b7cb1fb7c80e56122215d4011453cda3.ppt

- Количество слайдов: 26

Overview Of Blast Furnace Process BHEL ISG, Bangalore Date : 15 th july, 2014 PRESENTATION BY PREM PRAKASH ENGINEER, BG IIA

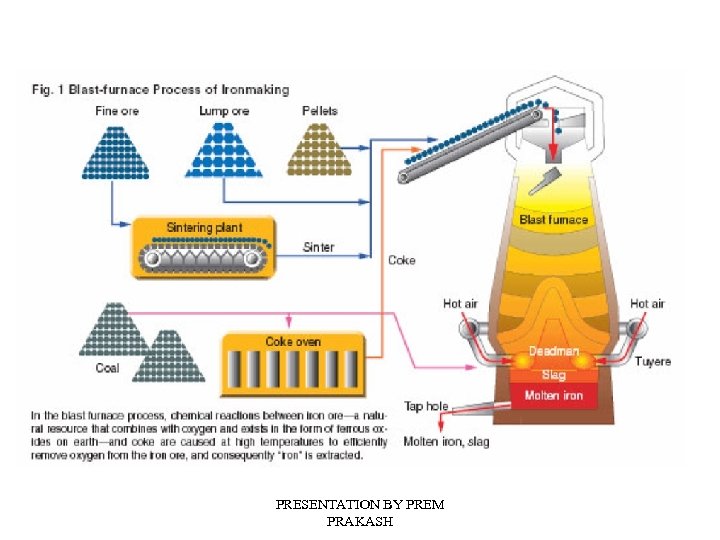

PRESENTATION BY PREM PRAKASH

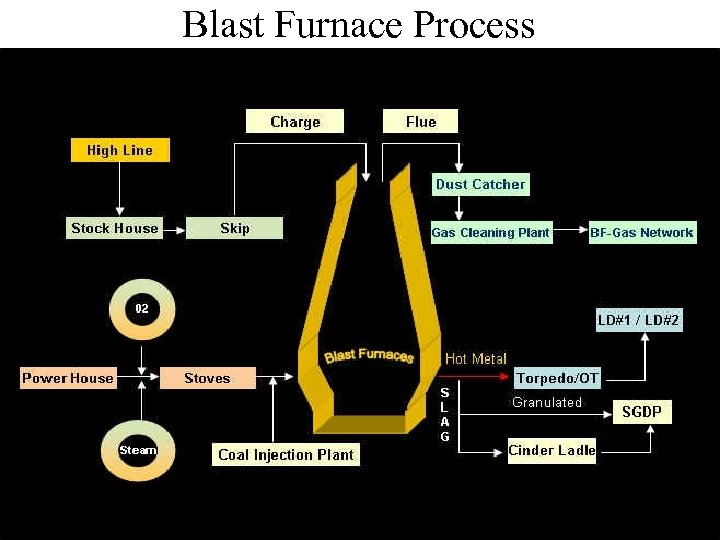

Blast Furnace Process PRESENTATION BY PREM PRAKASH

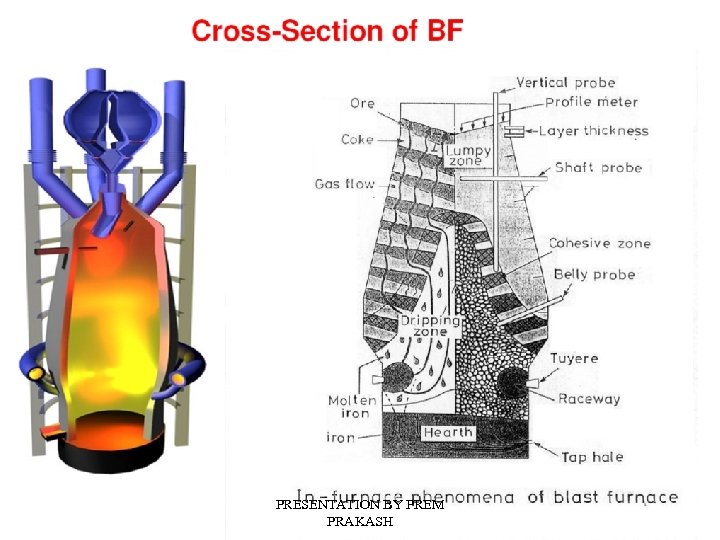

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

PRESENTATION BY PREM PRAKASH

BLAST FURNACES at Tata Steel PRESENTATION BY PREM PRAKASH

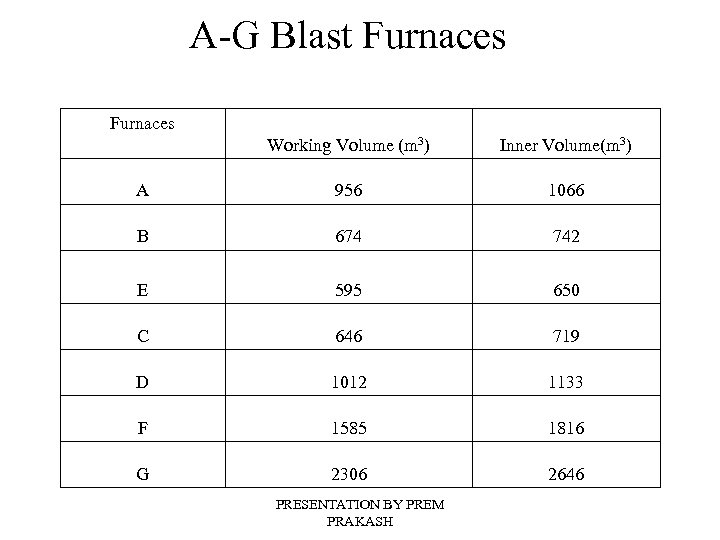

