0311ea3392e21b8ea93c8690445ed8d5.ppt

- Количество слайдов: 17

P 08002 -Automated Parallel Bars Ryan Hellems Justin Knowles Justin Vowles Jeff Osborne Jessica Stalker Dr. B. De. Bartolo Project Lead ME ME ME ISE Project Advisor Customer: Nazareth Physical Therapy Clinic, JJ Mowder Sponsor:

Project Description • The physical therapy clinic at Nazareth uses parallel bars to rehabilitate stroke and other neurological patients for walking. Device needs to simplify raising and lowering of parallel bars, and insuring they remain level. Key high level customer needs • • – – – Must be safe -Support 350 Lbs without drop -No pinch points or sharp edges -No trip or snag hazards -Accurate height adjustment Ease of use -<9 Lbs force to raise -Reasonable time to adjust (90 s) -Bars remain level along full length Reliable for 5 years of life

Current System

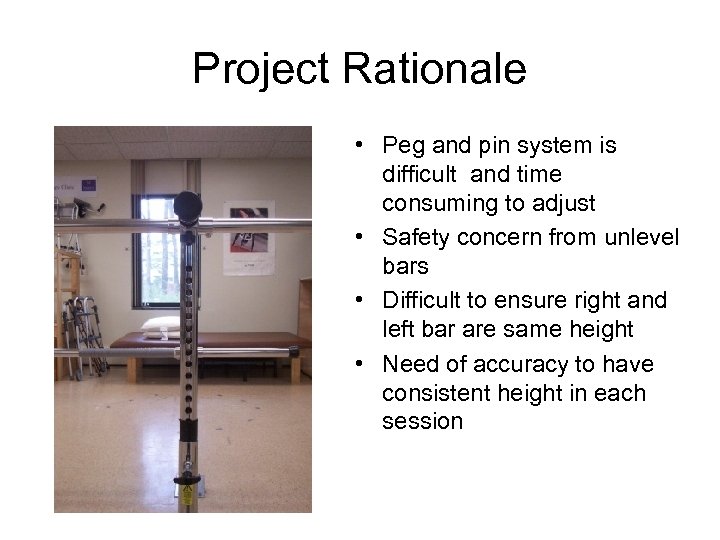

Project Rationale • Peg and pin system is difficult and time consuming to adjust • Safety concern from unlevel bars • Difficult to ensure right and left bar are same height • Need of accuracy to have consistent height in each session

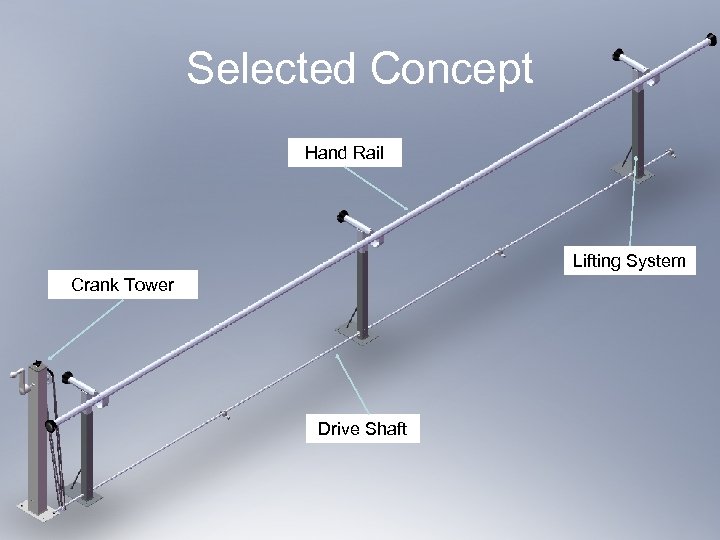

Selected Concept Hand Rail Lifting System Crank Tower Drive Shaft

Key Calculations • 0. 5 inches height change per revolution (4: 1 gear ratio) • Input force on handle is 2. 19 Lbs. – Ergonomic max is 8. 5 Lbs • Minimum bar height: 26 inches • Maximum bar height 44 inches • Ergonomic height of hand crank is 36 inches

Design Details

Design Details

Risk Assessment • Side-to-side deflection of uprights is too much, system wobbles – Resolution: Build one jack and measure. Reduce clearance, or add collar. • Use of a non-precision acme threaded rod could cause alignment or excessive torque issues. – Resolution: Build one jack and test for issues, if any, upgrade to precision threaded rod. • Using less expensive, jack miter gears could pose an excessive wear issue which would not be discovered until they fail in use. – Resolution: Testing has been completed comparing hardness of different miter gears. Results showed that jack miter gears will hold up for this application. • Unexpected frictional losses could cause the final system to be difficult to raise and lower. – Resolution: If losses present a torque issue gearing can be changed to make the system easier to raise and lower.

