f8b1bf2acf7e5bda968e622b2df001a7.ppt

- Количество слайдов: 42

Overview ATCE – Production Management 3/15/2018 Insert image here Inform IT Information Manager Insert image here

Overview ATCE – Production Management 3/15/2018 Insert image here Inform IT Information Manager Insert image here

Pressures on enterprises n global competition, weakening economies, n reduction in technical resources, n industry consolidation, n stricter environmental regulations, n higher raw material costs, n plummeting product lifecycles, n © Copyright 2003 ABB - 2 - n decreasing process life times, n increasingly demanding customers and shareholders

Pressures on enterprises n global competition, weakening economies, n reduction in technical resources, n industry consolidation, n stricter environmental regulations, n higher raw material costs, n plummeting product lifecycles, n © Copyright 2003 ABB - 2 - n decreasing process life times, n increasingly demanding customers and shareholders

What is your Goal? Improve Return on Assets (ROA) Focusing on financial performance through continued prudence in spending via: § Consolidation § Focusing on core competencies © Copyright 2003 ABB - 3 - § More attention to ROI in new projects Vital to a Successful Strategy

What is your Goal? Improve Return on Assets (ROA) Focusing on financial performance through continued prudence in spending via: § Consolidation § Focusing on core competencies © Copyright 2003 ABB - 3 - § More attention to ROI in new projects Vital to a Successful Strategy

Industries today § Tighter product specification control § Capacity & dispatching control § Emission monitoring § Spot market sales , i. e. hourly billing © Copyright 2003 ABB - 4 - § Flexible IT structure § Seamless workflow Increased operational efficiency Better process design methodology

Industries today § Tighter product specification control § Capacity & dispatching control § Emission monitoring § Spot market sales , i. e. hourly billing © Copyright 2003 ABB - 4 - § Flexible IT structure § Seamless workflow Increased operational efficiency Better process design methodology

Assistance for improving your Return on Assets Real-time decision support at the business level n Meeting the increased reporting requirements n Information for crucial production-based decisions n Decrease engineering and system maintenance costs n Turning raw data into actionable information n © Copyright 2003 ABB - 5 - n Handling complex data relationships

Assistance for improving your Return on Assets Real-time decision support at the business level n Meeting the increased reporting requirements n Information for crucial production-based decisions n Decrease engineering and system maintenance costs n Turning raw data into actionable information n © Copyright 2003 ABB - 5 - n Handling complex data relationships

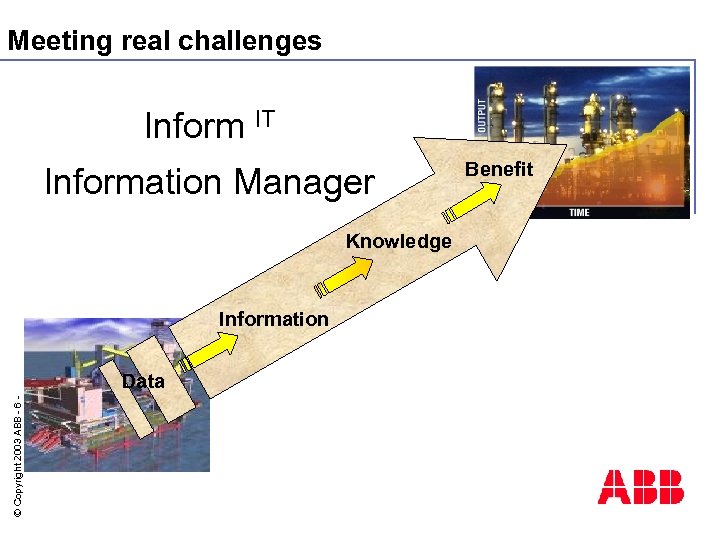

Meeting real challenges Inform IT Information Manager Knowledge Information © Copyright 2003 ABB - 6 - Data Benefit

Meeting real challenges Inform IT Information Manager Knowledge Information © Copyright 2003 ABB - 6 - Data Benefit

Issue: Real-time business decision making What’s my current production rate and energy consumption? n © Copyright 2003 ABB - 7 - n How does last week’s production compare to this week’s or even last year’s? n How do I get only the information I need without information overload?

Issue: Real-time business decision making What’s my current production rate and energy consumption? n © Copyright 2003 ABB - 7 - n How does last week’s production compare to this week’s or even last year’s? n How do I get only the information I need without information overload?

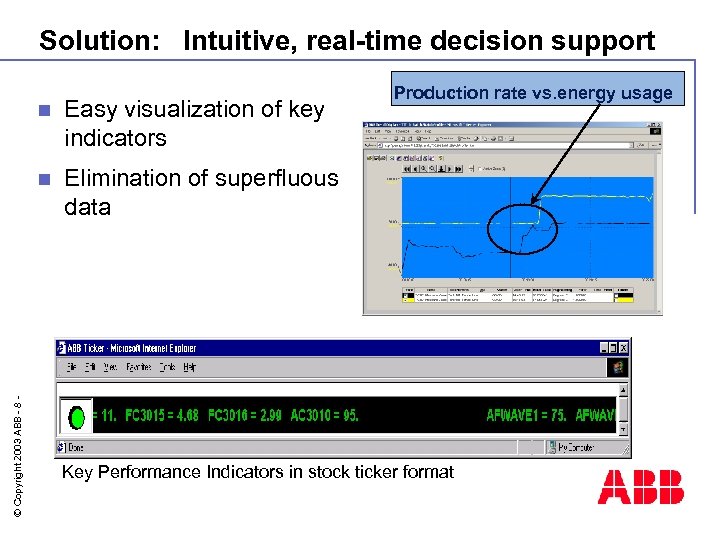

Solution: Intuitive, real-time decision support Easy visualization of key indicators n © Copyright 2003 ABB - 8 - n Production rate vs. energy usage Elimination of superfluous data Key Performance Indicators in stock ticker format

Solution: Intuitive, real-time decision support Easy visualization of key indicators n © Copyright 2003 ABB - 8 - n Production rate vs. energy usage Elimination of superfluous data Key Performance Indicators in stock ticker format

Issue: Reporting Requirements Abound n Production status reports for management n Standard reports for regulatory agencies n n n EPA FDA Status reports for operation personnel © Copyright 2003 ABB - 9 - n n without having to fumble through multiple reports in varying formats and media Reports need to be scheduled cyclically, on demand on event

Issue: Reporting Requirements Abound n Production status reports for management n Standard reports for regulatory agencies n n n EPA FDA Status reports for operation personnel © Copyright 2003 ABB - 9 - n n without having to fumble through multiple reports in varying formats and media Reports need to be scheduled cyclically, on demand on event

