9c9bdbf9d59342b4032f044814c71aab.ppt

- Количество слайдов: 26

P 2 Intern Working Group EPA’s Pollution Prevention GHG Calculator David A. Carter Kansas State University Pollution Prevention Institute July 6, 2010

P 2 Intern Working Group EPA’s Pollution Prevention GHG Calculator David A. Carter Kansas State University Pollution Prevention Institute July 6, 2010

``I think you should be more explicit here in step two. . . ''

``I think you should be more explicit here in step two. . . ''

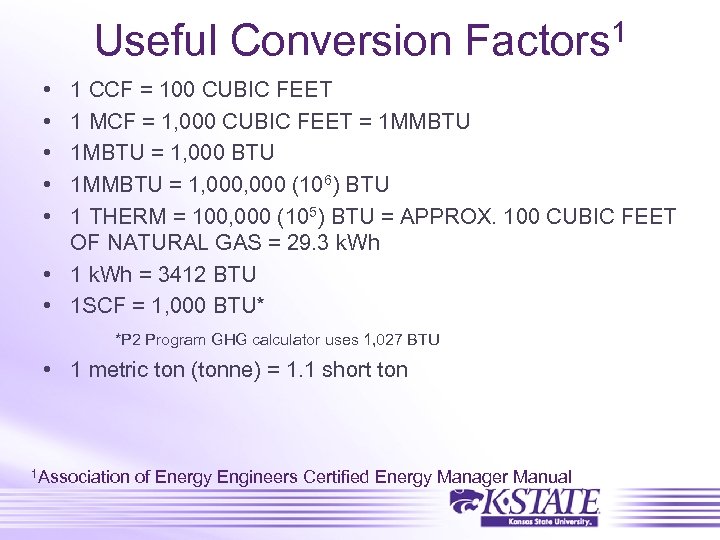

Useful Conversion Factors 1 • • • 1 CCF = 100 CUBIC FEET 1 MCF = 1, 000 CUBIC FEET = 1 MMBTU 1 MBTU = 1, 000 BTU 1 MMBTU = 1, 000 (106) BTU 1 THERM = 100, 000 (105) BTU = APPROX. 100 CUBIC FEET OF NATURAL GAS = 29. 3 k. Wh • 1 k. Wh = 3412 BTU • 1 SCF = 1, 000 BTU* *P 2 Program GHG calculator uses 1, 027 BTU • 1 metric ton (tonne) = 1. 1 short ton 1 Association of Energy Engineers Certified Energy Manager Manual

Useful Conversion Factors 1 • • • 1 CCF = 100 CUBIC FEET 1 MCF = 1, 000 CUBIC FEET = 1 MMBTU 1 MBTU = 1, 000 BTU 1 MMBTU = 1, 000 (106) BTU 1 THERM = 100, 000 (105) BTU = APPROX. 100 CUBIC FEET OF NATURAL GAS = 29. 3 k. Wh • 1 k. Wh = 3412 BTU • 1 SCF = 1, 000 BTU* *P 2 Program GHG calculator uses 1, 027 BTU • 1 metric ton (tonne) = 1. 1 short ton 1 Association of Energy Engineers Certified Energy Manager Manual

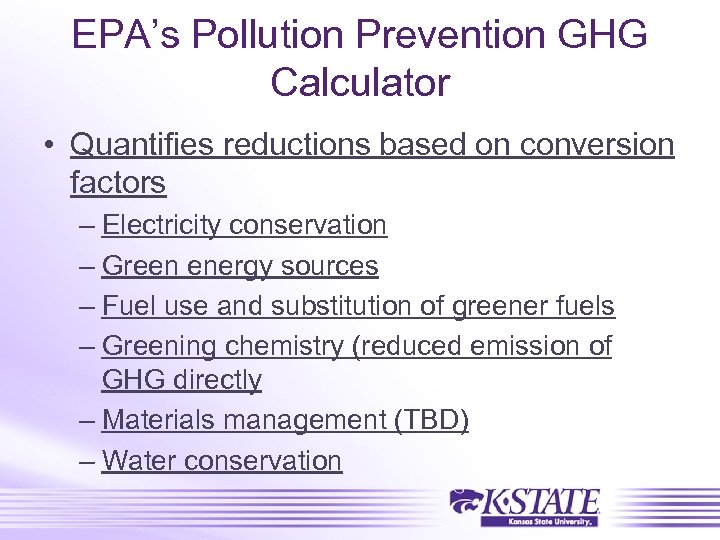

EPA’s Pollution Prevention GHG Calculator • Quantifies reductions based on conversion factors – Electricity conservation – Green energy sources – Fuel use and substitution of greener fuels – Greening chemistry (reduced emission of GHG directly – Materials management (TBD) – Water conservation

