a2c5d286a4bf213aaf19f48fdd225627.ppt

- Количество слайдов: 75

Particles and Fields Package (PFP) Instrument Preliminary Design Review Solar Wind Ion Analyzer (SWIA) Jasper Halekas Greg Dalton Ellen Taylor PFP IPDR 2010/6/14 -16 1

Particles and Fields Package (PFP) Instrument Preliminary Design Review Solar Wind Ion Analyzer (SWIA) Jasper Halekas Greg Dalton Ellen Taylor PFP IPDR 2010/6/14 -16 1

I. Introduction II. Science Requirements III. System Design IV. Optics Design Status V. Mechanical Design Status VI. Electrical Design Status VII. Schedule/Wrap Up PFP IPDR 2010/6/14 -16 Jasper Halekas Greg Dalton Ellen Taylor Jasper Halekas 2

I. Introduction II. Science Requirements III. System Design IV. Optics Design Status V. Mechanical Design Status VI. Electrical Design Status VII. Schedule/Wrap Up PFP IPDR 2010/6/14 -16 Jasper Halekas Greg Dalton Ellen Taylor Jasper Halekas 2

SWIA Team • SWIA Instrument Lead: Jasper Halekas – – – – – Lead Mechanical Engineer: Greg Dalton Lead Electrical Engineer: Ellen Taylor Thermal: Chris Smith FPGA: Dorothy Gordon FSW [PFDPU]: Peter Harvey Power Supplies: Peter Berg, Selda Heavner GSE: Tim Quinn Detectors: Mario Marckwordt Facilities: Steve Marker Purchasing/Contracts: Kate Harps, Jim Keenan, Misty Willer • PF Manager: Dave Curtis • PF Lead Mechanical Engineer: Paul Turin • STATIC Lead/SWIA Consultant: Jim Mc. Fadden PFP IPDR 2010/6/14 -16 3

SWIA Team • SWIA Instrument Lead: Jasper Halekas – – – – – Lead Mechanical Engineer: Greg Dalton Lead Electrical Engineer: Ellen Taylor Thermal: Chris Smith FPGA: Dorothy Gordon FSW [PFDPU]: Peter Harvey Power Supplies: Peter Berg, Selda Heavner GSE: Tim Quinn Detectors: Mario Marckwordt Facilities: Steve Marker Purchasing/Contracts: Kate Harps, Jim Keenan, Misty Willer • PF Manager: Dave Curtis • PF Lead Mechanical Engineer: Paul Turin • STATIC Lead/SWIA Consultant: Jim Mc. Fadden PFP IPDR 2010/6/14 -16 3

SWIA Status/Documentation • Designing to PF FRD, instrument specs, MICD, and numerous systems documents – – MAVEN-PFIS-RQMT-0016 MAVEN-PF-SWIA-001 h_Requirements MAVA 0240299_SWIA_MICD MAVEN_PF_SYS_002 - MAVEN_PF_SYS_023 • Schematics and mechanical design done for all boards – Anode board already in layout – Digital and Preamp/MCP boards going to layout soon – Leveraging STATIC prototype effort for HVPS, digital • FPGA specification complete, design in progress – MAVEN_PF_SWIA_012 B_FPGA_Specification • FSW specification complete – MAVEN_PF_FSW_002 C_SRS • Active parts list complete, passive parts list in progress, MCPs ordered • Ready to build EMs PFP IPDR 2010/6/14 -16 4

SWIA Status/Documentation • Designing to PF FRD, instrument specs, MICD, and numerous systems documents – – MAVEN-PFIS-RQMT-0016 MAVEN-PF-SWIA-001 h_Requirements MAVA 0240299_SWIA_MICD MAVEN_PF_SYS_002 - MAVEN_PF_SYS_023 • Schematics and mechanical design done for all boards – Anode board already in layout – Digital and Preamp/MCP boards going to layout soon – Leveraging STATIC prototype effort for HVPS, digital • FPGA specification complete, design in progress – MAVEN_PF_SWIA_012 B_FPGA_Specification • FSW specification complete – MAVEN_PF_FSW_002 C_SRS • Active parts list complete, passive parts list in progress, MCPs ordered • Ready to build EMs PFP IPDR 2010/6/14 -16 4

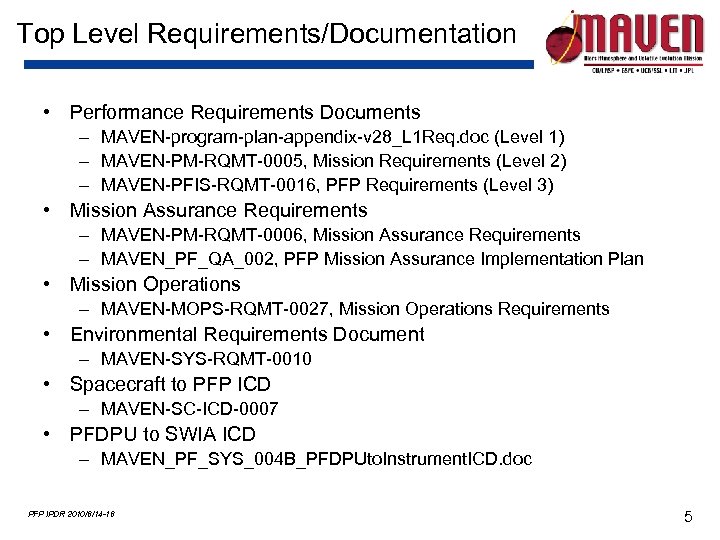

Top Level Requirements/Documentation • Performance Requirements Documents – MAVEN-program-plan-appendix-v 28_L 1 Req. doc (Level 1) – MAVEN-PM-RQMT-0005, Mission Requirements (Level 2) – MAVEN-PFIS-RQMT-0016, PFP Requirements (Level 3) • Mission Assurance Requirements – MAVEN-PM-RQMT-0006, Mission Assurance Requirements – MAVEN_PF_QA_002, PFP Mission Assurance Implementation Plan • Mission Operations – MAVEN-MOPS-RQMT-0027, Mission Operations Requirements • Environmental Requirements Document – MAVEN-SYS-RQMT-0010 • Spacecraft to PFP ICD – MAVEN-SC-ICD-0007 • PFDPU to SWIA ICD – MAVEN_PF_SYS_004 B_PFDPUto. Instrument. ICD. doc PFP IPDR 2010/6/14 -16 5

Top Level Requirements/Documentation • Performance Requirements Documents – MAVEN-program-plan-appendix-v 28_L 1 Req. doc (Level 1) – MAVEN-PM-RQMT-0005, Mission Requirements (Level 2) – MAVEN-PFIS-RQMT-0016, PFP Requirements (Level 3) • Mission Assurance Requirements – MAVEN-PM-RQMT-0006, Mission Assurance Requirements – MAVEN_PF_QA_002, PFP Mission Assurance Implementation Plan • Mission Operations – MAVEN-MOPS-RQMT-0027, Mission Operations Requirements • Environmental Requirements Document – MAVEN-SYS-RQMT-0010 • Spacecraft to PFP ICD – MAVEN-SC-ICD-0007 • PFDPU to SWIA ICD – MAVEN_PF_SYS_004 B_PFDPUto. Instrument. ICD. doc PFP IPDR 2010/6/14 -16 5

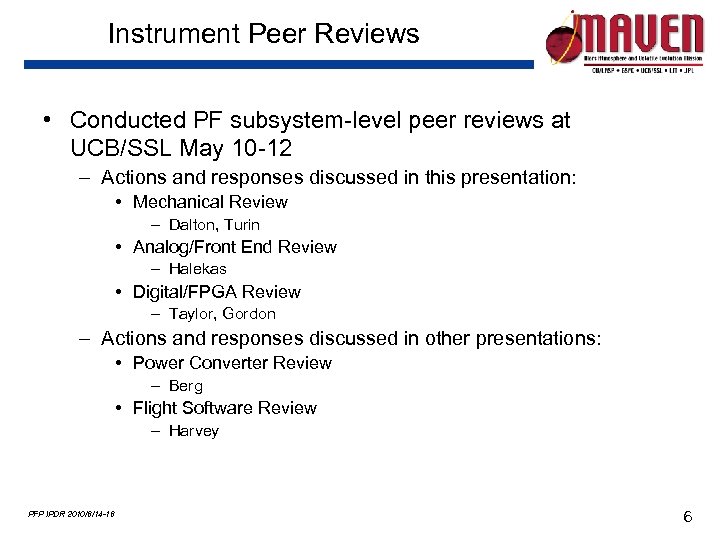

Instrument Peer Reviews • Conducted PF subsystem-level peer reviews at UCB/SSL May 10 -12 – Actions and responses discussed in this presentation: • Mechanical Review – Dalton, Turin • Analog/Front End Review – Halekas • Digital/FPGA Review – Taylor, Gordon – Actions and responses discussed in other presentations: • Power Converter Review – Berg • Flight Software Review – Harvey PFP IPDR 2010/6/14 -16 6

Instrument Peer Reviews • Conducted PF subsystem-level peer reviews at UCB/SSL May 10 -12 – Actions and responses discussed in this presentation: • Mechanical Review – Dalton, Turin • Analog/Front End Review – Halekas • Digital/FPGA Review – Taylor, Gordon – Actions and responses discussed in other presentations: • Power Converter Review – Berg • Flight Software Review – Harvey PFP IPDR 2010/6/14 -16 6

II. SWIA Science Requirements A. Requirements B. Compliance C. Trade Studies D. Data Products PFP IPDR 2010/6/14 -16 7

II. SWIA Science Requirements A. Requirements B. Compliance C. Trade Studies D. Data Products PFP IPDR 2010/6/14 -16 7

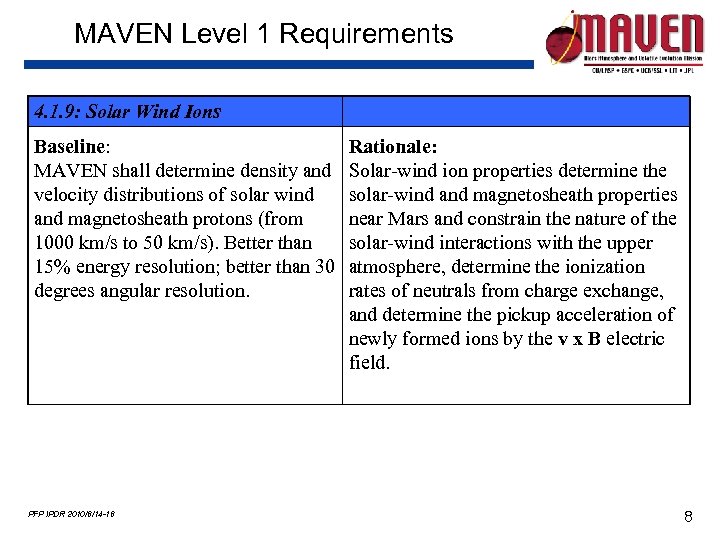

MAVEN Level 1 Requirements 4. 1. 9: Solar Wind Ions Baseline: MAVEN shall determine density and velocity distributions of solar wind and magnetosheath protons (from 1000 km/s to 50 km/s). Better than 15% energy resolution; better than 30 degrees angular resolution. PFP IPDR 2010/6/14 -16 Rationale: Solar-wind ion properties determine the solar-wind and magnetosheath properties near Mars and constrain the nature of the solar-wind interactions with the upper atmosphere, determine the ionization rates of neutrals from charge exchange, and determine the pickup acceleration of newly formed ions by the v x B electric field. 8

MAVEN Level 1 Requirements 4. 1. 9: Solar Wind Ions Baseline: MAVEN shall determine density and velocity distributions of solar wind and magnetosheath protons (from 1000 km/s to 50 km/s). Better than 15% energy resolution; better than 30 degrees angular resolution. PFP IPDR 2010/6/14 -16 Rationale: Solar-wind ion properties determine the solar-wind and magnetosheath properties near Mars and constrain the nature of the solar-wind interactions with the upper atmosphere, determine the ionization rates of neutrals from charge exchange, and determine the pickup acceleration of newly formed ions by the v x B electric field. 8

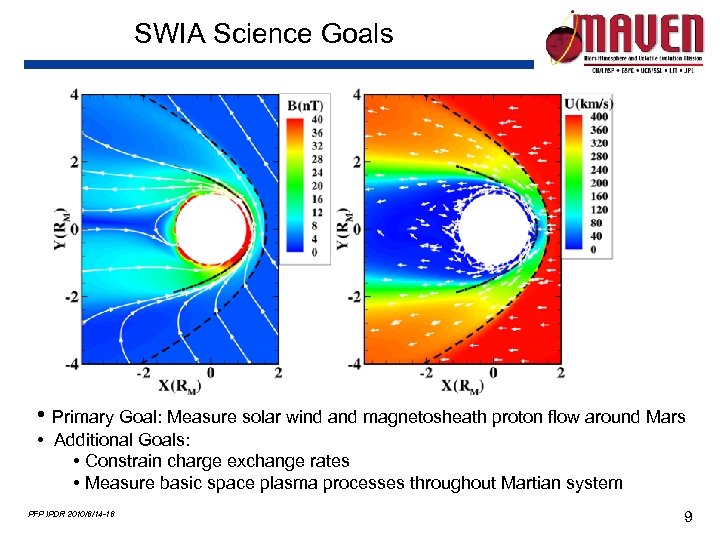

SWIA Science Goals • Primary Goal: Measure solar wind and magnetosheath proton flow around Mars • Additional Goals: • Constrain charge exchange rates • Measure basic space plasma processes throughout Martian system PFP IPDR 2010/6/14 -16 9

SWIA Science Goals • Primary Goal: Measure solar wind and magnetosheath proton flow around Mars • Additional Goals: • Constrain charge exchange rates • Measure basic space plasma processes throughout Martian system PFP IPDR 2010/6/14 -16 9

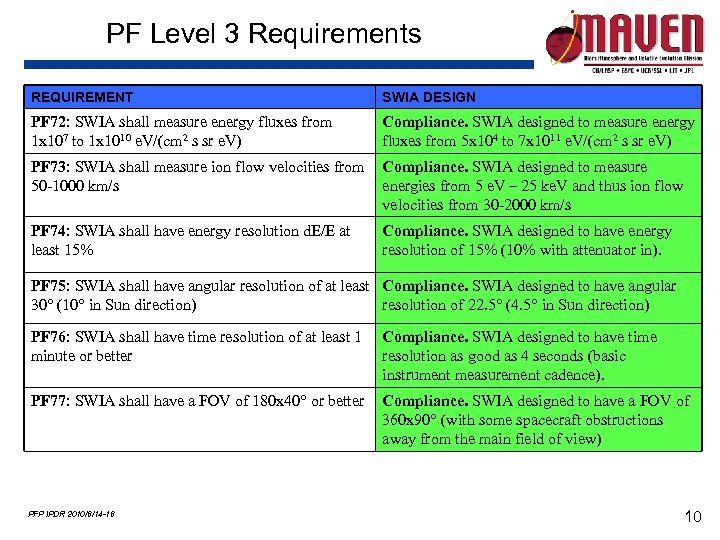

PF Level 3 Requirements REQUIREMENT SWIA DESIGN PF 72: SWIA shall measure energy fluxes from 1 x 107 to 1 x 1010 e. V/(cm 2 s sr e. V) Compliance. SWIA designed to measure energy fluxes from 5 x 104 to 7 x 1011 e. V/(cm 2 s sr e. V) PF 73: SWIA shall measure ion flow velocities from 50 -1000 km/s Compliance. SWIA designed to measure energies from 5 e. V – 25 ke. V and thus ion flow velocities from 30 -2000 km/s PF 74: SWIA shall have energy resolution d. E/E at least 15% Compliance. SWIA designed to have energy resolution of 15% (10% with attenuator in). PF 75: SWIA shall have angular resolution of at least Compliance. SWIA designed to have angular 30° (10° in Sun direction) resolution of 22. 5° (4. 5° in Sun direction) PF 76: SWIA shall have time resolution of at least 1 minute or better Compliance. SWIA designed to have time resolution as good as 4 seconds (basic instrument measurement cadence). PF 77: SWIA shall have a FOV of 180 x 40° or better Compliance. SWIA designed to have a FOV of 360 x 90° (with some spacecraft obstructions away from the main field of view) PFP IPDR 2010/6/14 -16 10

PF Level 3 Requirements REQUIREMENT SWIA DESIGN PF 72: SWIA shall measure energy fluxes from 1 x 107 to 1 x 1010 e. V/(cm 2 s sr e. V) Compliance. SWIA designed to measure energy fluxes from 5 x 104 to 7 x 1011 e. V/(cm 2 s sr e. V) PF 73: SWIA shall measure ion flow velocities from 50 -1000 km/s Compliance. SWIA designed to measure energies from 5 e. V – 25 ke. V and thus ion flow velocities from 30 -2000 km/s PF 74: SWIA shall have energy resolution d. E/E at least 15% Compliance. SWIA designed to have energy resolution of 15% (10% with attenuator in). PF 75: SWIA shall have angular resolution of at least Compliance. SWIA designed to have angular 30° (10° in Sun direction) resolution of 22. 5° (4. 5° in Sun direction) PF 76: SWIA shall have time resolution of at least 1 minute or better Compliance. SWIA designed to have time resolution as good as 4 seconds (basic instrument measurement cadence). PF 77: SWIA shall have a FOV of 180 x 40° or better Compliance. SWIA designed to have a FOV of 360 x 90° (with some spacecraft obstructions away from the main field of view) PFP IPDR 2010/6/14 -16 10