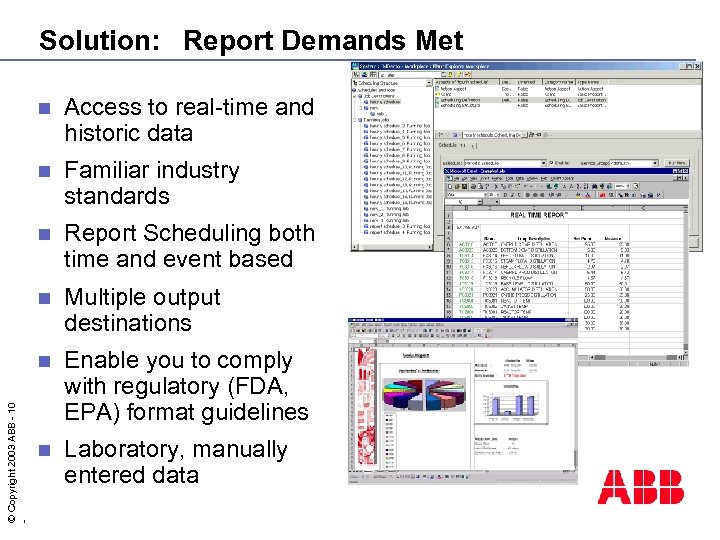

Solution: Report Demands Met Access to real-time and historic data n Familiar industry standards n Report Scheduling both time and event based n Multiple output destinations n © Copyright 2003 ABB - 10 - n Enable you to comply with regulatory (FDA, EPA) format guidelines n Laboratory, manually entered data

Solution: Report Demands Met Access to real-time and historic data n Familiar industry standards n Report Scheduling both time and event based n Multiple output destinations n © Copyright 2003 ABB - 10 - n Enable you to comply with regulatory (FDA, EPA) format guidelines n Laboratory, manually entered data

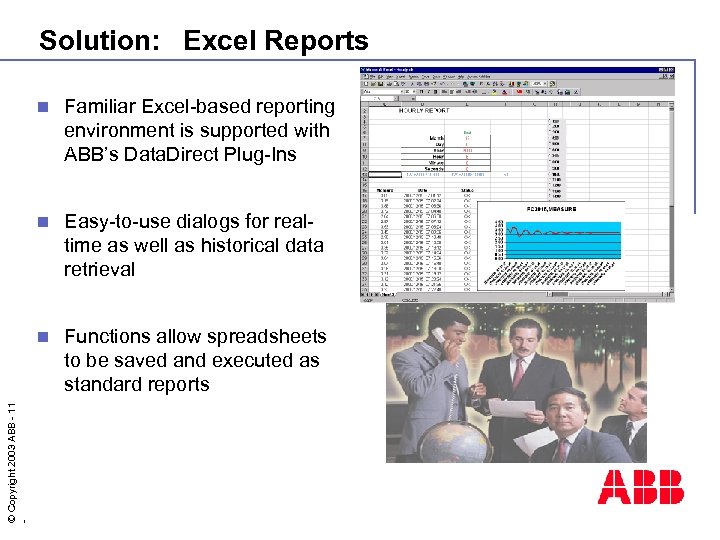

Solution: Excel Reports Familiar Excel-based reporting environment is supported with ABB’s Data. Direct Plug-Ins n Easy-to-use dialogs for realtime as well as historical data retrieval n © Copyright 2003 ABB - 11 - n Functions allow spreadsheets to be saved and executed as standard reports

Solution: Excel Reports Familiar Excel-based reporting environment is supported with ABB’s Data. Direct Plug-Ins n Easy-to-use dialogs for realtime as well as historical data retrieval n © Copyright 2003 ABB - 11 - n Functions allow spreadsheets to be saved and executed as standard reports

Issue: Improved production decision making If I only knew what was happening upstream or downstream of my process, I could be more efficient n I’ve got so many different systems …how can I ever keep everything straight? n © Copyright 2003 ABB - 12 - n I need one view to see information from all the different systems in the process - control systems

Issue: Improved production decision making If I only knew what was happening upstream or downstream of my process, I could be more efficient n I’ve got so many different systems …how can I ever keep everything straight? n © Copyright 2003 ABB - 12 - n I need one view to see information from all the different systems in the process - control systems

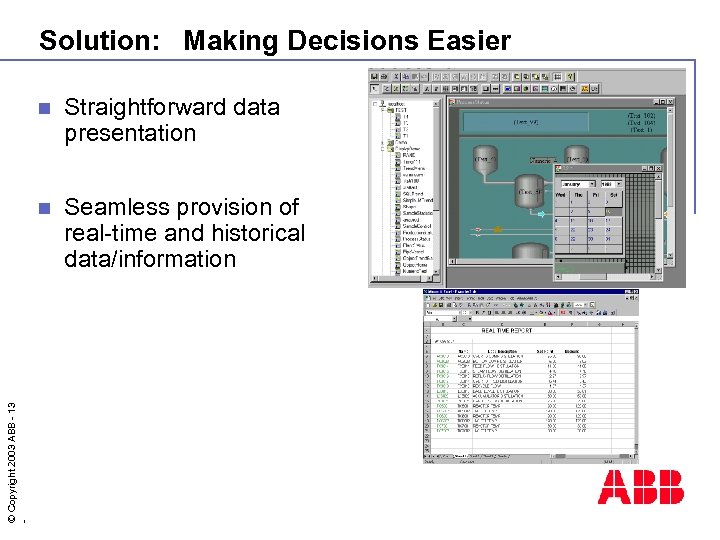

Solution: Making Decisions Easier Straightforward data presentation n © Copyright 2003 ABB - 13 - n Seamless provision of real-time and historical data/information

Solution: Making Decisions Easier Straightforward data presentation n © Copyright 2003 ABB - 13 - n Seamless provision of real-time and historical data/information

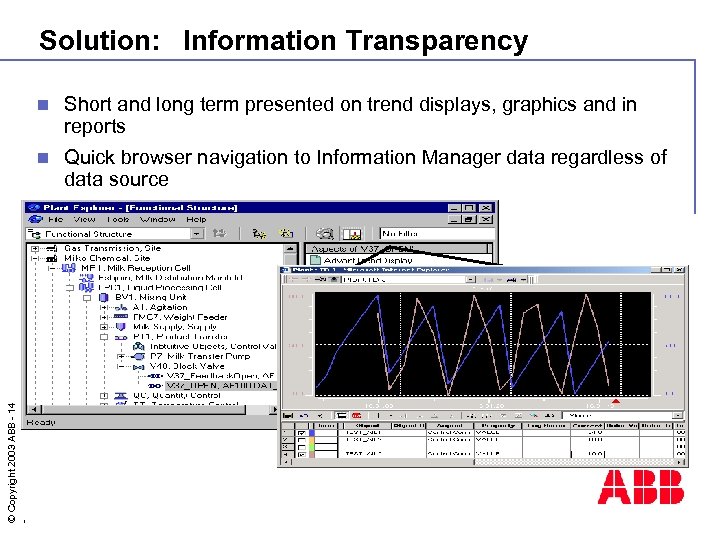

Solution: Information Transparency Short and long term presented on trend displays, graphics and in reports n © Copyright 2003 ABB - 14 - n Quick browser navigation to Information Manager data regardless of data source

Solution: Information Transparency Short and long term presented on trend displays, graphics and in reports n © Copyright 2003 ABB - 14 - n Quick browser navigation to Information Manager data regardless of data source