EPA’s Pollution Prevention GHG Calculator • Quantifies reductions based on conversion factors – Electricity conservation – Green energy sources – Fuel use and substitution of greener fuels – Greening chemistry (reduced emission of GHG directly – Materials management (TBD) – Water conservation

EPA Pollution Prevention Program’s GHG Calculator (cont) • Converts standard metrics into metric tons of carbon dioxide equivalent (MTCO 2 e) using standard national conversion factors • Aggregates by category and by total project (does not carry project titles forward) • National conversion factor 7. 21 x 10 -4 MTCO 2 e/k. Wh; can also use state-specific emission factors – – Iowa: MRO, 9. 54 x 10 -4 MTCO 2 e/k. Wh Kansas: SPP, 7. 1 x 10 -4 MTCO 2 e/k. Wh Missouri: RFC, 8. 58 x 10 -4 MTCO 2 e/k. Wh (Why? Should be SPP/SERC) Nebraska: MRO, 9. 54 x 10 -4 MTCO 2 e/k. Wh (also has WECC) • GHG Conversion Tool_April 7 2010. xls

EPA Pollution Prevention Program’s GHG Calculator (cont) • Converts standard metrics into metric tons of carbon dioxide equivalent (MTCO 2 e) using standard national conversion factors • Aggregates by category and by total project (does not carry project titles forward) • National conversion factor 7. 21 x 10 -4 MTCO 2 e/k. Wh; can also use state-specific emission factors – – Iowa: MRO, 9. 54 x 10 -4 MTCO 2 e/k. Wh Kansas: SPP, 7. 1 x 10 -4 MTCO 2 e/k. Wh Missouri: RFC, 8. 58 x 10 -4 MTCO 2 e/k. Wh (Why? Should be SPP/SERC) Nebraska: MRO, 9. 54 x 10 -4 MTCO 2 e/k. Wh (also has WECC) • GHG Conversion Tool_April 7 2010. xls

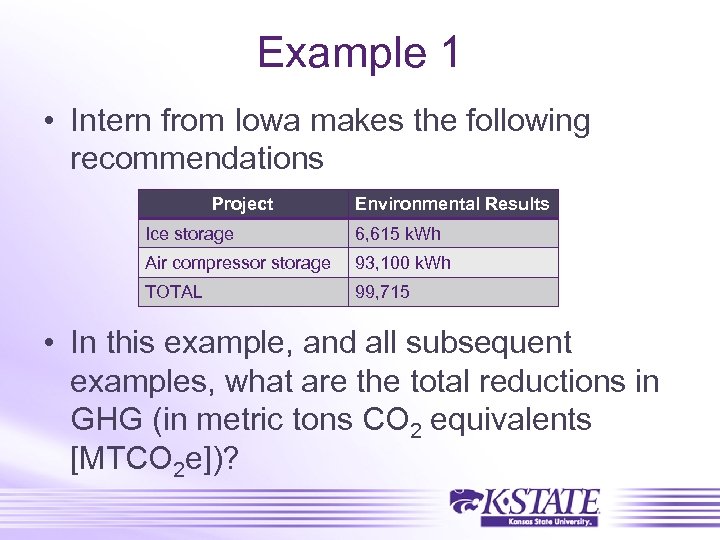

Example 1 • Intern from Iowa makes the following recommendations Project Environmental Results Ice storage 6, 615 k. Wh Air compressor storage 93, 100 k. Wh TOTAL 99, 715 • In this example, and all subsequent examples, what are the total reductions in GHG (in metric tons CO 2 equivalents [MTCO 2 e])?

Example 1 • Intern from Iowa makes the following recommendations Project Environmental Results Ice storage 6, 615 k. Wh Air compressor storage 93, 100 k. Wh TOTAL 99, 715 • In this example, and all subsequent examples, what are the total reductions in GHG (in metric tons CO 2 equivalents [MTCO 2 e])?

