e56964393fbde0f653c6a2b6a7446e00.ppt

- Количество слайдов: 19

P 3 – VISUAL MANAGEMENT INTRODUCTION 1. Provide real-time information on work place status by a combination of simple, effective visual information aids that allow employees to understand their influence on the organization overall performance hence allowing the employees to improve their performance.

P 3 – VISUAL MANAGEMENT INTRODUCTION 1. Provide real-time information on work place status by a combination of simple, effective visual information aids that allow employees to understand their influence on the organization overall performance hence allowing the employees to improve their performance.

P 3 – VISUAL MANAGEMENT OBJECTIVE 1. Expose waste so that it can be eliminated and prevented from recurring making the workplace more efficient. 2. Make abnormalities in the 4 Ms (Man, Machine, Material, Method) process inputs visible to everyone for prompt corrective action. 3. Enable trends in QCDMS & abnormalities to be visible for timely preventive action to be taken. 4. Motivates everybody to improve by clarifying key performance targets. 5. Makes operation standards quicker and easier to understand by all employees so they can follow them. 6. Builds participation through shared information. 7. Creates flow in the value stream and allows pull to the voice of the customer.

P 3 – VISUAL MANAGEMENT OBJECTIVE 1. Expose waste so that it can be eliminated and prevented from recurring making the workplace more efficient. 2. Make abnormalities in the 4 Ms (Man, Machine, Material, Method) process inputs visible to everyone for prompt corrective action. 3. Enable trends in QCDMS & abnormalities to be visible for timely preventive action to be taken. 4. Motivates everybody to improve by clarifying key performance targets. 5. Makes operation standards quicker and easier to understand by all employees so they can follow them. 6. Builds participation through shared information. 7. Creates flow in the value stream and allows pull to the voice of the customer.

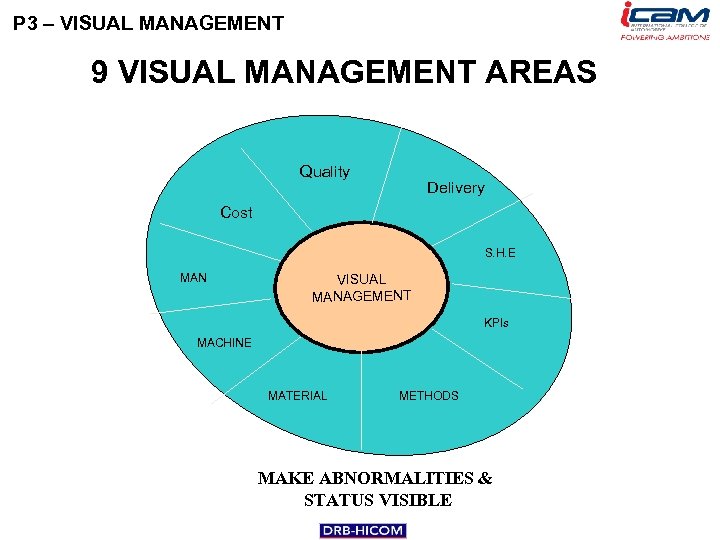

P 3 – VISUAL MANAGEMENT 9 VISUAL MANAGEMENT AREAS Quality Delivery Cost S. H. E MAN VISUAL MANAGEMENT KPIs MACHINE MATERIAL METHODS MAKE ABNORMALITIES & STATUS VISIBLE

P 3 – VISUAL MANAGEMENT 9 VISUAL MANAGEMENT AREAS Quality Delivery Cost S. H. E MAN VISUAL MANAGEMENT KPIs MACHINE MATERIAL METHODS MAKE ABNORMALITIES & STATUS VISIBLE

