4ad8c43ff7c9a06f5b337ffe9706d504.ppt

- Количество слайдов: 62

Particles and Fields Package Quarterly Status Review (QSR) April 19, 2011 Dave Curtis, PFP PM PFP QSR, 4/19/2011 1

Particles and Fields Package Quarterly Status Review (QSR) April 19, 2011 Dave Curtis, PFP PM PFP QSR, 4/19/2011 1

SSL Contracting Status • Funded through the end of April • More info in the Business Splinter presentation PFP QSR, 4/19/2011 2

SSL Contracting Status • Funded through the end of April • More info in the Business Splinter presentation PFP QSR, 4/19/2011 2

Schedule Status • EMs have made a lot of progress this month – – All EM PWBs in test but ~2 (HVPS boards, in fab) SEP, LPW, SWEA, MAG EM mechanical assembly complete STATIC EM TDC complete random vibe SWIA/STATIC analyzers parts out to fab – – – LPW, SEP, SWEA test with PFDPU complete EM ‘Early Payload Test’ with LM complete MAG next week Pushing to complete before CDR EM Instrument calibrations don’t complete till after Package I&T • EM Package I&T in progress • STATIC is on critical path – 13. 6 weeks margin to delivery – Driven be delays in EM I&T • Status at instrument CDR – – SWIA, STATIC EM will not be complete SWIA, STATIC attenuator life test not done SWIA, STATIC power converters may still be in test Rest of instrument EM will be complete, with perhaps some system level test still in progress PFP QSR, 4/19/2011 3

Schedule Status • EMs have made a lot of progress this month – – All EM PWBs in test but ~2 (HVPS boards, in fab) SEP, LPW, SWEA, MAG EM mechanical assembly complete STATIC EM TDC complete random vibe SWIA/STATIC analyzers parts out to fab – – – LPW, SEP, SWEA test with PFDPU complete EM ‘Early Payload Test’ with LM complete MAG next week Pushing to complete before CDR EM Instrument calibrations don’t complete till after Package I&T • EM Package I&T in progress • STATIC is on critical path – 13. 6 weeks margin to delivery – Driven be delays in EM I&T • Status at instrument CDR – – SWIA, STATIC EM will not be complete SWIA, STATIC attenuator life test not done SWIA, STATIC power converters may still be in test Rest of instrument EM will be complete, with perhaps some system level test still in progress PFP QSR, 4/19/2011 3

Manpower • RBSP-EFW instrument still not delivered – this month? – A number of problems encountered in thermal vacuum – Resolving those problems have impacted MAVEN power converter team, delayed STATIC & SWIA • We are still under planned FTE rate – but climbing a bit – Mostly due to people splitting time between projects • Note that 100% activity is often more than 40 hours/week in these cases – Plan was based on conservative assumptions about covering people PFP QSR, 4/19/2011 4

Manpower • RBSP-EFW instrument still not delivered – this month? – A number of problems encountered in thermal vacuum – Resolving those problems have impacted MAVEN power converter team, delayed STATIC & SWIA • We are still under planned FTE rate – but climbing a bit – Mostly due to people splitting time between projects • Note that 100% activity is often more than 40 hours/week in these cases – Plan was based on conservative assumptions about covering people PFP QSR, 4/19/2011 4

Accomplishments • • • LPW, SEP, SWEA EM integrated with PFDPU EM Early Payload test with Spacecraft EM SWEA Peer Review Completed STATIC Random Vibration Completed SEP Attenuator Life Test Completed • More in instrument sections… PFP QSR, 4/19/2011 5

Accomplishments • • • LPW, SEP, SWEA EM integrated with PFDPU EM Early Payload test with Spacecraft EM SWEA Peer Review Completed STATIC Random Vibration Completed SEP Attenuator Life Test Completed • More in instrument sections… PFP QSR, 4/19/2011 5

Ongoing Work • Supporting Project planning process • Supporting EMC, Payload, SDT working groups • Completing EM board testing • Completing SWIA/STATIC EM mechanical part fabrication • Complete PF Package EM I&T • Prepare for CDR PFP QSR, 4/19/2011 6

Ongoing Work • Supporting Project planning process • Supporting EMC, Payload, SDT working groups • Completing EM board testing • Completing SWIA/STATIC EM mechanical part fabrication • Complete PF Package EM I&T • Prepare for CDR PFP QSR, 4/19/2011 6

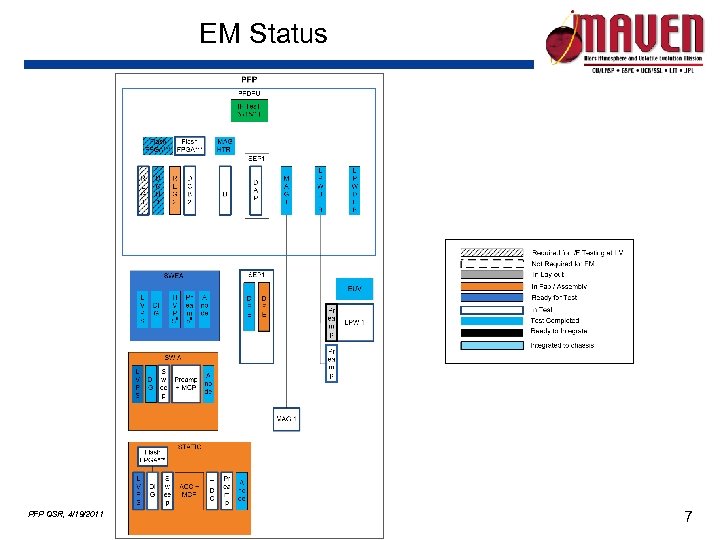

EM Status PFP QSR, 4/19/2011 7

EM Status PFP QSR, 4/19/2011 7

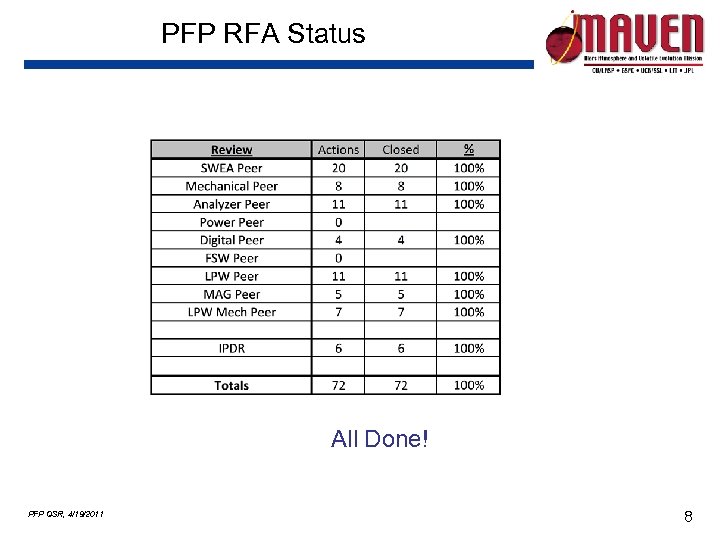

PFP RFA Status All Done! PFP QSR, 4/19/2011 8

PFP RFA Status All Done! PFP QSR, 4/19/2011 8

Trades, Issues • HV 801 issue still open – Current plan is to buy HV 801 s from LADEE NMS, who has parts on order they no longer need. – We still don’t have the parts in hand • Working on an analysis to decide if the PFDPU mechanical design needs to be augmented to support the PWBs to avoid excessive displacements in vibe – Analysis complete, passed on to GSFC expert for review. • LPW Stacer Plating issue (NEW) – After plating stacer with black Nickel it no longer stows properly – Need plating for thermal reasons (aeroheating, thruster heating) – Historically we have used a paint (DAG 213), but that will not survive atomic oxygen at Mars – Working with GSFC Materials on possible solutions PFP QSR, 4/19/2011 9

Trades, Issues • HV 801 issue still open – Current plan is to buy HV 801 s from LADEE NMS, who has parts on order they no longer need. – We still don’t have the parts in hand • Working on an analysis to decide if the PFDPU mechanical design needs to be augmented to support the PWBs to avoid excessive displacements in vibe – Analysis complete, passed on to GSFC expert for review. • LPW Stacer Plating issue (NEW) – After plating stacer with black Nickel it no longer stows properly – Need plating for thermal reasons (aeroheating, thruster heating) – Historically we have used a paint (DAG 213), but that will not survive atomic oxygen at Mars – Working with GSFC Materials on possible solutions PFP QSR, 4/19/2011 9

Thermal Status • Received ‘Thermal Memos’ as well as spacecraft thermal model • Some of the instruments are in trouble according to thermal memo – For example, STATIC goes to -100 C • We are working on identifying if the issue is the model or the design – Our preliminary results are more benign PFP QSR, 4/19/2011 10

Thermal Status • Received ‘Thermal Memos’ as well as spacecraft thermal model • Some of the instruments are in trouble according to thermal memo – For example, STATIC goes to -100 C • We are working on identifying if the issue is the model or the design – Our preliminary results are more benign PFP QSR, 4/19/2011 10