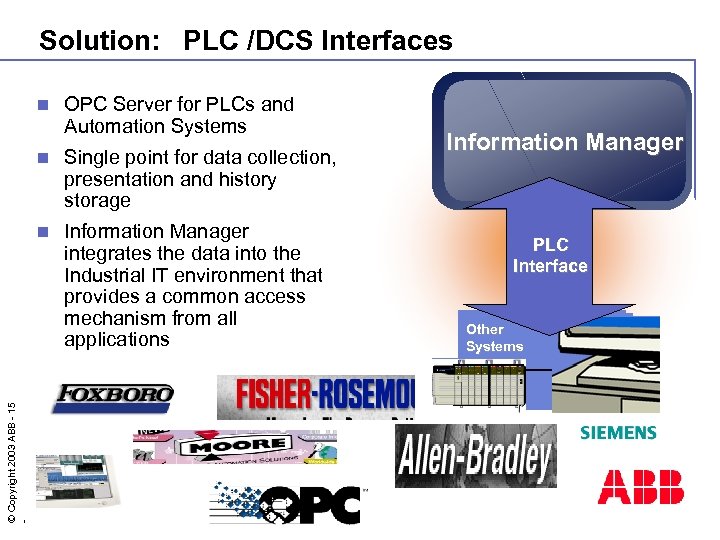

Solution: PLC /DCS Interfaces OPC Server for PLCs and Automation Systems n Single point for data collection, presentation and history storage n © Copyright 2003 ABB - 15 - n Information Manager integrates the data into the Industrial IT environment that provides a common access mechanism from all applications Information Manager PLC Interface Other Systems

Solution: PLC /DCS Interfaces OPC Server for PLCs and Automation Systems n Single point for data collection, presentation and history storage n © Copyright 2003 ABB - 15 - n Information Manager integrates the data into the Industrial IT environment that provides a common access mechanism from all applications Information Manager PLC Interface Other Systems

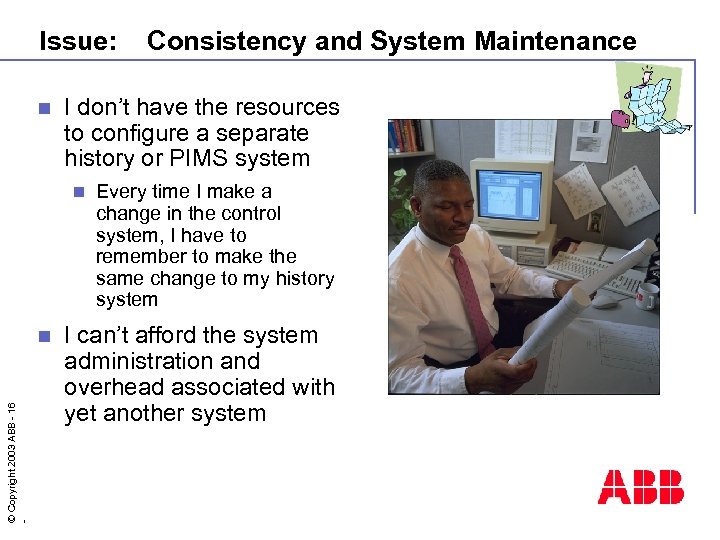

Issue: n I don’t have the resources to configure a separate history or PIMS system n © Copyright 2003 ABB - 16 - n Consistency and System Maintenance Every time I make a change in the control system, I have to remember to make the same change to my history system I can’t afford the system administration and overhead associated with yet another system

Issue: n I don’t have the resources to configure a separate history or PIMS system n © Copyright 2003 ABB - 16 - n Consistency and System Maintenance Every time I make a change in the control system, I have to remember to make the same change to my history system I can’t afford the system administration and overhead associated with yet another system

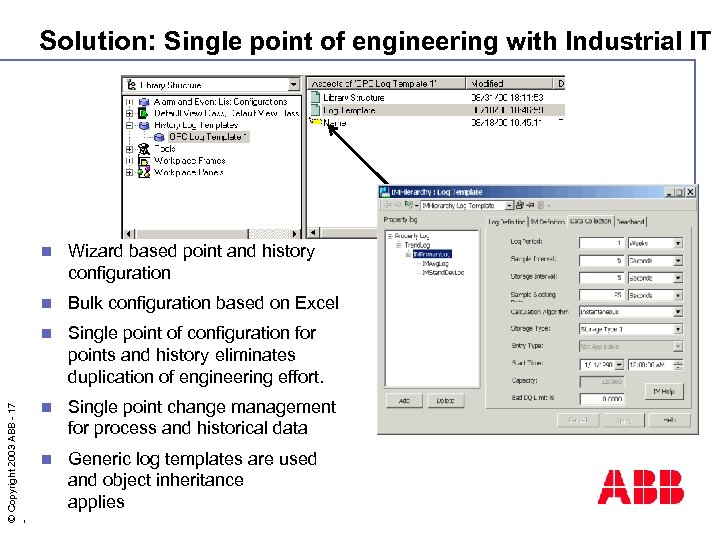

Solution: Single point of engineering with Industrial IT Wizard based point and history configuration n Bulk configuration based on Excel n © Copyright 2003 ABB - 17 - n Single point of configuration for points and history eliminates duplication of engineering effort. n Single point change management for process and historical data n Generic log templates are used and object inheritance applies

Solution: Single point of engineering with Industrial IT Wizard based point and history configuration n Bulk configuration based on Excel n © Copyright 2003 ABB - 17 - n Single point of configuration for points and history eliminates duplication of engineering effort. n Single point change management for process and historical data n Generic log templates are used and object inheritance applies

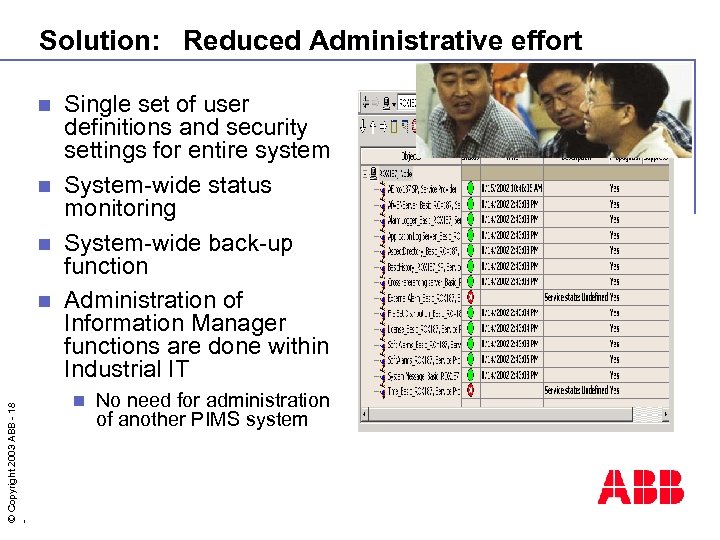

Solution: Reduced Administrative effort Single set of user definitions and security settings for entire system n System-wide status monitoring n System-wide back-up function n Administration of Information Manager functions are done within Industrial IT © Copyright 2003 ABB - 18 - n n No need for administration of another PIMS system

Solution: Reduced Administrative effort Single set of user definitions and security settings for entire system n System-wide status monitoring n System-wide back-up function n Administration of Information Manager functions are done within Industrial IT © Copyright 2003 ABB - 18 - n n No need for administration of another PIMS system

Issue: Life is more than just raw data points Value-added information must be provided so I can make the right decisions for better production. n © Copyright 2003 ABB - 19 - n An example of this are tank farm inputs. Temperature, flows and levels signals are inputs to the system. But… I need to know other characteristics such as density, viscosity, and volume, etc. and I need to run calculations on the data.