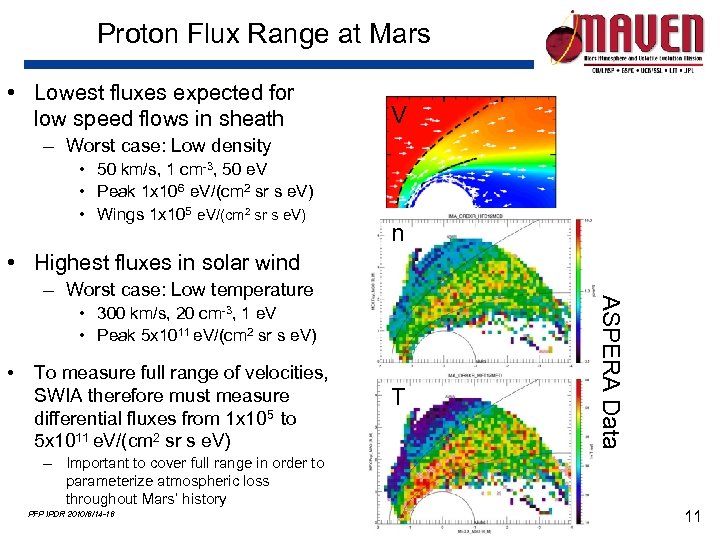

Proton Flux Range at Mars • Lowest fluxes expected for low speed flows in sheath V – Worst case: Low density • 50 km/s, 1 cm-3, 50 e. V • Peak 1 x 106 e. V/(cm 2 sr s e. V) • Wings 1 x 105 e. V/(cm 2 sr s e. V) n • Highest fluxes in solar wind • 300 km/s, 20 cm-3, 1 e. V • Peak 5 x 1011 e. V/(cm 2 sr s e. V) • To measure full range of velocities, SWIA therefore must measure differential fluxes from 1 x 105 to 5 x 1011 e. V/(cm 2 sr s e. V) T ASPERA Data – Worst case: Low temperature – Important to cover full range in order to parameterize atmospheric loss throughout Mars’ history PFP IPDR 2010/6/14 -16 11

Proton Flux Range at Mars • Lowest fluxes expected for low speed flows in sheath V – Worst case: Low density • 50 km/s, 1 cm-3, 50 e. V • Peak 1 x 106 e. V/(cm 2 sr s e. V) • Wings 1 x 105 e. V/(cm 2 sr s e. V) n • Highest fluxes in solar wind • 300 km/s, 20 cm-3, 1 e. V • Peak 5 x 1011 e. V/(cm 2 sr s e. V) • To measure full range of velocities, SWIA therefore must measure differential fluxes from 1 x 105 to 5 x 1011 e. V/(cm 2 sr s e. V) T ASPERA Data – Worst case: Low temperature – Important to cover full range in order to parameterize atmospheric loss throughout Mars’ history PFP IPDR 2010/6/14 -16 11

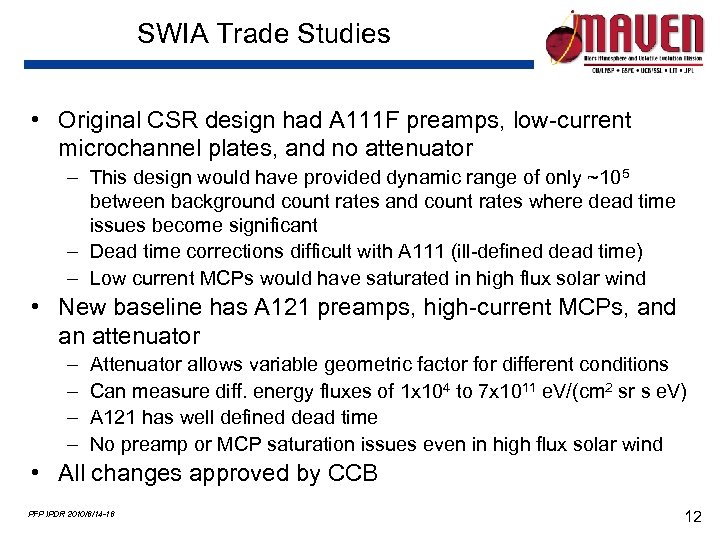

SWIA Trade Studies • Original CSR design had A 111 F preamps, low-current microchannel plates, and no attenuator – This design would have provided dynamic range of only ~105 between background count rates and count rates where dead time issues become significant – Dead time corrections difficult with A 111 (ill-defined dead time) – Low current MCPs would have saturated in high flux solar wind • New baseline has A 121 preamps, high-current MCPs, and an attenuator – – Attenuator allows variable geometric factor for different conditions Can measure diff. energy fluxes of 1 x 104 to 7 x 1011 e. V/(cm 2 sr s e. V) A 121 has well defined dead time No preamp or MCP saturation issues even in high flux solar wind • All changes approved by CCB PFP IPDR 2010/6/14 -16 12

SWIA Trade Studies • Original CSR design had A 111 F preamps, low-current microchannel plates, and no attenuator – This design would have provided dynamic range of only ~105 between background count rates and count rates where dead time issues become significant – Dead time corrections difficult with A 111 (ill-defined dead time) – Low current MCPs would have saturated in high flux solar wind • New baseline has A 121 preamps, high-current MCPs, and an attenuator – – Attenuator allows variable geometric factor for different conditions Can measure diff. energy fluxes of 1 x 104 to 7 x 1011 e. V/(cm 2 sr s e. V) A 121 has well defined dead time No preamp or MCP saturation issues even in high flux solar wind • All changes approved by CCB PFP IPDR 2010/6/14 -16 12

SWIA Count Rates (RFA: AFE I. A. 2) • SWIA geometric Factor 0. 0056 cm 2 sr e. V/e. V – 360° full sensor sensitivity, including grid transmission and MCP efficiency • Divided among 10 x 4. 5° anodes in sun direction (highest fluxes), 14 x 22. 5° anodes away from sun – Small anode geometric factor 0. 000070 cm 2 sr – Large anode geometric factor 0. 00035 cm 2 sr • SWIA (per anode) count rate capability ~1 Hz to 2 MHz – A 121 preamplifier count rate capability 2 MHz with no dead time corrections (up to 12 MHz periodic) – High current MCP count rate capability ~2 MHz per small anode – ~10 c/s sensor background spread over all anodes • Attenuator gives additional factor of ~25 dynamic range • SWIA differential energy flux range 1 x 104 to 7 x 1011 e. V/(cm 2 sr s e. V) – Sufficient to make quality measurements in sheath and solar wind for all conditions and achieve MAVEN science goals PFP IPDR 2010/6/14 -16 13

SWIA Count Rates (RFA: AFE I. A. 2) • SWIA geometric Factor 0. 0056 cm 2 sr e. V/e. V – 360° full sensor sensitivity, including grid transmission and MCP efficiency • Divided among 10 x 4. 5° anodes in sun direction (highest fluxes), 14 x 22. 5° anodes away from sun – Small anode geometric factor 0. 000070 cm 2 sr – Large anode geometric factor 0. 00035 cm 2 sr • SWIA (per anode) count rate capability ~1 Hz to 2 MHz – A 121 preamplifier count rate capability 2 MHz with no dead time corrections (up to 12 MHz periodic) – High current MCP count rate capability ~2 MHz per small anode – ~10 c/s sensor background spread over all anodes • Attenuator gives additional factor of ~25 dynamic range • SWIA differential energy flux range 1 x 104 to 7 x 1011 e. V/(cm 2 sr s e. V) – Sufficient to make quality measurements in sheath and solar wind for all conditions and achieve MAVEN science goals PFP IPDR 2010/6/14 -16 13

SWIA Data Products • P 0 = Full resolution data product – Huge data volume – Mainly for calibration purposes • P 1 = Full coverage “coarse resolution” data product – 48 energies X 16 angles X 4 deflection angles – 20% energy resolution, 22. 5° angular resolution – Mainly for magnetosheath/magnetosphere (also pickup ions) • P 2 = Reduced coverage “fine resolution” data product – – Pick region of phase space centered around solar wind beam 48 energies X 10 angles X 12 deflection angles 10% energy resolution, 4. 5° angular resolution For solar wind measurements PFP IPDR 2010/6/14 -16 14

SWIA Data Products • P 0 = Full resolution data product – Huge data volume – Mainly for calibration purposes • P 1 = Full coverage “coarse resolution” data product – 48 energies X 16 angles X 4 deflection angles – 20% energy resolution, 22. 5° angular resolution – Mainly for magnetosheath/magnetosphere (also pickup ions) • P 2 = Reduced coverage “fine resolution” data product – – Pick region of phase space centered around solar wind beam 48 energies X 10 angles X 12 deflection angles 10% energy resolution, 4. 5° angular resolution For solar wind measurements PFP IPDR 2010/6/14 -16 14

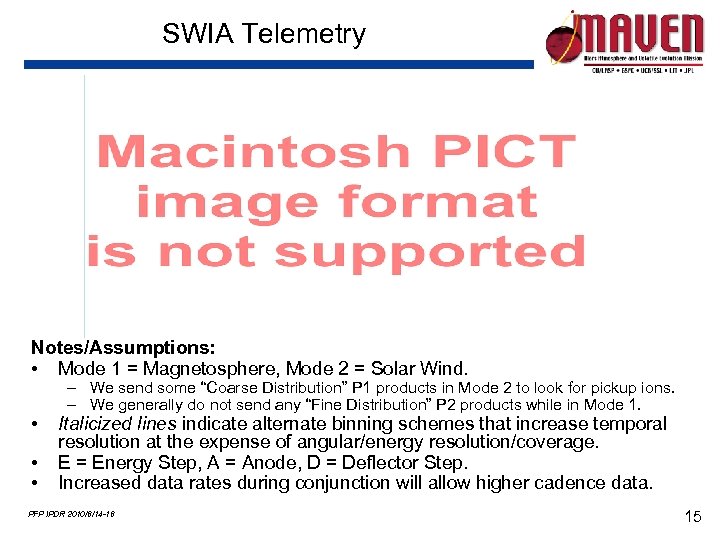

SWIA Telemetry Notes/Assumptions: • Mode 1 = Magnetosphere, Mode 2 = Solar Wind. • • • – We send some “Coarse Distribution” P 1 products in Mode 2 to look for pickup ions. – We generally do not send any “Fine Distribution” P 2 products while in Mode 1. Italicized lines indicate alternate binning schemes that increase temporal resolution at the expense of angular/energy resolution/coverage. E = Energy Step, A = Anode, D = Deflector Step. Increased data rates during conjunction will allow higher cadence data. PFP IPDR 2010/6/14 -16 15

SWIA Telemetry Notes/Assumptions: • Mode 1 = Magnetosphere, Mode 2 = Solar Wind. • • • – We send some “Coarse Distribution” P 1 products in Mode 2 to look for pickup ions. – We generally do not send any “Fine Distribution” P 2 products while in Mode 1. Italicized lines indicate alternate binning schemes that increase temporal resolution at the expense of angular/energy resolution/coverage. E = Energy Step, A = Anode, D = Deflector Step. Increased data rates during conjunction will allow higher cadence data. PFP IPDR 2010/6/14 -16 15

III. SWIA System Design A. Overview B. Block Diagram C. Heritage/Lessons Learned D. Accommodations E. Resources PFP IPDR 2010/6/14 -16 16

III. SWIA System Design A. Overview B. Block Diagram C. Heritage/Lessons Learned D. Accommodations E. Resources PFP IPDR 2010/6/14 -16 16

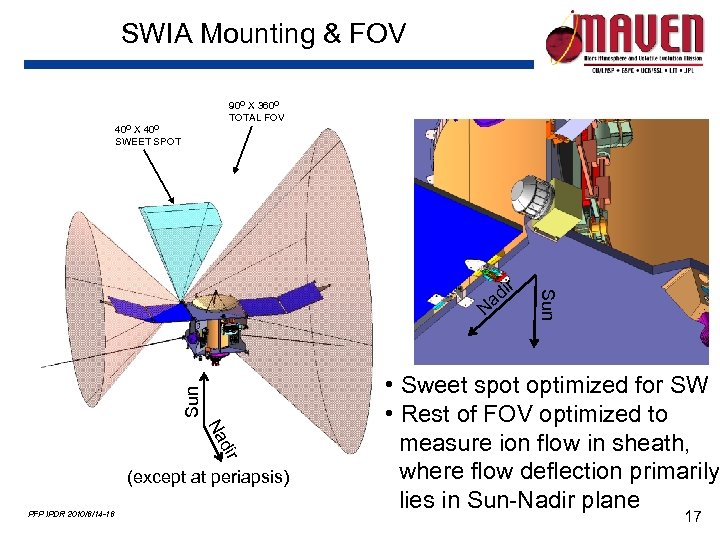

SWIA Mounting & FOV 90 O X 360 O TOTAL FOV 40 O X 40 O SWEET SPOT Sun ir d Na (except at periapsis) PFP IPDR 2010/6/14 -16 Sun r di Na • Sweet spot optimized for SW • Rest of FOV optimized to measure ion flow in sheath, where flow deflection primarily lies in Sun-Nadir plane 17

SWIA Mounting & FOV 90 O X 360 O TOTAL FOV 40 O X 40 O SWEET SPOT Sun ir d Na (except at periapsis) PFP IPDR 2010/6/14 -16 Sun r di Na • Sweet spot optimized for SW • Rest of FOV optimized to measure ion flow in sheath, where flow deflection primarily lies in Sun-Nadir plane 17

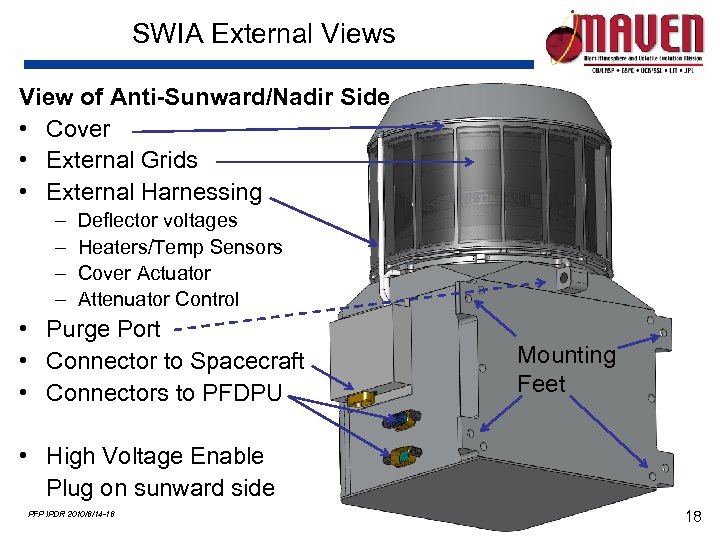

SWIA External Views View of Anti-Sunward/Nadir Side • Cover • External Grids • External Harnessing – – Deflector voltages Heaters/Temp Sensors Cover Actuator Attenuator Control • Purge Port • Connector to Spacecraft • Connectors to PFDPU Mounting Feet • High Voltage Enable Plug on sunward side PFP IPDR 2010/6/14 -16 18

SWIA External Views View of Anti-Sunward/Nadir Side • Cover • External Grids • External Harnessing – – Deflector voltages Heaters/Temp Sensors Cover Actuator Attenuator Control • Purge Port • Connector to Spacecraft • Connectors to PFDPU Mounting Feet • High Voltage Enable Plug on sunward side PFP IPDR 2010/6/14 -16 18

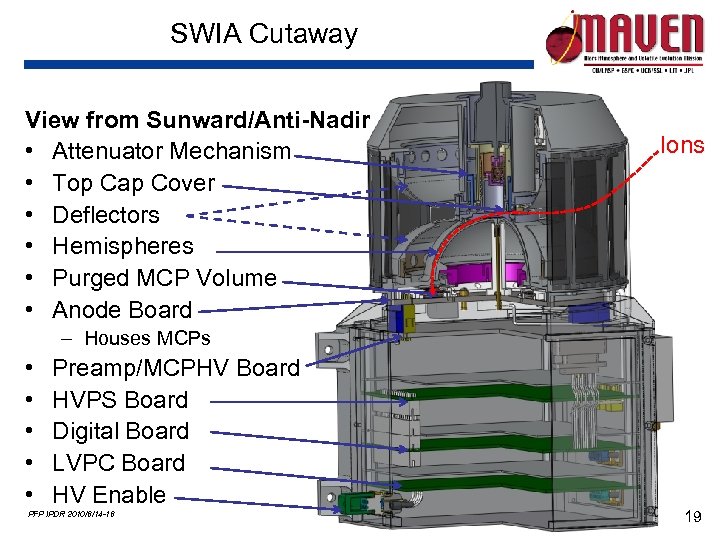

SWIA Cutaway View from Sunward/Anti-Nadir • Attenuator Mechanism • Top Cap Cover • Deflectors • Hemispheres • Purged MCP Volume • Anode Board Ions – Houses MCPs • • • Preamp/MCPHV Board HVPS Board Digital Board LVPC Board HV Enable PFP IPDR 2010/6/14 -16 19

SWIA Cutaway View from Sunward/Anti-Nadir • Attenuator Mechanism • Top Cap Cover • Deflectors • Hemispheres • Purged MCP Volume • Anode Board Ions – Houses MCPs • • • Preamp/MCPHV Board HVPS Board Digital Board LVPC Board HV Enable PFP IPDR 2010/6/14 -16 19

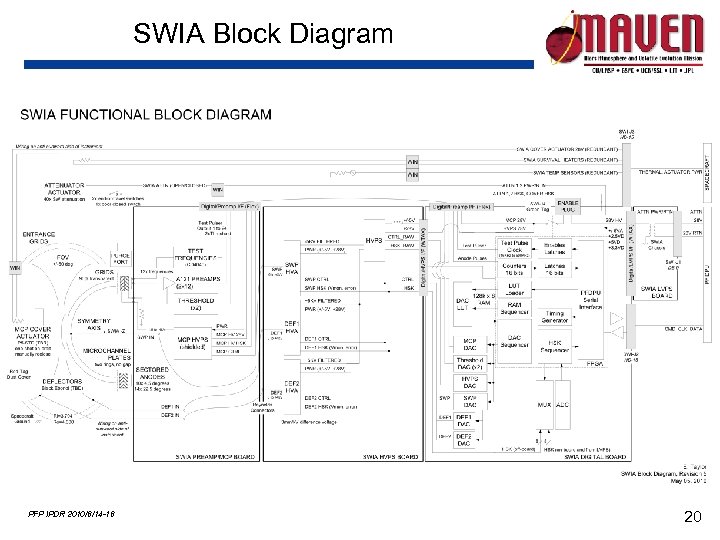

SWIA Block Diagram PFP IPDR 2010/6/14 -16 20

SWIA Block Diagram PFP IPDR 2010/6/14 -16 20

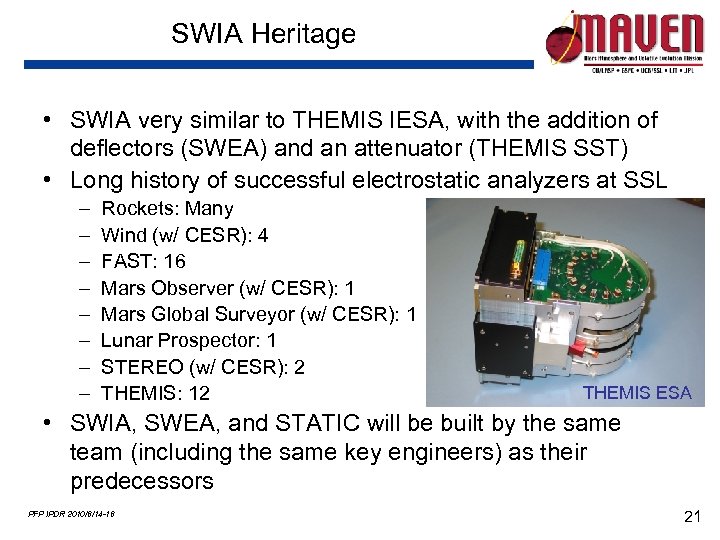

SWIA Heritage • SWIA very similar to THEMIS IESA, with the addition of deflectors (SWEA) and an attenuator (THEMIS SST) • Long history of successful electrostatic analyzers at SSL – – – – Rockets: Many Wind (w/ CESR): 4 FAST: 16 Mars Observer (w/ CESR): 1 Mars Global Surveyor (w/ CESR): 1 Lunar Prospector: 1 STEREO (w/ CESR): 2 THEMIS: 12 THEMIS ESA • SWIA, SWEA, and STATIC will be built by the same team (including the same key engineers) as their predecessors PFP IPDR 2010/6/14 -16 21

