8371ebd2ae436b82a6edb8a223c56dc4.ppt

- Количество слайдов: 15

Package Development Process - Post Mortem Reduction of Product Returns Caused by Improper Handling Mr. Alan Masnek, CPP (Seagate Technology) ETM 5131 Project July 28, 2003 1 Alan Masnek, CPP

Package Development Process - Post Mortem Reduction of Product Returns Caused by Improper Handling Mr. Alan Masnek, CPP (Seagate Technology) ETM 5131 Project July 28, 2003 1 Alan Masnek, CPP

Problem Statement: Develop a packaging container to decrease the problem: Product returns caused by improper handling are 35% of all returns that results in a profit impact of $70 million and customer dissatisfaction. 2 Alan Masnek, CPP

Problem Statement: Develop a packaging container to decrease the problem: Product returns caused by improper handling are 35% of all returns that results in a profit impact of $70 million and customer dissatisfaction. 2 Alan Masnek, CPP

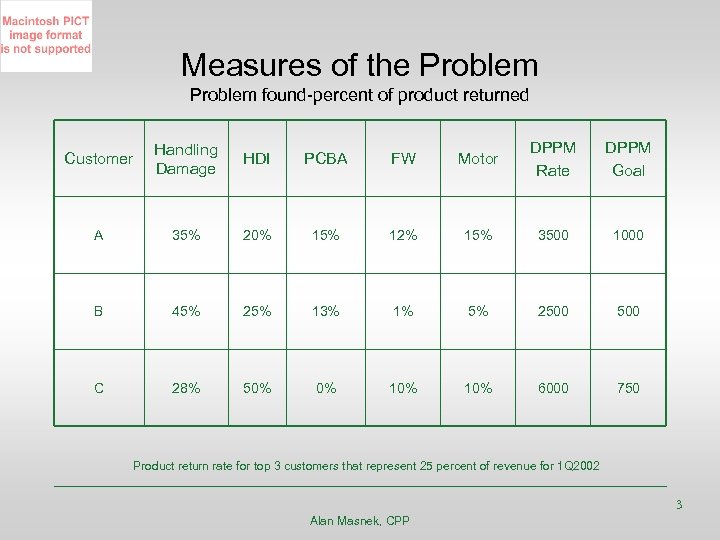

Measures of the Problem found-percent of product returned Customer Handling Damage HDI PCBA FW Motor DPPM Rate DPPM Goal A 35% 20% 15% 12% 15% 3500 1000 B 45% 25% 13% 1% 5% 2500 C 28% 50% 0% 10% 6000 750 Product return rate for top 3 customers that represent 25 percent of revenue for 1 Q 2002 3 Alan Masnek, CPP

Measures of the Problem found-percent of product returned Customer Handling Damage HDI PCBA FW Motor DPPM Rate DPPM Goal A 35% 20% 15% 12% 15% 3500 1000 B 45% 25% 13% 1% 5% 2500 C 28% 50% 0% 10% 6000 750 Product return rate for top 3 customers that represent 25 percent of revenue for 1 Q 2002 3 Alan Masnek, CPP

Measures of the Problem • The company sets aside a certain dollar amount to cover warranty related costs for each product it produces and ships. The warranty reserve is presently $3 -$4 per product produced. • Actual product returns drive this dollar amount up or down. Current cost for defective product from handling damage is $60 to $70 million. The MBB projects the proper solution can save 70 percent of that amount. • Balanced Scorecards supplied by customer. 4 Alan Masnek, CPP

Measures of the Problem • The company sets aside a certain dollar amount to cover warranty related costs for each product it produces and ships. The warranty reserve is presently $3 -$4 per product produced. • Actual product returns drive this dollar amount up or down. Current cost for defective product from handling damage is $60 to $70 million. The MBB projects the proper solution can save 70 percent of that amount. • Balanced Scorecards supplied by customer. 4 Alan Masnek, CPP