Issue: Life is more than just raw data points Value-added information must be provided so I can make the right decisions for better production. n © Copyright 2003 ABB - 19 - n An example of this are tank farm inputs. Temperature, flows and levels signals are inputs to the system. But… I need to know other characteristics such as density, viscosity, and volume, etc. and I need to run calculations on the data.

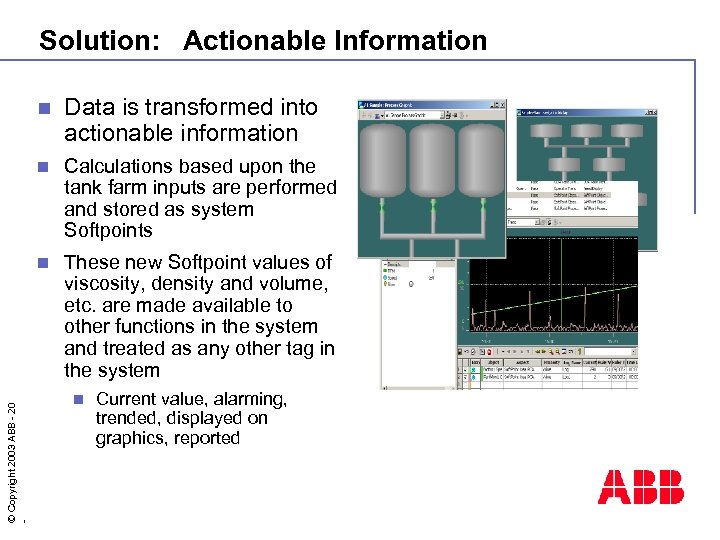

Solution: Actionable Information Data is transformed into actionable information n Calculations based upon the tank farm inputs are performed and stored as system Softpoints n © Copyright 2003 ABB - 20 - n These new Softpoint values of viscosity, density and volume, etc. are made available to other functions in the system and treated as any other tag in the system n Current value, alarming, trended, displayed on graphics, reported

Solution: Actionable Information Data is transformed into actionable information n Calculations based upon the tank farm inputs are performed and stored as system Softpoints n © Copyright 2003 ABB - 20 - n These new Softpoint values of viscosity, density and volume, etc. are made available to other functions in the system and treated as any other tag in the system n Current value, alarming, trended, displayed on graphics, reported

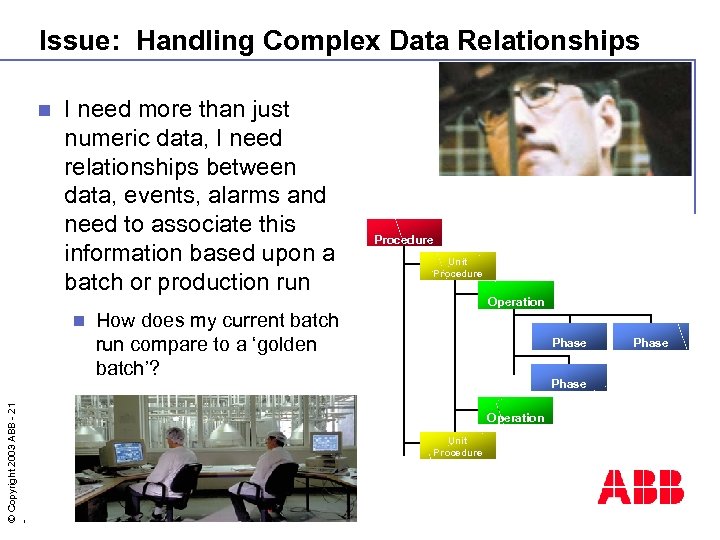

Issue: Handling Complex Data Relationships n I need more than just numeric data, I need relationships between data, events, alarms and need to associate this information based upon a batch or production run Procedure Unit Procedure Operation © Copyright 2003 ABB - 21 - n How does my current batch run compare to a ‘golden batch’? Phase Operation Unit Procedure Phase

Issue: Handling Complex Data Relationships n I need more than just numeric data, I need relationships between data, events, alarms and need to associate this information based upon a batch or production run Procedure Unit Procedure Operation © Copyright 2003 ABB - 21 - n How does my current batch run compare to a ‘golden batch’? Phase Operation Unit Procedure Phase

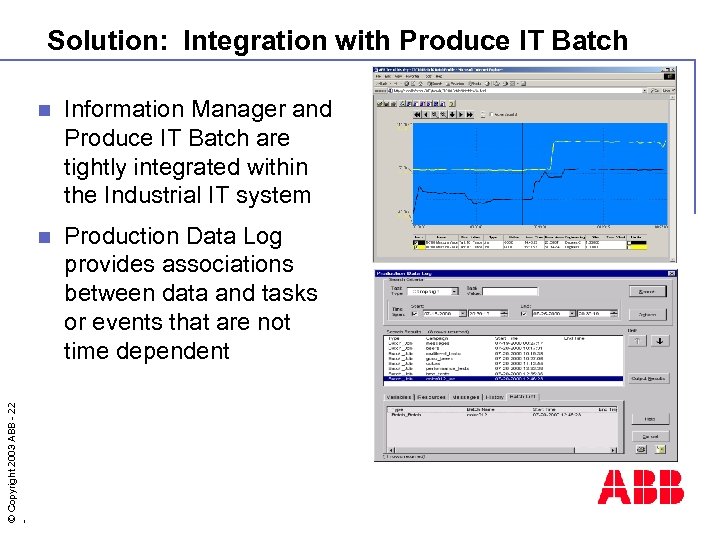

Solution: Integration with Produce IT Batch Information Manager and Produce IT Batch are tightly integrated within the Industrial IT system n © Copyright 2003 ABB - 22 - n Production Data Log provides associations between data and tasks or events that are not time dependent

Solution: Integration with Produce IT Batch Information Manager and Produce IT Batch are tightly integrated within the Industrial IT system n © Copyright 2003 ABB - 22 - n Production Data Log provides associations between data and tasks or events that are not time dependent

Product functionality ATCE – Production Management 3/15/2018 Insert image here Inform IT Information Manager Insert image here

Product functionality ATCE – Production Management 3/15/2018 Insert image here Inform IT Information Manager Insert image here