A-G Blast Furnaces Working Volume (m 3) Inner Volume(m 3) A 956 1066 B 674 742 E 595 650 C 646 719 D 1012 1133 F 1585 1816 G 2306 2646 PRESENTATION BY PREM PRAKASH

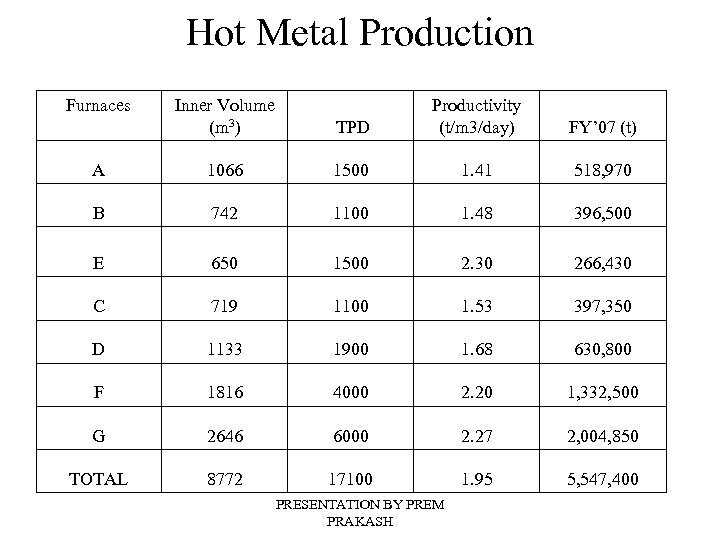

Hot Metal Production Furnaces Inner Volume (m 3) TPD Productivity (t/m 3/day) FY’ 07 (t) A 1066 1500 1. 41 518, 970 B 742 1100 1. 48 396, 500 E 650 1500 2. 30 266, 430 C 719 1100 1. 53 397, 350 D 1133 1900 1. 68 630, 800 F 1816 4000 2. 20 1, 332, 500 G 2646 6000 2. 27 2, 004, 850 TOTAL 8772 17100 1. 95 5, 547, 400 PRESENTATION BY PREM PRAKASH