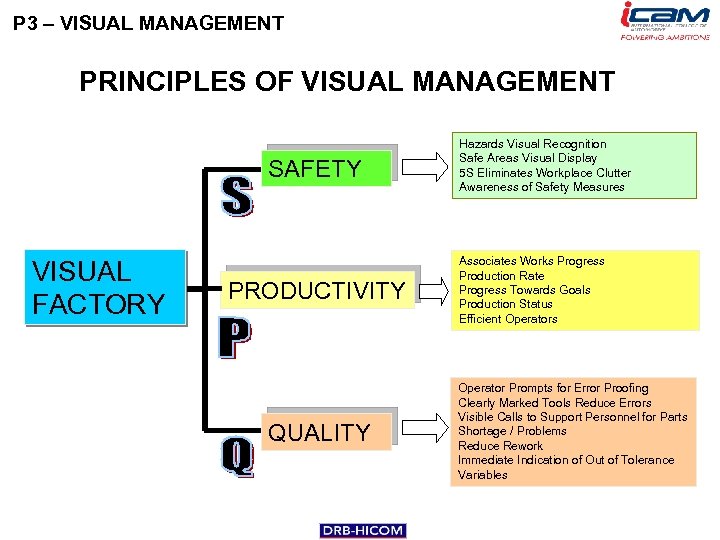

P 3 – VISUAL MANAGEMENT PRINCIPLES OF VISUAL MANAGEMENT SAFETY VISUAL FACTORY PRODUCTIVITY QUALITY Hazards Visual Recognition Safe Areas Visual Display 5 S Eliminates Workplace Clutter Awareness of Safety Measures Associates Works Progress Production Rate Progress Towards Goals Production Status Efficient Operators Operator Prompts for Error Proofing Clearly Marked Tools Reduce Errors Visible Calls to Support Personnel for Parts Shortage / Problems Reduce Rework Immediate Indication of Out of Tolerance Variables

P 3 – VISUAL MANAGEMENT PRINCIPLES OF VISUAL MANAGEMENT SAFETY VISUAL FACTORY PRODUCTIVITY QUALITY Hazards Visual Recognition Safe Areas Visual Display 5 S Eliminates Workplace Clutter Awareness of Safety Measures Associates Works Progress Production Rate Progress Towards Goals Production Status Efficient Operators Operator Prompts for Error Proofing Clearly Marked Tools Reduce Errors Visible Calls to Support Personnel for Parts Shortage / Problems Reduce Rework Immediate Indication of Out of Tolerance Variables

P 3 – VISUAL MANAGEMENT INITIATIVES 1. Visual Control Boards. 2. Andon 3. Footprints 4. Signage 5. Obeya 4. Hansei

P 3 – VISUAL MANAGEMENT INITIATIVES 1. Visual Control Boards. 2. Andon 3. Footprints 4. Signage 5. Obeya 4. Hansei

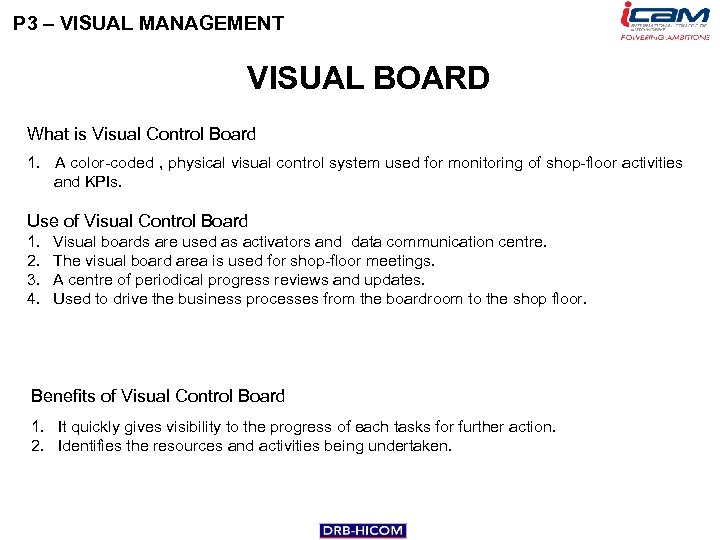

P 3 – VISUAL MANAGEMENT VISUAL BOARD What is Visual Control Board 1. A color-coded , physical visual control system used for monitoring of shop-floor activities and KPIs. Use of Visual Control Board 1. 2. 3. 4. Visual boards are used as activators and data communication centre. The visual board area is used for shop-floor meetings. A centre of periodical progress reviews and updates. Used to drive the business processes from the boardroom to the shop floor. Benefits of Visual Control Board 1. It quickly gives visibility to the progress of each tasks for further action. 2. Identifies the resources and activities being undertaken.