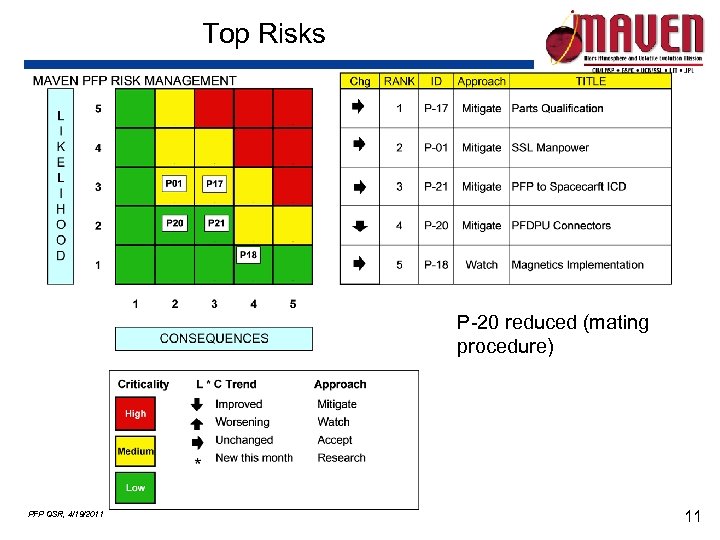

Top Risks P-20 reduced (mating procedure) PFP QSR, 4/19/2011 11

Top Risks P-20 reduced (mating procedure) PFP QSR, 4/19/2011 11

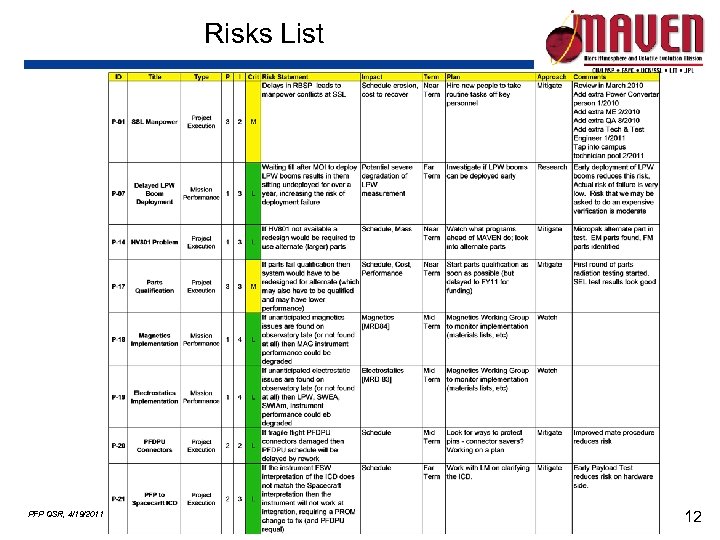

Risks List PFP QSR, 4/19/2011 12

Risks List PFP QSR, 4/19/2011 12

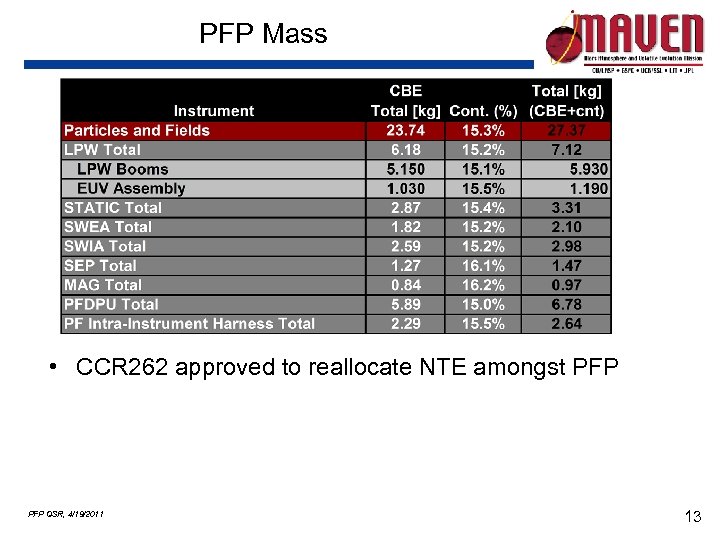

PFP Mass • CCR 262 approved to reallocate NTE amongst PFP QSR, 4/19/2011 13

PFP Mass • CCR 262 approved to reallocate NTE amongst PFP QSR, 4/19/2011 13

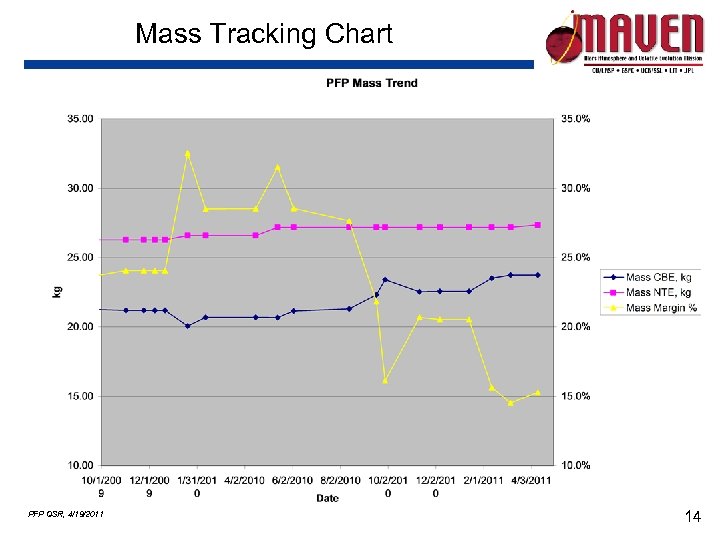

Mass Tracking Chart PFP QSR, 4/19/2011 14

Mass Tracking Chart PFP QSR, 4/19/2011 14

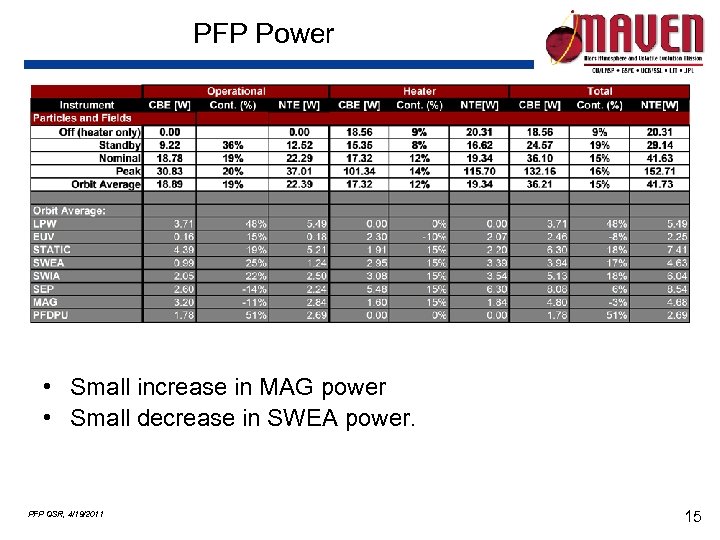

PFP Power • Small increase in MAG power • Small decrease in SWEA power. PFP QSR, 4/19/2011 15

PFP Power • Small increase in MAG power • Small decrease in SWEA power. PFP QSR, 4/19/2011 15

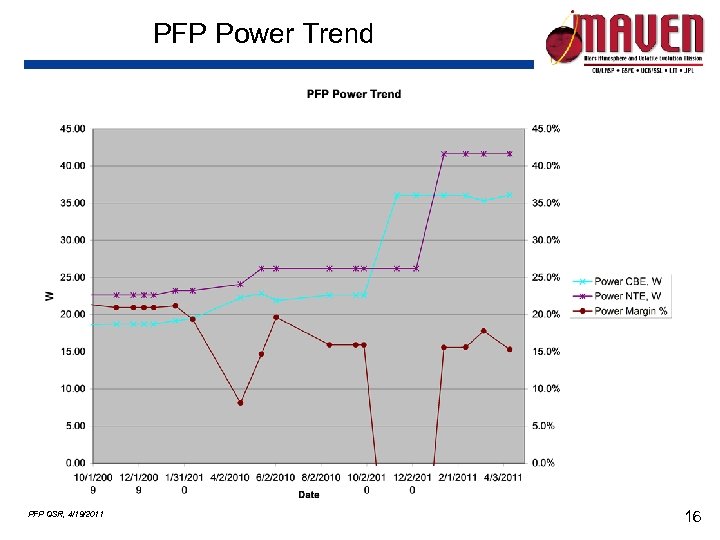

PFP Power Trend PFP QSR, 4/19/2011 16

PFP Power Trend PFP QSR, 4/19/2011 16

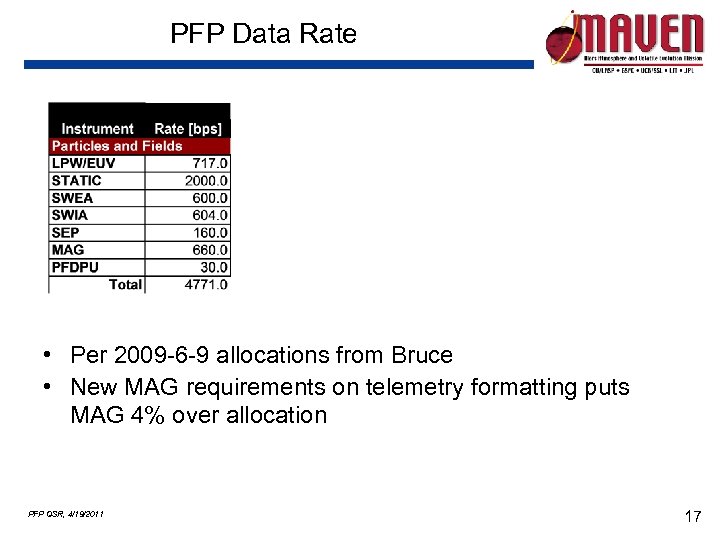

PFP Data Rate • Per 2009 -6 -9 allocations from Bruce • New MAG requirements on telemetry formatting puts MAG 4% over allocation PFP QSR, 4/19/2011 17

PFP Data Rate • Per 2009 -6 -9 allocations from Bruce • New MAG requirements on telemetry formatting puts MAG 4% over allocation PFP QSR, 4/19/2011 17

Requirements Verification Status • CCR (265) to update PFP Functional Requirements (Level 3) approved – some old requirements need updating • Verification matrix mostly complete – Have Functional, ERD, ICD requirements complete, in review • Boot software verification has started – against software level 5 requirements, which link back to FRD and ICD. • STATIC TOF EM Acoustics and Vibration test complete – All but coarsest grid with thinnest foils passed – Will not use coarsest grids – Will repeat on full EM and FM • EM Interface tests started – Reduces risk, not a qualification test • SEP Attenuator Mechanism Life Test complete PFP QSR, 4/19/2011 18

Requirements Verification Status • CCR (265) to update PFP Functional Requirements (Level 3) approved – some old requirements need updating • Verification matrix mostly complete – Have Functional, ERD, ICD requirements complete, in review • Boot software verification has started – against software level 5 requirements, which link back to FRD and ICD. • STATIC TOF EM Acoustics and Vibration test complete – All but coarsest grid with thinnest foils passed – Will not use coarsest grids – Will repeat on full EM and FM • EM Interface tests started – Reduces risk, not a qualification test • SEP Attenuator Mechanism Life Test complete PFP QSR, 4/19/2011 18

Life Testing • SEP Attenuator life test complete – 4100 cycles on EM twice expected life – ~1000 in air, ~3000 in vacuum – Will collect some more cycles over the next few months • SWIA, STATIC attenuator life test pending completion of EM attenuator – ~June • SWEA door mechanism identical to STEREO • SWEA, STATIC door mechanism functional, life test pending • LPW relay life test expected to start soon • LPW deployment life test expected to start soon – Stacer coating problem holding that up PFP QSR, 4/19/2011 19

Life Testing • SEP Attenuator life test complete – 4100 cycles on EM twice expected life – ~1000 in air, ~3000 in vacuum – Will collect some more cycles over the next few months • SWIA, STATIC attenuator life test pending completion of EM attenuator – ~June • SWEA door mechanism identical to STEREO • SWEA, STATIC door mechanism functional, life test pending • LPW relay life test expected to start soon • LPW deployment life test expected to start soon – Stacer coating problem holding that up PFP QSR, 4/19/2011 19