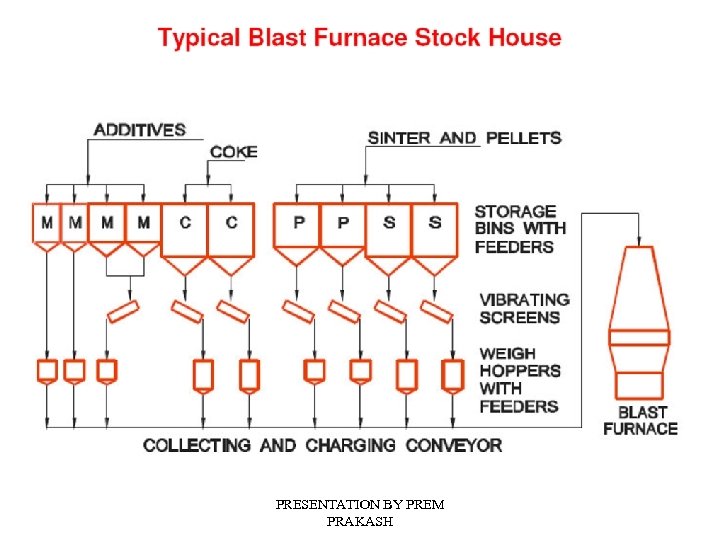

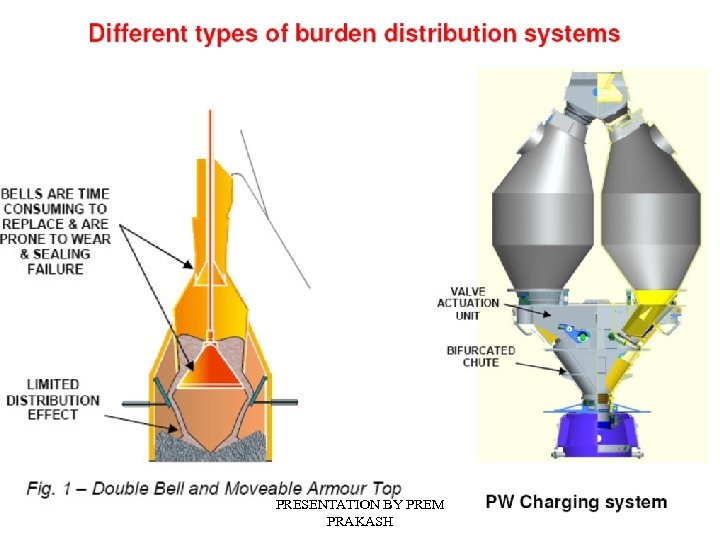

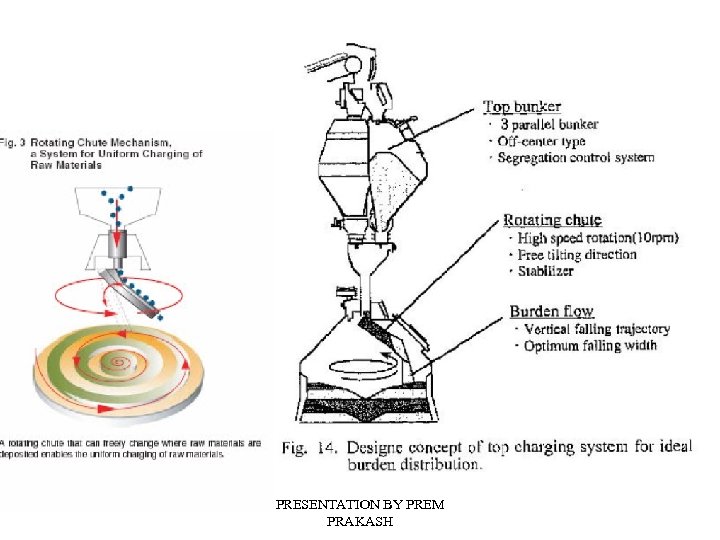

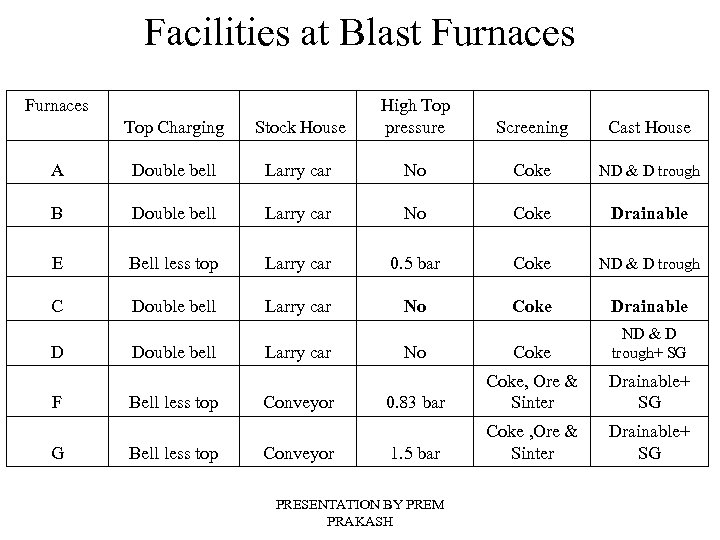

Facilities at Blast Furnaces Top Charging Stock House High Top pressure A Double bell Larry car No Coke ND & D trough B Double bell Larry car No Coke Drainable E Bell less top Larry car 0. 5 bar Coke ND & D trough C Double bell Larry car No Coke Drainable No Coke ND & D trough+ SG 0. 83 bar Coke, Ore & Sinter Drainable+ SG 1. 5 bar Coke , Ore & Sinter Drainable+ SG D F G Double bell Bell less top Larry car Conveyor PRESENTATION BY PREM PRAKASH Screening Cast House