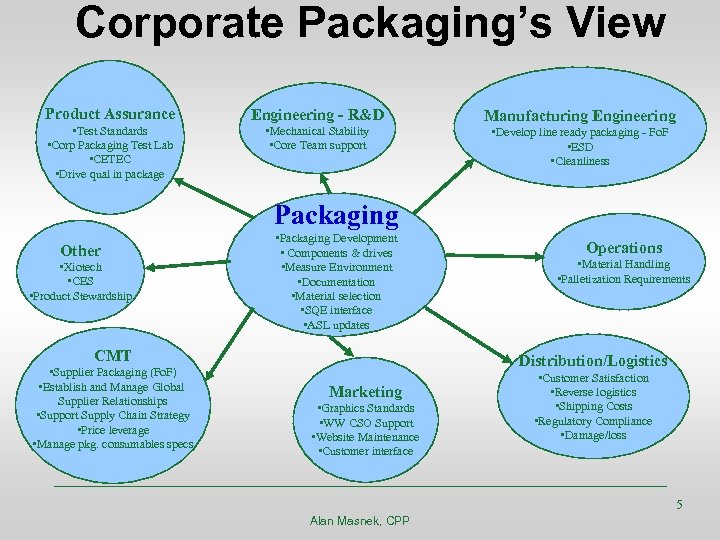

Corporate Packaging’s View Product Assurance Engineering - R&D • Test Standards • Corp Packaging Test Lab • CETEC • Drive qual in package • Mechanical Stability • Core Team support Manufacturing Engineering • Develop line ready packaging - Fo. F • ESD • Cleanliness Packaging Other • Xiotech • CES • Product Stewardship • Packaging Development • Components & drives • Measure Environment • Documentation • Material selection • SQE interface • ASL updates CMT • Supplier Packaging (Fo. F) • Establish and Manage Global Supplier Relationships • Support Supply Chain Strategy • Price leverage • Manage pkg. consumables specs Operations • Material Handling • Palletization Requirements Distribution/Logistics Marketing • Graphics Standards • WW CSO Support • Website Maintenance • Customer interface • Customer Satisfaction • Reverse logistics • Shipping Costs • Regulatory Compliance • Damage/loss 5 Alan Masnek, CPP

Corporate Packaging’s View Product Assurance Engineering - R&D • Test Standards • Corp Packaging Test Lab • CETEC • Drive qual in package • Mechanical Stability • Core Team support Manufacturing Engineering • Develop line ready packaging - Fo. F • ESD • Cleanliness Packaging Other • Xiotech • CES • Product Stewardship • Packaging Development • Components & drives • Measure Environment • Documentation • Material selection • SQE interface • ASL updates CMT • Supplier Packaging (Fo. F) • Establish and Manage Global Supplier Relationships • Support Supply Chain Strategy • Price leverage • Manage pkg. consumables specs Operations • Material Handling • Palletization Requirements Distribution/Logistics Marketing • Graphics Standards • WW CSO Support • Website Maintenance • Customer interface • Customer Satisfaction • Reverse logistics • Shipping Costs • Regulatory Compliance • Damage/loss 5 Alan Masnek, CPP

Project Objectives • Develop a solution that will do the following: – Reduce product returns due to handling damage from 35% to 5 - 10% within one year [and justify any product packaging cost increase that may accompany the solution]. – Create and capture customer value. (Solve other problems perhaps? ) – With a breakthrough idea, capitalize on and make packaging, an area normally taken for granted, a differentiator. 6 Alan Masnek, CPP

Project Objectives • Develop a solution that will do the following: – Reduce product returns due to handling damage from 35% to 5 - 10% within one year [and justify any product packaging cost increase that may accompany the solution]. – Create and capture customer value. (Solve other problems perhaps? ) – With a breakthrough idea, capitalize on and make packaging, an area normally taken for granted, a differentiator. 6 Alan Masnek, CPP

Deliverables • Reduced product returns • Improved profitability • Increased customer delight 7 Alan Masnek, CPP

Deliverables • Reduced product returns • Improved profitability • Increased customer delight 7 Alan Masnek, CPP

