c079098b96c2fed0de42f283c9c4db1c.ppt

- Количество слайдов: 38

OVERVIEW Scheduled Maintenance Program History Philosophy Initiating a Scheduled Maintenance Program Best Practices CFC Program Compliance Tracking Refrigerants EPA Leak Detection Requirement Additional Recordkeeping Requirement

OVERVIEW Scheduled Maintenance Program History Philosophy Initiating a Scheduled Maintenance Program Best Practices CFC Program Compliance Tracking Refrigerants EPA Leak Detection Requirement Additional Recordkeeping Requirement

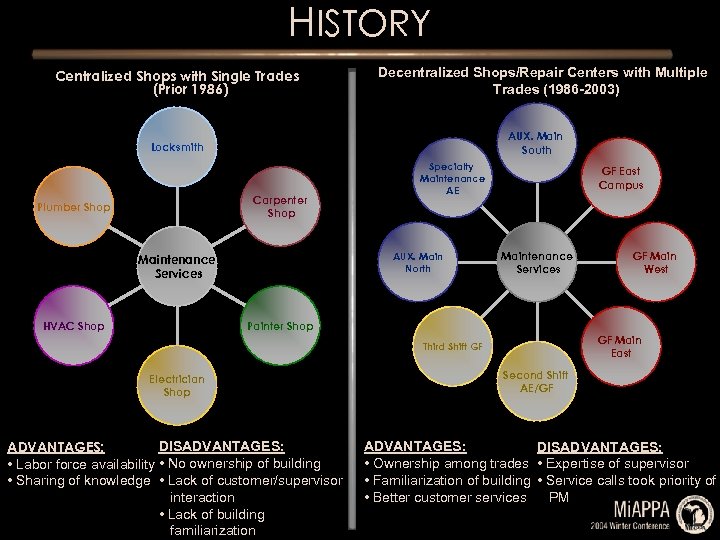

HISTORY Centralized Shops with Single Trades (Prior 1986) Decentralized Shops/Repair Centers with Multiple Trades (1986 -2003) AUX. Main South Locksmith Carpenter Shop Plumber Shop AUX. Main North Maintenance Services HVAC Shop Specialty Maintenance AE GF East Campus Maintenance Services GF Main West Painter Shop GF Main East Third Shift GF Electrician Shop DISADVANTAGES: • Labor force availability • No ownership of building • Sharing of knowledge • Lack of customer/supervisor interaction • Lack of building familiarization Second Shift AE/GF ADVANTAGES: • Ownership among trades • Familiarization of building • Better customer services DISADVANTAGES: • Expertise of supervisor • Service calls took priority of PM

HISTORY Centralized Shops with Single Trades (Prior 1986) Decentralized Shops/Repair Centers with Multiple Trades (1986 -2003) AUX. Main South Locksmith Carpenter Shop Plumber Shop AUX. Main North Maintenance Services HVAC Shop Specialty Maintenance AE GF East Campus Maintenance Services GF Main West Painter Shop GF Main East Third Shift GF Electrician Shop DISADVANTAGES: • Labor force availability • No ownership of building • Sharing of knowledge • Lack of customer/supervisor interaction • Lack of building familiarization Second Shift AE/GF ADVANTAGES: • Ownership among trades • Familiarization of building • Better customer services DISADVANTAGES: • Expertise of supervisor • Service calls took priority of PM

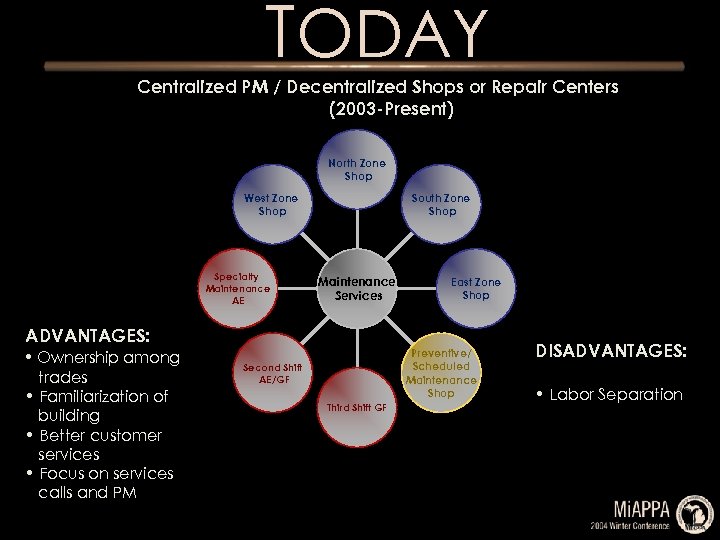

TODAY Centralized PM / Decentralized Shops or Repair Centers (2003 -Present) North Zone Shop West Zone Shop Specialty Maintenance AE ADVANTAGES: • Ownership among trades • Familiarization of building • Better customer services • Focus on services calls and PM South Zone Shop Maintenance Services East Zone Shop Preventive/ Scheduled Maintenance Shop Second Shift AE/GF Third Shift GF DISADVANTAGES: • Labor Separation