Example 1 A. 95. 157 MTCO 2 e B. 71. 92 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

Example 1 A. 95. 157 MTCO 2 e B. 71. 92 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

Example 2 • An intern at a facility in Knoxville, Iowa recommended a waste heat recovery project, reducing 264, 310 therms of natural gas.

Example 2 • An intern at a facility in Knoxville, Iowa recommended a waste heat recovery project, reducing 264, 310 therms of natural gas.

Example 2 A. 14. 440 MTCO 2 e B. 1, 406. 023 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

Example 2 A. 14. 440 MTCO 2 e B. 1, 406. 023 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

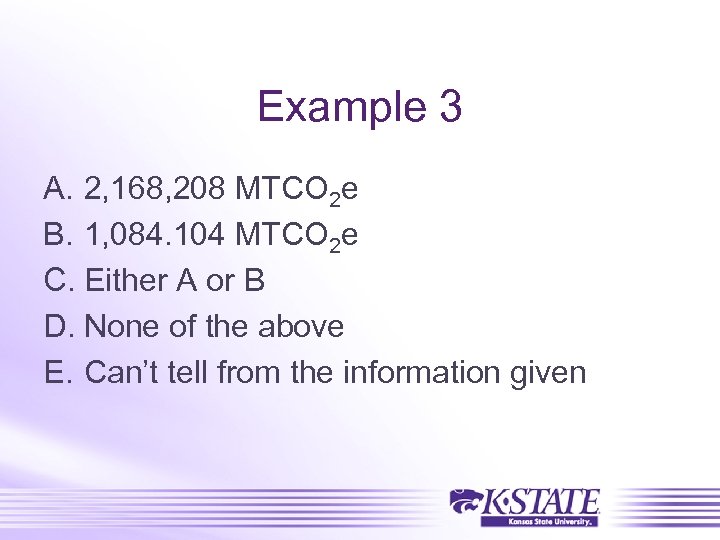

Example 3 • Intern at Minnesota facility works on SF 6 replacement project that saves the facility $200, 000 per year.

Example 3 • Intern at Minnesota facility works on SF 6 replacement project that saves the facility $200, 000 per year.

Example 3 A. 2, 168, 208 MTCO 2 e B. 1, 084. 104 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

Example 3 A. 2, 168, 208 MTCO 2 e B. 1, 084. 104 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

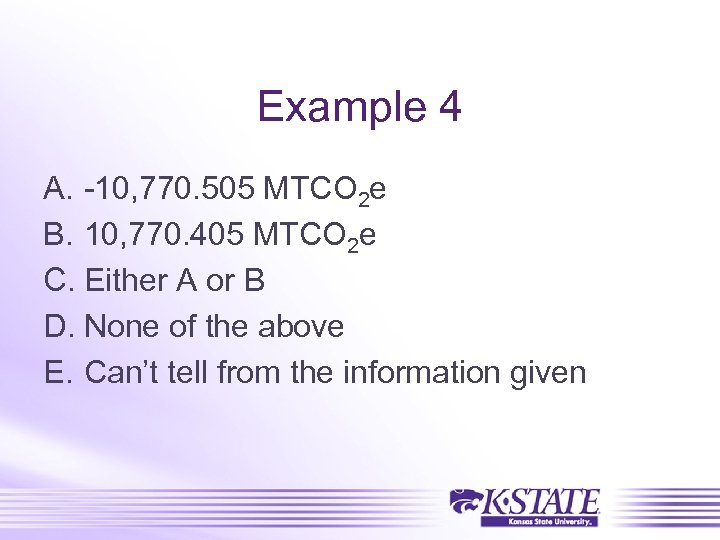

Example 4 • Intern at Minnesota facility recommends replacing 1, 000 pounds of SF 6 with 1, 000 pounds of N 2 O/CO 2 mix (50/50).

Example 4 • Intern at Minnesota facility recommends replacing 1, 000 pounds of SF 6 with 1, 000 pounds of N 2 O/CO 2 mix (50/50).

