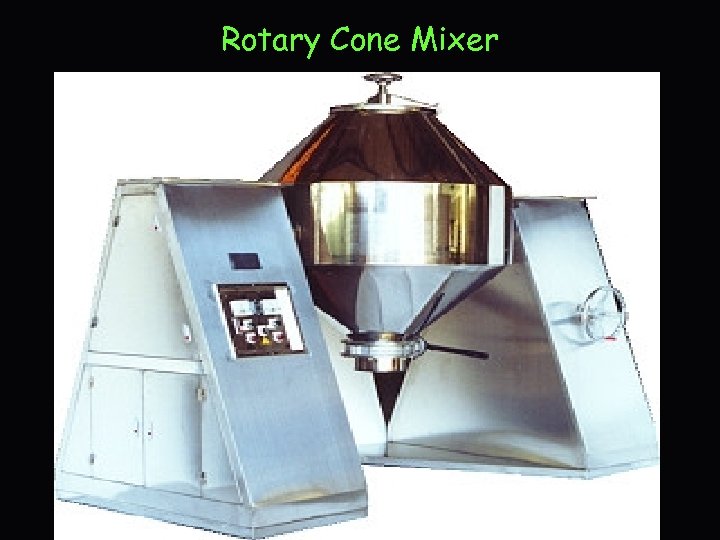

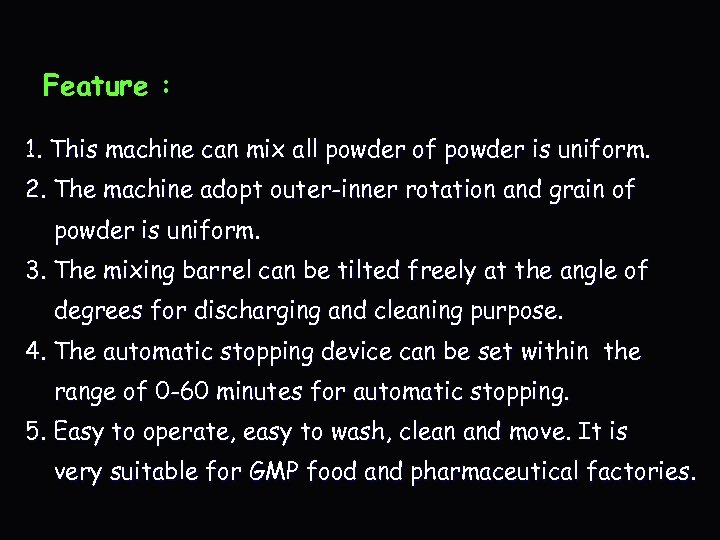

Rotary Cone Mixer

Feature : 1. This machine can mix all powder of powder is uniform. 2. The machine adopt outer-inner rotation and grain of powder is uniform. 3. The mixing barrel can be tilted freely at the angle of degrees for discharging and cleaning purpose. 4. The automatic stopping device can be set within the range of 0 -60 minutes for automatic stopping. 5. Easy to operate, easy to wash, clean and move. It is very suitable for GMP food and pharmaceutical factories.