TODAY Centralized PM / Decentralized Shops or Repair Centers (2003 -Present) North Zone Shop West Zone Shop Specialty Maintenance AE ADVANTAGES: • Ownership among trades • Familiarization of building • Better customer services • Focus on services calls and PM South Zone Shop Maintenance Services East Zone Shop Preventive/ Scheduled Maintenance Shop Second Shift AE/GF Third Shift GF DISADVANTAGES: • Labor Separation

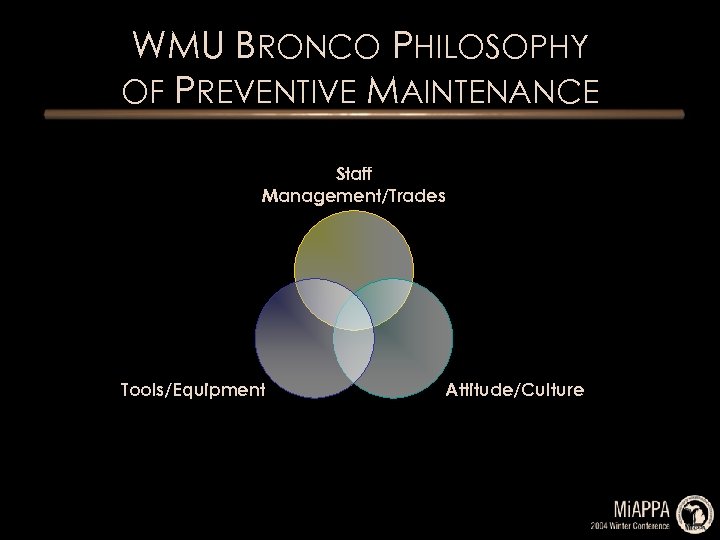

WMU BRONCO PHILOSOPHY OF PREVENTIVE MAINTENANCE Staff Management/Trades Tools/Equipment Attitude/Culture

WMU BRONCO PHILOSOPHY OF PREVENTIVE MAINTENANCE Staff Management/Trades Tools/Equipment Attitude/Culture

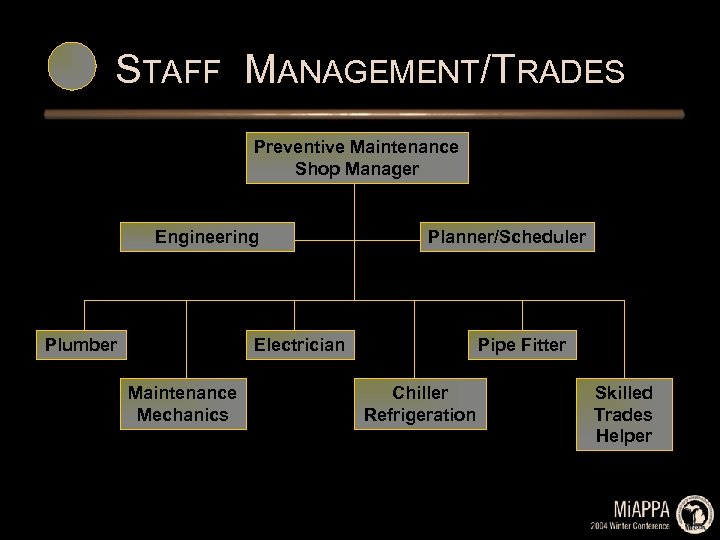

STAFF MANAGEMENT/TRADES Preventive Maintenance Shop Manager Engineering Plumber Planner/Scheduler Electrician Maintenance Mechanics Pipe Fitter Chiller Refrigeration Skilled Trades Helper

STAFF MANAGEMENT/TRADES Preventive Maintenance Shop Manager Engineering Plumber Planner/Scheduler Electrician Maintenance Mechanics Pipe Fitter Chiller Refrigeration Skilled Trades Helper

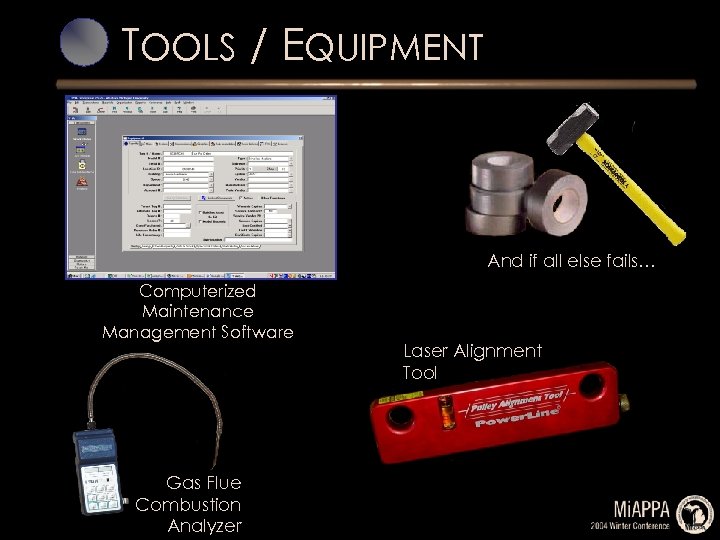

TOOLS / EQUIPMENT And if all else fails… Computerized Maintenance Management Software Gas Flue Combustion Analyzer Laser Alignment Tool