Example 4 A. -10, 770. 505 MTCO 2 e B. 10, 770. 405 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

Example 4 A. -10, 770. 505 MTCO 2 e B. 10, 770. 405 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

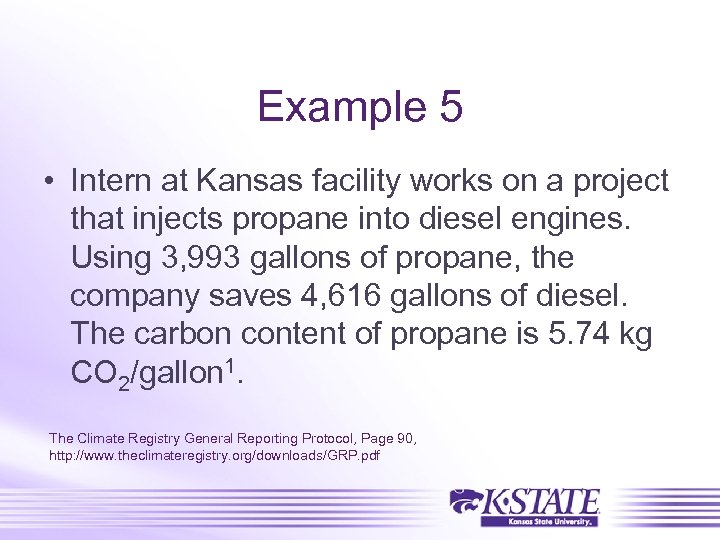

Example 5 • Intern at Kansas facility works on a project that injects propane into diesel engines. Using 3, 993 gallons of propane, the company saves 4, 616 gallons of diesel. The carbon content of propane is 5. 74 kg CO 2/gallon 1. The Climate Registry General Reporting Protocol, Page 90, http: //www. theclimateregistry. org/downloads/GRP. pdf

Example 5 • Intern at Kansas facility works on a project that injects propane into diesel engines. Using 3, 993 gallons of propane, the company saves 4, 616 gallons of diesel. The carbon content of propane is 5. 74 kg CO 2/gallon 1. The Climate Registry General Reporting Protocol, Page 90, http: //www. theclimateregistry. org/downloads/GRP. pdf

Example 5 A. 24. 199 MTCO 2 e B. 66. 519 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

Example 5 A. 24. 199 MTCO 2 e B. 66. 519 MTCO 2 e C. Either A or B D. None of the above E. Can’t tell from the information given

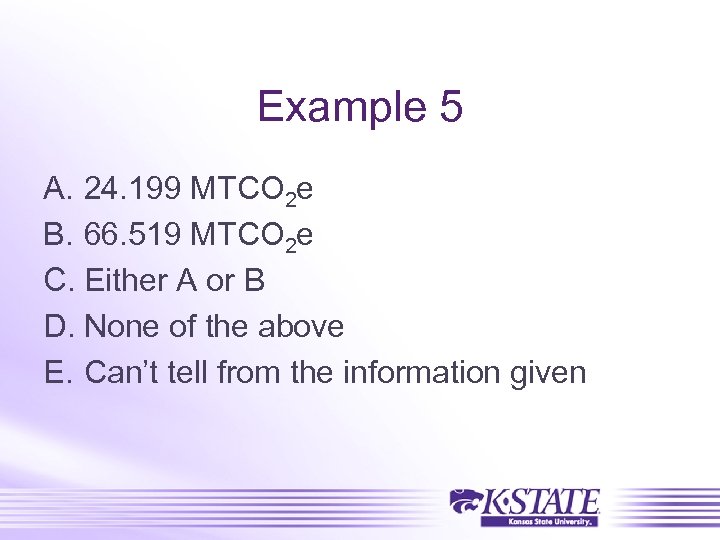

Example 6 • Intern at a nuclear power plant in Kansas conducts an HVAC replacement project that conserves 215, 280 k. Wh of electricity and replaces 768 pounds of HCFC-22 with R-410 a.

Example 6 • Intern at a nuclear power plant in Kansas conducts an HVAC replacement project that conserves 215, 280 k. Wh of electricity and replaces 768 pounds of HCFC-22 with R-410 a.