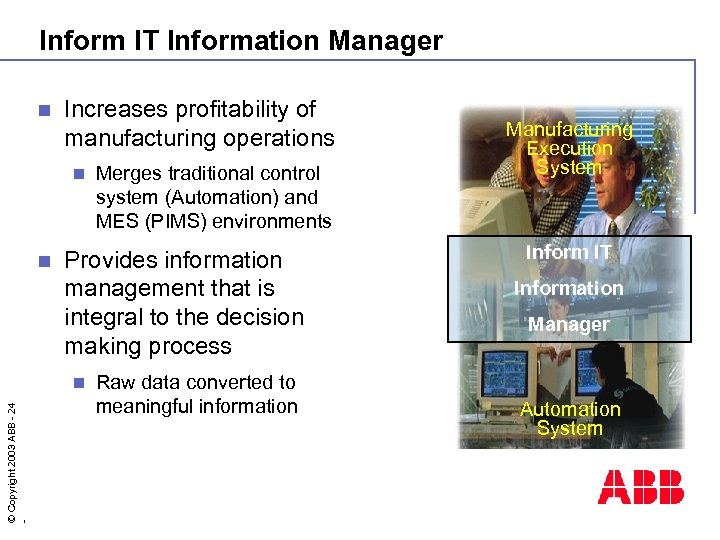

Inform IT Information Manager n Increases profitability of manufacturing operations n n Provides information management that is integral to the decision making process n © Copyright 2003 ABB - 24 - Merges traditional control system (Automation) and MES (PIMS) environments Raw data converted to meaningful information Manufacturing Execution System Inform IT Information Manager Automation System

Inform IT Information Manager n Increases profitability of manufacturing operations n n Provides information management that is integral to the decision making process n © Copyright 2003 ABB - 24 - Merges traditional control system (Automation) and MES (PIMS) environments Raw data converted to meaningful information Manufacturing Execution System Inform IT Information Manager Automation System

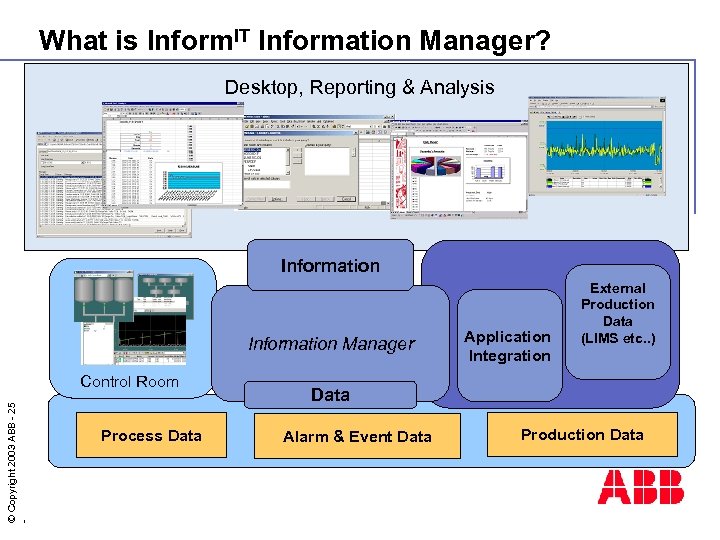

What is Inform. IT Information Manager? Desktop, Reporting & Analysis Information Manager © Copyright 2003 ABB - 25 - Control Room Process Data Application Integration External Production Data (LIMS etc. . ) Data Alarm & Event Data Production Data

What is Inform. IT Information Manager? Desktop, Reporting & Analysis Information Manager © Copyright 2003 ABB - 25 - Control Room Process Data Application Integration External Production Data (LIMS etc. . ) Data Alarm & Event Data Production Data

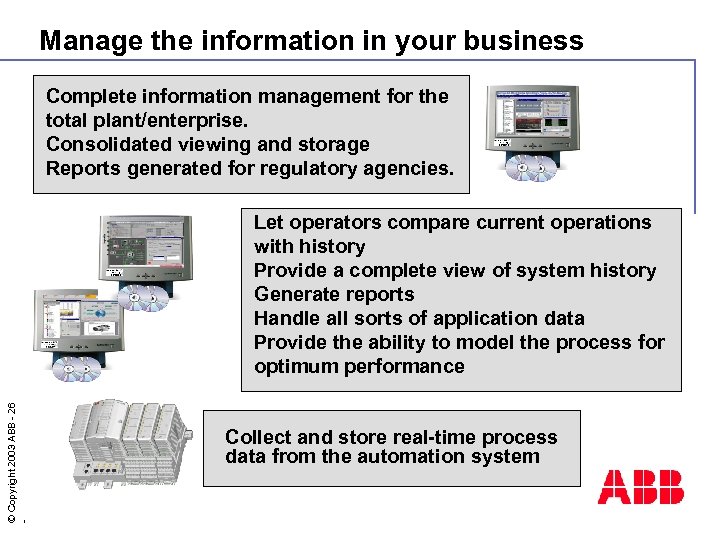

Manage the information in your business Complete information management for the total plant/enterprise. Consolidated viewing and storage Reports generated for regulatory agencies. © Copyright 2003 ABB - 26 - Let operators compare current operations with history Provide a complete view of system history Generate reports Handle all sorts of application data Provide the ability to model the process for optimum performance Collect and store real-time process data from the automation system

Manage the information in your business Complete information management for the total plant/enterprise. Consolidated viewing and storage Reports generated for regulatory agencies. © Copyright 2003 ABB - 26 - Let operators compare current operations with history Provide a complete view of system history Generate reports Handle all sorts of application data Provide the ability to model the process for optimum performance Collect and store real-time process data from the automation system

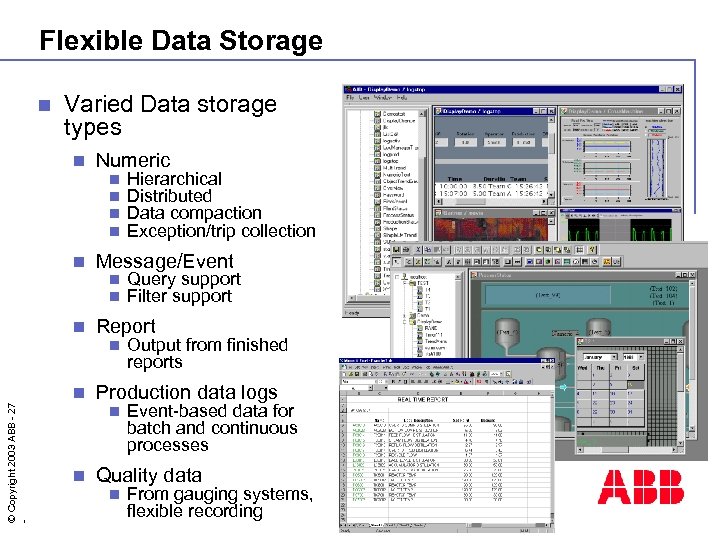

Flexible Data Storage n Varied Data storage types n Numeric n n n Message/Event n n n © Copyright 2003 ABB - 27 - Output from finished reports Production data logs n n Query support Filter support Report n n Hierarchical Distributed Data compaction Exception/trip collection Event-based data for batch and continuous processes Quality data n From gauging systems, flexible recording

Flexible Data Storage n Varied Data storage types n Numeric n n n Message/Event n n n © Copyright 2003 ABB - 27 - Output from finished reports Production data logs n n Query support Filter support Report n n Hierarchical Distributed Data compaction Exception/trip collection Event-based data for batch and continuous processes Quality data n From gauging systems, flexible recording

