a07817fcd9e98d5e440fe74080746827.ppt

- Количество слайдов: 45

Overview of Biomass Heat and Power Scott Haase National Renewable Energy Laboratory

Presentation Outline • Technologies • Economics • Supply – Urban wood waste – Forest residues • NREL system

Biomass Resources • The term "biomass" means any plant derived organic matter available on a renewable basis • States have various definitions of eligible biomass resources for state RPS targets, e. g. : – Colorado has the term “slash and brush” forest biomass – Urban wood waste must be clean and free of contaminants

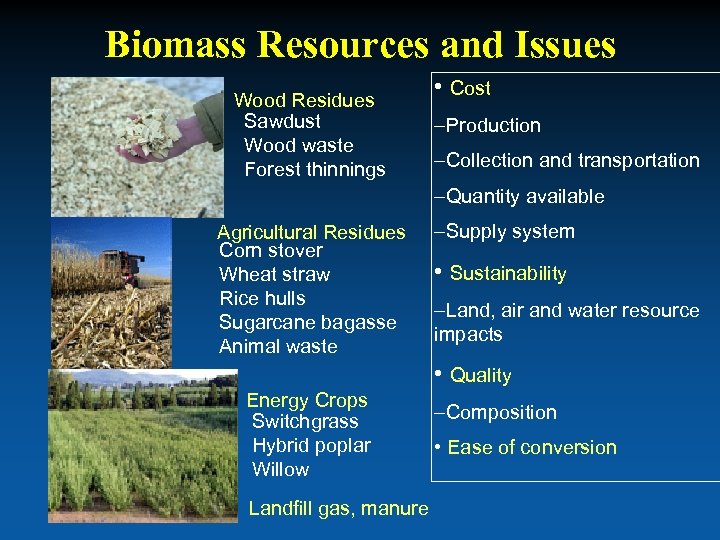

Biomass Resources and Issues Wood Residues Sawdust Wood waste Forest thinnings • Cost –Production –Collection and transportation –Quantity available Agricultural Residues Corn stover Wheat straw Rice hulls Sugarcane bagasse Animal waste –Supply system • Sustainability –Land, air and water resource impacts • Quality Energy Crops Switchgrass Hybrid poplar Willow Landfill gas, manure –Composition • Ease of conversion

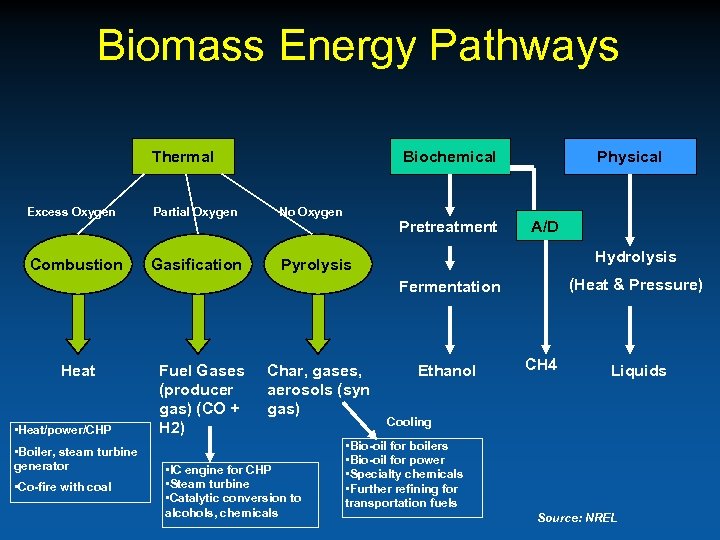

Biomass Energy Pathways Thermal Biochemical Excess Oxygen Partial Oxygen No Oxygen Combustion Gasification Physical Pyrolysis Pretreatment A/D Hydrolysis (Heat & Pressure) Fermentation Heat • Heat/power/CHP • Boiler, steam turbine generator • Co-fire with coal Fuel Gases (producer gas) (CO + H 2) Char, gases, aerosols (syn gas) • IC engine for CHP • Steam turbine • Catalytic conversion to alcohols, chemicals Ethanol CH 4 Liquids Cooling • Bio-oil for boilers • Bio-oil for power • Specialty chemicals • Further refining for transportation fuels Source: NREL