Inner Oil Spraying Device

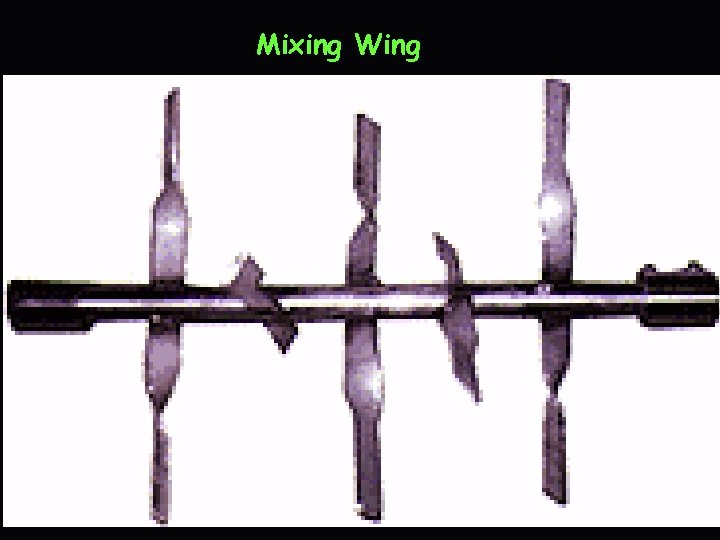

Mixing Wing

With Oil Spraying Device

Mixing Principle Instruction

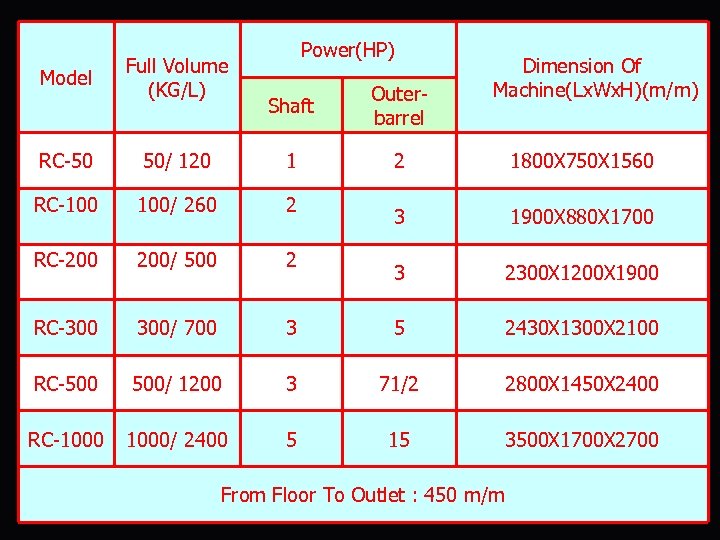

Model Full Volume (KG/L) Power(HP) Dimension Of Machine(Lx. Wx. H)(m/m) Shaft Outerbarrel 2 1800 X 750 X 1560 3 1900 X 880 X 1700 3 2300 X 1200 X 1900 RC-50 50/ 120 1 RC-100 100/ 260 2 RC-200 200/ 500 2 RC-300 300/ 700 3 5 2430 X 1300 X 2100 RC-500 500/ 1200 3 71/2 2800 X 1450 X 2400 RC-1000/ 2400 5 15 3500 X 1700 X 2700 From Floor To Outlet : 450 m/m