MAVEN Magnetometer Status April 2011 Connerney, Sheppard, Schnurr, Oliversen, Espley, etc. PFP QSR, 4/19/2011 20

MAVEN Magnetometer Status April 2011 Connerney, Sheppard, Schnurr, Oliversen, Espley, etc. PFP QSR, 4/19/2011 20

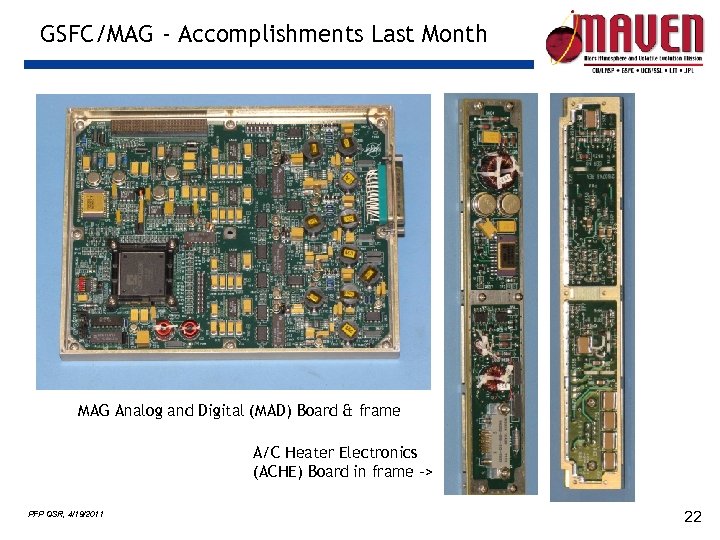

GSFC/MAG - Accomplishments Last Month • • • EM sensor assembly, pigtail, GSE sensor harness completed. Breakout PWBs fabrication completed. Draft MAG Flight Software Requirements Specification (for PFDPU). Completed Safe-to-Mate procedures for MAD board (MAVEN-MAGPROC-0026). Completed EM Magnetometer board scale factors calibration at GSFC 22’ MAG Test Site; scale factor resistors installed on board. FPGA (rev 0) burned at Aeroflex, received and installed on MAD board. Functional testing in progress. GSE (UCB emulator) development continues; CMD and TLM successfully flowing between GSE and MAD board. Sensor non-magnetic heaters design received from vendor (Tayco), under review. Frames for MAD board and ACHE board fabricated at GSFC; boards installed in frames (see pix). PFP QSR, 4/19/2011 21

GSFC/MAG - Accomplishments Last Month • • • EM sensor assembly, pigtail, GSE sensor harness completed. Breakout PWBs fabrication completed. Draft MAG Flight Software Requirements Specification (for PFDPU). Completed Safe-to-Mate procedures for MAD board (MAVEN-MAGPROC-0026). Completed EM Magnetometer board scale factors calibration at GSFC 22’ MAG Test Site; scale factor resistors installed on board. FPGA (rev 0) burned at Aeroflex, received and installed on MAD board. Functional testing in progress. GSE (UCB emulator) development continues; CMD and TLM successfully flowing between GSE and MAD board. Sensor non-magnetic heaters design received from vendor (Tayco), under review. Frames for MAD board and ACHE board fabricated at GSFC; boards installed in frames (see pix). PFP QSR, 4/19/2011 21

GSFC/MAG - Accomplishments Last Month MAG Analog and Digital (MAD) Board & frame A/C Heater Electronics (ACHE) Board in frame -> PFP QSR, 4/19/2011 22

GSFC/MAG - Accomplishments Last Month MAG Analog and Digital (MAD) Board & frame A/C Heater Electronics (ACHE) Board in frame -> PFP QSR, 4/19/2011 22

GSFC/MAG Near Term Plans & Open Issues • Mature MAG software requirements draft w/UCB. • Hypertronics KPC 120 connectors installation and mating issues. • Radiation test plan for MIL spec CD 4066 quad bilateral switches completed; testing scheduled to begin April 18, 2011. • Integration and test of MAG (MAD board and sensor) w/ PFDPU at UCB scheduled April 26 -28, 2011. • MAD board frame modifications (test connector placement, mechanical mod for center board support) pending final approval. • Continue winding FM sensor ring cores, feedback/sense bobbins, and magnetic piece parts per technician availability; fabricate sensor assembly terminal boards. • Draft worst case analysis of MAD board. • MAG Peer Review scheduled for May 5, 2011 @ GSFC. • Workload: RBSP FM post-environmental test evaluation drags on; Juno FM system integration work in progress @ Astrotech, KSC. PFP QSR, 4/19/2011 23

GSFC/MAG Near Term Plans & Open Issues • Mature MAG software requirements draft w/UCB. • Hypertronics KPC 120 connectors installation and mating issues. • Radiation test plan for MIL spec CD 4066 quad bilateral switches completed; testing scheduled to begin April 18, 2011. • Integration and test of MAG (MAD board and sensor) w/ PFDPU at UCB scheduled April 26 -28, 2011. • MAD board frame modifications (test connector placement, mechanical mod for center board support) pending final approval. • Continue winding FM sensor ring cores, feedback/sense bobbins, and magnetic piece parts per technician availability; fabricate sensor assembly terminal boards. • Draft worst case analysis of MAD board. • MAG Peer Review scheduled for May 5, 2011 @ GSFC. • Workload: RBSP FM post-environmental test evaluation drags on; Juno FM system integration work in progress @ Astrotech, KSC. PFP QSR, 4/19/2011 23

MAVEN PFP SWIA Status April 2011 Jasper Halekas, SWIA Lead PFP QSR, 4/19/2011 24

MAVEN PFP SWIA Status April 2011 Jasper Halekas, SWIA Lead PFP QSR, 4/19/2011 24

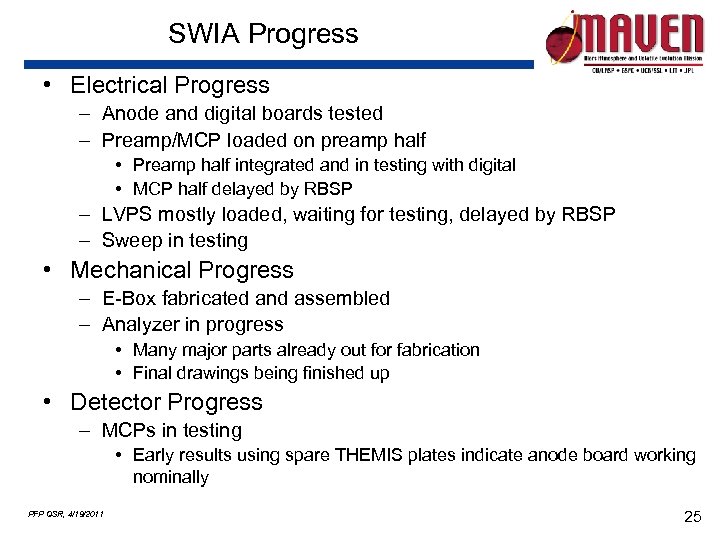

SWIA Progress • Electrical Progress – Anode and digital boards tested – Preamp/MCP loaded on preamp half • Preamp half integrated and in testing with digital • MCP half delayed by RBSP – LVPS mostly loaded, waiting for testing, delayed by RBSP – Sweep in testing • Mechanical Progress – E-Box fabricated and assembled – Analyzer in progress • Many major parts already out for fabrication • Final drawings being finished up • Detector Progress – MCPs in testing • Early results using spare THEMIS plates indicate anode board working nominally PFP QSR, 4/19/2011 25

SWIA Progress • Electrical Progress – Anode and digital boards tested – Preamp/MCP loaded on preamp half • Preamp half integrated and in testing with digital • MCP half delayed by RBSP – LVPS mostly loaded, waiting for testing, delayed by RBSP – Sweep in testing • Mechanical Progress – E-Box fabricated and assembled – Analyzer in progress • Many major parts already out for fabrication • Final drawings being finished up • Detector Progress – MCPs in testing • Early results using spare THEMIS plates indicate anode board working nominally PFP QSR, 4/19/2011 25

SWIA EM Electronics & Chassis PFP QSR, 4/19/2011 26

SWIA EM Electronics & Chassis PFP QSR, 4/19/2011 26

SWIA Issues • Staffing/Schedule – More RBSP delays hurting mechanical and power supplies – Mechanical parts may not all be done in time for peer reviews – Power supplies waiting for loading and testing PFP QSR, 4/19/2011 27

SWIA Issues • Staffing/Schedule – More RBSP delays hurting mechanical and power supplies – Mechanical parts may not all be done in time for peer reviews – Power supplies waiting for loading and testing PFP QSR, 4/19/2011 27

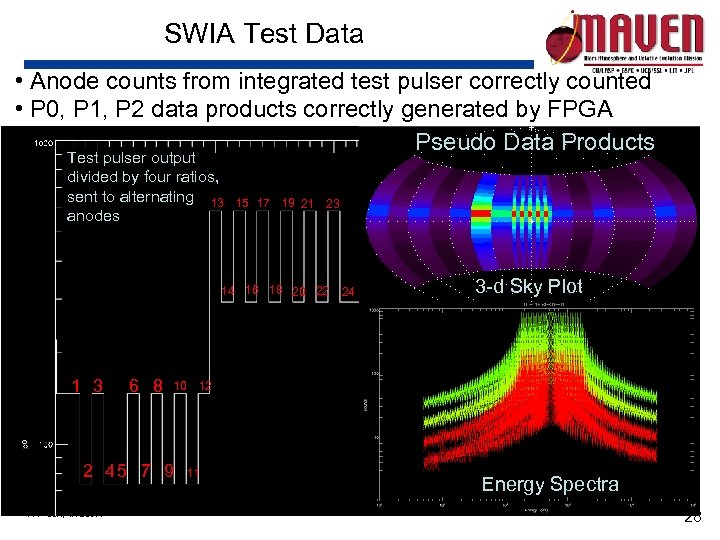

SWIA Test Data • Anode counts from integrated test pulser correctly counted • P 0, P 1, P 2 data products correctly generated by FPGA Pseudo Data Products Test pulser output divided by four ratios, sent to alternating 13 anodes 15 17 19 21 23 14 16 18 20 22 1 3 6 8 2 45 7 9 PFP QSR, 4/19/2011 24 3 -d Sky Plot 10 12 11 Energy Spectra 28