Example 6 A. 152. 916 MTCO 2 e B. 783. 456 MTCO 2 e C. 785. 827 MTCO 2 e D. None of the above E. Can’t tell from the information given

Example 6 A. 152. 916 MTCO 2 e B. 783. 456 MTCO 2 e C. 785. 827 MTCO 2 e D. None of the above E. Can’t tell from the information given

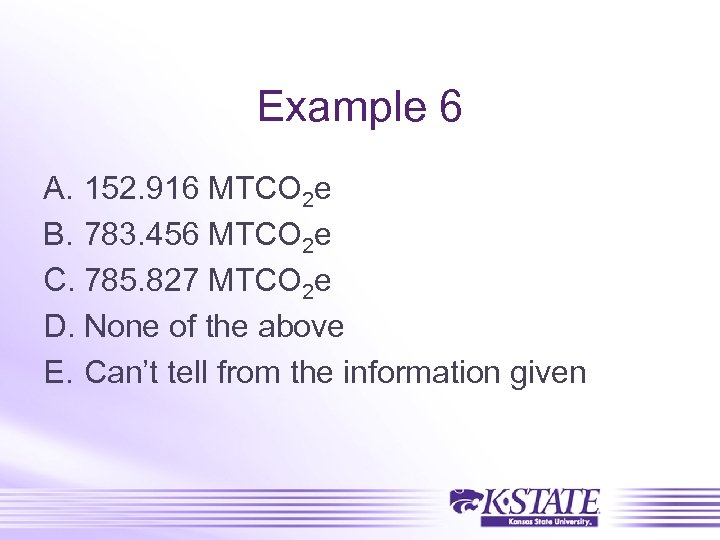

Example 7 - Iowa Project $ Savings Env. Impacts Operational Savings 31569. 84 268, 272 k. Wh Laser Proposal 27, 165. 29 232, 320 k. Wh Distribution Replacement 34, 128. 87 359, 251 k. Wh Heat Recovery 27, 168 32, 907 therms (natural gas) Loss Reduction 25, 258. 84 235, 089 k. Wh

Example 7 - Iowa Project $ Savings Env. Impacts Operational Savings 31569. 84 268, 272 k. Wh Laser Proposal 27, 165. 29 232, 320 k. Wh Distribution Replacement 34, 128. 87 359, 251 k. Wh Heat Recovery 27, 168 32, 907 therms (natural gas) Loss Reduction 25, 258. 84 235, 089 k. Wh

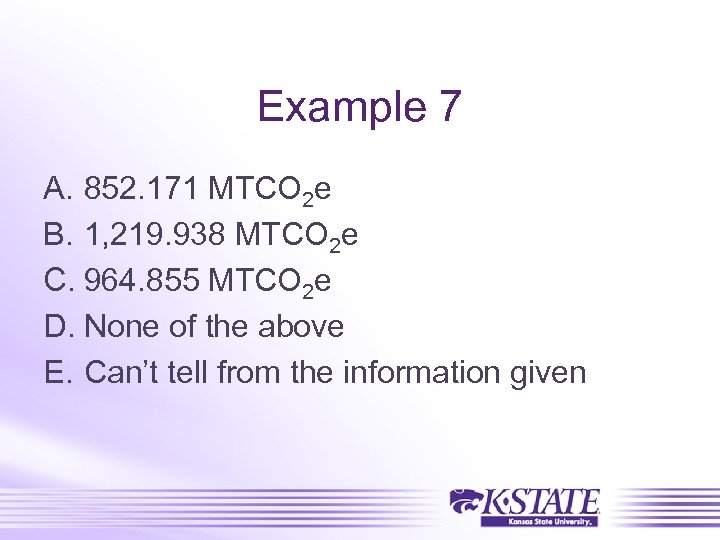

Example 7 A. 852. 171 MTCO 2 e B. 1, 219. 938 MTCO 2 e C. 964. 855 MTCO 2 e D. None of the above E. Can’t tell from the information given

Example 7 A. 852. 171 MTCO 2 e B. 1, 219. 938 MTCO 2 e C. 964. 855 MTCO 2 e D. None of the above E. Can’t tell from the information given