TOOLS / EQUIPMENT And if all else fails… Computerized Maintenance Management Software Gas Flue Combustion Analyzer Laser Alignment Tool

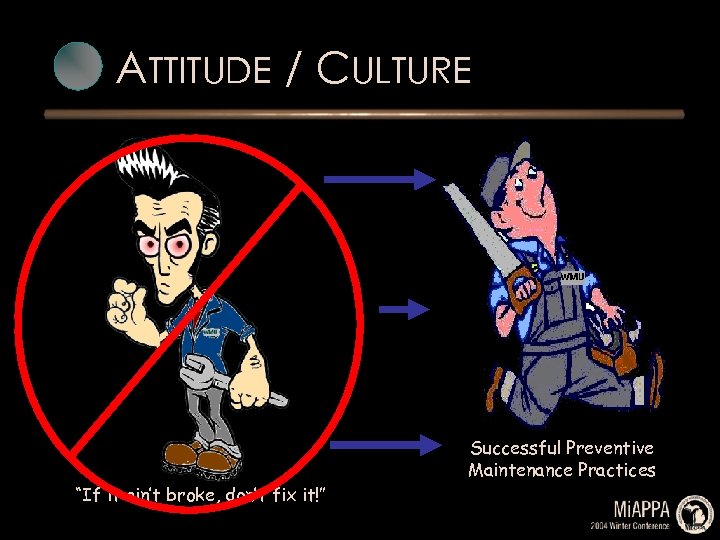

ATTITUDE / CULTURE “If it ain’t broke, don’t fix it!” Successful Preventive Maintenance Practices

ATTITUDE / CULTURE “If it ain’t broke, don’t fix it!” Successful Preventive Maintenance Practices

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

INITIATING A CENTRALIZED PM PROGRAM • Inventory of Equipment • Tagging and Database Entry • Creating Task Procedures and Frequency • Percentage of Labor Hours Dedicated to Preventive Maintenance • Checks and Balances • Constant Program Review

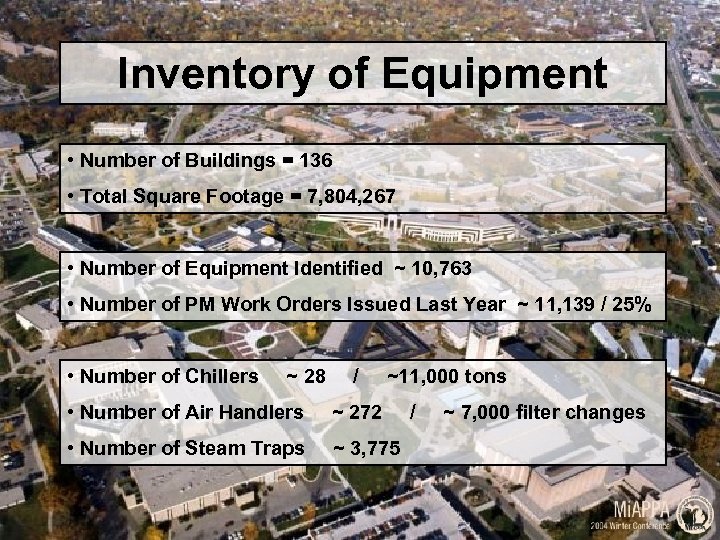

Inventory of Equipment • Number of Buildings = 136 • Total Square Footage = 7, 804, 267 • Number of Equipment Identified ~ 10, 763 • Number of PM Work Orders Issued Last Year ~ 11, 139 / 25% • Number of Chillers ~ 28 / ~11, 000 tons • Number of Air Handlers ~ 272 • Number of Steam Traps ~ 3, 775 / ~ 7, 000 filter changes

Inventory of Equipment • Number of Buildings = 136 • Total Square Footage = 7, 804, 267 • Number of Equipment Identified ~ 10, 763 • Number of PM Work Orders Issued Last Year ~ 11, 139 / 25% • Number of Chillers ~ 28 / ~11, 000 tons • Number of Air Handlers ~ 272 • Number of Steam Traps ~ 3, 775 / ~ 7, 000 filter changes