SWIA Test Data • Anode counts from integrated test pulser correctly counted • P 0, P 1, P 2 data products correctly generated by FPGA Pseudo Data Products Test pulser output divided by four ratios, sent to alternating 13 anodes 15 17 19 21 23 14 16 18 20 22 1 3 6 8 2 45 7 9 PFP QSR, 4/19/2011 24 3 -d Sky Plot 10 12 11 Energy Spectra 28

MAVEN PFP SWEA Status April 2011 Dave Mitchell, SWEA Lead PFP QSR, 4/19/2011 29

MAVEN PFP SWEA Status April 2011 Dave Mitchell, SWEA Lead PFP QSR, 4/19/2011 29

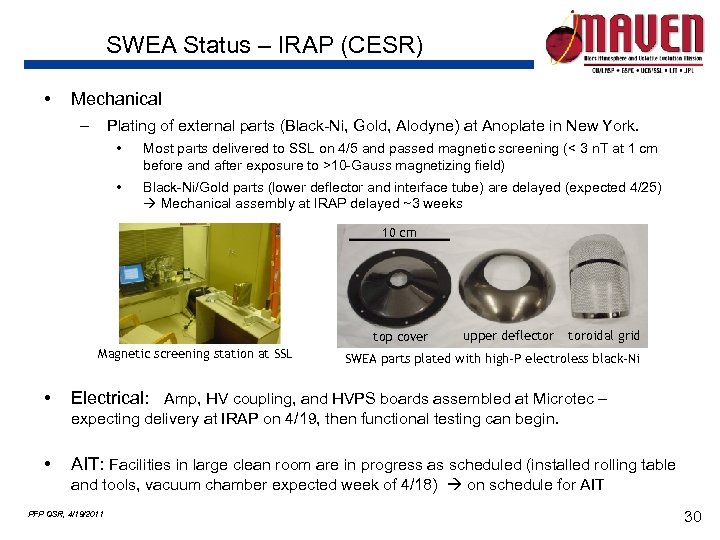

SWEA Status – IRAP (CESR) • Mechanical – Plating of external parts (Black-Ni, Gold, Alodyne) at Anoplate in New York. • Most parts delivered to SSL on 4/5 and passed magnetic screening (< 3 n. T at 1 cm before and after exposure to >10 -Gauss magnetizing field) • Black-Ni/Gold parts (lower deflector and interface tube) are delayed (expected 4/25) Mechanical assembly at IRAP delayed ~3 weeks 10 cm top cover Magnetic screening station at SSL • upper deflector toroidal grid SWEA parts plated with high-P electroless black-Ni Electrical: Amp, HV coupling, and HVPS boards assembled at Microtec – expecting delivery at IRAP on 4/19, then functional testing can begin. • AIT: Facilities in large clean room are in progress as scheduled (installed rolling table and tools, vacuum chamber expected week of 4/18) on schedule for AIT PFP QSR, 4/19/2011 30

SWEA Status – IRAP (CESR) • Mechanical – Plating of external parts (Black-Ni, Gold, Alodyne) at Anoplate in New York. • Most parts delivered to SSL on 4/5 and passed magnetic screening (< 3 n. T at 1 cm before and after exposure to >10 -Gauss magnetizing field) • Black-Ni/Gold parts (lower deflector and interface tube) are delayed (expected 4/25) Mechanical assembly at IRAP delayed ~3 weeks 10 cm top cover Magnetic screening station at SSL • upper deflector toroidal grid SWEA parts plated with high-P electroless black-Ni Electrical: Amp, HV coupling, and HVPS boards assembled at Microtec – expecting delivery at IRAP on 4/19, then functional testing can begin. • AIT: Facilities in large clean room are in progress as scheduled (installed rolling table and tools, vacuum chamber expected week of 4/18) on schedule for AIT PFP QSR, 4/19/2011 30

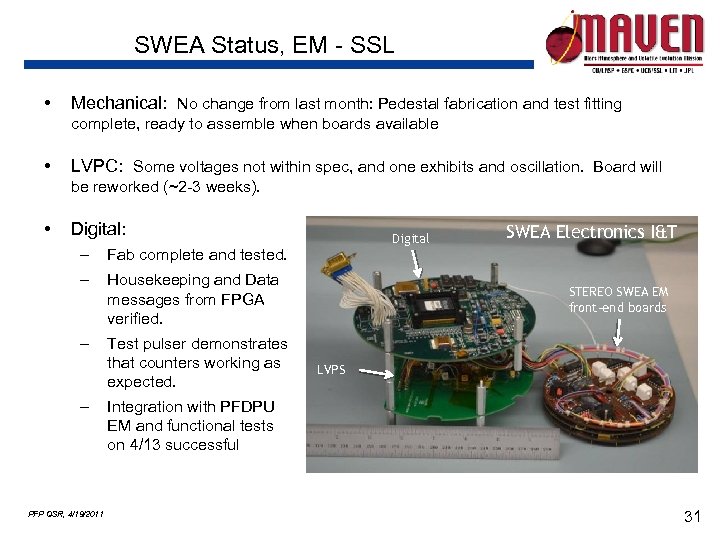

SWEA Status, EM - SSL • Mechanical: No change from last month: Pedestal fabrication and test fitting complete, ready to assemble when boards available • LVPC: Some voltages not within spec, and one exhibits and oscillation. Board will be reworked (~2 -3 weeks). • Digital: – Housekeeping and Data messages from FPGA verified. – Test pulser demonstrates that counters working as expected. SWEA Electronics I&T Fab complete and tested. – Digital – PFP QSR, 4/19/2011 STEREO SWEA EM front-end boards LVPS Integration with PFDPU EM and functional tests on 4/13 successful 31

SWEA Status, EM - SSL • Mechanical: No change from last month: Pedestal fabrication and test fitting complete, ready to assemble when boards available • LVPC: Some voltages not within spec, and one exhibits and oscillation. Board will be reworked (~2 -3 weeks). • Digital: – Housekeeping and Data messages from FPGA verified. – Test pulser demonstrates that counters working as expected. SWEA Electronics I&T Fab complete and tested. – Digital – PFP QSR, 4/19/2011 STEREO SWEA EM front-end boards LVPS Integration with PFDPU EM and functional tests on 4/13 successful 31

MAVEN PFP STATIC Status April 2011 Jim Mc. Fadden, STATIC Lead PFP QSR, 4/19/2011 32

MAVEN PFP STATIC Status April 2011 Jim Mc. Fadden, STATIC Lead PFP QSR, 4/19/2011 32

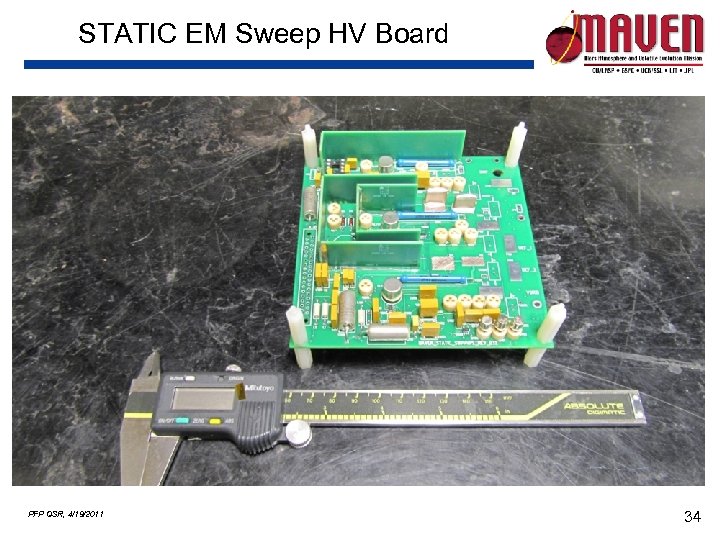

STATIC Accomplishments • Carbon foils mounted in TOF units survive vibration test – automated software used to evaluate foil breakage • Ordered carbon foils on mica slides to improve mounting yield • The design of START foil grid-frames was modified to compensate for poor clamping due to fabrication tolerances - new grid-frames ordered. • Design of attenuator motor completed, drawings for ETU in process • Energy analyzer/deflector parts drafted and ordered • EM TDC board bench testing complete, part modifications made • EM preamp 1 modified and working adequately for integration w/ TDC board – will be used while optimized preamp board is developed • EM Anode, Preamp and TDC boards integrated – working • EM Digital board passed power and PFDPU simulator interface testing, ready for interface test with TDC • EM Sweep HV board partly loaded and in test (see pictures) • Clean room equipment installed – racks, SS table, GN 2 purge, etc. • Helmholtz coil template fabricated, waiting on welding before assembly PFP QSR, 4/19/2011 33

STATIC Accomplishments • Carbon foils mounted in TOF units survive vibration test – automated software used to evaluate foil breakage • Ordered carbon foils on mica slides to improve mounting yield • The design of START foil grid-frames was modified to compensate for poor clamping due to fabrication tolerances - new grid-frames ordered. • Design of attenuator motor completed, drawings for ETU in process • Energy analyzer/deflector parts drafted and ordered • EM TDC board bench testing complete, part modifications made • EM preamp 1 modified and working adequately for integration w/ TDC board – will be used while optimized preamp board is developed • EM Anode, Preamp and TDC boards integrated – working • EM Digital board passed power and PFDPU simulator interface testing, ready for interface test with TDC • EM Sweep HV board partly loaded and in test (see pictures) • Clean room equipment installed – racks, SS table, GN 2 purge, etc. • Helmholtz coil template fabricated, waiting on welding before assembly PFP QSR, 4/19/2011 33

STATIC EM Sweep HV Board PFP QSR, 4/19/2011 34

STATIC EM Sweep HV Board PFP QSR, 4/19/2011 34

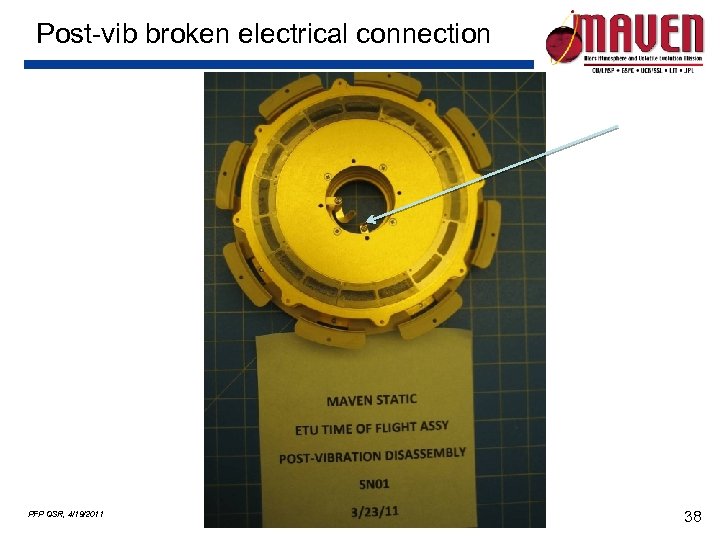

STATIC Open Issues • One of two TOF electrical connections broke in 1 of the 3 units during vibration test (see pics) – connection redesigned for stress relief • Mounting fixtures for handling flight carbon foil frames need to be fabricated before additional EM carbon foils are loaded • New START foil grid-frames will require inspections after fabrication • Preamp design changes nearly complete for optimal dynamic range – may require new layout • EM 15 k. V-MCP board changed, MCP “stack stick” multiplier abandoned in favor of a pair of VMI multipliers and a tapped transformer – EM waiting on part placement changes (Berg). • Digital board FPGA still in development • EM LVPS loaded – waiting to be tested • Manipulator fixtures for calibration chamber testing in development • Some test harnesses and test cables still on order • New calibration chamber ordered – delivery late May • SS sink for clean room assembled – waiting for drain assembly PFP QSR, 4/19/2011 35