Bioenergy Plant Overview 1. Fuel Handling 1. 2. Storage, sizing, movement Conversion technology 1. Combustion, gasification, pyrolysis, 1. 2. 3. Prime mover (only if doing power) 1. 2. 4. 5. 6. 7. 8. Boiler to produce steam Gasifier – producer gas or syn gas Steam turbine and generator set Internal combustion engine, gas turbine Control system and programs Emissions control Ash removal Water treatment and cooling (power) Product delivery (pipes for hot water, power lines, tanks, trucks)

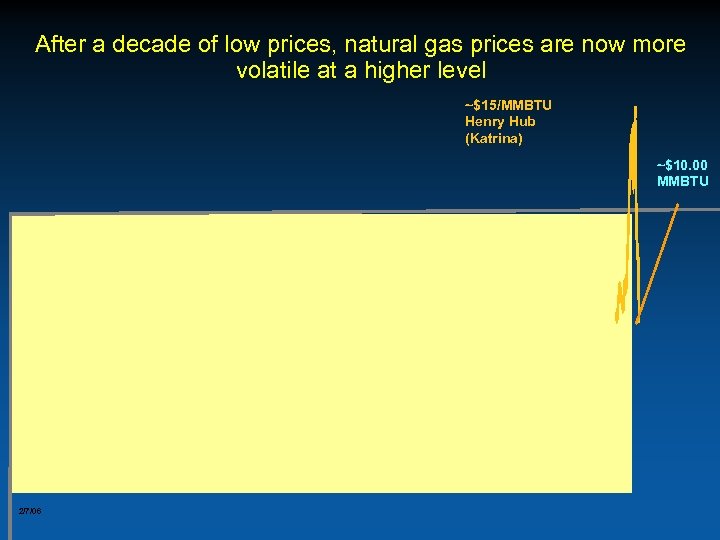

After a decade of low prices, natural gas prices are now more volatile at a higher level ~$15/MMBTU Henry Hub (Katrina) ~$10. 00 MMBTU 2/7/06

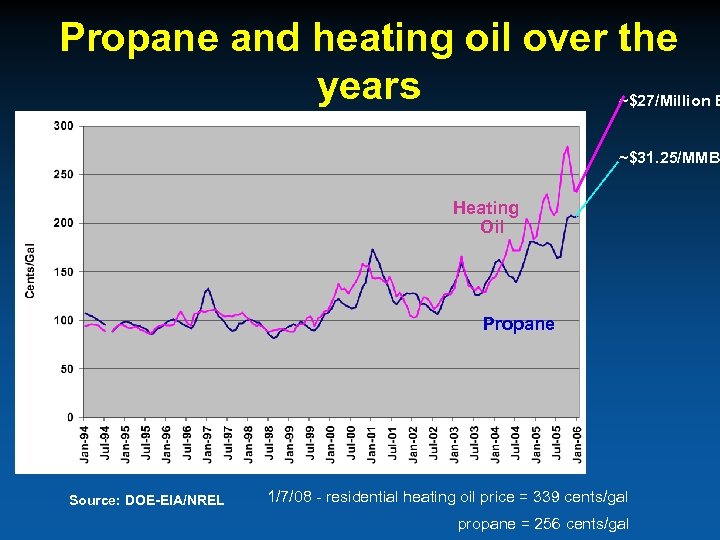

Propane and heating oil over the years ~$27/Million B ~$31. 25/MMB Heating Oil Propane Source: DOE-EIA/NREL 1/7/08 - residential heating oil price = 339 cents/gal propane = 256 cents/gal

Sample fuel cost comparisons ($/MMBtu delivered)