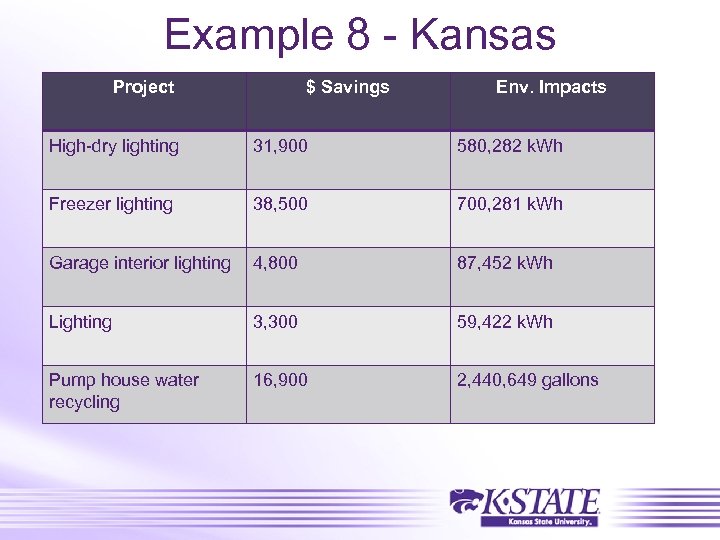

Example 8 - Kansas Project $ Savings Env. Impacts High-dry lighting 31, 900 580, 282 k. Wh Freezer lighting 38, 500 700, 281 k. Wh Garage interior lighting 4, 800 87, 452 k. Wh Lighting 3, 300 59, 422 k. Wh Pump house water recycling 16, 900 2, 440, 649 gallons

Example 8 - Kansas Project $ Savings Env. Impacts High-dry lighting 31, 900 580, 282 k. Wh Freezer lighting 38, 500 700, 281 k. Wh Garage interior lighting 4, 800 87, 452 k. Wh Lighting 3, 300 59, 422 k. Wh Pump house water recycling 16, 900 2, 440, 649 gallons

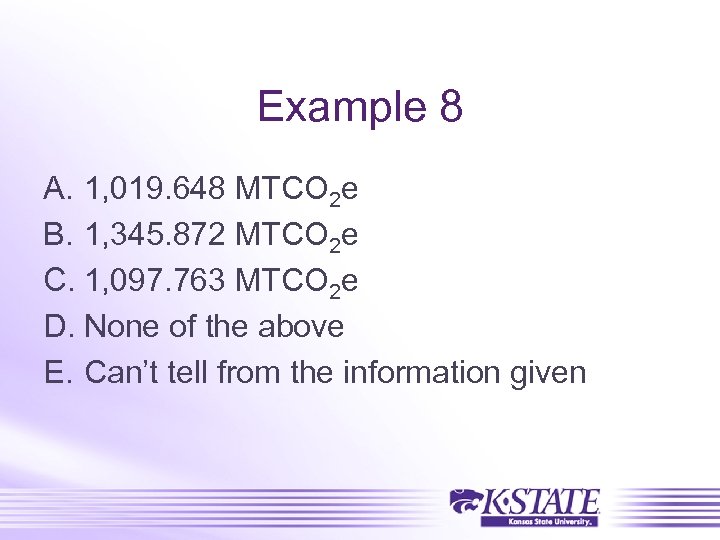

Example 8 A. 1, 019. 648 MTCO 2 e B. 1, 345. 872 MTCO 2 e C. 1, 097. 763 MTCO 2 e D. None of the above E. Can’t tell from the information given

Example 8 A. 1, 019. 648 MTCO 2 e B. 1, 345. 872 MTCO 2 e C. 1, 097. 763 MTCO 2 e D. None of the above E. Can’t tell from the information given

Example 9 - Missouri Project $ Savings Env. Impacts 63 rd St. lighting 2, 085 35, 646 k. Wh Boiler insulation 1, 290 Chemical elimination 36, 205 Chiller VFD 29, 000 495, 726 k. Wh New humidifier 56, 898 407, 288 k. Wh Time clock 585 9, 979 k. Wh Oak St. lighting 3, 317 56, 699 k. Wh Makeup meters 2, 880 E. 8 th St. lighting 28, 037 Pipe insulation 667 Drinking fountains 383 6, 540 k. Wh Low-level dampers 8, 539 89, 183 k. Wh Belt retrofit 17, 467 212, 190 k. Wh Total 187, 353 1, 730, 015 k. Wh 416, 764 k. Wh