SWIA Heritage • SWIA very similar to THEMIS IESA, with the addition of deflectors (SWEA) and an attenuator (THEMIS SST) • Long history of successful electrostatic analyzers at SSL – – – – Rockets: Many Wind (w/ CESR): 4 FAST: 16 Mars Observer (w/ CESR): 1 Mars Global Surveyor (w/ CESR): 1 Lunar Prospector: 1 STEREO (w/ CESR): 2 THEMIS: 12 THEMIS ESA • SWIA, SWEA, and STATIC will be built by the same team (including the same key engineers) as their predecessors PFP IPDR 2010/6/14 -16 21

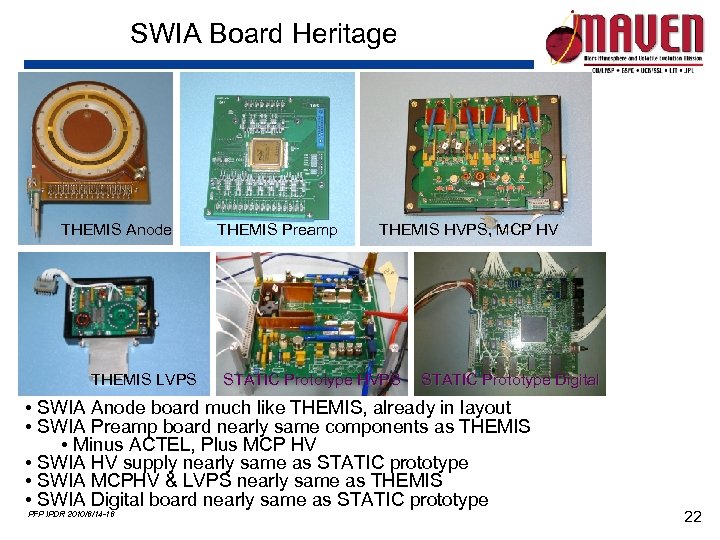

SWIA Board Heritage THEMIS Anode THEMIS LVPS THEMIS Preamp THEMIS HVPS, MCP HV STATIC Prototype HVPS STATIC Prototype Digital • SWIA Anode board much like THEMIS, already in layout • SWIA Preamp board nearly same components as THEMIS • Minus ACTEL, Plus MCP HV • SWIA HV supply nearly same as STATIC prototype • SWIA MCPHV & LVPS nearly same as THEMIS • SWIA Digital board nearly same as STATIC prototype PFP IPDR 2010/6/14 -16 22

SWIA Board Heritage THEMIS Anode THEMIS LVPS THEMIS Preamp THEMIS HVPS, MCP HV STATIC Prototype HVPS STATIC Prototype Digital • SWIA Anode board much like THEMIS, already in layout • SWIA Preamp board nearly same components as THEMIS • Minus ACTEL, Plus MCP HV • SWIA HV supply nearly same as STATIC prototype • SWIA MCPHV & LVPS nearly same as THEMIS • SWIA Digital board nearly same as STATIC prototype PFP IPDR 2010/6/14 -16 22

Lessons Learned • NASA Lessons Learned – Numerous lessons, but some recurring highlights • Test in an “as flown” configuration • Watch out for ESD • Careful parts selection and proper installation is crucial – Another lesson: LLIS database is only accessible ~50% of the time, and not when you want to look at it! • SSL Lessons Learned – Build modularly • Make sure it’s easy to assemble/disassemble and test components separately – Test how you fly • Make sure GSE/ground software works the same as DPU/flight software – Heritage designs usually had a good reason for their choices • We have returned to FAST/THEMIS designs for many components PFP IPDR 2010/6/14 -16 23

Lessons Learned • NASA Lessons Learned – Numerous lessons, but some recurring highlights • Test in an “as flown” configuration • Watch out for ESD • Careful parts selection and proper installation is crucial – Another lesson: LLIS database is only accessible ~50% of the time, and not when you want to look at it! • SSL Lessons Learned – Build modularly • Make sure it’s easy to assemble/disassemble and test components separately – Test how you fly • Make sure GSE/ground software works the same as DPU/flight software – Heritage designs usually had a good reason for their choices • We have returned to FAST/THEMIS designs for many components PFP IPDR 2010/6/14 -16 23

SWIA Accommodations • SWIA sensor mounted on the sun-facing deck – Provides a clear FOV in the sunward direction – Mounted such that the 360 x 90° FOV is mostly clear, and oriented to provide good velocity measurements in the sheath – Nominally thermally isolated from the deck • Power, Commands, and Telemetry via PFDPU – Attenuator controlled by PFDPU – Voltage sweep controlled by PFDPU – Data processing via PFDPU • Two redundant spacecraft-monitored temp sensors and heater wires • Spacecraft-powered redundant 1 -time non-explosive actuator for top cap cover (contamination control) • Purge Connection PFP IPDR 2010/6/14 -16 24

SWIA Accommodations • SWIA sensor mounted on the sun-facing deck – Provides a clear FOV in the sunward direction – Mounted such that the 360 x 90° FOV is mostly clear, and oriented to provide good velocity measurements in the sheath – Nominally thermally isolated from the deck • Power, Commands, and Telemetry via PFDPU – Attenuator controlled by PFDPU – Voltage sweep controlled by PFDPU – Data processing via PFDPU • Two redundant spacecraft-monitored temp sensors and heater wires • Spacecraft-powered redundant 1 -time non-explosive actuator for top cap cover (contamination control) • Purge Connection PFP IPDR 2010/6/14 -16 24

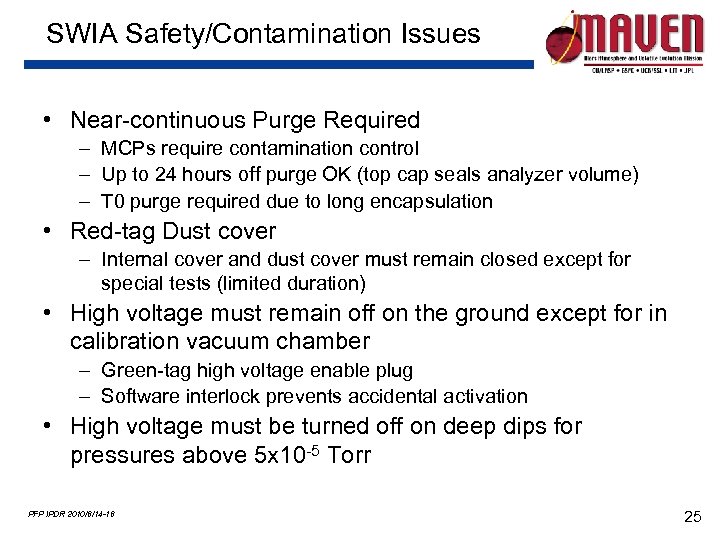

SWIA Safety/Contamination Issues • Near-continuous Purge Required – MCPs require contamination control – Up to 24 hours off purge OK (top cap seals analyzer volume) – T 0 purge required due to long encapsulation • Red-tag Dust cover – Internal cover and dust cover must remain closed except for special tests (limited duration) • High voltage must remain off on the ground except for in calibration vacuum chamber – Green-tag high voltage enable plug – Software interlock prevents accidental activation • High voltage must be turned off on deep dips for pressures above 5 x 10 -5 Torr PFP IPDR 2010/6/14 -16 25

SWIA Safety/Contamination Issues • Near-continuous Purge Required – MCPs require contamination control – Up to 24 hours off purge OK (top cap seals analyzer volume) – T 0 purge required due to long encapsulation • Red-tag Dust cover – Internal cover and dust cover must remain closed except for special tests (limited duration) • High voltage must remain off on the ground except for in calibration vacuum chamber – Green-tag high voltage enable plug – Software interlock prevents accidental activation • High voltage must be turned off on deep dips for pressures above 5 x 10 -5 Torr PFP IPDR 2010/6/14 -16 25

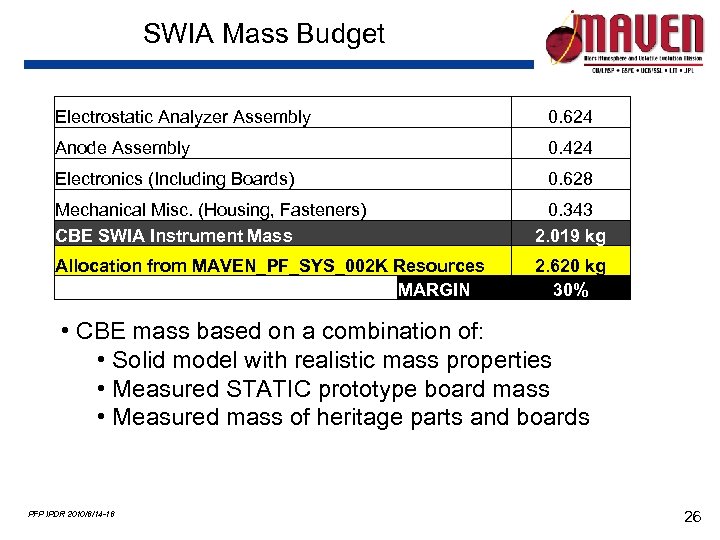

SWIA Mass Budget Electrostatic Analyzer Assembly 0. 624 Anode Assembly 0. 424 Electronics (Including Boards) 0. 628 Mechanical Misc. (Housing, Fasteners) CBE SWIA Instrument Mass 0. 343 2. 019 kg Allocation from MAVEN_PF_SYS_002 K Resources MARGIN 2. 620 kg 30% • CBE mass based on a combination of: • Solid model with realistic mass properties • Measured STATIC prototype board mass • Measured mass of heritage parts and boards PFP IPDR 2010/6/14 -16 26

SWIA Mass Budget Electrostatic Analyzer Assembly 0. 624 Anode Assembly 0. 424 Electronics (Including Boards) 0. 628 Mechanical Misc. (Housing, Fasteners) CBE SWIA Instrument Mass 0. 343 2. 019 kg Allocation from MAVEN_PF_SYS_002 K Resources MARGIN 2. 620 kg 30% • CBE mass based on a combination of: • Solid model with realistic mass properties • Measured STATIC prototype board mass • Measured mass of heritage parts and boards PFP IPDR 2010/6/14 -16 26

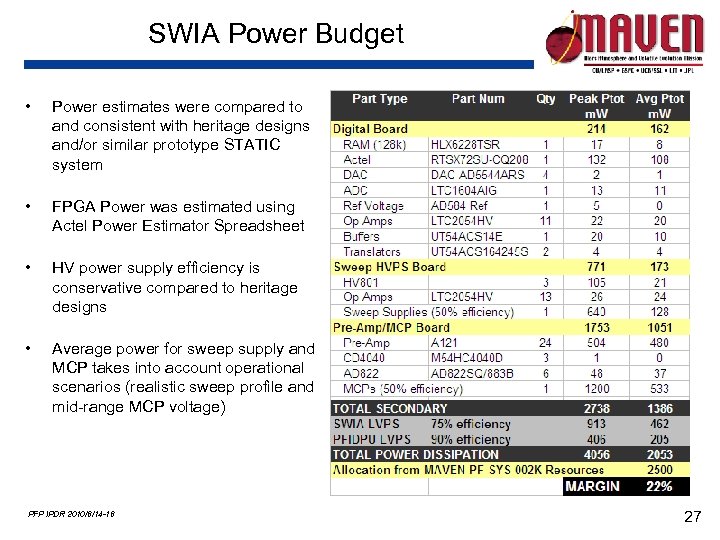

SWIA Power Budget • Power estimates were compared to and consistent with heritage designs and/or similar prototype STATIC system • FPGA Power was estimated using Actel Power Estimator Spreadsheet • HV power supply efficiency is conservative compared to heritage designs • Average power for sweep supply and MCP takes into account operational scenarios (realistic sweep profile and mid-range MCP voltage) PFP IPDR 2010/6/14 -16 27

SWIA Power Budget • Power estimates were compared to and consistent with heritage designs and/or similar prototype STATIC system • FPGA Power was estimated using Actel Power Estimator Spreadsheet • HV power supply efficiency is conservative compared to heritage designs • Average power for sweep supply and MCP takes into account operational scenarios (realistic sweep profile and mid-range MCP voltage) PFP IPDR 2010/6/14 -16 27

IV. SWIA Optics Design Status A. Overview B. Attenuator C. Deflectors D. Calibration/Testing E. RFA Closeout PFP IPDR 2010/6/14 -16 28

IV. SWIA Optics Design Status A. Overview B. Attenuator C. Deflectors D. Calibration/Testing E. RFA Closeout PFP IPDR 2010/6/14 -16 28

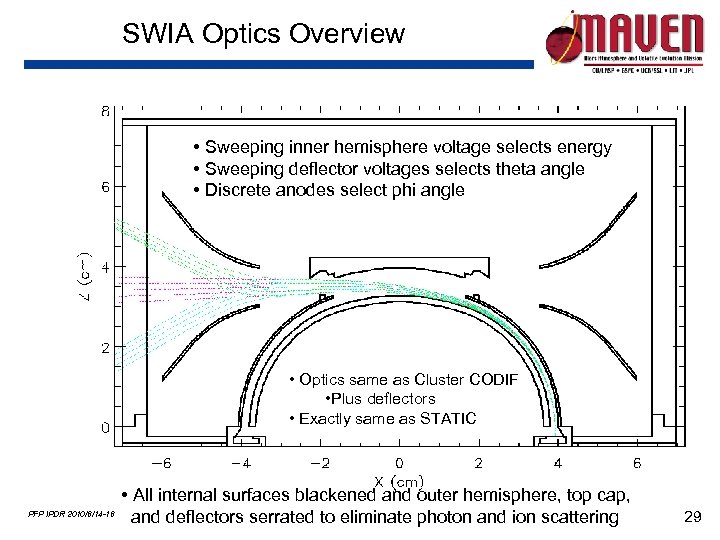

SWIA Optics Overview • Sweeping inner hemisphere voltage selects energy • Sweeping deflector voltages selects theta angle • Discrete anodes select phi angle • Optics same as Cluster CODIF • Plus deflectors • Exactly same as STATIC PFP IPDR 2010/6/14 -16 • All internal surfaces blackened and outer hemisphere, top cap, and deflectors serrated to eliminate photon and ion scattering 29

SWIA Optics Overview • Sweeping inner hemisphere voltage selects energy • Sweeping deflector voltages selects theta angle • Discrete anodes select phi angle • Optics same as Cluster CODIF • Plus deflectors • Exactly same as STATIC PFP IPDR 2010/6/14 -16 • All internal surfaces blackened and outer hemisphere, top cap, and deflectors serrated to eliminate photon and ion scattering 29

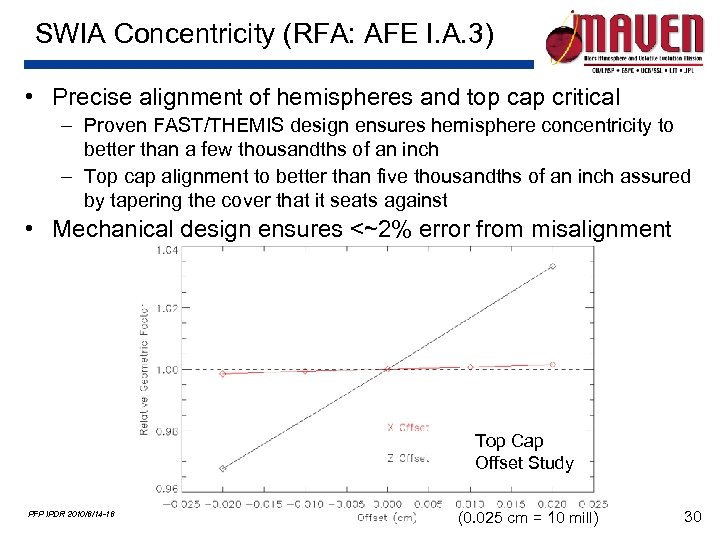

SWIA Concentricity (RFA: AFE I. A. 3) • Precise alignment of hemispheres and top cap critical – Proven FAST/THEMIS design ensures hemisphere concentricity to better than a few thousandths of an inch – Top cap alignment to better than five thousandths of an inch assured by tapering the cover that it seats against • Mechanical design ensures <~2% error from misalignment Top Cap Offset Study PFP IPDR 2010/6/14 -16 (0. 025 cm = 10 mill) 30

SWIA Concentricity (RFA: AFE I. A. 3) • Precise alignment of hemispheres and top cap critical – Proven FAST/THEMIS design ensures hemisphere concentricity to better than a few thousandths of an inch – Top cap alignment to better than five thousandths of an inch assured by tapering the cover that it seats against • Mechanical design ensures <~2% error from misalignment Top Cap Offset Study PFP IPDR 2010/6/14 -16 (0. 025 cm = 10 mill) 30