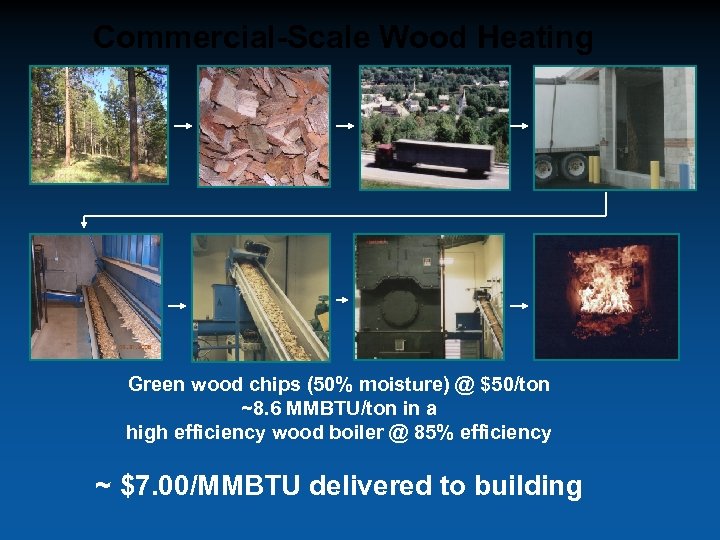

Commercial-Scale Wood Heating Green wood chips (50% moisture) @ $50/ton ~8. 6 MMBTU/ton in a high efficiency wood boiler @ 85% efficiency ~ $7. 00/MMBTU delivered to building

• Commercial, proven technologies Biomass Thermal – Hot water or low pressure steam – Chiptec, Messersmith, Advanced Recycling, Garn leading vendors for nonresidential systems – Positive operator experience – Automated to hand fed – Clean burning – Wood chips, cord wood or pellets – Moisture up to 50 -60% • Low to moderate payback periods depending on wood cost and alternate fuel cost

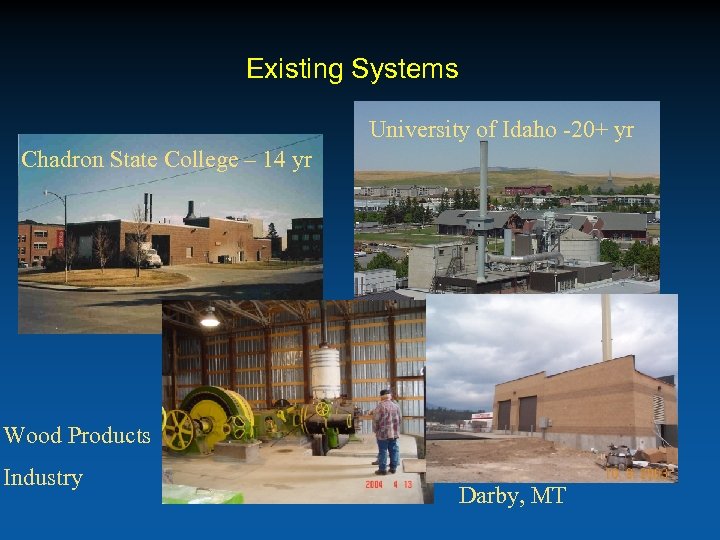

Existing Systems University of Idaho -20+ yr Chadron State College – 14 yr Wood Products Industry Darby, MT

Court House Middlebury, VT Facility Heated With Biomass

Four Main Sizes of Commercial Biomass Heating Systems Large, automated wood chip – Typically buildings over 100, 000 square feet • Smaller buildings if they have year round need for hot water (prison, hospital – Must have large heating bills to justify the investment Semi-automated surge bin – 10, 000 – 100, 000 square feet – Bucket loader Pellet-fired – 5, 000 square feet and up – Systems less expensive, less storage Cord wood – 5, 000 – 50, 000 square feet – Manual loading of fire wood 1 -3 times per day

Automated chip heating systems • High capital costs, • Storage needs, • Fuel must be consistent, no sticks • Minimal labor