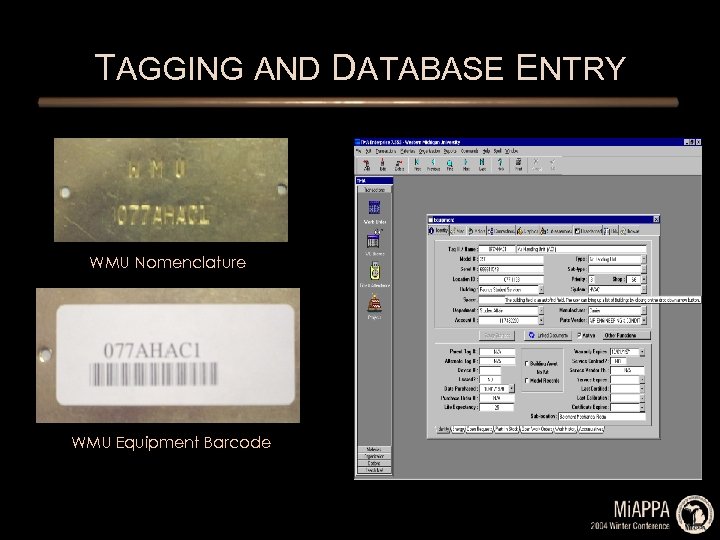

TAGGING AND DATABASE ENTRY WMU Nomenclature WMU Equipment Barcode

TAGGING AND DATABASE ENTRY WMU Nomenclature WMU Equipment Barcode

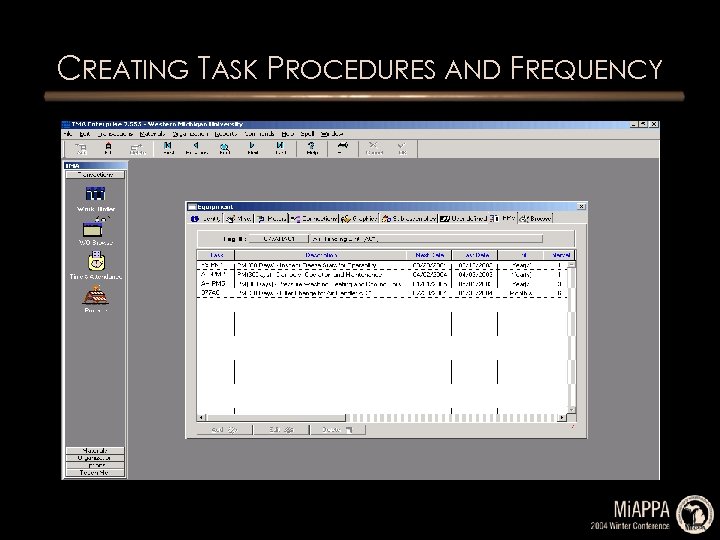

CREATING TASK PROCEDURES AND FREQUENCY

CREATING TASK PROCEDURES AND FREQUENCY

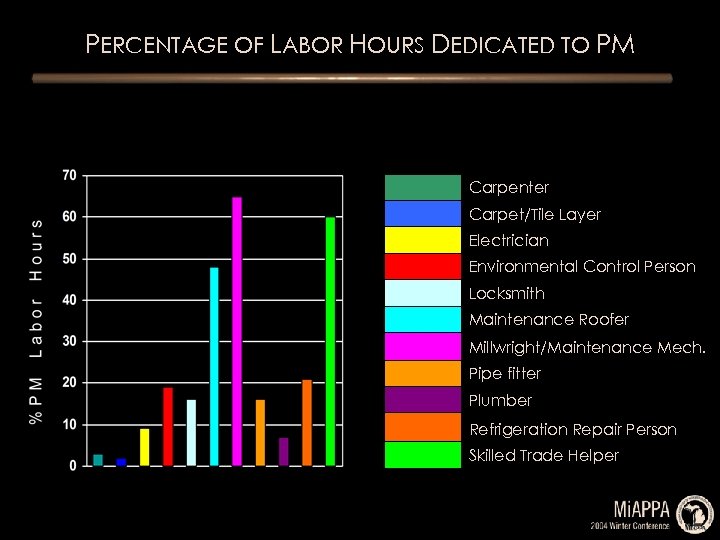

PERCENTAGE OF LABOR HOURS DEDICATED TO PM Carpenter Carpet/Tile Layer Electrician Environmental Control Person Locksmith Maintenance Roofer Millwright/Maintenance Mech. Pipe fitter Plumber Refrigeration Repair Person Skilled Trade Helper

PERCENTAGE OF LABOR HOURS DEDICATED TO PM Carpenter Carpet/Tile Layer Electrician Environmental Control Person Locksmith Maintenance Roofer Millwright/Maintenance Mech. Pipe fitter Plumber Refrigeration Repair Person Skilled Trade Helper

CHECKS AND BALANCES • Dedicated Staff • Review Completed Work Order • Perform Site Visits

CHECKS AND BALANCES • Dedicated Staff • Review Completed Work Order • Perform Site Visits

CHECKS AND BALANCES • Dedicated Staff • Review Completed Work Order • Perform Site Visits