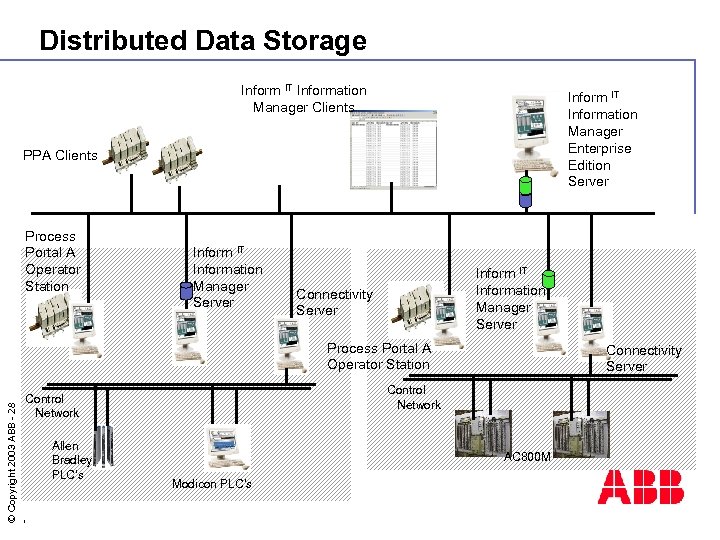

Distributed Data Storage Inform IT Information Manager Clients Inform IT Information Manager Enterprise Edition Server PPA Clients Process Portal A Operator Station Inform IT Information Manager Server Connectivity Server Process Portal A Operator Station Control Network © Copyright 2003 ABB - 28 - Control Network Allen Bradley PLC’s Connectivity Server AC 800 M Modicon PLC’s

Distributed Data Storage Inform IT Information Manager Clients Inform IT Information Manager Enterprise Edition Server PPA Clients Process Portal A Operator Station Inform IT Information Manager Server Connectivity Server Process Portal A Operator Station Control Network © Copyright 2003 ABB - 28 - Control Network Allen Bradley PLC’s Connectivity Server AC 800 M Modicon PLC’s

External Application Data Support Data handling with Softpoint Aspects n Data created in Information Manager environment is automatically available to the control system n Defines points which does not exist in the underlying system n Data is available to other functions in the system n © Copyright 2003 ABB - 29 - n Treated as any other tag in the system n Current value, Alarming, History, Displayed on graphics, Reports n Object Types can be imported and exported

External Application Data Support Data handling with Softpoint Aspects n Data created in Information Manager environment is automatically available to the control system n Defines points which does not exist in the underlying system n Data is available to other functions in the system n © Copyright 2003 ABB - 29 - n Treated as any other tag in the system n Current value, Alarming, History, Displayed on graphics, Reports n Object Types can be imported and exported

External Application Data Support n Optimization with user-defined Calculations Aspects n A calculation can be applied to any object e. g. unit, vessel, pump, softpoint & includes n Data quality support n Alarm generation support A calculation may be scheduled on a time basis or on event n © Copyright 2003 ABB - 30 - n Calculations are developed with VBScript n Calculations can provide an easy mechanism for simple integration with external systems

External Application Data Support n Optimization with user-defined Calculations Aspects n A calculation can be applied to any object e. g. unit, vessel, pump, softpoint & includes n Data quality support n Alarm generation support A calculation may be scheduled on a time basis or on event n © Copyright 2003 ABB - 30 - n Calculations are developed with VBScript n Calculations can provide an easy mechanism for simple integration with external systems

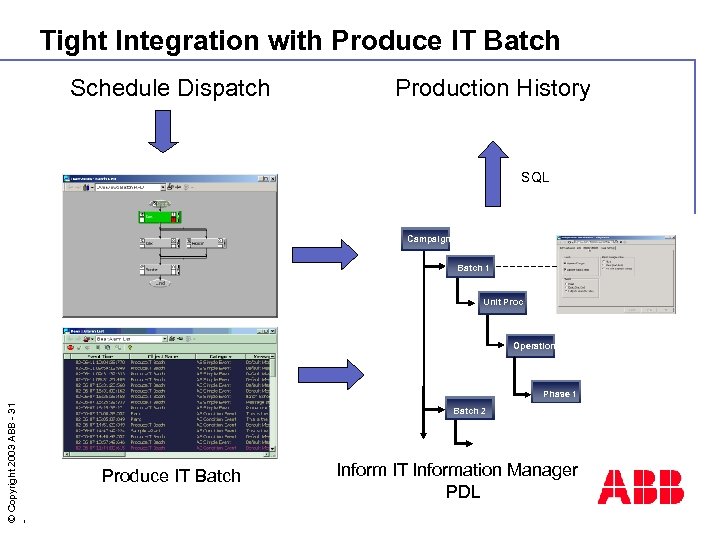

Tight Integration with Produce IT Batch Schedule Dispatch Production History SQL Campaign Batch 1 Unit Proc Operation 1 © Copyright 2003 ABB - 31 - Phase 1 Batch 2 Produce IT Batch Inform IT Information Manager PDL

Tight Integration with Produce IT Batch Schedule Dispatch Production History SQL Campaign Batch 1 Unit Proc Operation 1 © Copyright 2003 ABB - 31 - Phase 1 Batch 2 Produce IT Batch Inform IT Information Manager PDL

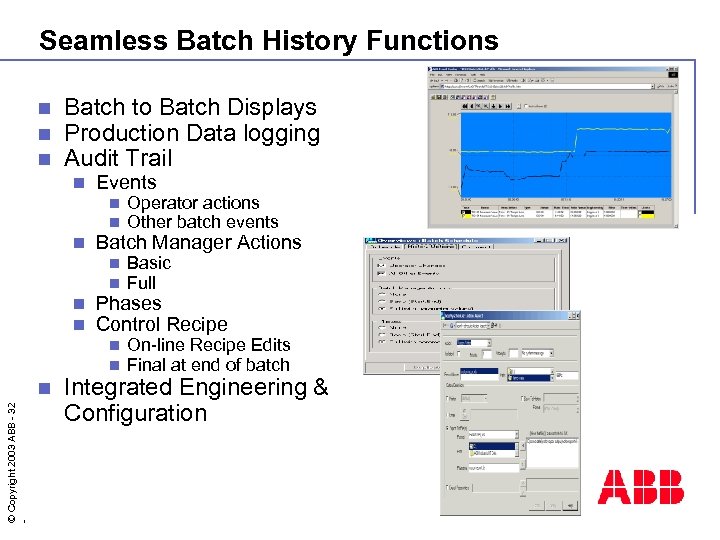

Seamless Batch History Functions n n n Batch to Batch Displays Production Data logging Audit Trail n Events n n n © Copyright 2003 ABB - 32 - n Basic Full n n n Operator actions Other batch events On-line Recipe Edits Final at end of batch Batch Manager Actions Phases Control Recipe Integrated Engineering & Configuration

Seamless Batch History Functions n n n Batch to Batch Displays Production Data logging Audit Trail n Events n n n © Copyright 2003 ABB - 32 - n Basic Full n n n Operator actions Other batch events On-line Recipe Edits Final at end of batch Batch Manager Actions Phases Control Recipe Integrated Engineering & Configuration