Vermont Army National Guard

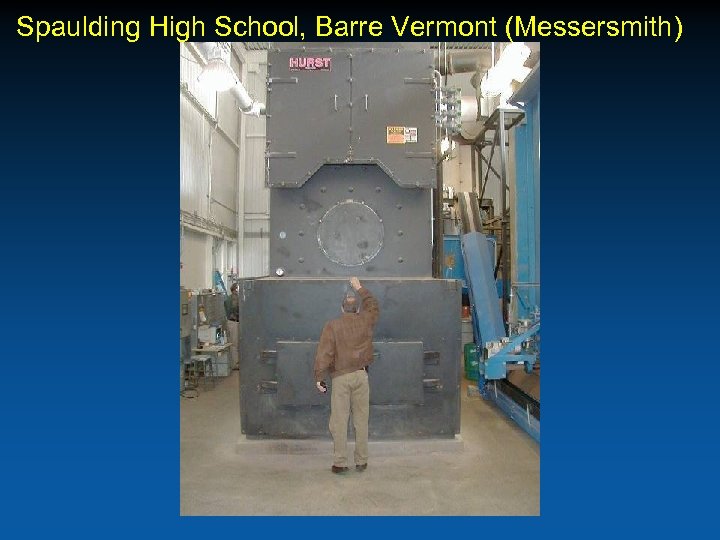

Spaulding High School, Barre Vermont (Messersmith)

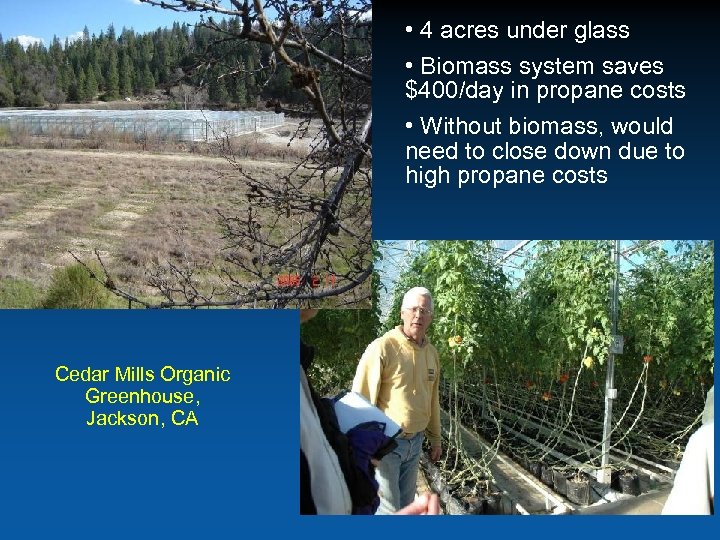

• 4 acres under glass • Biomass system saves $400/day in propane costs • Without biomass, would need to close down due to high propane costs Cedar Mills Organic Greenhouse, Jackson, CA

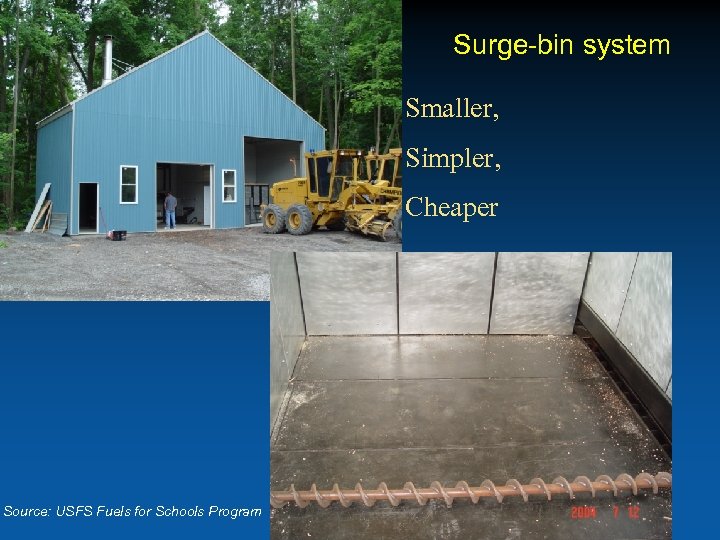

Surge-bin system Smaller, Simpler, Cheaper Source: USFS Fuels for Schools Program