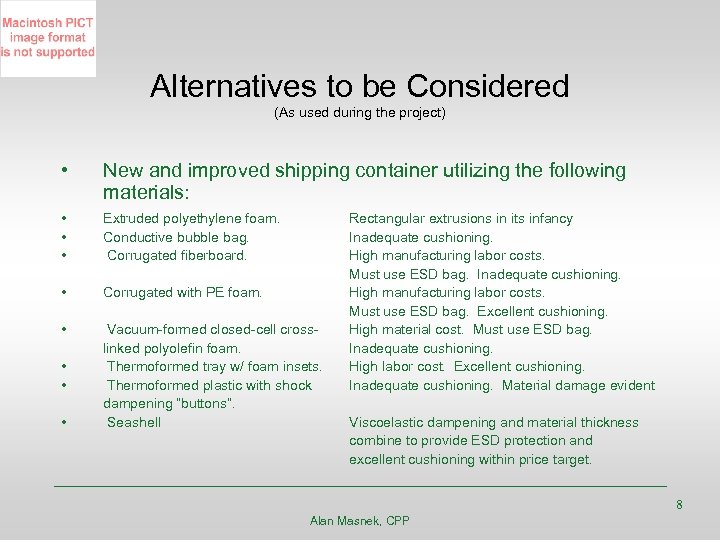

Alternatives to be Considered (As used during the project) • New and improved shipping container utilizing the following materials: • • • Extruded polyethylene foam. Conductive bubble bag. Corrugated fiberboard. • Corrugated with PE foam. • Vacuum-formed closed-cell crosslinked polyolefin foam. Thermoformed tray w/ foam insets. Thermoformed plastic with shock dampening “buttons”. Seashell • • • Rectangular extrusions in its infancy Inadequate cushioning. High manufacturing labor costs. Must use ESD bag. Excellent cushioning. High material cost. Must use ESD bag. Inadequate cushioning. High labor cost. Excellent cushioning. Inadequate cushioning. Material damage evident Viscoelastic dampening and material thickness combine to provide ESD protection and excellent cushioning within price target. 8 Alan Masnek, CPP

Alternatives to be Considered (As used during the project) • New and improved shipping container utilizing the following materials: • • • Extruded polyethylene foam. Conductive bubble bag. Corrugated fiberboard. • Corrugated with PE foam. • Vacuum-formed closed-cell crosslinked polyolefin foam. Thermoformed tray w/ foam insets. Thermoformed plastic with shock dampening “buttons”. Seashell • • • Rectangular extrusions in its infancy Inadequate cushioning. High manufacturing labor costs. Must use ESD bag. Excellent cushioning. High material cost. Must use ESD bag. Inadequate cushioning. High labor cost. Excellent cushioning. Inadequate cushioning. Material damage evident Viscoelastic dampening and material thickness combine to provide ESD protection and excellent cushioning within price target. 8 Alan Masnek, CPP

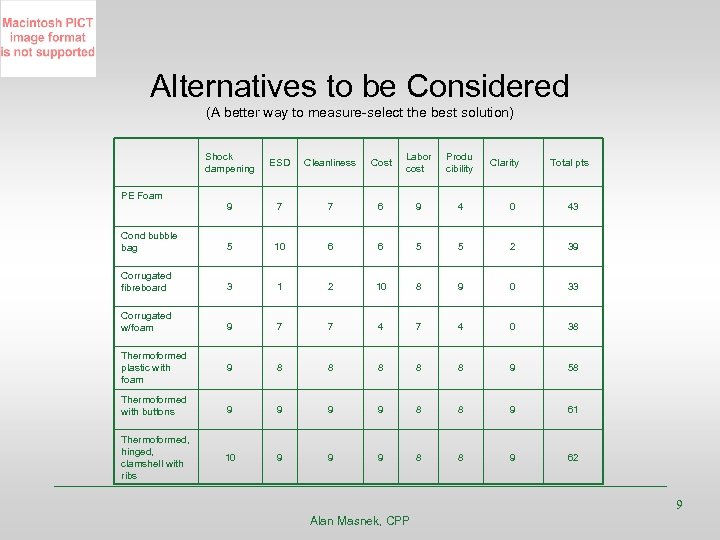

Alternatives to be Considered (A better way to measure-select the best solution) Shock dampening ESD Cleanliness Cost Labor cost Produ cibility 9 7 7 6 9 4 0 43 Cond bubble bag 5 10 6 6 5 5 2 39 Corrugated fibreboard 3 1 2 10 8 9 0 33 Corrugated w/foam 9 7 7 4 0 38 Thermoformed plastic with foam 9 8 8 8 9 58 Thermoformed with buttons 9 9 8 8 9 61 Thermoformed, hinged, clamshell with ribs 10 9 9 9 8 8 9 62 PE Foam Clarity Total pts 9 Alan Masnek, CPP

Alternatives to be Considered (A better way to measure-select the best solution) Shock dampening ESD Cleanliness Cost Labor cost Produ cibility 9 7 7 6 9 4 0 43 Cond bubble bag 5 10 6 6 5 5 2 39 Corrugated fibreboard 3 1 2 10 8 9 0 33 Corrugated w/foam 9 7 7 4 0 38 Thermoformed plastic with foam 9 8 8 8 9 58 Thermoformed with buttons 9 9 8 8 9 61 Thermoformed, hinged, clamshell with ribs 10 9 9 9 8 8 9 62 PE Foam Clarity Total pts 9 Alan Masnek, CPP

Project Approach and Criteria for (Evaluating Alternatives-The way it should be done) • DMAIC Six Sigma for Operational Excellence approach will be used: (Emphasis on solution-After. Next Principle) – – – Define Measure Analyze Improve Control • Each alternative will be evaluated against the deliverables: 10 Alan Masnek, CPP