P 3 – VISUAL MANAGEMENT VISUAL BOARD What is Visual Control Board 1. A color-coded , physical visual control system used for monitoring of shop-floor activities and KPIs. Use of Visual Control Board 1. 2. 3. 4. Visual boards are used as activators and data communication centre. The visual board area is used for shop-floor meetings. A centre of periodical progress reviews and updates. Used to drive the business processes from the boardroom to the shop floor. Benefits of Visual Control Board 1. It quickly gives visibility to the progress of each tasks for further action. 2. Identifies the resources and activities being undertaken.

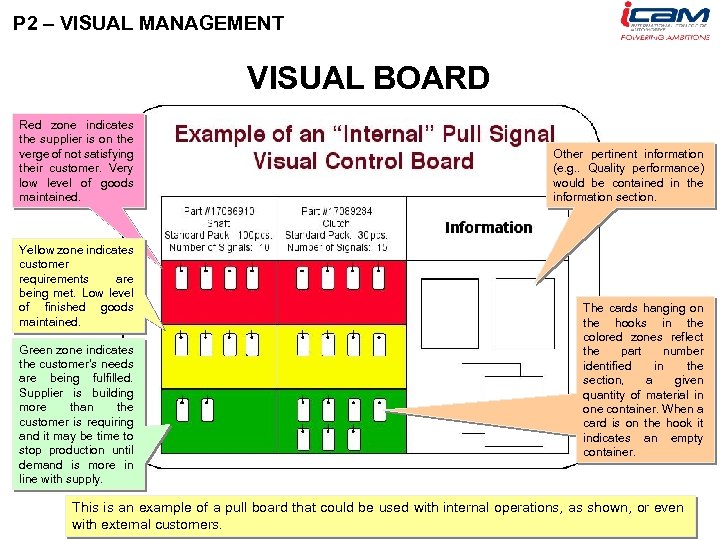

P 2 – VISUAL MANAGEMENT VISUAL BOARD Red zone indicates the supplier is on the verge of not satisfying their customer. Very low level of goods maintained. Yellow zone indicates customer requirements are being met. Low level of finished goods maintained. Green zone indicates the customer’s needs are being fulfilled. Supplier is building more than the customer is requiring and it may be time to stop production until demand is more in line with supply. Other pertinent information (e. g. . Quality performance) would be contained in the information section. The cards hanging on the hooks in the colored zones reflect the part number identified in the section, a given quantity of material in one container. When a card is on the hook it indicates an empty container. This is an example of a pull board that could be used with internal operations, as shown, or even with external customers.

P 2 – VISUAL MANAGEMENT VISUAL BOARD Red zone indicates the supplier is on the verge of not satisfying their customer. Very low level of goods maintained. Yellow zone indicates customer requirements are being met. Low level of finished goods maintained. Green zone indicates the customer’s needs are being fulfilled. Supplier is building more than the customer is requiring and it may be time to stop production until demand is more in line with supply. Other pertinent information (e. g. . Quality performance) would be contained in the information section. The cards hanging on the hooks in the colored zones reflect the part number identified in the section, a given quantity of material in one container. When a card is on the hook it indicates an empty container. This is an example of a pull board that could be used with internal operations, as shown, or even with external customers.

P 3 – VISUAL MANAGEMENT ANDON What is Andon 1. Andon (Japanese for lantern) is a tool for visual management and refers to a system of signals used to indicate the operational status (at a glance) of a machine or work center. 2. It can be used manually or automatically. 3. It also one of the principle elements of the Jidoka quality-control method.

P 3 – VISUAL MANAGEMENT ANDON What is Andon 1. Andon (Japanese for lantern) is a tool for visual management and refers to a system of signals used to indicate the operational status (at a glance) of a machine or work center. 2. It can be used manually or automatically. 3. It also one of the principle elements of the Jidoka quality-control method.

P 3 – VISUAL MANAGEMENT ANDON Use of Andon 1. Alerts management and other workers to quality or process problem. 2. Gives the worker the ability to stop production when a defect is found, and immediately call for assistance. 3. Indicates where the alert was generated, and may also provide a description of the trouble whether shortage of material or maintenance call or supervisor call. .