Pellet Systems • Fuel is more expensive • Storage smaller, cheaper • Boiler smaller, cheaper Source: USFS Fuels for Schools Program

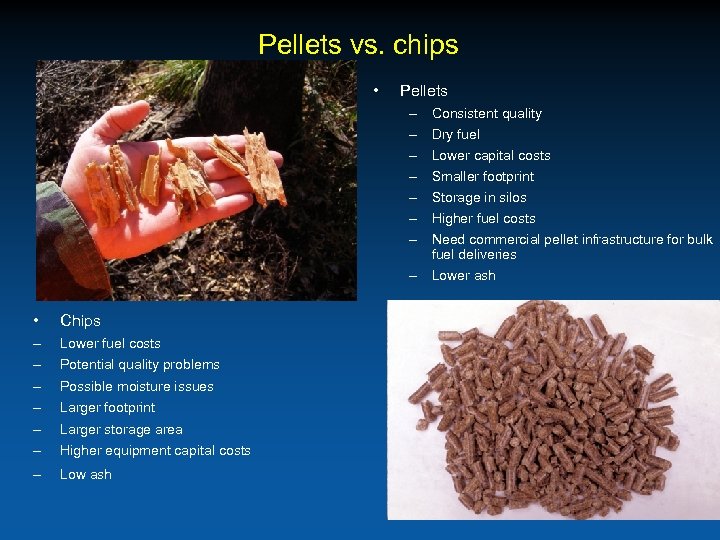

Pellets vs. chips • Pellets – – – – Consistent quality Dry fuel Lower capital costs Smaller footprint Storage in silos Higher fuel costs Need commercial pellet infrastructure for bulk fuel deliveries – Lower ash • Chips – – – Lower fuel costs – Low ash Potential quality problems Possible moisture issues Larger footprint Larger storage area Higher equipment capital costs

Garn – Cordwood Source: USFS Fuels for Schools Program

NREL’s Renewable Fuel Heating Plant

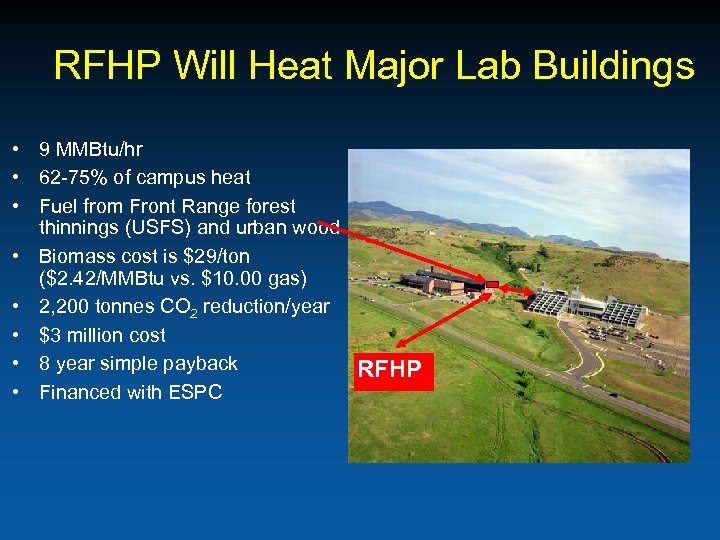

RFHP Will Heat Major Lab Buildings • 9 MMBtu/hr • 62 -75% of campus heat • Fuel from Front Range forest thinnings (USFS) and urban wood • Biomass cost is $29/ton ($2. 42/MMBtu vs. $10. 00 gas) • 2, 200 tonnes CO 2 reduction/year • $3 million cost • 8 year simple payback RFHP • Financed with ESPC