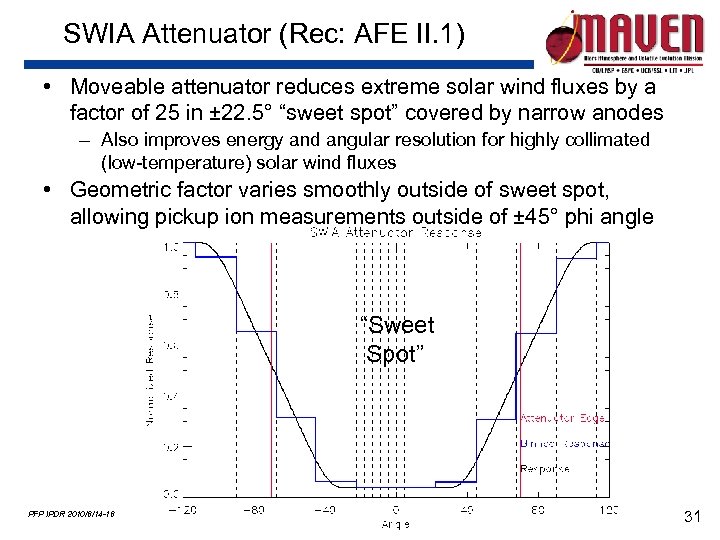

SWIA Attenuator (Rec: AFE II. 1) • Moveable attenuator reduces extreme solar wind fluxes by a factor of 25 in ± 22. 5° “sweet spot” covered by narrow anodes – Also improves energy and angular resolution for highly collimated (low-temperature) solar wind fluxes • Geometric factor varies smoothly outside of sweet spot, allowing pickup ion measurements outside of ± 45° phi angle “Sweet Spot” PFP IPDR 2010/6/14 -16 31

SWIA Attenuator (Rec: AFE II. 1) • Moveable attenuator reduces extreme solar wind fluxes by a factor of 25 in ± 22. 5° “sweet spot” covered by narrow anodes – Also improves energy and angular resolution for highly collimated (low-temperature) solar wind fluxes • Geometric factor varies smoothly outside of sweet spot, allowing pickup ion measurements outside of ± 45° phi angle “Sweet Spot” PFP IPDR 2010/6/14 -16 31

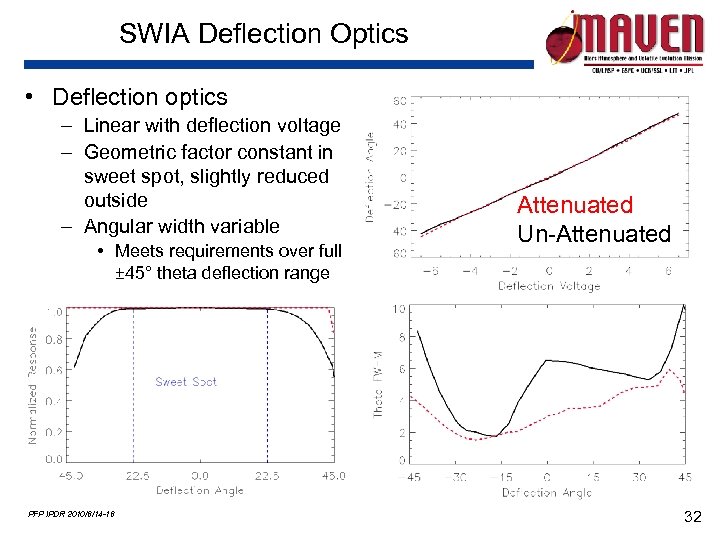

SWIA Deflection Optics • Deflection optics – Linear with deflection voltage – Geometric factor constant in sweet spot, slightly reduced outside – Angular width variable • Meets requirements over full ± 45° theta deflection range PFP IPDR 2010/6/14 -16 Attenuated Un-Attenuated 32

SWIA Deflection Optics • Deflection optics – Linear with deflection voltage – Geometric factor constant in sweet spot, slightly reduced outside – Angular width variable • Meets requirements over full ± 45° theta deflection range PFP IPDR 2010/6/14 -16 Attenuated Un-Attenuated 32

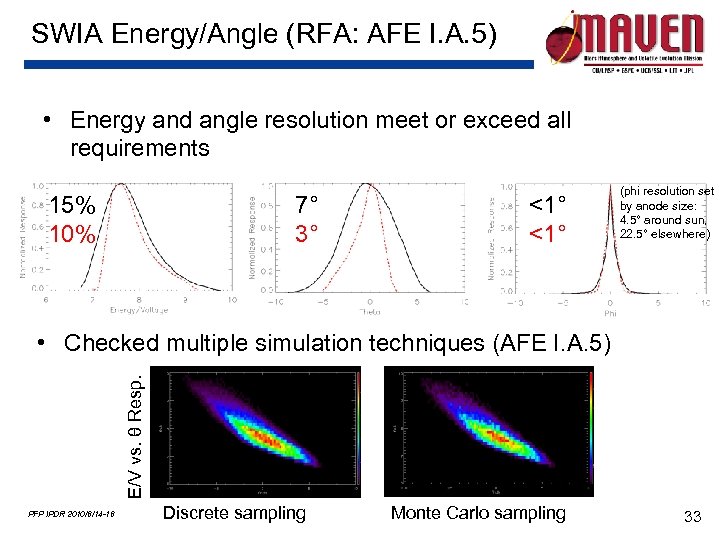

SWIA Energy/Angle (RFA: AFE I. A. 5) • Energy and angle resolution meet or exceed all requirements 15% 10% 7° 3° <1° (phi resolution set by anode size: 4. 5° around sun, 22. 5° elsewhere) E/V vs. θ Resp. • Checked multiple simulation techniques (AFE I. A. 5) PFP IPDR 2010/6/14 -16 Discrete sampling Monte Carlo sampling 33

SWIA Energy/Angle (RFA: AFE I. A. 5) • Energy and angle resolution meet or exceed all requirements 15% 10% 7° 3° <1° (phi resolution set by anode size: 4. 5° around sun, 22. 5° elsewhere) E/V vs. θ Resp. • Checked multiple simulation techniques (AFE I. A. 5) PFP IPDR 2010/6/14 -16 Discrete sampling Monte Carlo sampling 33

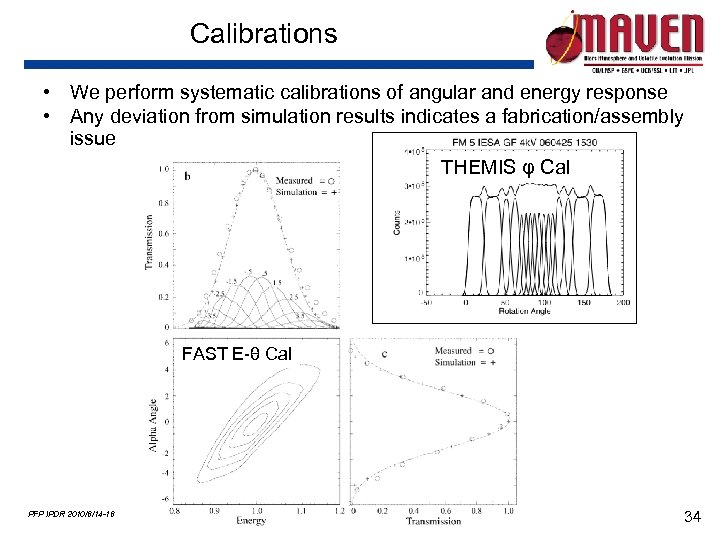

Calibrations • We perform systematic calibrations of angular and energy response • Any deviation from simulation results indicates a fabrication/assembly issue THEMIS φ Cal FAST E-θ Cal PFP IPDR 2010/6/14 -16 34

Calibrations • We perform systematic calibrations of angular and energy response • Any deviation from simulation results indicates a fabrication/assembly issue THEMIS φ Cal FAST E-θ Cal PFP IPDR 2010/6/14 -16 34

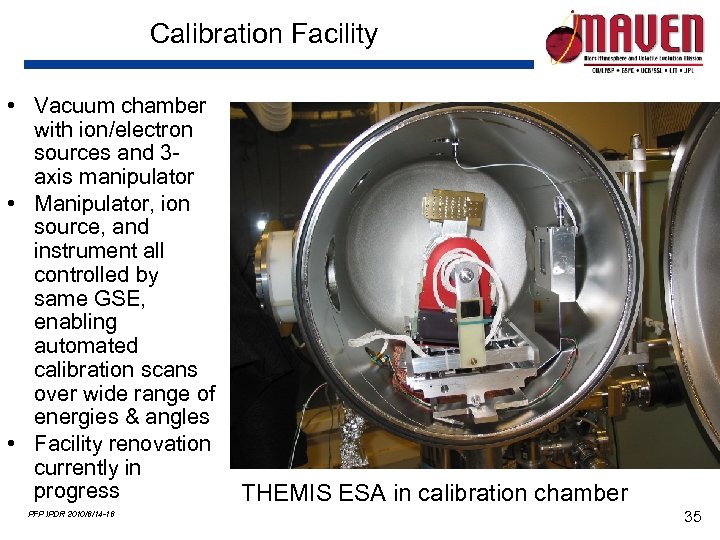

Calibration Facility • Vacuum chamber with ion/electron sources and 3 axis manipulator • Manipulator, ion source, and instrument all controlled by same GSE, enabling automated calibration scans over wide range of energies & angles • Facility renovation currently in progress THEMIS ESA in calibration chamber PFP IPDR 2010/6/14 -16 35

Calibration Facility • Vacuum chamber with ion/electron sources and 3 axis manipulator • Manipulator, ion source, and instrument all controlled by same GSE, enabling automated calibration scans over wide range of energies & angles • Facility renovation currently in progress THEMIS ESA in calibration chamber PFP IPDR 2010/6/14 -16 35

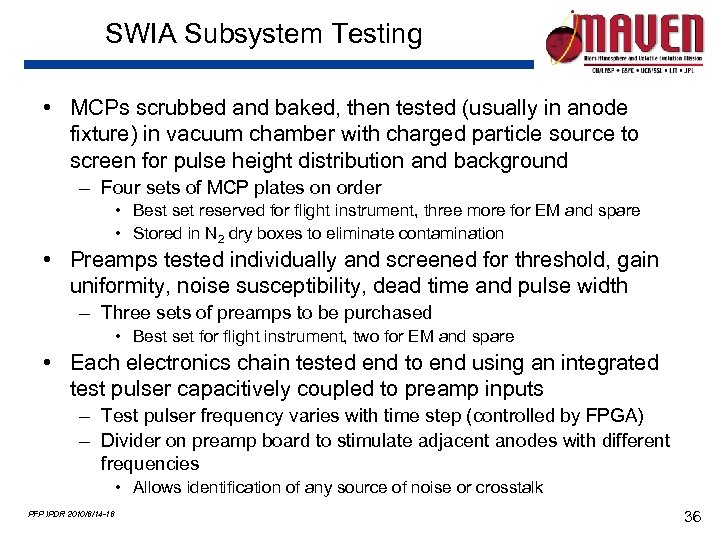

SWIA Subsystem Testing • MCPs scrubbed and baked, then tested (usually in anode fixture) in vacuum chamber with charged particle source to screen for pulse height distribution and background – Four sets of MCP plates on order • Best set reserved for flight instrument, three more for EM and spare • Stored in N 2 dry boxes to eliminate contamination • Preamps tested individually and screened for threshold, gain uniformity, noise susceptibility, dead time and pulse width – Three sets of preamps to be purchased • Best set for flight instrument, two for EM and spare • Each electronics chain tested end to end using an integrated test pulser capacitively coupled to preamp inputs – Test pulser frequency varies with time step (controlled by FPGA) – Divider on preamp board to stimulate adjacent anodes with different frequencies • Allows identification of any source of noise or crosstalk PFP IPDR 2010/6/14 -16 36

SWIA Subsystem Testing • MCPs scrubbed and baked, then tested (usually in anode fixture) in vacuum chamber with charged particle source to screen for pulse height distribution and background – Four sets of MCP plates on order • Best set reserved for flight instrument, three more for EM and spare • Stored in N 2 dry boxes to eliminate contamination • Preamps tested individually and screened for threshold, gain uniformity, noise susceptibility, dead time and pulse width – Three sets of preamps to be purchased • Best set for flight instrument, two for EM and spare • Each electronics chain tested end to end using an integrated test pulser capacitively coupled to preamp inputs – Test pulser frequency varies with time step (controlled by FPGA) – Divider on preamp board to stimulate adjacent anodes with different frequencies • Allows identification of any source of noise or crosstalk PFP IPDR 2010/6/14 -16 36

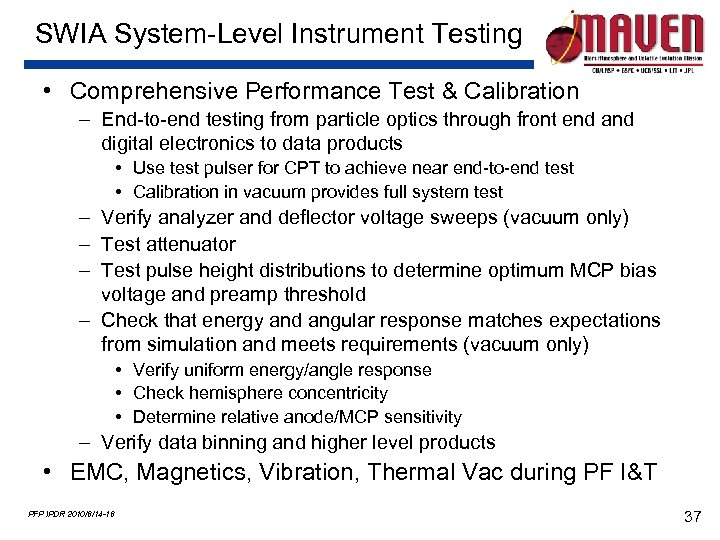

SWIA System-Level Instrument Testing • Comprehensive Performance Test & Calibration – End-to-end testing from particle optics through front end and digital electronics to data products • Use test pulser for CPT to achieve near end-to-end test • Calibration in vacuum provides full system test – Verify analyzer and deflector voltage sweeps (vacuum only) – Test attenuator – Test pulse height distributions to determine optimum MCP bias voltage and preamp threshold – Check that energy and angular response matches expectations from simulation and meets requirements (vacuum only) • Verify uniform energy/angle response • Check hemisphere concentricity • Determine relative anode/MCP sensitivity – Verify data binning and higher level products • EMC, Magnetics, Vibration, Thermal Vac during PF I&T PFP IPDR 2010/6/14 -16 37

SWIA System-Level Instrument Testing • Comprehensive Performance Test & Calibration – End-to-end testing from particle optics through front end and digital electronics to data products • Use test pulser for CPT to achieve near end-to-end test • Calibration in vacuum provides full system test – Verify analyzer and deflector voltage sweeps (vacuum only) – Test attenuator – Test pulse height distributions to determine optimum MCP bias voltage and preamp threshold – Check that energy and angular response matches expectations from simulation and meets requirements (vacuum only) • Verify uniform energy/angle response • Check hemisphere concentricity • Determine relative anode/MCP sensitivity – Verify data binning and higher level products • EMC, Magnetics, Vibration, Thermal Vac during PF I&T PFP IPDR 2010/6/14 -16 37

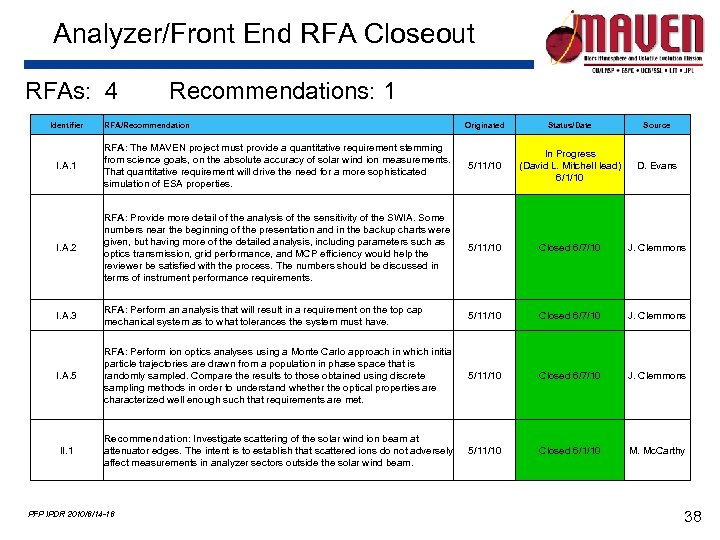

Analyzer/Front End RFA Closeout RFAs: 4 Identifier Recommendations: 1 RFA/Recommendation Originated Status/Date Source I. A. 1 RFA: The MAVEN project must provide a quantitative requirement stemming from science goals, on the absolute accuracy of solar wind ion measurements. That quantitative requirement will drive the need for a more sophisticated simulation of ESA properties. 5/11/10 In Progress (David L. Mitchell lead) 6/1/10 D. Evans I. A. 2 RFA: Provide more detail of the analysis of the sensitivity of the SWIA. Some numbers near the beginning of the presentation and in the backup charts were given, but having more of the detailed analysis, including parameters such as optics transmission, grid performance, and MCP efficiency would help the reviewer be satisfied with the process. The numbers should be discussed in terms of instrument performance requirements. 5/11/10 Closed 6/7/10 J. Clemmons I. A. 3 RFA: Perform an analysis that will result in a requirement on the top cap mechanical system as to what tolerances the system must have. 5/11/10 Closed 6/7/10 J. Clemmons I. A. 5 RFA: Perform ion optics analyses using a Monte Carlo approach in which initial particle trajectories are drawn from a population in phase space that is randomly sampled. Compare the results to those obtained using discrete sampling methods in order to understand whether the optical properties are characterized well enough such that requirements are met. 5/11/10 Closed 6/7/10 J. Clemmons II. 1 Recommendation: Investigate scattering of the solar wind ion beam at attenuator edges. The intent is to establish that scattered ions do not adversely affect measurements in analyzer sectors outside the solar wind beam. 5/11/10 Closed 6/1/10 M. Mc. Carthy PFP IPDR 2010/6/14 -16 38