P 3 – VISUAL MANAGEMENT ANDON Use of Andon 1. Alerts management and other workers to quality or process problem. 2. Gives the worker the ability to stop production when a defect is found, and immediately call for assistance. 3. Indicates where the alert was generated, and may also provide a description of the trouble whether shortage of material or maintenance call or supervisor call. .

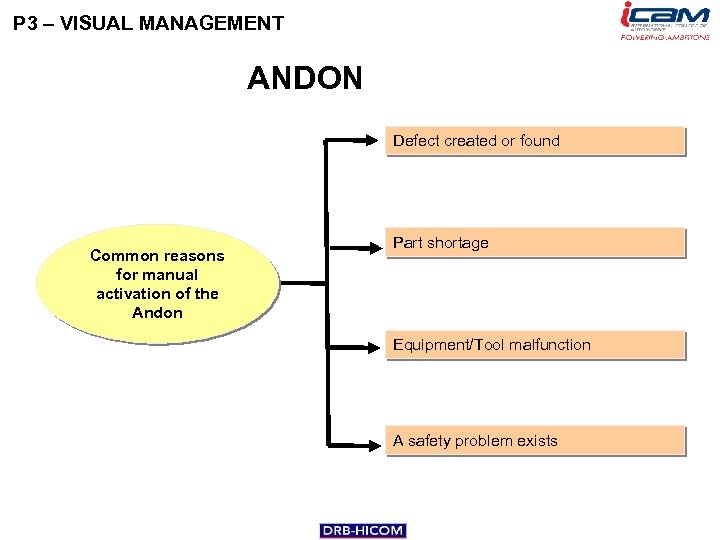

P 3 – VISUAL MANAGEMENT ANDON Defect created or found Common reasons for manual activation of the Andon Part shortage Equipment/Tool malfunction A safety problem exists

P 3 – VISUAL MANAGEMENT ANDON Defect created or found Common reasons for manual activation of the Andon Part shortage Equipment/Tool malfunction A safety problem exists

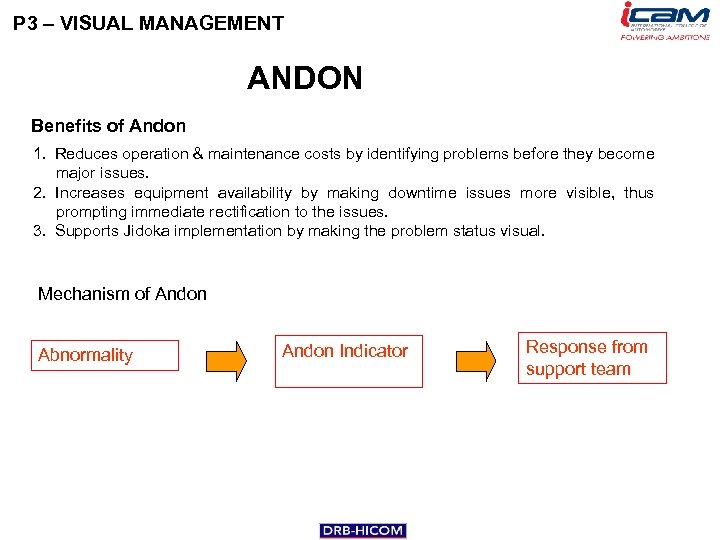

P 3 – VISUAL MANAGEMENT ANDON Benefits of Andon 1. Reduces operation & maintenance costs by identifying problems before they become major issues. 2. Increases equipment availability by making downtime issues more visible, thus prompting immediate rectification to the issues. 3. Supports Jidoka implementation by making the problem status visual. Mechanism of Andon Abnormality Andon Indicator Response from support team

P 3 – VISUAL MANAGEMENT ANDON Benefits of Andon 1. Reduces operation & maintenance costs by identifying problems before they become major issues. 2. Increases equipment availability by making downtime issues more visible, thus prompting immediate rectification to the issues. 3. Supports Jidoka implementation by making the problem status visual. Mechanism of Andon Abnormality Andon Indicator Response from support team