CHECKS AND BALANCES • Dedicated Staff • Review Completed Work Order • Perform Site Visits

CHECKS AND BALANCES • Dedicated Staff • Review Completed Work Order • Perform Site Visits

CHECKS AND BALANCES • Dedicated Staff • Review Completed Work Order • Perform Site Visits

CHECKS AND BALANCES • Dedicated Staff • Review Completed Work Order • Perform Site Visits

CHECKS AND BALANCES • Dedicated Staff • Review Completed Work Order • Perform Site Visits

THEORY OF PREVENTIVE MAINTENANCE EVOLUTION

THEORY OF PREVENTIVE MAINTENANCE EVOLUTION

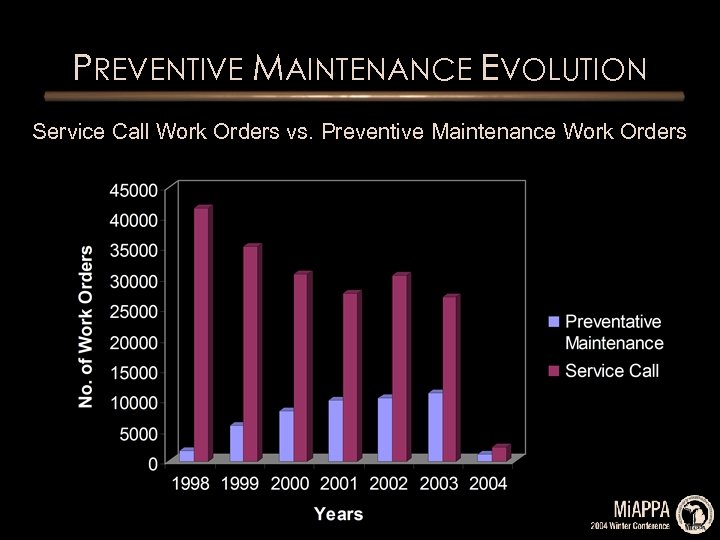

PREVENTIVE MAINTENANCE EVOLUTION Service Call Work Orders vs. Preventive Maintenance Work Orders

PREVENTIVE MAINTENANCE EVOLUTION Service Call Work Orders vs. Preventive Maintenance Work Orders