Analyzer/Front End RFA Closeout RFAs: 4 Identifier Recommendations: 1 RFA/Recommendation Originated Status/Date Source I. A. 1 RFA: The MAVEN project must provide a quantitative requirement stemming from science goals, on the absolute accuracy of solar wind ion measurements. That quantitative requirement will drive the need for a more sophisticated simulation of ESA properties. 5/11/10 In Progress (David L. Mitchell lead) 6/1/10 D. Evans I. A. 2 RFA: Provide more detail of the analysis of the sensitivity of the SWIA. Some numbers near the beginning of the presentation and in the backup charts were given, but having more of the detailed analysis, including parameters such as optics transmission, grid performance, and MCP efficiency would help the reviewer be satisfied with the process. The numbers should be discussed in terms of instrument performance requirements. 5/11/10 Closed 6/7/10 J. Clemmons I. A. 3 RFA: Perform an analysis that will result in a requirement on the top cap mechanical system as to what tolerances the system must have. 5/11/10 Closed 6/7/10 J. Clemmons I. A. 5 RFA: Perform ion optics analyses using a Monte Carlo approach in which initial particle trajectories are drawn from a population in phase space that is randomly sampled. Compare the results to those obtained using discrete sampling methods in order to understand whether the optical properties are characterized well enough such that requirements are met. 5/11/10 Closed 6/7/10 J. Clemmons II. 1 Recommendation: Investigate scattering of the solar wind ion beam at attenuator edges. The intent is to establish that scattered ions do not adversely affect measurements in analyzer sectors outside the solar wind beam. 5/11/10 Closed 6/1/10 M. Mc. Carthy PFP IPDR 2010/6/14 -16 38

IV. Mechanical Design Status A. Overview B. Materials/Construction C. Mechanical Details D. Analysis E. RFA Closeout PFP IPDR 2010/6/14 -16 39

IV. Mechanical Design Status A. Overview B. Materials/Construction C. Mechanical Details D. Analysis E. RFA Closeout PFP IPDR 2010/6/14 -16 39

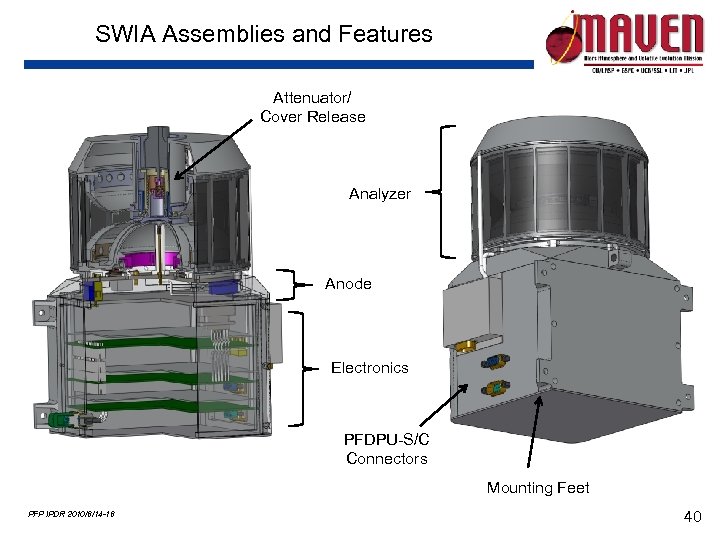

SWIA Assemblies and Features Attenuator/ Cover Release Analyzer Anode Electronics PFDPU-S/C Connectors Mounting Feet PFP IPDR 2010/6/14 -16 40

SWIA Assemblies and Features Attenuator/ Cover Release Analyzer Anode Electronics PFDPU-S/C Connectors Mounting Feet PFP IPDR 2010/6/14 -16 40

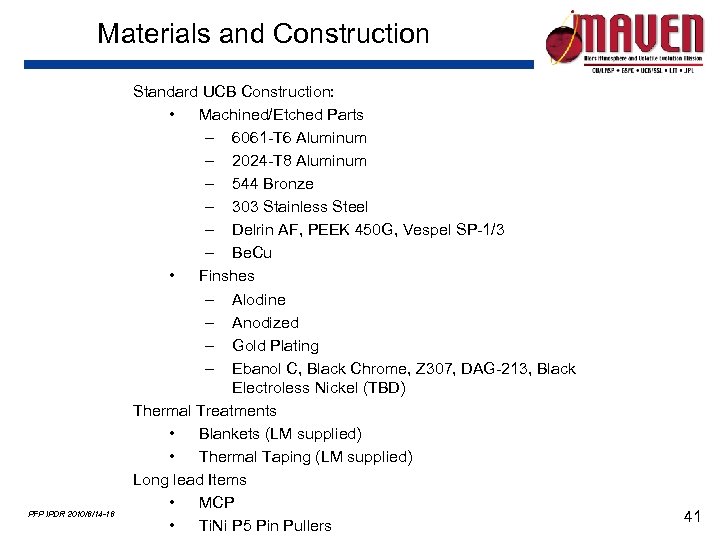

Materials and Construction PFP IPDR 2010/6/14 -16 Standard UCB Construction: • Machined/Etched Parts – 6061 -T 6 Aluminum – 2024 -T 8 Aluminum – 544 Bronze – 303 Stainless Steel – Delrin AF, PEEK 450 G, Vespel SP-1/3 – Be. Cu • Finshes – Alodine – Anodized – Gold Plating – Ebanol C, Black Chrome, Z 307, DAG-213, Black Electroless Nickel (TBD) Thermal Treatments • Blankets (LM supplied) • Thermal Taping (LM supplied) Long lead Items • MCP • Ti. Ni P 5 Pin Pullers 41

Materials and Construction PFP IPDR 2010/6/14 -16 Standard UCB Construction: • Machined/Etched Parts – 6061 -T 6 Aluminum – 2024 -T 8 Aluminum – 544 Bronze – 303 Stainless Steel – Delrin AF, PEEK 450 G, Vespel SP-1/3 – Be. Cu • Finshes – Alodine – Anodized – Gold Plating – Ebanol C, Black Chrome, Z 307, DAG-213, Black Electroless Nickel (TBD) Thermal Treatments • Blankets (LM supplied) • Thermal Taping (LM supplied) Long lead Items • MCP • Ti. Ni P 5 Pin Pullers 41

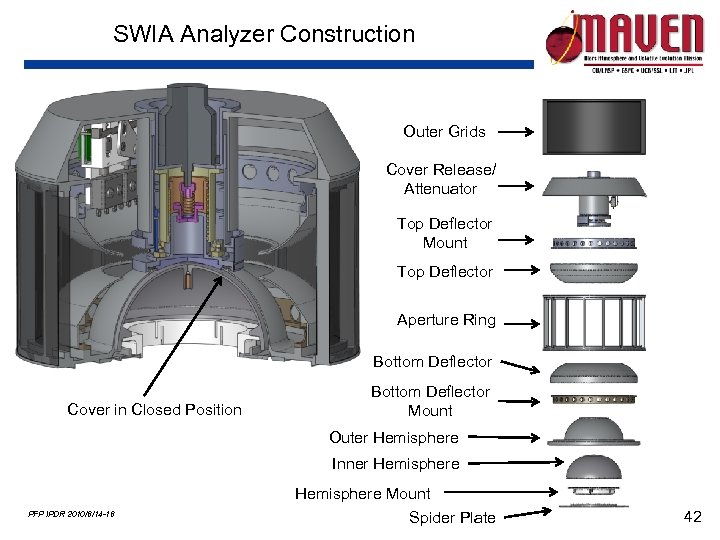

SWIA Analyzer Construction Outer Grids Cover Release/ Attenuator Top Deflector Mount Top Deflector Aperture Ring Bottom Deflector Cover in Closed Position Bottom Deflector Mount Outer Hemisphere Inner Hemisphere PFP IPDR 2010/6/14 -16 Hemisphere Mount Spider Plate 42

SWIA Analyzer Construction Outer Grids Cover Release/ Attenuator Top Deflector Mount Top Deflector Aperture Ring Bottom Deflector Cover in Closed Position Bottom Deflector Mount Outer Hemisphere Inner Hemisphere PFP IPDR 2010/6/14 -16 Hemisphere Mount Spider Plate 42

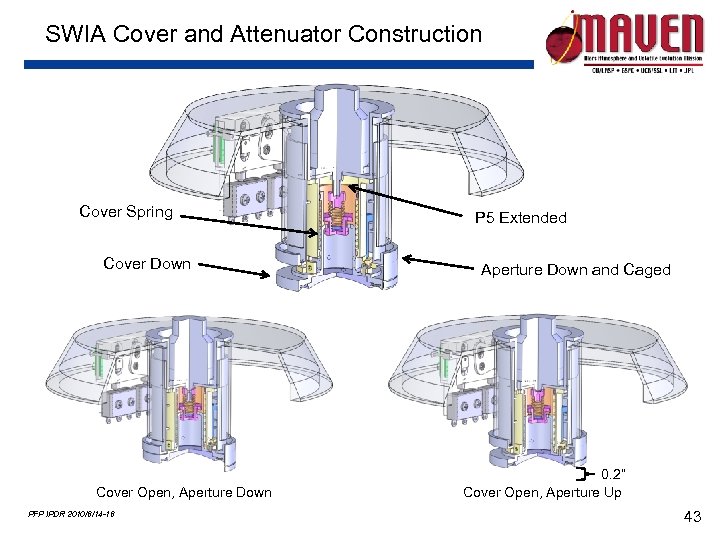

SWIA Cover and Attenuator Construction Cover Spring Cover Down Cover Open, Aperture Down PFP IPDR 2010/6/14 -16 P 5 Extended Aperture Down and Caged 0. 2” Cover Open, Aperture Up 43

SWIA Cover and Attenuator Construction Cover Spring Cover Down Cover Open, Aperture Down PFP IPDR 2010/6/14 -16 P 5 Extended Aperture Down and Caged 0. 2” Cover Open, Aperture Up 43

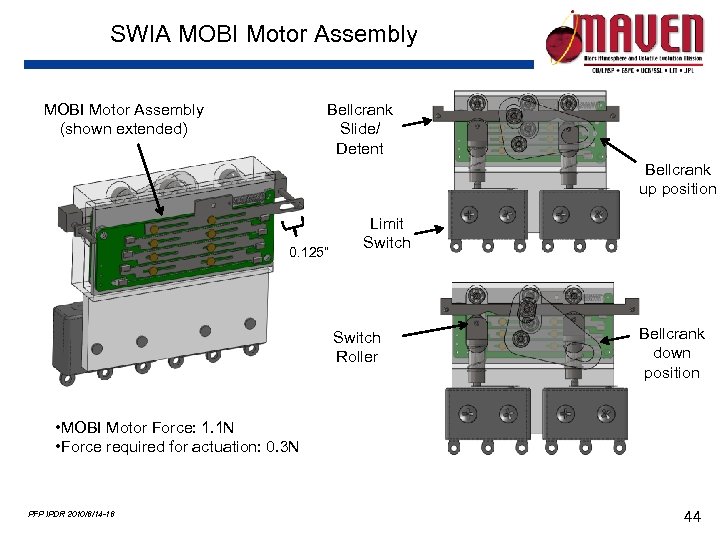

SWIA MOBI Motor Assembly (shown extended) Bellcrank Slide/ Detent Bellcrank up position 0. 125” Limit Switch Roller Bellcrank down position • MOBI Motor Force: 1. 1 N • Force required for actuation: 0. 3 N PFP IPDR 2010/6/14 -16 44

SWIA MOBI Motor Assembly (shown extended) Bellcrank Slide/ Detent Bellcrank up position 0. 125” Limit Switch Roller Bellcrank down position • MOBI Motor Force: 1. 1 N • Force required for actuation: 0. 3 N PFP IPDR 2010/6/14 -16 44

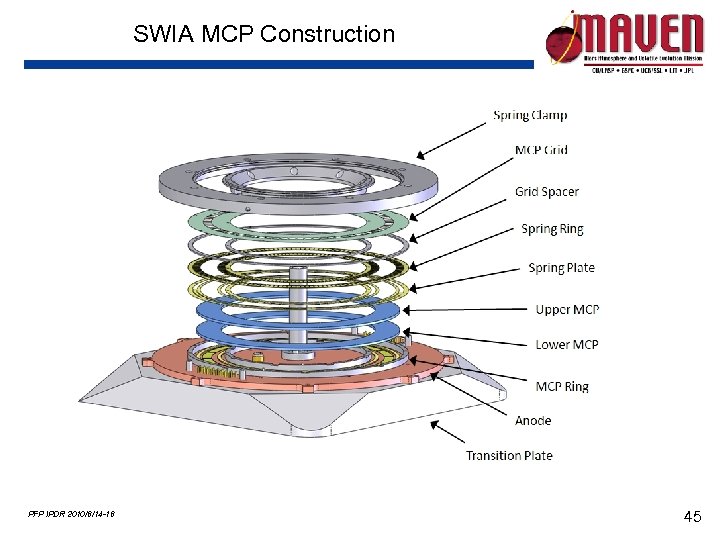

SWIA MCP Construction PFP IPDR 2010/6/14 -16 45

SWIA MCP Construction PFP IPDR 2010/6/14 -16 45

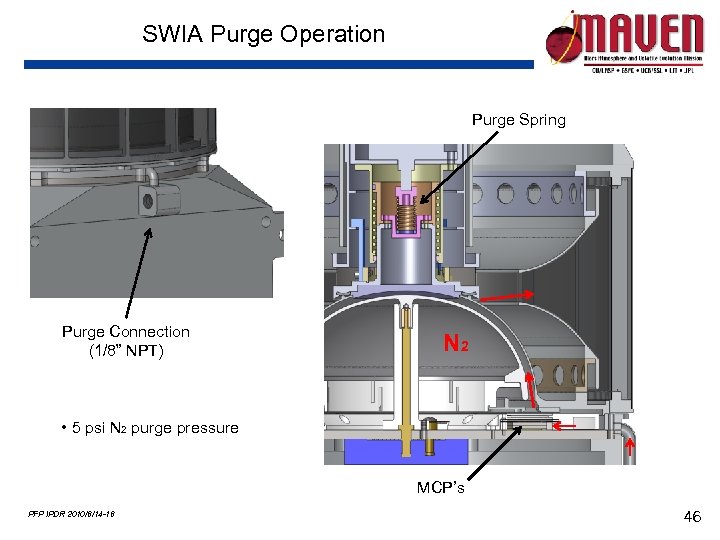

SWIA Purge Operation Purge Spring Purge Connection (1/8” NPT) N 2 • 5 psi N 2 purge pressure MCP’s PFP IPDR 2010/6/14 -16 46

SWIA Purge Operation Purge Spring Purge Connection (1/8” NPT) N 2 • 5 psi N 2 purge pressure MCP’s PFP IPDR 2010/6/14 -16 46

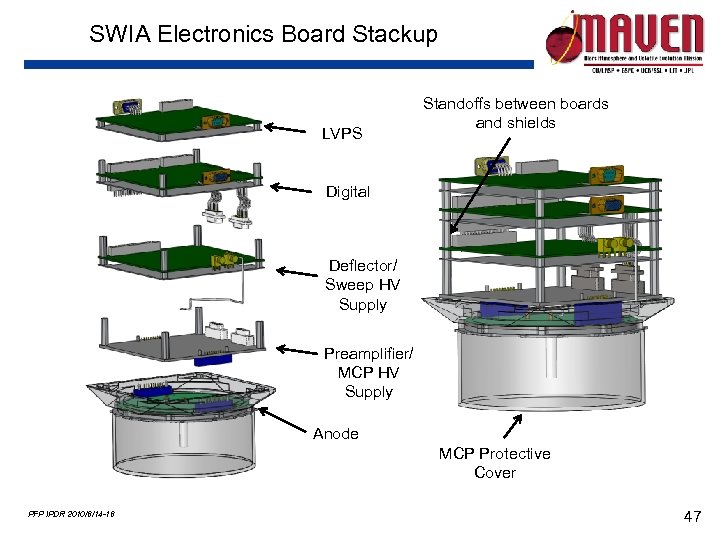

SWIA Electronics Board Stackup LVPS Standoffs between boards and shields Digital Deflector/ Sweep HV Supply Preamplifier/ MCP HV Supply Anode MCP Protective Cover PFP IPDR 2010/6/14 -16 47

SWIA Electronics Board Stackup LVPS Standoffs between boards and shields Digital Deflector/ Sweep HV Supply Preamplifier/ MCP HV Supply Anode MCP Protective Cover PFP IPDR 2010/6/14 -16 47

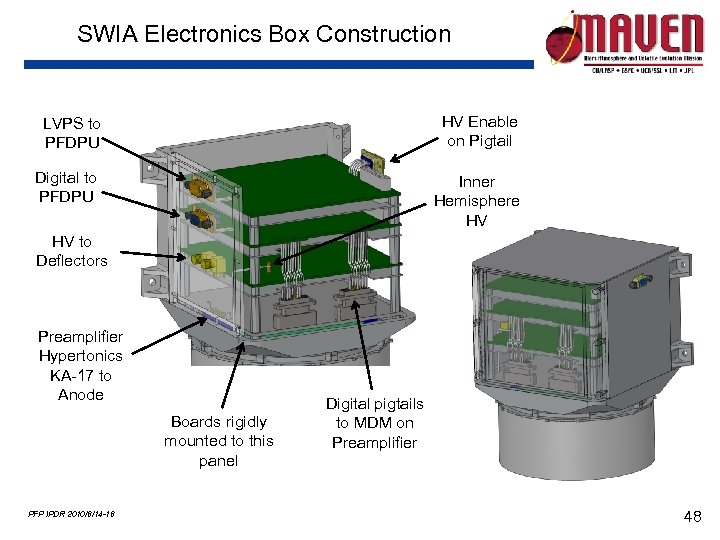

SWIA Electronics Box Construction LVPS to PFDPU HV Enable on Pigtail Digital to PFDPU Inner Hemisphere HV HV to Deflectors Preamplifier Hypertonics KA-17 to Anode Boards rigidly mounted to this panel PFP IPDR 2010/6/14 -16 Digital pigtails to MDM on Preamplifier 48

SWIA Electronics Box Construction LVPS to PFDPU HV Enable on Pigtail Digital to PFDPU Inner Hemisphere HV HV to Deflectors Preamplifier Hypertonics KA-17 to Anode Boards rigidly mounted to this panel PFP IPDR 2010/6/14 -16 Digital pigtails to MDM on Preamplifier 48