STATIC Open Issues • One of two TOF electrical connections broke in 1 of the 3 units during vibration test (see pics) – connection redesigned for stress relief • Mounting fixtures for handling flight carbon foil frames need to be fabricated before additional EM carbon foils are loaded • New START foil grid-frames will require inspections after fabrication • Preamp design changes nearly complete for optimal dynamic range – may require new layout • EM 15 k. V-MCP board changed, MCP “stack stick” multiplier abandoned in favor of a pair of VMI multipliers and a tapped transformer – EM waiting on part placement changes (Berg). • Digital board FPGA still in development • EM LVPS loaded – waiting to be tested • Manipulator fixtures for calibration chamber testing in development • Some test harnesses and test cables still on order • New calibration chamber ordered – delivery late May • SS sink for clean room assembled – waiting for drain assembly PFP QSR, 4/19/2011 35

STATIC EM TOF Post Vib Disassembly PFP QSR, 4/19/2011 36

STATIC EM TOF Post Vib Disassembly PFP QSR, 4/19/2011 36

Post-vib broken electrical connection PFP QSR, 4/19/2011 37

Post-vib broken electrical connection PFP QSR, 4/19/2011 37

Post-vib broken electrical connection PFP QSR, 4/19/2011 38

Post-vib broken electrical connection PFP QSR, 4/19/2011 38

MAVEN PFP SEP Status April, 2011 Davin Larson, SEP Lead PFP QSR, 4/19/2011 39

MAVEN PFP SEP Status April, 2011 Davin Larson, SEP Lead PFP QSR, 4/19/2011 39

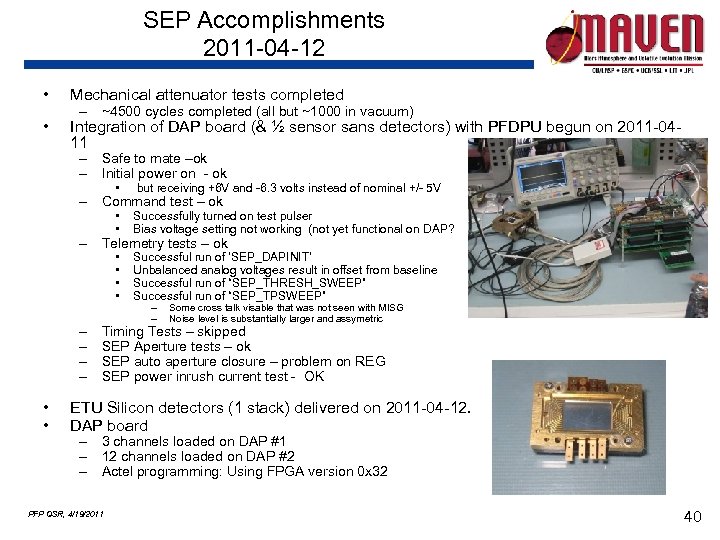

SEP Accomplishments 2011 -04 -12 • Mechanical attenuator tests completed • Integration of DAP board (& ½ sensor sans detectors) with PFDPU begun on 2011 -0411 – ~4500 cycles completed (all but ~1000 in vacuum) – Safe to mate –ok – Initial power on - ok • but receiving +6 V and -6. 3 volts instead of nominal +/- 5 V • • Successfully turned on test pulser Bias voltage setting not working (not yet functional on DAP? • • Successful run of ‘SEP_DAPINIT’ Unbalanced analog voltages result in offset from baseline Successful run of “SEP_THRESH_SWEEP” Successful run of “SEP_TPSWEEP” – Command test – ok – Telemetry tests – ok – – • • – – Some cross talk visable that was not seen with MISG Noise level is substantially larger and assymetric Timing Tests – skipped SEP Aperture tests – ok SEP auto aperture closure – problem on REG SEP power inrush current test - OK ETU Silicon detectors (1 stack) delivered on 2011 -04 -12. DAP board – 3 channels loaded on DAP #1 – 12 channels loaded on DAP #2 – Actel programming: Using FPGA version 0 x 32 PFP QSR, 4/19/2011 40

SEP Accomplishments 2011 -04 -12 • Mechanical attenuator tests completed • Integration of DAP board (& ½ sensor sans detectors) with PFDPU begun on 2011 -0411 – ~4500 cycles completed (all but ~1000 in vacuum) – Safe to mate –ok – Initial power on - ok • but receiving +6 V and -6. 3 volts instead of nominal +/- 5 V • • Successfully turned on test pulser Bias voltage setting not working (not yet functional on DAP? • • Successful run of ‘SEP_DAPINIT’ Unbalanced analog voltages result in offset from baseline Successful run of “SEP_THRESH_SWEEP” Successful run of “SEP_TPSWEEP” – Command test – ok – Telemetry tests – ok – – • • – – Some cross talk visable that was not seen with MISG Noise level is substantially larger and assymetric Timing Tests – skipped SEP Aperture tests – ok SEP auto aperture closure – problem on REG SEP power inrush current test - OK ETU Silicon detectors (1 stack) delivered on 2011 -04 -12. DAP board – 3 channels loaded on DAP #1 – 12 channels loaded on DAP #2 – Actel programming: Using FPGA version 0 x 32 PFP QSR, 4/19/2011 40

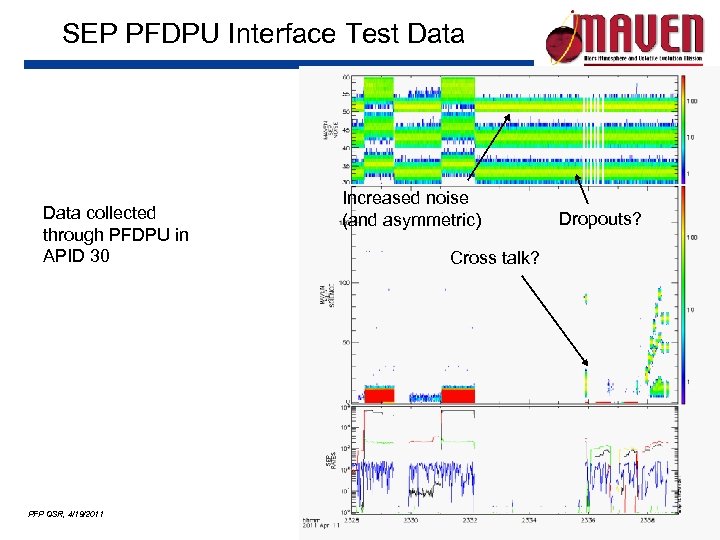

SEP PFDPU Interface Test Data collected through PFDPU in APID 30 PFP QSR, 4/19/2011 Increased noise (and asymmetric) Dropouts? Cross talk? 41

SEP PFDPU Interface Test Data collected through PFDPU in APID 30 PFP QSR, 4/19/2011 Increased noise (and asymmetric) Dropouts? Cross talk? 41

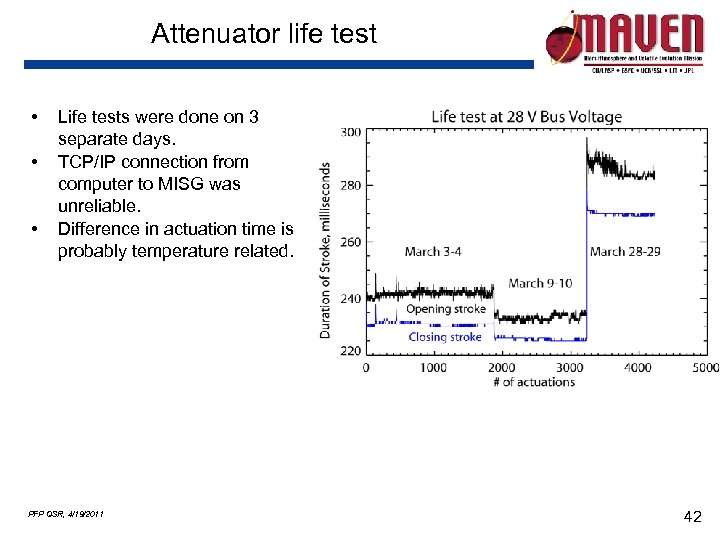

Attenuator life test • • • Life tests were done on 3 separate days. TCP/IP connection from computer to MISG was unreliable. Difference in actuation time is probably temperature related. PFP QSR, 4/19/2011 42

Attenuator life test • • • Life tests were done on 3 separate days. TCP/IP connection from computer to MISG was unreliable. Difference in actuation time is probably temperature related. PFP QSR, 4/19/2011 42

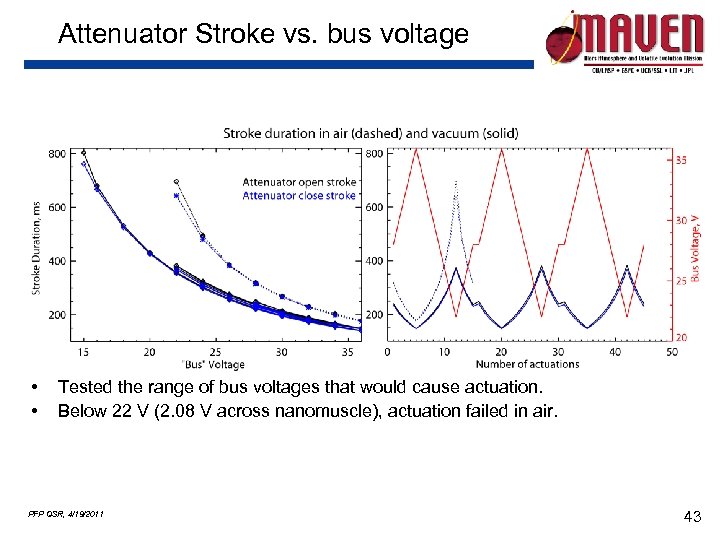

Attenuator Stroke vs. bus voltage • • Tested the range of bus voltages that would cause actuation. Below 22 V (2. 08 V across nanomuscle), actuation failed in air. PFP QSR, 4/19/2011 43