Example 9 - Missouri Project $ Savings Env. Impacts 63 rd St. lighting 2, 085 35, 646 k. Wh Boiler insulation 1, 290 Chemical elimination 36, 205 Chiller VFD 29, 000 495, 726 k. Wh New humidifier 56, 898 407, 288 k. Wh Time clock 585 9, 979 k. Wh Oak St. lighting 3, 317 56, 699 k. Wh Makeup meters 2, 880 E. 8 th St. lighting 28, 037 Pipe insulation 667 Drinking fountains 383 6, 540 k. Wh Low-level dampers 8, 539 89, 183 k. Wh Belt retrofit 17, 467 212, 190 k. Wh Total 187, 353 1, 730, 015 k. Wh 416, 764 k. Wh

Example 9 A. 1, 247. 904 MTCO 2 e B. 1, 485. 065 MTCO 2 e C. 1, 361. 721 MTCO 2 e D. None of the above E. All of the above

Example 9 A. 1, 247. 904 MTCO 2 e B. 1, 485. 065 MTCO 2 e C. 1, 361. 721 MTCO 2 e D. None of the above E. All of the above

Example 10 - Nebraska Project Env. Impacts Cover kettle 85, 000 therms* Install heat exchanger 89, 000 therms Adjust fan placement 75 therms Insulate small kettle 2, 690 therms Cover small kettle 46, 500 therms Cover acid/flux bath 140, 000 k. Wh; 450, 000 gallons; 13, 000 therms Divert bearing cooling water 111, 000 gallons Install WW evaporator 3, 866 therms Install rapid roll door 55, 550 therms Total 295, 681 therms; 140, 000 k. Wh; 561, 000 gallons of water *therms (natural gas)

Example 10 - Nebraska Project Env. Impacts Cover kettle 85, 000 therms* Install heat exchanger 89, 000 therms Adjust fan placement 75 therms Insulate small kettle 2, 690 therms Cover small kettle 46, 500 therms Cover acid/flux bath 140, 000 k. Wh; 450, 000 gallons; 13, 000 therms Divert bearing cooling water 111, 000 gallons Install WW evaporator 3, 866 therms Install rapid roll door 55, 550 therms Total 295, 681 therms; 140, 000 k. Wh; 561, 000 gallons of water *therms (natural gas)

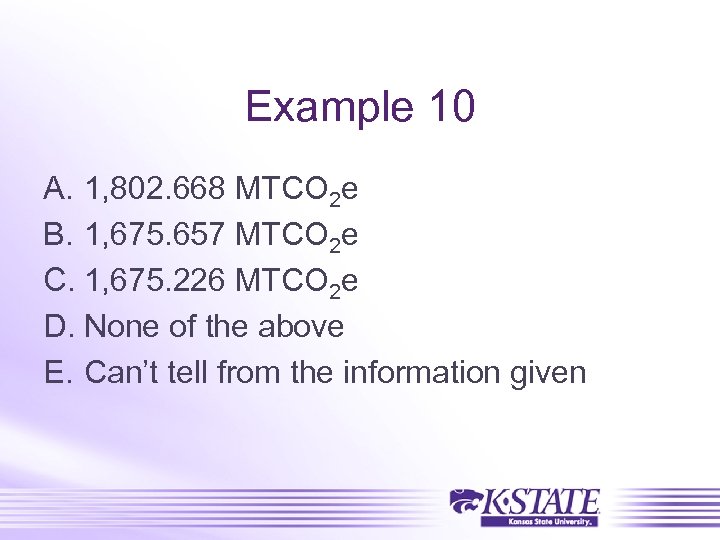

Example 10 A. 1, 802. 668 MTCO 2 e B. 1, 675. 657 MTCO 2 e C. 1, 675. 226 MTCO 2 e D. None of the above E. Can’t tell from the information given

Example 10 A. 1, 802. 668 MTCO 2 e B. 1, 675. 657 MTCO 2 e C. 1, 675. 226 MTCO 2 e D. None of the above E. Can’t tell from the information given

Contact David A. Carter Kansas State University Pollution Prevention Institute 785 -532 -4998 dcarter@ksu. edu

Contact David A. Carter Kansas State University Pollution Prevention Institute 785 -532 -4998 dcarter@ksu. edu