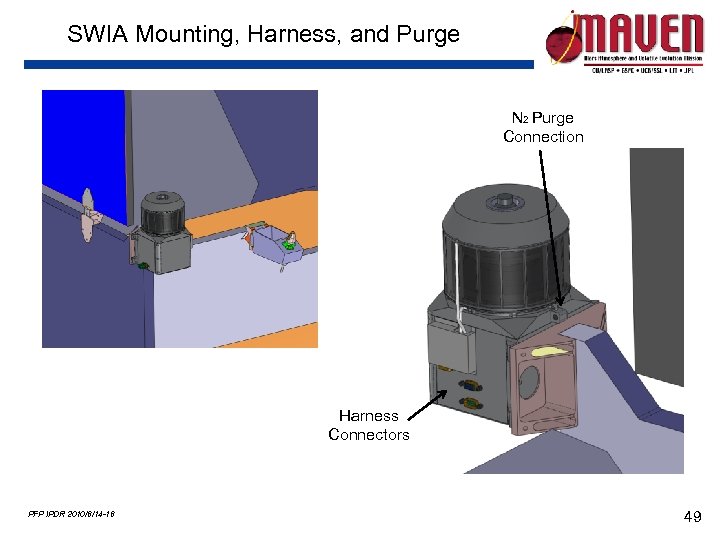

SWIA Mounting, Harness, and Purge N 2 Purge Connection Harness Connectors PFP IPDR 2010/6/14 -16 49

SWIA Mounting, Harness, and Purge N 2 Purge Connection Harness Connectors PFP IPDR 2010/6/14 -16 49

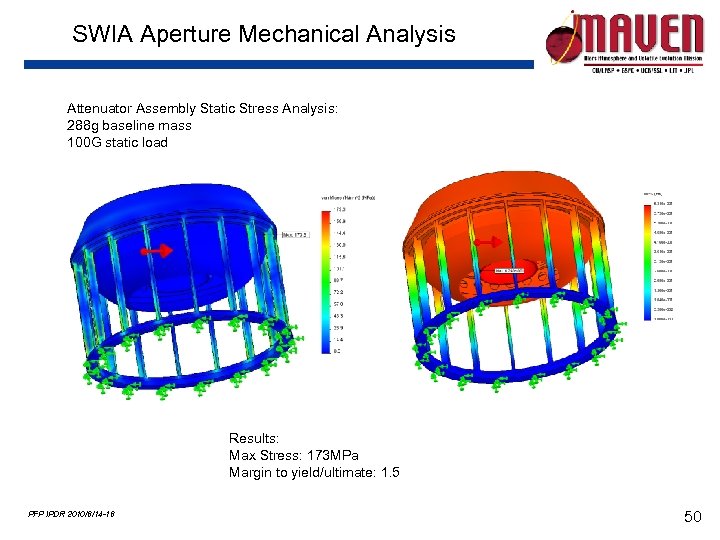

SWIA Aperture Mechanical Analysis Attenuator Assembly Static Stress Analysis: 288 g baseline mass 100 G static load Results: Max Stress: 173 MPa Margin to yield/ultimate: 1. 5 PFP IPDR 2010/6/14 -16 50

SWIA Aperture Mechanical Analysis Attenuator Assembly Static Stress Analysis: 288 g baseline mass 100 G static load Results: Max Stress: 173 MPa Margin to yield/ultimate: 1. 5 PFP IPDR 2010/6/14 -16 50

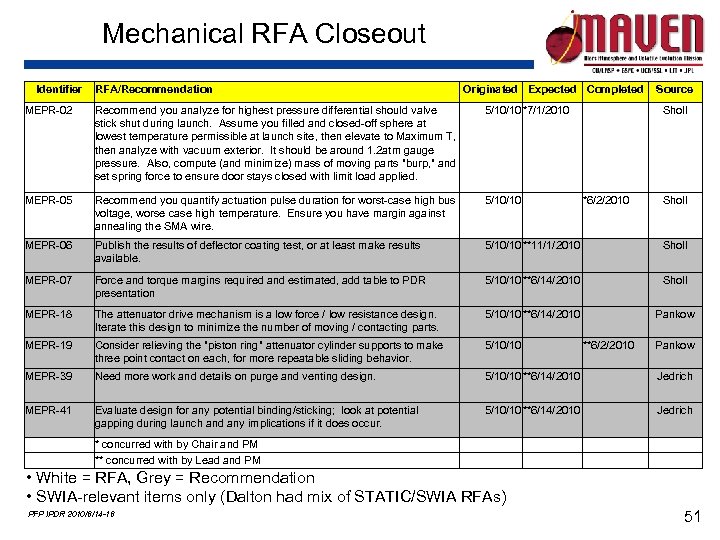

Mechanical RFA Closeout Identifier RFA/Recommendation Originated Expected Completed Source MEPR-02 Recommend you analyze for highest pressure differential should valve stick shut during launch. Assume you filled and closed-off sphere at lowest temperature permissible at launch site, then elevate to Maximum T, then analyze with vacuum exterior. It should be around 1. 2 atm gauge pressure. Also, compute (and minimize) mass of moving parts "burp, " and set spring force to ensure door stays closed with limit load applied. 5/10/10*7/1/2010 Sholl MEPR-05 Recommend you quantify actuation pulse duration for worst-case high bus voltage, worse case high temperature. Ensure you have margin against annealing the SMA wire. 5/10/10 *6/2/2010 Sholl MEPR-06 Publish the results of deflector coating test, or at least make results available. 5/10/10**11/1/2010 Sholl MEPR-07 Force and torque margins required and estimated, add table to PDR presentation 5/10/10**6/14/2010 Sholl MEPR-18 The attenuator drive mechanism is a low force / low resistance design. Iterate this design to minimize the number of moving / contacting parts. 5/10/10**6/14/2010 Pankow MEPR-19 Consider relieving the "piston ring" attenuator cylinder supports to make three point contact on each, for more repeatable sliding behavior. 5/10/10 Pankow MEPR-39 Need more work and details on purge and venting design. 5/10/10**6/14/2010 Jedrich MEPR-41 Evaluate design for any potential binding/sticking; look at potential gapping during launch and any implications if it does occur. 5/10/10**6/14/2010 Jedrich * concurred with by Chair and PM ** concurred with by Lead and PM **6/2/2010 • White = RFA, Grey = Recommendation • SWIA-relevant items only (Dalton had mix of STATIC/SWIA RFAs) PFP IPDR 2010/6/14 -16 51

Mechanical RFA Closeout Identifier RFA/Recommendation Originated Expected Completed Source MEPR-02 Recommend you analyze for highest pressure differential should valve stick shut during launch. Assume you filled and closed-off sphere at lowest temperature permissible at launch site, then elevate to Maximum T, then analyze with vacuum exterior. It should be around 1. 2 atm gauge pressure. Also, compute (and minimize) mass of moving parts "burp, " and set spring force to ensure door stays closed with limit load applied. 5/10/10*7/1/2010 Sholl MEPR-05 Recommend you quantify actuation pulse duration for worst-case high bus voltage, worse case high temperature. Ensure you have margin against annealing the SMA wire. 5/10/10 *6/2/2010 Sholl MEPR-06 Publish the results of deflector coating test, or at least make results available. 5/10/10**11/1/2010 Sholl MEPR-07 Force and torque margins required and estimated, add table to PDR presentation 5/10/10**6/14/2010 Sholl MEPR-18 The attenuator drive mechanism is a low force / low resistance design. Iterate this design to minimize the number of moving / contacting parts. 5/10/10**6/14/2010 Pankow MEPR-19 Consider relieving the "piston ring" attenuator cylinder supports to make three point contact on each, for more repeatable sliding behavior. 5/10/10 Pankow MEPR-39 Need more work and details on purge and venting design. 5/10/10**6/14/2010 Jedrich MEPR-41 Evaluate design for any potential binding/sticking; look at potential gapping during launch and any implications if it does occur. 5/10/10**6/14/2010 Jedrich * concurred with by Chair and PM ** concurred with by Lead and PM **6/2/2010 • White = RFA, Grey = Recommendation • SWIA-relevant items only (Dalton had mix of STATIC/SWIA RFAs) PFP IPDR 2010/6/14 -16 51

V. Electrical Design Status A. Overview B. Requirements C. Interconnect/Block Diagrams D. Subsystem Design/Layout Details E. RFA Closeout PFP IPDR 2010/6/14 -16 52

V. Electrical Design Status A. Overview B. Requirements C. Interconnect/Block Diagrams D. Subsystem Design/Layout Details E. RFA Closeout PFP IPDR 2010/6/14 -16 52

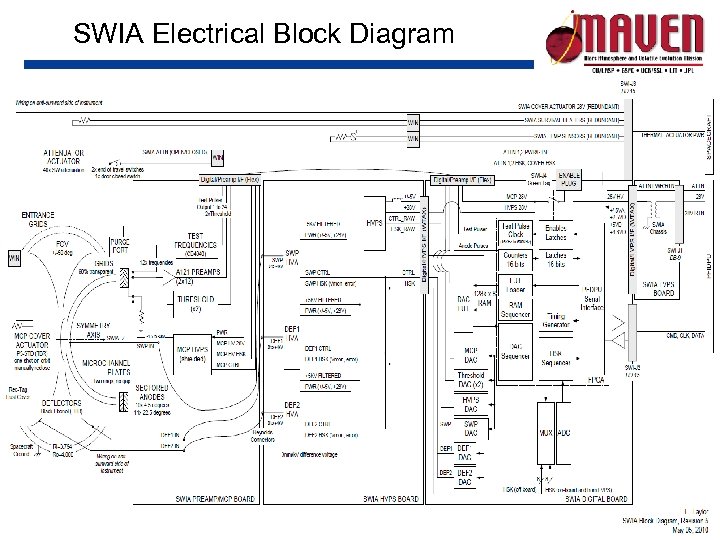

SWIA Electrical Block Diagram PFP IPDR 2010/6/14 -16 53

SWIA Electrical Block Diagram PFP IPDR 2010/6/14 -16 53

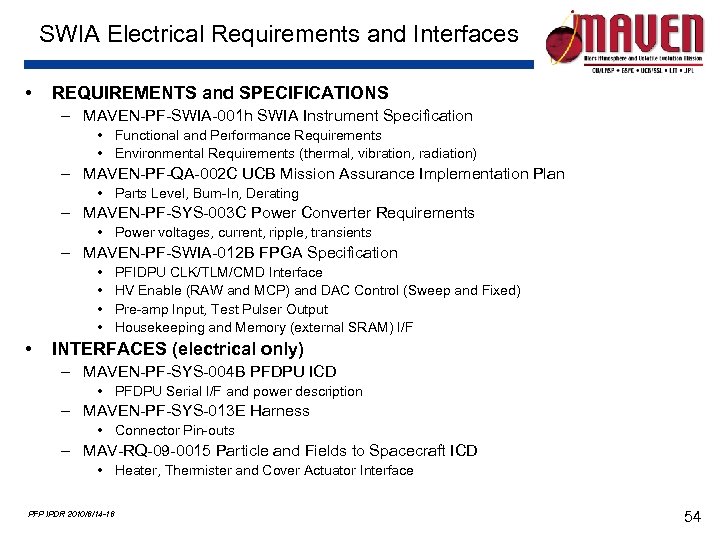

SWIA Electrical Requirements and Interfaces • REQUIREMENTS and SPECIFICATIONS – MAVEN-PF-SWIA-001 h SWIA Instrument Specification • Functional and Performance Requirements • Environmental Requirements (thermal, vibration, radiation) – MAVEN-PF-QA-002 C UCB Mission Assurance Implementation Plan • Parts Level, Burn-In, Derating – MAVEN-PF-SYS-003 C Power Converter Requirements • Power voltages, current, ripple, transients – MAVEN-PF-SWIA-012 B FPGA Specification • • • PFIDPU CLK/TLM/CMD Interface HV Enable (RAW and MCP) and DAC Control (Sweep and Fixed) Pre-amp Input, Test Pulser Output Housekeeping and Memory (external SRAM) I/F INTERFACES (electrical only) – MAVEN-PF-SYS-004 B PFDPU ICD • PFDPU Serial I/F and power description – MAVEN-PF-SYS-013 E Harness • Connector Pin-outs – MAV-RQ-09 -0015 Particle and Fields to Spacecraft ICD • Heater, Thermister and Cover Actuator Interface PFP IPDR 2010/6/14 -16 54

SWIA Electrical Requirements and Interfaces • REQUIREMENTS and SPECIFICATIONS – MAVEN-PF-SWIA-001 h SWIA Instrument Specification • Functional and Performance Requirements • Environmental Requirements (thermal, vibration, radiation) – MAVEN-PF-QA-002 C UCB Mission Assurance Implementation Plan • Parts Level, Burn-In, Derating – MAVEN-PF-SYS-003 C Power Converter Requirements • Power voltages, current, ripple, transients – MAVEN-PF-SWIA-012 B FPGA Specification • • • PFIDPU CLK/TLM/CMD Interface HV Enable (RAW and MCP) and DAC Control (Sweep and Fixed) Pre-amp Input, Test Pulser Output Housekeeping and Memory (external SRAM) I/F INTERFACES (electrical only) – MAVEN-PF-SYS-004 B PFDPU ICD • PFDPU Serial I/F and power description – MAVEN-PF-SYS-013 E Harness • Connector Pin-outs – MAV-RQ-09 -0015 Particle and Fields to Spacecraft ICD • Heater, Thermister and Cover Actuator Interface PFP IPDR 2010/6/14 -16 54

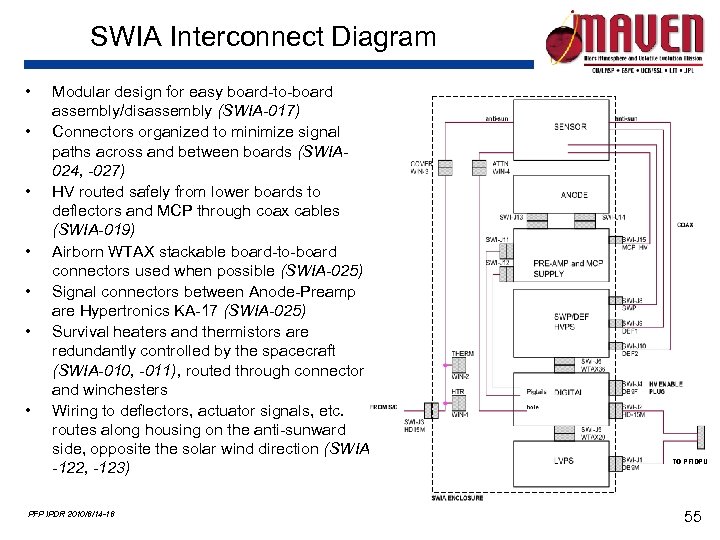

SWIA Interconnect Diagram • • Modular design for easy board-to-board assembly/disassembly (SWIA-017) Connectors organized to minimize signal paths across and between boards (SWIA 024, -027) HV routed safely from lower boards to deflectors and MCP through coax cables (SWIA-019) Airborn WTAX stackable board-to-board connectors used when possible (SWIA-025) Signal connectors between Anode-Preamp are Hypertronics KA-17 (SWIA-025) Survival heaters and thermistors are redundantly controlled by the spacecraft (SWIA-010, -011), routed through connector and winchesters Wiring to deflectors, actuator signals, etc. routes along housing on the anti-sunward side, opposite the solar wind direction (SWIA -122, -123) PFP IPDR 2010/6/14 -16 TO PFIDPU 55

SWIA Interconnect Diagram • • Modular design for easy board-to-board assembly/disassembly (SWIA-017) Connectors organized to minimize signal paths across and between boards (SWIA 024, -027) HV routed safely from lower boards to deflectors and MCP through coax cables (SWIA-019) Airborn WTAX stackable board-to-board connectors used when possible (SWIA-025) Signal connectors between Anode-Preamp are Hypertronics KA-17 (SWIA-025) Survival heaters and thermistors are redundantly controlled by the spacecraft (SWIA-010, -011), routed through connector and winchesters Wiring to deflectors, actuator signals, etc. routes along housing on the anti-sunward side, opposite the solar wind direction (SWIA -122, -123) PFP IPDR 2010/6/14 -16 TO PFIDPU 55

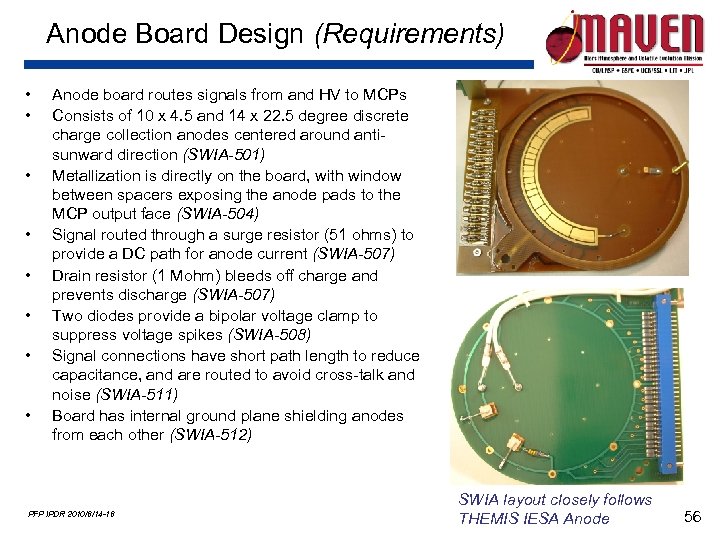

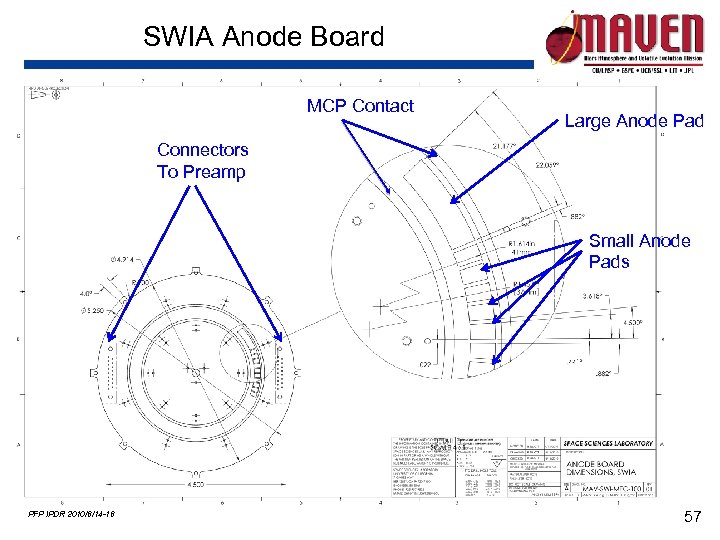

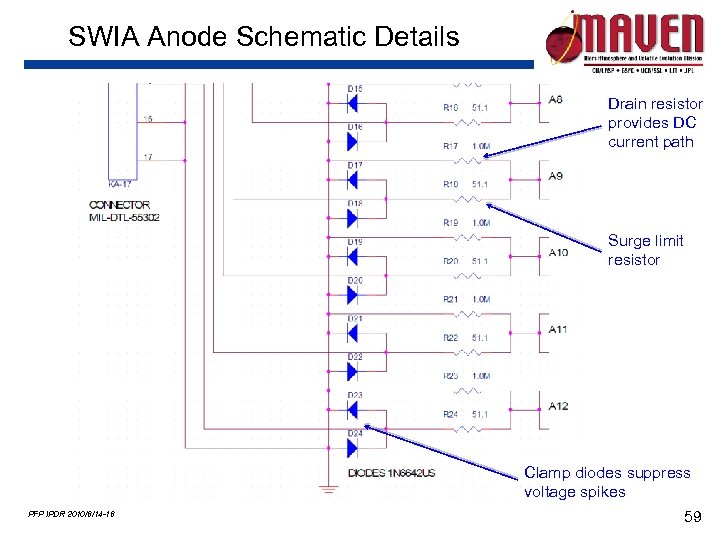

Anode Board Design (Requirements) • • Anode board routes signals from and HV to MCPs Consists of 10 x 4. 5 and 14 x 22. 5 degree discrete charge collection anodes centered around antisunward direction (SWIA-501) Metallization is directly on the board, with window between spacers exposing the anode pads to the MCP output face (SWIA-504) Signal routed through a surge resistor (51 ohms) to provide a DC path for anode current (SWIA-507) Drain resistor (1 Mohm) bleeds off charge and prevents discharge (SWIA-507) Two diodes provide a bipolar voltage clamp to suppress voltage spikes (SWIA-508) Signal connections have short path length to reduce capacitance, and are routed to avoid cross-talk and noise (SWIA-511) Board has internal ground plane shielding anodes from each other (SWIA-512) PFP IPDR 2010/6/14 -16 SWIA layout closely follows THEMIS IESA Anode 56