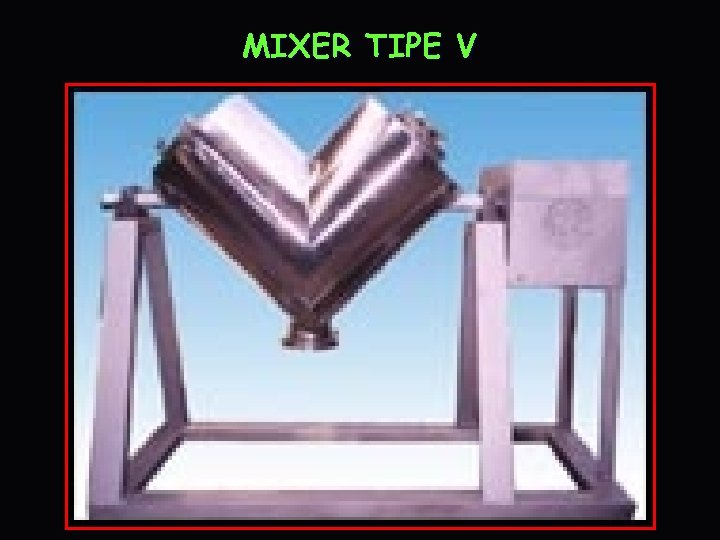

MIXER TIPE V

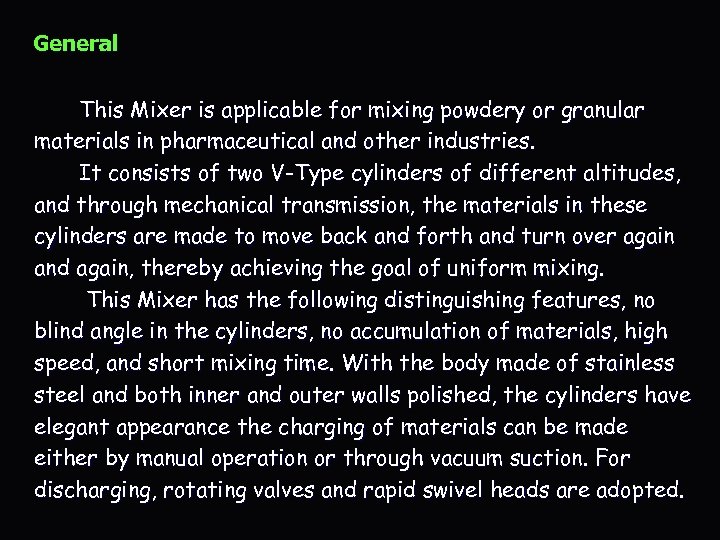

General This Mixer is applicable for mixing powdery or granular materials in pharmaceutical and other industries. It consists of two V-Type cylinders of different altitudes, and through mechanical transmission, the materials in these cylinders are made to move back and forth and turn over again and again, thereby achieving the goal of uniform mixing. This Mixer has the following distinguishing features, no blind angle in the cylinders, no accumulation of materials, high speed, and short mixing time. With the body made of stainless steel and both inner and outer walls polished, the cylinders have elegant appearance the charging of materials can be made either by manual operation or through vacuum suction. For discharging, rotating valves and rapid swivel heads are adopted.

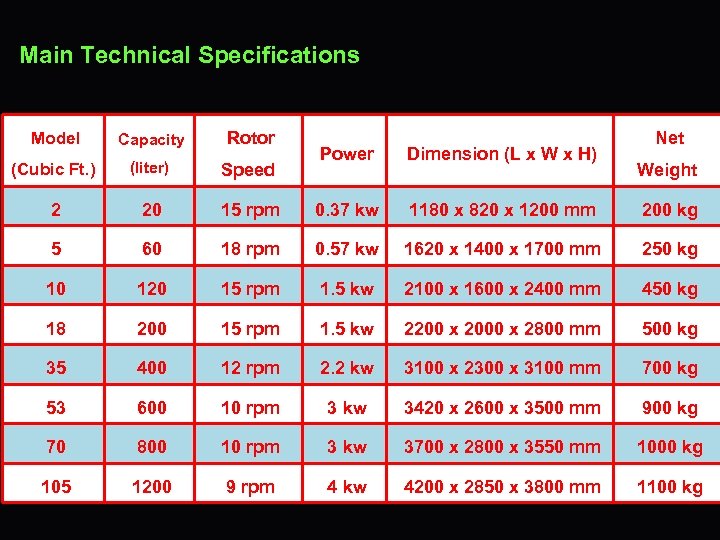

Main Technical Specifications Model Capacity Rotor (Cubic Ft. ) (liter) Speed 2 20 5 Net Power Dimension (L x W x H) 15 rpm 0. 37 kw 1180 x 820 x 1200 mm 200 kg 60 18 rpm 0. 57 kw 1620 x 1400 x 1700 mm 250 kg 10 120 15 rpm 1. 5 kw 2100 x 1600 x 2400 mm 450 kg 18 200 15 rpm 1. 5 kw 2200 x 2000 x 2800 mm 500 kg 35 400 12 rpm 2. 2 kw 3100 x 2300 x 3100 mm 700 kg 53 600 10 rpm 3 kw 3420 x 2600 x 3500 mm 900 kg 70 800 10 rpm 3 kw 3700 x 2800 x 3550 mm 1000 kg 105 1200 9 rpm 4 kw 4200 x 2850 x 3800 mm 1100 kg Weight