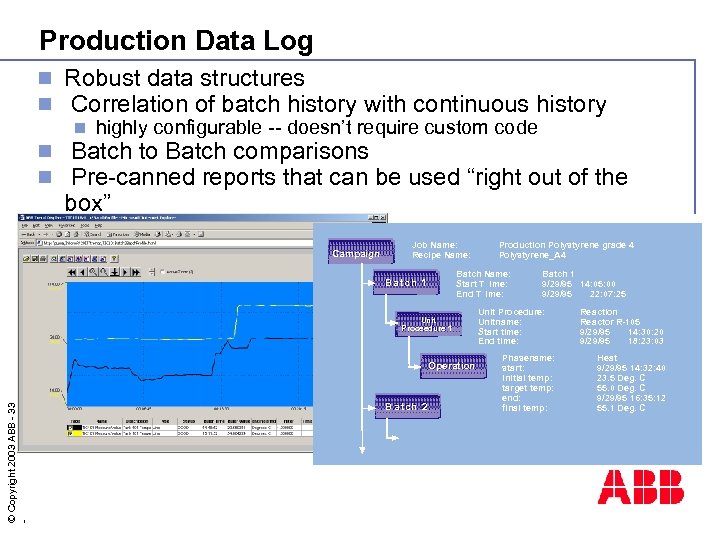

Production Data Log n Robust data structures n Correlation of batch history with continuous history n highly configurable -- doesn’t require custom code n Batch to Batch comparisons n Pre-canned reports that can be used “right out of the box” Campaign Job Name: Recipe Name: Batch Name: Start T ime: End T ime: B a tc h 1 Unit Proceedure 1 © Copyright 2003 ABB - 33 - Operation B a tc h 2 Production Polystyrene grade 4 Polystyrene_A 4 Batch 1 9/29/95 14: 05: 00 9/29/95 22: 07: 25 Unit Procedure: Unitname: Start time: End time: Phasename: start: initial temp: target temp: end: final temp: Reaction Reactor R-105 9/29/95 14: 30: 20 9/29/95 18: 23: 03 Heat 9/29/95 14: 32: 40 23. 5 Deg. C 55. 0 Deg. C 9/29/95 16: 35: 12 55. 1 Deg. C

Production Data Log n Robust data structures n Correlation of batch history with continuous history n highly configurable -- doesn’t require custom code n Batch to Batch comparisons n Pre-canned reports that can be used “right out of the box” Campaign Job Name: Recipe Name: Batch Name: Start T ime: End T ime: B a tc h 1 Unit Proceedure 1 © Copyright 2003 ABB - 33 - Operation B a tc h 2 Production Polystyrene grade 4 Polystyrene_A 4 Batch 1 9/29/95 14: 05: 00 9/29/95 22: 07: 25 Unit Procedure: Unitname: Start time: End time: Phasename: start: initial temp: target temp: end: final temp: Reaction Reactor R-105 9/29/95 14: 30: 20 9/29/95 18: 23: 03 Heat 9/29/95 14: 32: 40 23. 5 Deg. C 55. 0 Deg. C 9/29/95 16: 35: 12 55. 1 Deg. C

Report Scheduling n Inform IT Data. Direct n n Excel © Copyright 2003 ABB - 34 - n n Add-on program for Excel. Integration into an Excel spreadsheet of real-time and historical data from Information Manager applications, OCS applications and SQL data sources. Also possible to access historical and real-time data from Information Manager independent of Data. Direct via OLE DB or ODBC. Crystal Reports n Access real time and historical data from Information Manager.

Report Scheduling n Inform IT Data. Direct n n Excel © Copyright 2003 ABB - 34 - n n Add-on program for Excel. Integration into an Excel spreadsheet of real-time and historical data from Information Manager applications, OCS applications and SQL data sources. Also possible to access historical and real-time data from Information Manager independent of Data. Direct via OLE DB or ODBC. Crystal Reports n Access real time and historical data from Information Manager.

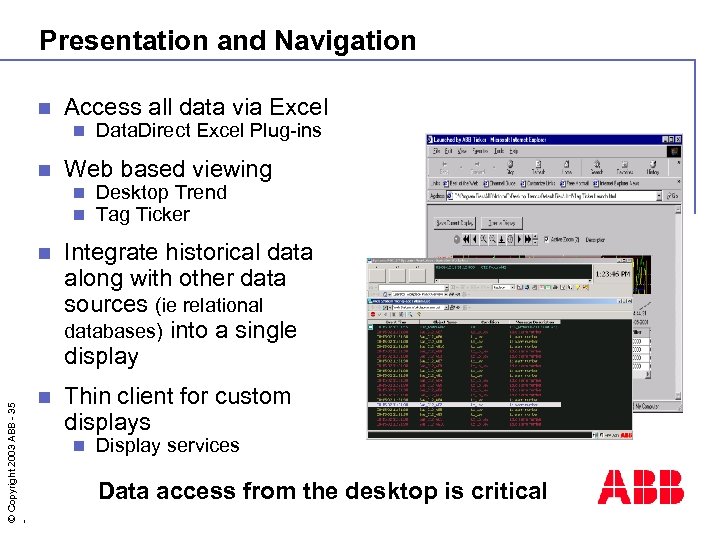

Presentation and Navigation n Access all data via Excel n n Data. Direct Excel Plug-ins Web based viewing n n Desktop Trend Tag Ticker © Copyright 2003 ABB - 35 - n Integrate historical data along with other data sources (ie relational databases) into a single display n Thin client for custom displays n Display services Data access from the desktop is critical

Presentation and Navigation n Access all data via Excel n n Data. Direct Excel Plug-ins Web based viewing n n Desktop Trend Tag Ticker © Copyright 2003 ABB - 35 - n Integrate historical data along with other data sources (ie relational databases) into a single display n Thin client for custom displays n Display services Data access from the desktop is critical

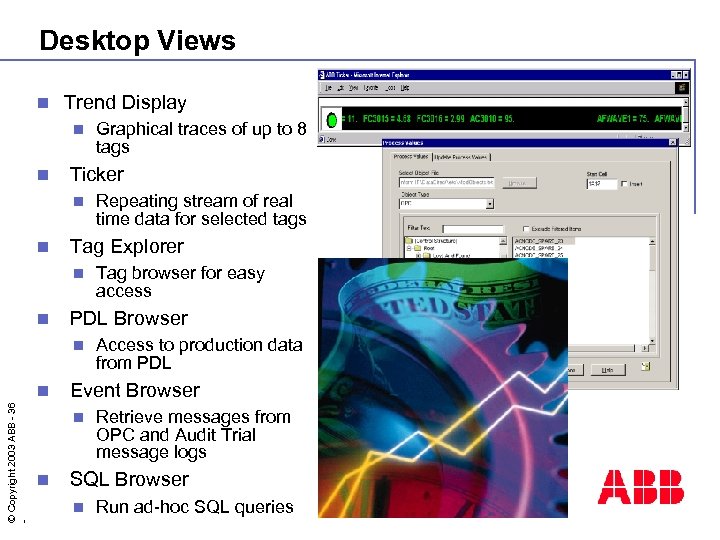

Desktop Views n Trend Display n n Ticker n n © Copyright 2003 ABB - 36 - Access to production data from PDL Event Browser n n Tag browser for easy access PDL Browser n n Repeating stream of real time data for selected tags Tag Explorer n n Graphical traces of up to 8 tags Retrieve messages from OPC and Audit Trial message logs SQL Browser n Run ad-hoc SQL queries