Anode Board Design (Requirements) • • Anode board routes signals from and HV to MCPs Consists of 10 x 4. 5 and 14 x 22. 5 degree discrete charge collection anodes centered around antisunward direction (SWIA-501) Metallization is directly on the board, with window between spacers exposing the anode pads to the MCP output face (SWIA-504) Signal routed through a surge resistor (51 ohms) to provide a DC path for anode current (SWIA-507) Drain resistor (1 Mohm) bleeds off charge and prevents discharge (SWIA-507) Two diodes provide a bipolar voltage clamp to suppress voltage spikes (SWIA-508) Signal connections have short path length to reduce capacitance, and are routed to avoid cross-talk and noise (SWIA-511) Board has internal ground plane shielding anodes from each other (SWIA-512) PFP IPDR 2010/6/14 -16 SWIA layout closely follows THEMIS IESA Anode 56

SWIA Anode Board MCP Contact Large Anode Pad Connectors To Preamp Small Anode Pads PFP IPDR 2010/6/14 -16 57

SWIA Anode Board MCP Contact Large Anode Pad Connectors To Preamp Small Anode Pads PFP IPDR 2010/6/14 -16 57

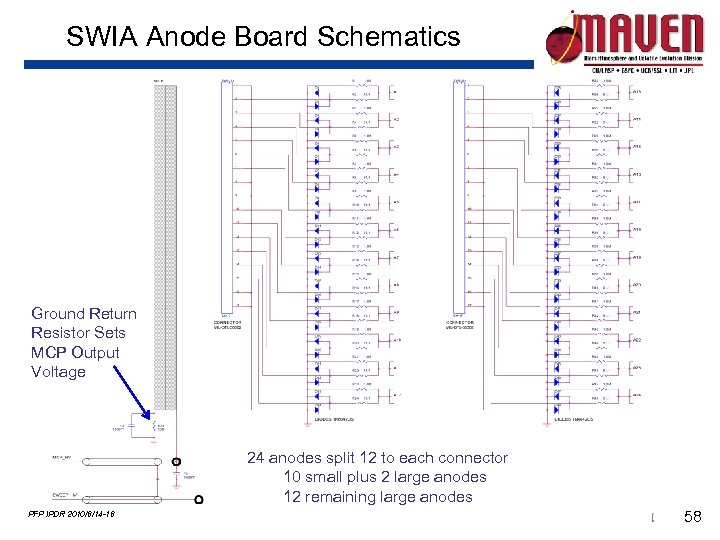

SWIA Anode Board Schematics Ground Return Resistor Sets MCP Output Voltage 24 anodes split 12 to each connector 10 small plus 2 large anodes 12 remaining large anodes PFP IPDR 2010/6/14 -16 58

SWIA Anode Board Schematics Ground Return Resistor Sets MCP Output Voltage 24 anodes split 12 to each connector 10 small plus 2 large anodes 12 remaining large anodes PFP IPDR 2010/6/14 -16 58

SWIA Anode Schematic Details Drain resistor provides DC current path Surge limit resistor Clamp diodes suppress voltage spikes PFP IPDR 2010/6/14 -16 59

SWIA Anode Schematic Details Drain resistor provides DC current path Surge limit resistor Clamp diodes suppress voltage spikes PFP IPDR 2010/6/14 -16 59

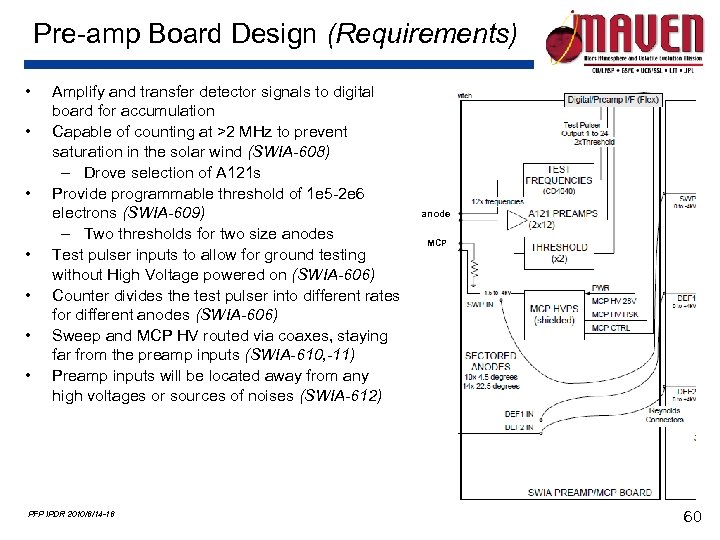

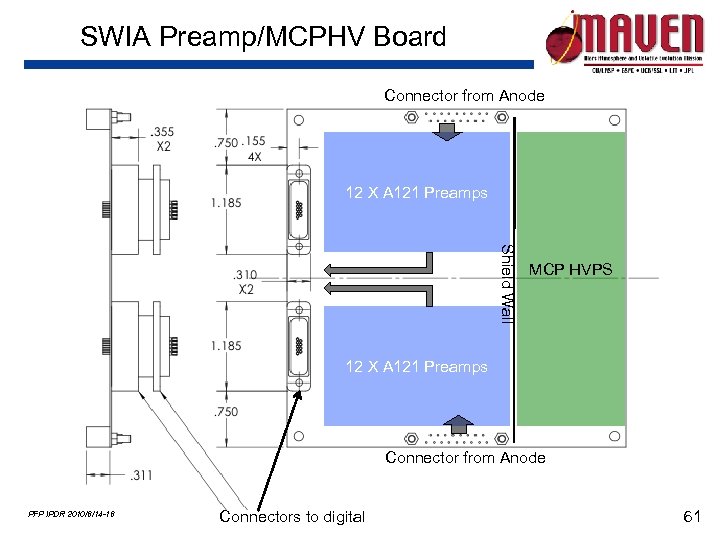

Pre-amp Board Design (Requirements) • • Amplify and transfer detector signals to digital board for accumulation Capable of counting at >2 MHz to prevent saturation in the solar wind (SWIA-608) – Drove selection of A 121 s Provide programmable threshold of 1 e 5 -2 e 6 electrons (SWIA-609) – Two thresholds for two size anodes Test pulser inputs to allow for ground testing without High Voltage powered on (SWIA-606) Counter divides the test pulser into different rates for different anodes (SWIA-606) Sweep and MCP HV routed via coaxes, staying far from the preamp inputs (SWIA-610, -11) Preamp inputs will be located away from any high voltages or sources of noises (SWIA-612) PFP IPDR 2010/6/14 -16 anode MCP 60

Pre-amp Board Design (Requirements) • • Amplify and transfer detector signals to digital board for accumulation Capable of counting at >2 MHz to prevent saturation in the solar wind (SWIA-608) – Drove selection of A 121 s Provide programmable threshold of 1 e 5 -2 e 6 electrons (SWIA-609) – Two thresholds for two size anodes Test pulser inputs to allow for ground testing without High Voltage powered on (SWIA-606) Counter divides the test pulser into different rates for different anodes (SWIA-606) Sweep and MCP HV routed via coaxes, staying far from the preamp inputs (SWIA-610, -11) Preamp inputs will be located away from any high voltages or sources of noises (SWIA-612) PFP IPDR 2010/6/14 -16 anode MCP 60

SWIA Preamp/MCPHV Board Connector from Anode 12 X A 121 Preamps Shield Wall MCP HVPS 12 X A 121 Preamps Connector from Anode PFP IPDR 2010/6/14 -16 Connectors to digital 61

SWIA Preamp/MCPHV Board Connector from Anode 12 X A 121 Preamps Shield Wall MCP HVPS 12 X A 121 Preamps Connector from Anode PFP IPDR 2010/6/14 -16 Connectors to digital 61

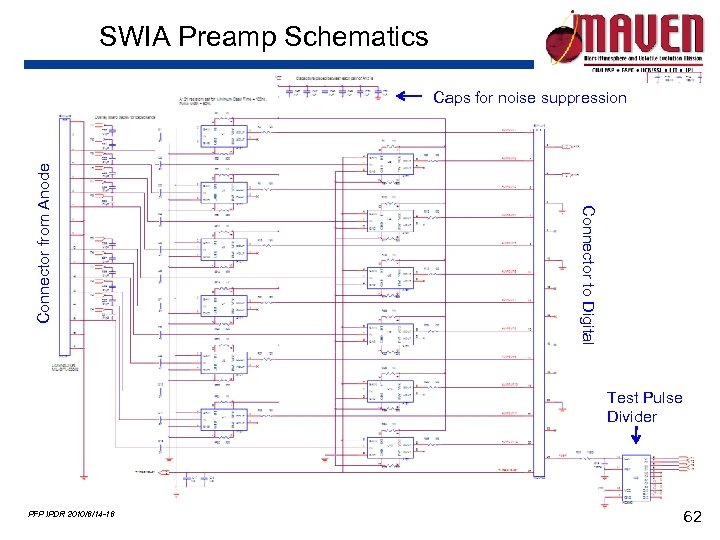

SWIA Preamp Schematics Connector to Digital Connector from Anode Caps for noise suppression Test Pulse Divider PFP IPDR 2010/6/14 -16 62

SWIA Preamp Schematics Connector to Digital Connector from Anode Caps for noise suppression Test Pulse Divider PFP IPDR 2010/6/14 -16 62

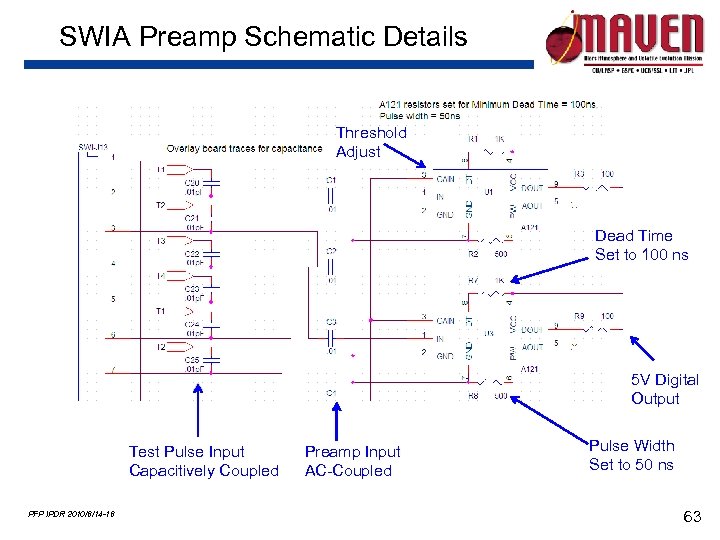

SWIA Preamp Schematic Details Threshold Adjust Dead Time Set to 100 ns 5 V Digital Output Test Pulse Input Capacitively Coupled PFP IPDR 2010/6/14 -16 Preamp Input AC-Coupled Pulse Width Set to 50 ns 63

SWIA Preamp Schematic Details Threshold Adjust Dead Time Set to 100 ns 5 V Digital Output Test Pulse Input Capacitively Coupled PFP IPDR 2010/6/14 -16 Preamp Input AC-Coupled Pulse Width Set to 50 ns 63

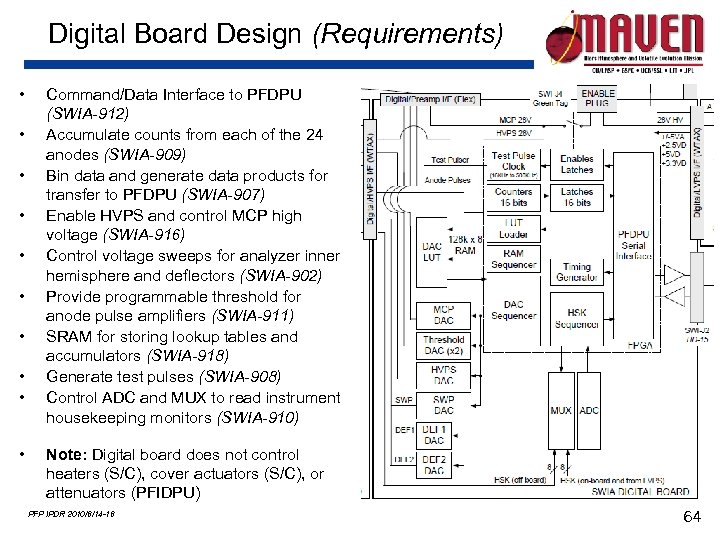

Digital Board Design (Requirements) • • • Command/Data Interface to PFDPU (SWIA-912) Accumulate counts from each of the 24 anodes (SWIA-909) Bin data and generate data products for transfer to PFDPU (SWIA-907) Enable HVPS and control MCP high voltage (SWIA-916) Control voltage sweeps for analyzer inner hemisphere and deflectors (SWIA-902) Provide programmable threshold for anode pulse amplifiers (SWIA-911) SRAM for storing lookup tables and accumulators (SWIA-918) Generate test pulses (SWIA-908) Control ADC and MUX to read instrument housekeeping monitors (SWIA-910) Note: Digital board does not control heaters (S/C), cover actuators (S/C), or attenuators (PFIDPU) PFP IPDR 2010/6/14 -16 64

Digital Board Design (Requirements) • • • Command/Data Interface to PFDPU (SWIA-912) Accumulate counts from each of the 24 anodes (SWIA-909) Bin data and generate data products for transfer to PFDPU (SWIA-907) Enable HVPS and control MCP high voltage (SWIA-916) Control voltage sweeps for analyzer inner hemisphere and deflectors (SWIA-902) Provide programmable threshold for anode pulse amplifiers (SWIA-911) SRAM for storing lookup tables and accumulators (SWIA-918) Generate test pulses (SWIA-908) Control ADC and MUX to read instrument housekeeping monitors (SWIA-910) Note: Digital board does not control heaters (S/C), cover actuators (S/C), or attenuators (PFIDPU) PFP IPDR 2010/6/14 -16 64

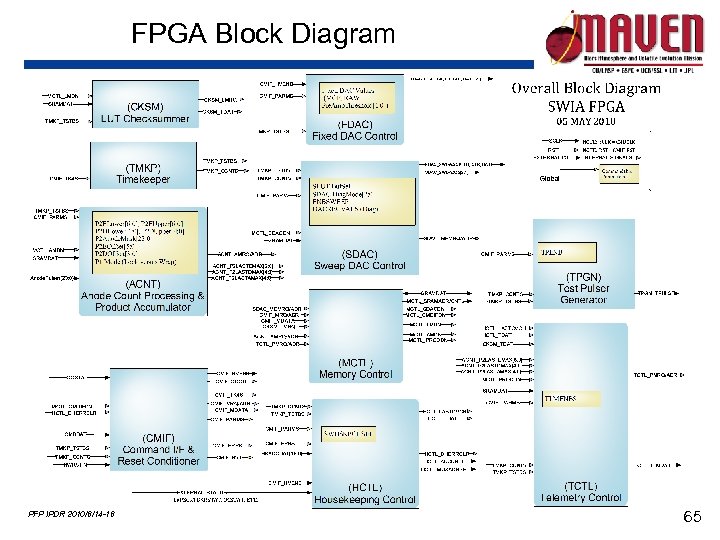

FPGA Block Diagram PFP IPDR 2010/6/14 -16 65

FPGA Block Diagram PFP IPDR 2010/6/14 -16 65

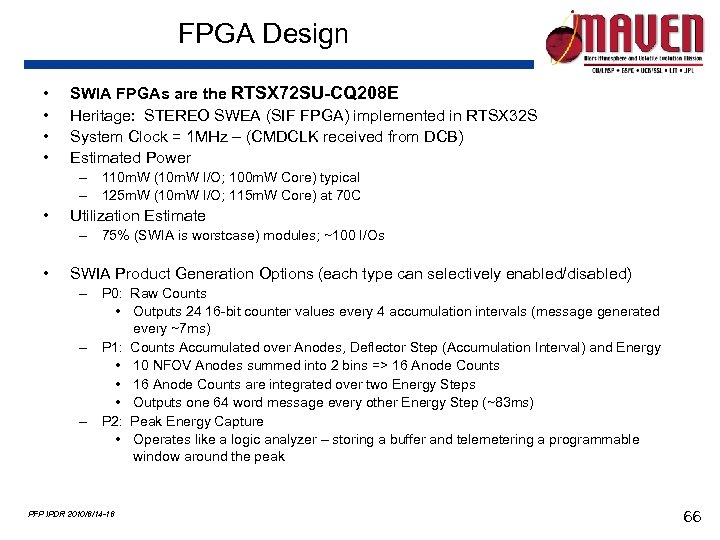

FPGA Design • • SWIA FPGAs are the RTSX 72 SU-CQ 208 E Heritage: STEREO SWEA (SIF FPGA) implemented in RTSX 32 S System Clock = 1 MHz – (CMDCLK received from DCB) Estimated Power – 110 m. W (10 m. W I/O; 100 m. W Core) typical – 125 m. W (10 m. W I/O; 115 m. W Core) at 70 C • Utilization Estimate – 75% (SWIA is worstcase) modules; ~100 I/Os • SWIA Product Generation Options (each type can selectively enabled/disabled) – P 0: Raw Counts • Outputs 24 16 -bit counter values every 4 accumulation intervals (message generated every ~7 ms) – P 1: Counts Accumulated over Anodes, Deflector Step (Accumulation Interval) and Energy • 10 NFOV Anodes summed into 2 bins => 16 Anode Counts • 16 Anode Counts are integrated over two Energy Steps • Outputs one 64 word message every other Energy Step (~83 ms) – P 2: Peak Energy Capture • Operates like a logic analyzer – storing a buffer and telemetering a programmable window around the peak PFP IPDR 2010/6/14 -16 66