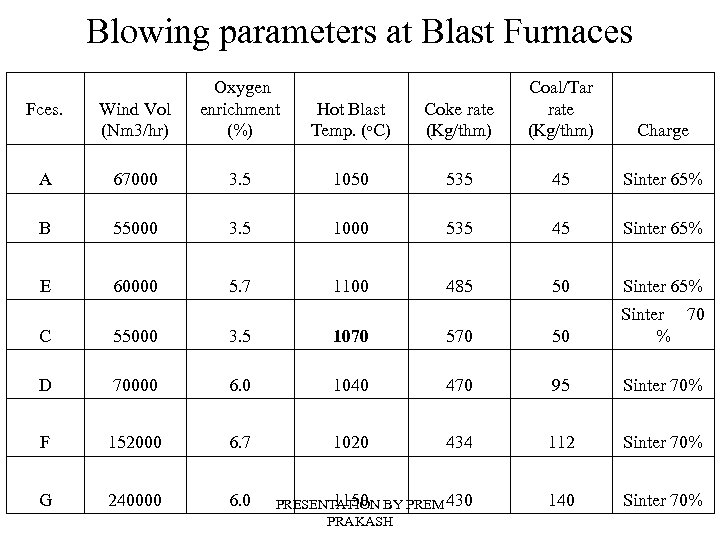

Blowing parameters at Blast Furnaces Wind Vol (Nm 3/hr) Oxygen enrichment (%) Hot Blast Temp. (o. C) A 67000 3. 5 B 55000 E 60000 Fces. Coke rate (Kg/thm) Coal/Tar rate (Kg/thm) Charge 1050 535 45 Sinter 65% 3. 5 1000 535 45 Sinter 65% 5. 7 1100 485 50 Sinter 65% C 55000 3. 5 1070 50 Sinter 70 % D 70000 6. 0 1040 470 95 Sinter 70% F 152000 6. 7 1020 434 112 Sinter 70% G 240000 6. 0 1150 PRESENTATION BY PREM 430 PRAKASH 140 Sinter 70%