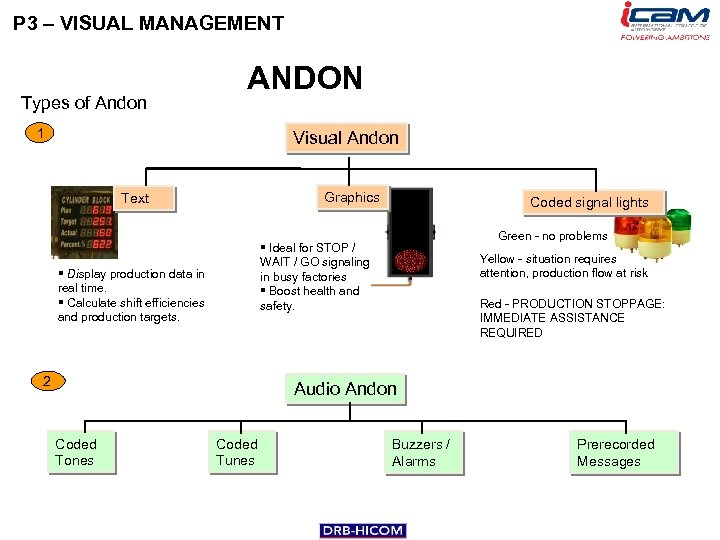

P 3 – VISUAL MANAGEMENT Types of Andon ANDON 1 Visual Andon Graphics Text Coded signal lights Green - no problems § Ideal for STOP / WAIT / GO signaling in busy factories § Boost health and safety. § Display production data in real time. § Calculate shift efficiencies and production targets. 2 Yellow - situation requires attention, production flow at risk Red - PRODUCTION STOPPAGE: IMMEDIATE ASSISTANCE REQUIRED Audio Andon Coded Tones Coded Tunes Buzzers / Alarms Prerecorded Messages

P 3 – VISUAL MANAGEMENT Types of Andon ANDON 1 Visual Andon Graphics Text Coded signal lights Green - no problems § Ideal for STOP / WAIT / GO signaling in busy factories § Boost health and safety. § Display production data in real time. § Calculate shift efficiencies and production targets. 2 Yellow - situation requires attention, production flow at risk Red - PRODUCTION STOPPAGE: IMMEDIATE ASSISTANCE REQUIRED Audio Andon Coded Tones Coded Tunes Buzzers / Alarms Prerecorded Messages

P 3 – VISUAL MANAGEMENT FOOTPRINT What is Footprint 1. Markings on the floor or work area outlining specifically where items should be placed. Benefit 1. To ease employees during storage or retrieval. 2. It avoids employees wasting time looking for things or pondering their next move. 3. The workplace becomes clean and better organized. 4. Operation on the shop floor and office become easier and safer q. 5. Visible location of parts or equipment for easy traceability and save time of searching

P 3 – VISUAL MANAGEMENT FOOTPRINT What is Footprint 1. Markings on the floor or work area outlining specifically where items should be placed. Benefit 1. To ease employees during storage or retrieval. 2. It avoids employees wasting time looking for things or pondering their next move. 3. The workplace becomes clean and better organized. 4. Operation on the shop floor and office become easier and safer q. 5. Visible location of parts or equipment for easy traceability and save time of searching

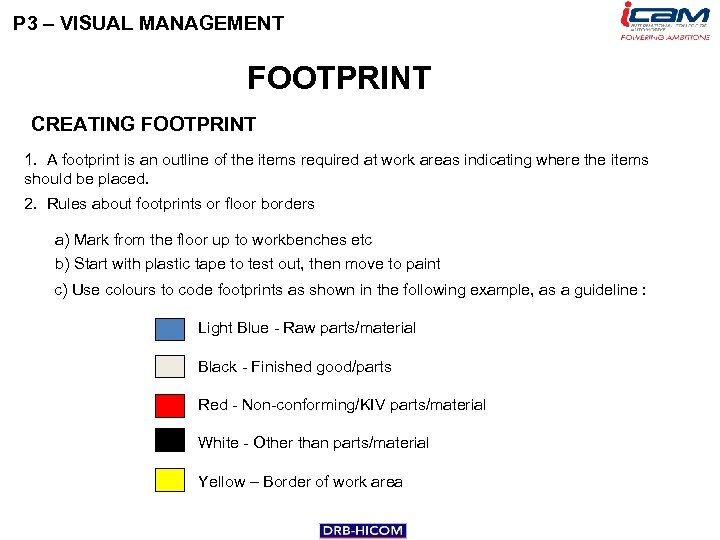

P 3 – VISUAL MANAGEMENT FOOTPRINT CREATING FOOTPRINT 1. A footprint is an outline of the items required at work areas indicating where the items should be placed. 2. Rules about footprints or floor borders a) Mark from the floor up to workbenches etc b) Start with plastic tape to test out, then move to paint c) Use colours to code footprints as shown in the following example, as a guideline : Light Blue - Raw parts/material Black - Finished good/parts Red - Non-conforming/KIV parts/material White - Other than parts/material Yellow – Border of work area