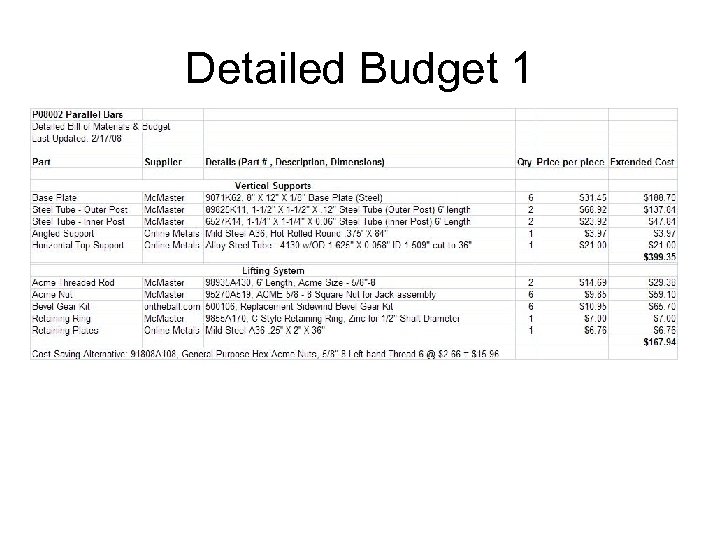

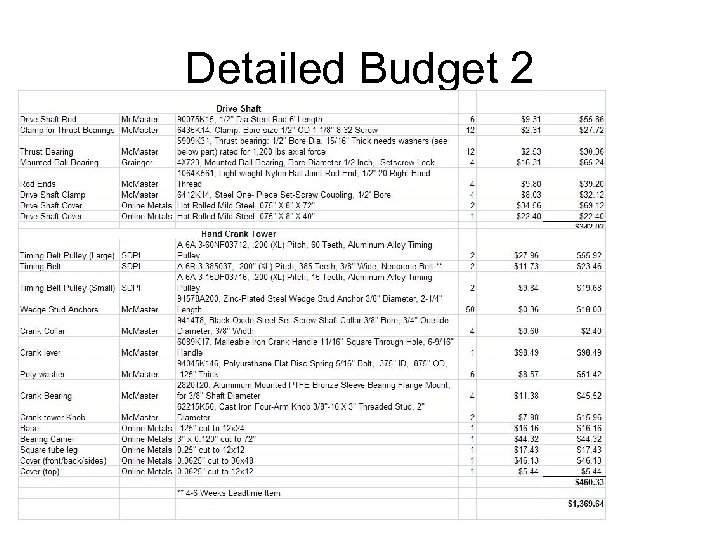

Budget Vertical Support Total – $399. 35 Lifting System - $167. 94 Drive Shaft System - $342. 02 Hand Crank Tower – $460. 33 Total Cost - $1, 369. 64

Current State Of Design • Design meets all customer needs • Design meets engineering specifications except: – 2 inches less of range of motion, lower max height – Deflection at full-extension unknown, maybe an issue • Budget: Below target, extra funds for Powder Coating • Schedule: – Design completed on schedule, some analysis remaining (completed over break) – Long Lead items ordered (miter gears and pulleys) • Mitigations: – Build high-risk components early, and test. Alternative design options identified. – Modular design- main subsystems will be built independently