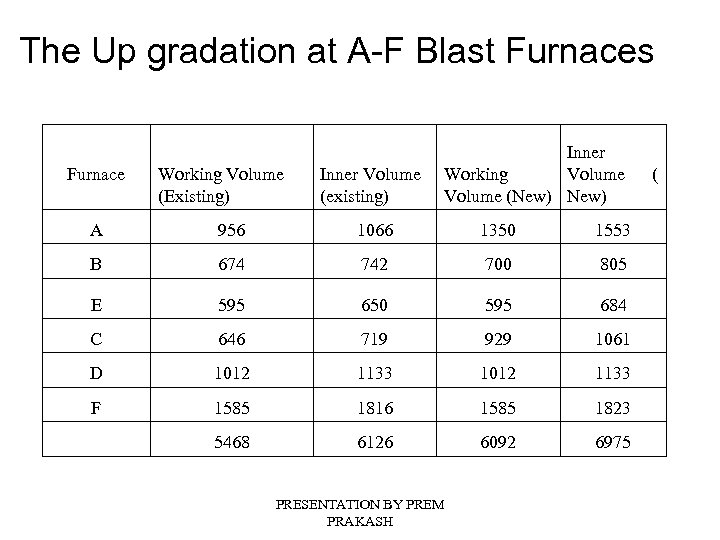

The Up gradation at A-F Blast Furnaces Furnace Working Volume (Existing) Inner Volume (existing) Inner Volume ( Working Volume (New) A 956 1066 1350 1553 B 674 742 700 805 E 595 650 595 684 C 646 719 929 1061 D 1012 1133 F 1585 1816 1585 1823 5468 6126 6092 6975 PRESENTATION BY PREM PRAKASH

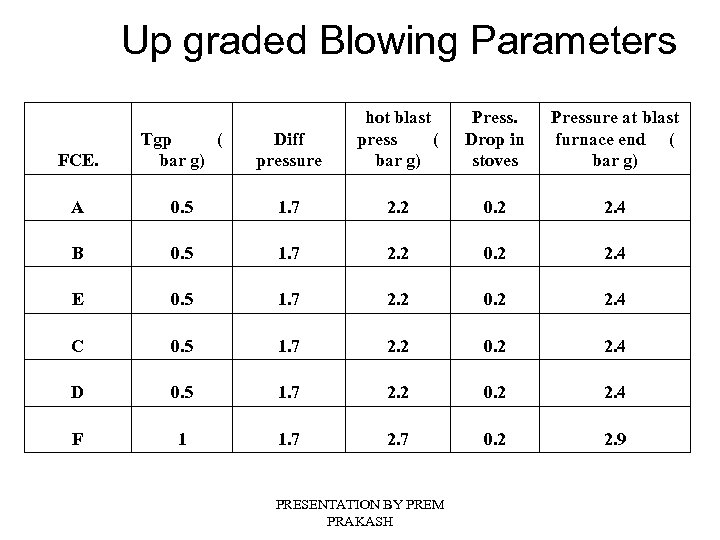

Up graded Blowing Parameters FCE. Tgp ( bar g) Diff pressure hot blast press ( bar g) A 0. 5 1. 7 2. 2 0. 2 2. 4 B 0. 5 1. 7 2. 2 0. 2 2. 4 E 0. 5 1. 7 2. 2 0. 2 2. 4 C 0. 5 1. 7 2. 2 0. 2 2. 4 D 0. 5 1. 7 2. 2 0. 2 2. 4 F 1 1. 7 2. 7 0. 2 2. 9 PRESENTATION BY PREM PRAKASH Press. Drop in stoves Pressure at blast furnace end ( bar g)