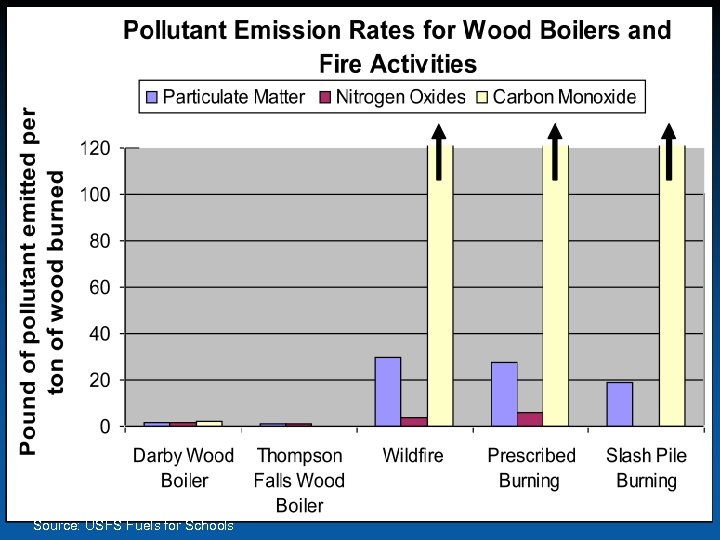

Source: USFS Fuels for Schools

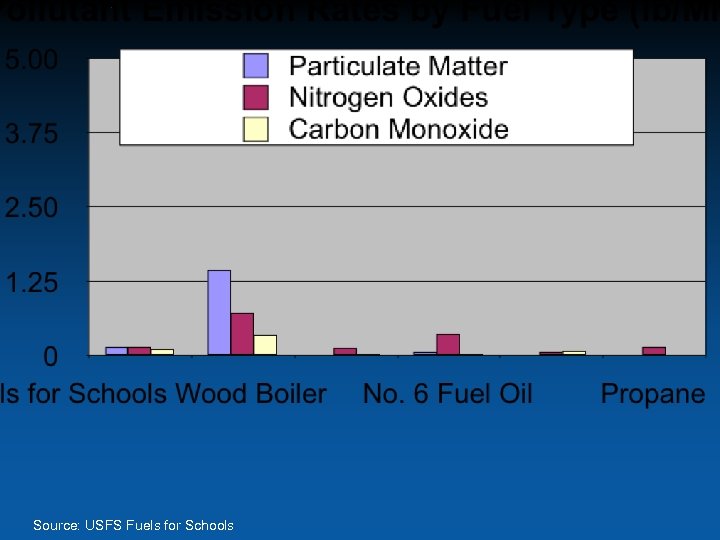

Source: USFS Fuels for Schools

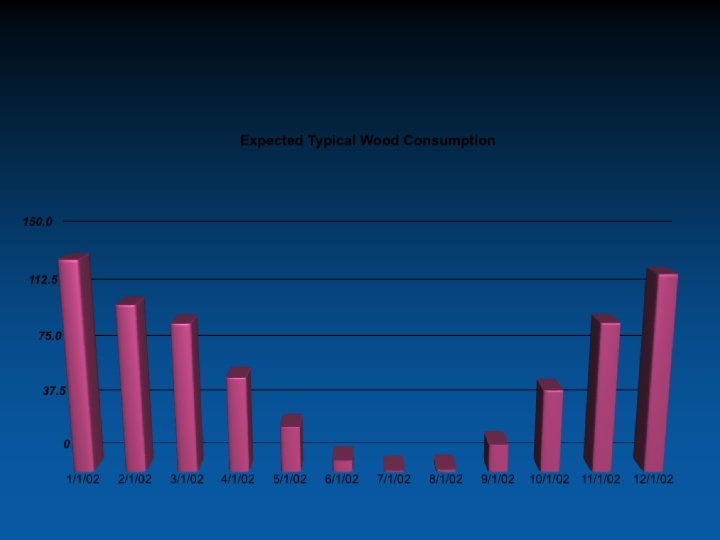

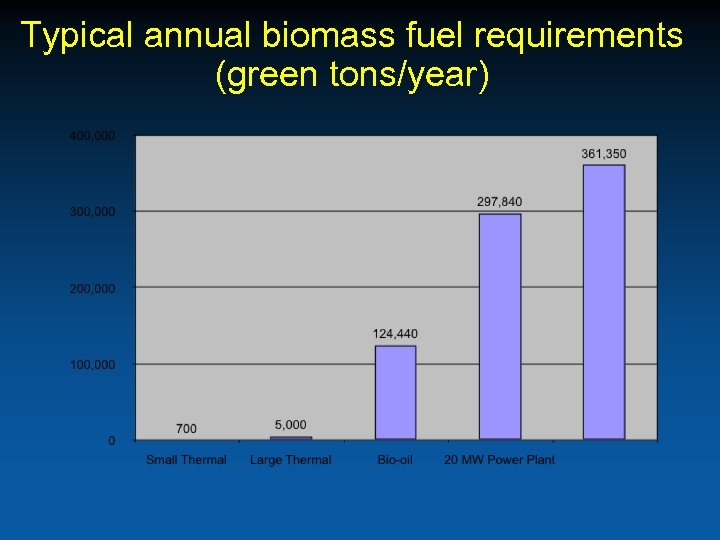

Typical annual biomass fuel requirements (green tons/year)

Capital costs of bioenergy applications (million $)

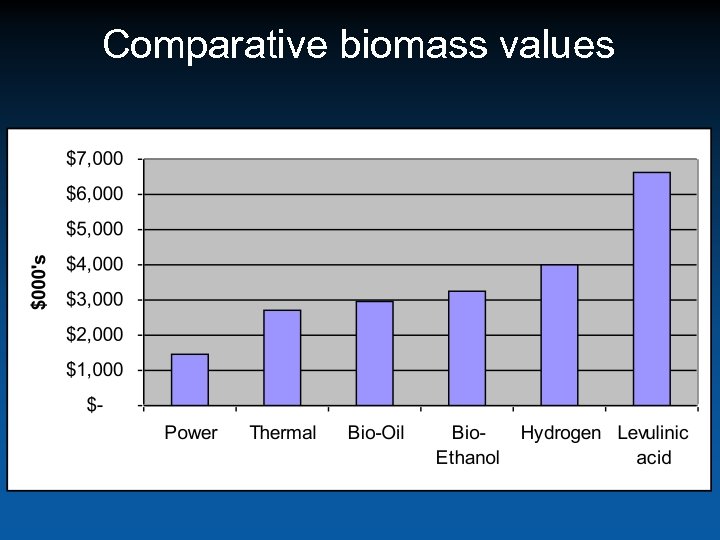

Comparative biomass values Source: Mc. Neil Technologies

Colorado Projects • • Boulder County (operational) Gilpin County (operational) NREL (construction) CSU (design) Fort Lupton greenhouse (on hold) Summit county (feasibility) Jefferson county jail (on-hold) About 10 -12 schools and other public buildings are in evaluation phase • Jefferson county pellet mill • Grand/Jackson county pellet mills

Fuel supply and quality are the single most important factors in a successful project

Biomass Supply Questions • How much do I need? • Where is it going to come from? • How reliable is the source? • Who will bring it to me? • What will it cost? • What is the quality of the fuel? • Sizing, storing?