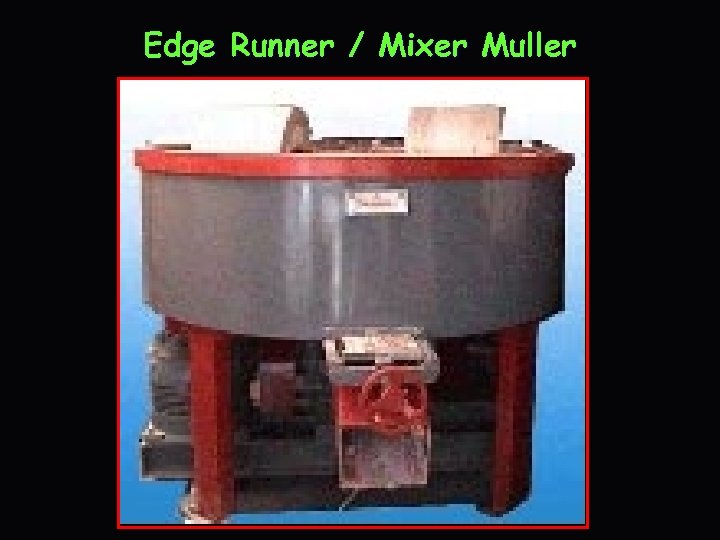

Edge Runner / Mixer Muller

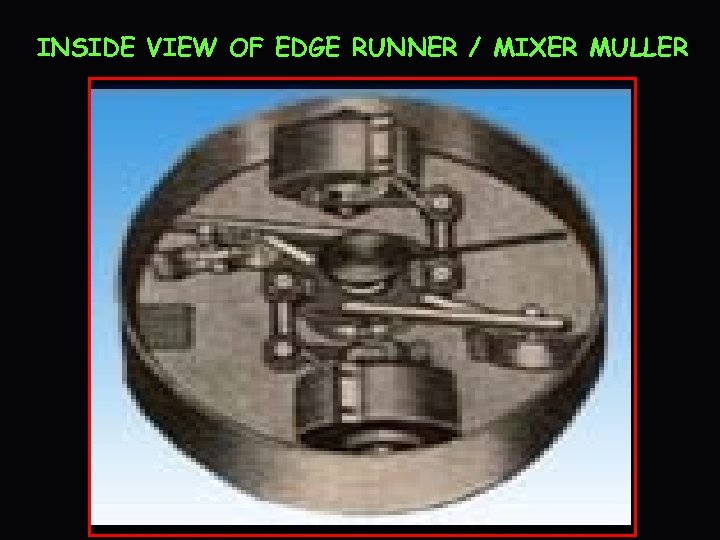

INSIDE VIEW OF EDGE RUNNER / MIXER MULLER

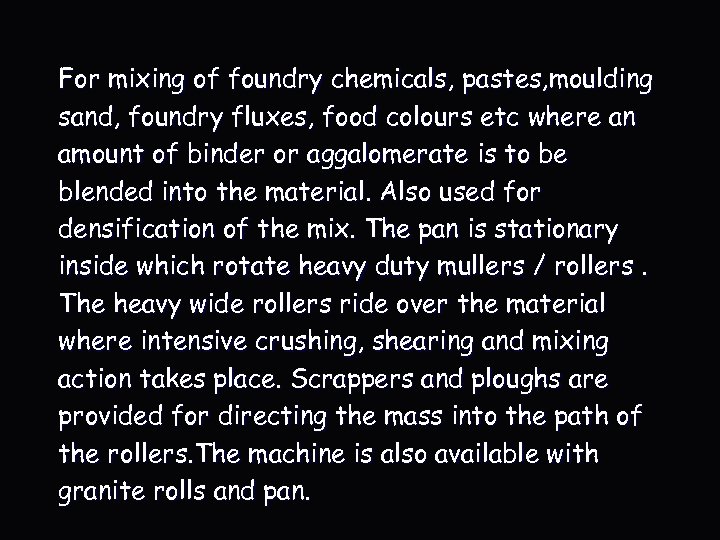

For mixing of foundry chemicals, pastes, moulding sand, foundry fluxes, food colours etc where an amount of binder or aggalomerate is to be blended into the material. Also used for densification of the mix. The pan is stationary inside which rotate heavy duty mullers / rollers. The heavy wide rollers ride over the material where intensive crushing, shearing and mixing action takes place. Scrappers and ploughs are provided for directing the mass into the path of the rollers. The machine is also available with granite rolls and pan.