Attenuator Stroke vs. bus voltage • • Tested the range of bus voltages that would cause actuation. Below 22 V (2. 08 V across nanomuscle), actuation failed in air. PFP QSR, 4/19/2011 43

SEP Open issues • What voltage to use for +/- 5 VA supply. • Mods needed for flight DAP board: • Sensor • FPGA Mods from version 0 x 32 • Testing: • PFDPU testing – – – Analog supply NOT currently regulated Need secondary regulation for A 250? Eliminate requirement of 5 V Digital altogether – – – Use faster transisters on pulse generator (fixes 3. 3 volt logic problem) Use 2. 5 V reference instead of 5 VA for baseline trim Use Valid signal for hysteresis on peak detect Gain change on peak detect circuit (perhaps not needed now) Switch from 10 MΩ to 1 MΩ resister on bias voltage control 5 MΩ resistor to -5 VA (-2. 5 R? ) to correct for Op. Amp input current (this mod is questionable if BLRena mode is working properly) – – Add detectors!!!! Insert caps on attenuator lines to clean up some noise – – – Eliminate secondary pulse by applying BLRena for 6 μsec on test pulse return Extend test pulse duration from 10 μsec to 20 μsec 16 bit counters on no peak counters Ability to turn off housekeeping measurement Event mode resolution – – – Purchase new nimbin and test pulser to replace AWOL test pulser Test for correct coincidence determination with FPGA New radiation source – – Cross talk observed in PFDPU but not MISG? Increased Noise observed in PFDPU (probably resolved with shield boards) Telemetry dropouts from PFDPU science packets Possible change in opto coupler wiring of actuator control on DCB to eliminate any possibility of noise • Baseline shift at high count rates – (probably not an issue) • 1 mv shift in baseline shortly after the 1 pps signal PFP QSR, 4/19/2011 • More to come 44

SEP Open issues • What voltage to use for +/- 5 VA supply. • Mods needed for flight DAP board: • Sensor • FPGA Mods from version 0 x 32 • Testing: • PFDPU testing – – – Analog supply NOT currently regulated Need secondary regulation for A 250? Eliminate requirement of 5 V Digital altogether – – – Use faster transisters on pulse generator (fixes 3. 3 volt logic problem) Use 2. 5 V reference instead of 5 VA for baseline trim Use Valid signal for hysteresis on peak detect Gain change on peak detect circuit (perhaps not needed now) Switch from 10 MΩ to 1 MΩ resister on bias voltage control 5 MΩ resistor to -5 VA (-2. 5 R? ) to correct for Op. Amp input current (this mod is questionable if BLRena mode is working properly) – – Add detectors!!!! Insert caps on attenuator lines to clean up some noise – – – Eliminate secondary pulse by applying BLRena for 6 μsec on test pulse return Extend test pulse duration from 10 μsec to 20 μsec 16 bit counters on no peak counters Ability to turn off housekeeping measurement Event mode resolution – – – Purchase new nimbin and test pulser to replace AWOL test pulser Test for correct coincidence determination with FPGA New radiation source – – Cross talk observed in PFDPU but not MISG? Increased Noise observed in PFDPU (probably resolved with shield boards) Telemetry dropouts from PFDPU science packets Possible change in opto coupler wiring of actuator control on DCB to eliminate any possibility of noise • Baseline shift at high count rates – (probably not an issue) • 1 mv shift in baseline shortly after the 1 pps signal PFP QSR, 4/19/2011 • More to come 44

MAVEN PFP DCB, Power Converter & GSE Status April 2011 Dorothy Gordon Timothy Quinn Peter Berg Chris Tiu PFP QSR, 4/19/2011 45

MAVEN PFP DCB, Power Converter & GSE Status April 2011 Dorothy Gordon Timothy Quinn Peter Berg Chris Tiu PFP QSR, 4/19/2011 45

PFDPU/DCB Status PFDPU Overall Integration o DCB/REG o Functional and electrical verification ongoing o Actuator Control, Housekeeping, Instrument Current Monitoring o DCB/REG/IIB o Verified LPW signal routing through IIB and Low Voltage Power Supply o DCB/REG/IIB/LPW (see next page) o Upcoming PFDPU integration tests o Remaining power services and signal routing to be checked on a per instrument basis PFP QSR, 4/19/2011 46

PFDPU/DCB Status PFDPU Overall Integration o DCB/REG o Functional and electrical verification ongoing o Actuator Control, Housekeeping, Instrument Current Monitoring o DCB/REG/IIB o Verified LPW signal routing through IIB and Low Voltage Power Supply o DCB/REG/IIB/LPW (see next page) o Upcoming PFDPU integration tests o Remaining power services and signal routing to be checked on a per instrument basis PFP QSR, 4/19/2011 46

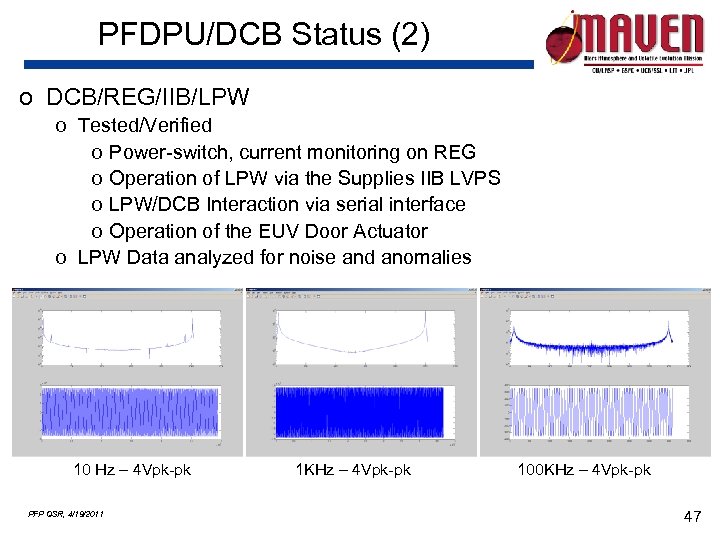

PFDPU/DCB Status (2) o DCB/REG/IIB/LPW o Tested/Verified o Power-switch, current monitoring on REG o Operation of LPW via the Supplies IIB LVPS o LPW/DCB Interaction via serial interface o Operation of the EUV Door Actuator o LPW Data analyzed for noise and anomalies 10 Hz – 4 Vpk-pk PFP QSR, 4/19/2011 1 KHz – 4 Vpk-pk 100 KHz – 4 Vpk-pk 47

PFDPU/DCB Status (2) o DCB/REG/IIB/LPW o Tested/Verified o Power-switch, current monitoring on REG o Operation of LPW via the Supplies IIB LVPS o LPW/DCB Interaction via serial interface o Operation of the EUV Door Actuator o LPW Data analyzed for noise and anomalies 10 Hz – 4 Vpk-pk PFP QSR, 4/19/2011 1 KHz – 4 Vpk-pk 100 KHz – 4 Vpk-pk 47

PFDPU/DCB Status (3) PFDPU – S/C Interface Test o DCB/REG Verification at Lockheed-Martin o Integrated power subsystem o Inrush current characterized o Tested S/C Discrete commands and Side Select o Reset, TIME commands verified o Operated PFDPU with the Lockheed-Martin Spacecraft Emulator o Verified signal protocol of RS 422 command telemetry interfaces o Operation with Flight Software – sent a variety of packets in order to work through the checksum generation algorithm. FSW is working this issue with Lockheed-Martin. PFP QSR, 4/19/2011 48

PFDPU/DCB Status (3) PFDPU – S/C Interface Test o DCB/REG Verification at Lockheed-Martin o Integrated power subsystem o Inrush current characterized o Tested S/C Discrete commands and Side Select o Reset, TIME commands verified o Operated PFDPU with the Lockheed-Martin Spacecraft Emulator o Verified signal protocol of RS 422 command telemetry interfaces o Operation with Flight Software – sent a variety of packets in order to work through the checksum generation algorithm. FSW is working this issue with Lockheed-Martin. PFP QSR, 4/19/2011 48

DCB Status DCB ETU Build o o o DCB ETU #2 Build complete Delivered (along with FLASH FPGA daughter board) Short on main DCB power supply (3. 3 V) o Problem needs to be identified and fixed DCB FPGA o o Changes added to support the S/C interface modifications Functional design is complete; undergoing life-test with flight software and PFDPU Integration PFP QSR, 4/19/2011 49

DCB Status DCB ETU Build o o o DCB ETU #2 Build complete Delivered (along with FLASH FPGA daughter board) Short on main DCB power supply (3. 3 V) o Problem needs to be identified and fixed DCB FPGA o o Changes added to support the S/C interface modifications Functional design is complete; undergoing life-test with flight software and PFDPU Integration PFP QSR, 4/19/2011 49

GSE Hardware Status MISG Instrument Simulator o First cut operational instrument simulator delivered o o o uses the MISG-FPGA Block RAM Implements the final Instrument Mode functionality o covers all 8 Instrument Interfaces o with a subset of the final pattern generator buffer space Next Steps o o PFP QSR, 4/19/2011 Use MISG based SDRAM for Instrument Pattern storage (allowing for increased buffer space) Incorporate new modules into next MISG-FPGA release 50

GSE Hardware Status MISG Instrument Simulator o First cut operational instrument simulator delivered o o o uses the MISG-FPGA Block RAM Implements the final Instrument Mode functionality o covers all 8 Instrument Interfaces o with a subset of the final pattern generator buffer space Next Steps o o PFP QSR, 4/19/2011 Use MISG based SDRAM for Instrument Pattern storage (allowing for increased buffer space) Incorporate new modules into next MISG-FPGA release 50

GSE Software Status • SSG – Software updated to handle special case where calculated checksum equals zero. When this occurs checksum is set to 0 x. FFFF • GSEOS – Python modules added to perform checksum processing and verification on PFDPU telemetry – Python module added to support PFDPU Memory Loads – Delivered first rev of STATIC configuration – Created Python module for playing back raw data over TCP link with GSEOS – Supported LPW EM integration testing PFP QSR, 4/19/2011 51

GSE Software Status • SSG – Software updated to handle special case where calculated checksum equals zero. When this occurs checksum is set to 0 x. FFFF • GSEOS – Python modules added to perform checksum processing and verification on PFDPU telemetry – Python module added to support PFDPU Memory Loads – Delivered first rev of STATIC configuration – Created Python module for playing back raw data over TCP link with GSEOS – Supported LPW EM integration testing PFP QSR, 4/19/2011 51