Project Approach and Criteria for (Evaluating Alternatives-The way it should be done) • DMAIC Six Sigma for Operational Excellence approach will be used: (Emphasis on solution-After. Next Principle) – – – Define Measure Analyze Improve Control • Each alternative will be evaluated against the deliverables: 10 Alan Masnek, CPP

Project Approach and Criteria for Evaluating Alternatives (Questions not developed or answered before project start. ) Meets shock and vibration requirements. Does it improve protection of the product? Does it meet the physical requirements? Improve handling of the product. Does it make it easier for the customer to prevent dropping the product. Improved visibility of the product Recyclable, reusable? Stackable? Is it patentable? Can we lock out competitors from obtaining it? 11 Alan Masnek, CPP

Project Approach and Criteria for Evaluating Alternatives (Questions not developed or answered before project start. ) Meets shock and vibration requirements. Does it improve protection of the product? Does it meet the physical requirements? Improve handling of the product. Does it make it easier for the customer to prevent dropping the product. Improved visibility of the product Recyclable, reusable? Stackable? Is it patentable? Can we lock out competitors from obtaining it? 11 Alan Masnek, CPP

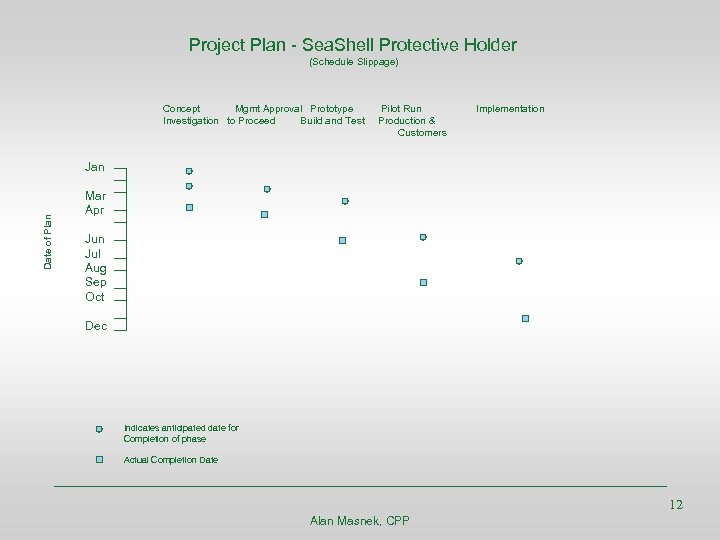

Project Plan - Sea. Shell Protective Holder (Schedule Slippage) Concept Mgmt Approval Prototype Investigation to Proceed Build and Test Pilot Run Production & Customers Implementation Date of Plan Jan Mar Apr Jun Jul Aug Sep Oct Dec Indicates anticipated date for Completion of phase Actual Completion Date 12 Alan Masnek, CPP

Project Plan - Sea. Shell Protective Holder (Schedule Slippage) Concept Mgmt Approval Prototype Investigation to Proceed Build and Test Pilot Run Production & Customers Implementation Date of Plan Jan Mar Apr Jun Jul Aug Sep Oct Dec Indicates anticipated date for Completion of phase Actual Completion Date 12 Alan Masnek, CPP

Problems Encountered • Inadequate/wrong team members selected. • Lack of buy-in from organizations. • Poor and flawed definition and quantification of the problem. • No cost guideline. • Manufacturability not established. 13 Alan Masnek, CPP

Problems Encountered • Inadequate/wrong team members selected. • Lack of buy-in from organizations. • Poor and flawed definition and quantification of the problem. • No cost guideline. • Manufacturability not established. 13 Alan Masnek, CPP

Problems Encountered • Poor timeline and project planning. • Customer acceptance not defined. • Life cycle analysis not performed. • Criteria for measuring and evaluating alternative. • What exactly was the deliverable. 14 Alan Masnek, CPP

Problems Encountered • Poor timeline and project planning. • Customer acceptance not defined. • Life cycle analysis not performed. • Criteria for measuring and evaluating alternative. • What exactly was the deliverable. 14 Alan Masnek, CPP

Recommendations • Training for Six Sigma DMAIC concepts for proper project execution should be administered to the group. • Development team must devise a plan to seek and obtain involvement from colleagues across the organization. Don’t assume the team members know or understand the problem and the plan. 15 Alan Masnek, CPP

Recommendations • Training for Six Sigma DMAIC concepts for proper project execution should be administered to the group. • Development team must devise a plan to seek and obtain involvement from colleagues across the organization. Don’t assume the team members know or understand the problem and the plan. 15 Alan Masnek, CPP