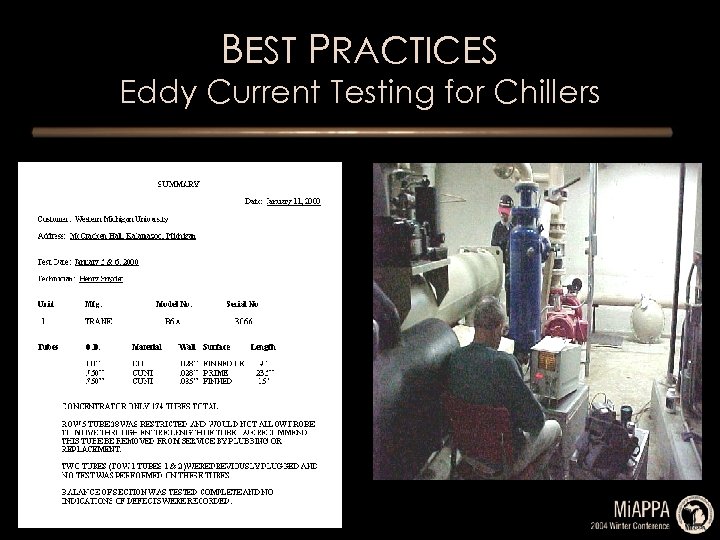

BEST PRACTICES Eddy Current Testing for Chillers

BEST PRACTICES Eddy Current Testing for Chillers

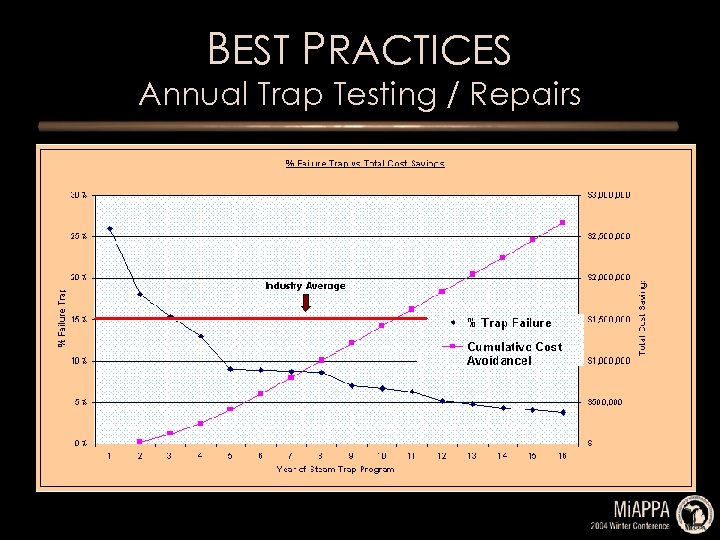

BEST PRACTICES Annual Trap Testing / Repairs

BEST PRACTICES Annual Trap Testing / Repairs

BEST PRACTICES Laser Alignment

BEST PRACTICES Laser Alignment

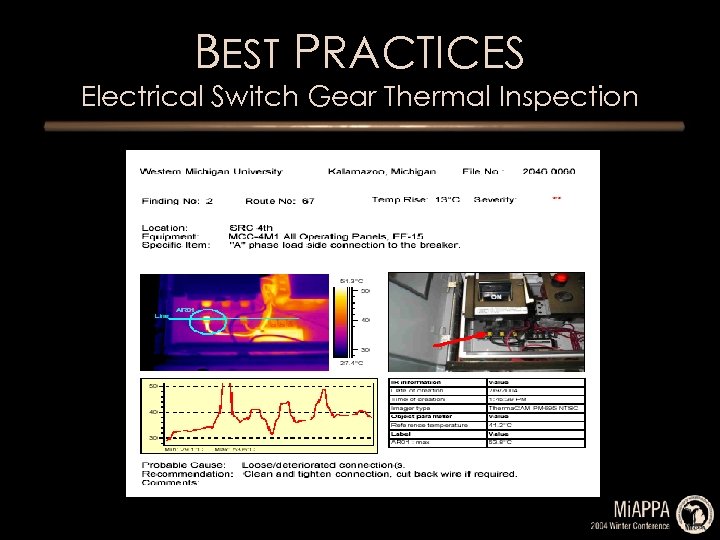

BEST PRACTICES Electrical Switch Gear Thermal Inspection

BEST PRACTICES Electrical Switch Gear Thermal Inspection

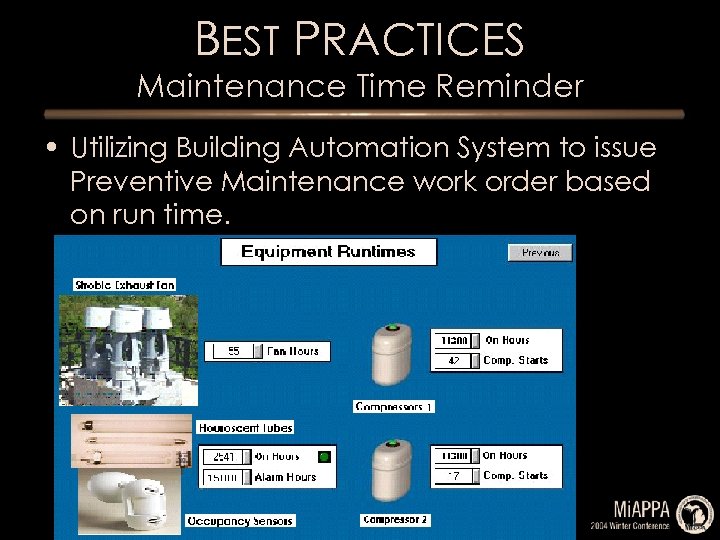

BEST PRACTICES Maintenance Time Reminder • Utilizing Building Automation System to issue Preventive Maintenance work order based on run time.

BEST PRACTICES Maintenance Time Reminder • Utilizing Building Automation System to issue Preventive Maintenance work order based on run time.

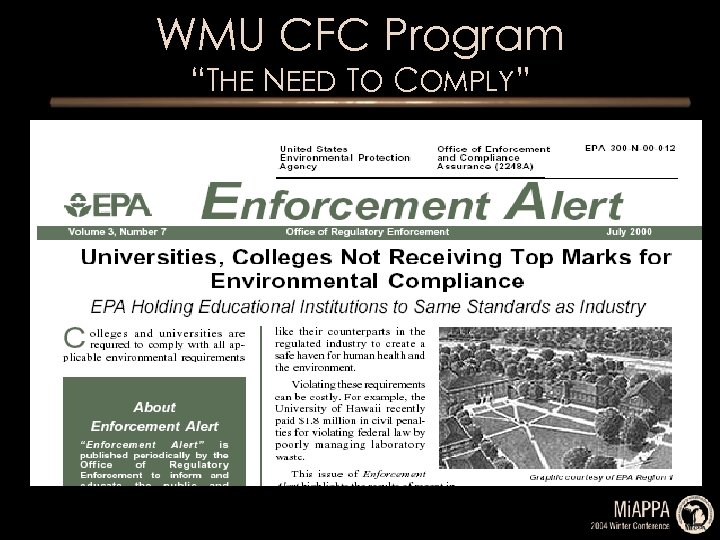

WMU CFC Program “THE NEED TO COMPLY”

WMU CFC Program “THE NEED TO COMPLY”