Power Converter Status (1) • REG Board • We are working on a second PCB layout for the REG board ETU#2 due to a connector mis-wiring issue on the first layout. This re-layout process has begun. • The REG board tester was built and is now in operation • All REG based switchable services have been tested • Still pending: adjustment/tuning of the current monitoring subsystem; complete verification of the digital portion of the circuit • REG Board system checkout via PFDPU I/F Tests • DCB Interface/Housekeeping addressing • Instrument Power Switches PFP QSR, 4/19/2011 52

Power Converter Status (1) • REG Board • We are working on a second PCB layout for the REG board ETU#2 due to a connector mis-wiring issue on the first layout. This re-layout process has begun. • The REG board tester was built and is now in operation • All REG based switchable services have been tested • Still pending: adjustment/tuning of the current monitoring subsystem; complete verification of the digital portion of the circuit • REG Board system checkout via PFDPU I/F Tests • DCB Interface/Housekeeping addressing • Instrument Power Switches PFP QSR, 4/19/2011 52

Power Converter Status (2) • IIB board • All power converter sections of the EM board have been tested with only the magnetics of MAG 2 and off board connectors for STATIC, SWIA, and MAG left to be populated. (This excludes the MAG HEATER daughter boards from Goddard that are to be mounted on the IIB at a later date. ) • The ± 90 V outputs on the LPW section sat at 114 V when integrated with the system. This would indicate an unloaded state as the voltage would normally drop closer to ± 90 V when loaded (10 m. A peak). • The 5 VD regulator on the SEP section will be changed to an LDO as the actual load is much lower with the system. The LTC 1877 may have stability issues with such a low load. • ACTEL turn-off delay circuit for the LPW section will be added and tested on the EM board. • Optimization for noise, efficiency, and voltage levels will also be done after and in between integration. PFP QSR, 4/19/2011 53

Power Converter Status (2) • IIB board • All power converter sections of the EM board have been tested with only the magnetics of MAG 2 and off board connectors for STATIC, SWIA, and MAG left to be populated. (This excludes the MAG HEATER daughter boards from Goddard that are to be mounted on the IIB at a later date. ) • The ± 90 V outputs on the LPW section sat at 114 V when integrated with the system. This would indicate an unloaded state as the voltage would normally drop closer to ± 90 V when loaded (10 m. A peak). • The 5 VD regulator on the SEP section will be changed to an LDO as the actual load is much lower with the system. The LTC 1877 may have stability issues with such a low load. • ACTEL turn-off delay circuit for the LPW section will be added and tested on the EM board. • Optimization for noise, efficiency, and voltage levels will also be done after and in between integration. PFP QSR, 4/19/2011 53

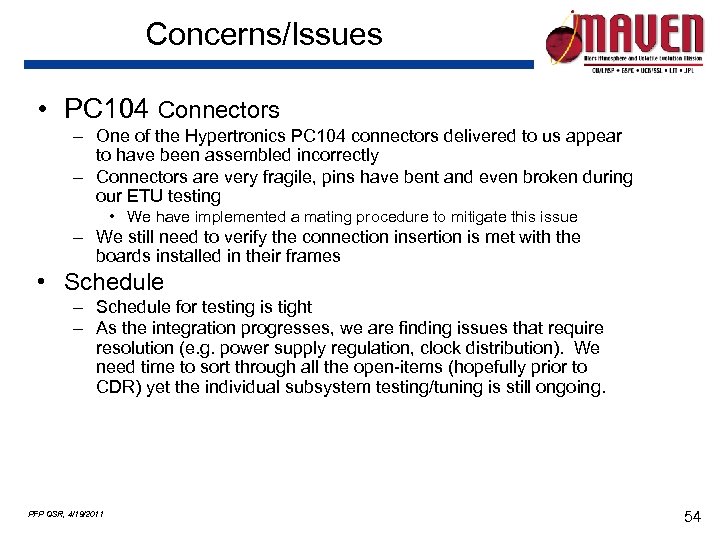

Concerns/Issues • PC 104 Connectors – One of the Hypertronics PC 104 connectors delivered to us appear to have been assembled incorrectly – Connectors are very fragile, pins have bent and even broken during our ETU testing • We have implemented a mating procedure to mitigate this issue – We still need to verify the connection insertion is met with the boards installed in their frames • Schedule – Schedule for testing is tight – As the integration progresses, we are finding issues that require resolution (e. g. power supply regulation, clock distribution). We need time to sort through all the open-items (hopefully prior to CDR) yet the individual subsystem testing/tuning is still ongoing. PFP QSR, 4/19/2011 54

Concerns/Issues • PC 104 Connectors – One of the Hypertronics PC 104 connectors delivered to us appear to have been assembled incorrectly – Connectors are very fragile, pins have bent and even broken during our ETU testing • We have implemented a mating procedure to mitigate this issue – We still need to verify the connection insertion is met with the boards installed in their frames • Schedule – Schedule for testing is tight – As the integration progresses, we are finding issues that require resolution (e. g. power supply regulation, clock distribution). We need time to sort through all the open-items (hopefully prior to CDR) yet the individual subsystem testing/tuning is still ongoing. PFP QSR, 4/19/2011 54

MAVEN PFP Flight Software Status April 12 2011 Peter Harvey PFP QSR, 4/19/2011 55

MAVEN PFP Flight Software Status April 12 2011 Peter Harvey PFP QSR, 4/19/2011 55

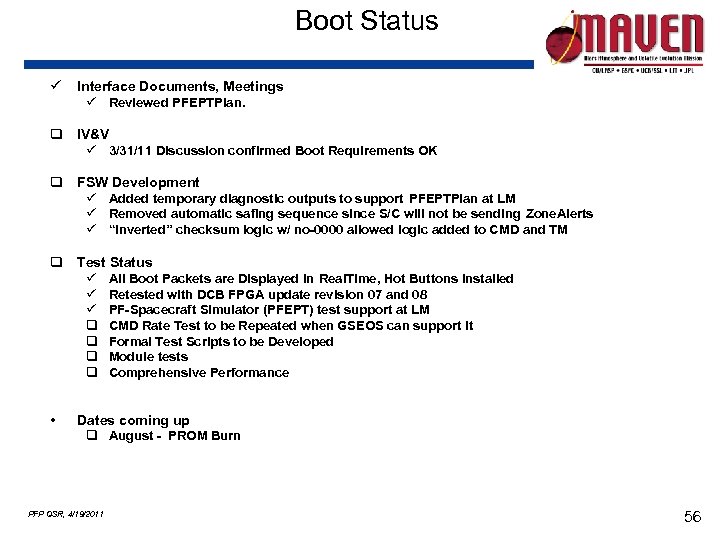

Boot Status ü Interface Documents, Meetings ü Reviewed PFEPTPlan. q IV&V ü 3/31/11 Discussion confirmed Boot Requirements OK q FSW Development ü Added temporary diagnostic outputs to support PFEPTPlan at LM ü Removed automatic safing sequence since S/C will not be sending Zone. Alerts ü “Inverted” checksum logic w/ no-0000 allowed logic added to CMD and TM q Test Status ü ü ü q q • All Boot Packets are Displayed in Real. Time, Hot Buttons installed Retested with DCB FPGA update revision 07 and 08 PF-Spacecraft Simulator (PFEPT) test support at LM CMD Rate Test to be Repeated when GSEOS can support it Formal Test Scripts to be Developed Module tests Comprehensive Performance Dates coming up q August - PROM Burn PFP QSR, 4/19/2011 56

Boot Status ü Interface Documents, Meetings ü Reviewed PFEPTPlan. q IV&V ü 3/31/11 Discussion confirmed Boot Requirements OK q FSW Development ü Added temporary diagnostic outputs to support PFEPTPlan at LM ü Removed automatic safing sequence since S/C will not be sending Zone. Alerts ü “Inverted” checksum logic w/ no-0000 allowed logic added to CMD and TM q Test Status ü ü ü q q • All Boot Packets are Displayed in Real. Time, Hot Buttons installed Retested with DCB FPGA update revision 07 and 08 PF-Spacecraft Simulator (PFEPT) test support at LM CMD Rate Test to be Repeated when GSEOS can support it Formal Test Scripts to be Developed Module tests Comprehensive Performance Dates coming up q August - PROM Burn PFP QSR, 4/19/2011 56

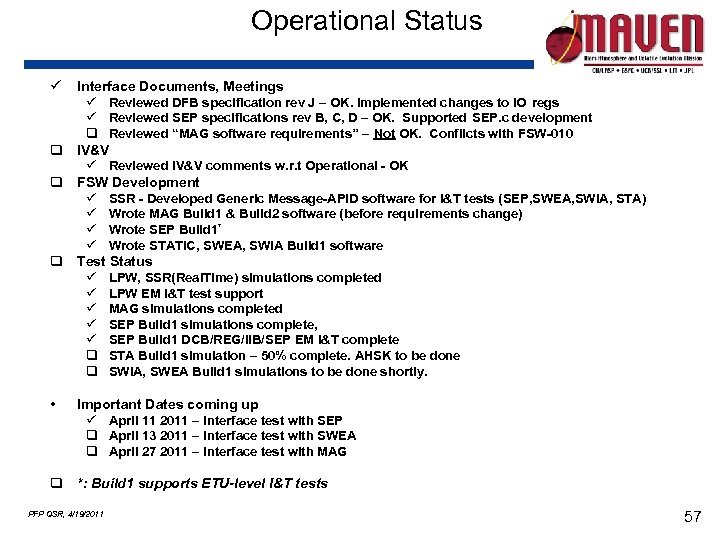

Operational Status ü q q q • Interface Documents, Meetings ü Reviewed DFB specification rev J – OK. Implemented changes to IO regs ü Reviewed SEP specifications rev B, C, D – OK. Supported SEP. c development q Reviewed “MAG software requirements” – Not OK. Conflicts with FSW-010 IV&V ü Reviewed IV&V comments w. r. t Operational - OK FSW Development ü SSR - Developed Generic Message-APID software for I&T tests (SEP, SWEA, SWIA, STA) ü Wrote MAG Build 1 & Build 2 software (before requirements change) ü Wrote SEP Build 1* ü Wrote STATIC, SWEA, SWIA Build 1 software Test Status ü LPW, SSR(Real. Time) simulations completed ü LPW EM I&T test support ü MAG simulations completed ü SEP Build 1 simulations complete, ü SEP Build 1 DCB/REG/IIB/SEP EM I&T complete q STA Build 1 simulation – 50% complete. AHSK to be done q SWIA, SWEA Build 1 simulations to be done shortly. Important Dates coming up ü April 11 2011 – Interface test with SEP q April 13 2011 – Interface test with SWEA q April 27 2011 – Interface test with MAG q *: Build 1 supports ETU-level I&T tests PFP QSR, 4/19/2011 57