Fuel handling issues

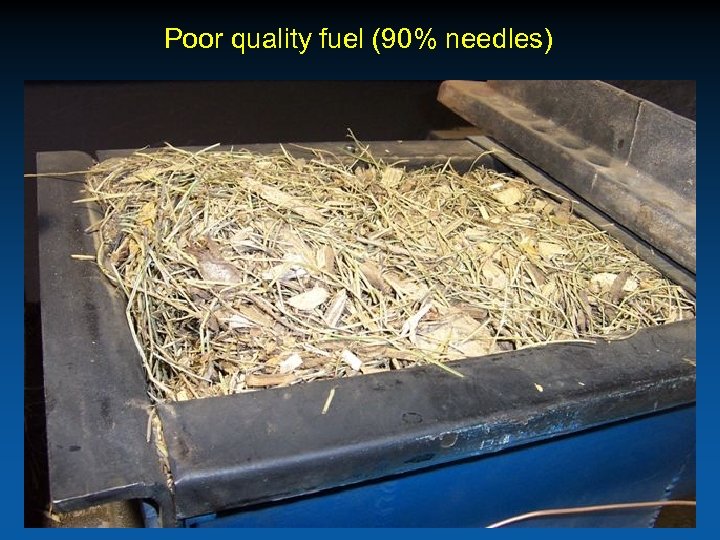

Poor quality wood

Poor quality fuel (90% needles)

Clinker, due to sand in fuel

Biomass Heating Feasibility Studies: Steps • • • Supply: resource assessment and costs Determine your heating load Technology characterization and sizing Environmental review Estimate capital costs, operations and maintenance Economic analysis Community support Fatal flaw analysis Financing Procurement and construction Start-up and operations

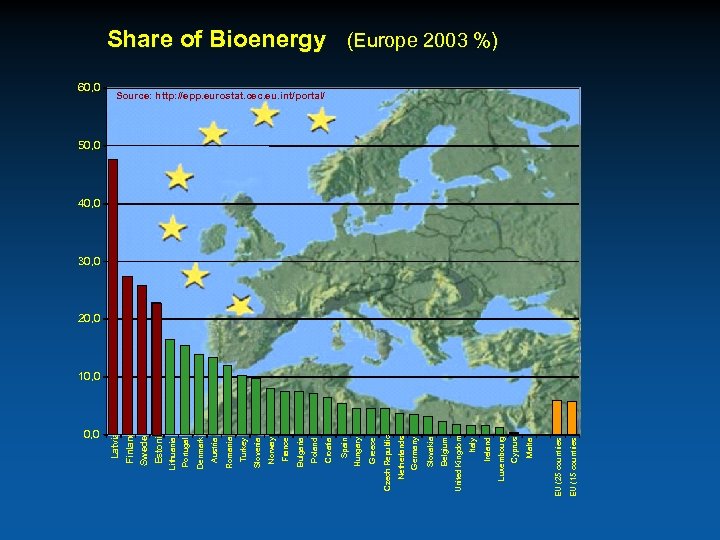

0, 0 EU (15 countries) EU (25 countries) Malta Cyprus Luxembourg Ireland Italy United Kingdom Belgium Slovakia Germany Netherlands Czech Republic Greece Hungary Spain Croatia Poland Bulgaria France Norway Slovenia Turkey Romania Austria Denmark Portugal Lithuania Finland Sweden Estonia 60, 0 Latvia Share of Bioenergy (Europe 2003 %) Source: http: //epp. eurostat. cec. eu. int/portal/ 50, 0 40, 0 30, 0 20, 0 10, 0

• Supply – – Bioenergy Success Factors Low cost resource Flexible contracts from multiple sources Permit plant for multiple fuels Develop the business models to deliver biomass • Electrical or thermal value of competing fuels • Location – Proximity to supply, power lines – Strategic value, strategic facility • Technology – Reliable, efficient, fuel flexible

• Thermal energy applications are generally most cost effective – Power, CHP, liquid fuel projects are complex Summary • Technology is commercial, proven and simple • Evaluate biomass thermal opportunities on any public building • Biomass supply questions are important – Cost, quantity, quality, supply network, sizing, storage • A local champion is needed • Every biomass project is unique

Contact Information Scott Haase 1617 Cole Blvd, MS 302 Golden, CO 80401 NREL 303 -275 -3057 Scott_Haase@nrel. gov

a07817fcd9e98d5e440fe74080746827.ppt