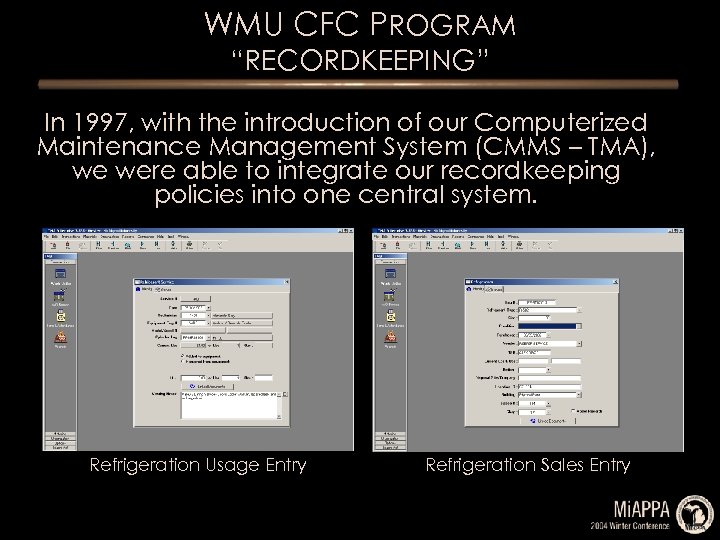

WMU CFC PROGRAM “RECORDKEEPING” In 1997, with the introduction of our Computerized Maintenance Management System (CMMS – TMA), we were able to integrate our recordkeeping policies into one central system. Refrigeration Usage Entry Refrigeration Sales Entry

WMU CFC PROGRAM “RECORDKEEPING” In 1997, with the introduction of our Computerized Maintenance Management System (CMMS – TMA), we were able to integrate our recordkeeping policies into one central system. Refrigeration Usage Entry Refrigeration Sales Entry

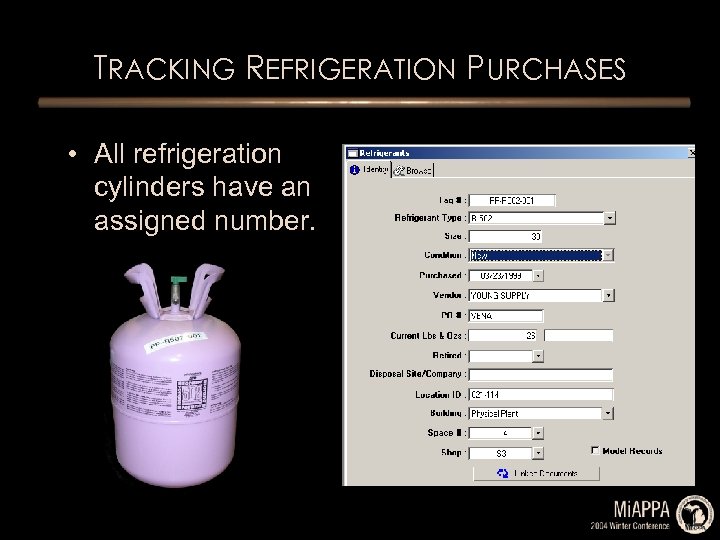

TRACKING REFRIGERATION PURCHASES • All refrigeration cylinders have an assigned number.

TRACKING REFRIGERATION PURCHASES • All refrigeration cylinders have an assigned number.