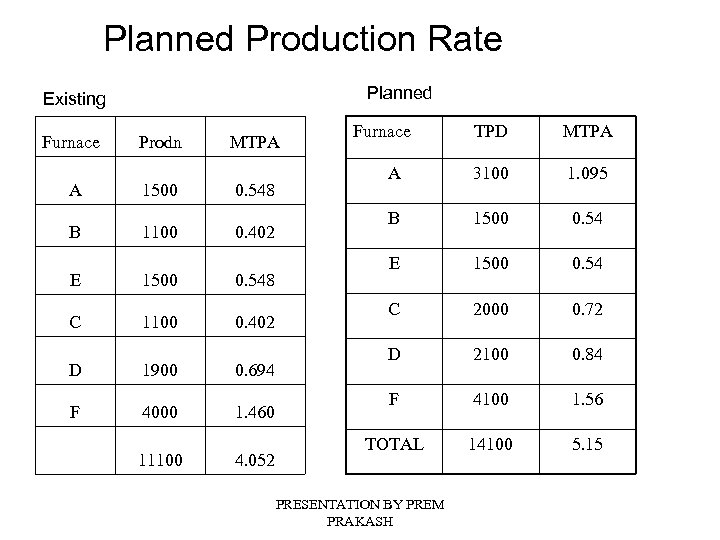

Planned Production Rate Planned Existing Furnace Prodn A 1500 0. 548 B 1100 0. 402 E C 1500 1100 0. 548 0. 402 D 0. 694 F 1900 4000 1. 460 11100 4. 052 TPD MTPA A 3100 1. 095 B 1500 0. 54 E 1500 0. 54 C 2000 0. 72 D 2100 0. 84 F 4100 1. 56 TOTAL MTPA Furnace 14100 5. 15 PRESENTATION BY PREM PRAKASH

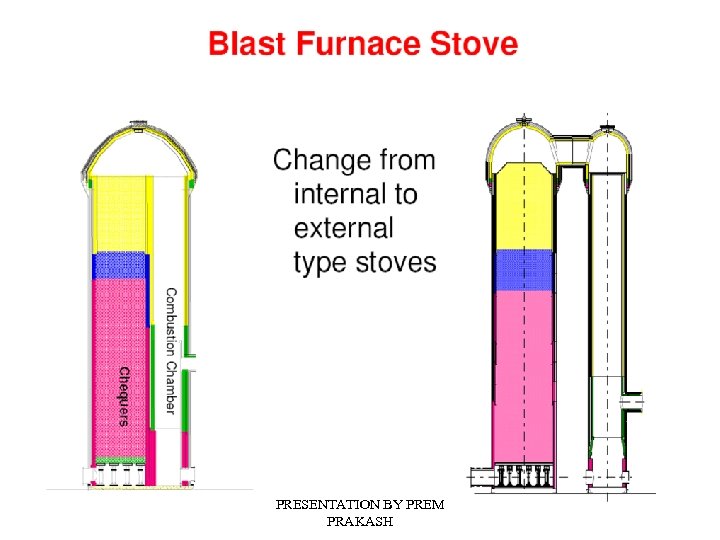

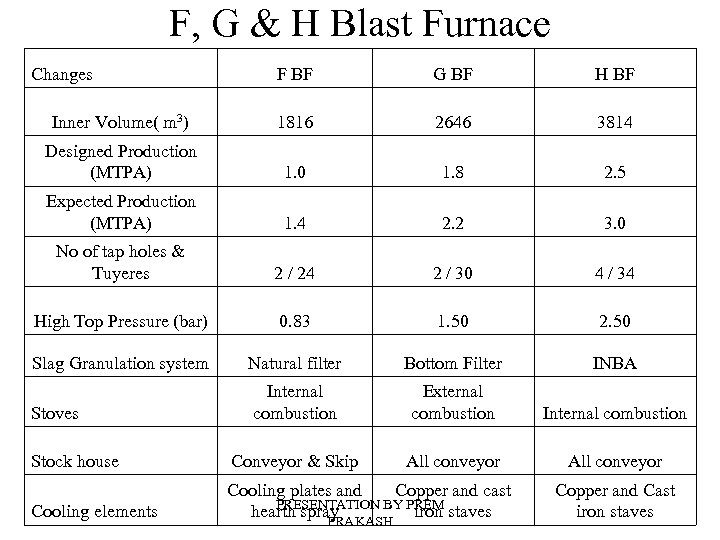

F, G & H Blast Furnace Changes F BF G BF H BF Inner Volume( m 3) 1816 2646 3814 Designed Production (MTPA) 1. 0 1. 8 2. 5 Expected Production (MTPA) 1. 4 2. 2 3. 0 No of tap holes & Tuyeres 2 / 24 2 / 30 4 / 34 High Top Pressure (bar) 0. 83 1. 50 2. 50 Slag Granulation system Natural filter Bottom Filter INBA Stoves Internal combustion External combustion Internal combustion Stock house Conveyor & Skip All conveyor Cooling elements Cooling plates and Copper and cast PRESENTATION BY PREM hearth spray iron staves PRAKASH Copper and Cast iron staves

PRESENTATION BY PREM PRAKASH

b7cb1fb7c80e56122215d4011453cda3.ppt