Operational Status ü q q q • Interface Documents, Meetings ü Reviewed DFB specification rev J – OK. Implemented changes to IO regs ü Reviewed SEP specifications rev B, C, D – OK. Supported SEP. c development q Reviewed “MAG software requirements” – Not OK. Conflicts with FSW-010 IV&V ü Reviewed IV&V comments w. r. t Operational - OK FSW Development ü SSR - Developed Generic Message-APID software for I&T tests (SEP, SWEA, SWIA, STA) ü Wrote MAG Build 1 & Build 2 software (before requirements change) ü Wrote SEP Build 1* ü Wrote STATIC, SWEA, SWIA Build 1 software Test Status ü LPW, SSR(Real. Time) simulations completed ü LPW EM I&T test support ü MAG simulations completed ü SEP Build 1 simulations complete, ü SEP Build 1 DCB/REG/IIB/SEP EM I&T complete q STA Build 1 simulation – 50% complete. AHSK to be done q SWIA, SWEA Build 1 simulations to be done shortly. Important Dates coming up ü April 11 2011 – Interface test with SEP q April 13 2011 – Interface test with SWEA q April 27 2011 – Interface test with MAG q *: Build 1 supports ETU-level I&T tests PFP QSR, 4/19/2011 57

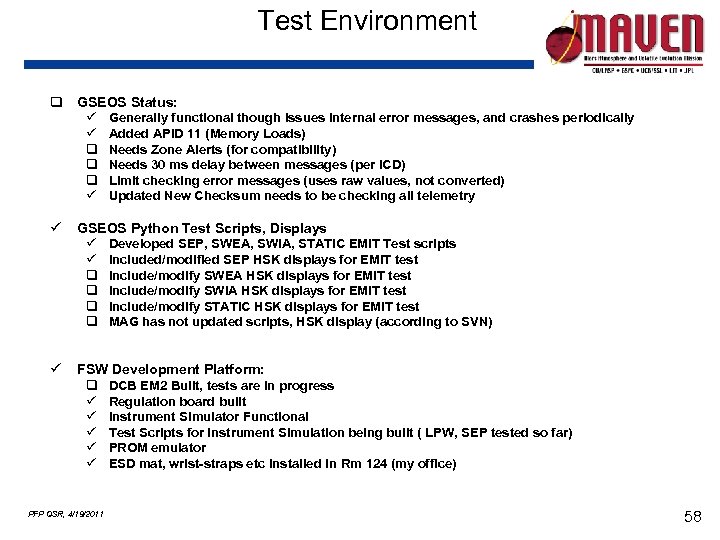

Test Environment q GSEOS Status: ü ü q q q ü Generally functional though issues internal error messages, and crashes periodically Added APID 11 (Memory Loads) Needs Zone Alerts (for compatibility) Needs 30 ms delay between messages (per ICD) Limit checking error messages (uses raw values, not converted) Updated New Checksum needs to be checking all telemetry ü GSEOS Python Test Scripts, Displays ü Developed SEP, SWEA, SWIA, STATIC EMIT Test scripts ü Included/modified SEP HSK displays for EMIT test q Include/modify SWEA HSK displays for EMIT test q Include/modify SWIA HSK displays for EMIT test q Include/modify STATIC HSK displays for EMIT test q MAG has not updated scripts, HSK display (according to SVN) ü FSW Development Platform: q DCB EM 2 Built, tests are in progress ü Regulation board built ü Instrument Simulator Functional ü Test Scripts for Instrument Simulation being built ( LPW, SEP tested so far) ü PROM emulator ü ESD mat, wrist-straps etc installed in Rm 124 (my office) PFP QSR, 4/19/2011 58

Test Environment q GSEOS Status: ü ü q q q ü Generally functional though issues internal error messages, and crashes periodically Added APID 11 (Memory Loads) Needs Zone Alerts (for compatibility) Needs 30 ms delay between messages (per ICD) Limit checking error messages (uses raw values, not converted) Updated New Checksum needs to be checking all telemetry ü GSEOS Python Test Scripts, Displays ü Developed SEP, SWEA, SWIA, STATIC EMIT Test scripts ü Included/modified SEP HSK displays for EMIT test q Include/modify SWEA HSK displays for EMIT test q Include/modify SWIA HSK displays for EMIT test q Include/modify STATIC HSK displays for EMIT test q MAG has not updated scripts, HSK display (according to SVN) ü FSW Development Platform: q DCB EM 2 Built, tests are in progress ü Regulation board built ü Instrument Simulator Functional ü Test Scripts for Instrument Simulation being built ( LPW, SEP tested so far) ü PROM emulator ü ESD mat, wrist-straps etc installed in Rm 124 (my office) PFP QSR, 4/19/2011 58

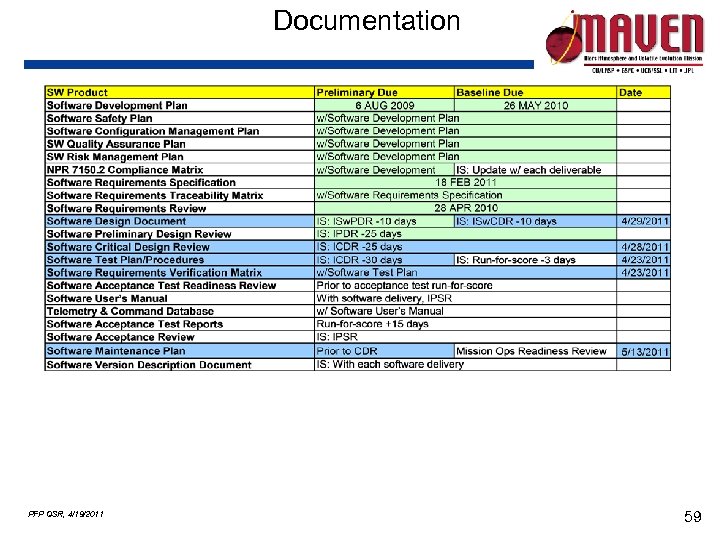

Documentation PFP QSR, 4/19/2011 59

Documentation PFP QSR, 4/19/2011 59

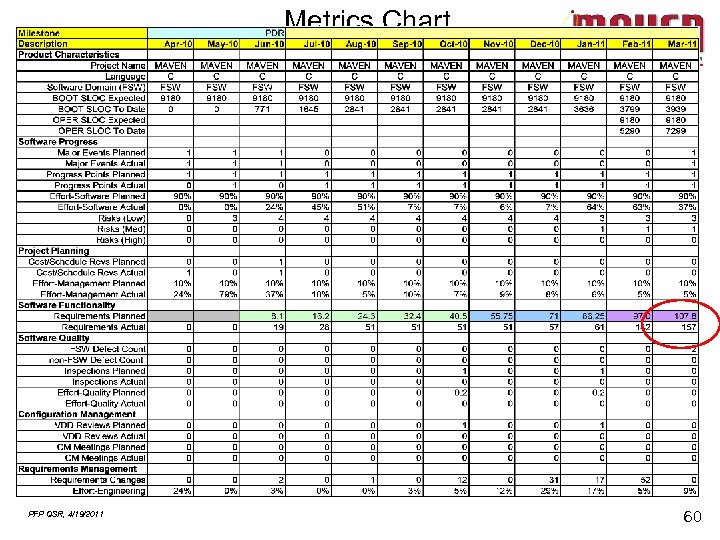

Metrics Chart PFP QSR, 4/19/2011 60

Metrics Chart PFP QSR, 4/19/2011 60

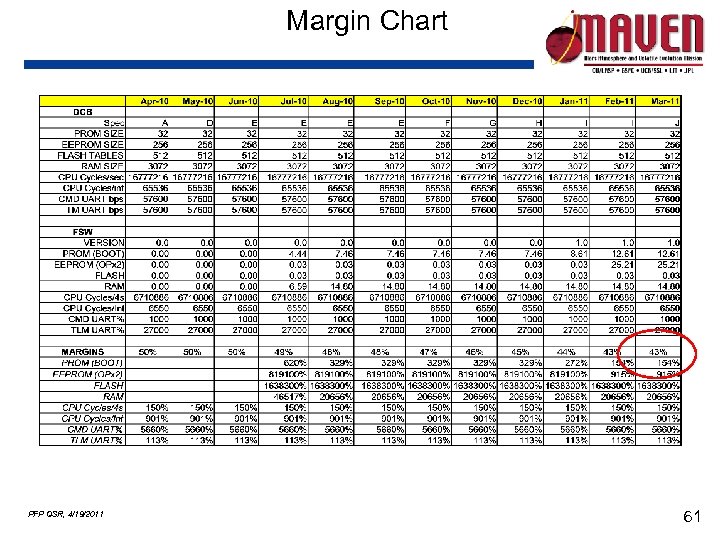

Margin Chart PFP QSR, 4/19/2011 61

Margin Chart PFP QSR, 4/19/2011 61

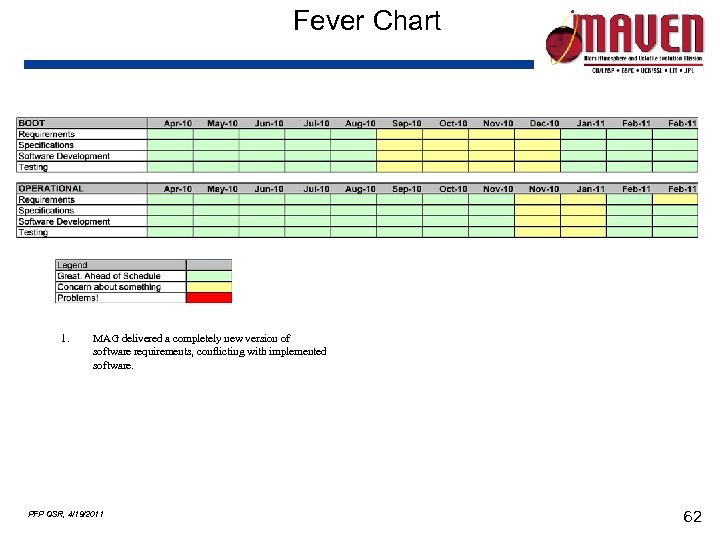

Fever Chart 1. MAG delivered a completely new version of software requirements, conflicting with implemented software. PFP QSR, 4/19/2011 62

Fever Chart 1. MAG delivered a completely new version of software requirements, conflicting with implemented software. PFP QSR, 4/19/2011 62