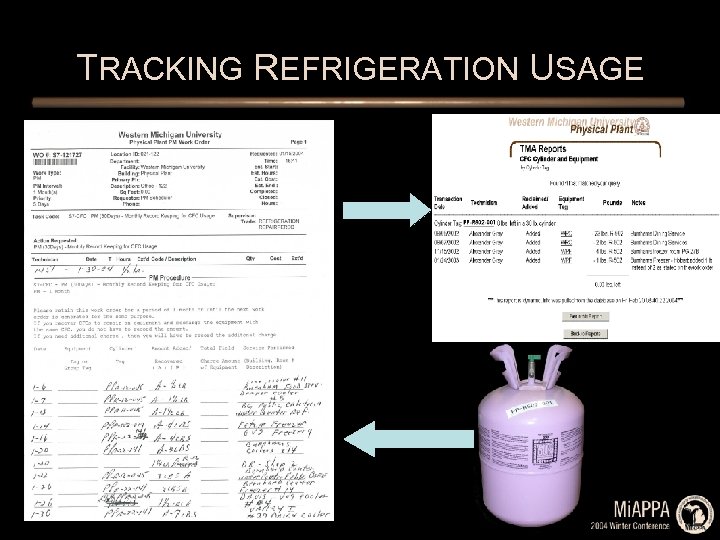

TRACKING REFRIGERATION USAGE

TRACKING REFRIGERATION USAGE

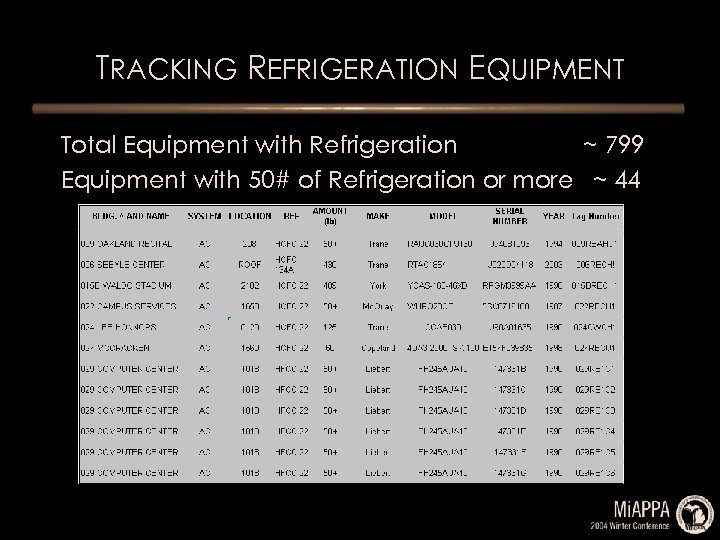

TRACKING REFRIGERATION EQUIPMENT Total Equipment with Refrigeration ~ 799 Equipment with 50# of Refrigeration or more ~ 44

TRACKING REFRIGERATION EQUIPMENT Total Equipment with Refrigeration ~ 799 Equipment with 50# of Refrigeration or more ~ 44

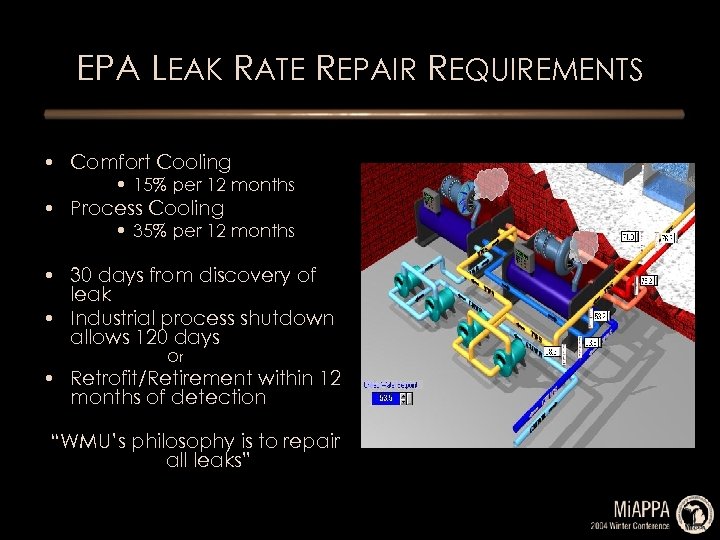

EPA LEAK RATE REPAIR REQUIREMENTS • Comfort Cooling • 15% per 12 months • Process Cooling • 35% per 12 months • 30 days from discovery of leak • Industrial process shutdown allows 120 days Or • Retrofit/Retirement within 12 months of detection “WMU’s philosophy is to repair all leaks”

EPA LEAK RATE REPAIR REQUIREMENTS • Comfort Cooling • 15% per 12 months • Process Cooling • 35% per 12 months • 30 days from discovery of leak • Industrial process shutdown allows 120 days Or • Retrofit/Retirement within 12 months of detection “WMU’s philosophy is to repair all leaks”

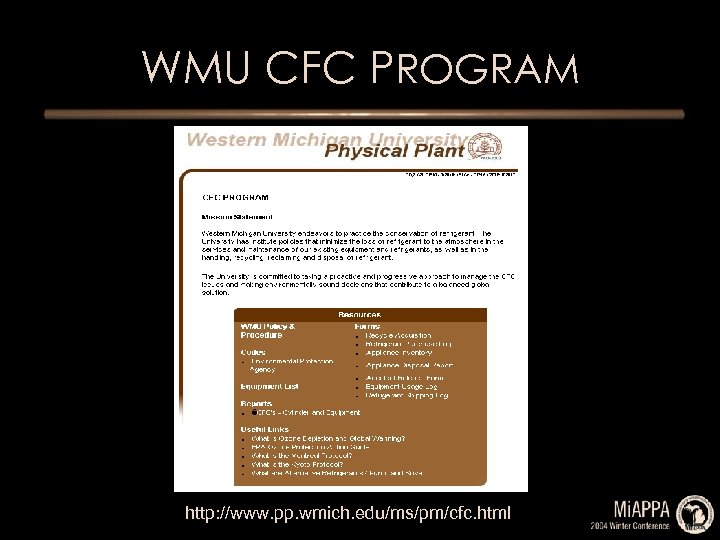

WMU CFC PROGRAM http: //www. pp. wmich. edu/ms/pm/cfc. html

WMU CFC PROGRAM http: //www. pp. wmich. edu/ms/pm/cfc. html

Thank You! anand. sankey@wmich. edu

Thank You! anand. sankey@wmich. edu