FPGA Design • • SWIA FPGAs are the RTSX 72 SU-CQ 208 E Heritage: STEREO SWEA (SIF FPGA) implemented in RTSX 32 S System Clock = 1 MHz – (CMDCLK received from DCB) Estimated Power – 110 m. W (10 m. W I/O; 100 m. W Core) typical – 125 m. W (10 m. W I/O; 115 m. W Core) at 70 C • Utilization Estimate – 75% (SWIA is worstcase) modules; ~100 I/Os • SWIA Product Generation Options (each type can selectively enabled/disabled) – P 0: Raw Counts • Outputs 24 16 -bit counter values every 4 accumulation intervals (message generated every ~7 ms) – P 1: Counts Accumulated over Anodes, Deflector Step (Accumulation Interval) and Energy • 10 NFOV Anodes summed into 2 bins => 16 Anode Counts • 16 Anode Counts are integrated over two Energy Steps • Outputs one 64 word message every other Energy Step (~83 ms) – P 2: Peak Energy Capture • Operates like a logic analyzer – storing a buffer and telemetering a programmable window around the peak PFP IPDR 2010/6/14 -16 66

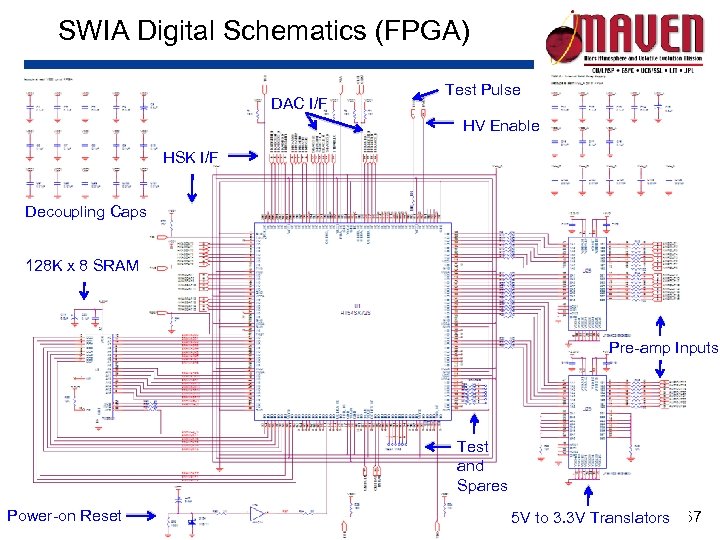

SWIA Digital Schematics (FPGA) DAC I/F Test Pulse HV Enable HSK I/F Decoupling Caps 128 K x 8 SRAM Pre-amp Inputs Test and Spares PFP IPDR 2010/6/14 -16 Power-on Reset 5 V to 3. 3 V Translators 67

SWIA Digital Schematics (FPGA) DAC I/F Test Pulse HV Enable HSK I/F Decoupling Caps 128 K x 8 SRAM Pre-amp Inputs Test and Spares PFP IPDR 2010/6/14 -16 Power-on Reset 5 V to 3. 3 V Translators 67

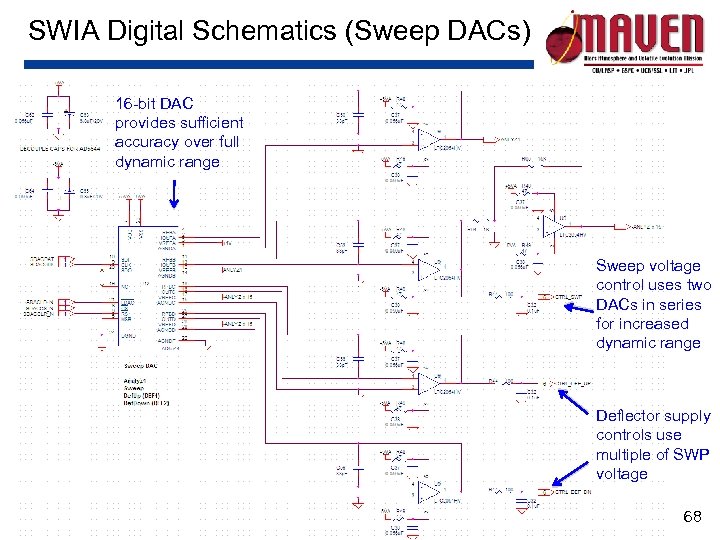

SWIA Digital Schematics (Sweep DACs) 16 -bit DAC provides sufficient accuracy over full dynamic range Sweep voltage control uses two DACs in series for increased dynamic range Deflector supply controls use multiple of SWP voltage PFP IPDR 2010/6/14 -16 68

SWIA Digital Schematics (Sweep DACs) 16 -bit DAC provides sufficient accuracy over full dynamic range Sweep voltage control uses two DACs in series for increased dynamic range Deflector supply controls use multiple of SWP voltage PFP IPDR 2010/6/14 -16 68

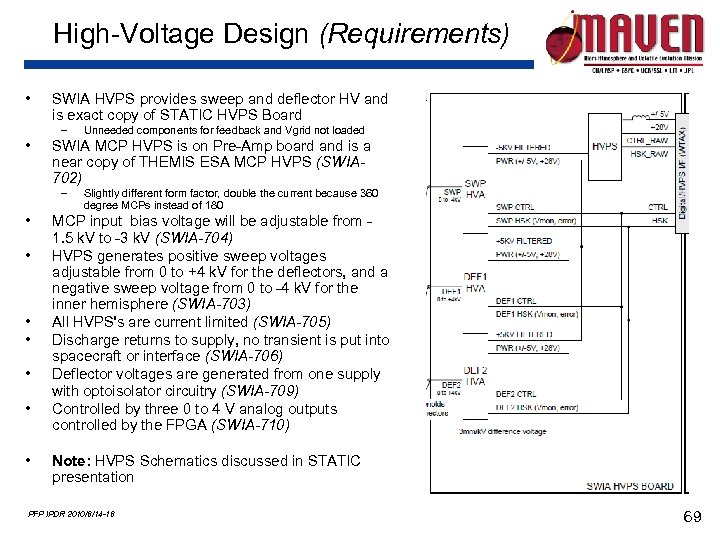

High-Voltage Design (Requirements) • SWIA HVPS provides sweep and deflector HV and is exact copy of STATIC HVPS Board – • SWIA MCP HVPS is on Pre-Amp board and is a near copy of THEMIS ESA MCP HVPS (SWIA 702) – • • Unneeded components for feedback and Vgrid not loaded Slightly different form factor, double the current because 360 degree MCPs instead of 180 MCP input bias voltage will be adjustable from 1. 5 k. V to -3 k. V (SWIA-704) HVPS generates positive sweep voltages adjustable from 0 to +4 k. V for the deflectors, and a negative sweep voltage from 0 to -4 k. V for the inner hemisphere (SWIA-703) All HVPS's are current limited (SWIA-705) Discharge returns to supply, no transient is put into spacecraft or interface (SWIA-706) Deflector voltages are generated from one supply with optoisolator circuitry (SWIA-709) Controlled by three 0 to 4 V analog outputs controlled by the FPGA (SWIA-710) Note: HVPS Schematics discussed in STATIC presentation PFP IPDR 2010/6/14 -16 69

High-Voltage Design (Requirements) • SWIA HVPS provides sweep and deflector HV and is exact copy of STATIC HVPS Board – • SWIA MCP HVPS is on Pre-Amp board and is a near copy of THEMIS ESA MCP HVPS (SWIA 702) – • • Unneeded components for feedback and Vgrid not loaded Slightly different form factor, double the current because 360 degree MCPs instead of 180 MCP input bias voltage will be adjustable from 1. 5 k. V to -3 k. V (SWIA-704) HVPS generates positive sweep voltages adjustable from 0 to +4 k. V for the deflectors, and a negative sweep voltage from 0 to -4 k. V for the inner hemisphere (SWIA-703) All HVPS's are current limited (SWIA-705) Discharge returns to supply, no transient is put into spacecraft or interface (SWIA-706) Deflector voltages are generated from one supply with optoisolator circuitry (SWIA-709) Controlled by three 0 to 4 V analog outputs controlled by the FPGA (SWIA-710) Note: HVPS Schematics discussed in STATIC presentation PFP IPDR 2010/6/14 -16 69

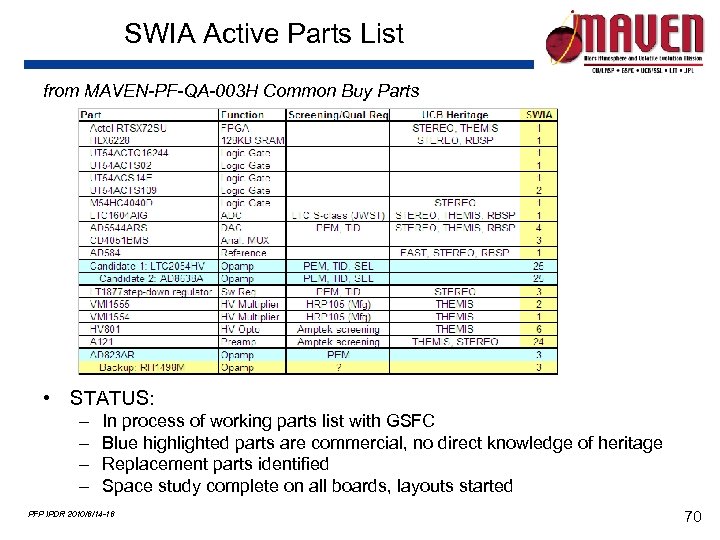

SWIA Active Parts List from MAVEN-PF-QA-003 H Common Buy Parts • STATUS: – – In process of working parts list with GSFC Blue highlighted parts are commercial, no direct knowledge of heritage Replacement parts identified Space study complete on all boards, layouts started PFP IPDR 2010/6/14 -16 70

SWIA Active Parts List from MAVEN-PF-QA-003 H Common Buy Parts • STATUS: – – In process of working parts list with GSFC Blue highlighted parts are commercial, no direct knowledge of heritage Replacement parts identified Space study complete on all boards, layouts started PFP IPDR 2010/6/14 -16 70

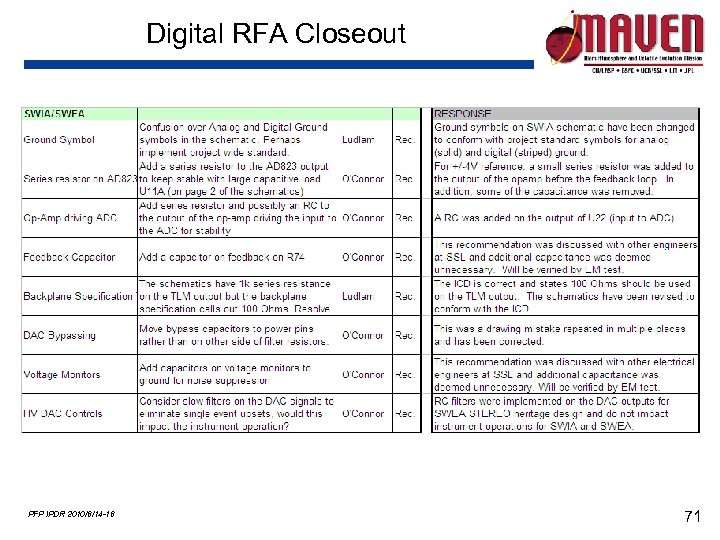

Digital RFA Closeout PFP IPDR 2010/6/14 -16 71

Digital RFA Closeout PFP IPDR 2010/6/14 -16 71

VI. Conclusion A. RFA Closeout Summary B. Schedule C. Done! PFP IPDR 2010/6/14 -16 72

VI. Conclusion A. RFA Closeout Summary B. Schedule C. Done! PFP IPDR 2010/6/14 -16 72

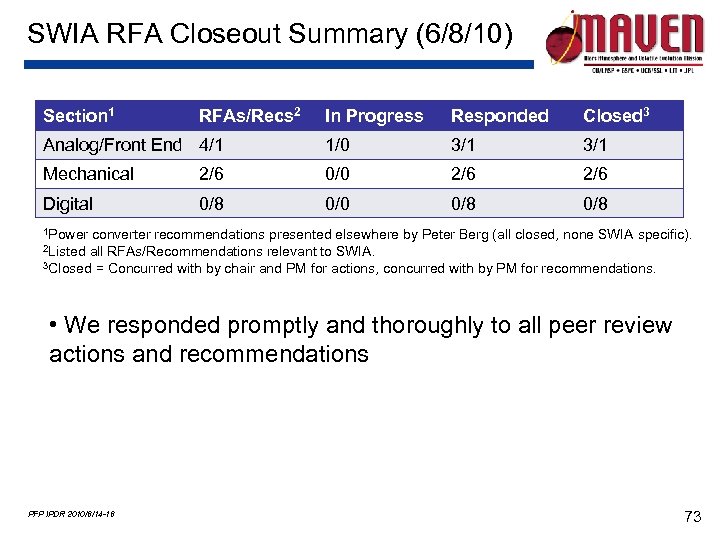

SWIA RFA Closeout Summary (6/8/10) Section 1 RFAs/Recs 2 In Progress Responded Closed 3 Analog/Front End 4/1 1/0 3/1 Mechanical 2/6 0/0 2/6 Digital 0/8 0/0 0/8 1 Power converter recommendations presented elsewhere by Peter Berg (all closed, none SWIA specific). 2 Listed all RFAs/Recommendations relevant to SWIA. 3 Closed = Concurred with by chair and PM for actions, concurred with by PM for recommendations. • We responded promptly and thoroughly to all peer review actions and recommendations PFP IPDR 2010/6/14 -16 73

SWIA RFA Closeout Summary (6/8/10) Section 1 RFAs/Recs 2 In Progress Responded Closed 3 Analog/Front End 4/1 1/0 3/1 Mechanical 2/6 0/0 2/6 Digital 0/8 0/0 0/8 1 Power converter recommendations presented elsewhere by Peter Berg (all closed, none SWIA specific). 2 Listed all RFAs/Recommendations relevant to SWIA. 3 Closed = Concurred with by chair and PM for actions, concurred with by PM for recommendations. • We responded promptly and thoroughly to all peer review actions and recommendations PFP IPDR 2010/6/14 -16 73

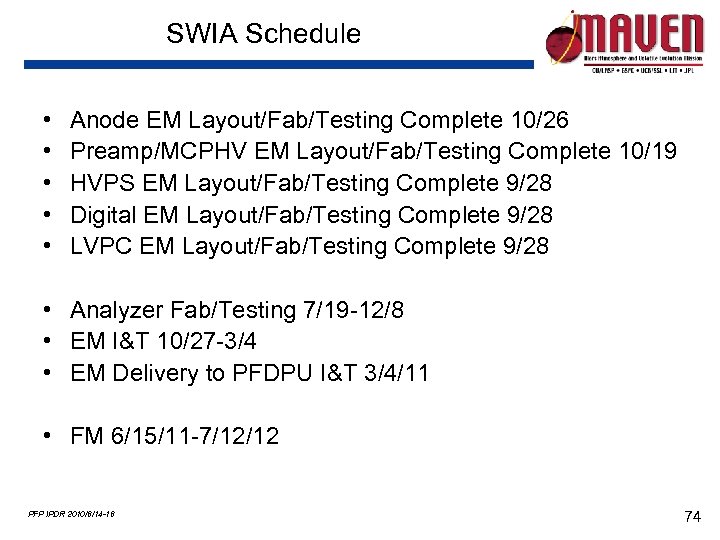

SWIA Schedule • • • Anode EM Layout/Fab/Testing Complete 10/26 Preamp/MCPHV EM Layout/Fab/Testing Complete 10/19 HVPS EM Layout/Fab/Testing Complete 9/28 Digital EM Layout/Fab/Testing Complete 9/28 LVPC EM Layout/Fab/Testing Complete 9/28 • Analyzer Fab/Testing 7/19 -12/8 • EM I&T 10/27 -3/4 • EM Delivery to PFDPU I&T 3/4/11 • FM 6/15/11 -7/12/12 PFP IPDR 2010/6/14 -16 74

SWIA Schedule • • • Anode EM Layout/Fab/Testing Complete 10/26 Preamp/MCPHV EM Layout/Fab/Testing Complete 10/19 HVPS EM Layout/Fab/Testing Complete 9/28 Digital EM Layout/Fab/Testing Complete 9/28 LVPC EM Layout/Fab/Testing Complete 9/28 • Analyzer Fab/Testing 7/19 -12/8 • EM I&T 10/27 -3/4 • EM Delivery to PFDPU I&T 3/4/11 • FM 6/15/11 -7/12/12 PFP IPDR 2010/6/14 -16 74

Conclusions • We’re excited to start building and testing engineering models! • Questions? PFP IPDR 2010/6/14 -16 75

Conclusions • We’re excited to start building and testing engineering models! • Questions? PFP IPDR 2010/6/14 -16 75