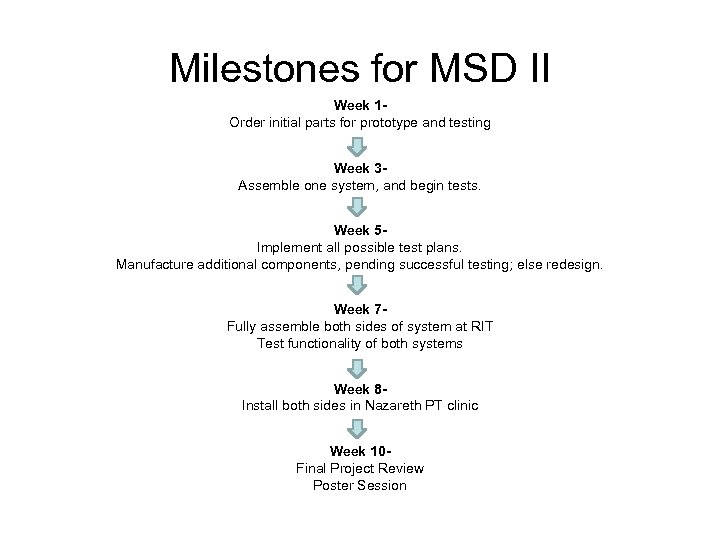

Milestones for MSD II Week 1 Order initial parts for prototype and testing Week 3 Assemble one system, and begin tests. Week 5 Implement all possible test plans. Manufacture additional components, pending successful testing; else redesign. Week 7 Fully assemble both sides of system at RIT Test functionality of both systems Week 8 Install both sides in Nazareth PT clinic Week 10 Final Project Review Poster Session

Questions?

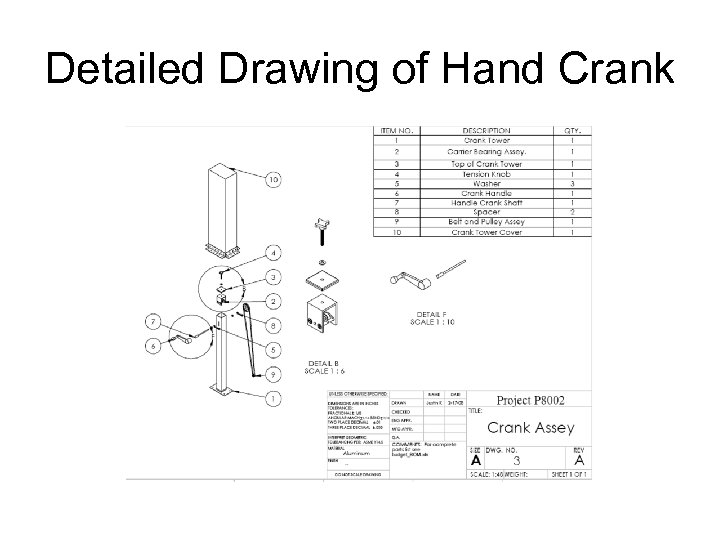

Detailed Drawing of Hand Crank

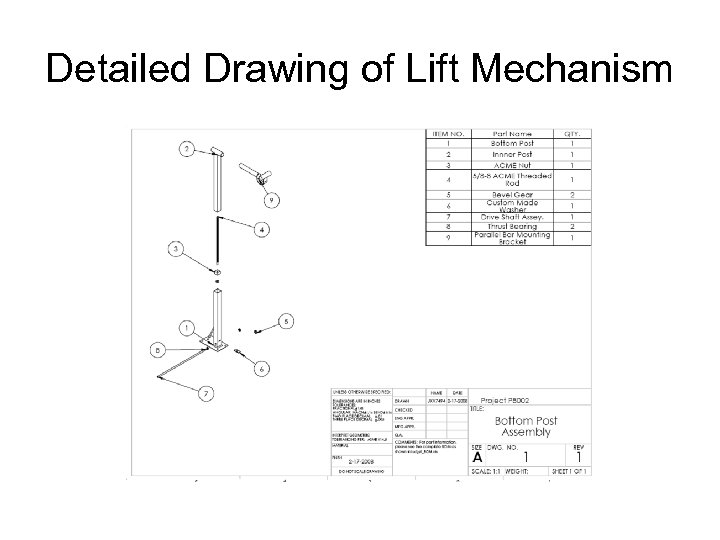

Detailed Drawing of Lift Mechanism

Detailed Budget 1

Detailed Budget 2

0311ea3392e21b8ea93c8690445ed8d5.ppt