Desktop Views n Trend Display n n Ticker n n © Copyright 2003 ABB - 36 - Access to production data from PDL Event Browser n n Tag browser for easy access PDL Browser n n Repeating stream of real time data for selected tags Tag Explorer n n Graphical traces of up to 8 tags Retrieve messages from OPC and Audit Trial message logs SQL Browser n Run ad-hoc SQL queries

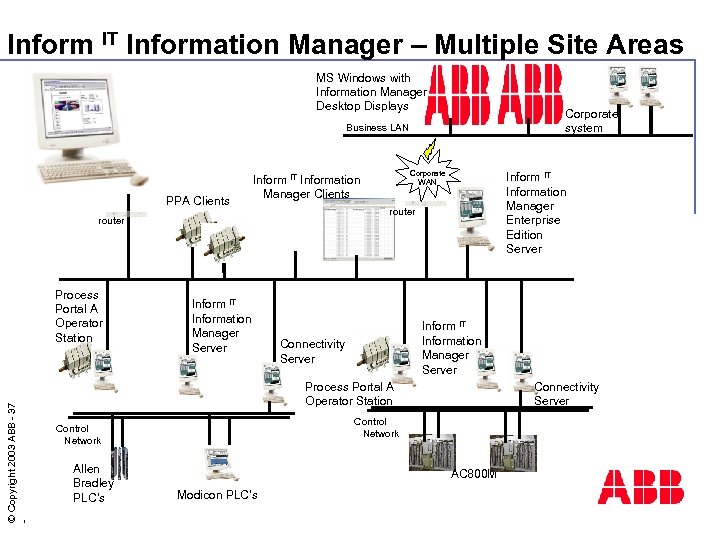

Inform IT Information Manager – Multiple Site Areas MS Windows with Information Manager Desktop Displays Corporate system Business LAN PPA Clients © Copyright 2003 ABB - 37 - Inform IT Information Manager Server Inform IT Information Manager Enterprise Edition Server router Process Portal A Operator Station Corporate WAN Inform IT Information Manager Clients Inform IT Information Manager Server Connectivity Server Process Portal A Operator Station Control Network Allen Bradley PLC’s AC 800 M Modicon PLC’s

Inform IT Information Manager – Multiple Site Areas MS Windows with Information Manager Desktop Displays Corporate system Business LAN PPA Clients © Copyright 2003 ABB - 37 - Inform IT Information Manager Server Inform IT Information Manager Enterprise Edition Server router Process Portal A Operator Station Corporate WAN Inform IT Information Manager Clients Inform IT Information Manager Server Connectivity Server Process Portal A Operator Station Control Network Allen Bradley PLC’s AC 800 M Modicon PLC’s

Secure Data Storage n Secure historical data storage n Archival/retrieval from external media © Copyright 2003 ABB - 38 - n Disc files backed up to CD or DVD n Magneto Optical device n Disk arrays n Remote disk location n Direct read of archived tag data n Archive based on production event such as batch end n Distributed data storage n Secure report storage n User access control

Secure Data Storage n Secure historical data storage n Archival/retrieval from external media © Copyright 2003 ABB - 38 - n Disc files backed up to CD or DVD n Magneto Optical device n Disk arrays n Remote disk location n Direct read of archived tag data n Archive based on production event such as batch end n Distributed data storage n Secure report storage n User access control

Efficient Engineering One historical solution and database for information management and process control n Information Manager configuration is built as aspects of objects that already exist from control system definition n © Copyright 2003 ABB - 39 - n Configuration created in both environments, transparent to various users – operator, engineer, plant manager, etc. n Automatic creation of tag in PIMS system when control system tag created n No manual procedure to keep the systems consistent

Efficient Engineering One historical solution and database for information management and process control n Information Manager configuration is built as aspects of objects that already exist from control system definition n © Copyright 2003 ABB - 39 - n Configuration created in both environments, transparent to various users – operator, engineer, plant manager, etc. n Automatic creation of tag in PIMS system when control system tag created n No manual procedure to keep the systems consistent

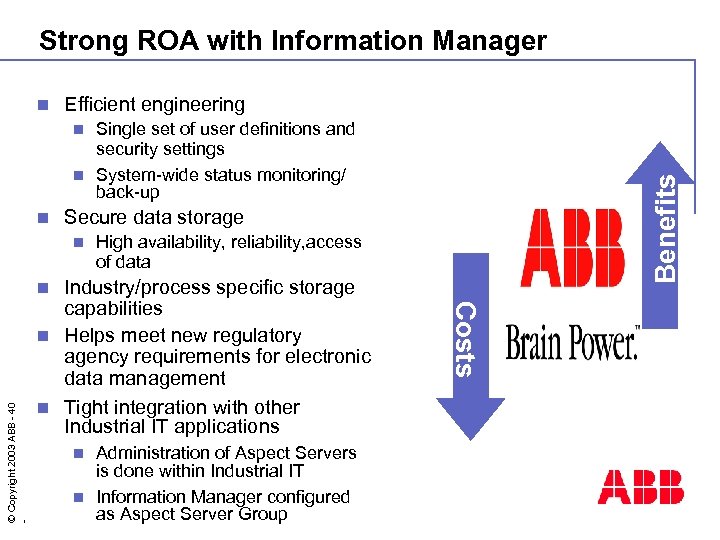

Strong ROA with Information Manager n Efficient engineering Single set of user definitions and security settings n System-wide status monitoring/ back-up n Benefits n Secure data storage n High availability, reliability, access of data Industry/process specific storage capabilities n Helps meet new regulatory agency requirements for electronic data management n Tight integration with other Industrial IT applications Administration of Aspect Servers is done within Industrial IT n Information Manager configured as Aspect Server Group n Costs © Copyright 2003 ABB - 40 - n

Strong ROA with Information Manager n Efficient engineering Single set of user definitions and security settings n System-wide status monitoring/ back-up n Benefits n Secure data storage n High availability, reliability, access of data Industry/process specific storage capabilities n Helps meet new regulatory agency requirements for electronic data management n Tight integration with other Industrial IT applications Administration of Aspect Servers is done within Industrial IT n Information Manager configured as Aspect Server Group n Costs © Copyright 2003 ABB - 40 - n

Information Manager Benefits n Operational efficiencies provided with Integrated Information n Better decision making using integrated, up-to-date process and production information Intuitive desktop presentation and efficient navigation Providing Key Performance improvements through Increased throughput n © Copyright 2003 ABB - 41 - n Less downtime n Better overall quality n More efficient and cost effective operations

Information Manager Benefits n Operational efficiencies provided with Integrated Information n Better decision making using integrated, up-to-date process and production information Intuitive desktop presentation and efficient navigation Providing Key Performance improvements through Increased throughput n © Copyright 2003 ABB - 41 - n Less downtime n Better overall quality n More efficient and cost effective operations

© Copyright 2003 ABB - 42 -

© Copyright 2003 ABB - 42 -