P 3 – VISUAL MANAGEMENT FOOTPRINT CREATING FOOTPRINT 1. A footprint is an outline of the items required at work areas indicating where the items should be placed. 2. Rules about footprints or floor borders a) Mark from the floor up to workbenches etc b) Start with plastic tape to test out, then move to paint c) Use colours to code footprints as shown in the following example, as a guideline : Light Blue - Raw parts/material Black - Finished good/parts Red - Non-conforming/KIV parts/material White - Other than parts/material Yellow – Border of work area

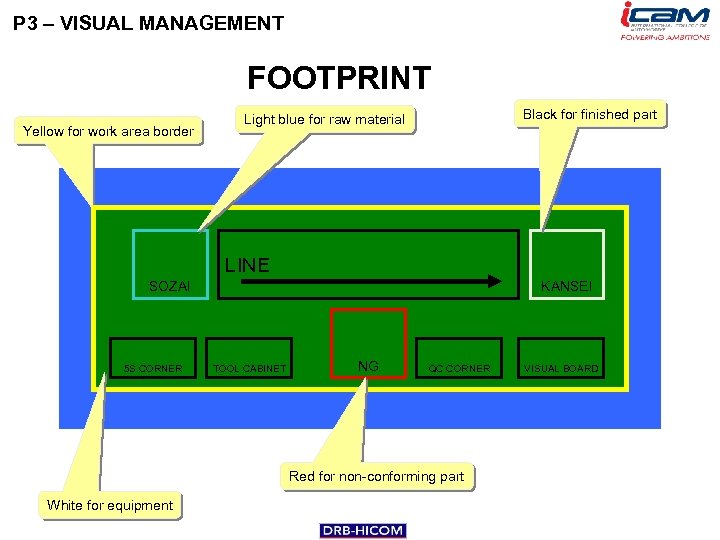

P 3 – VISUAL MANAGEMENT FOOTPRINT Yellow for work area border Black for finished part Light blue for raw material LINE SOZAI 5 S CORNER KANSEI TOOL CABINET NG QC CORNER Red for non-conforming part White for equipment VISUAL BOARD

P 3 – VISUAL MANAGEMENT FOOTPRINT Yellow for work area border Black for finished part Light blue for raw material LINE SOZAI 5 S CORNER KANSEI TOOL CABINET NG QC CORNER Red for non-conforming part White for equipment VISUAL BOARD

P 3 – VISUAL MANAGEMENT SIGNAGE Signage is any kind of graphics created to display information. Two types of signage 1. Displays q A visual display relates information and data to employees in the area. For example, charts showing the monthly revenues of the company or a graphic depicting a certain type of quality issue that group members should be aware of. 2. Controls q A visual control is intended to actually control or guide the action of the group members. Examples of controls are: stop signs at intersections, handicap parking signs, or no smoking signs.

P 3 – VISUAL MANAGEMENT SIGNAGE Signage is any kind of graphics created to display information. Two types of signage 1. Displays q A visual display relates information and data to employees in the area. For example, charts showing the monthly revenues of the company or a graphic depicting a certain type of quality issue that group members should be aware of. 2. Controls q A visual control is intended to actually control or guide the action of the group members. Examples of controls are: stop signs at intersections, handicap parking signs, or no smoking signs.