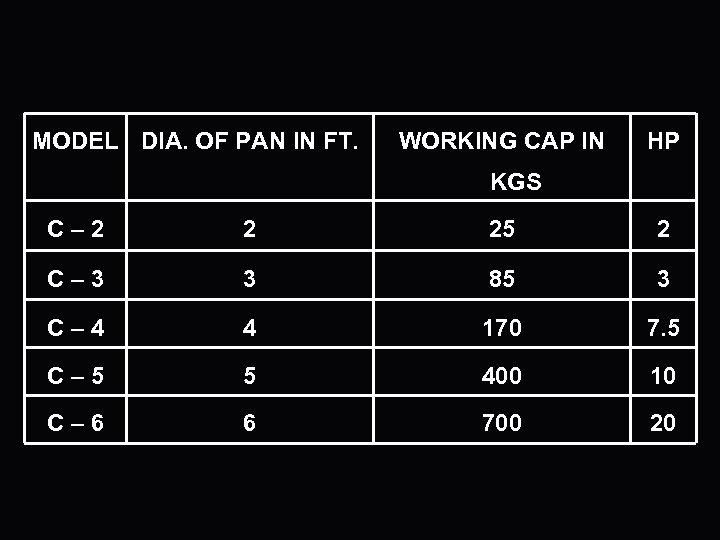

MODEL DIA. OF PAN IN FT. WORKING CAP IN HP KGS C – 2 2 25 2 C – 3 3 85 3 C – 4 4 170 7. 5 C – 5 5 400 10 C – 6 6 700 20

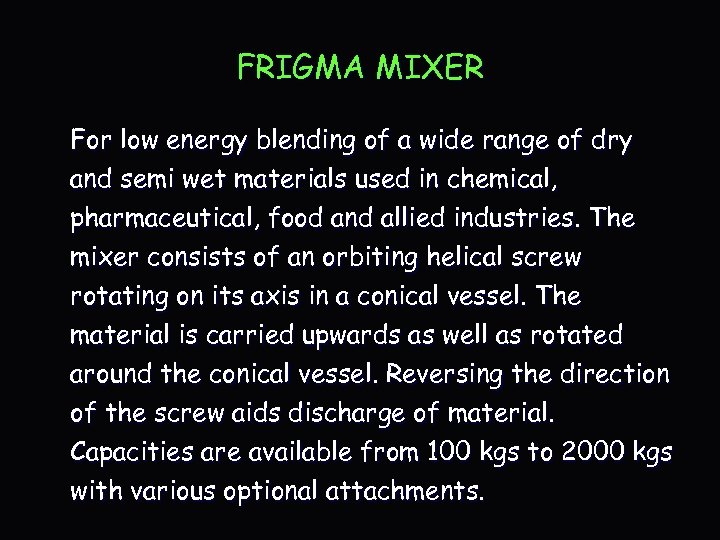

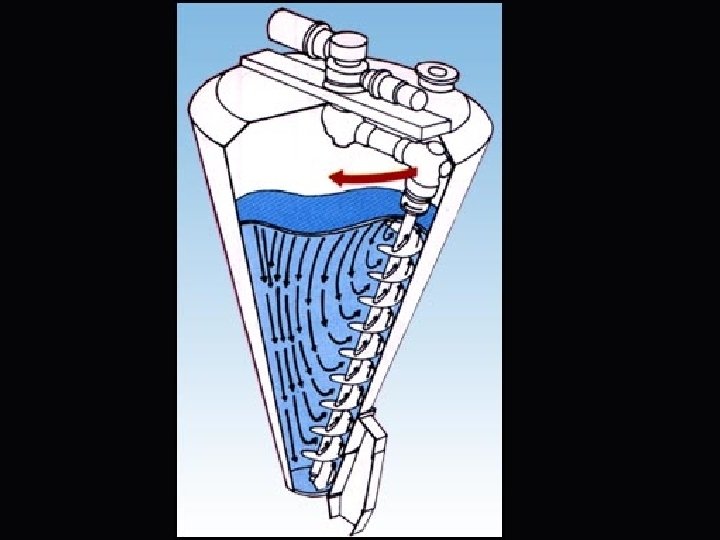

FRIGMA MIXER For low energy blending of a wide range of dry and semi wet materials used in chemical, pharmaceutical, food and allied industries. The mixer consists of an orbiting helical screw rotating on its axis in a conical vessel. The material is carried upwards as well as rotated around the conical vessel. Reversing the direction of the screw aids discharge of material. Capacities are available from 100 kgs to 2000 kgs with various optional attachments.

TERIMA KASIH

e0f70d0144806ccc9e4ccf4505e56a29.ppt