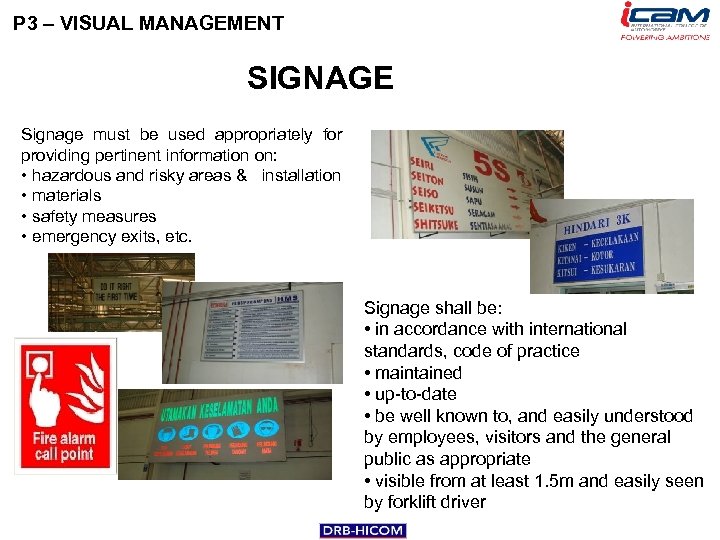

P 3 – VISUAL MANAGEMENT SIGNAGE Signage must be used appropriately for providing pertinent information on: • hazardous and risky areas & installation • materials • safety measures • emergency exits, etc. Signage shall be: • in accordance with international standards, code of practice • maintained • up-to-date • be well known to, and easily understood by employees, visitors and the general public as appropriate • visible from at least 1. 5 m and easily seen by forklift driver

P 3 – VISUAL MANAGEMENT SIGNAGE Signage must be used appropriately for providing pertinent information on: • hazardous and risky areas & installation • materials • safety measures • emergency exits, etc. Signage shall be: • in accordance with international standards, code of practice • maintained • up-to-date • be well known to, and easily understood by employees, visitors and the general public as appropriate • visible from at least 1. 5 m and easily seen by forklift driver

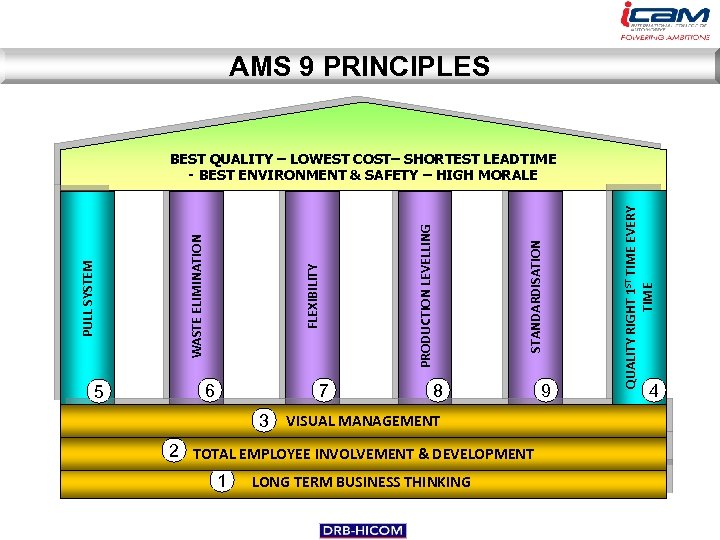

AMS 9 PRINCIPLES 7 STANDARDISATION PRODUCTION LEVELLING FLEXIBILITY 6 8 3 VISUAL MANAGEMENT 2 TOTAL EMPLOYEE INVOLVEMENT & DEVELOPMENT 1 LONG TERM BUSINESS THINKING 9 QUALITY RIGHT 1 ST TIME EVERY TIME 5 WASTE ELIMINATION PULL SYSTEM BEST QUALITY – LOWEST COST– SHORTEST LEADTIME - BEST ENVIRONMENT & SAFETY – HIGH MORALE 4

AMS 9 PRINCIPLES 7 STANDARDISATION PRODUCTION LEVELLING FLEXIBILITY 6 8 3 VISUAL MANAGEMENT 2 TOTAL EMPLOYEE INVOLVEMENT & DEVELOPMENT 1 LONG TERM BUSINESS THINKING 9 QUALITY RIGHT 1 ST TIME EVERY TIME 5 WASTE ELIMINATION PULL SYSTEM BEST QUALITY – LOWEST COST– SHORTEST LEADTIME - BEST ENVIRONMENT & SAFETY – HIGH MORALE 4